Nano carbon tube based field emitting cathode and its preparing method

A field emission cathode and carbon nanotube technology, which is applied in cold cathode manufacturing, discharge tube/lamp manufacturing, electrode system manufacturing, etc., can solve the difficult and restrictive conditions of carbon tube growth, and can not control the quality of carbon tubes well and other issues, to achieve the effect of reducing production cost, improving performance, and increasing field enhancement factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

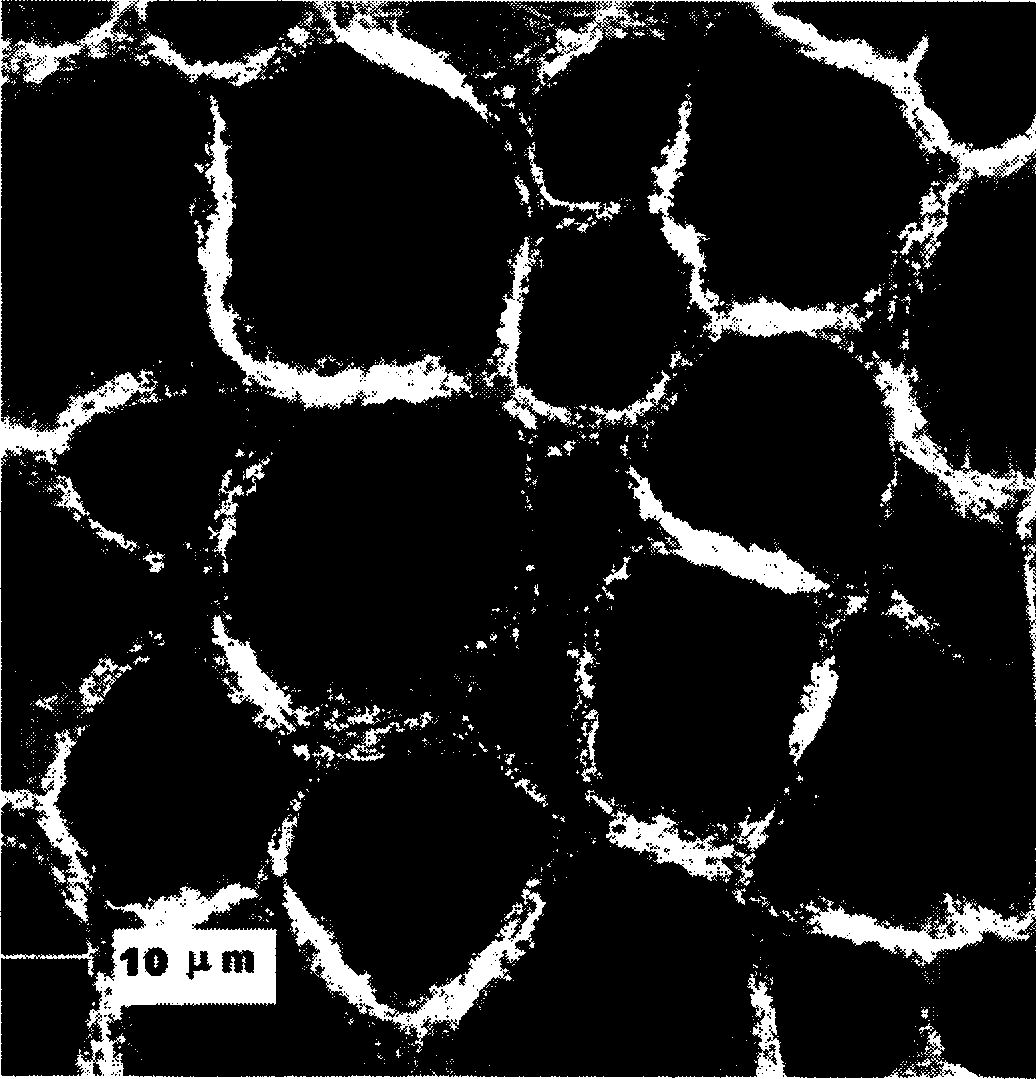

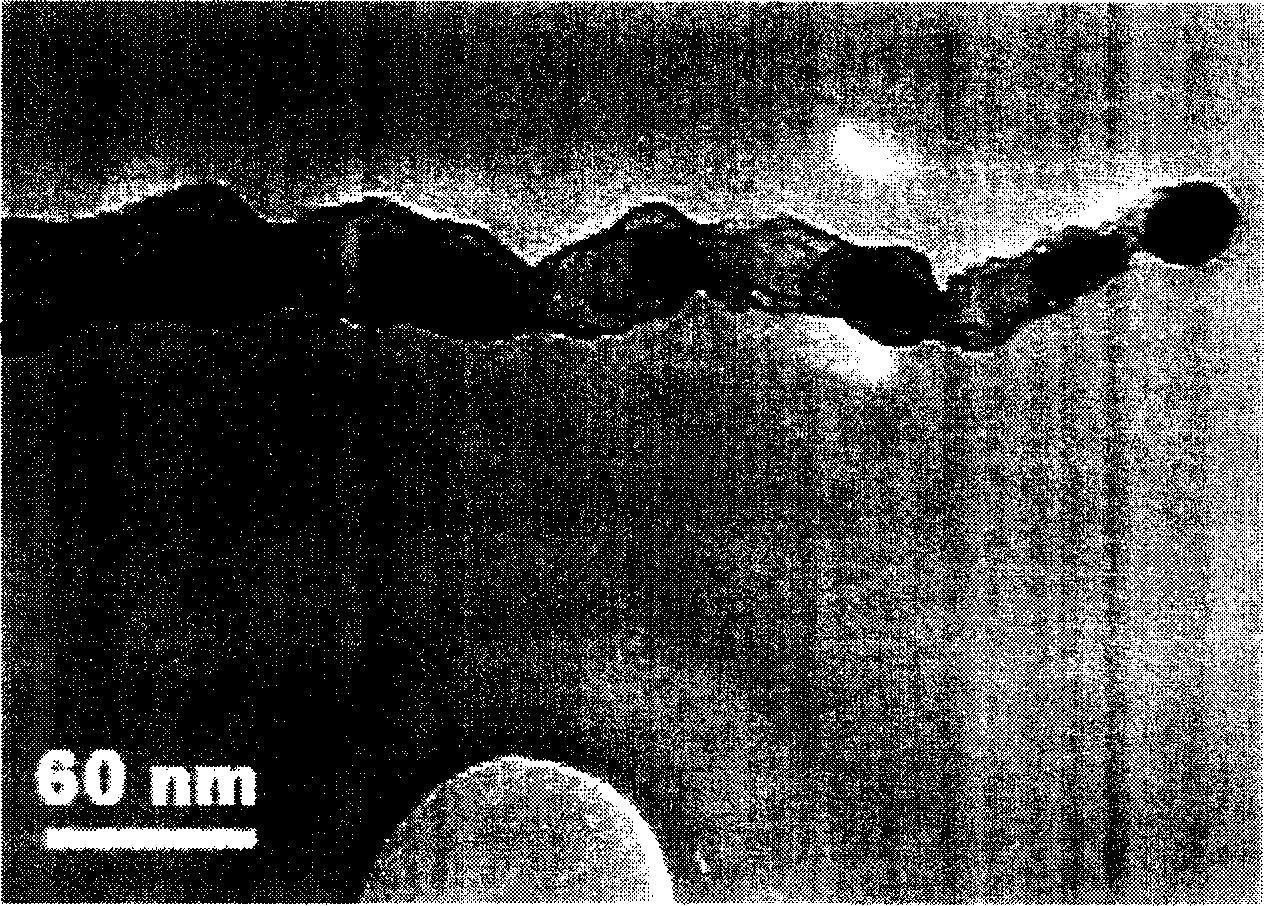

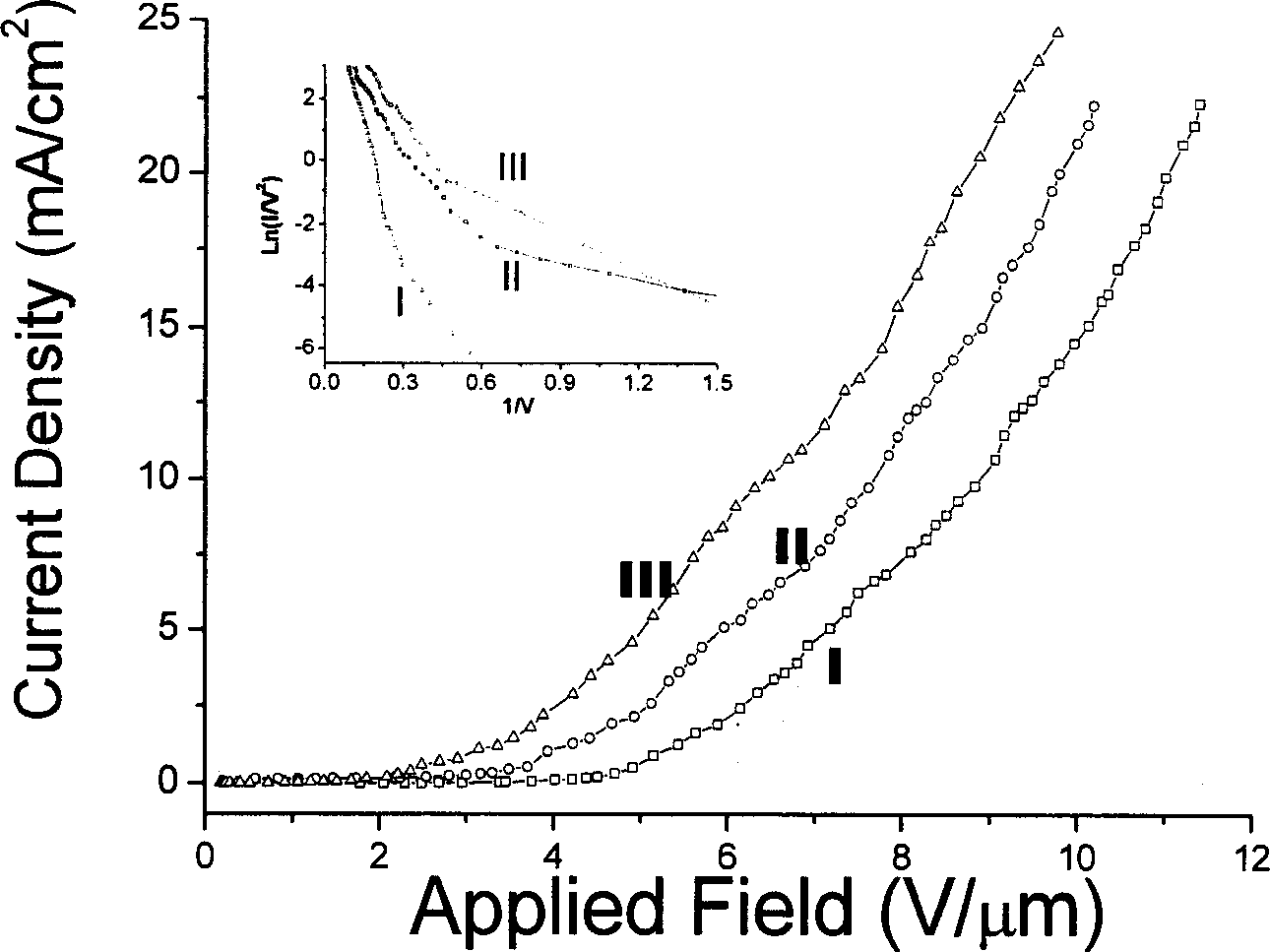

[0025] The carbon nanotubes of the present invention are arranged on the field emission cathode plate in a flat manner. The interior of the carbon nanotube of the present invention is filled with metal or metal oxide particles, and the filled particles make the outer wall of the carbon nanotube form a plurality of geometric protrusions. Wherein, carbon nanotubes can be prepared by the following steps:

[0026] (1) Select the metal catalyst according to the target filler, and prepare a mixed solution for generating the metal catalyst / carrier;

[0027] (2) prepare a thin film on the substrate with the solution prepared in step (1);

[0028] (3) heat-treating the substrate covered with the film in the air or in an environment with oxygen to solidify the film on the substrate and form a metal catalyst / carrier composite film;

[0029] (4) Put the substrate covered with the metal catalyst / carrier composite thin film in a heating furnace to heat, the atmosphere is an inert gas or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com