Patents

Literature

42 results about "Wall suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

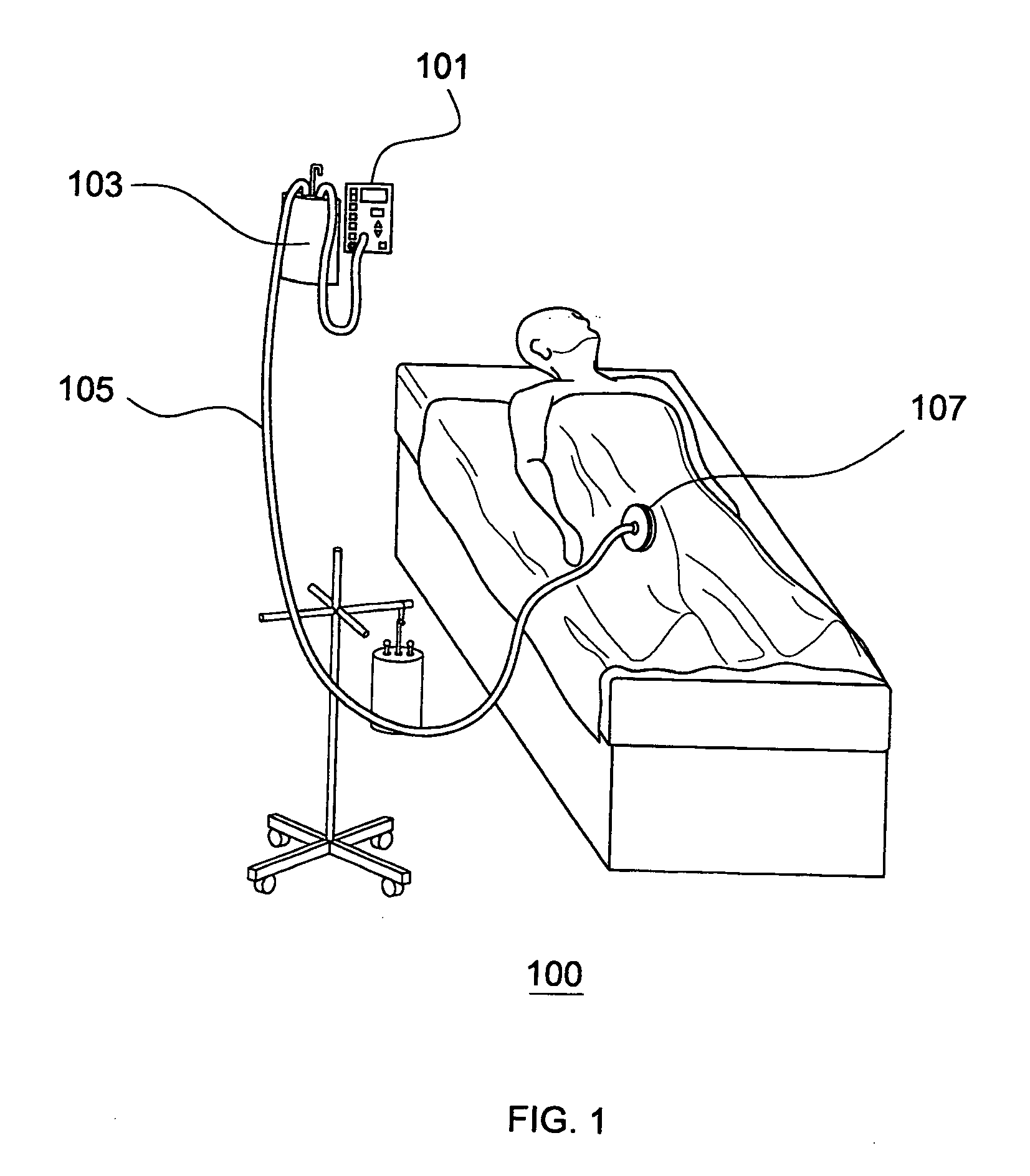

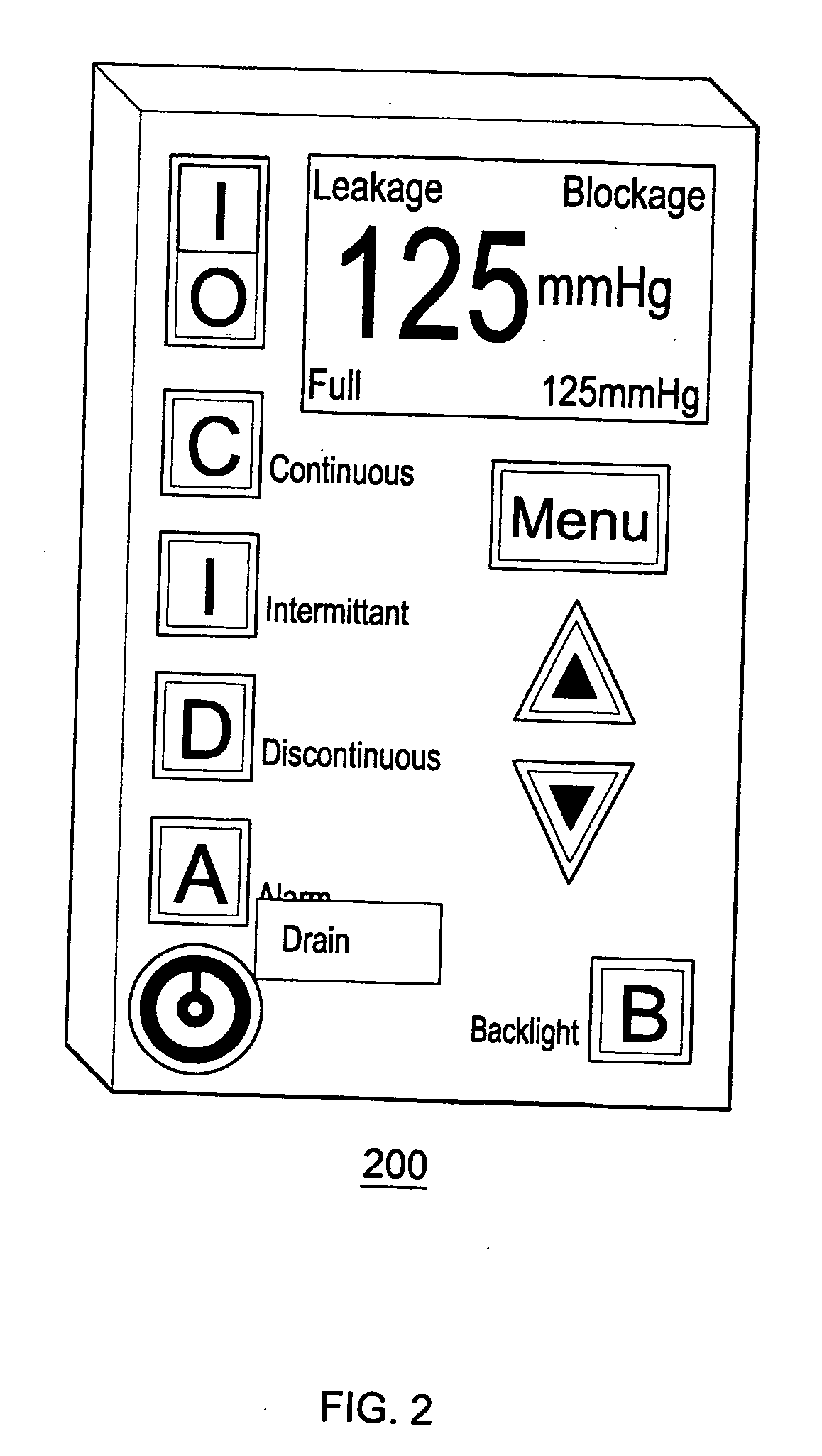

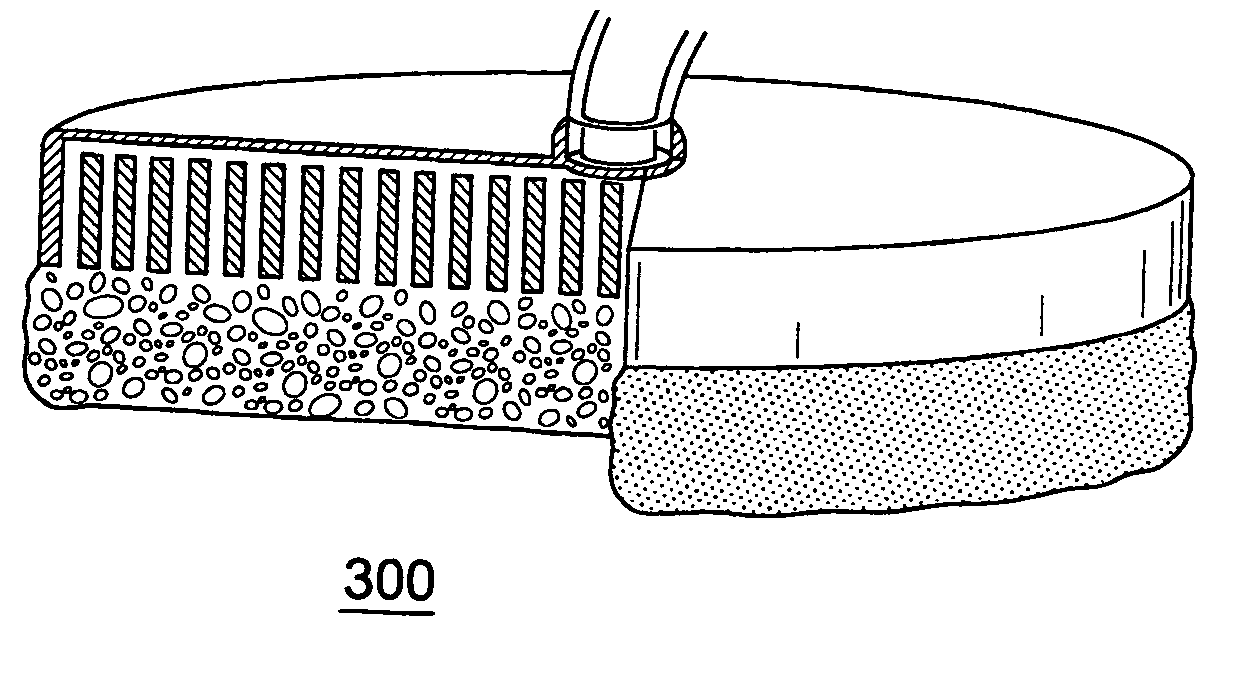

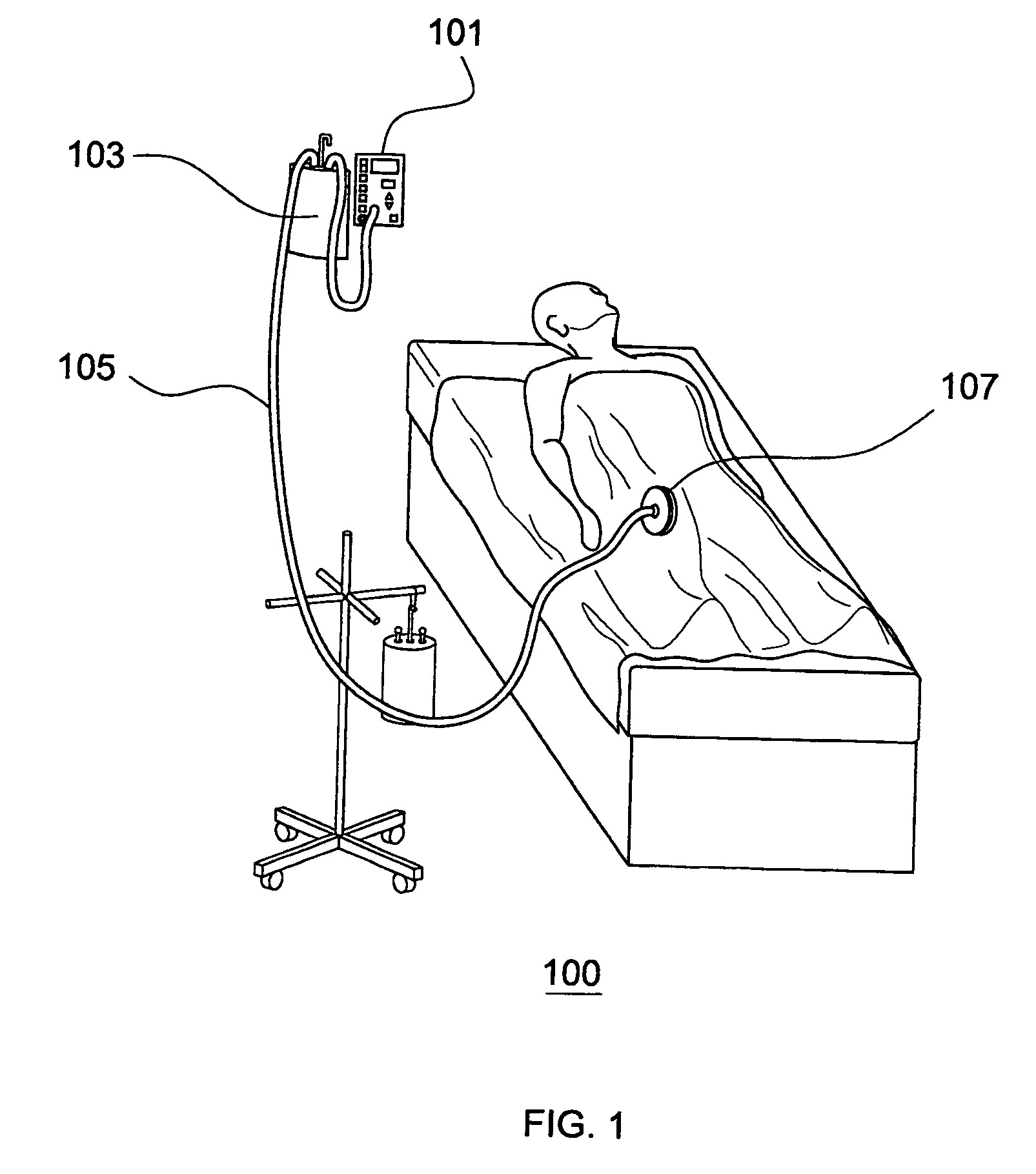

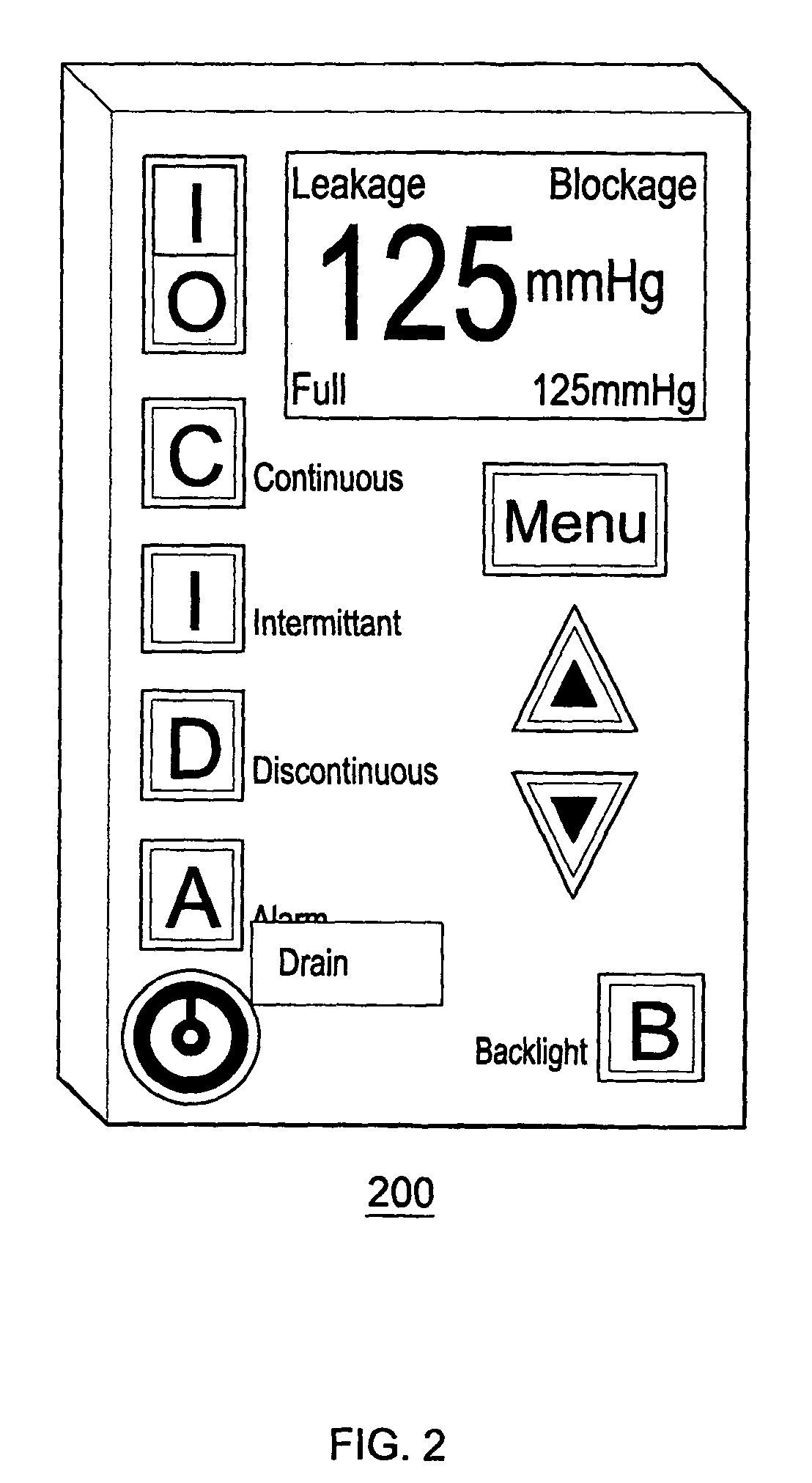

Sub-atmospheric Wound-Care System

Methods and systems are provided for a sub-atmospheric wound-care (SAWS) system for treating an open wound. The SAWS system includes a regulated vacuum source for developing a negative pressure, a flow rate meter configured to measure a flow rate of liquid removed from the wound, a primary pressure regulating sensor located proximate the wound for directly measuring the negative pressure at the wound, a backup pressure regulating sensor located vacuum tube, a porous dressing suitable to be sealed airtight which is positioned within a wound interface chamber, a collection canister configured to collect said liquid removed from the wound, and an adapter configured to use wall suction a primary regulated vacuum source.

Owner:J&M SHULER MEDICAL

Sub-atmospheric wound-care system

Owner:J&M SHULER MEDICAL

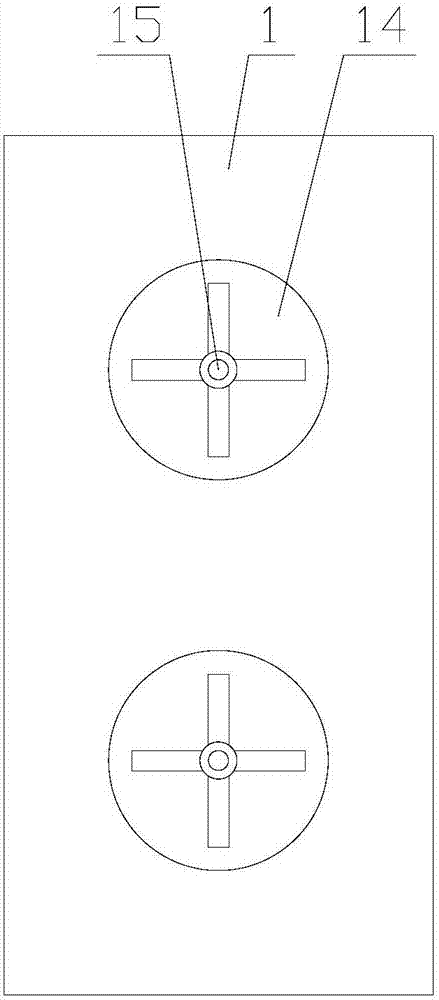

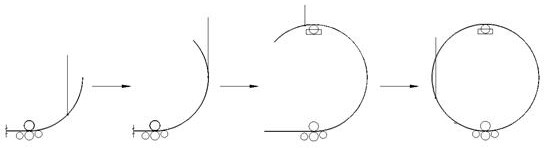

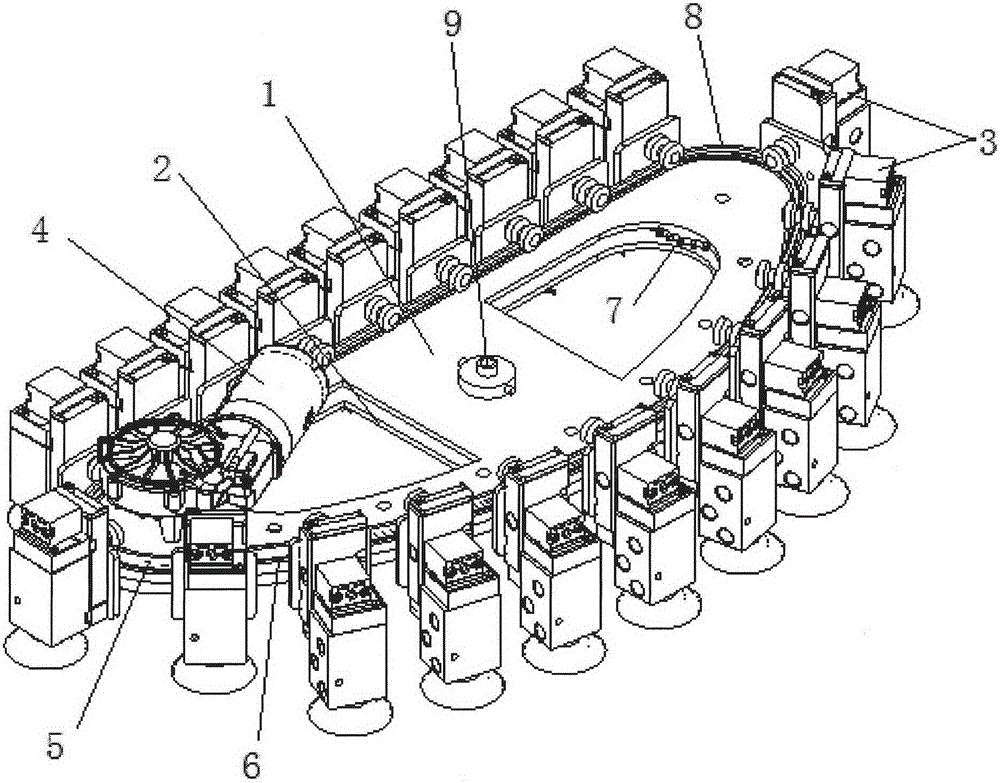

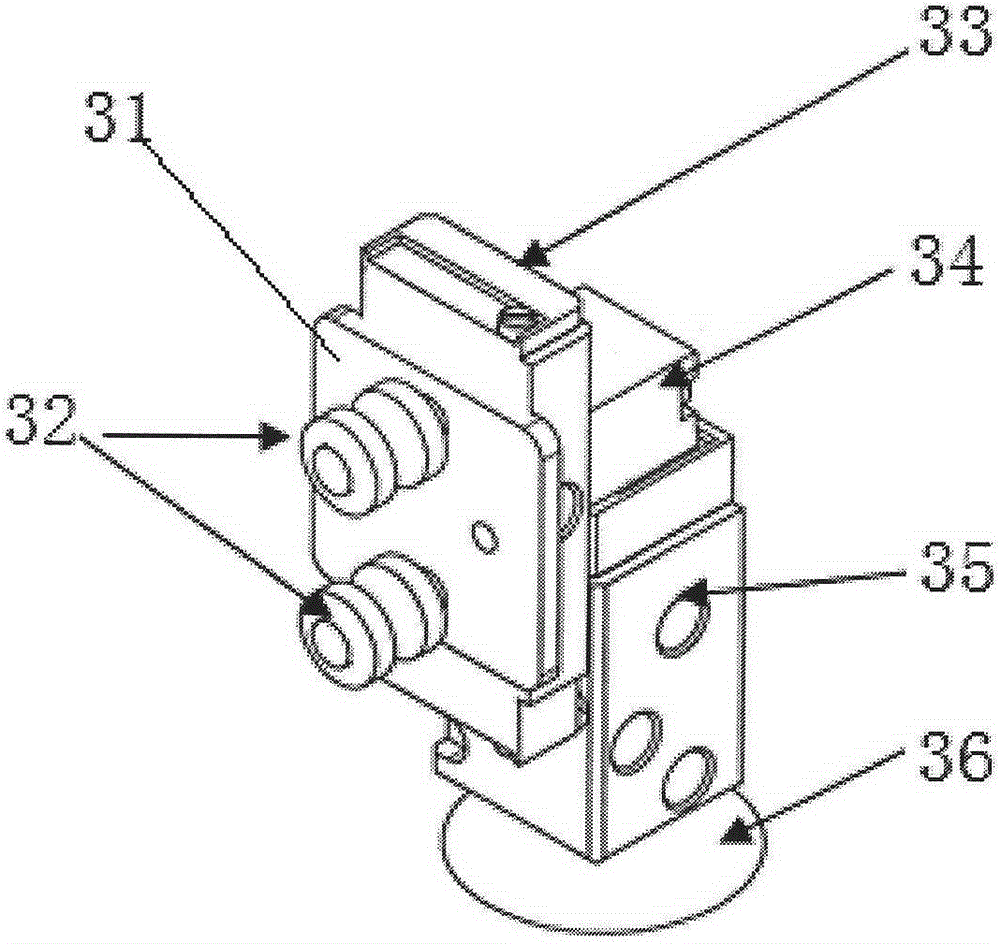

Curtain wall cleaning robot using wall suction movement mechanism

