Patents

Literature

42results about How to "Improve launch stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

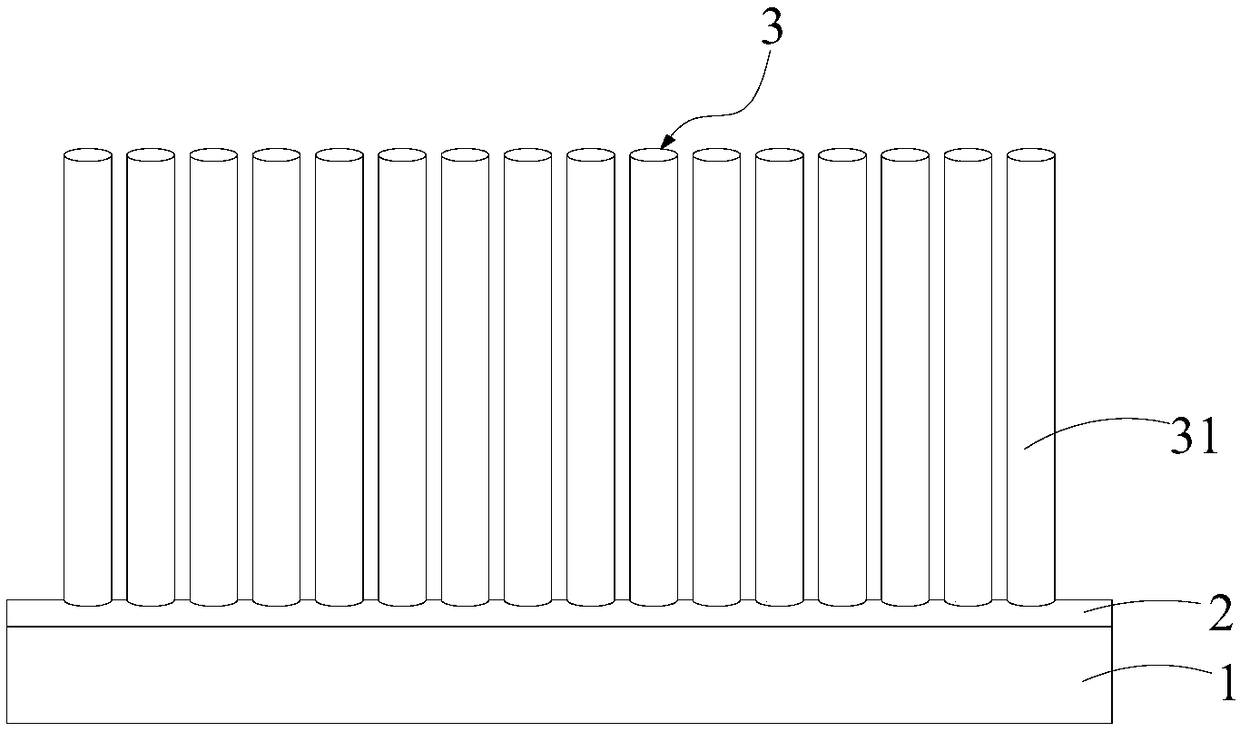

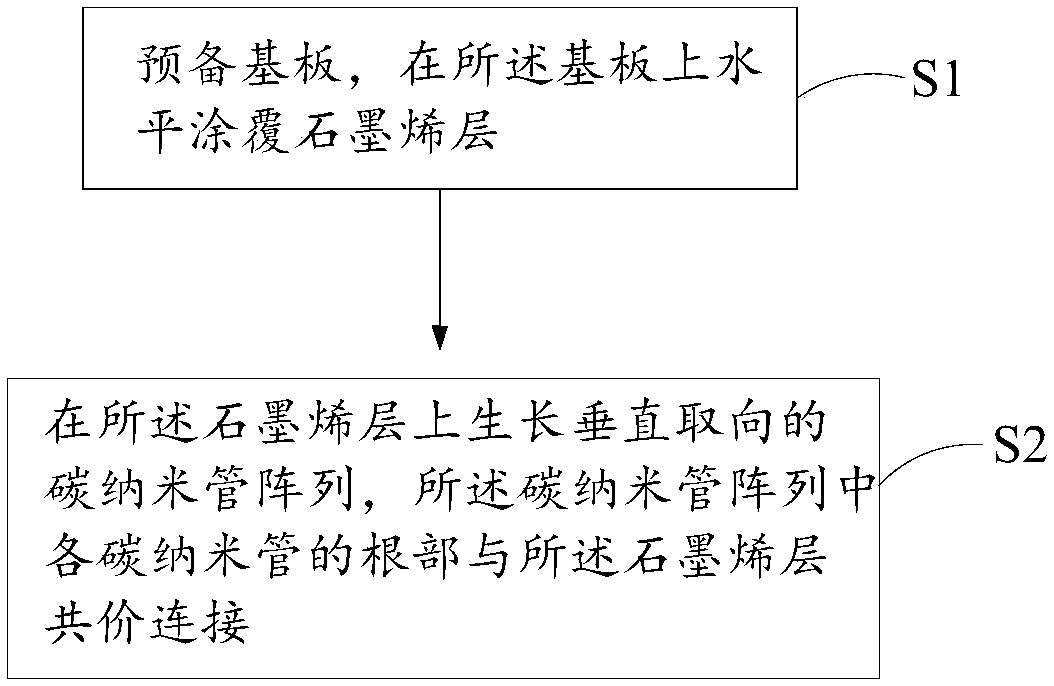

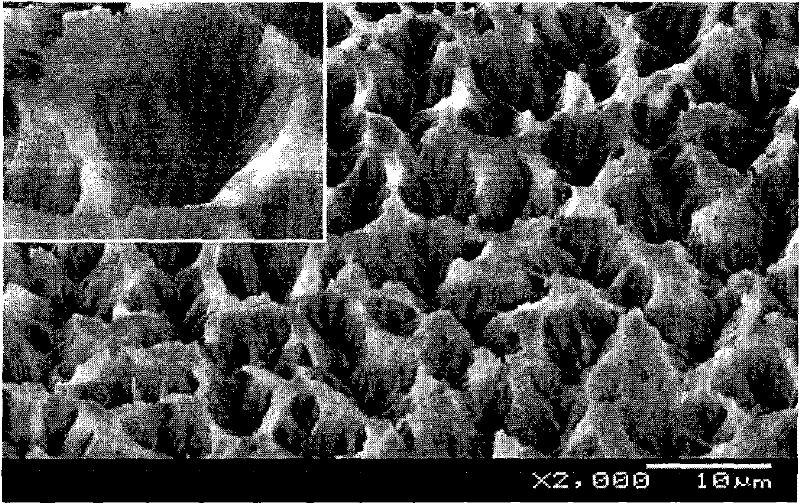

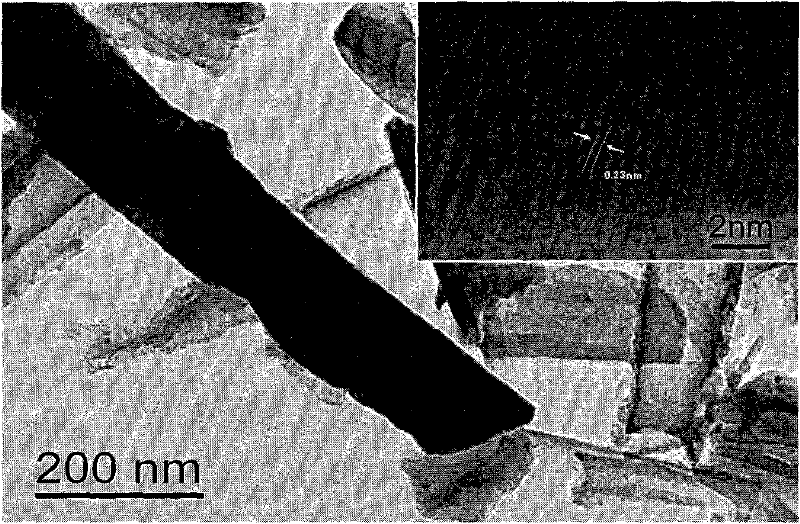

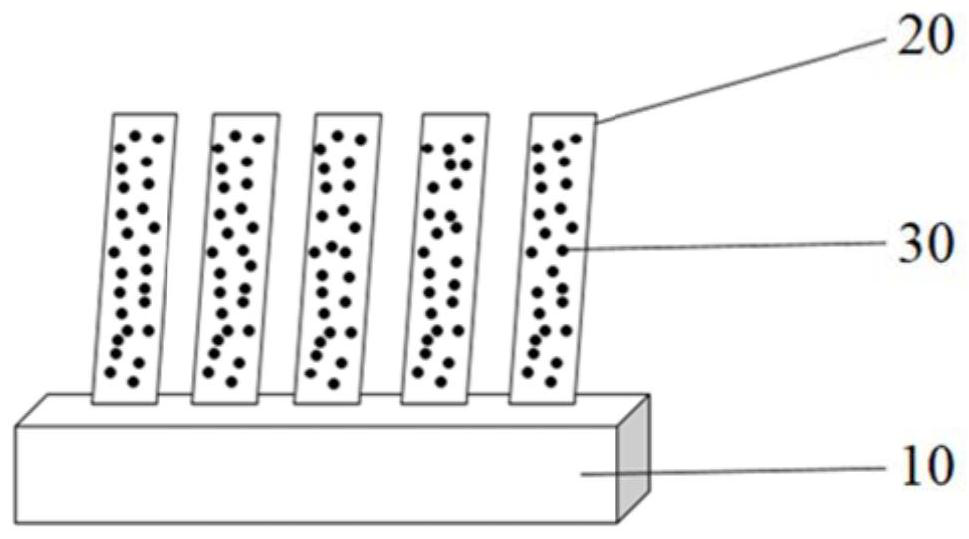

Carbon-nano-field emission cathode and manufacturing method and application

ActiveCN108172488ALaunch stableReduce the turn-on electric fieldCathode ray tubes/electron beam tubesX-ray tube electrodesElectrical resistance and conductancePower flow

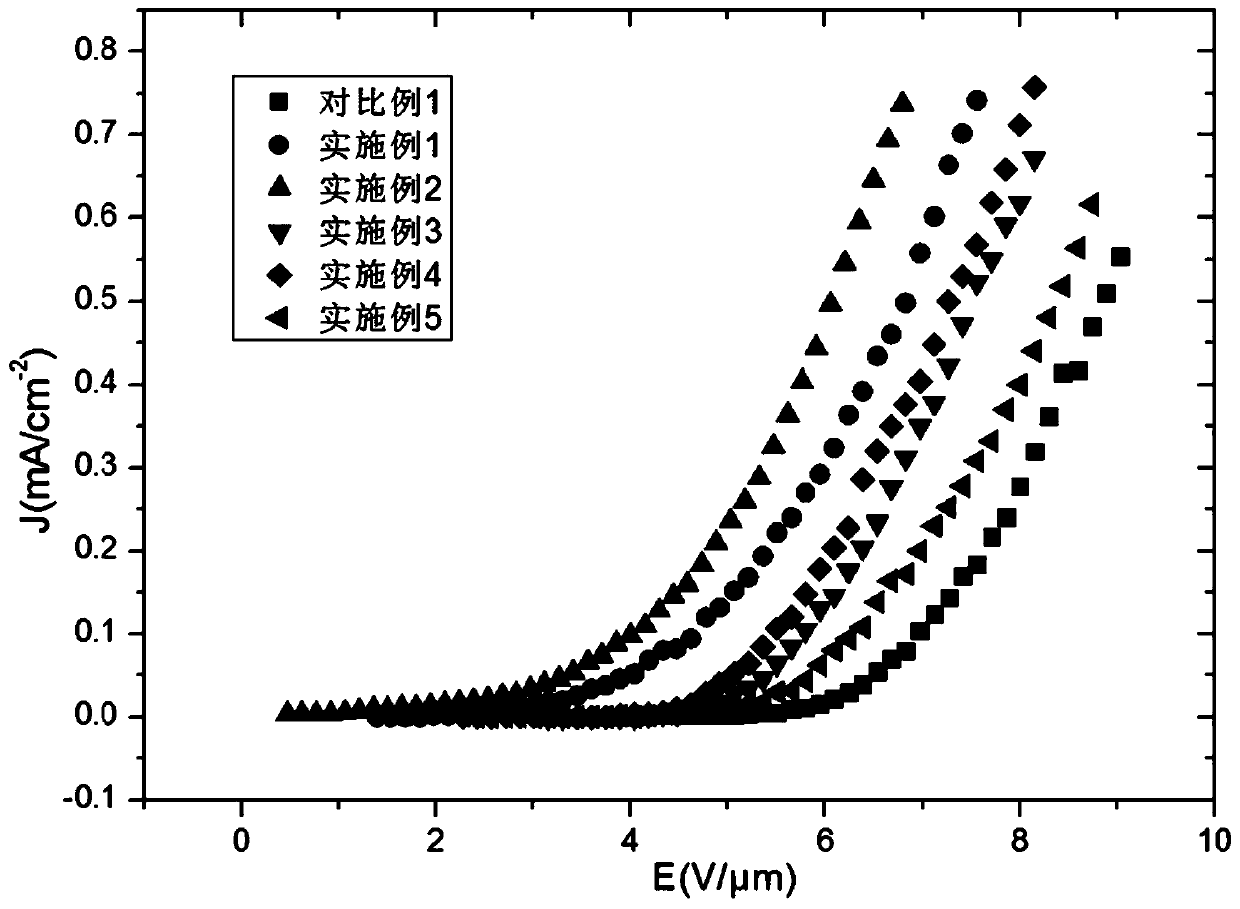

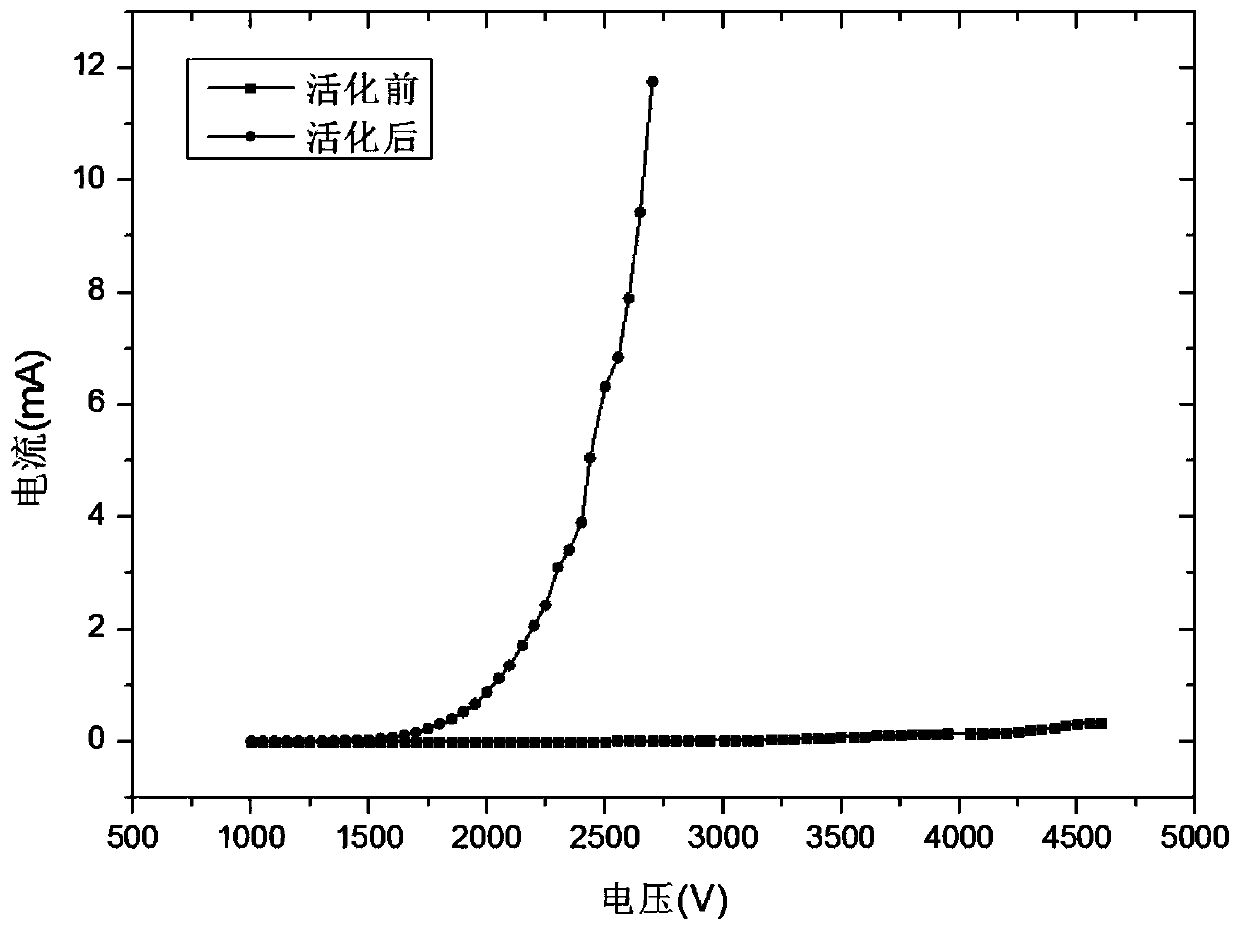

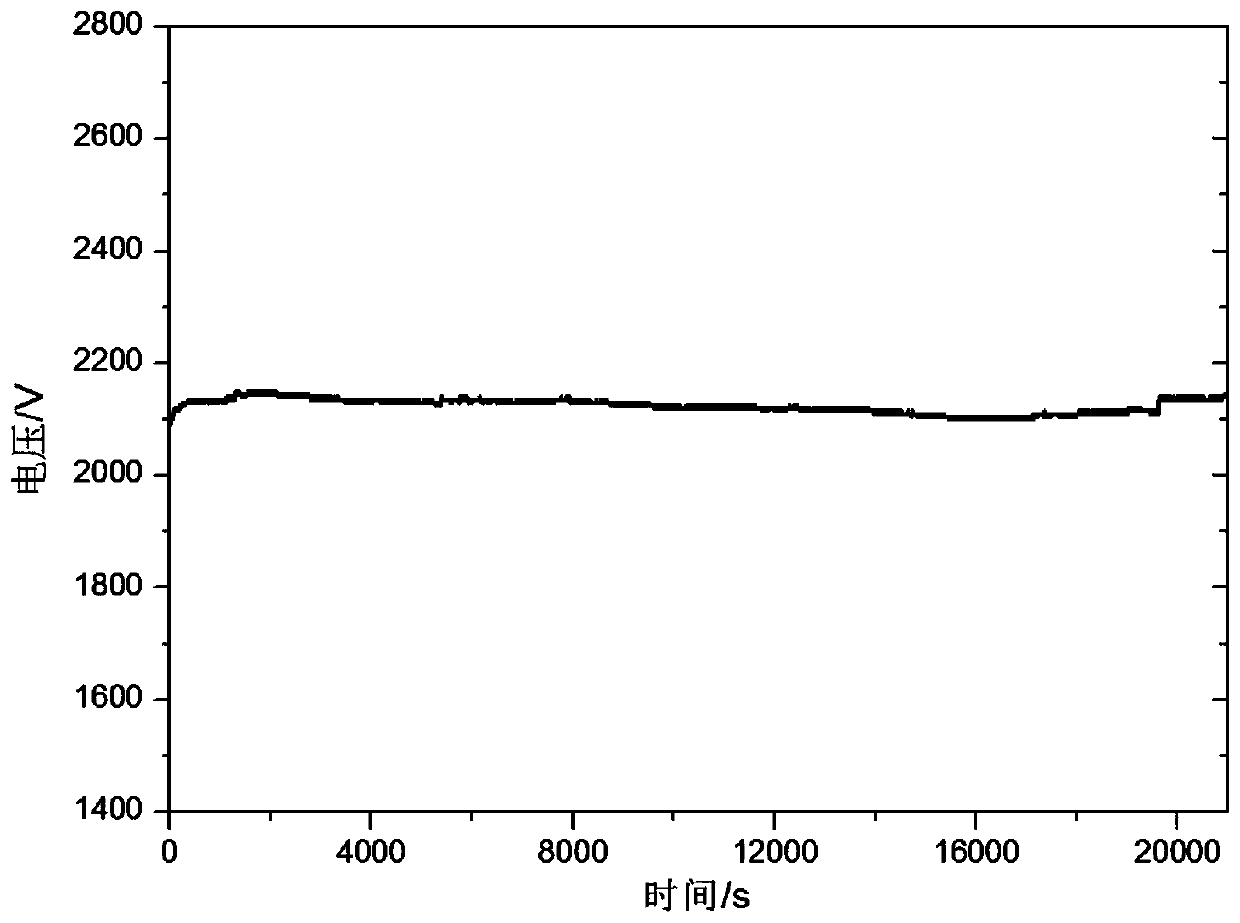

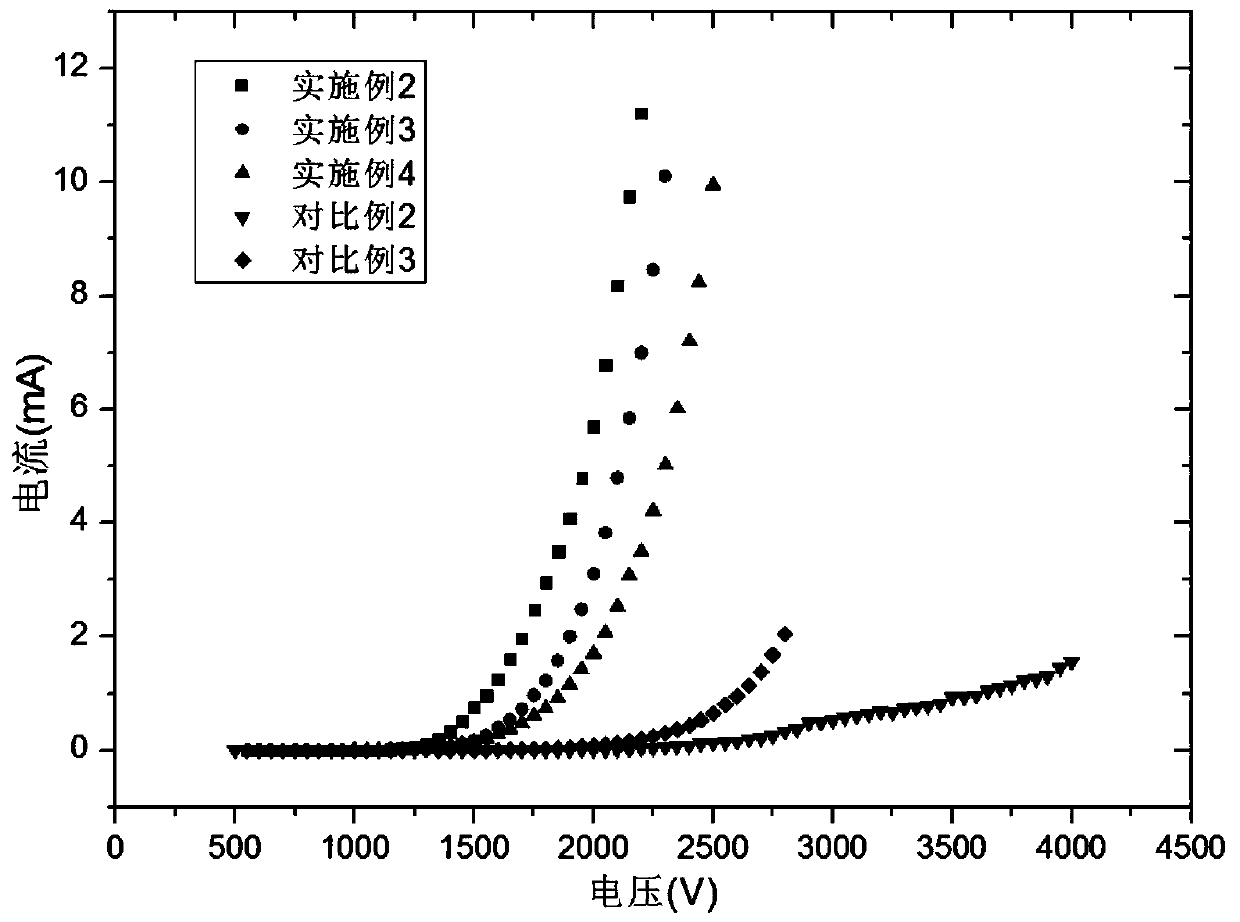

The invention, which relates to the technical field of field emission, provides a carbon-nano-field emission cathode and a manufacturing method and application. The carbon-nano-field emission cathodecomprises a substrate, a graphene layer horizontally coated on the substrate, and a carbon nanotube array arranged on the graphene layer. Roots of all carbon nanotubes in the carbon nanotube array arein covalent linkage with the graphene layer. According to the invention, because the roots of all carbon nanotubes are in covalent linkage with the graphene layer, the interface resistance is extremely low and thus the carbon nanostructure has excellent conductivity, so that the opening electric field of the cathode is reduced obviously; the heat generated during the field emission process is lowand thus the cathode can be emitted stably at the high current, so that the operating current of the cathode is improved substantially. Moreover, because the three-dimensional covalent structure hasexcellent thermal conductivity, the emission stability of the cathode is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Method for preparing bunchy bismuth nanostructure material

