Application of B-doped SiC nanowire in field emission cathode material

A field emission cathode and emission cathode technology, which is applied in the field of nanomaterials, can solve the problems of SiC flexible cathodes being insufficient, and achieve the effects of good cost controllability, high electron emission stability, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

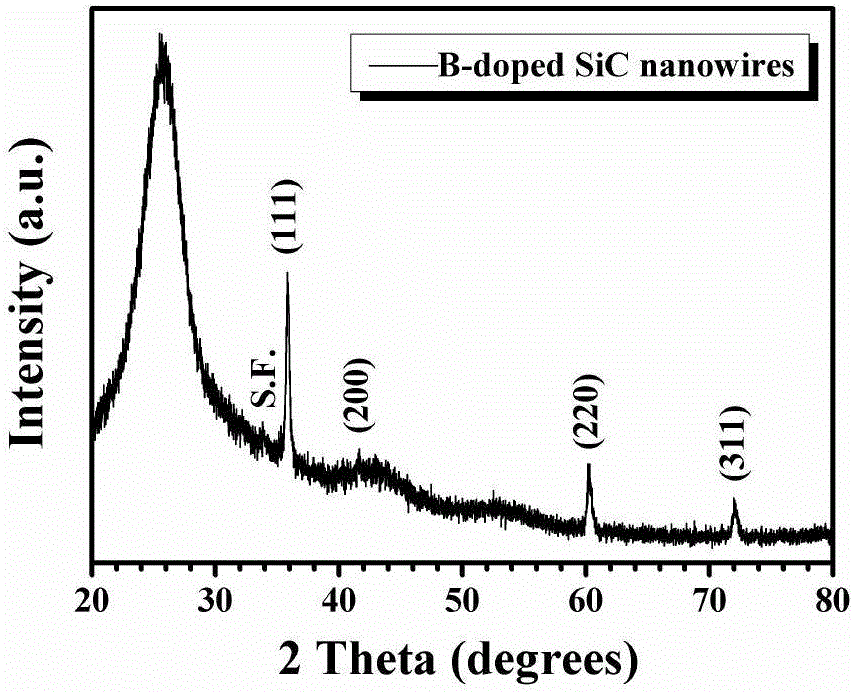

[0046] The initial raw material is polysilazane, in N 2 Under the protection of the atmosphere, heat preservation at 260°C for 30 minutes for thermal crosslinking and curing. Put the solidified SiCN solid into a nylon resin ball mill tank, and ball mill it into powder. Weigh 300mg polysilazane powder and 60mg B 2 o 3 Powder, mix the powder evenly and place it at the bottom of the graphite crucible. Cut the carbon cloth 5×5cm (length×width), in 0.05mol / L Co(NO 3 ) 3 Immerse in ethanol solution and sonicate for 10s, take it out and let it dry naturally in air environment. The treated carbon cloth substrate is placed on the top of the graphite crucible, and then put into the atmosphere sintering furnace heated by graphite resistance together with the crucible. The atmosphere furnace is first evacuated to 10- 4 Pa, and then filled with high-purity argon (purity: 99.99%) until the pressure is one atmospheric pressure (~0.11Mpa), after which the pressure is constant. Then heat...

Embodiment 2

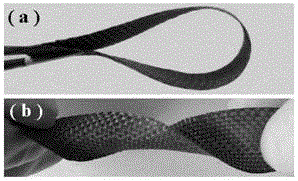

[0049] Taking the B-doped SiC nanowire grown on the carbon fiber cloth in Example 1 as the flexible cathode, it was cut into five pieces of 0.4×0.6cm 2 Bending five pieces of flexible cathodes for 0, 50, 100, 150 and 200 times respectively (the bending radius is 1.2cm), then put the cathodes in a planar structure into the field emission test system in turn, and vacuum the system to 1.5×10 - 7 Pa, and finally the field emission performance test of the flexible cathode was carried out at room temperature. Figure 6 A digital photo of the flexible field emission cathode used for testing, showing that the cathode has high flexibility. Figure 7 It is the field emission current density-electric field intensity curve of the flexible cathode after 0, 50, 100, 150 and 200 times of bending, indicating that after different bending times, the open electric field of the flexible cathode is 0.94, 0.93, 0.95, 0.91, 0.92V / μm, has a very low turn-on electric field, and remains basically u...

Embodiment 3

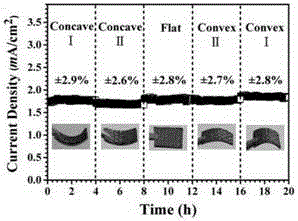

[0051] Using the B-doped SiC nanowire grown on carbon fiber cloth in Example 1 as a flexible cathode, it was cut into five pieces of 0.4×0.6cm 2 The five flexible cathodes are bent into concave type I, concave type II, planar type, convex type I and convex type II structures respectively (wherein, the bending radius of concave surface I and convex surface I is 1.2cm, concave surface II and convex surface II has a bending radius of 0.4cm), then the cathodes are sequentially loaded into the field emission test system, and the system is evacuated to 1.5×10 -7 Pa, and finally the field emission performance test of the flexible cathodes with five structures was carried out at room temperature. Figure 9 It is the field emission current density-electric field intensity curve of the flexible cathode in five bending states, which shows that in different bending states, the open electric field of the flexible cathode is only 1.01, 0.98, 0.94, 0.89 and 0.86V / μm, indicating that in It h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com