PendingCN105030144AImprove work efficiencyResolve continuityWindow cleanersEngineeringWork productivity

Owner:苑雪山

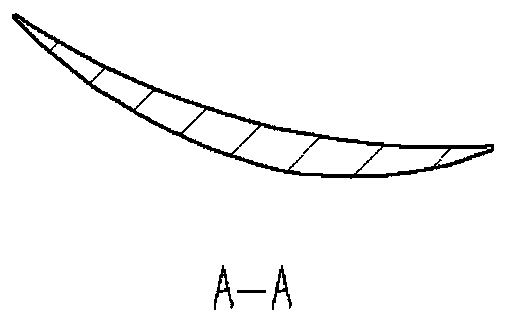

Combined suction layout method for controlling compressor stator corner separation

The invention relates to a combined suction scheme for controlling compressor stator corner separation. The combined suction scheme is characterized in that a suction groove is formed in an end wall of an axial-flow compressor stator cascade channel circumferentially, a suction groove is formed in a blade suction surface in a blade height direction, a suction groove in the end wall is parallel to a forehead line, the control on different axial positions and different suction groove lengths can be realized, and the suction groove in the end wall and the suction groove in the blade suction surface can also be controlled through different combination forms of positions. Compared with a single suction scheme, the combined suction scheme can combine advantages of suction surface suction and end wall suction, so that the development of boundary layers on the suction surface and the end wall can be prevented more effectively, gathering and mixing of the boundary layers at corners can also be prevented, the corner separation can be inhibited obviously, the total pressure loss can be reduced, and the stability and the efficiency of a compressor can be improved.