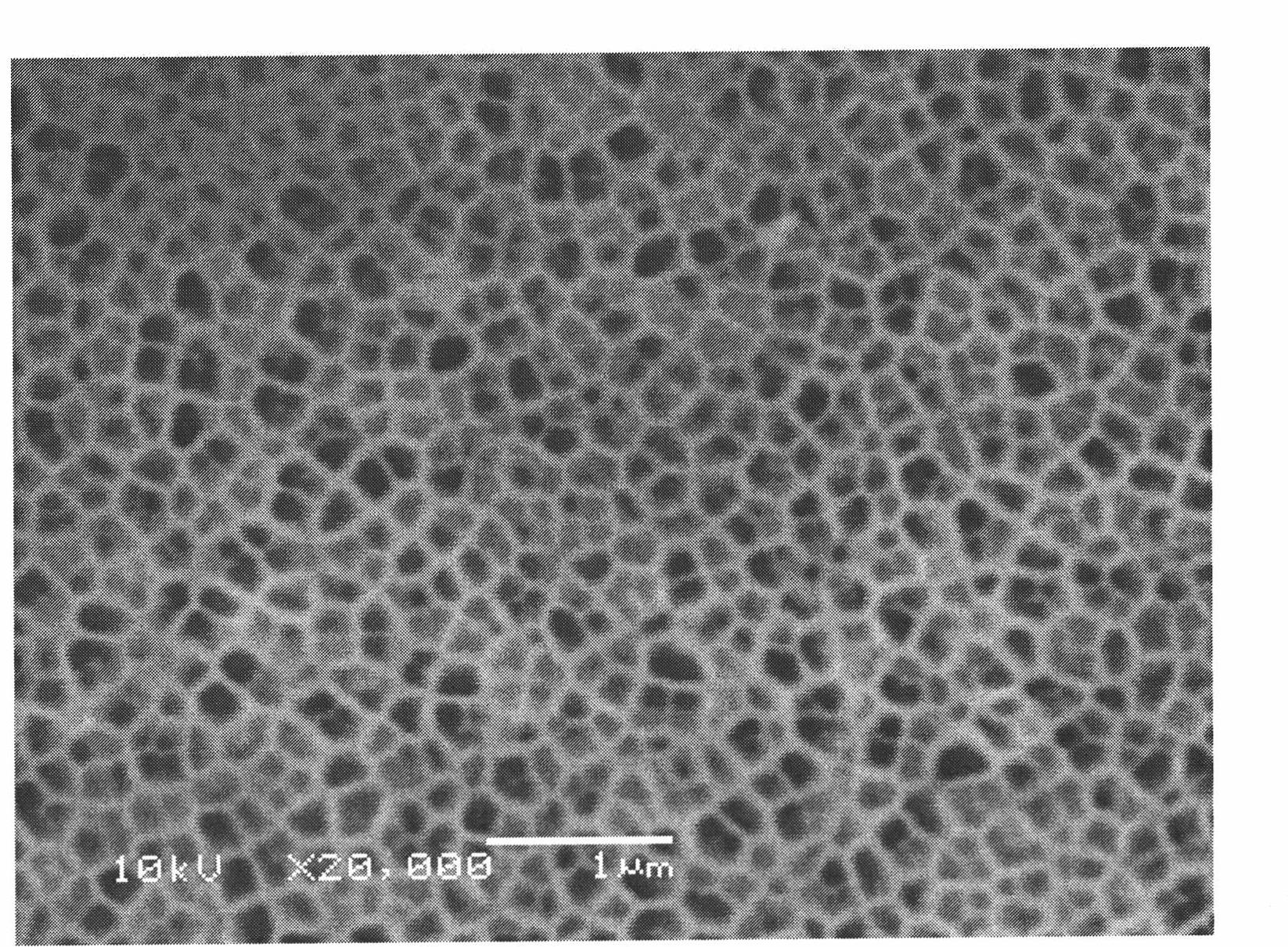

The invention discloses a method for preparing a bunchy bismuth nanostructure material, which comprises the following steps: performing ultrasonic cleaning of an alumina AAO template in an alcohol solution, performing electrodeposition by multi-potential step, and removing the alumina membrane so as to obtain the bunchy bismuth nanostructure material. The invention has simple preparation and high filling ratio. The invention also discloses the prepared bunchy bismuth nanostructure material which has a unique high-density nano-wire array structure, can receive various heat energy from the environment, and has wide commercial application perspectives.

Owner:EAST CHINA NORMAL UNIVERSITY

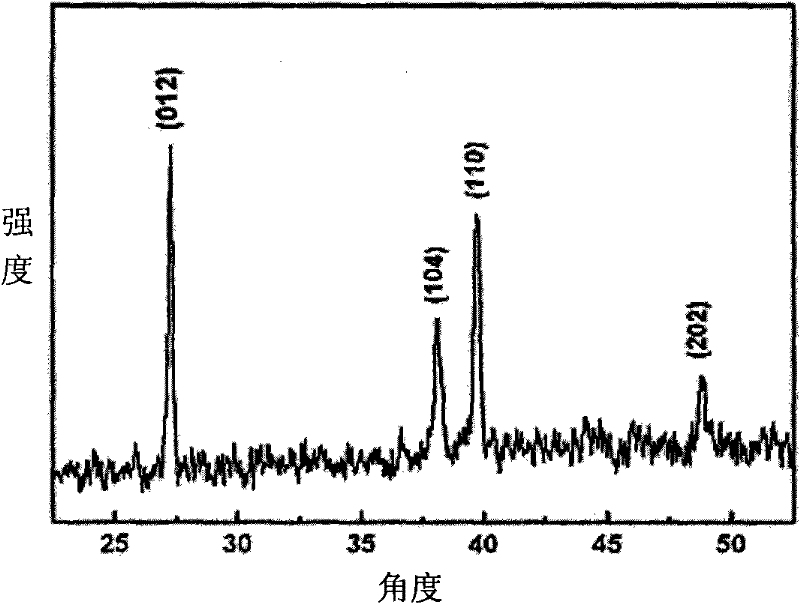

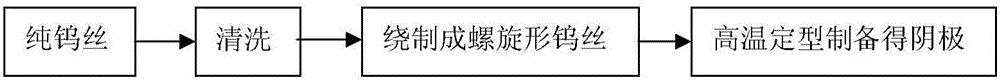

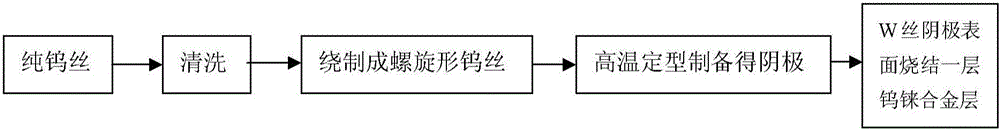

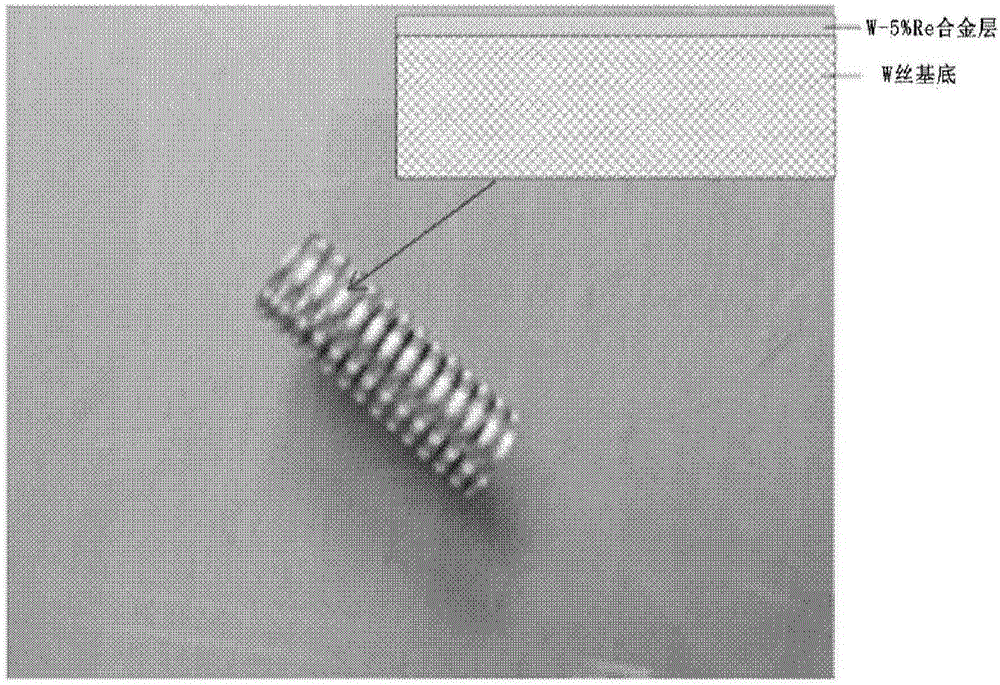

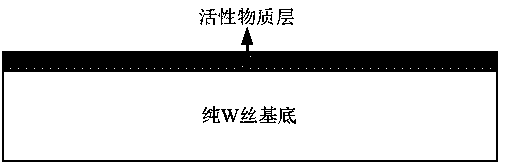

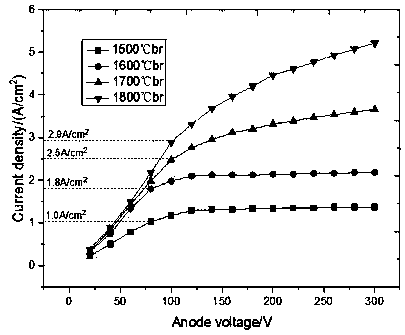

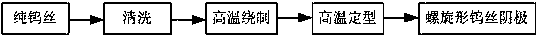

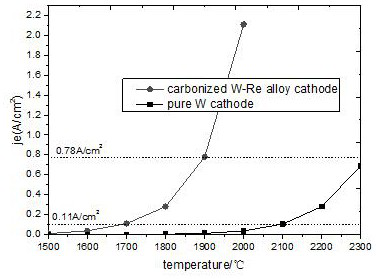

Rhenium doped tungsten-based alloy cathode and preparation method thereof

InactiveCN105702542AImprove launch stabilityLower working temperatureTransit-tube cathodesCold cathode manufactureRheniumHydrogen

The invention provides a preparation method of a rhenium doped tungsten-based alloy cathode. The preparation method comprises the steps of: mixing metal tungsten powder with rhenium powder to obtain evenly mixed tungsten-rhenium alloy powder; mixing the tungsten-rhenium alloy powder with 1.5wt% nitro-cotton solution evenly, applying the mixed solution to the surface of a tungsten cathode substrate, and baking; and placing a tungsten wire with the tungsten-rhenium alloy powder applied on surface into a high-temperature hydrogen furnace, and keeping the tungsten wire at the temperature of 1600+ / -50 DEG C for 10-15 minutes, thereby preparing the rhenium doped tungsten-based alloy cathode. The invention further provides the rhenium doped tungsten-based alloy cathode prepared by adopting the method. The rhenium doped tungsten-based alloy cathode provided by the invention can increase emission current density of a pure tungsten cathode used for a high-power continuous wave magnetron, reduce working temperature of the pure tungsten cathode, reducing surface evaporation rate of the cathode, and further prolonging service life of the cathode.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

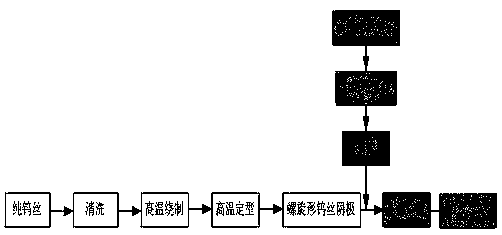

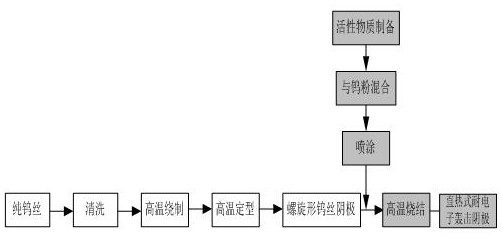

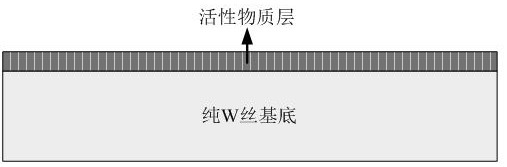

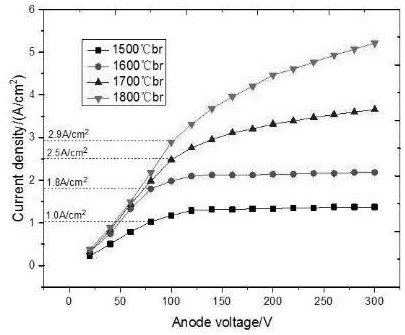

A preparation method of a direct-heating type electron-bombardment-resistant cathode

ActiveCN109037007AExtended service lifeGood launch stabilityTransit-tube cathodesHeat inorganic powder coatingTungstenDirect heating

A preparation method of a direct-heating electron-bombardment-resistant cathode includes mixing tungsten powder and Y2O3-Gd2O3-HfO2 / ZrO2(Y-Gd-Hf / Zr-O) active material powder to obtain uniformly mixedY-Gd-Hf / Zr-O active material powder; uniformly mixing active material-containing powder with (1.5-3)wt% of a gun cotton solution, applying the mixed solution to the surface of a tungsten wire cathodesubstrate and baking; putting a tungsten wire to the surface of which the active material-containing powder is applied in a high temperature hydrogen furnace, and performing heat preservation at 1500+ / - 50 DEG C for 3 to 10 minutes to prepare a direct-heating type electron-bombardment-resistant cathode. The direct-heating type electron-bombardment-resistant cathode of the invention has relativelygood electron-bombardment resistance, and the emission current density of a pure tungsten wire cathode for a magnetron can be increased, and the working temperature and surface evaporation rate of the pure tungsten wire cathode are reduced, thereby prolonging the lives of the cathode and magnetron are prolonged.

Owner:JIUJIANG UNIVERSITY

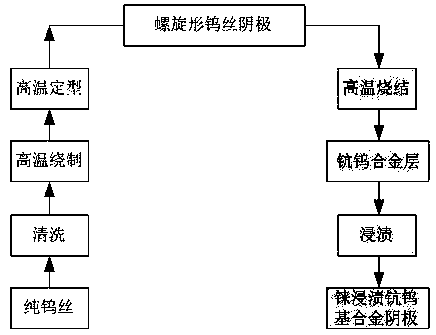

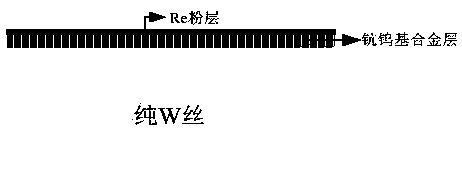

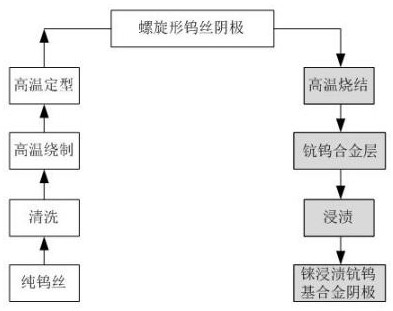

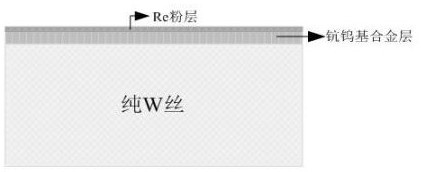

A method for prepare a rhenium-impregnated scandium-tungsten-based alloy cathode

ActiveCN109065424AImprove launch stabilityExtended service lifeTransit-tube cathodesSolid state diffusion coatingRheniumHydrogen

A method for prepare a rhenium impregnated scandium-tungsten base alloy cathode comprises mixing metal scandium powder and tungsten pow to obtain uniformly mixed scandium-tungsten alloy powder; The scandium-tungsten alloy powder is uniformly mixed with (1.5-3) wt% nitrocellulose solution, the mixed solution is applied on the surface of the tungsten wire cathode substrate and baked; Putting tungsten wires with scandium-tungsten alloy powder on the surface into a high-temperature hydrogen furnace, keeping the temperature at 1350 +-50 DEG C for 5-10 minutes to prepare a scandium-tungsten base alloy layer; Then, impregnating a mixed solution of metal rhenium powder and (1.5-3) wt% nitrocellulose solution on the surface of the scandium-tungsten based alloy layer, and baking; The tungsten wire impregnated with rhenium powder on the surface of Sc-W based alloy layer was put into a high temperature hydrogen furnace and kept at 1500 + / - 50 DEG C for 5 - 10 minutes. The cathode of Re-impregnatedSc-W based alloy was prepared. The rhenium-impregnated scandium-tungsten-base alloy cathode prepared by the method of the invention can improve the emission current density of the pure tungsten wirecathode for magnetron, reduce the working temperature and the surface evaporation rate of the pure tungsten wire cathode, thereby prolonging the service life of the cathode and the magnetron.

Owner:JIUJIANG UNIVERSITY

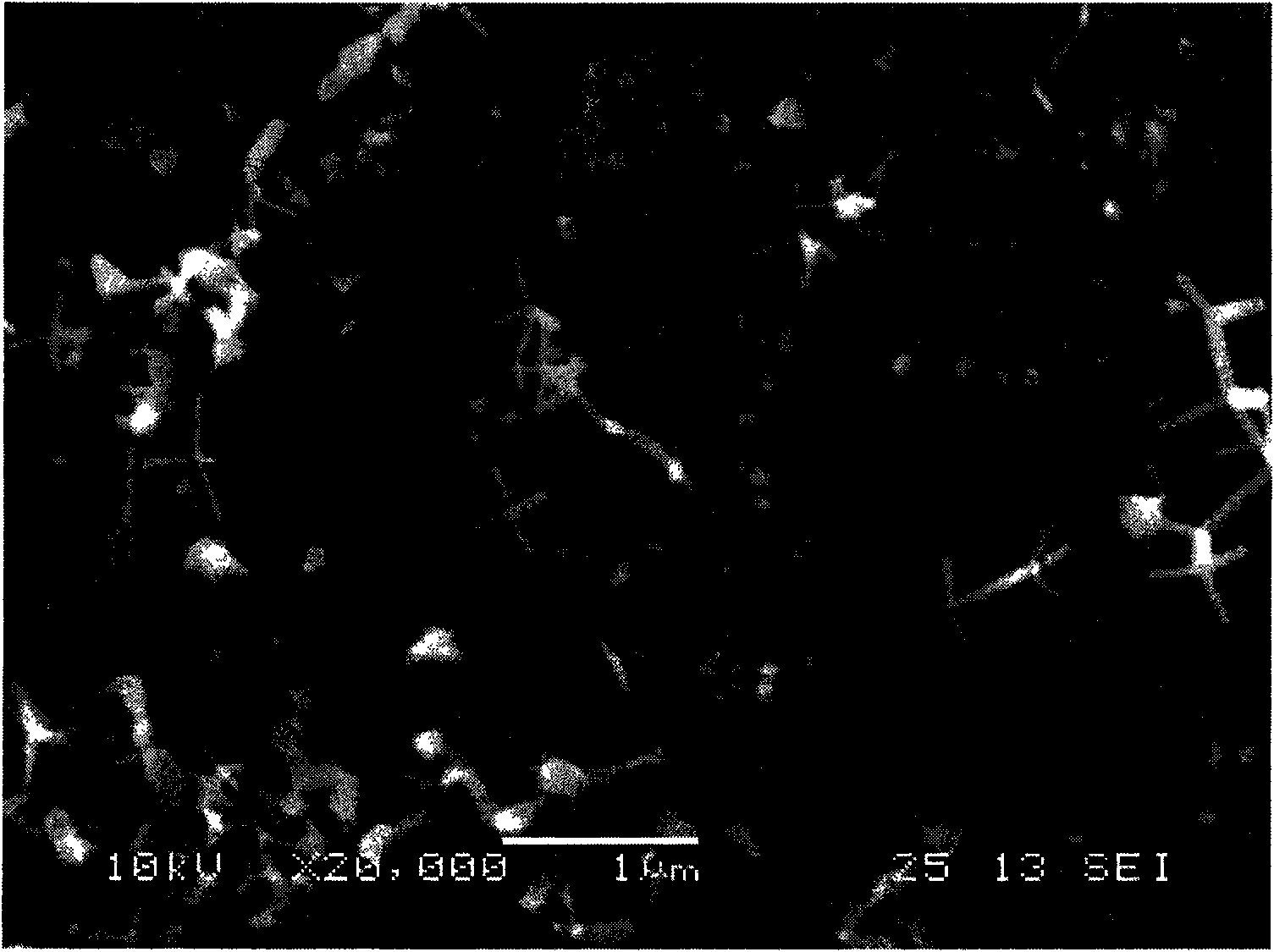

Method for preparing zinc oxide nano-layer structure on supportless carbon nano-tube film

InactiveCN101560640AImprove field emission characteristicsImprove field emission performanceVacuum evaporation coatingSputtering coatingField emission currentNitrogen

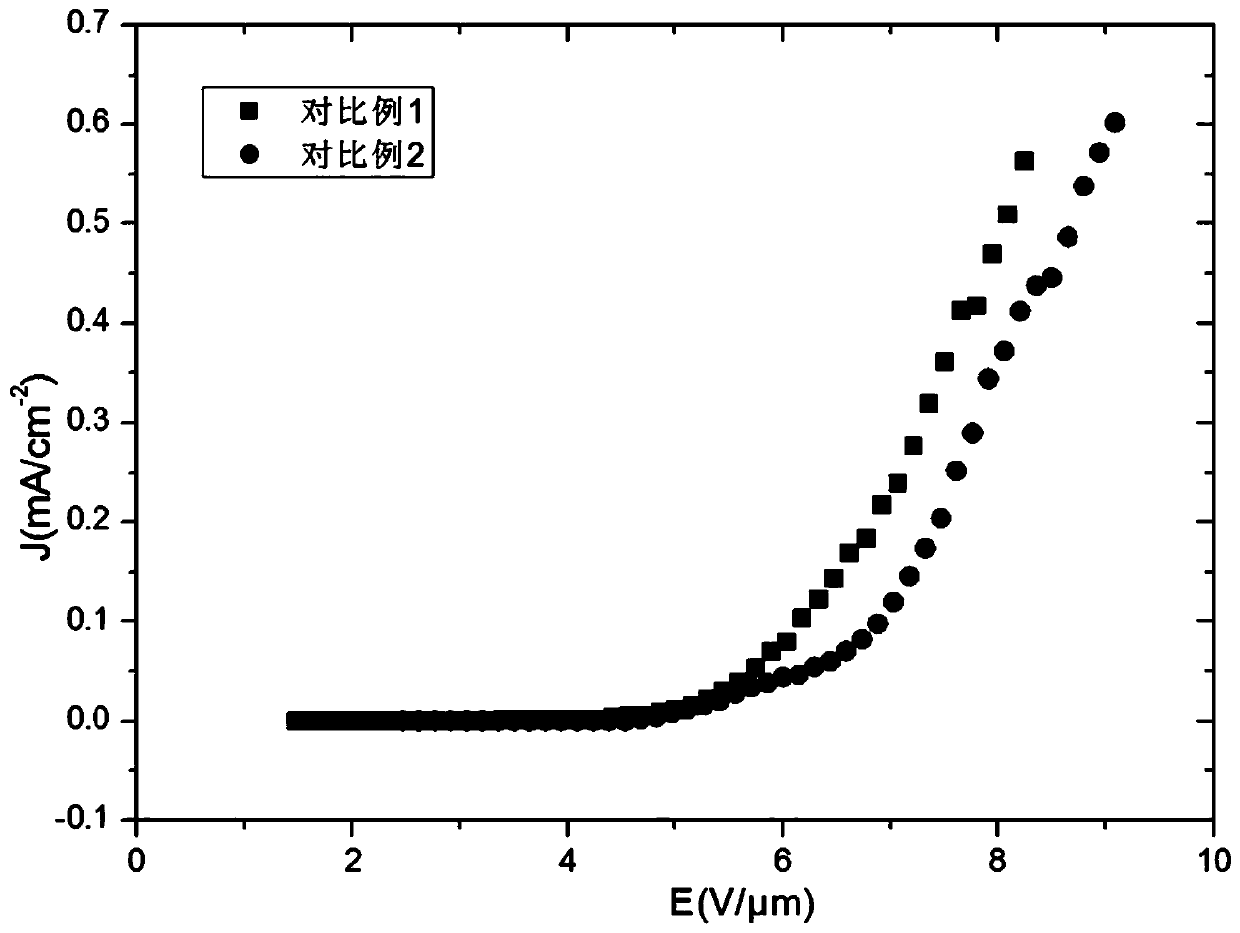

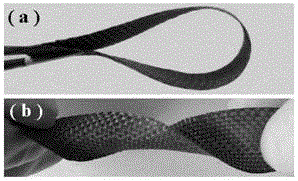

The invention discloses a method for preparing a zinc oxide nano-layer structure on a supportless carbon nano-tube film, which is characterized in that zinc oxide is evenly attached to the supportless carbon nano-tube film to form the zinc oxide nano-layer structure through thermal evaporation by using nitrogen as carrier gas, wherein the zinc oxide nano-layer has a needle-like structure; the length thereof is 1mu m; and the particle size of zinc oxide particles is about 100 nanometers. The method improves the field emission characteristic of a carbon tube, improves the field emission performance and increases the field emission current density with lower turn-on electric field and good emission stability; and compared with the prior art, the method has the advantages of simple manufacturing process, low cost and good repeatability, is particularly suitable for large-area manufacture, and can perform kinking and clipping.

