Triple pole structure of plane type field emission, and preparation method

A field emission, planar technology, applied in electroluminescent light sources, lighting devices, light sources, etc., can solve problems such as high operating temperature, glass substrate damage, emitter damage, etc., to improve emission stability, overcome positioning difficulties, Reduce the effect of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

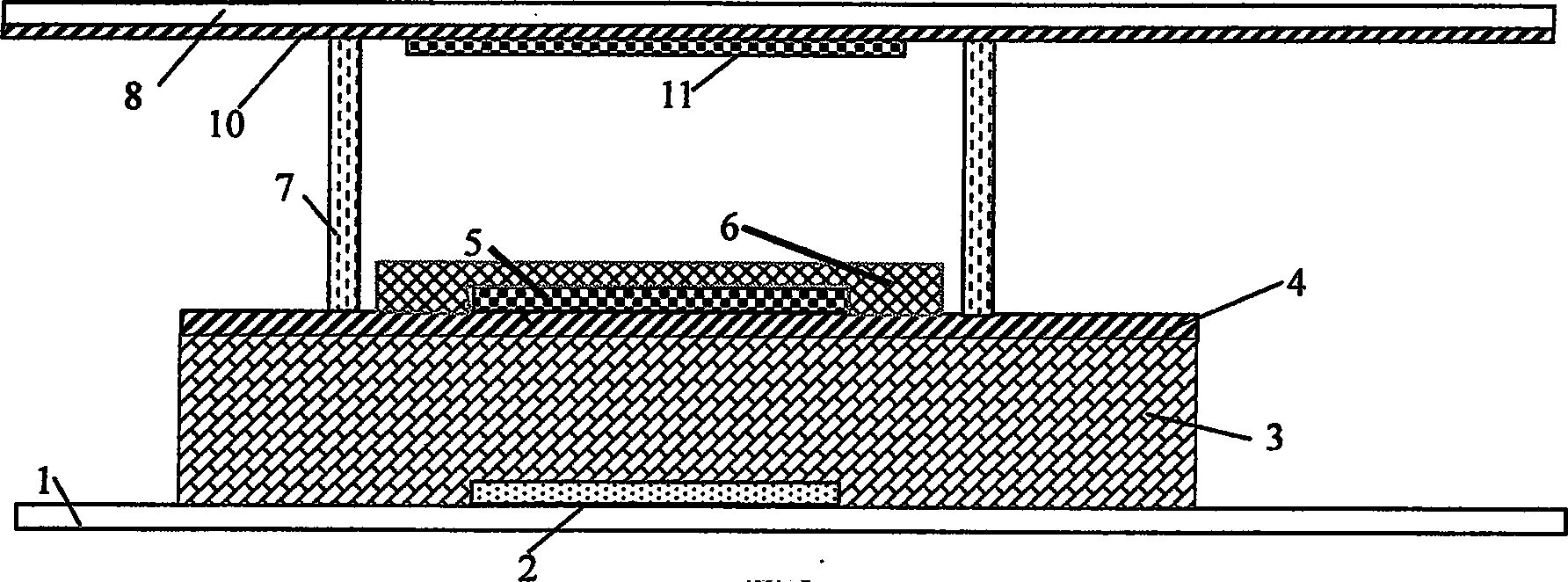

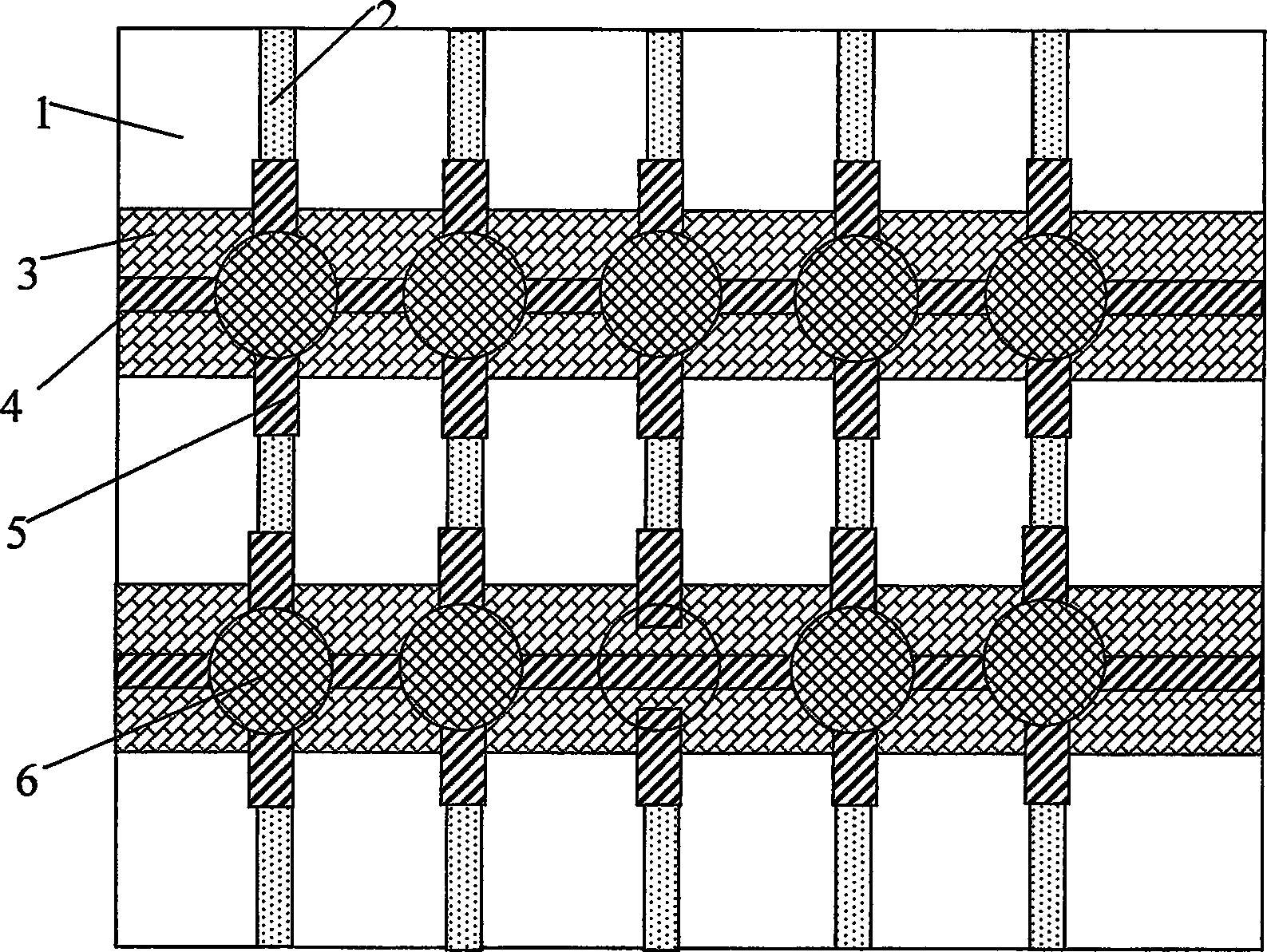

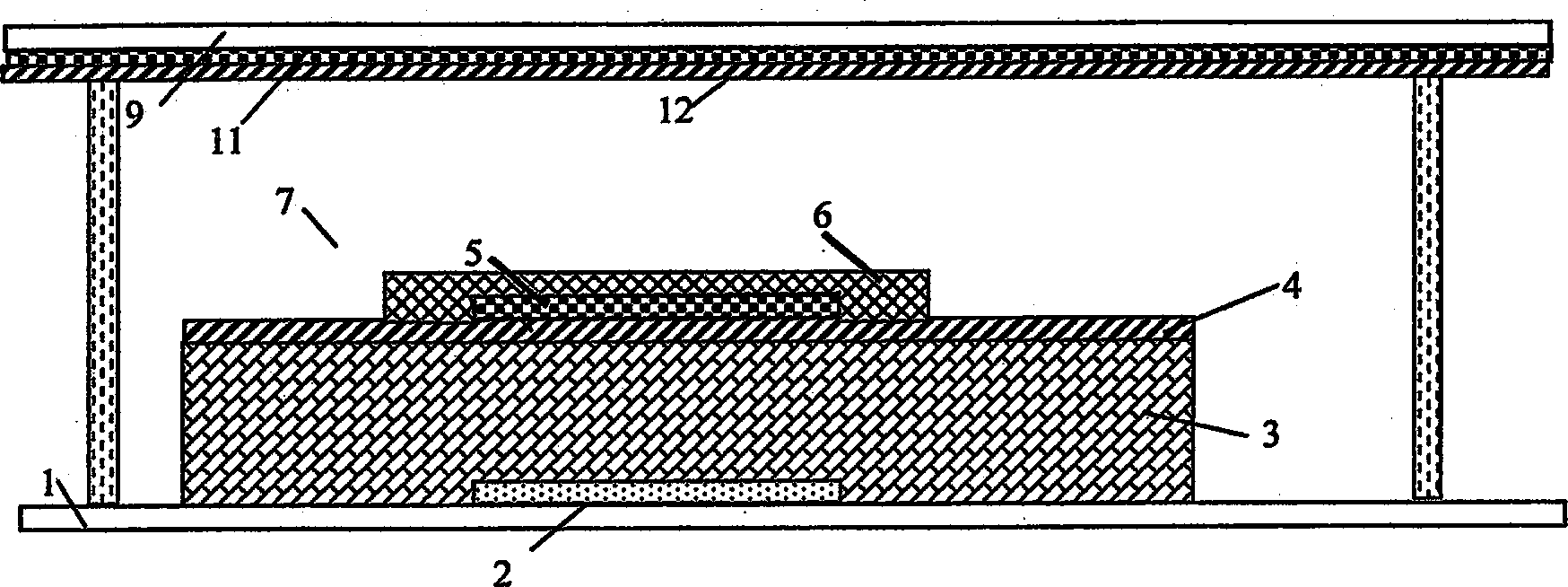

[0027] In the novel planar field emission triode structure of the present invention, a data electrode 2 is arranged on the cathode glass substrate 1, and a horizontal stripe-shaped dielectric layer 3 perpendicular thereto is arranged on the data electrode 2. The row scan electrode 4 is provided with a connection electrode 5 parallel to the data electrode 2 on the row scan electrode 4, and a field emission material 6 with a certain resistance characteristic is provided at the gap between the connection electrode 5 and the row scan electrode 4; A support body 7 is provided on the cathode glass substrate 1 or the dielectric layer 3, an anode glass substrate 8 is provided on the support body 7, an anode electrode 10 is provided on the lower surface of the anode glass substrate 8, and an anode electrode 10 is provided on the lower surface of the anode electrode 10. Phosphor layer 11.

[0028] The anode glass substrate 8 is made up of the transparent conductive film on the transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com