Owner:BEIHANG UNIV

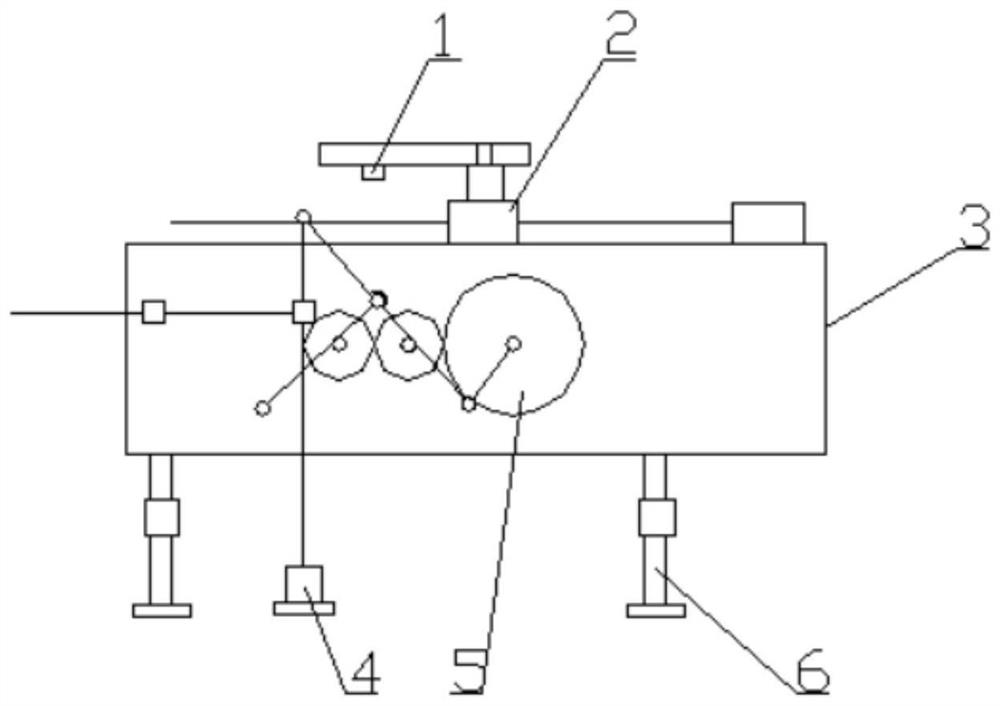

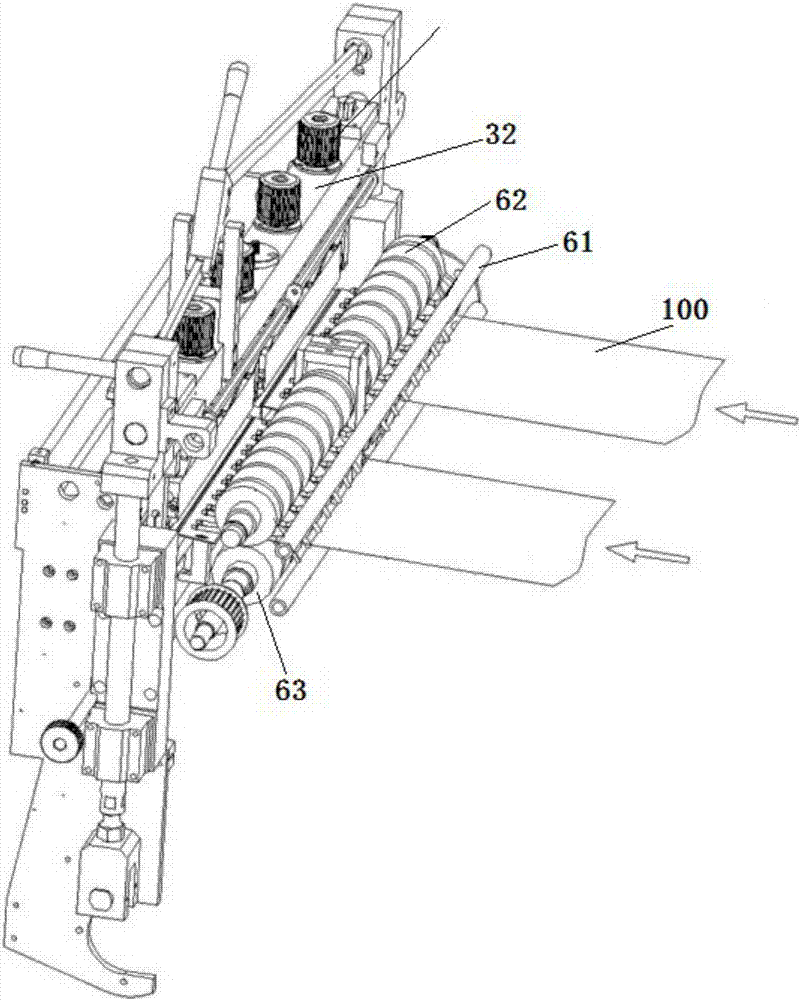

Cutting device for steel plate

InactiveCN107138957ACompact structureEasy to useOther manufacturing equipments/toolsBristleDrive shaft

The invention discloses a steel plate cutting device, which comprises a frame, a drive motor, a drive main shaft, a drive sub-shaft, a cam, an eccentric wheel, a beam, a guide pole, a frame arm, a cylinder, a swing arm, a discharge plate, a cutting Mechanism and processing mechanism; the cutting mechanism includes a shearing knife and a shearing seat; the processing mechanism includes several parallel cleaning roller groups and flattening and polishing roller groups, and the cleaning roller group includes upper cleaning rollers and lower cleaning rollers, upper cleaning rollers and lower cleaning rollers. Cleaning brushes are evenly arranged on the roller wall of the cleaning roller, and a number of dust suction holes are also opened on the roller wall of the lower cleaning roller; The groups are arranged at intervals along the conveying direction, and the roughness of the surface of the emery roller gradually decreases along the conveying direction. The invention has compact structure and high degree of automation, can complete automatic feeding, flattening, polishing, cleaning, cutting and unloading operations of steel plates, and is very convenient to use.

Owner:嘉善优联物流装备有限公司

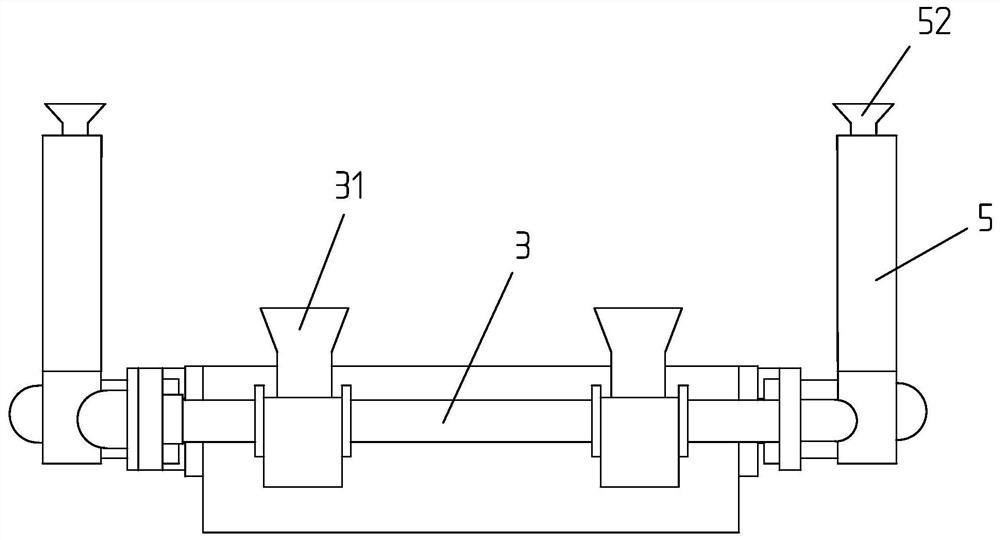

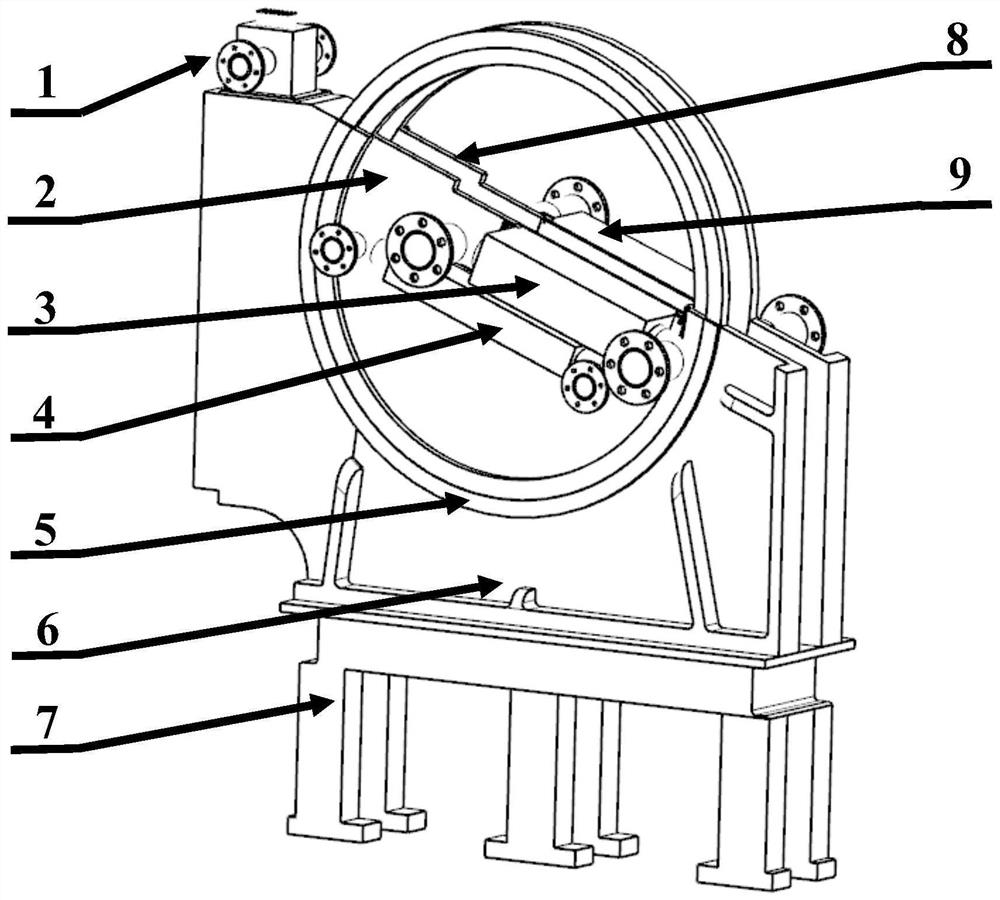

Combined suction system for improving periodicity of planar cascade and quality of outlet flow field

PendingCN112304556ARealize the control effectGood periodicityAerodynamic testingEngineeringWall suction

The invention provides a combined suction system for improving the periodicity of a planar cascade and the quality of an outlet flow field. The combined suction system comprises an upper end wall suction cavity, a left turntable, a left turntable slideway, a cascade wind tunnel experiment table, a cascade wind tunnel experiment table fixing seat, a right turntable and a right turntable slideway. In the system, symmetric suction is conducted through the left grid plate and the right grid plate, symmetric suction is conducted through the front boundary layer structure of the left grid plate andthe right grid plate, the suction device arranged on the blade grid is controlled through the throttle valve, and control over the periodicity and the dense flow ratio of a flow field in the blade grid is achieved; according to the requirements of different blade grids. the number and the relative positions of the suction holes formed in the left grid plate and the right grid plate are adjusted, and the control effect of the periodicity and the dense flow ratio of a blade grid outlet flow field is achieved more efficiently in an energy-saving mode.

Owner:DALIAN MARITIME UNIVERSITY

Modified reinforcing and toughening thin-wall suction pipe material and preparation method thereof

The invention relates to a modified reinforcing and toughening thin-wall suction pipe material which is composed of the following raw materials in parts by weight: 100 parts of polypropylene, 8-15 parts of hollow glass microspheres and 10-25 parts of elastomer. A preparation method comprises the following steps of: (I) mixing: uniformly mixing the polypropylene and the elastomer in a mixer to form a mixture; (II) extrusion: performing melt extrusion of the mixture through screw extrusion equipment, wherein the temperature in an area 1 of the extrusion equipment is 150-175 DEG C, the temperature in an area 2 is 155-180 DEG C, and the die temperature is 155-185 DEG C; and (III) filling: adding the hollow glass microspheres while extruding at the front end of a screw, wherein the rotation speed of the charging screw is 12-20rpm; and cooling to obtain the modified reinforcing and toughening thin-wall suction pipe material. Under the condition of the same wall thickness, the suction pipe provided by the invention has the advantage that the pipe wall has better rigidity, excellent tensile strength and elongation at break and good cracking resistance.