Owner:EAST CHINA NORMAL UNIV

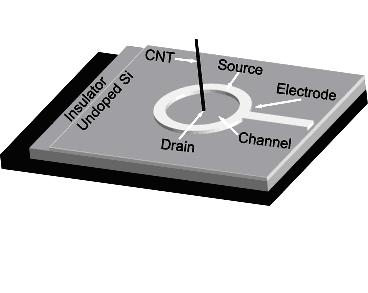

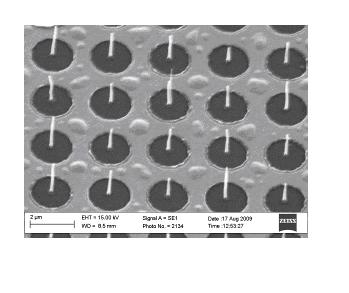

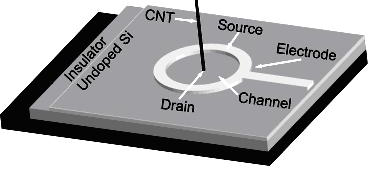

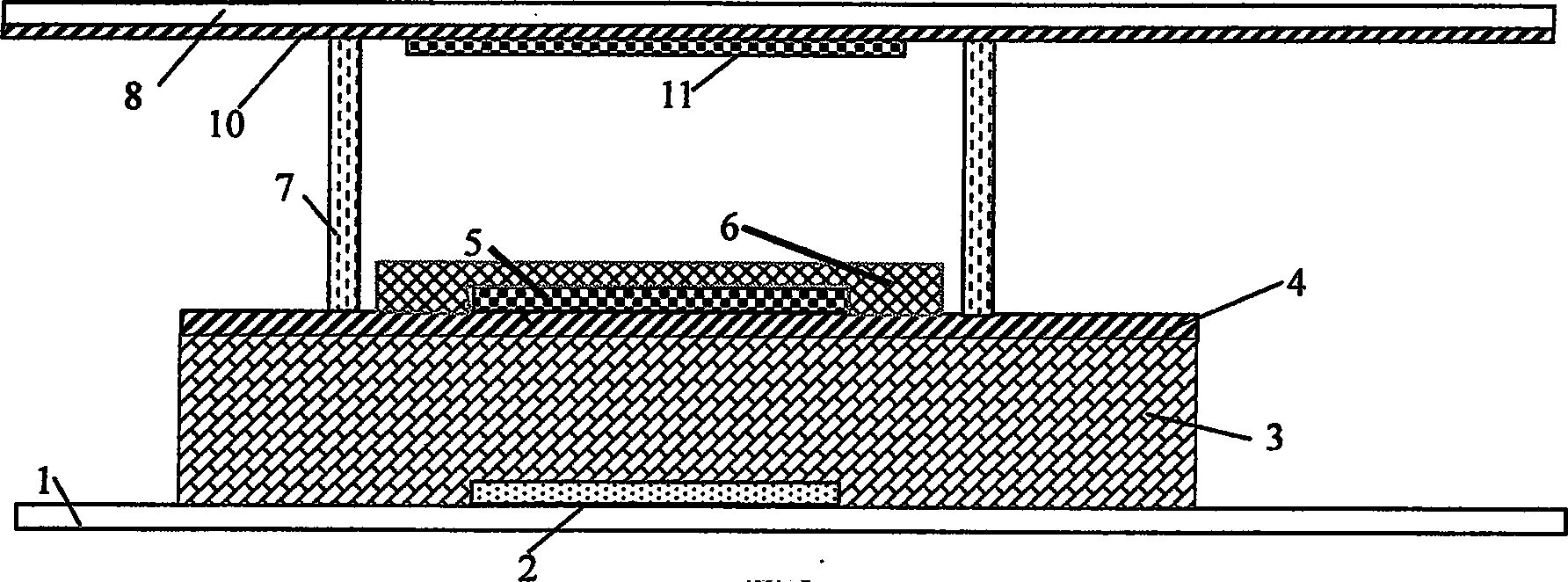

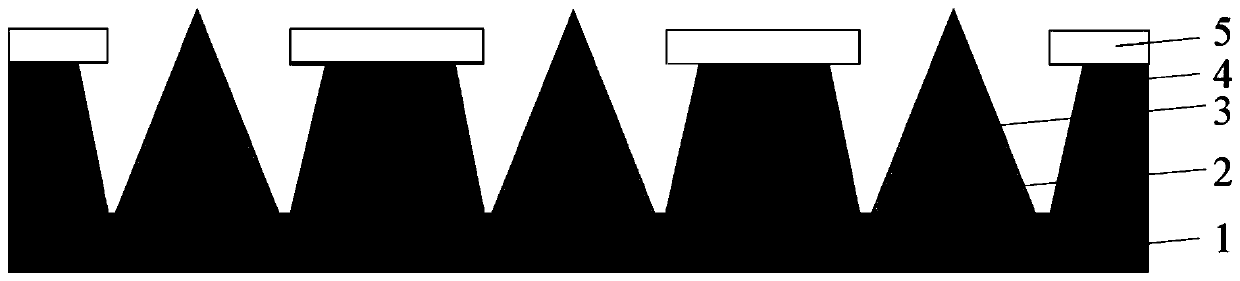

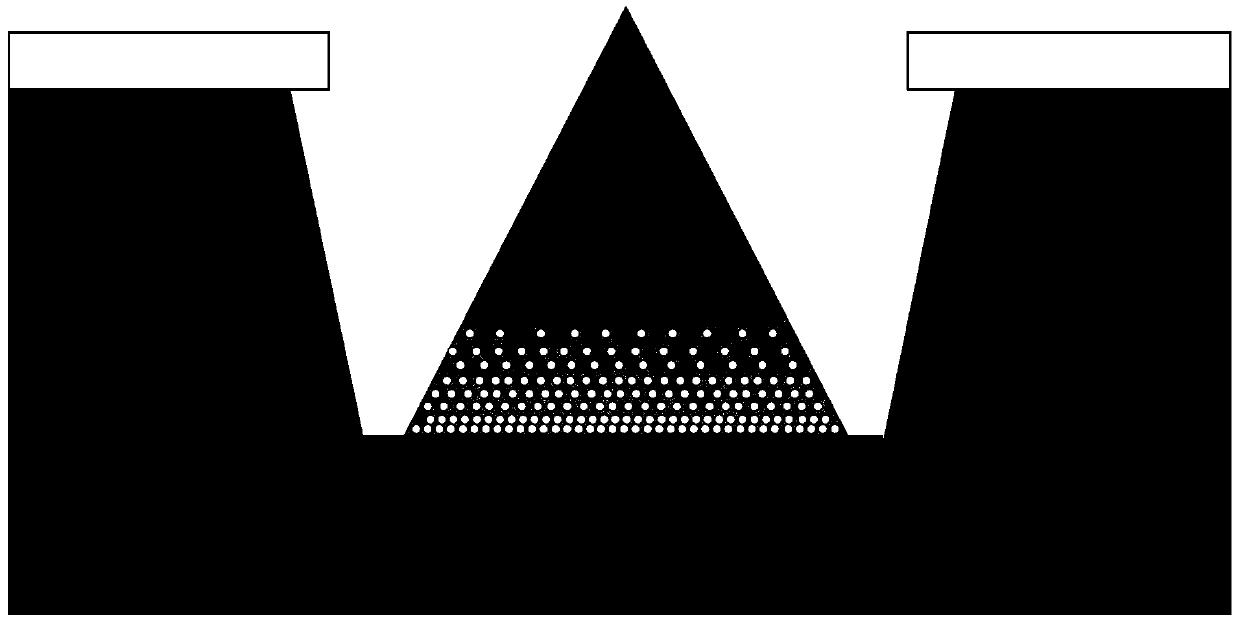

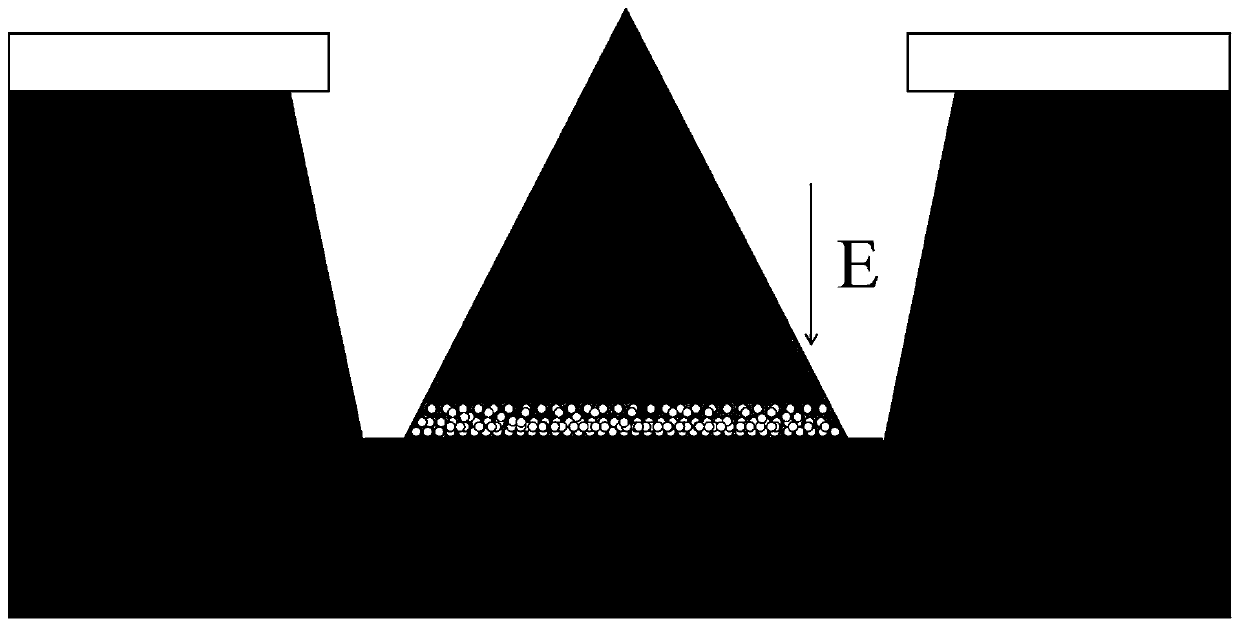

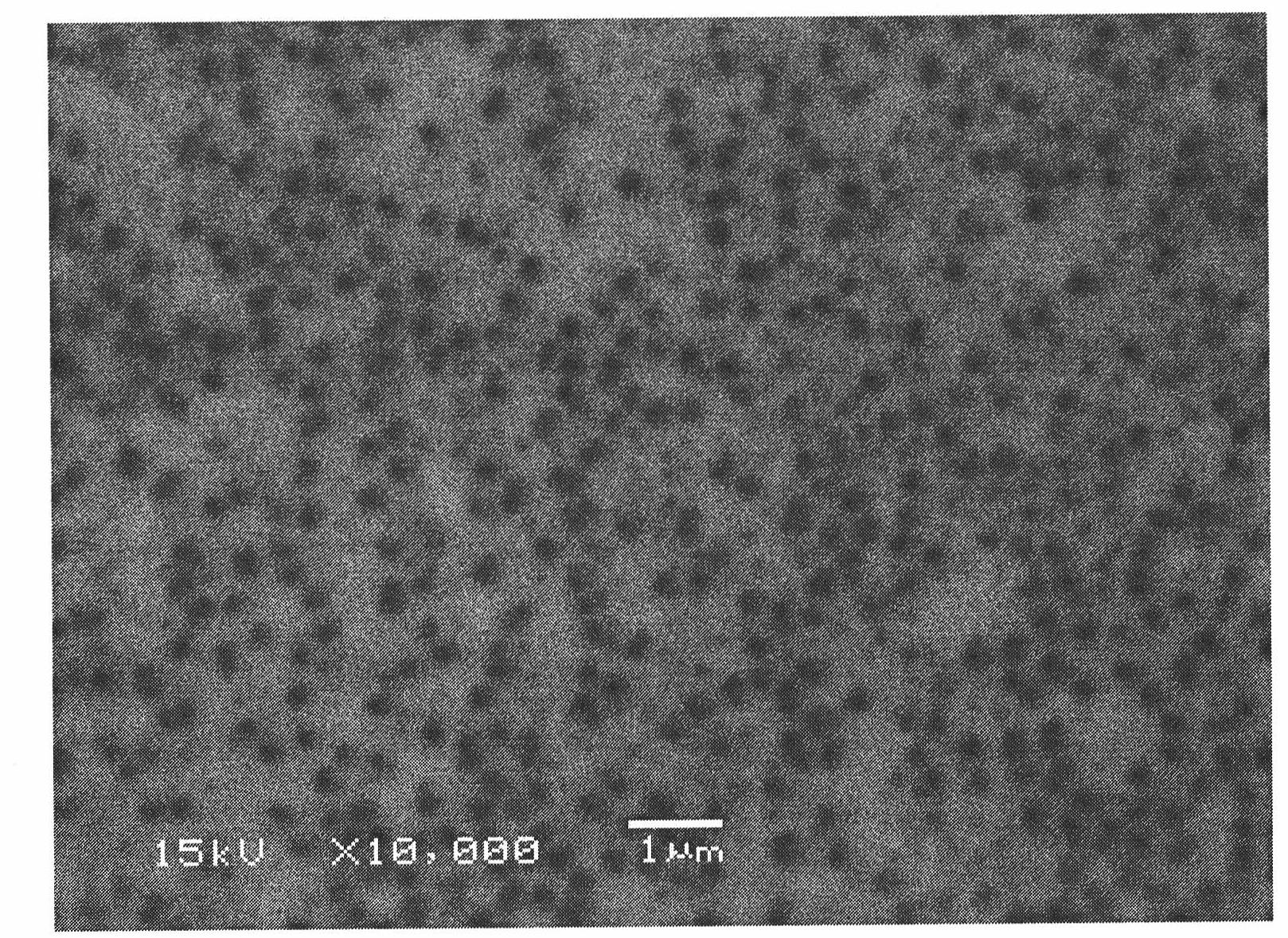

CNT (carbon nano tube) field emission array with current limiting transistors and preparation thereof

InactiveCN102306595AIncreased emission current densityHigh densityDischarge tube/lamp detailsCold cathode manufactureTransistor arrayCurrent limiting

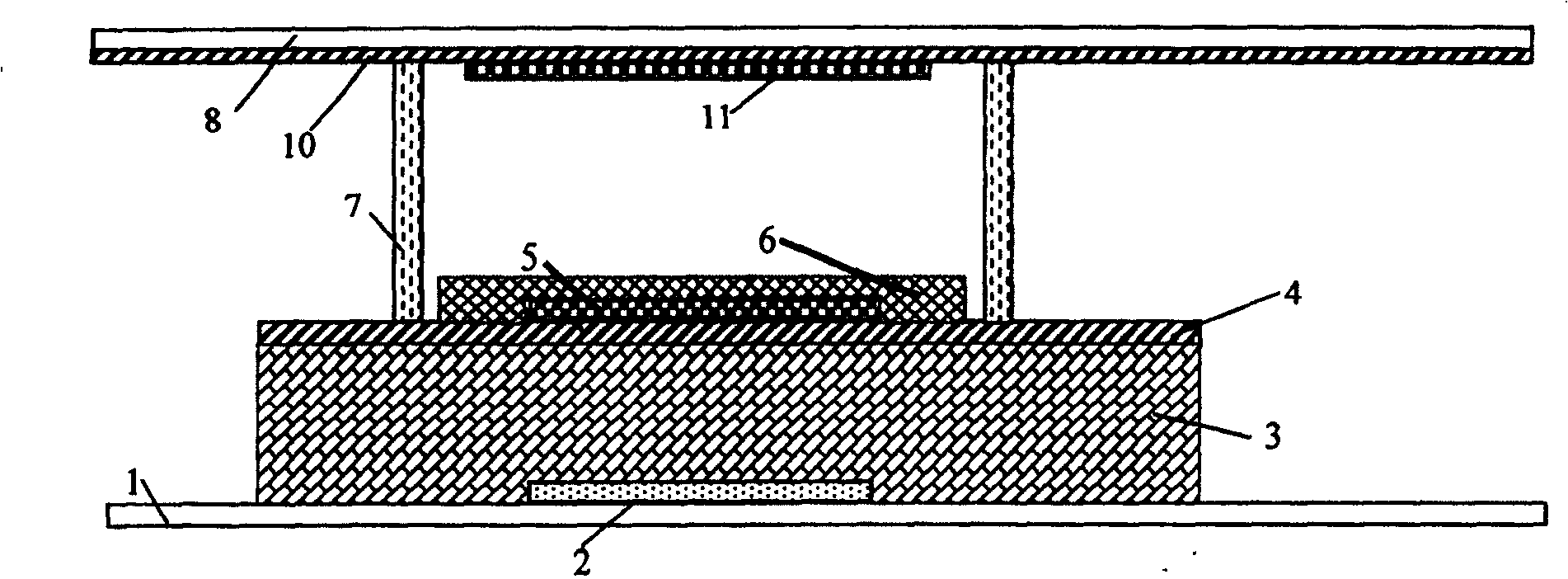

A CNT (carbon nano tube) field emission array with current limiting transistors comprises a cathode, a gate below the cathode, an insulating layer between the cathode and the gate and a semiconductor layer, wherein a conductive substrate is used as the gate; the insulating layer is arranged on the conductive substrate, a semiconductor film is arranged on the insulating layer; a grid-shaped or annular metal electrode which is used as the cathode is arranged on the semiconductor film; the central position of a grid-shaped or annular hole of the grid-shaped or annular metal electrode is provided with a single CNT which grows perpendicular to the substrate; one end of the CNT is electrically connected with the semiconductor layer, and the CNT is electrically connected with the cathode through the semiconductor layer; and CNT field emission elements with the current limiting transistors arrayed in a plane can form a field emission array, and the electrode is a grid-shaped metal electrode. In the invention, each CNT in the CNT field emission array is connected with a current limiting transistor in series, thus an emission element with the large emission current density and the high emission stability can be obtained.

