Method for preparing bunchy bismuth nanostructure material

A nanostructure and structural material technology, applied in the field of preparing bundled bismuth nanostructure materials, can solve the problems of inability to control a single size of a large area, inaccurate control of deposition time, low filling rate of filled nanowires, etc. Strong controllability and good periodicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

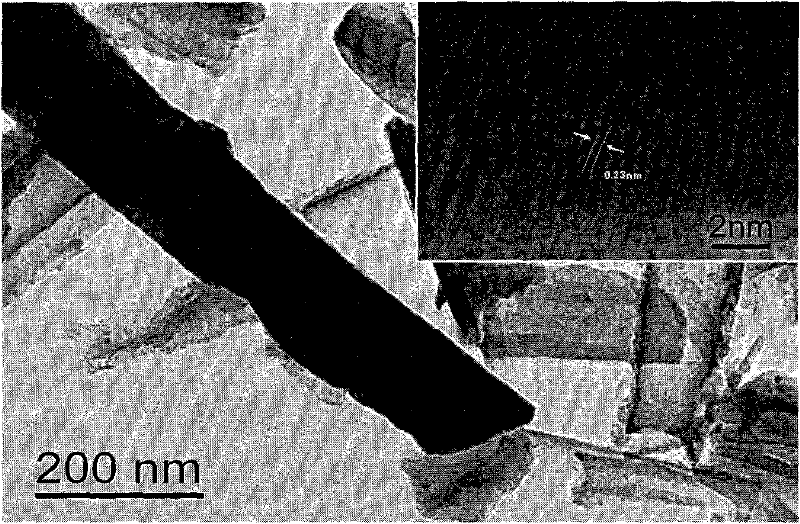

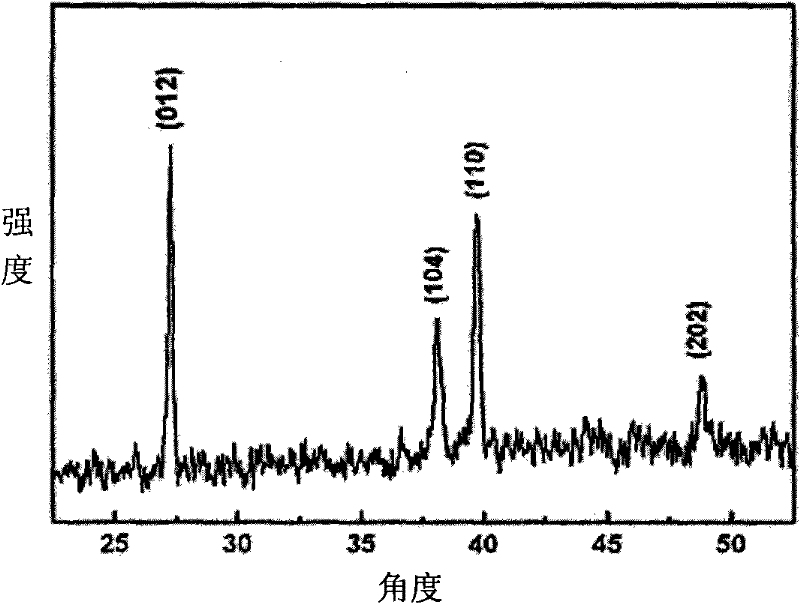

[0021] Preparation of bismuth beam nanostructure material, the specific steps are as follows:

[0022] a) Cut the alumina template into small pieces of 1cm×2cm, and then ultrasonically clean them in alcohol solution.

[0023] b) Prepare an electrodeposition solution consisting of 10 g / l BiCl 3 , 50g / l tartaric acid, 95g / l glycerol and 50g / l NaCl solution, the pH of the solution was adjusted to 0.9 with dilute hydrochloric acid.

[0024] c) Use CH1660C electrochemical workstation to conduct electrodeposition on alumina template, stage 1: at high level 1.5v, duration 0.4ms (milliseconds); low level 0v, duration 0.8ms (milliseconds), pulse under the above conditions Deposition for 40min (minutes). Stage 2: 2.5V DC electrodeposition for 1h (hour). Close the electrochemical deposition software to end the deposition.

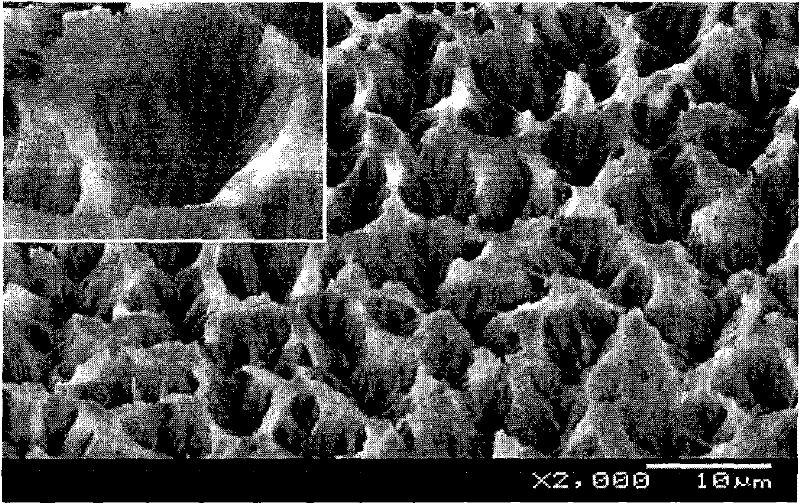

[0025] d) After the electrodeposition is completed, the template is taken out, placed in deionized water, ultrasonically cleaned, then placed in NaOH (0.5 mol / l) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com