Owner:NANJING PRIDE PLASTIC TECH

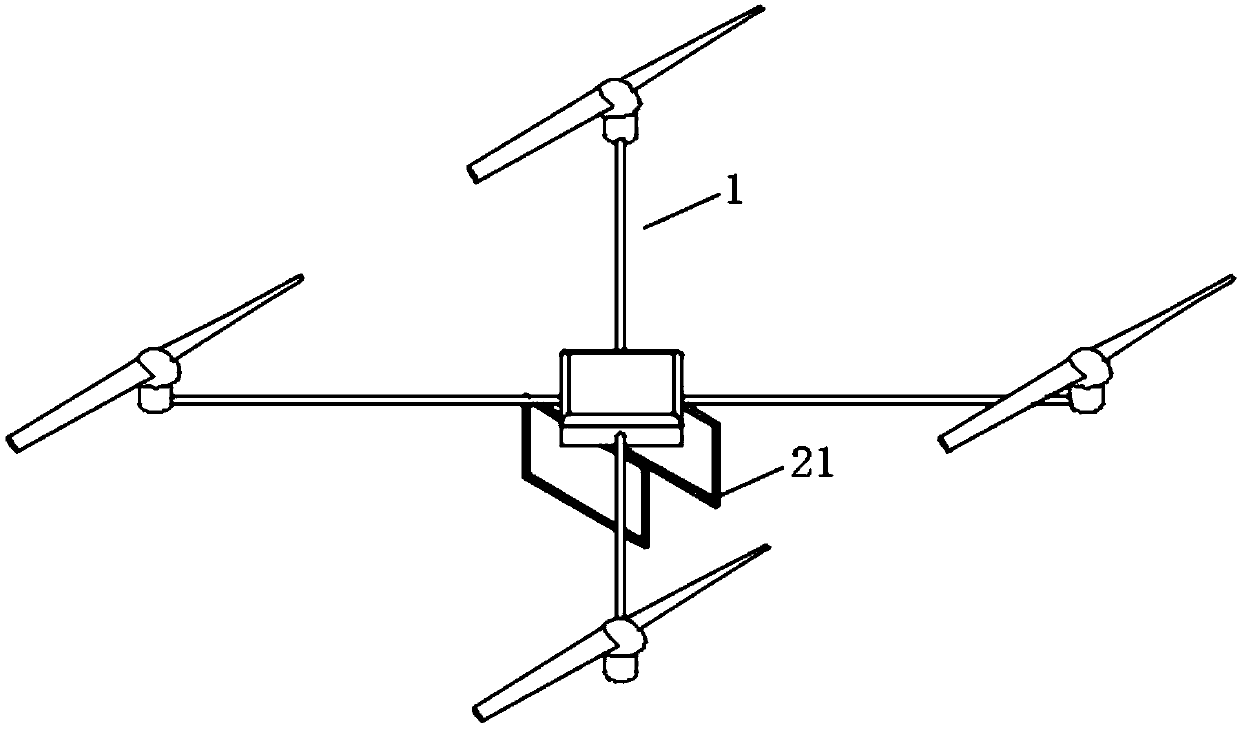

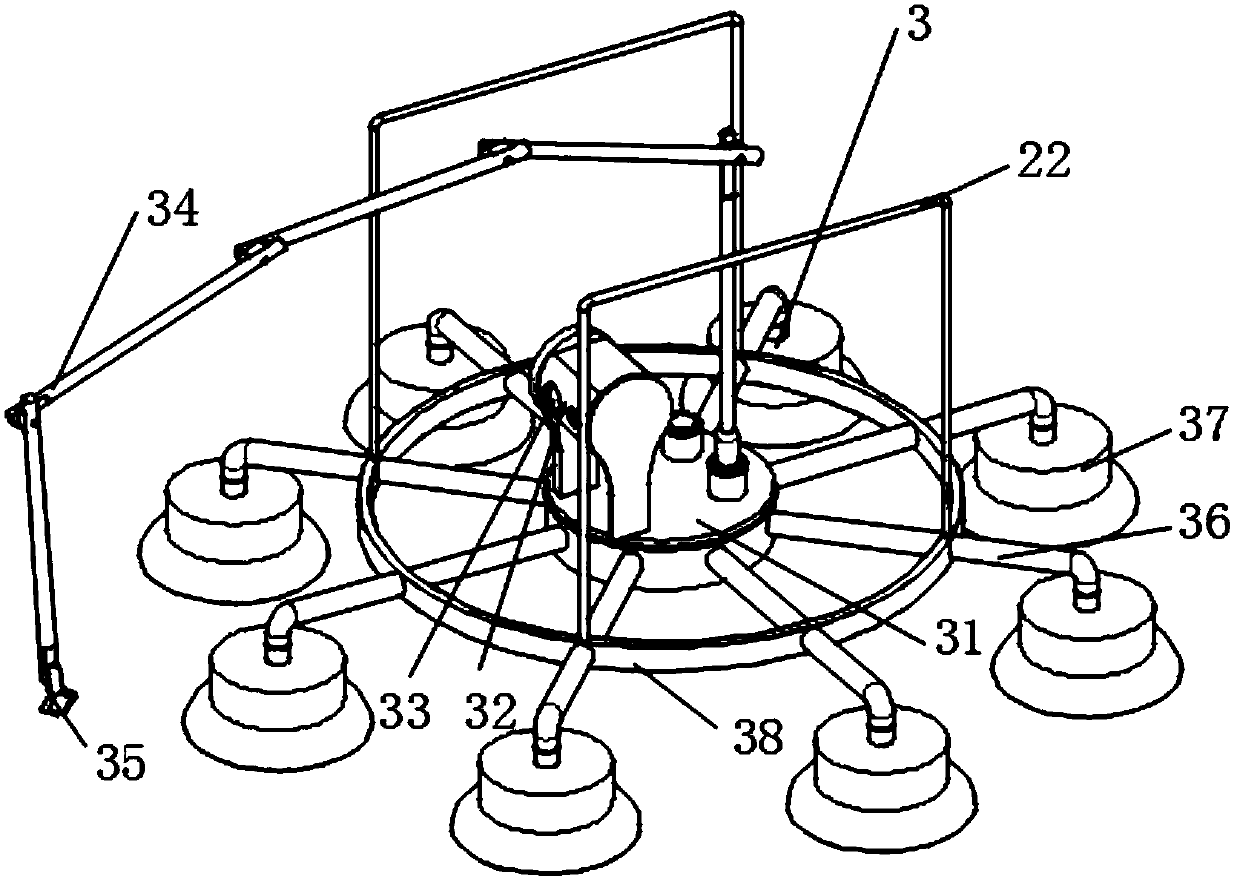

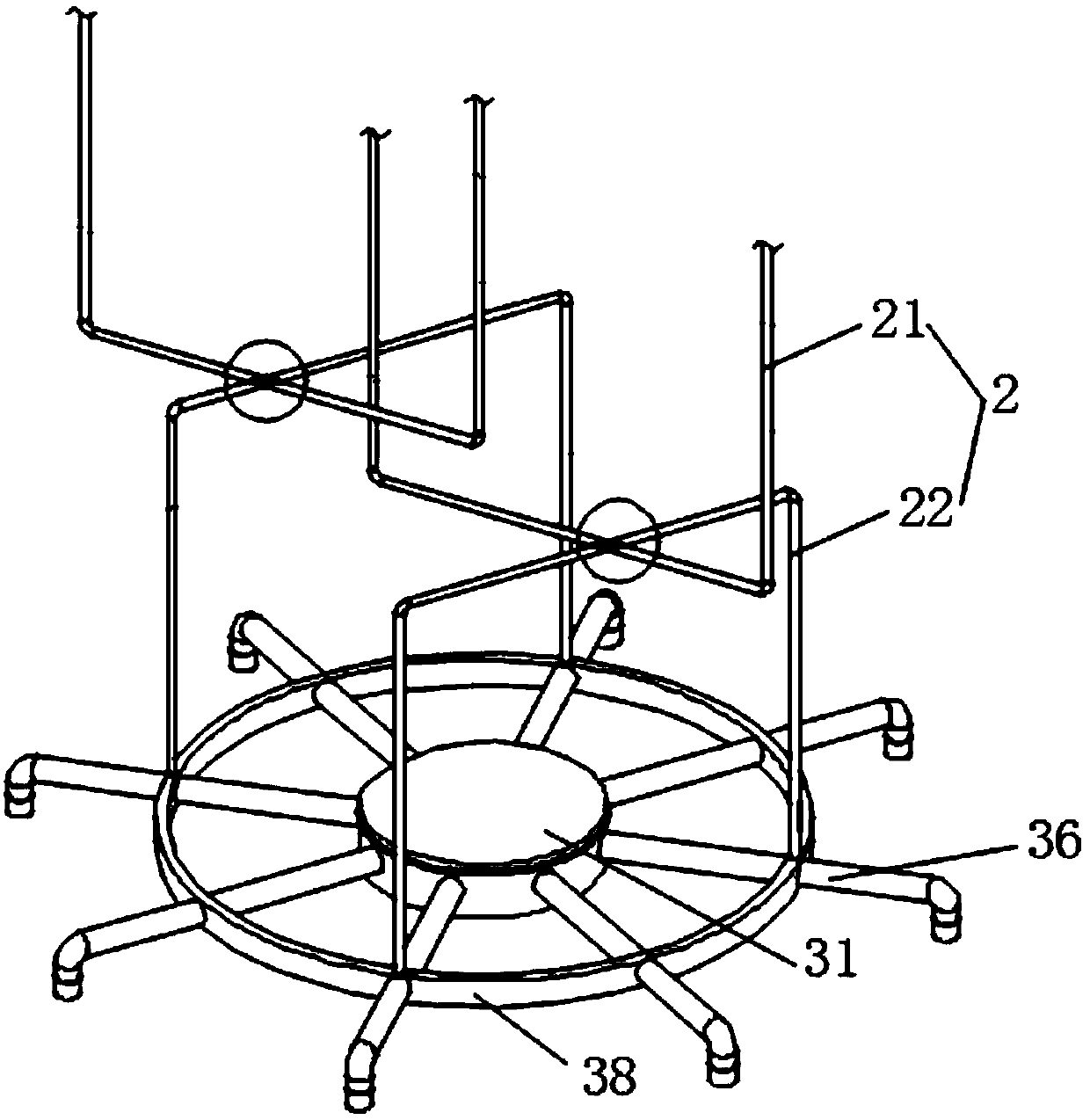

Unmanned plane-based wall suction robot detection device, control system and method

InactiveCN108680924AAchieve separationEnable connectivityElectromagnetic wave reradiationControl systemUncrewed vehicle

The invention relates to an unmanned plane-based wall suction robot detection device, a control system and method; the detection device comprises an unmanned plane, a lifting device and a robot; the control system comprises a ground control system, an unmanned plane control system arranged in the unmanned plane, and a robot control system arranged in the robot; the invention combines advantages ofan existing unmanned plane and a wall climber robot, and designs the combined detection device and the control system and method thereof, thus realizing unmanned detection of high rise buildings andhigh risk buildings; the detection device is safe and efficient, suitable for precision detection and internal defect detection, and the unmanned plane and the robot can be separated and connected viaa lock buckle and a lock hole on the lifting device.

Owner:武汉珈鹰智能科技有限公司

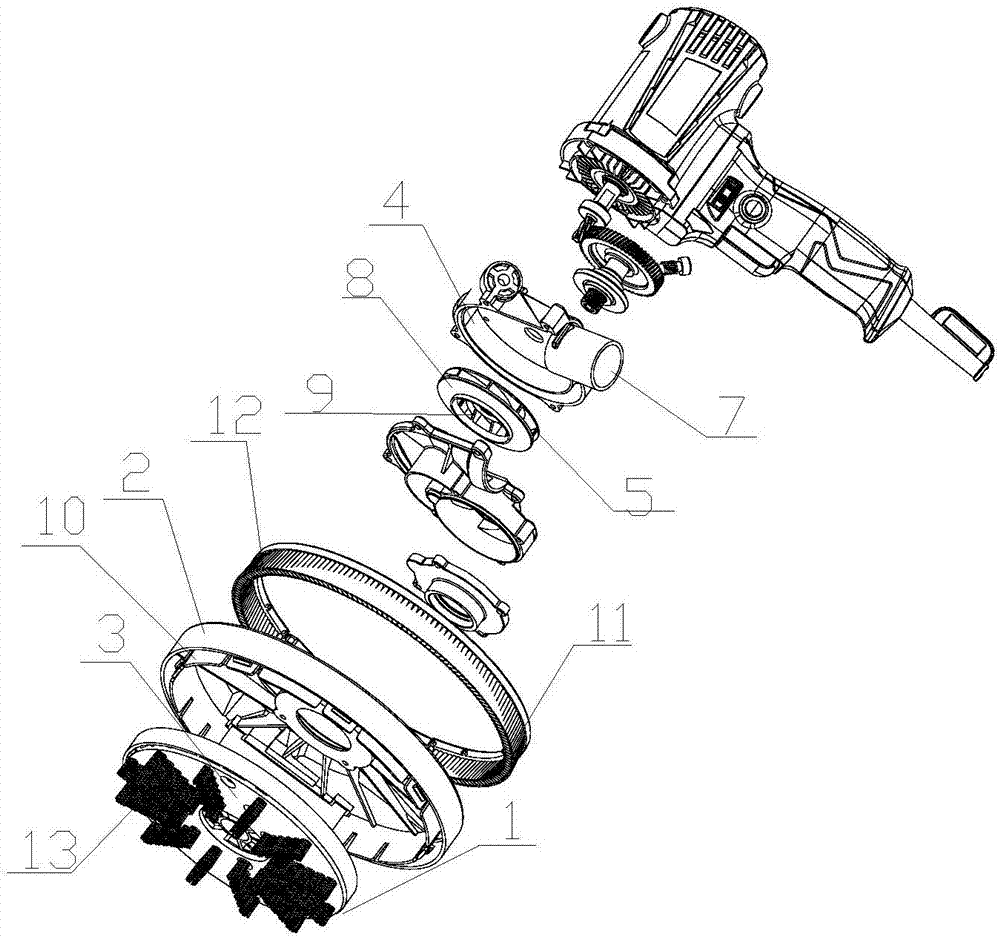

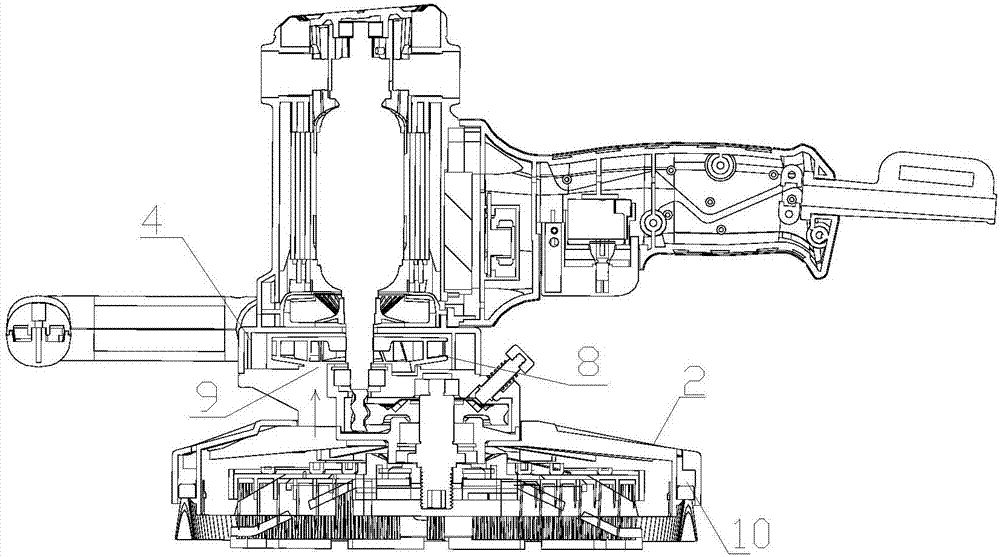

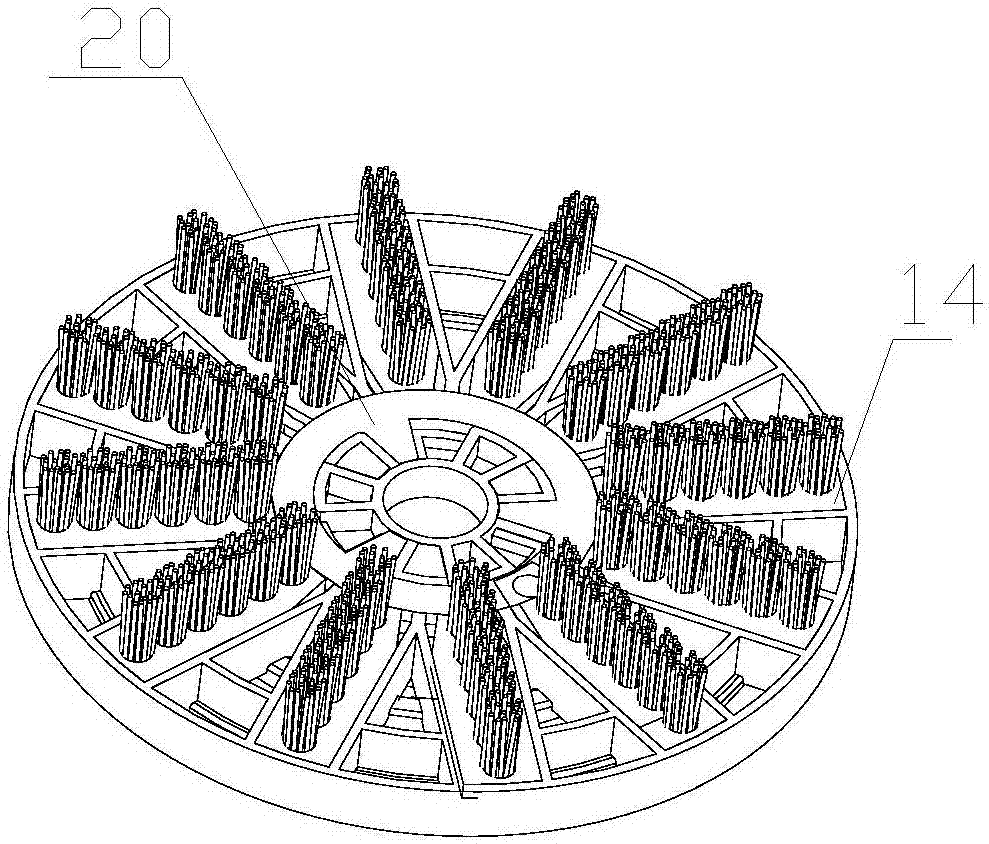

Wall face grinding machine with dust collection device

PendingCN107877282AHas gas gathering effectImprove vacuuming effectFlexible-parts wheelsPlane surface grinding machinesPulp and paper industryWall suction

The invention provides a wall face grinding machine with a dust collection device. The wall face grinding machine comprises a grinding disc, a disc, a dust collection system, a gear transmission mechanism and a motor, wherein the motor drives the grinding disc to move through the gear transmission mechanism; the grinding disc is covered with the disc, the dust collection system comprises a dust collection disc, a dust collection cover and dust collection fan blades, the dust collection disc is arranged behind the grinding disc and connected with the output end of the gear transmission mechanism, and the dust collection disc is provided with dust collection hole units; and the dust collection fan blades are fixedly connected to an output shaft of the motor, an air suction channel is formedbetween the grinding disc and the disc, the air suction channel communicates with the dust collection cover, and the dust collection cover is provided with air vents. According to the wall face grinding machine with the dust collection device, the dust collection effect is high, when a grinding brush on a hairbrush base is damaged, replacing is more convenient, the cost is reduced, at the same time, the hairbrush can be made of different materials and mounted on a hairbrush seat body in a strip-shaped mode, and using flexibility is great.