Owner:上海康众光电科技有限公司

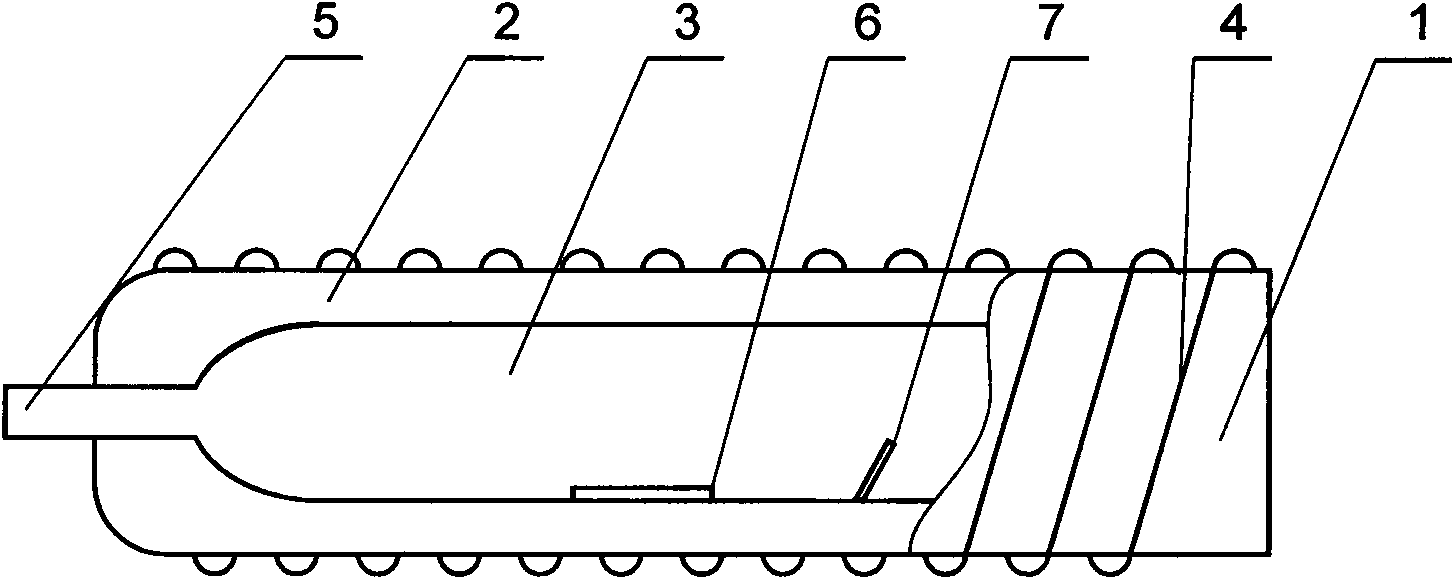

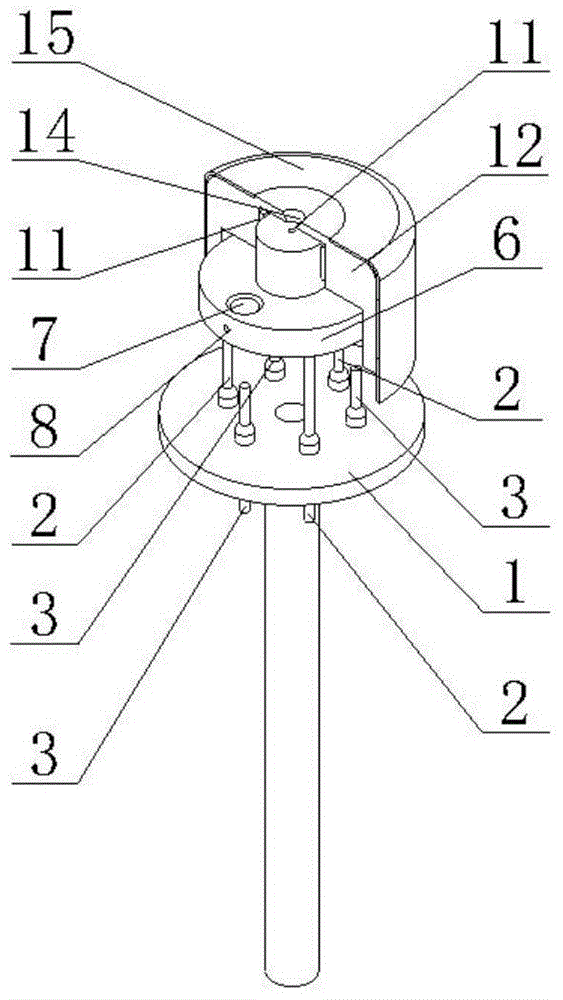

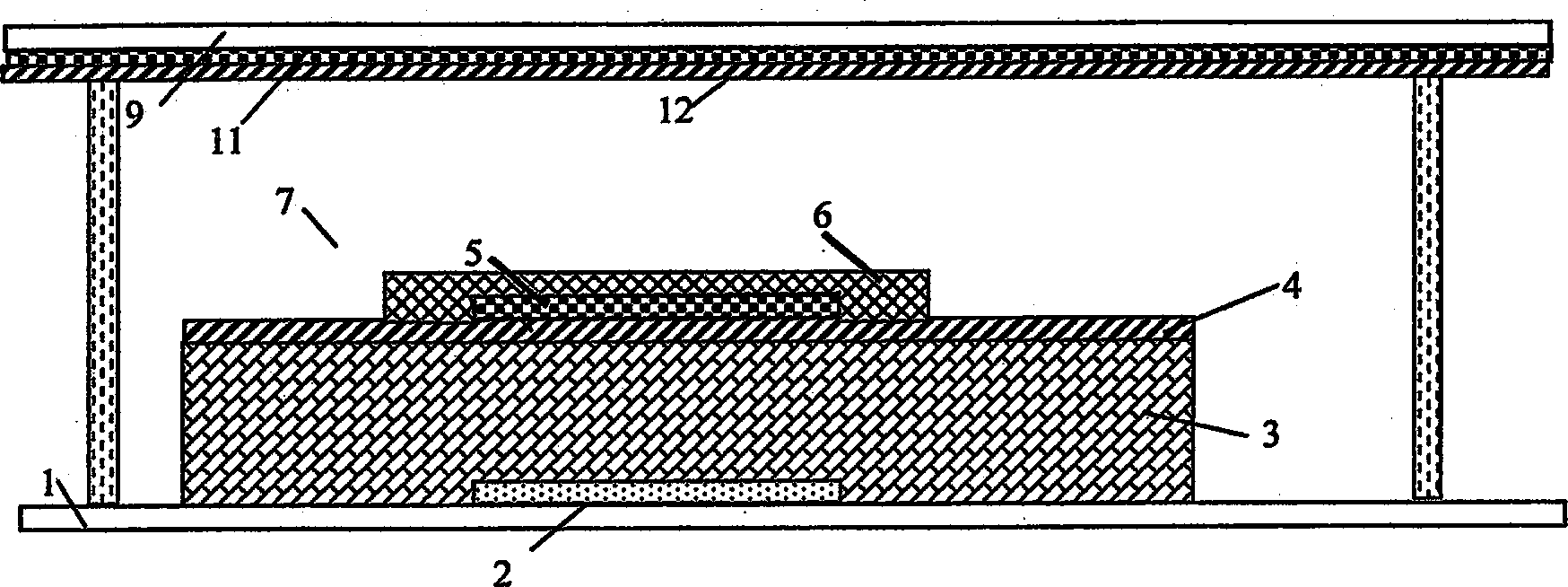

Cathode of cold-cathode X-ray tube

The invention provides a cathode of a cold-cathode X-ray tube. The cathode of the cold-cathode X-ray tube comprises a cathode base and a grid electrode, wherein the cathode base is composed of an upper cylinder and a lower cylinder which are coaxially arranged, the section of the cathode base is in an inverted-T shape, a cathode bar through hole is formed in the central axis of the cathode base, a cathode bar is arranged in the through hole, the three-dimensional size of the cathode bar can be controlled, an electron emitter is arranged on a cathode head, the grid electrode is of an cup-shaped structure, an inverted-T-shaped groove which is matched with the cathode base is formed inside the grid electrode, the cathode base can be embedded in the groove of the grid electrode and does not make contact with the inner wall of the grid electrode, and a semi-conical electron transmission hole used for focusing electrons emitted by the cathode is formed in the center of the grid electrode. According to the cathode of the cold-cathode X-ray tube, the cold cathode made of carbon nanomaterials is used as the X-ray tube of an electron emission source, and preparation of the cathode and the emission area can be effectively controlled through the size of the cathode bar; the three-pole structure is adopted, a small focus point can be obtained through focusing of the grid electrode, and the resolution ratio of X-ray imaging is increased.

Owner:南京康众光电科技有限公司

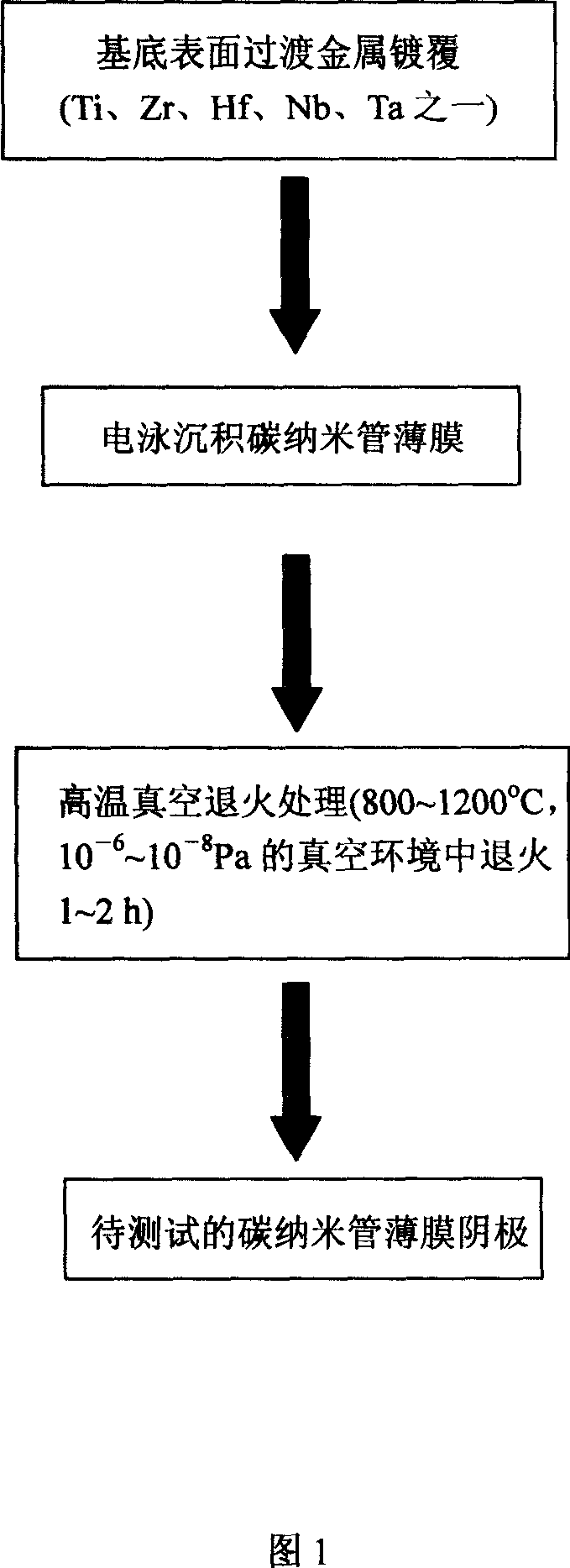

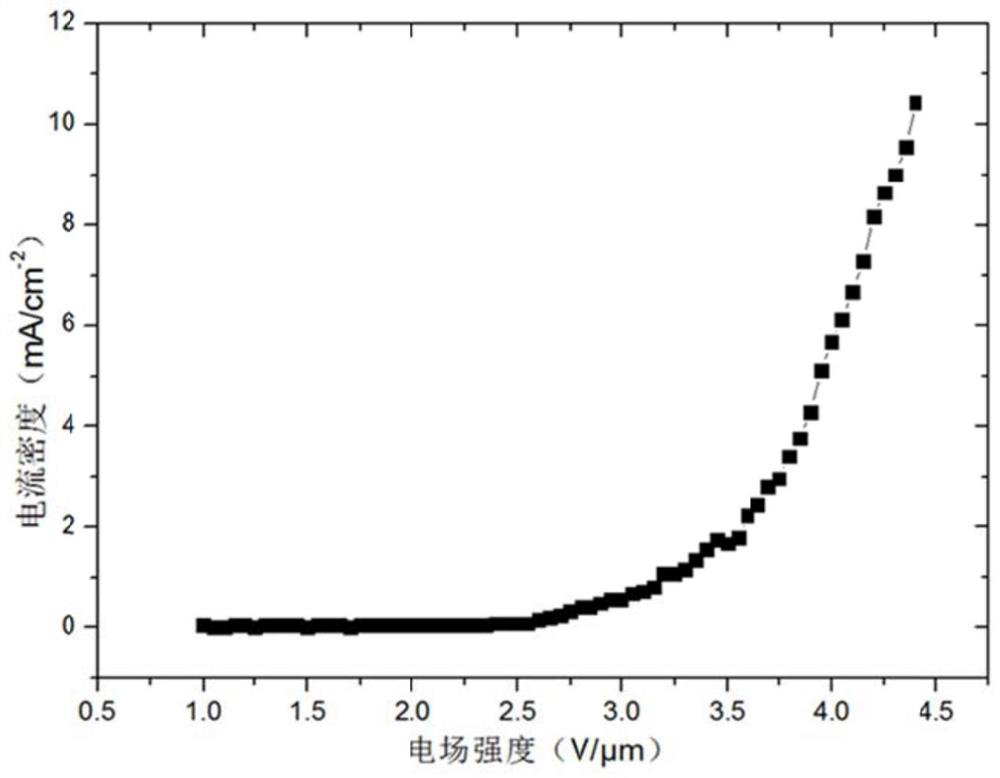

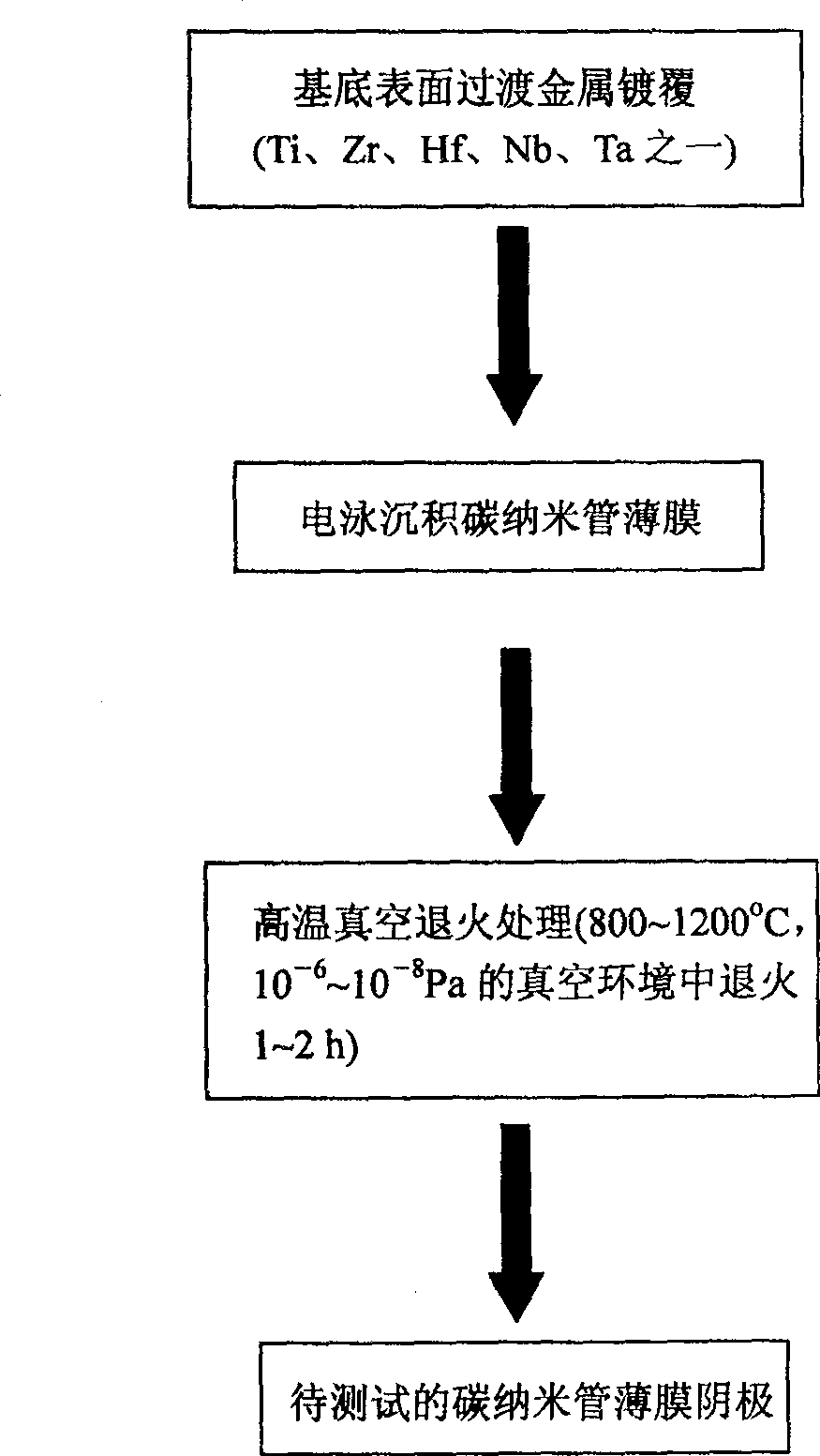

Method for improving emission property of deposited carbon nano-tube thin film electronic field by electrophorisis method

InactiveCN101000845AImprove adhesionExtended service lifeNanostructure manufactureVacuum evaporation coatingField emission currentGas phase

A method for improving performance of carbon nanotube film electronic field emission by electrophoresis deposit means includes plating transition metal film on conductive substrate material by physical gas phase depositing process, utilizing plated conductive substrate as cathode to deposit carbon nanotube film on said cathode through electrophoresis depositing process and carrying out annealing treatment on cathode deposited with carbon nanotube film for raising field emission current density.

Owner:TIANJIN UNIV

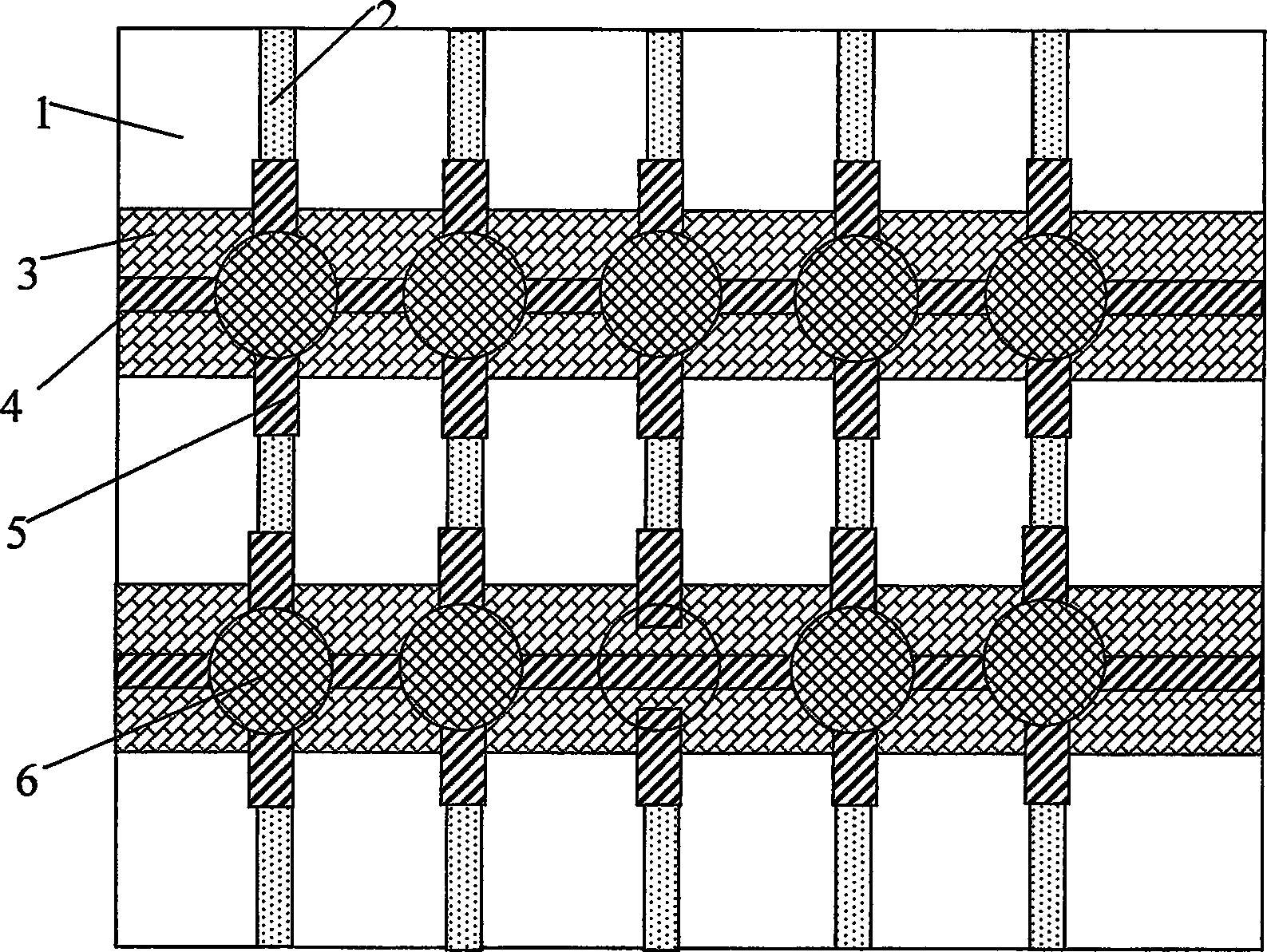

Triple pole structure of plane type field emission, and preparation method

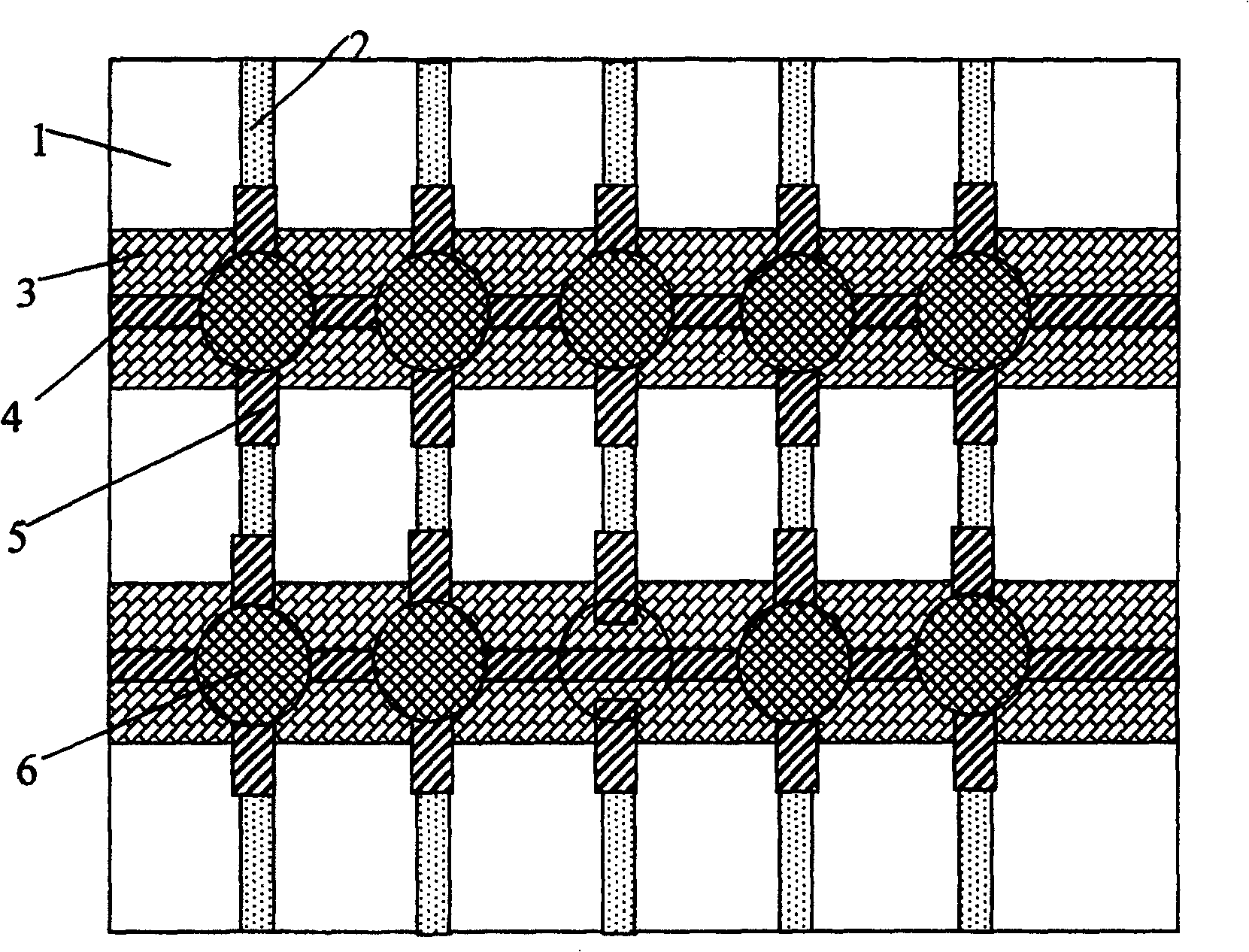

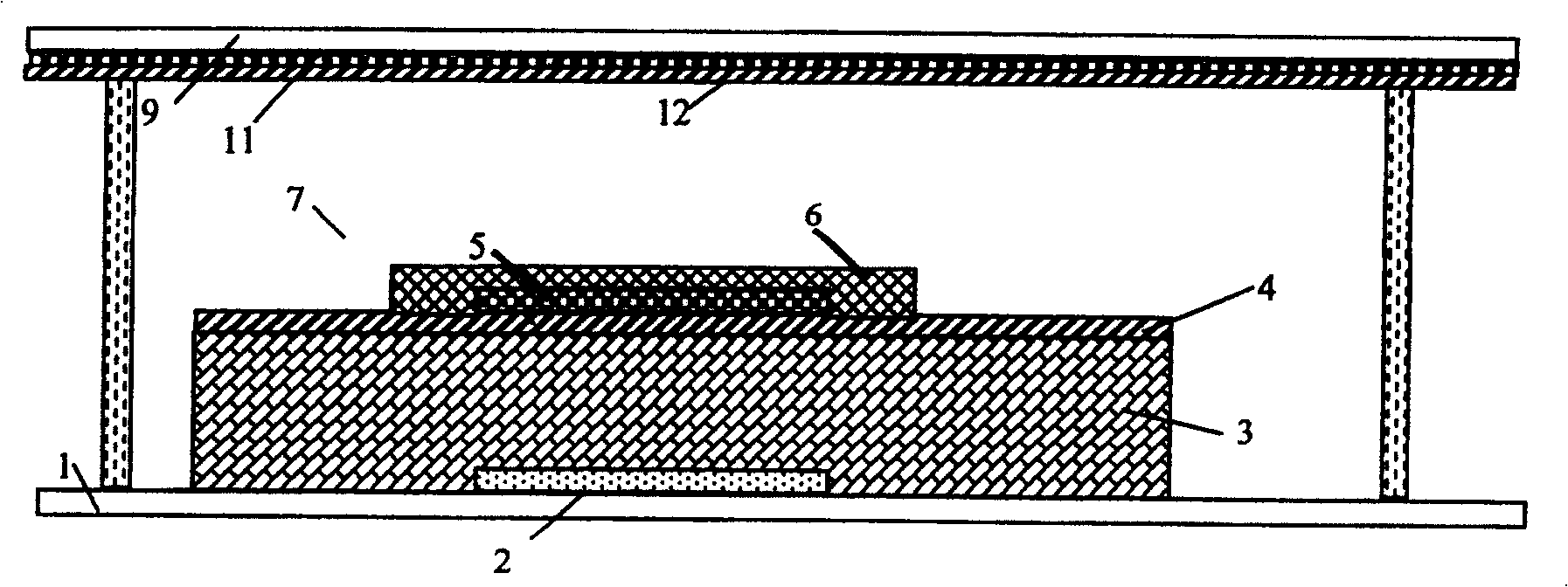

InactiveCN1874625AIncreasing the thicknessReduce leakage currentElectrical apparatusElectroluminescent light sourcesFluorescenceField electron emission

The method comprises: setting the data electrode on the glass cathode baseboard; on the data electrode, setting the dielectric layer with a horizontal bar shape and perpendicular with the data electrode; on the dielectric layer, setting the row scanning electrode; on the row scanning electrode, setting the connection electrode parallel with the data electrode; at the gap between the connection electrode and the row scanning electrode, setting a field emission material with a certain resistance property; on the glass cathode base board and the dielectric layer, setting the supporter; on the supporter, setting a anode glass baseboard; on the lower surface the glass anode baseboard, setting the anode electrode; on the lower surface of the anode electrode, setting a fluorescent powder layer.

