Method for improving emission property of deposited carbon nano-tube thin film electronic field by electrophorisis method

A technology of emission performance and carbon deposition, applied in the manufacture of discharge tubes/lamps, electrophoretic plating, nanotechnology, etc., can solve problems such as restricting the practical application of electrophoresis, easy peeling of carbon nanotube films, unstable field emission current, etc. , to enhance the anti-ion bombardment ability, eliminate the interface barrier, and improve the emission stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

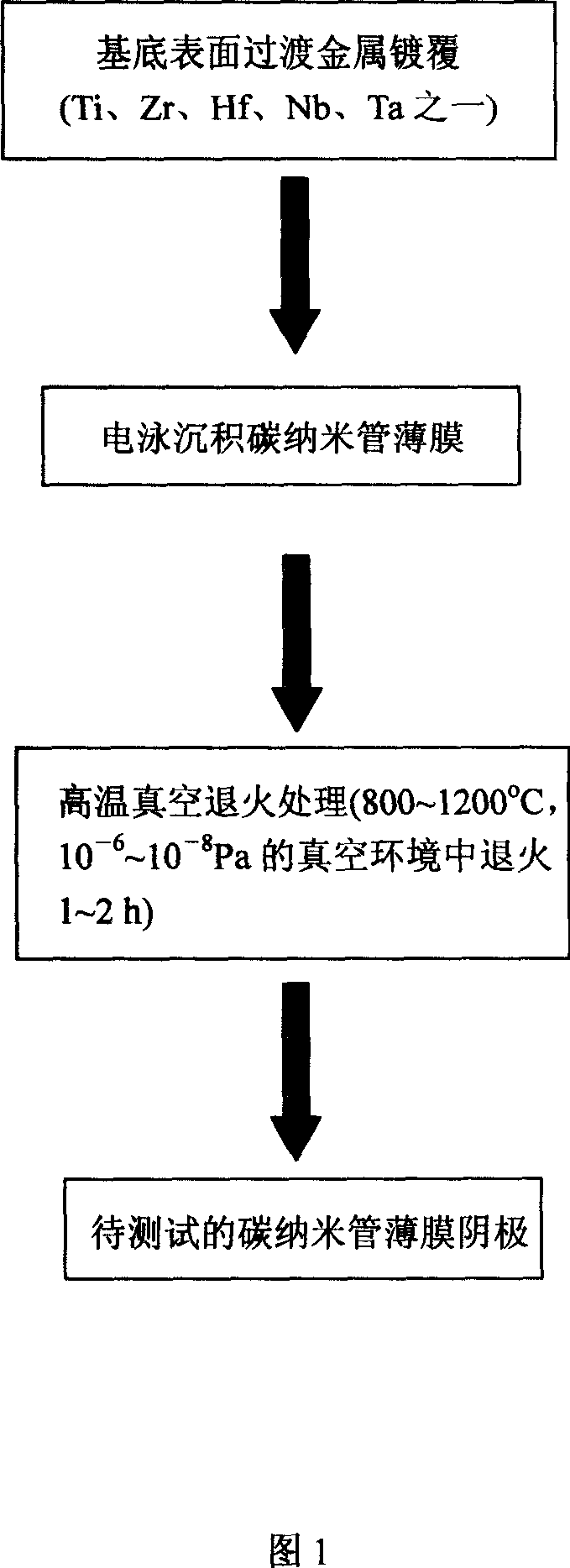

Method used

Image

Examples

Embodiment 1

[0022] (1) Coating a transition metal thin film on the base material by radio frequency magnetron sputtering coating method. The transition metal is Ti, and the base material is p-type (100) Si sheet. The specific sputtering coating conditions are as follows: adjust the sputtering power to 80W so that the deposition rate is 0.22nm / s, the sputtering time is 15min, and the sputtering vacuum is 3×10 -4 Pa, the thickness of the plated Ti film is 200nm.

[0023] (2) The Si substrate coated with Ti film was used as the cathode, and the carbon nanotube film was deposited by electrophoresis, and the film thickness was 30 μm. The electrophoretic fluid consists of 0.3g carbon nanotubes and 0.2g Mg(NO 3 ) 2 ·6H 2 O is dispersed in 200ml of isopropanol, ultrasonically oscillated for 2 hours, and then deposited for 1 hour to obtain it; the process conditions during electrophoresis are: electrophoresis voltage 100V, electrophoresis time 2min, distance between cathode and anode 2cm; the ...

Embodiment 2

[0026] (1) Coating a transition metal thin film on the base material by vacuum evaporation coating method. The transition metal is Ta, and the base material is p-type (100) Si sheet. The process conditions are: the deposition rate is 0.4nm / s, and the deposition vacuum is 6×10 -5 Pa, deposition time 4min, sputtering vacuum 3×10 -4 Pa, the thickness of the plated Ta film is 100nm.

[0027](2) The Si substrate coated with Ta film was used as the cathode, and the carbon nanotube film was deposited by electrophoresis, and the film thickness was 30 μm. The electrophoretic fluid consists of 0.3g carbon nanotubes and 0.2g Mg(NO 3 ) 2 ·6H 2 O is dispersed in 200ml of isopropanol, ultrasonically oscillated for 2h, and then settled for 1h to obtain; the anode used is a platinum electrode; the process conditions during electrophoresis are: electrophoresis voltage 60V, electrophoresis time 5min, and the distance between cathode and anode is 3cm. Carbon nanotubes used Multi-walled car...

Embodiment 3

[0030] (1) Coating a transition metal thin film on the base material by radio frequency magnetron sputtering coating method. The transition metal is Hf, and the base material is p-type (100) Si sheet. The process conditions are: adjust the sputtering power to 200W so that the deposition rate is 0.8nm / s, the sputtering time is 8min, and the sputtering vacuum is 3×10 -4 Pa, the thickness of the plated Hf film is 400nm.

[0031] (2) The Si substrate coated with Ta film was used as the cathode, and the carbon nanotube film was deposited by electrophoresis, and the film thickness was 25 μm. The electrophoretic fluid consists of 0.3g carbon nanotubes and 0.2g Mg(NO 3 ) 2 ·6H 2 O is dispersed in 200ml of isopropanol, ultrasonically oscillated for 2 hours, and then settled for 1 hour; the anode used is a stainless steel electrode; the process conditions during electrophoresis are: electrophoresis voltage 60V, electrophoresis time 5min, and the distance between cathode and anode is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com