Owner:ZHEJIANG BURLEY TOOLS

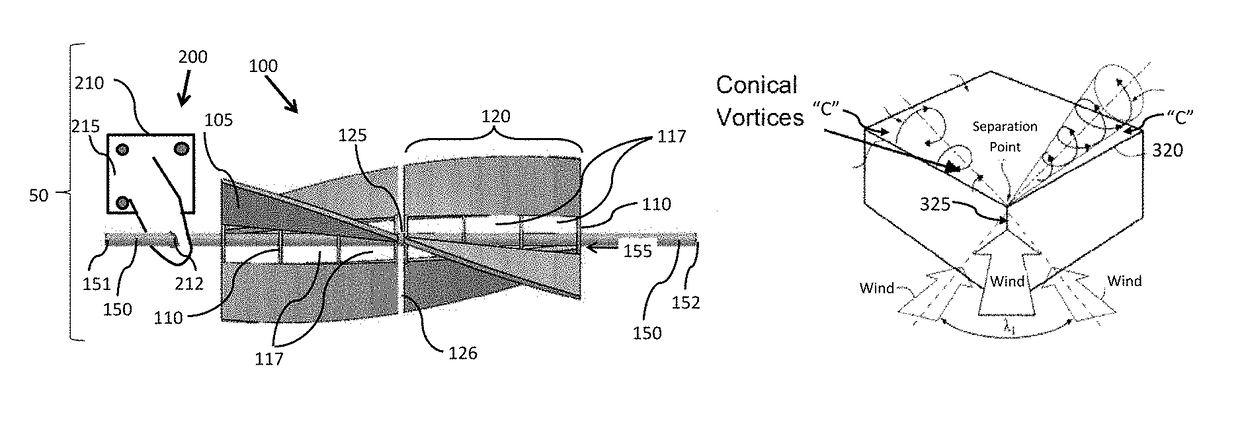

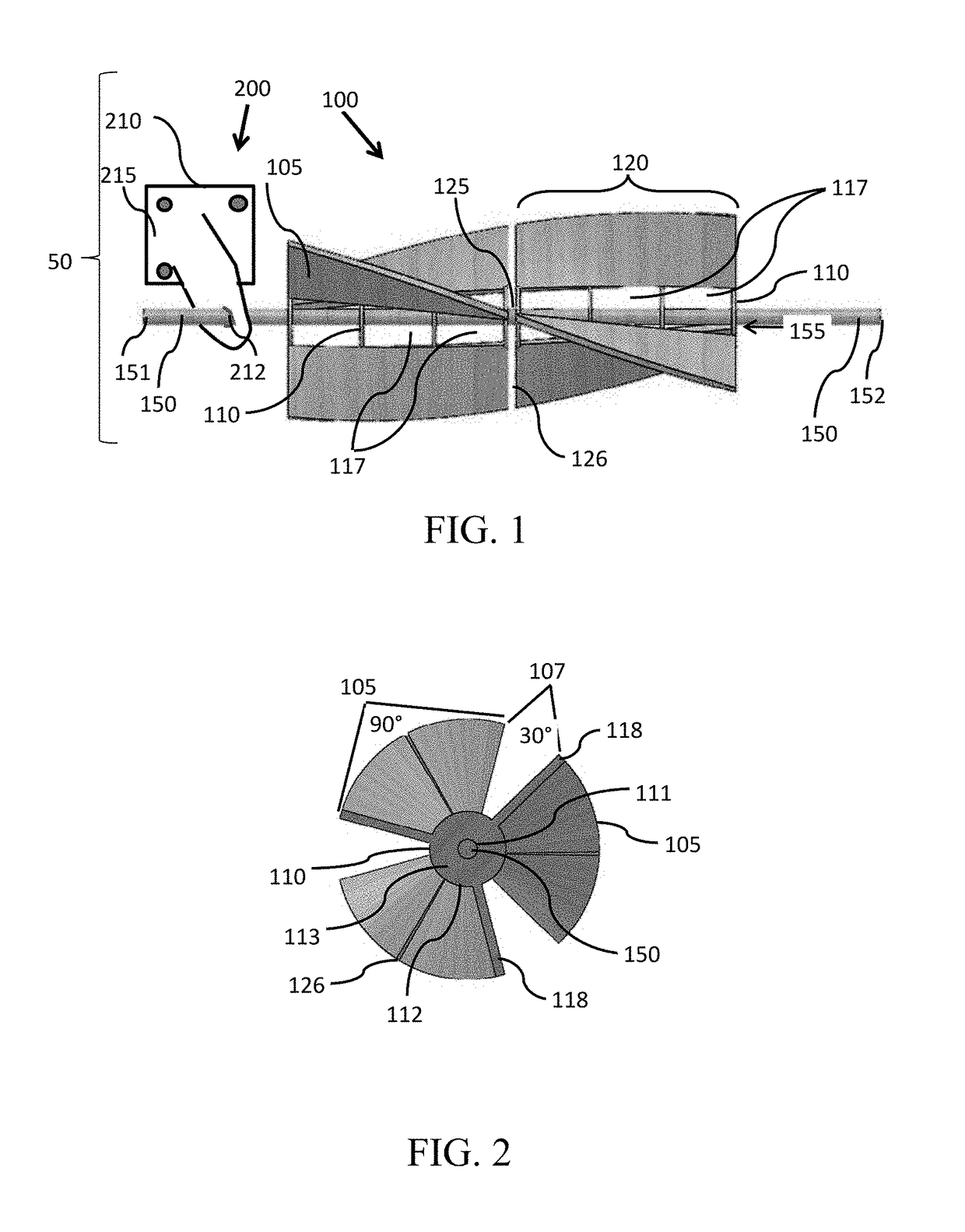

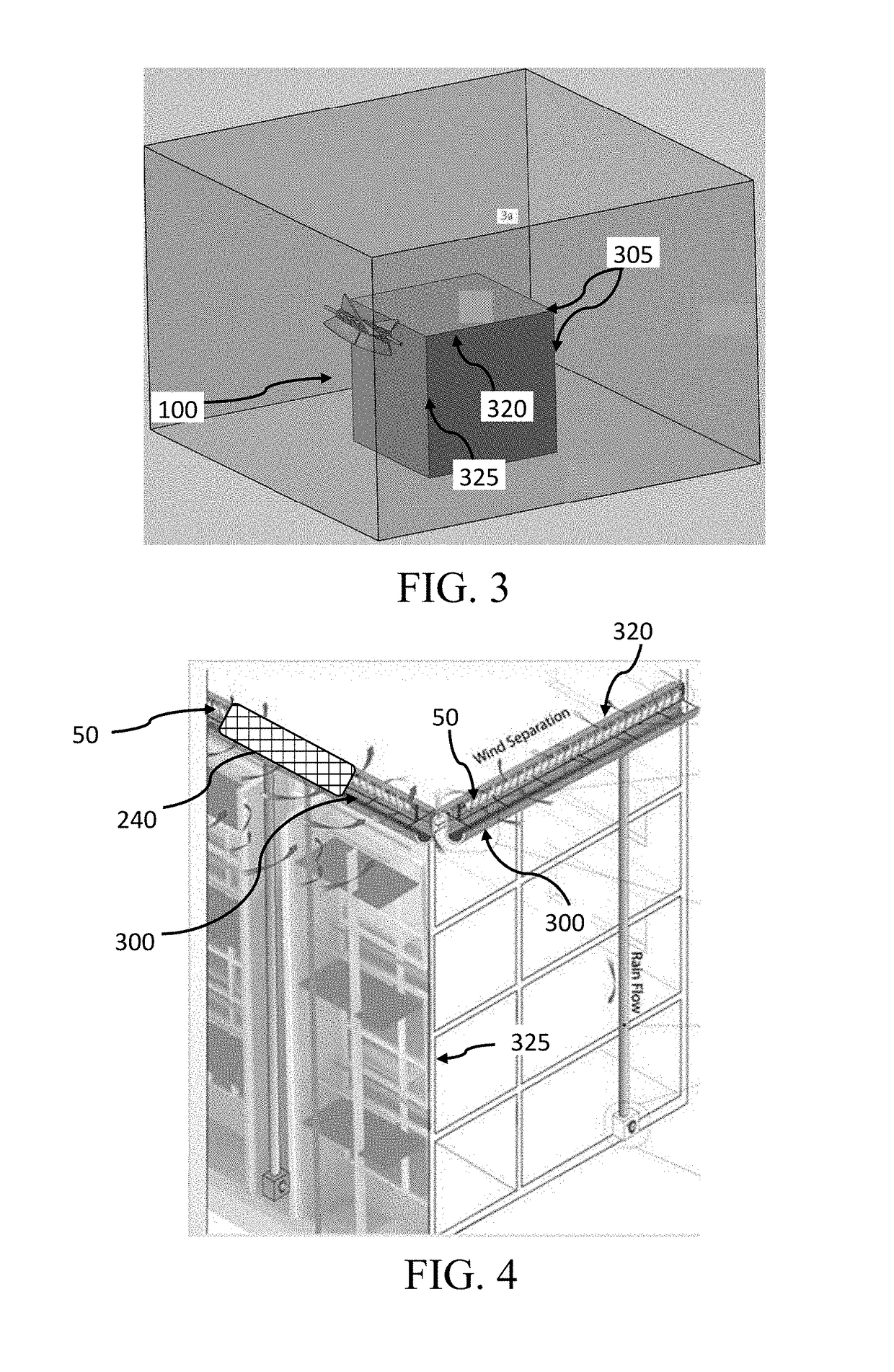

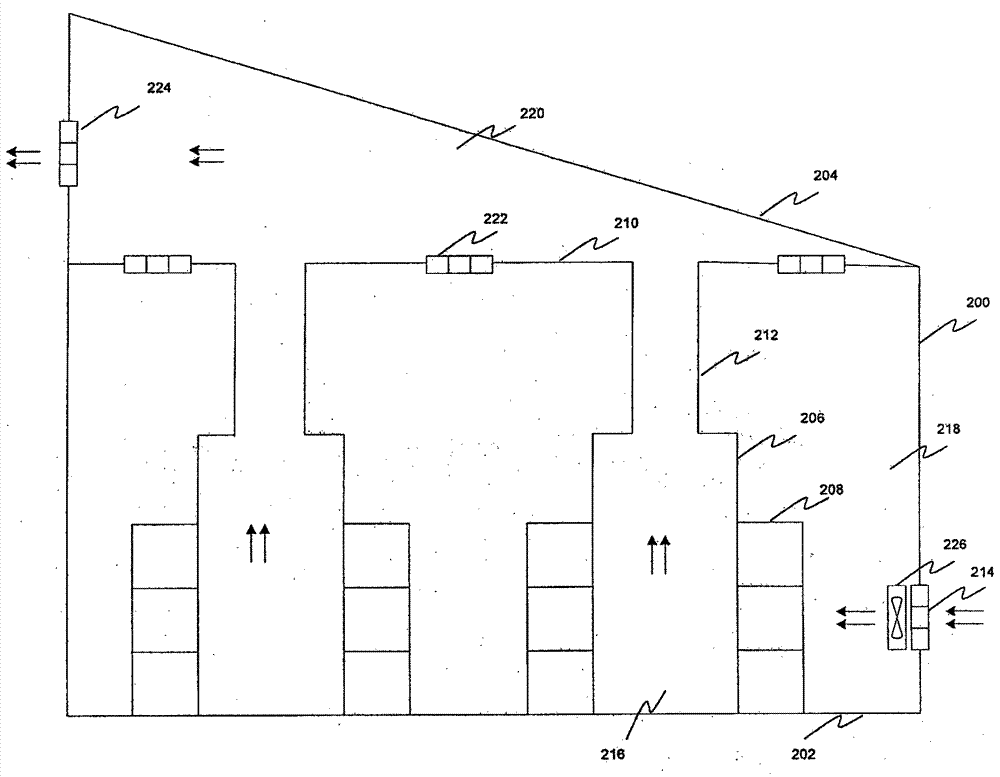

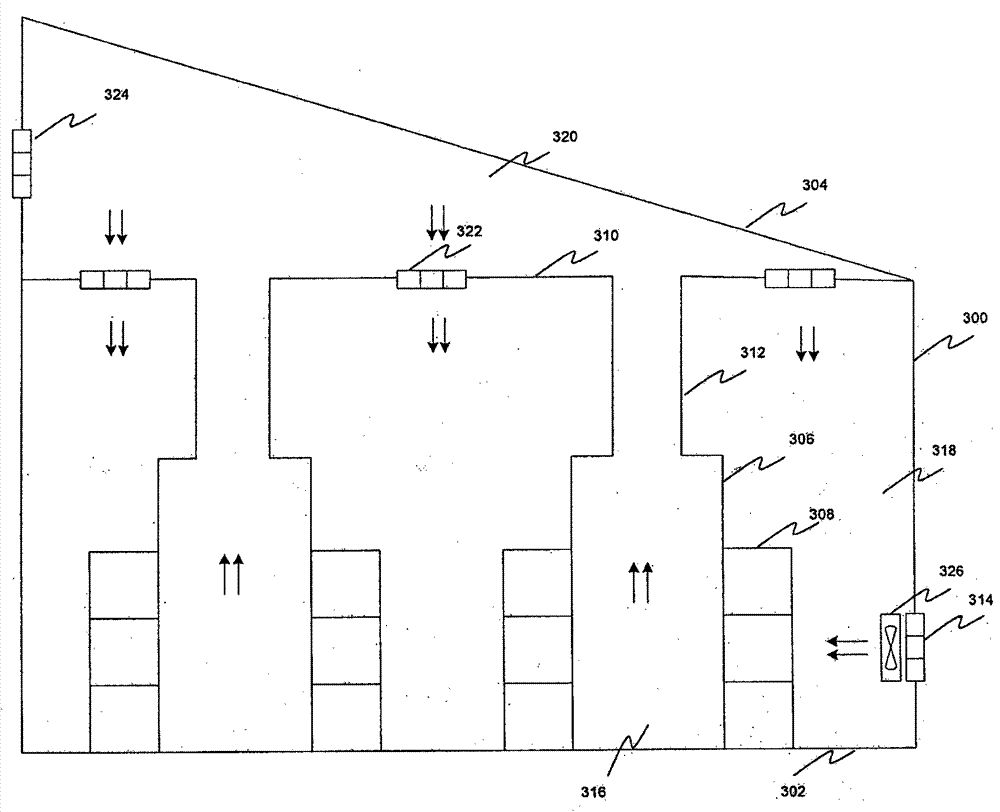