Owner:SOUTHEAST UNIV

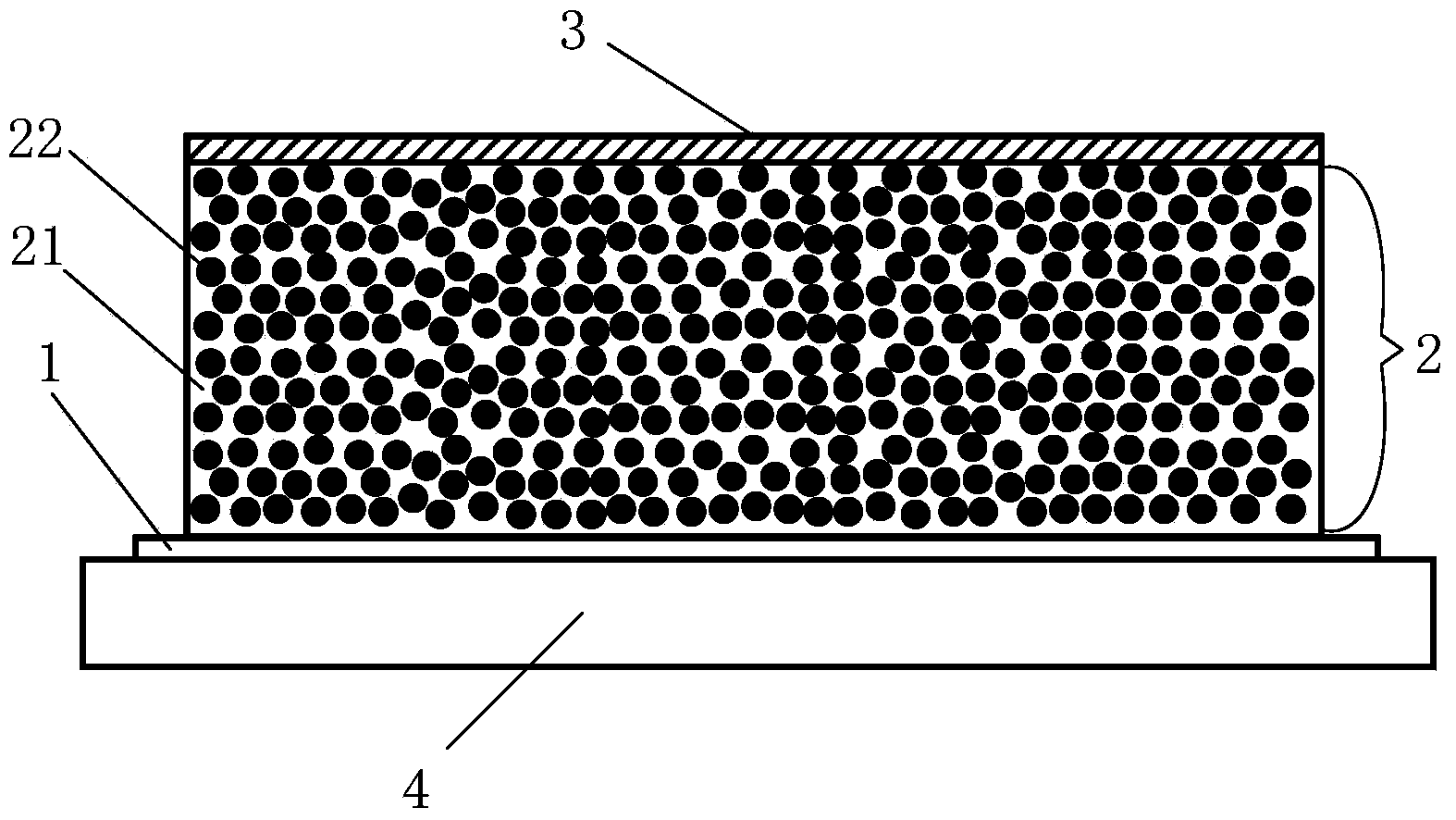

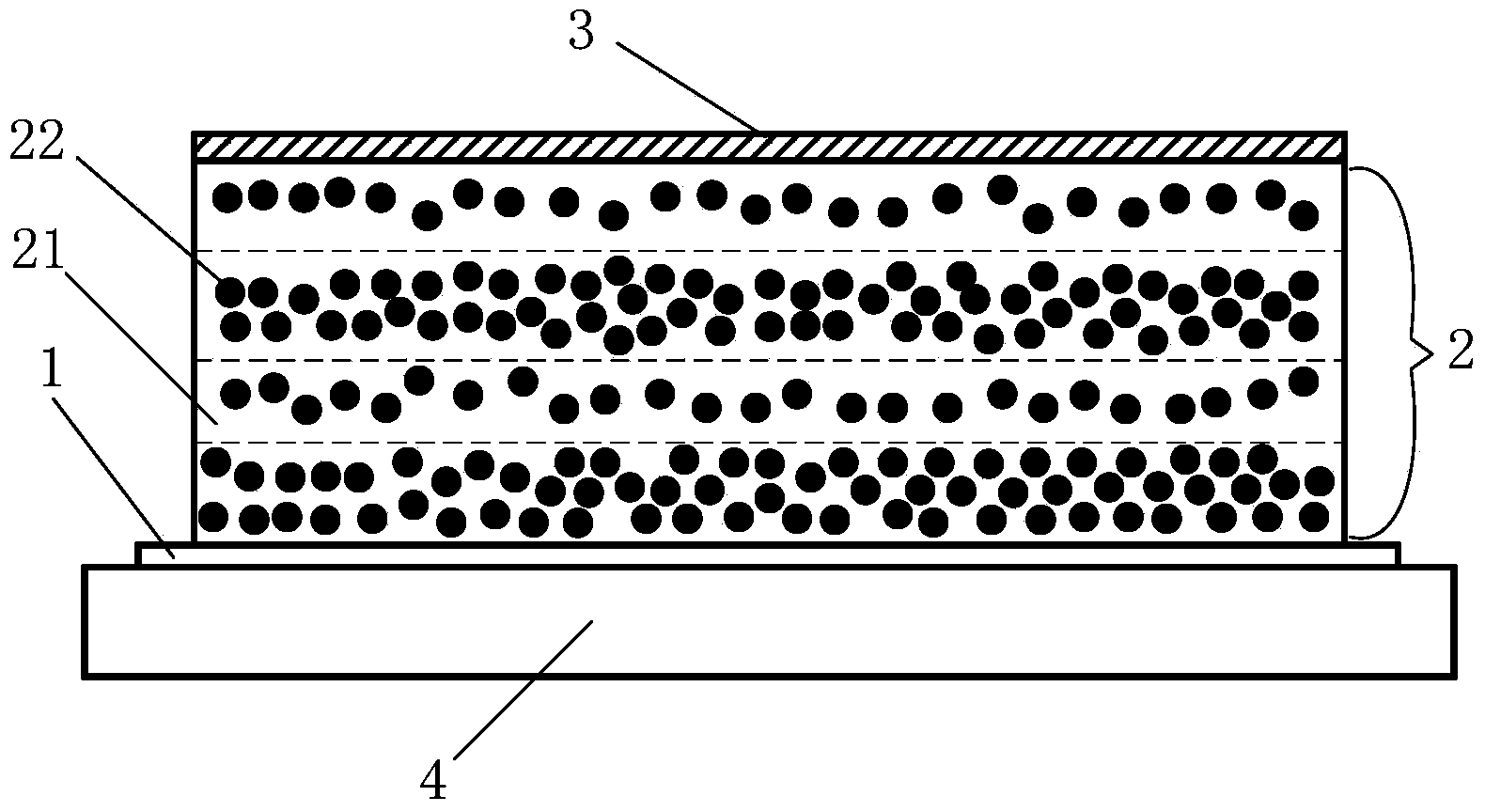

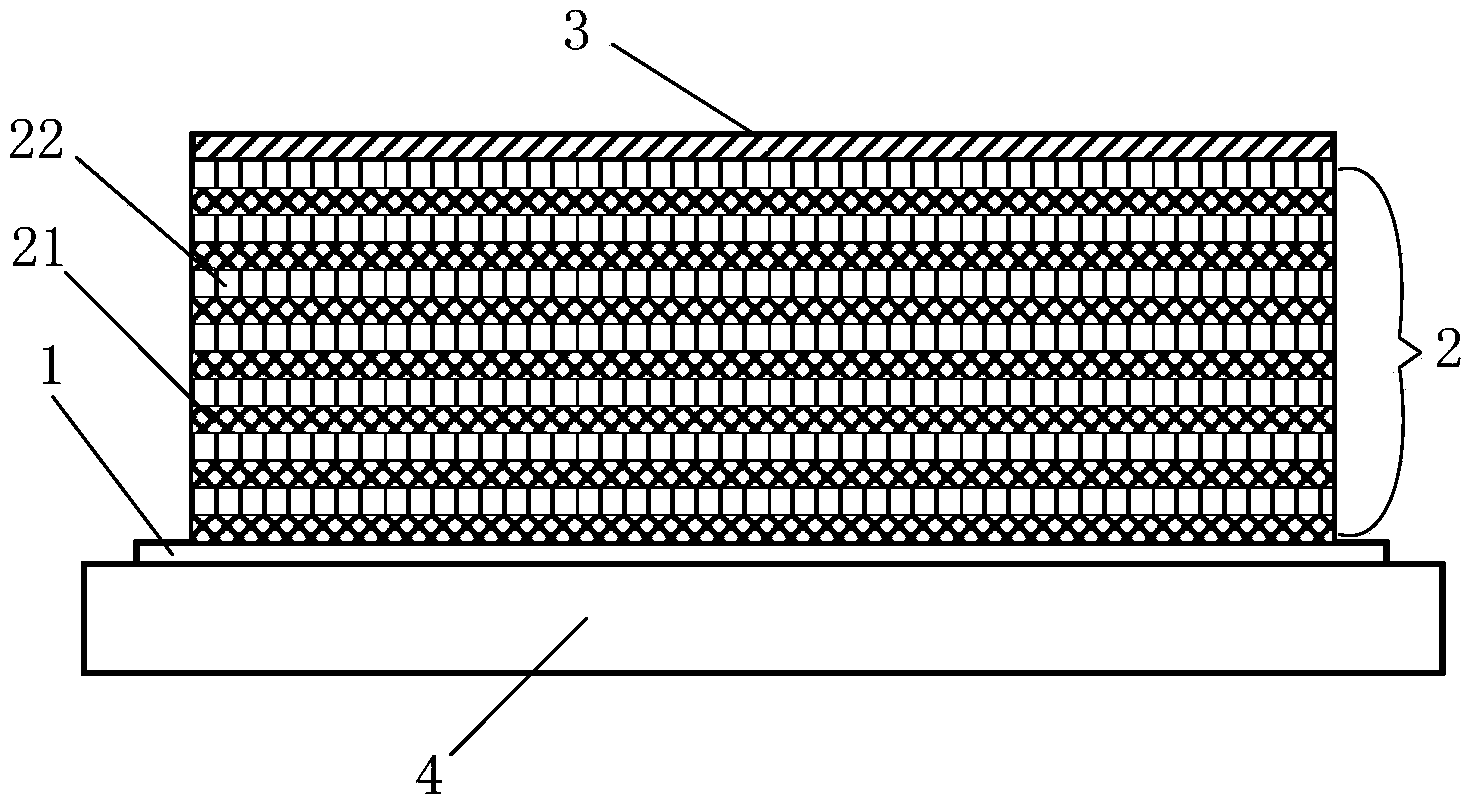

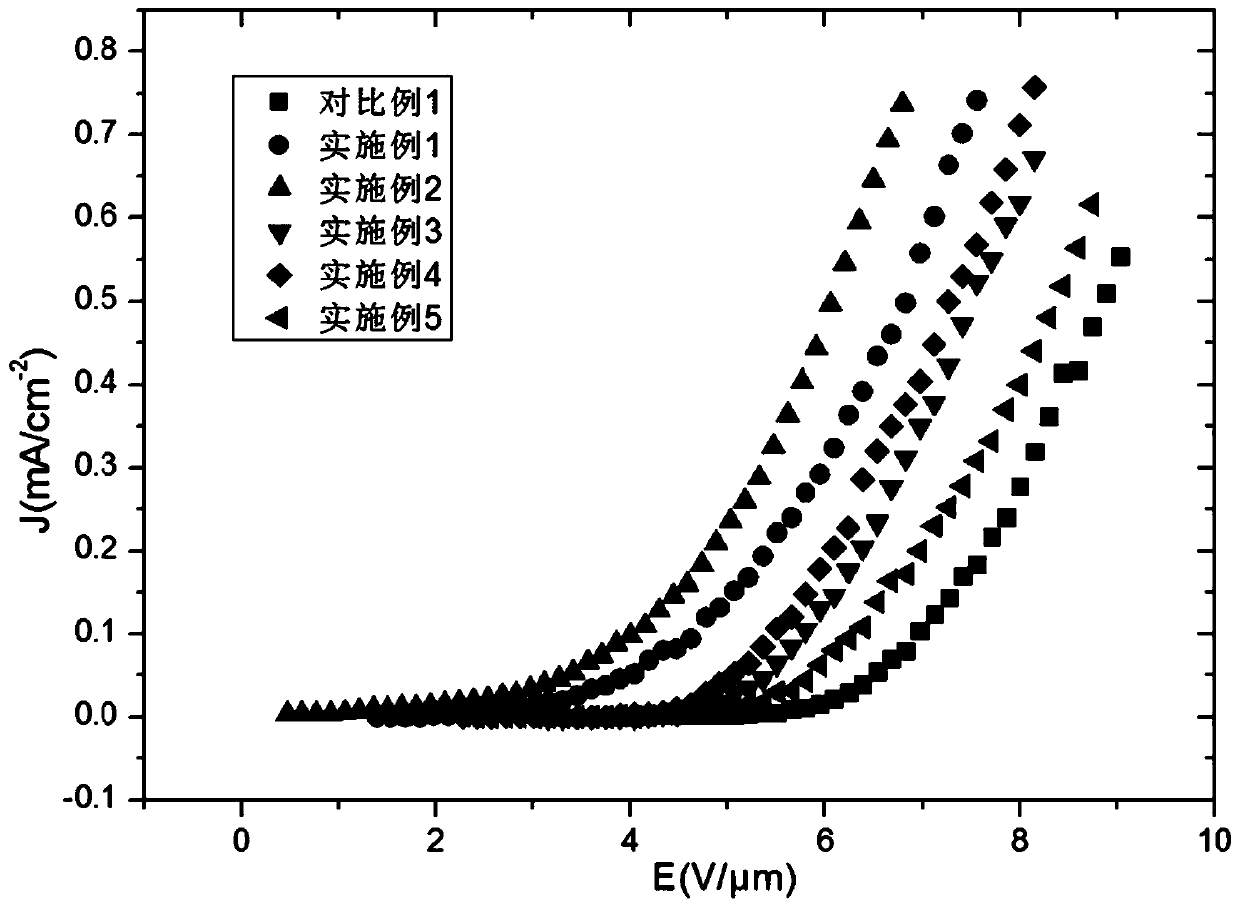

Nanometer silicon film cathode and manufacturing method thereof

InactiveCN104357800AGood repeatabilityIncrease the electric field strengthVacuum evaporation coatingSputtering coatingDensity distributionNanometre

The invention discloses a nanometer silicon film cathode and a manufacturing method thereof. The nanometer silicon film cathode consists of a bottom electrode, a nanocrystalline silicon-containing silicon dioxide layer (nanocrystalline silicon particles are embedded into silicon dioxide) and a top electrode, which are sequentially manufactured on a substrate, wherein the nanocrystalline silicon-containing silicon dioxide layer is prepared by combining a sputtering method with a high-temperature annealing process. In a preparation process of the nanocrystalline silicon-containing silicon dioxide layer, the partial pressure ratio of argon and oxygen, which are introduced into a coating cavity, or the sputtering power of a silicon target and a silicon dioxide target is regulated to control the sizes and density distribution of the nanocrystalline silicon particles in the nanocrystalline silicon-containing silicon dioxide layer to realize the periodically changing layered distribution of the density of the nanocrystalline silicon particles with proper particle sizes in the nanocrystalline silicon-containing silicon dioxide layer. A manufacturing process for the nanometer silicon film cathode is compatible with a silicon microelectronic processing process, and stable electron emission performance is achieved.

Owner:XI AN JIAOTONG UNIV

Graphene field emission cathode and preparation method thereof

PendingCN111128634AIncreased probability of electron tunnelingReduce the turn-on electric fieldElectric discharge tubesDischarge tube/lamp detailsField emission currentElectrically conductive

The invention provides a graphene field emission cathode, which comprises a conductive substrate and a graphene / nano-metal composite layer combined on one surface of the conductive substrate, whereinthe graphene / nano-metal composite layer comprises a graphene layer and a nano-metal material layer combined on the graphene layer, the nano-metal material layer is arranged on the surface, which deviates from the conductive substrate, of the graphene layer, the metal-nano material layer is composed of metal nanoparticles, and the work function of the metal nanoparticles is less than or equal to 4.5eV. By arranging the low-work-function metal nanoparticles on the surface of graphene, the starting electric field of the graphene cathode is remarkably reduced, the field emission current density isimproved, and the current emission stability of the graphene field emission cathode is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

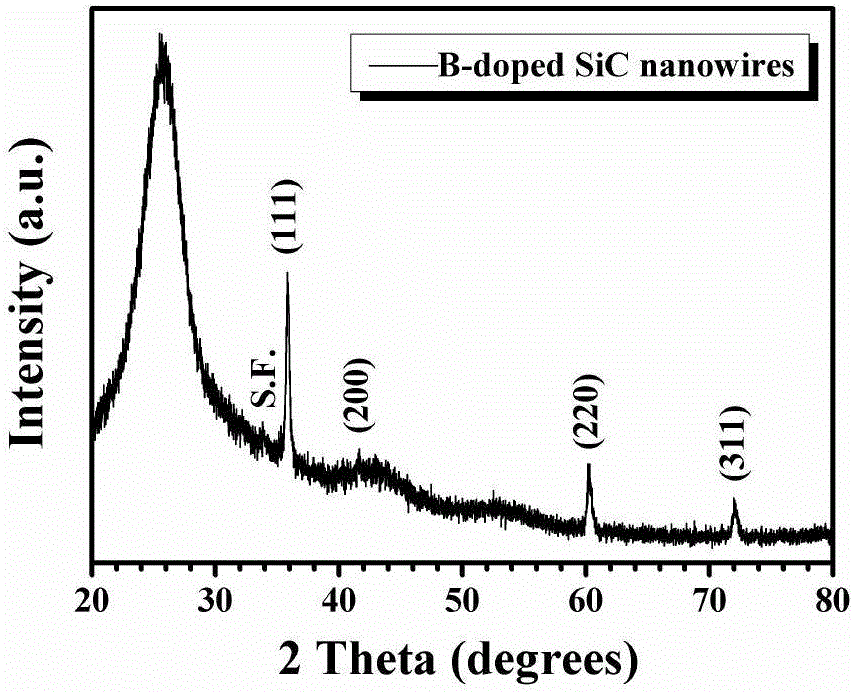

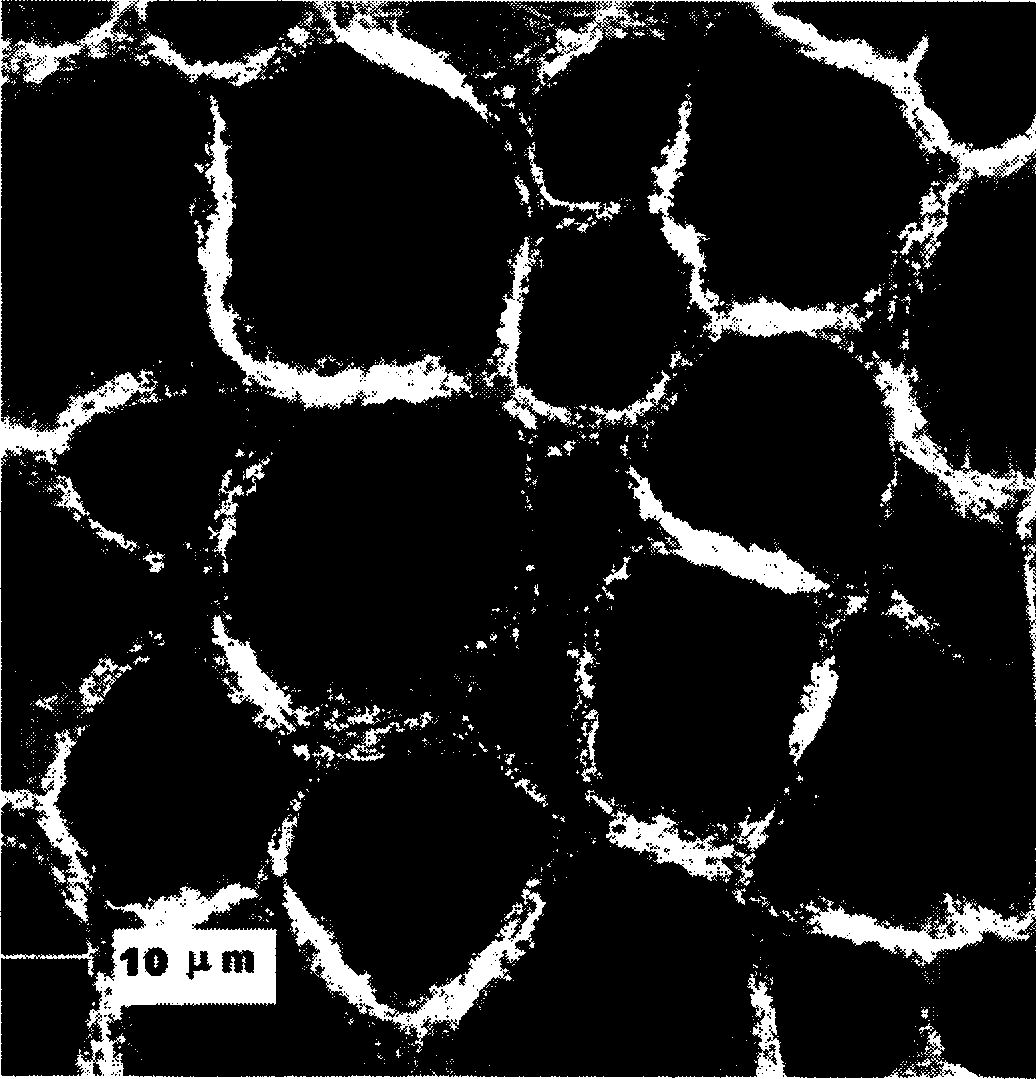

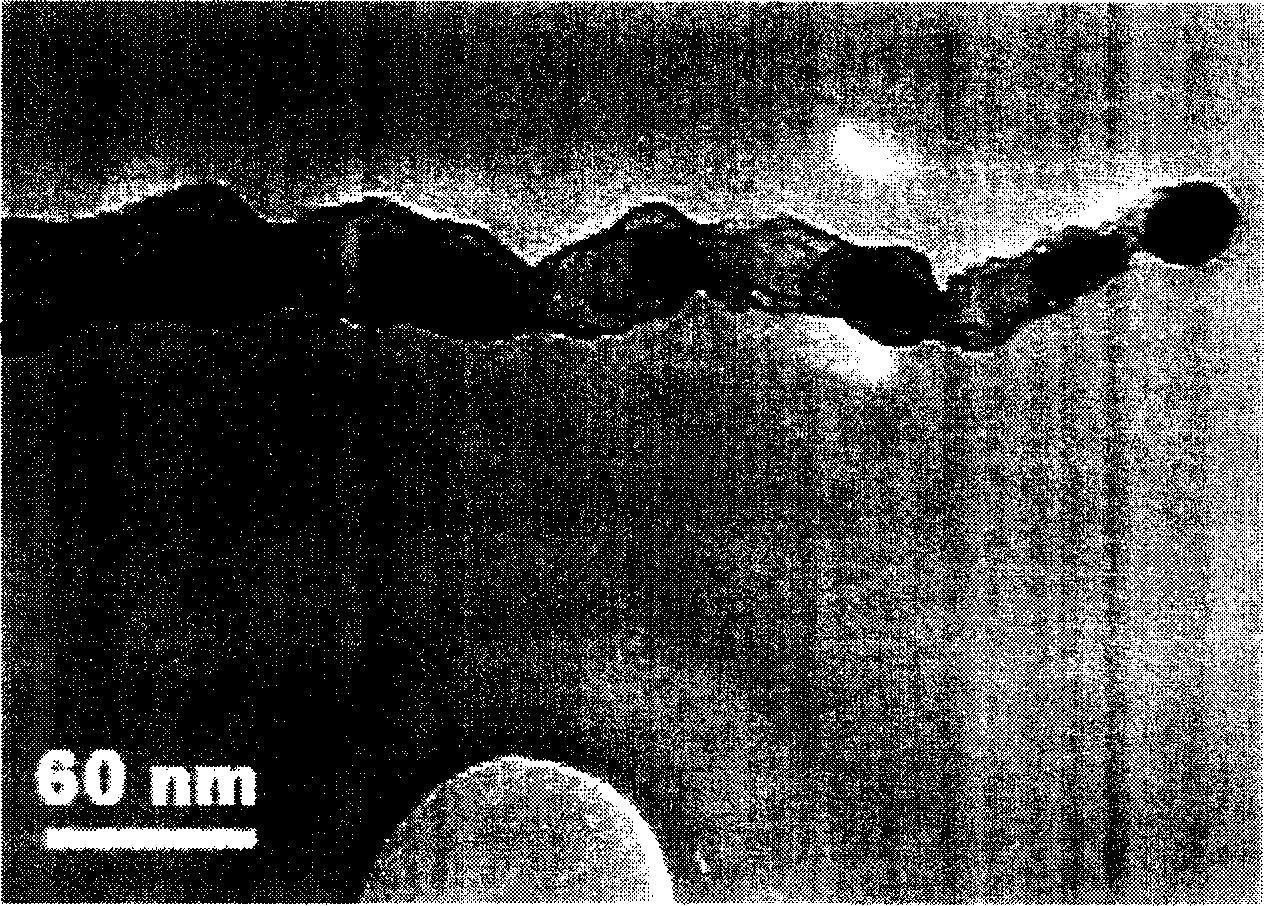

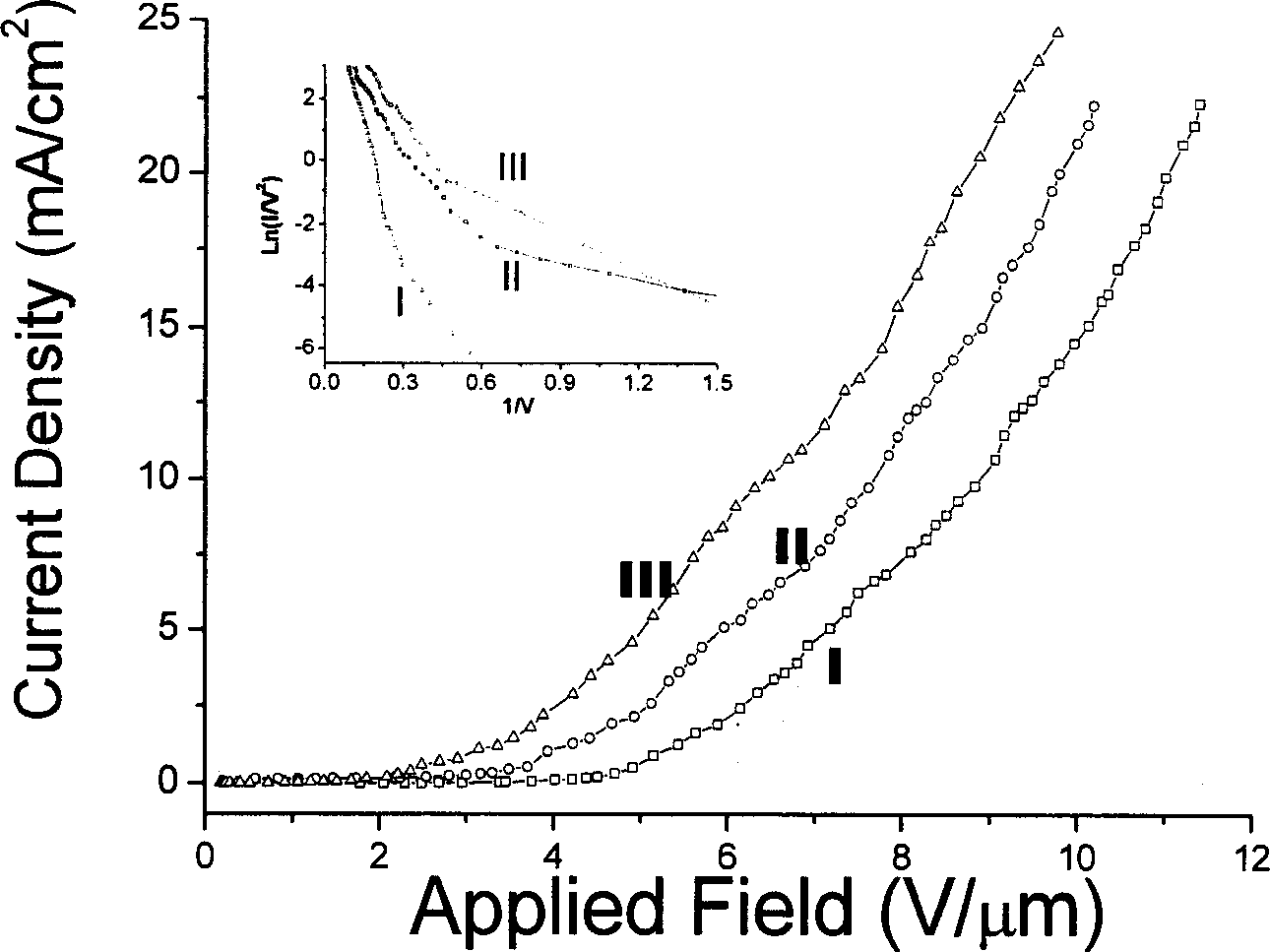

Application of B-doped SiC nanowire in field emission cathode material

ActiveCN106057606AEasy to controlRealize fine controlMaterial nanotechnologyDischarge tube/lamp detailsNanowireControllability

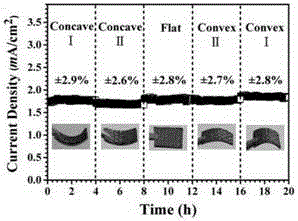

The invention relates to nanowire material applied in field emission material, particularly relates to application of a B-doped SiC nanowire in field emission cathode material, and belongs to the technical field of nano-material. The B-doped SiC nanowire is a field emission cathode. An emission electric field is formed between the field emission cathode and a field emission anode in voltage applying. The turn-on field intensity of the field emission cathode is 0.6-1.05V / muA when emission current density is 10muA / cm2 under the condition of vacuum. The B-doped SiC nanowire field emission cathode material is convenient to process, great in cost controllability, stable in performance and high in flexibility; the material has low turn-on electric field after different bending frequency and basically remains unchanged and maintains high electron emission stability; the material has low turn-on electric field under different bending states and basically remains unchanged and maintains high electron emission stability; and the material has low turn-on electric field under different temperature and maintains high electron emission stability.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

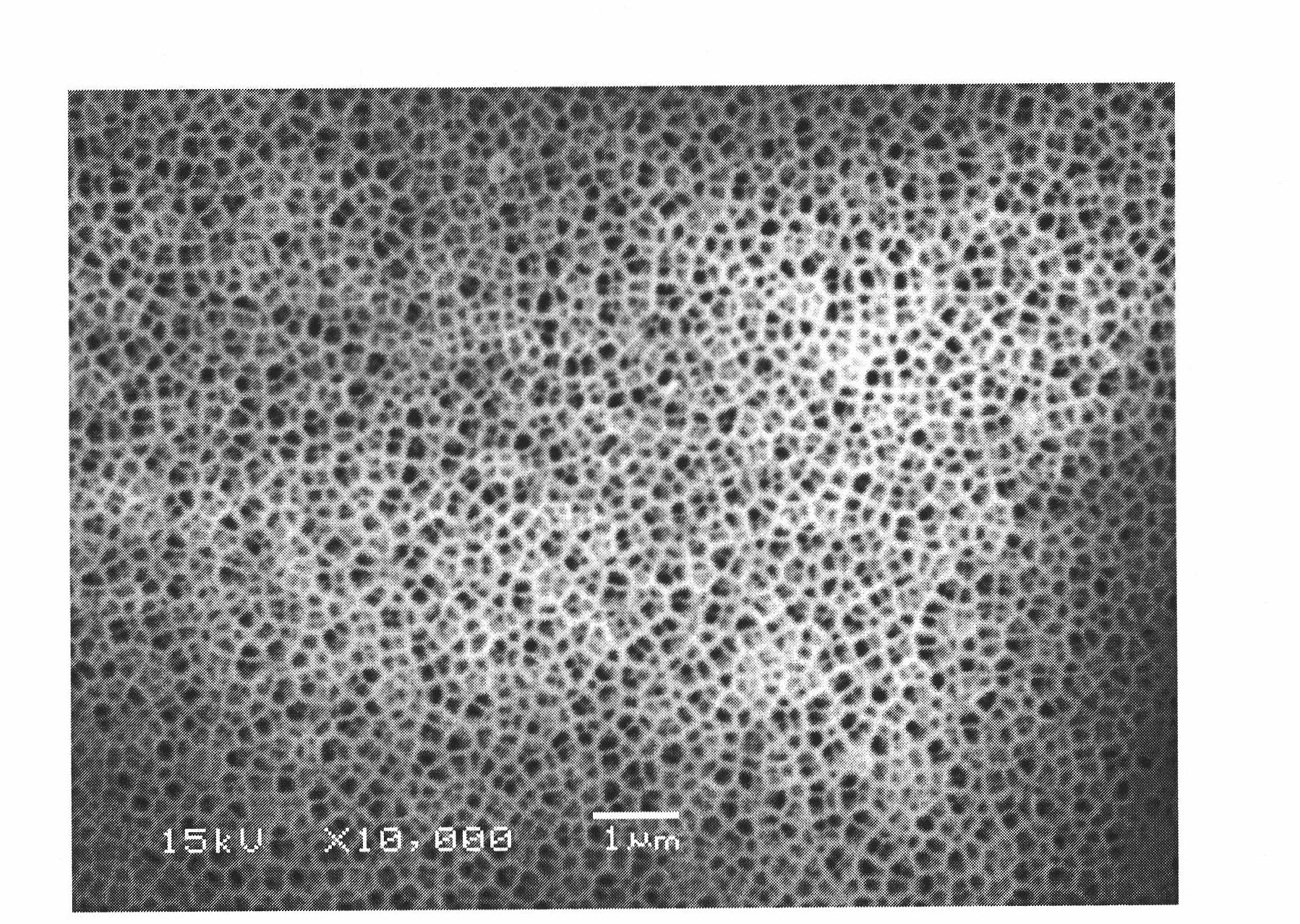

Nano carbon tube based field emitting cathode and its preparing method

InactiveCN1744254AImprove performanceImprove launch stabilityDischarge tube/lamp detailsCold cathode manufactureAlcoholNano carbon

Nano carbon tubes in mode of lain low are distributed on pole plate of field-emissive cathode. The preparation includes following steps: putting Nano carbon tubes to alcohol or other solvent, and mixing it round to prepare solution; dropping the solution obtained to the said pole plate of cathode; air drying the said solution on the pole plate naturally. Advantages are: simplifying technique, lowering cost, raising performance, and avoiding difficulty of arranging Nano carbon tubes vertically.

Owner:PEKING UNIV

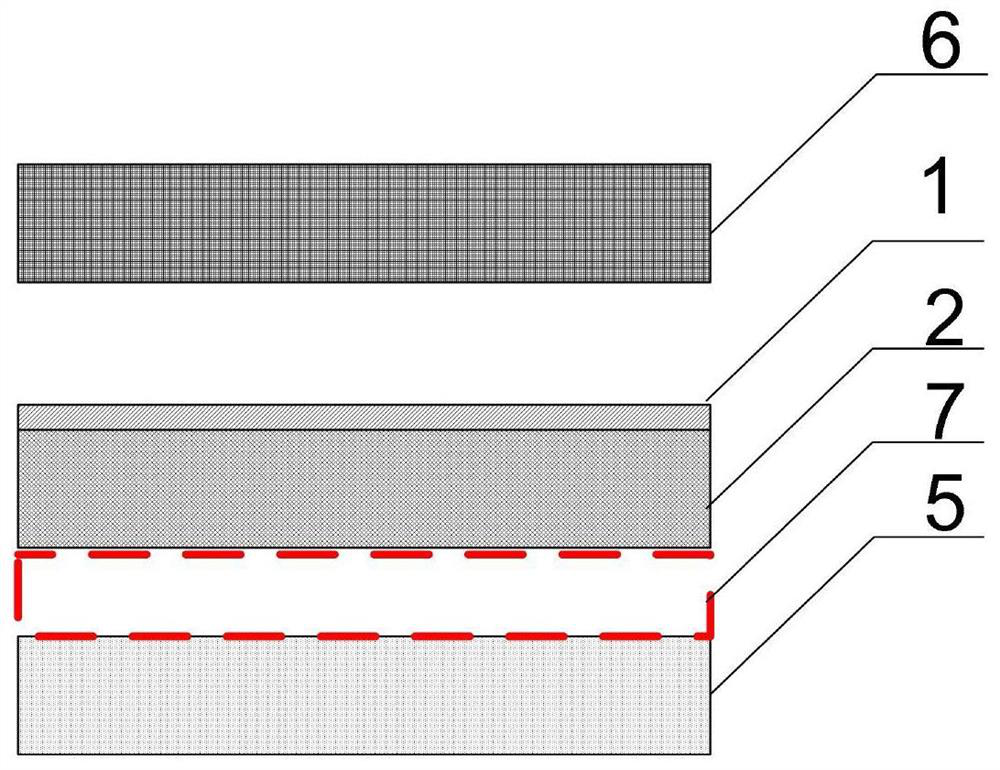

Field emission cathode structure with current limiting resistive switching layer and preparation method thereof

ActiveCN110189967ALimit the maximum emission currentReduce manufacturing costDischarge tube/lamp detailsCold cathode manufactureHigh resistanceField emission current

The invention relates to a field emission cathode structure with a current limiting resistive switching layer and a preparation method thereof, which belong to the technical field of field electron emission. A composite memristor material doped with metal ions is used as a resistive switching layer between each cathode emitter and a substrate in a field emission array cathode, and the resistive switching layer under each cathode emitter controls the migration of metal ions in the resistive switching layer by its own current change. The resistive switching layer is in a low-resistance state during normal emission of the cathode emitter. Under short-circuit or over-current emission, the resistive switching layer is switched to a high-resistance state. The different cathode emitters do not affect one another, and the maximum emission current of a single cathode emitter can be limited to restrain short-circuit or over-current emission. The field emission current limiting structure providedby the invention is simpler than the existing current limiting structure, and has low preparation cost. Because of the existence of the resistive switching layer, the emission stability of the fieldemission cathode is improved without affecting the field emission characteristic, and the field emission cathode structure is of great significance for improving the performance of the existing fieldemission cathode.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Graphene coated tungsten-based hot cathode and preparation method thereof

PendingCN112117170AImprove launch performanceImprove stabilityDischarge tube/lamp detailsThermionic cathode manufactureGraphiteSingle layer graphene

The graphene coated tungsten-based hot cathode comprises a graphene layer and a tungsten-based cathode layer, the upper surface of the tungsten-based cathode layer is coated with the graphene layer, and a lamp filament is arranged below the tungsten-based cathode layer. The preparation method comprises the following steps: (1) preparing a tungsten substrate with a smooth surface; (2) coating the tungsten substrate with a graphene layer; and (3) assembling the cathode heater assembly. The invention provides a metal coated tungsten-based hot cathode which is simple in structure, easy to prepareand excellent in emission performance. Simulation shows that the surface work function of the metal coated tungsten-based hot cathode is 1.745 eV under the condition that the surface of the metal coated tungsten-based hot cathode is coated with single-layer graphene.

Owner:SOUTHEAST UNIV

Triple pole structure of plane type field emission, and preparation method

InactiveCN100444697CIncreasing the thicknessReduce leakage currentElectrical apparatusElectroluminescent light sourcesFluorescenceField electron emission

The method comprises: setting the data electrode on the glass cathode baseboard; on the data electrode, setting the dielectric layer with a horizontal bar shape and perpendicular with the data electrode; on the dielectric layer, setting the row scanning electrode; on the row scanning electrode, setting the connection electrode parallel with the data electrode; at the gap between the connection electrode and the row scanning electrode, setting a field emission material with a certain resistance property; on the glass cathode base board and the dielectric layer, setting the supporter; on the supporter, setting a anode glass baseboard; on the lower surface the glass anode baseboard, setting the anode electrode; on the lower surface of the anode electrode, setting a fluorescent powder layer.

Owner:SOUTHEAST UNIV

Method for preparing bismuth nano wire array thermoelectric materials

The invention discloses a method for preparing bismuth nano wire array thermoelectric materials. The method is to take a high-purity BiCl3, glycerol and ammonia water solution as an electrodeposition solution, adopt electrochemical technology and utilize cyclic voltammetry to perform electrodeposition on an alumina template, and finally obtain the one-dimensional orderly Bi nano wire array thermoelectric materials with high thermoelectric conversion efficiency. The invention has simple preparation method and high filling rate; the maximum characteristic of the materials is that the materials can receive various forms of heat energy (including various types of radiant heat, solar energy, body temperature, heat generated in the system operation process, various types of waste heat and the like) from the environment and highly efficiently and directly convert the heat energy into electric energy which is then outputted; and due to the characteristics of the special high-density nano wirearray structure, oxidation resistance, high temperature resistance, high field emission current density, low turn-on field, good emission stability and the like, the application of the materials to field emission microelectronic devices as cathode materials can be realized and the materials have wide commercial application prospect.

Owner:EAST CHINA NORMAL UNIV

A kind of preparation method of rhenium-impregnated scandium-tungsten-based alloy cathode

ActiveCN109065424BImprove launch stabilityExtended service lifeTransit-tube cathodesSolid state diffusion coatingRutheniumMetal powder

A method for preparing a rhenium-impregnated scandium-tungsten-based alloy cathode, the preparation method comprising: mixing metal scandium powder and tungsten powder to obtain evenly mixed scandium-tungsten alloy powder; mixing the scandium-tungsten alloy powder with (1.5-3)wt % nitrocellulose solution is evenly mixed, and the mixed solution is applied to the surface of the tungsten wire cathode substrate, and baked; the tungsten wire with scandium-tungsten alloy powder applied on the surface is placed in a high-temperature hydrogen furnace, and kept at 1350±50°C for 5-10 Minutes, the scandium-tungsten-based alloy layer is prepared; then, the surface of the scandium-tungsten-based alloy layer is impregnated with a mixture of metal rhenium powder and (1.5-3) wt% nitrocellulose solution, and then baked; the surface of the scandium-tungsten-based alloy layer is impregnated Put the tungsten wire with metal rhenium powder into a high-temperature hydrogen furnace, and keep it warm at 1500±50° C. for 5 to 10 minutes to prepare a rhenium-impregnated scandium-tungsten-based alloy cathode. The rhenium-impregnated scandium-tungsten-based alloy cathode prepared by the method of the present invention can increase the emission current density of the pure tungsten wire cathode for a magnetron, reduce the working temperature and surface evaporation rate of the pure tungsten wire cathode, thereby prolonging the life of the cathode and the magnetron .