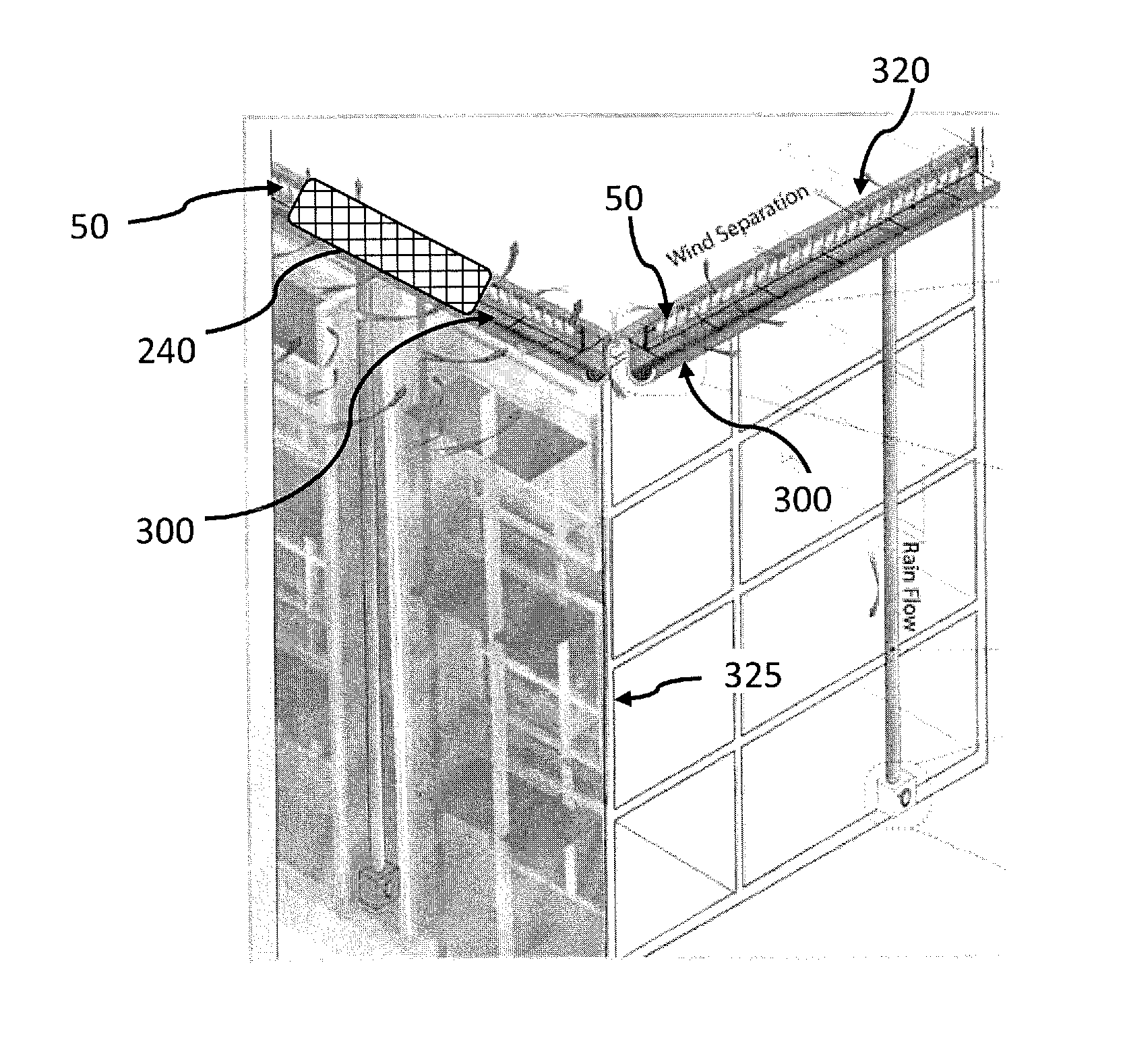

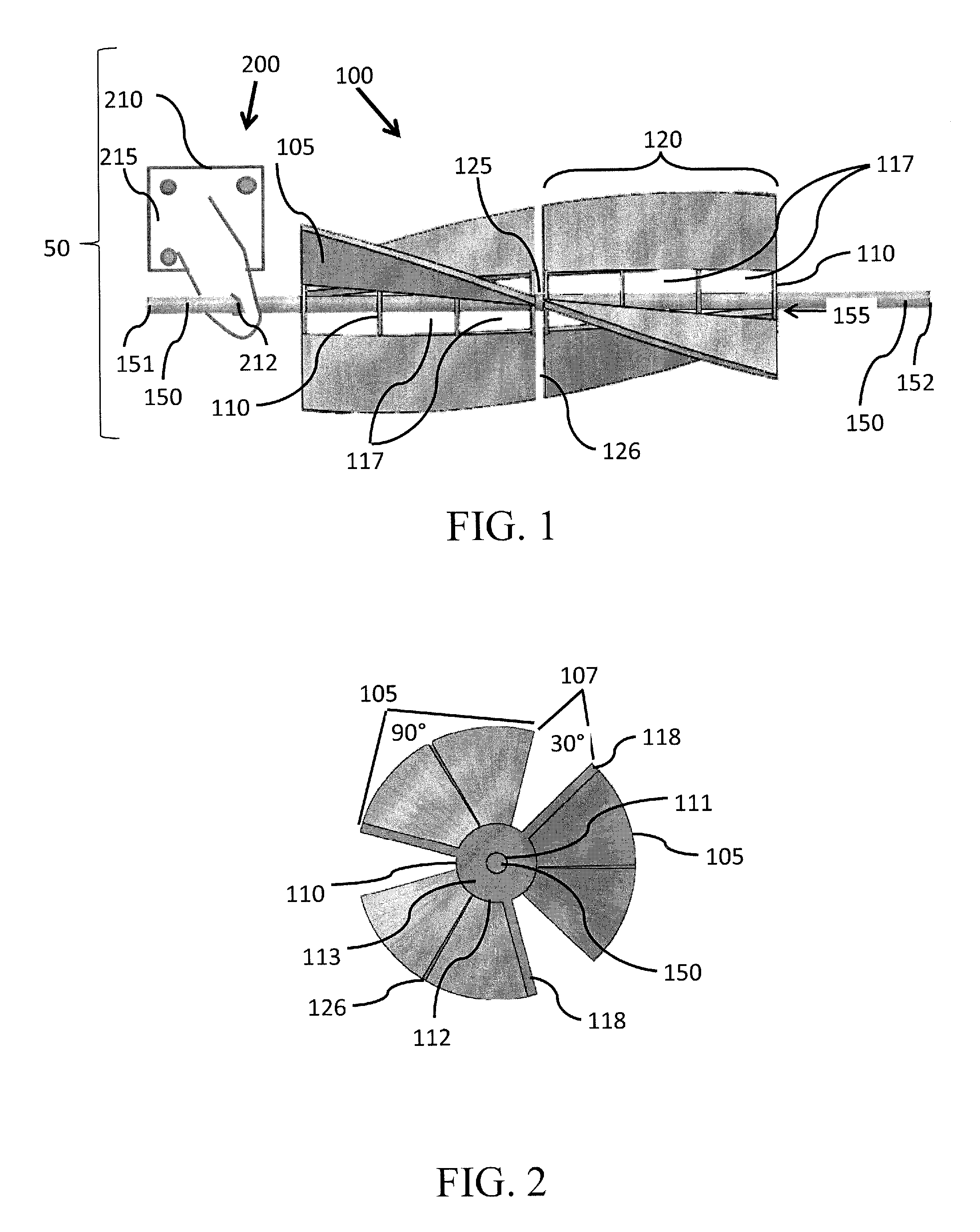

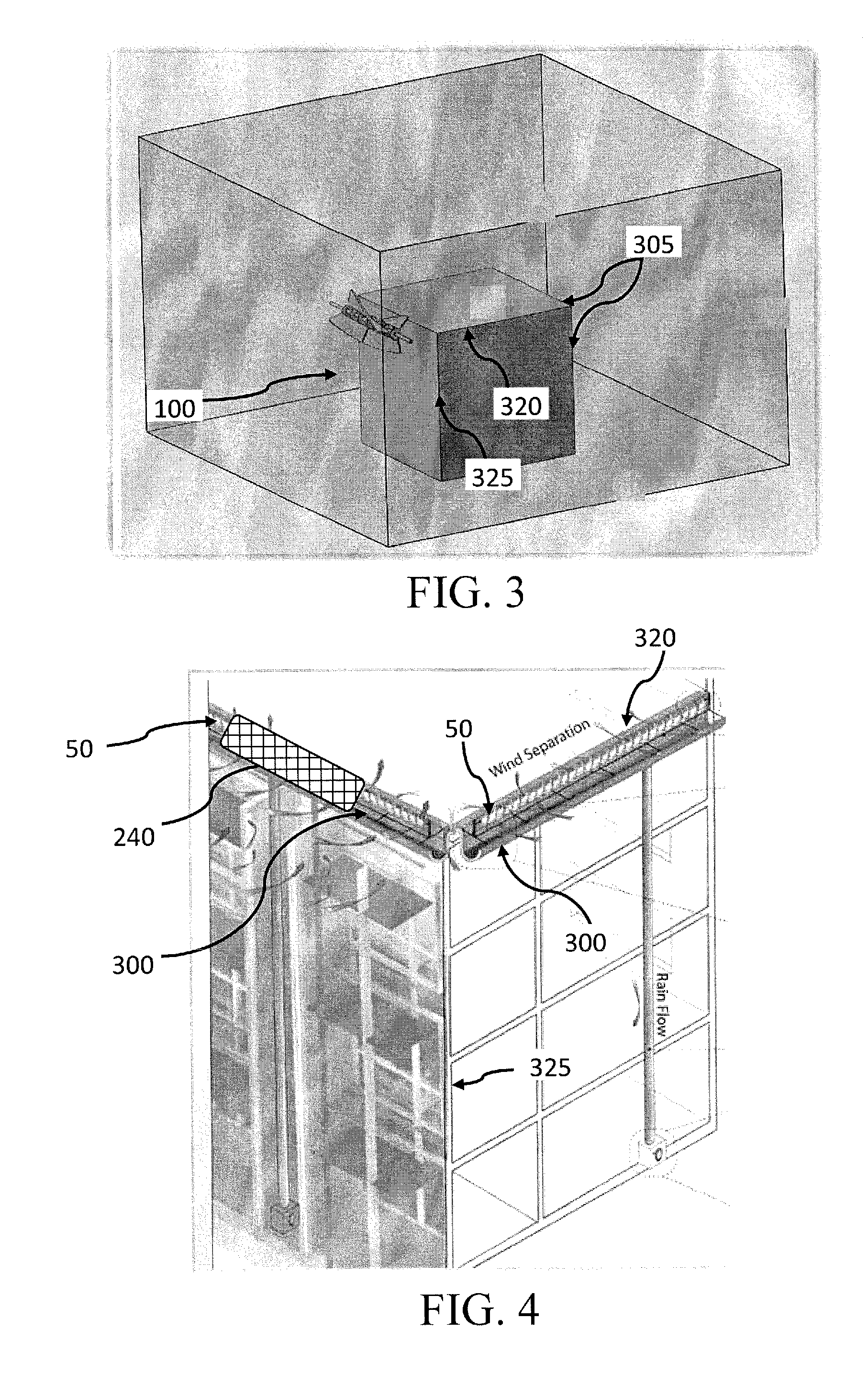

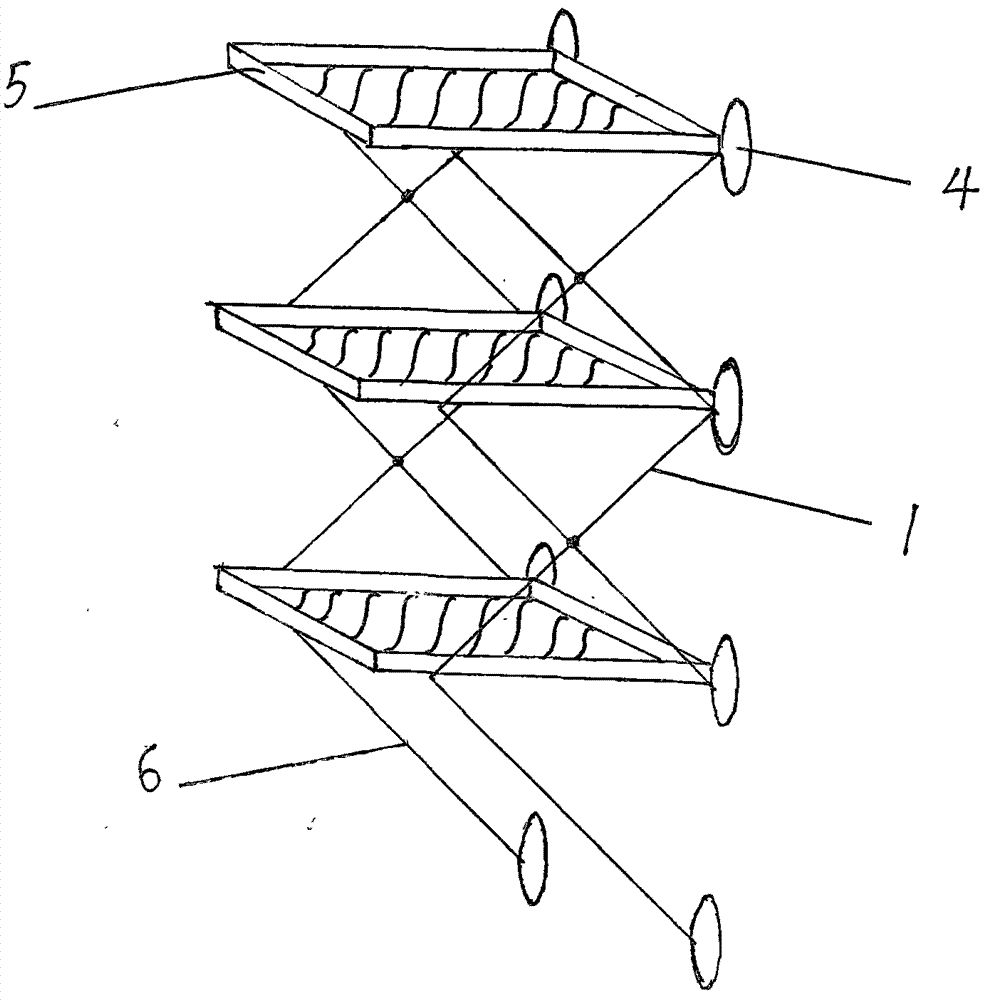

Active aerodynamics mitigation and power production system for buildings and other structures