Owner:JIUJIANG UNIVERSITY

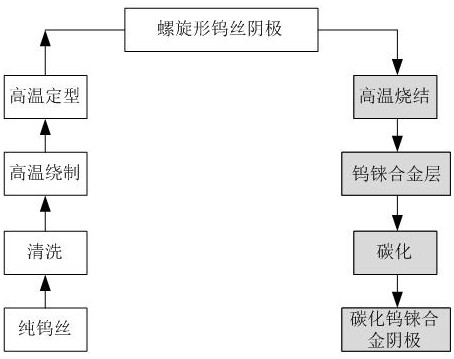

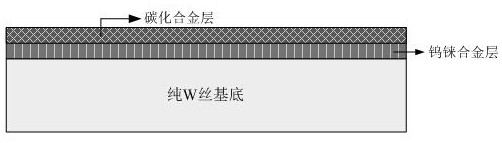

A kind of preparation method of direct heating type high temperature tungsten-rhenium alloy cathode

InactiveCN109065422BLarge thermal emission current densityImprove anti-poisoning performanceCathodes manufactureTransit-tube cathodesRheniumAlloy

A method for preparing a direct-heating high-temperature tungsten-rhenium alloy cathode, the method steps comprising: mixing metal tungsten powder and rhenium powder to obtain evenly mixed tungsten-rhenium alloy powder; mixing the tungsten-rhenium alloy powder with 1.5-3 wt% nitric acid Mix the cotton solution evenly, apply the mixed solution on the surface of the tungsten wire cathode substrate, and bake; put the tungsten wire coated with tungsten-rhenium alloy powder on the surface into a high-temperature hydrogen furnace, and keep it warm at 1500±50°C for 5 to 10 minutes. The tungsten-rhenium alloy layer is prepared; then, the tungsten wire with the tungsten-rhenium alloy layer sintered on the surface is placed in an air pressure of 10 ‑3 ~10 ‑1 In the benzene atmosphere of Pa, the high-temperature chemical reaction is carried out at the temperature of the tungsten wire at 2000-2400K, and the reaction time is 0.5-2 minutes, and the direct-heating high-temperature tungsten-rhenium alloy cathode is prepared. The direct-heating high-temperature tungsten-rhenium alloy cathode of the invention can increase the emission current density of the pure tungsten wire cathode for a magnetron, reduce the working temperature and surface evaporation rate of the pure tungsten wire cathode, thereby prolonging the life of the cathode and the magnetron.

Owner:JIUJIANG UNIVERSITY

A kind of preparation method of direct heating type anti-electron bombardment cathode

ActiveCN109037007BHigh densityReduce evaporationTransit-tube cathodesHeat inorganic powder coatingChemical physicsElectron bombardment

A method for preparing a direct-heating electron bombardment-resistant cathode, the method comprising: metal tungsten powder and Y 2 o 3 -Gd 2 o 3 -HfO 2 / ZrO 2 (Y-Gd-Hf / Zr-O) active substance powders are mixed to obtain uniformly mixed Y-Gd-Hf / Zr-O active substance powders; Mix the cotton solution evenly, apply the mixed solution on the surface of the tungsten wire cathode substrate, and bake it; put the tungsten wire coated with active substance powder on the surface into a high-temperature hydrogen furnace, and keep it warm at 1500±50°C for 3 to 10 minutes. A directly heated cathode resistant to electron bombardment was prepared. The direct-heating electron bombardment-resistant cathode of the present invention has better resistance to electron bombardment, and the cathode can increase the emission current density of the pure tungsten wire cathode for a magnetron, reduce the working temperature and surface evaporation rate of the pure tungsten wire cathode, Thereby prolonging the life of the cathode and the magnetron.

Owner:JIUJIANG UNIVERSITY

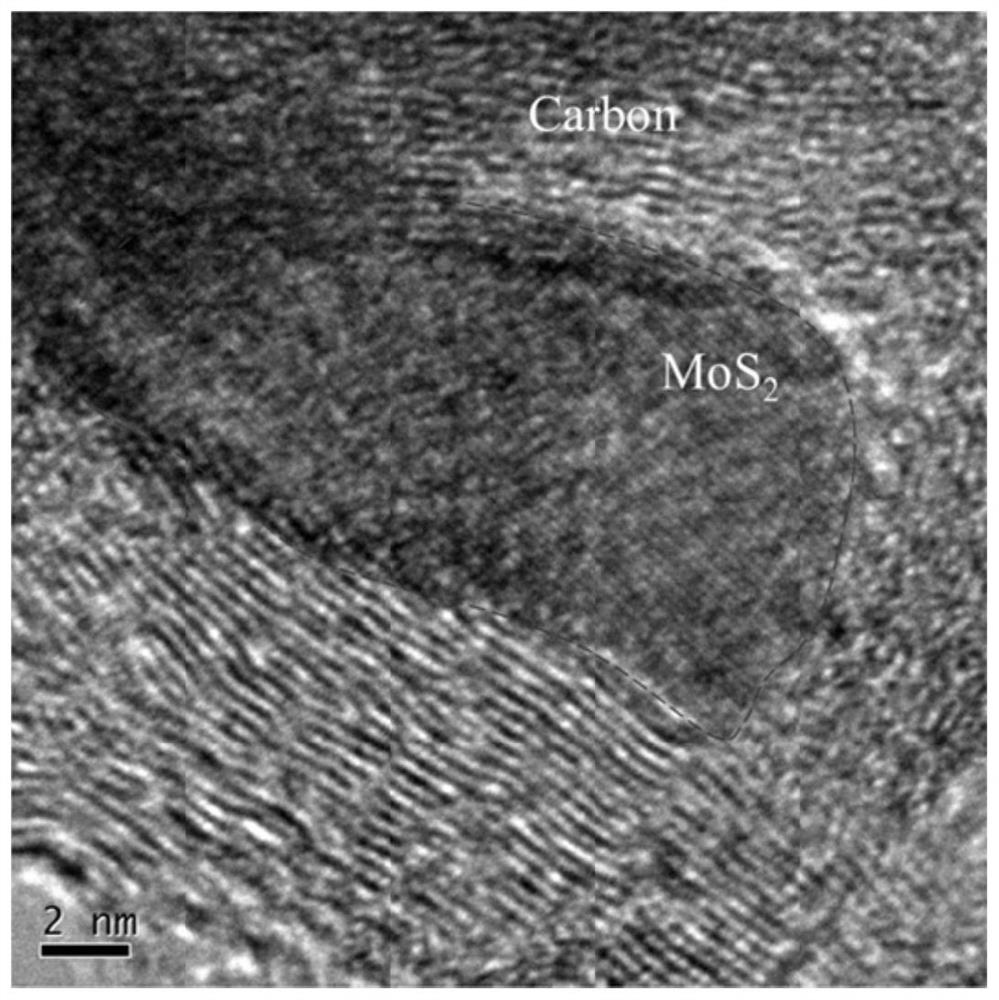

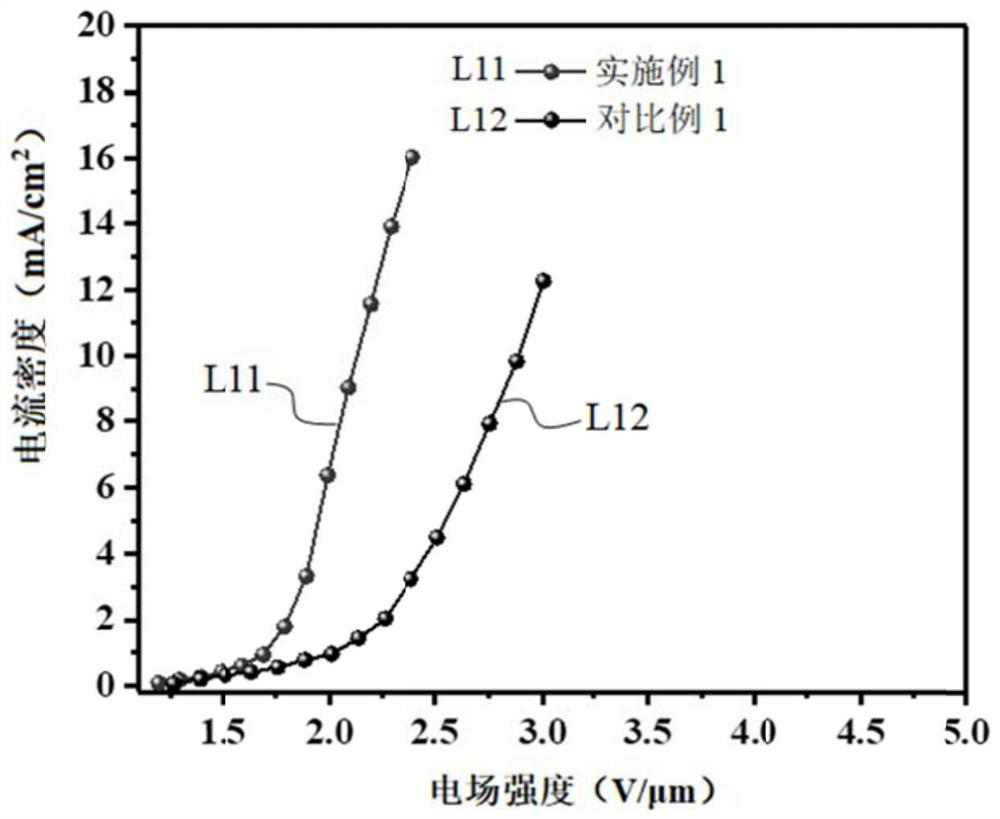

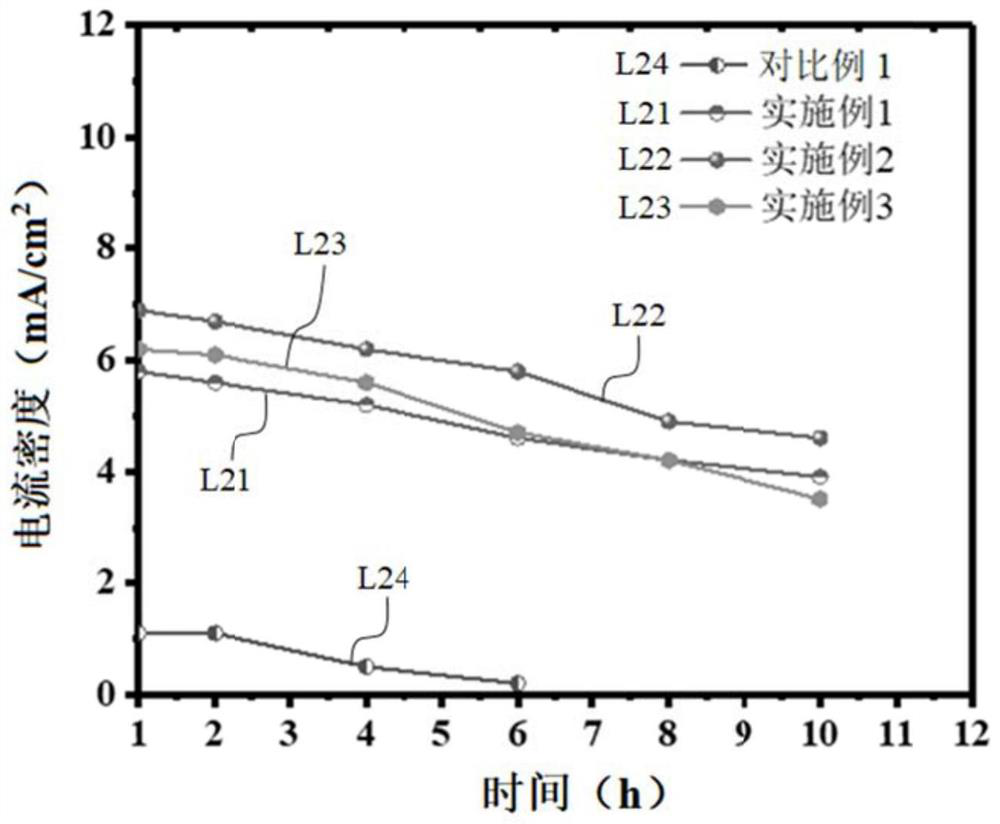

Carbon nanotube field emission cathode and preparation method thereof

PendingCN113990721ALarge specific surface areaReduce the turn-on electric fieldMaterial nanotechnologyNanoinformaticsActive agentCarboxylic acid

The invention discloses a carbon nanotube field emission cathode. The cathode comprises: a conductive substrate; a carbon nanotube formed on the conductive substrate; and molybdenum sulfide nanoparticles bonded on the surface of the carbon nanotube. The preparation method of the carbon nanotube field emission cathode comprises the following steps: providing a carbon nanotube and enabling the surface of the carbon nanotube to have carboxylic acid groups through a surface treatment process; dissolving the carbon nanotube, a molybdenum source, a sulfur source and a surfactant in a solvent, carrying out ultrasonic dispersion, and then carrying out a heating reaction to obtain a carbon nanotube of which the surface is combined with molybdenum sulfide nanoparticles; placing the carbon nanotube in a ball milling tank, adding an organic solvent and a ball milling auxiliary agent, and carrying out ball milling to obtain carbon nanotube slurry; printing the carbon nanotube slurry on a conductive substrate through a screen printing process; and heating and curing the conductive substrate, and carrying out annealing treatment to prepare the carbon nanotube field emission cathode. The carbon nanotube field emission cathode provided by the invention can reduce the starting electric field and improve the emission stability.

Owner:SHENZHEN INST OF ADVANCED TECH +1

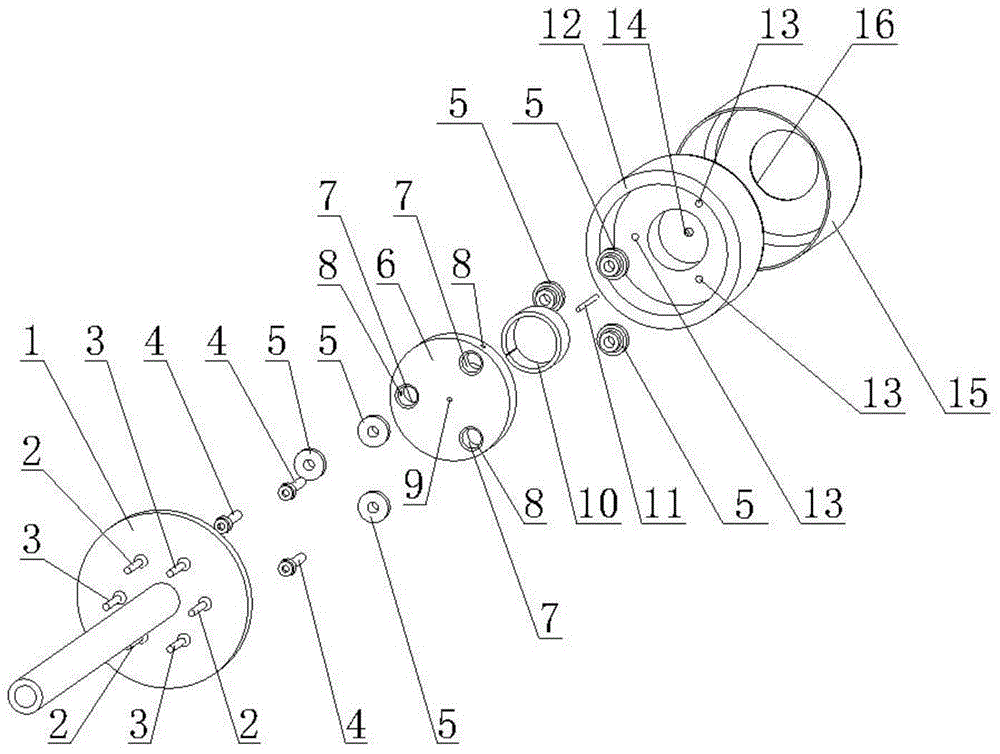

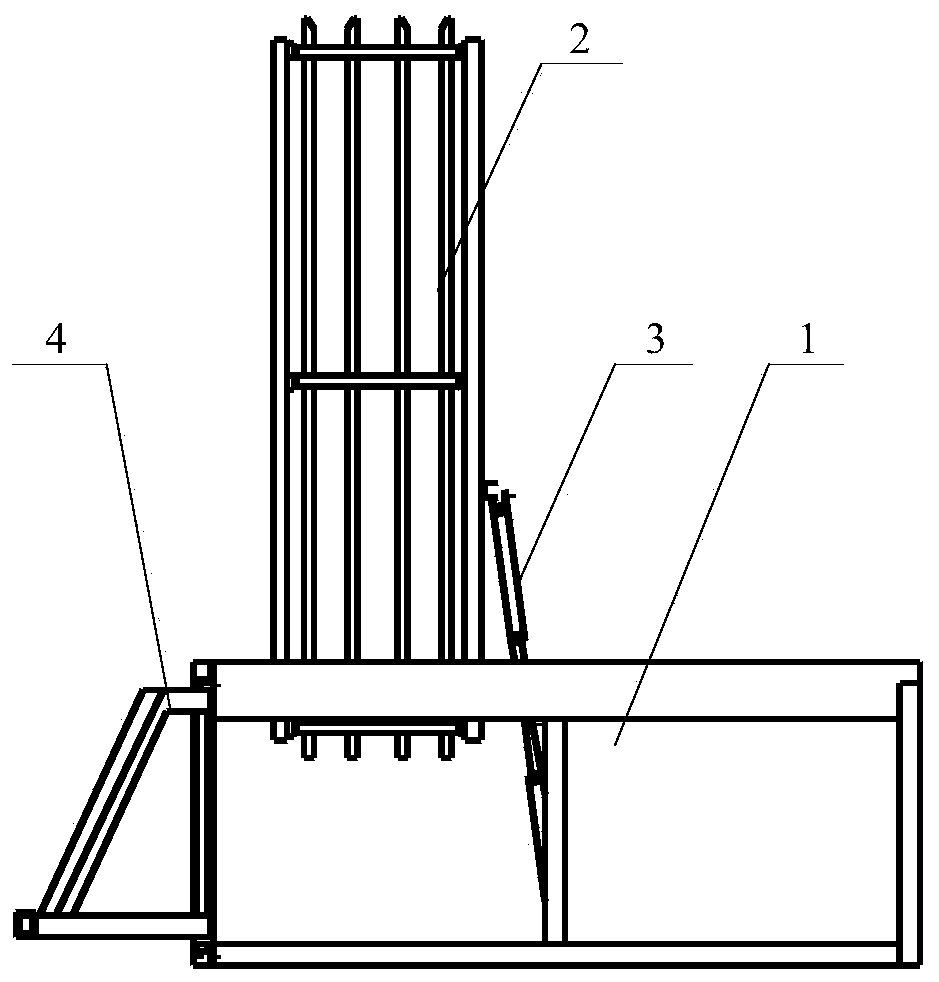

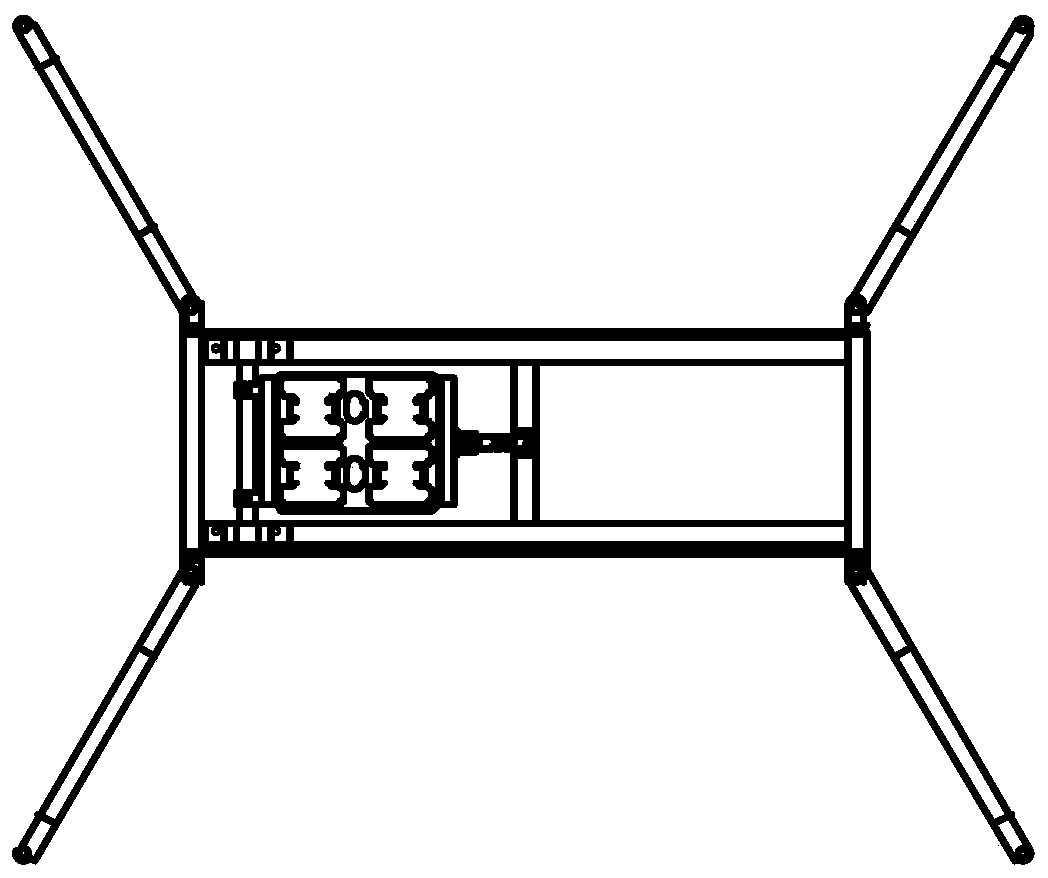

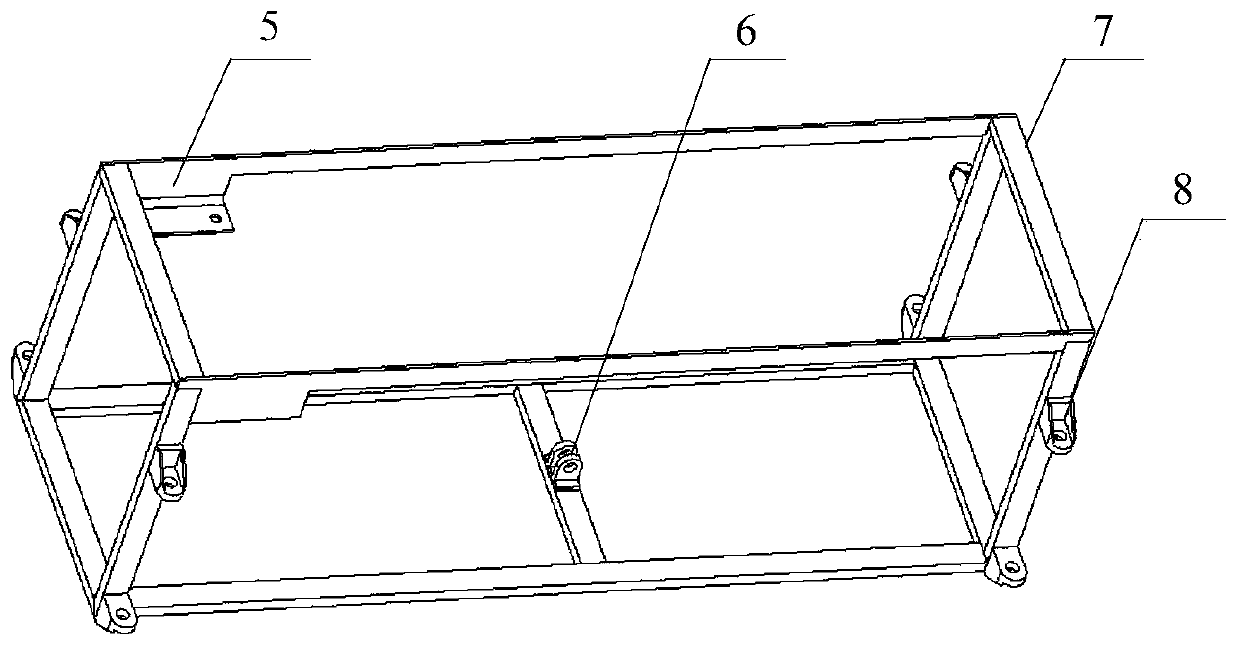

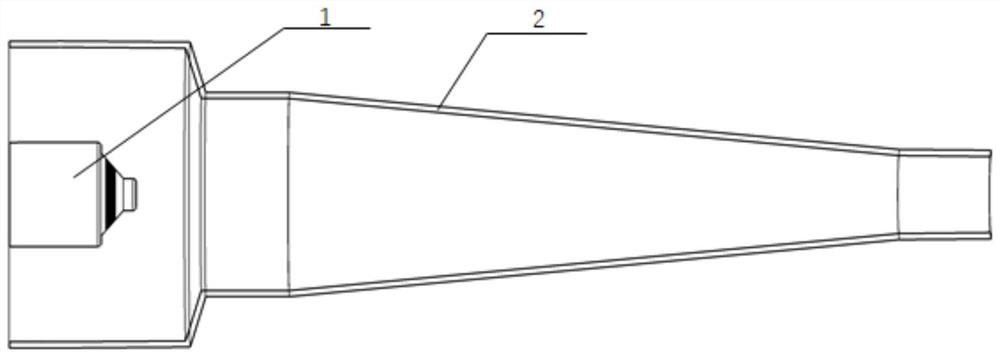

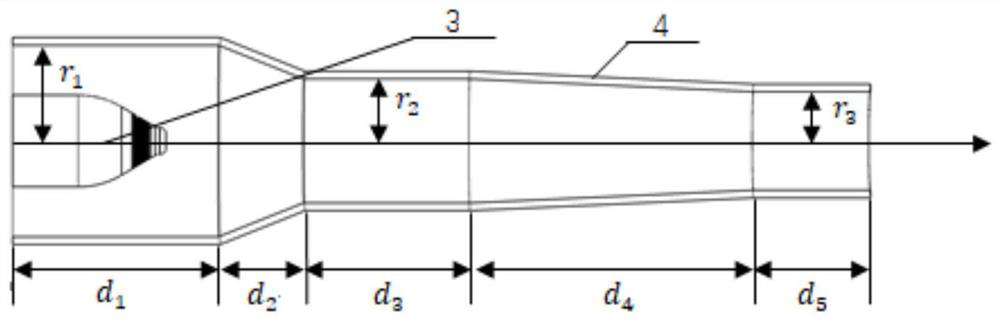

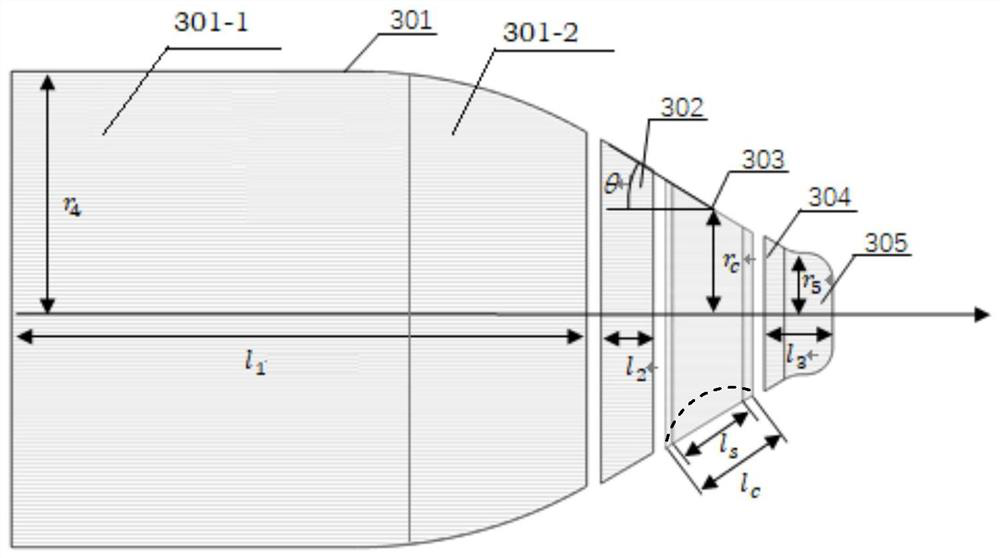

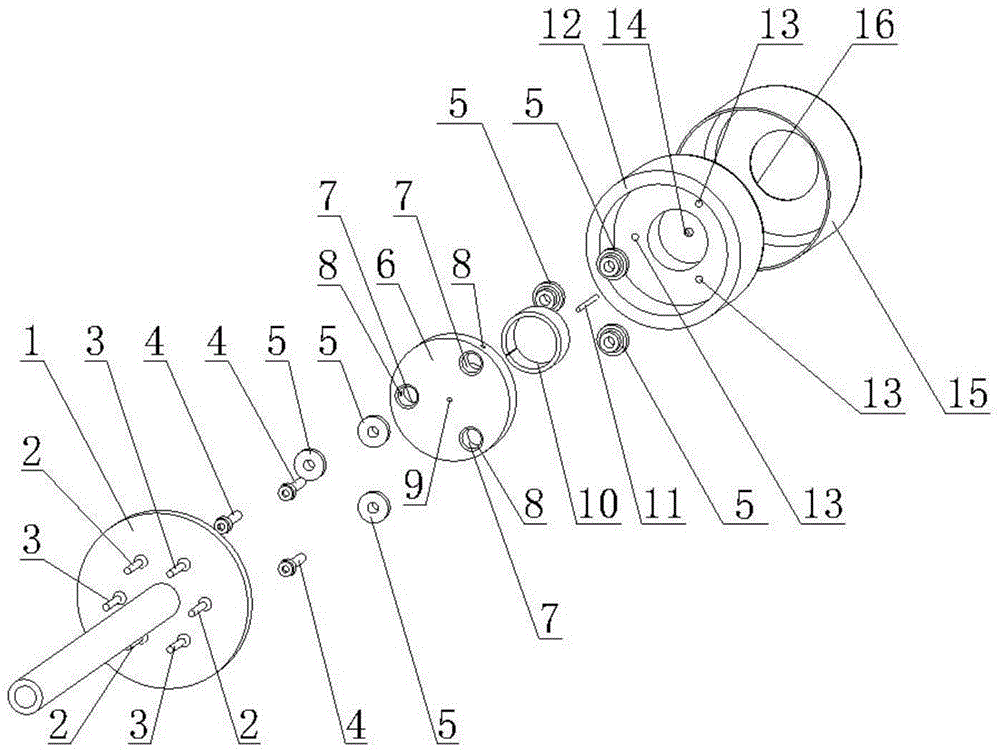

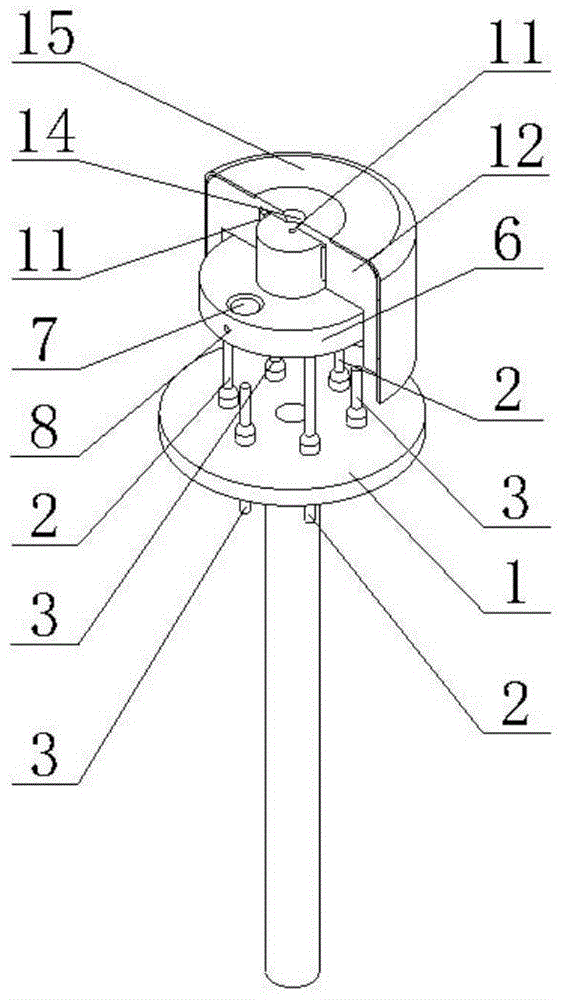

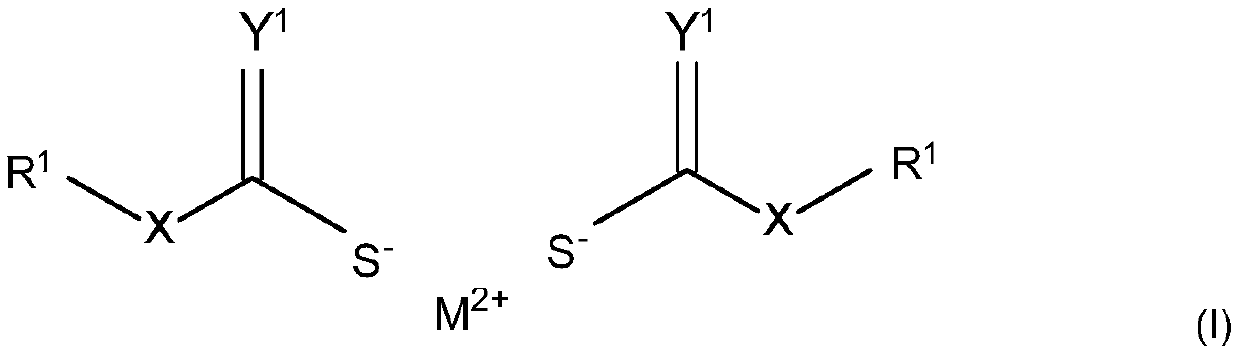

Multi-channel foldable box type low-altitude sounding rocket launching device

PendingCN111547266AShorten the lengthAchieve regulationLaunch systemsCosmonautic partsRocket launchSounding rocket

The invention provides a multi-channel foldable box type low-altitude sounding rocket launching device which comprises a box body, an orientator assembly, a supporting rod and supporting legs. The orientator assembly is connected with the box body through a support lug shaft; one end of the supporting rod is connected with a supporting lug at the bottom of the box body, the other end of the supporting rod is connected with a supporting lug on the orientator assembly, the length of the supporting rod is adjustable, and the launching angle of the orientator assembly is adjusted by adjusting thelength of the supporting rod. The four supporting legs are connected to the box body through the supporting leg shafts, the supporting legs can rotate around the supporting leg shafts, the supportingarea formed by the four supporting legs is adjusted by changing the rotation angles, and therefore the launching stability is improved.

Owner:SHAANXI ZHONGTIAN ROCKET TECH CO LTD

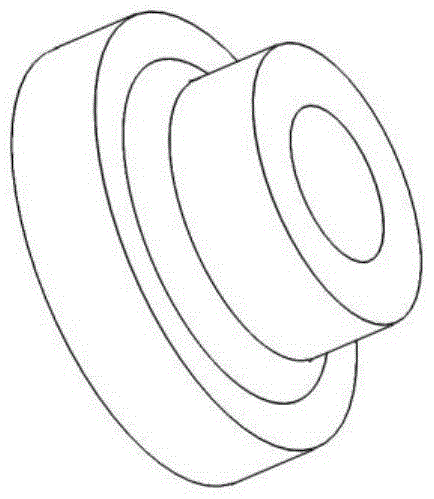

A compact low magnetic compression ratio magnetron injection electron gun

ActiveCN113690117BContinuous changeReduce the problem of over-sensitivity to electric field changesTransit-time tubesLow frequency bandMiniaturization

The invention belongs to the field of vacuum electronic devices, in particular to a compact low magnetic compression ratio magnetron injection electron gun. Based on the electron gun design theory, the present invention improves the cathode structure of the traditional magnetron injection electron gun. The improvement points are as follows: the post-forming pole is composed of a cylindrical part and a circular truncated part, and the bus bar of the circular truncated post-forming pole is the first circle. Arc-shaped curve; the launch belt is in the shape of a truncated cone, and the busbar of the truncated cone of the launch belt is a second arc-shaped curve; the front forming pole is cylindrical, and the connection between the busbar of the front forming pole cylinder and the transition section of the front forming pole is A smooth curve that is concave inward. Through the above improvements, the miniaturization of the low-frequency magnetron injection electron gun is realized, and the cathode electric field adjustment capability of the electron gun is further improved, so that the electron gun has better overall performance. Compared with the traditional design method, the electron gun of the present invention is smaller in size, and can be used for vehicle-mounted radar or electronic countermeasure system mobile platform.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A cold cathode x-ray tube cathode

The invention provides a cathode of a cold-cathode X-ray tube. The cathode of the cold-cathode X-ray tube comprises a cathode base and a grid electrode, wherein the cathode base is composed of an upper cylinder and a lower cylinder which are coaxially arranged, the section of the cathode base is in an inverted-T shape, a cathode bar through hole is formed in the central axis of the cathode base, a cathode bar is arranged in the through hole, the three-dimensional size of the cathode bar can be controlled, an electron emitter is arranged on a cathode head, the grid electrode is of an cup-shaped structure, an inverted-T-shaped groove which is matched with the cathode base is formed inside the grid electrode, the cathode base can be embedded in the groove of the grid electrode and does not make contact with the inner wall of the grid electrode, and a semi-conical electron transmission hole used for focusing electrons emitted by the cathode is formed in the center of the grid electrode. According to the cathode of the cold-cathode X-ray tube, the cold cathode made of carbon nanomaterials is used as the X-ray tube of an electron emission source, and preparation of the cathode and the emission area can be effectively controlled through the size of the cathode bar; the three-pole structure is adopted, a small focus point can be obtained through focusing of the grid electrode, and the resolution ratio of X-ray imaging is increased.

Owner:南京康众光电科技有限公司

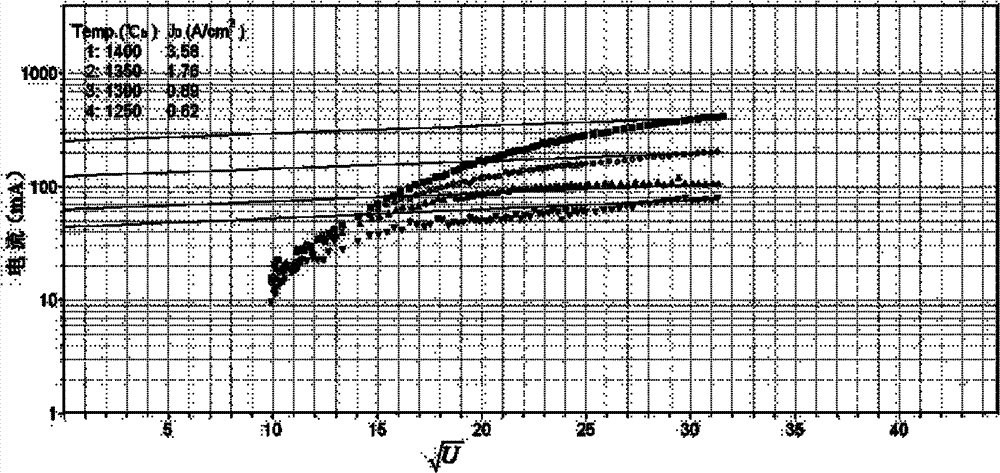

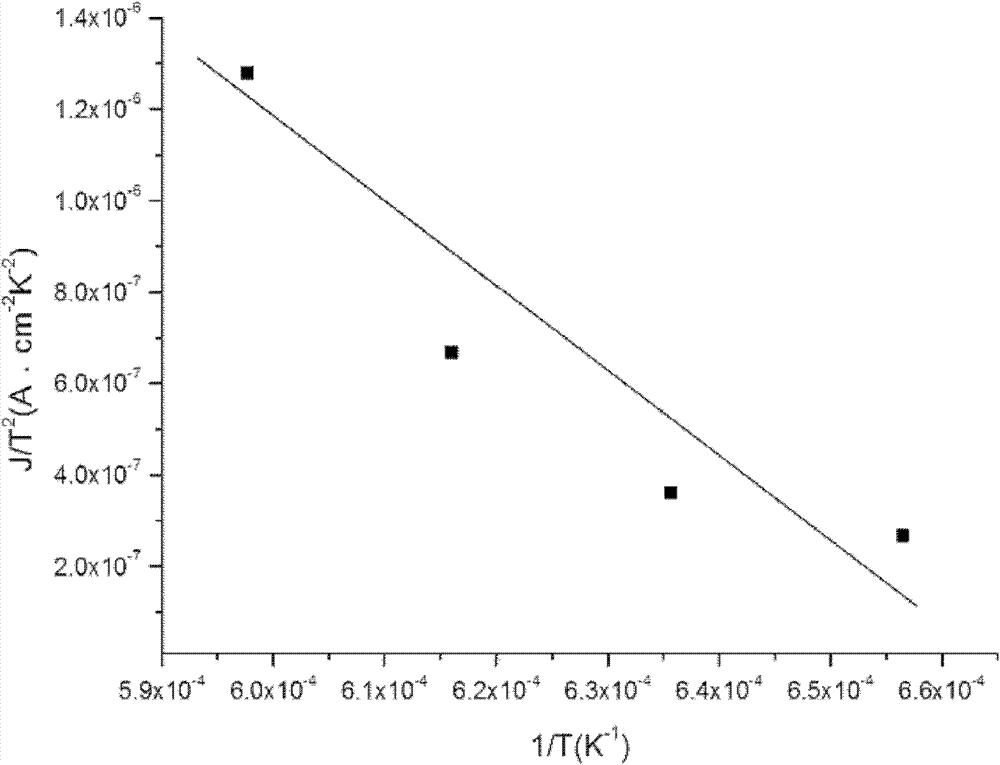

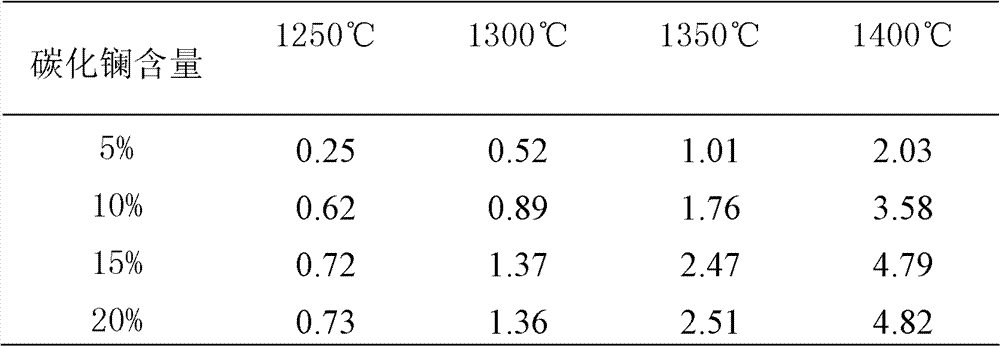

Lanthanum-carbide-tungsten hot cathode material and preparation method thereof

InactiveCN102184818BEasy to prepareGood thermal electron emission capabilityDischarge tube/lamp detailsThermionic cathode manufactureArgon atmosphereTungsten

Owner:BEIJING UNIV OF TECH

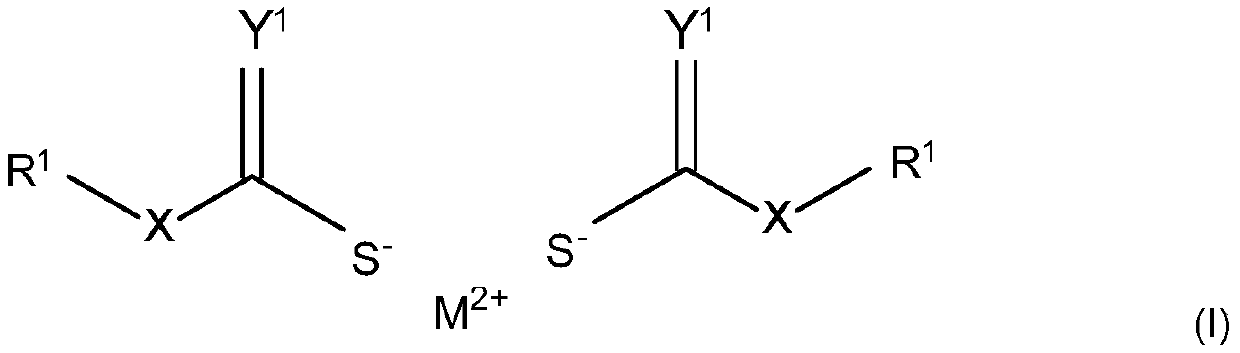

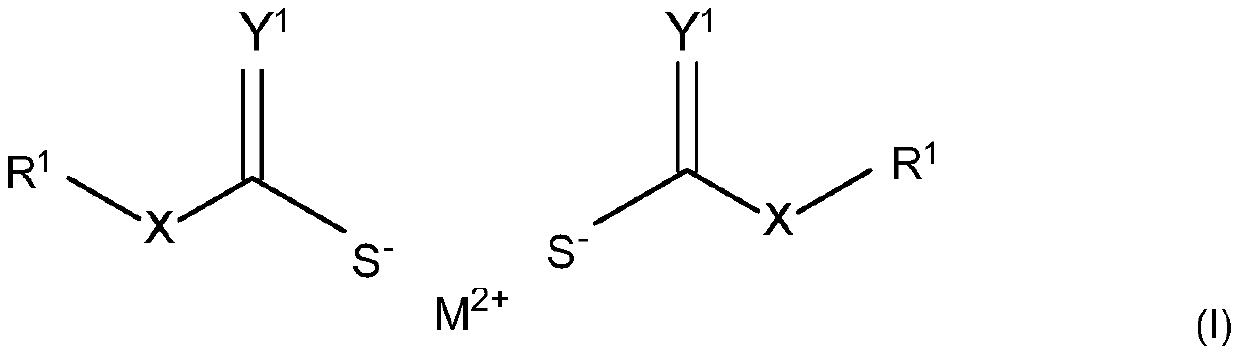

Semiconducting light emitting material

ActiveCN111201302AImprove launch stabilityStable quantum yieldOrganic chemistryDiagnosticsLuminescent materialSemiconductor

Owner:MERCK PATENT GMBH

Graphene field emission cathode and preparation method thereof

PendingCN113838725AChange electronic structureLower work functionNanoinformaticsDischarge tube/lamp detailsField emission currentGraphite

The invention discloses a graphene field emission cathode and a preparation method thereof. The graphene field emission cathode comprises a conductive substrate; a graphene nanosheet vertically grown on the conductive substrate; and metal nanoparticles combined on the surface of the graphene nanosheet. According to the graphene field emission cathode provided by the invention, the density of electron emission tips and the number of effective emission tips can be greatly increased, and the field emission current can be improved.

Owner:SHENZHEN INST OF ADVANCED TECH +1

Method for improving emission property of deposited carbon nano-tube thin film electronic field by electrophorisis method

InactiveCN100481301CImprove adhesionExtended service lifeNanostructure manufactureVacuum evaporation coatingField emission currentGas phase

Owner:TIANJIN UNIV

Field emission cathode and preparation method thereof

ActiveCN111081504AHigh field emission currentImprove launch stabilityDischarge tube/lamp detailsCold cathode manufactureHexagonal boron nitrideBoron nitride

The invention provides a preparation method of a field emission cathode. The preparation method comprises the steps of providing a conductive substrate; preparing a hexagonal boron nitride nanosheet dispersion liquid, depositing the hexagonal boron nitride nanosheet dispersion liquid on the conductive substrate, and drying to form a hexagonal boron nitride nanosheet film so as to obtain a substrate containing the hexagonal boron nitride nanosheet film; providing an anode, taking the substrate containing the hexagonal boron nitride nanosheet film as a cathode, and grounding the cathode; and placing the cathode and the anode in a vacuum environment, and applying gradually increasing forward voltage to the anode until a sparking phenomenon occurs so as to obtain the hexagonal boron nitride nanosheet field emission cathode.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com