ActiveUS20150345472A1Avoid wind damageSame energyPropellersWind motor supports/mountsWind damageEngineering

The current invention provides apparatuses and methods for protecting buildings / structures from wind damage and simultaneously harvesting energy from wind. The apparatuses of the current invention comprise horizontal axial wind turbines integrated to the roof-edge of the buildings / structures in an aerodynamically conducive and structurally viable configuration to reduce roof suction. The apparatuses of the current invention can further comprise aerodynamic roof gutter and structural supports / connections to alleviate wind-induced suction (negative pressures) on building roofs generated by separated flows and vortices. The apparatuses of the current invention can also comprise vertical axial wind turbines integrated to the wall-edge of the structures / buildings in an aerodynamically conducive and structurally viable configuration to reduce wind induced wall suction generated by separated flows and vortices.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

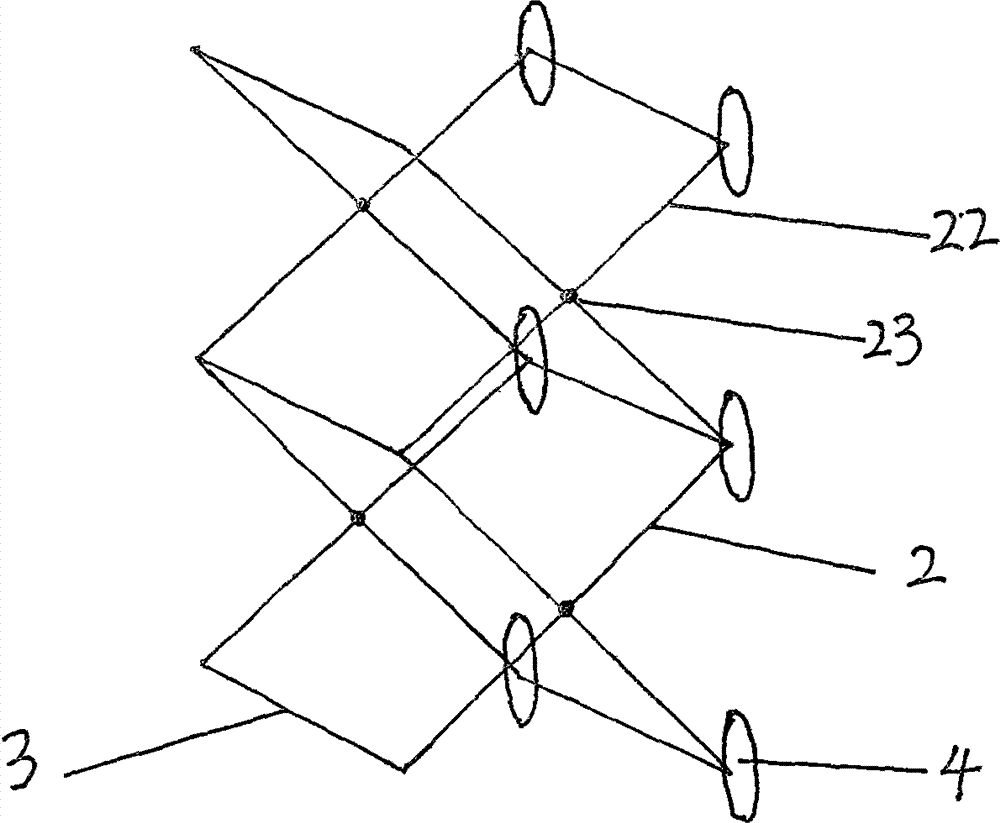

Wall-suction type lifting storage rack

InactiveCN103654248AHeight adjustable between floorsHeight adjustableKitchen equipmentDomestic articlesLiving roomWall suction

The invention provides a wall-suction type lifting storage rack. The wall-suction type lifting storage rack comprises a lifting mechanism, vacuum chucks, an object carrying tray and a supporting rod. The wall-suction type lifting storage rack is characterized in that the lifting mechanism is formed by connecting multiple identical lifting supports through cross rods, and the vacuum chucks are fixed to the two ends of the cross rods arranged on one side of the lifting mechanism. The wall-suction type lifting storage rack is convenient to mount and dismount, a wall is not damaged, no ground surface is occupied, the height between layers of the storage rack is adjustable, and the storage rack is suitable for application to various occasions including a kitchen, a living room, a bathroom, a study, an office room and the like.

Owner:吴善锁

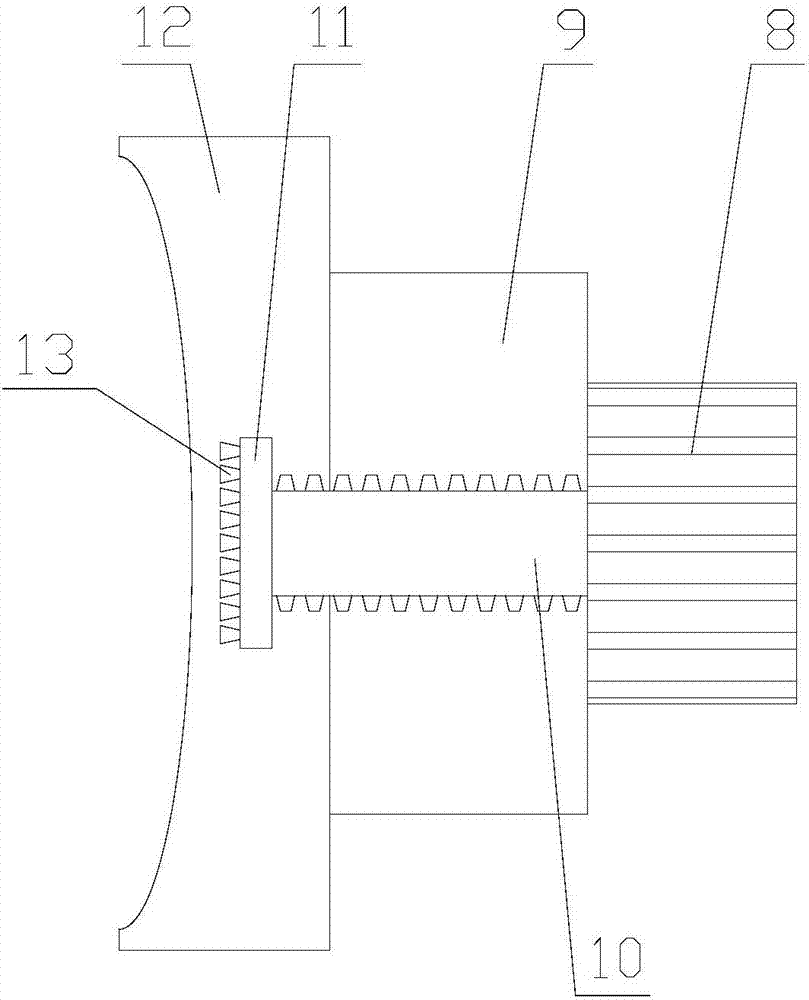

Dust collecting chalk sleeve

InactiveCN107901664ASoft writingWeight increaseBoard cleaning devicesWriting connectorsHandwritingEngineering

The invention discloses a dust-absorbing chalk cover, which comprises a hollow casing and a dust-absorbing tube. The dust-absorbing tube is sleeved on the outside of the hollow casing. There is also a dust suction chamber on the outside of the dust suction pipe, and a piston is arranged on the top of the hollow sleeve. The piston is in sealing and sliding contact with the dust suction chamber. The outer wall of the dust suction pipe is sealed with a sealing rubber ring, and a detachable dust filter chamber is arranged outside the lower part of the dust suction chamber. The dust-absorbing chalk case of the present invention does not need power consumption, is very light and handy, and at the same time, the written characters can be softer.

Owner:丁云友

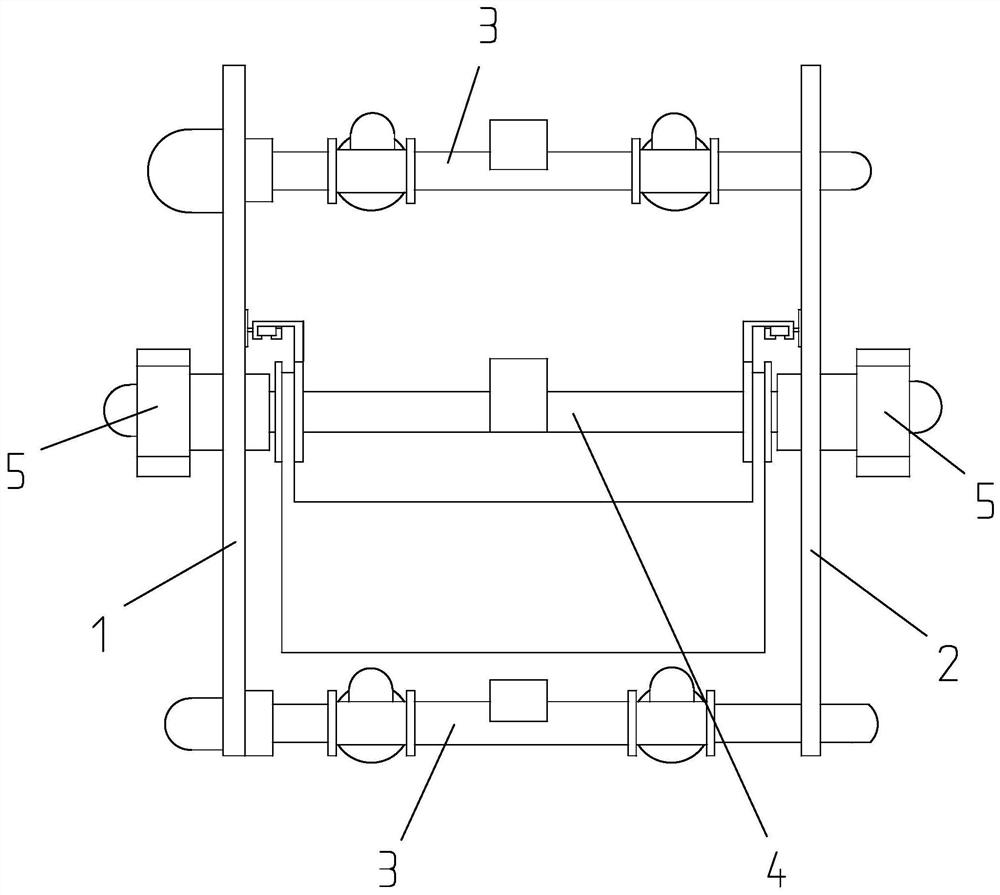

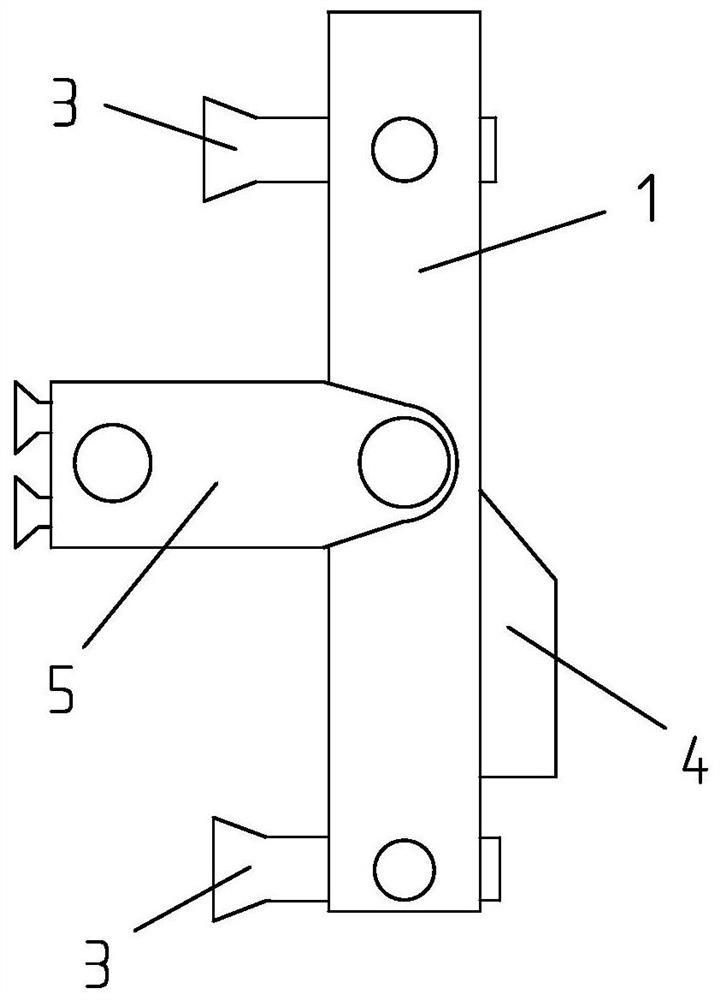

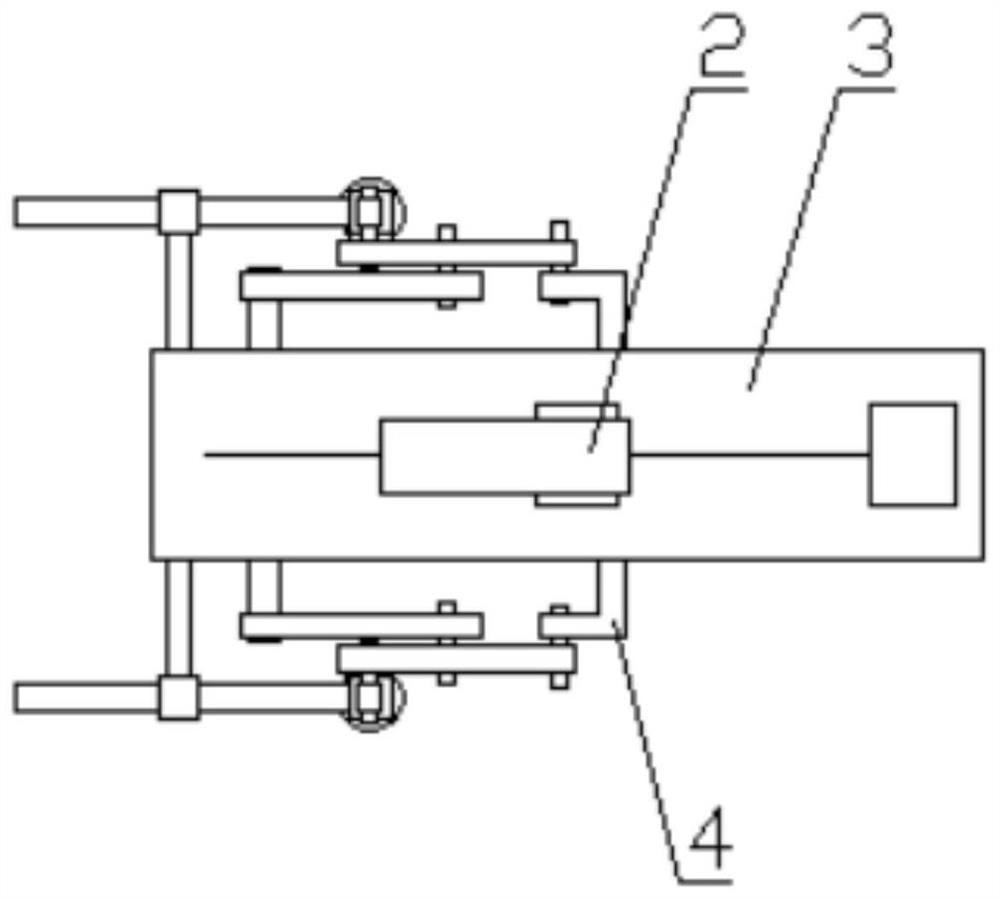

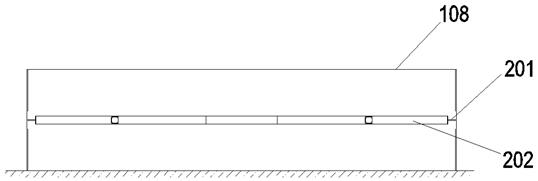

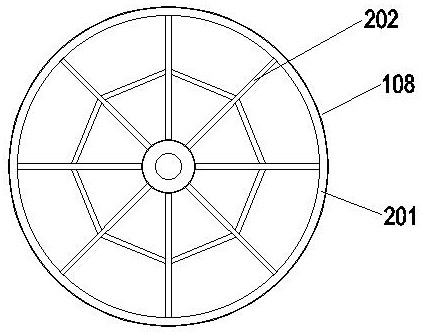

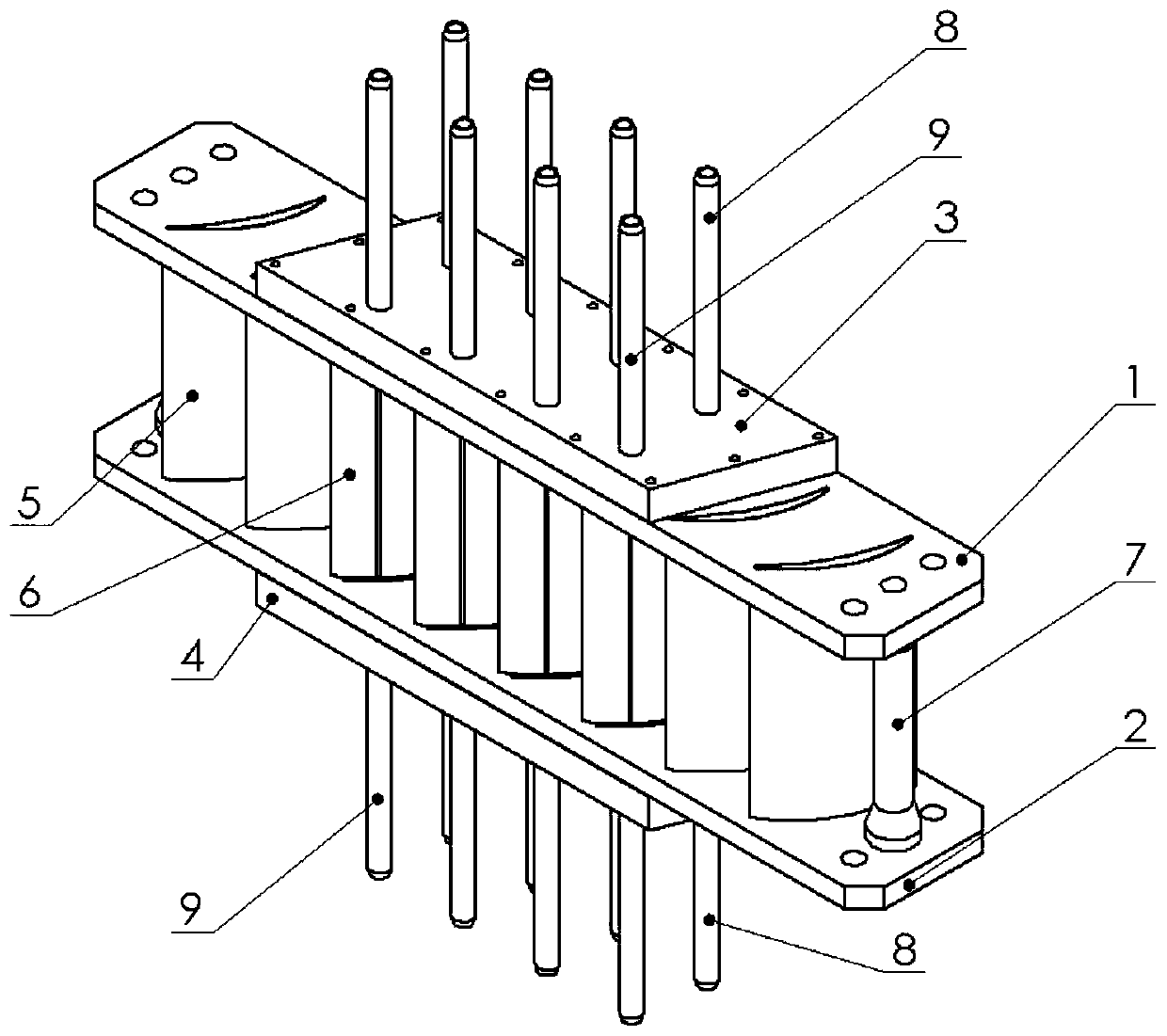

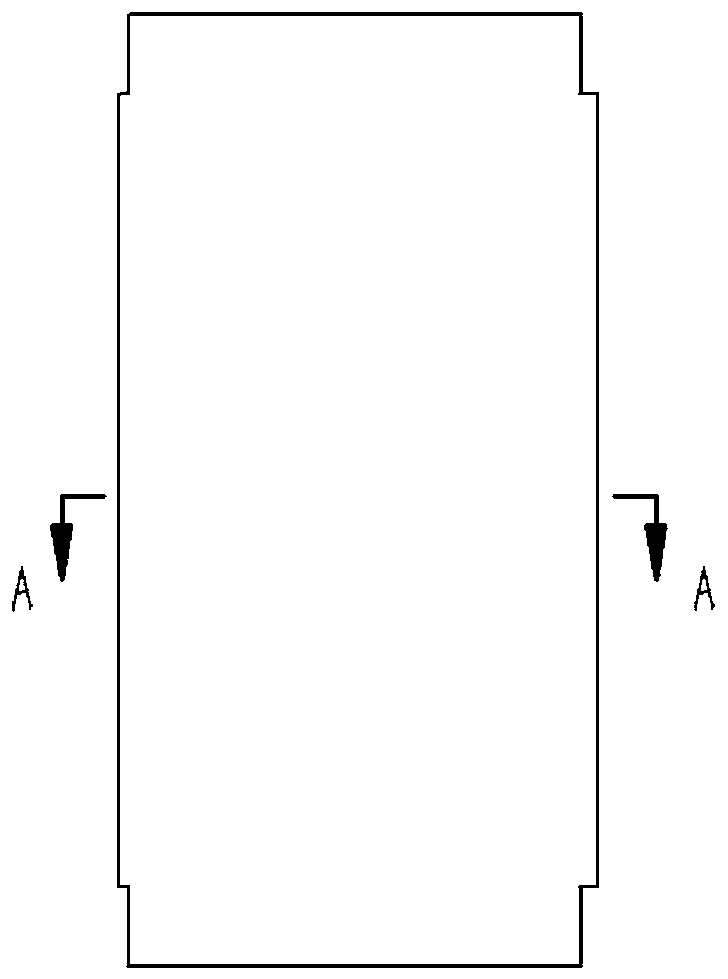

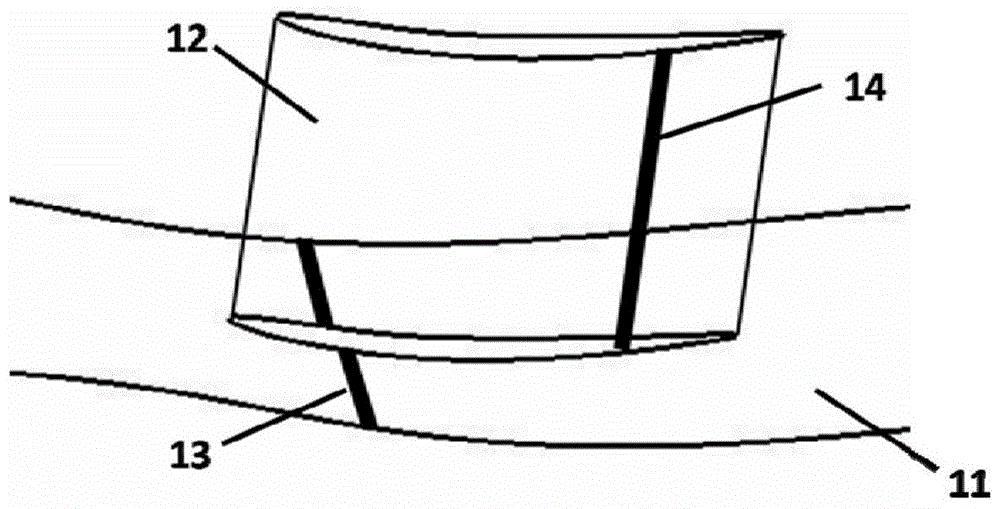

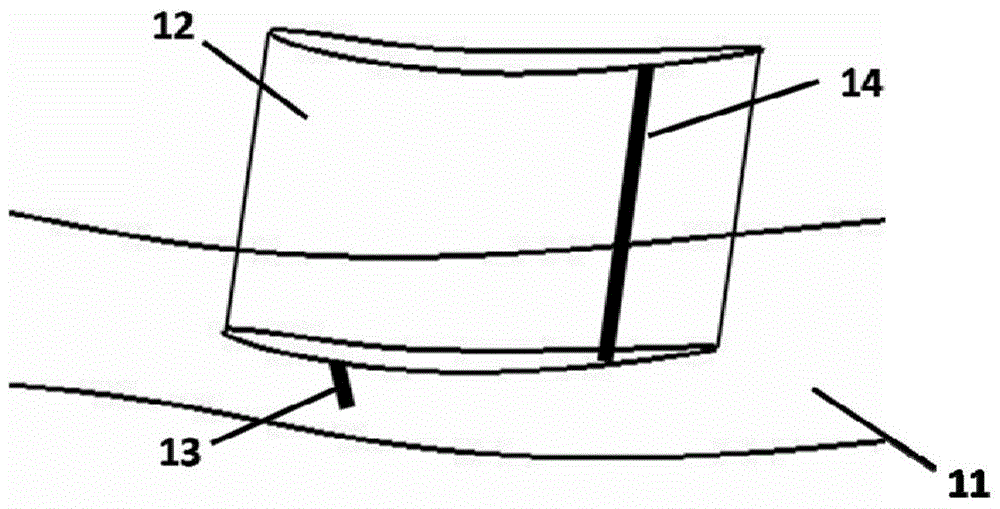

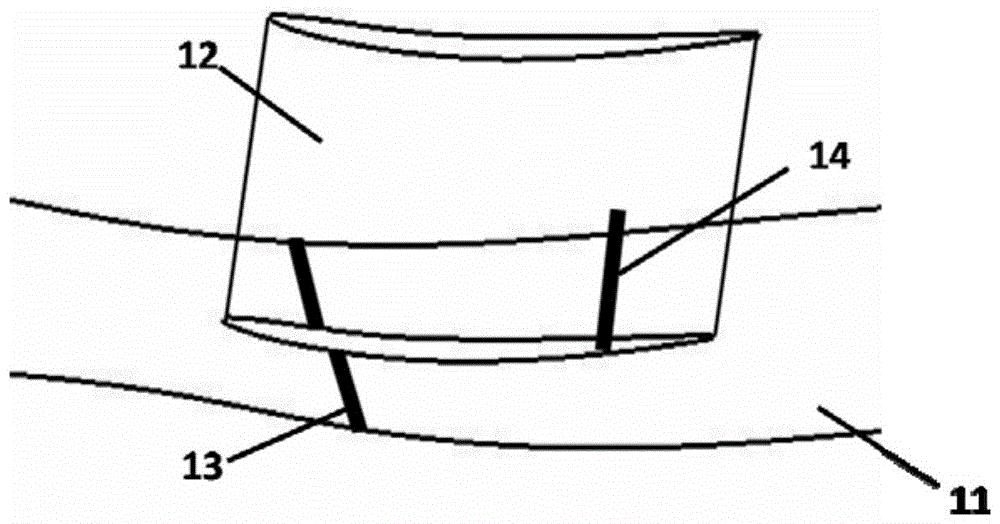

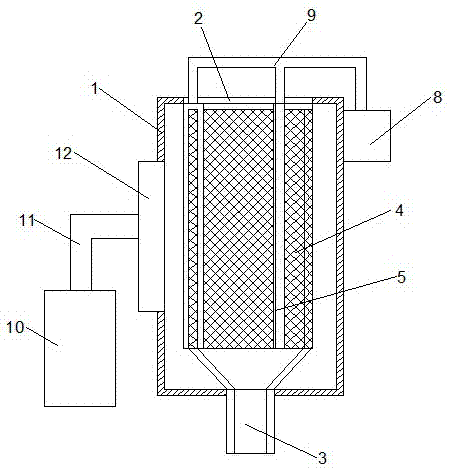

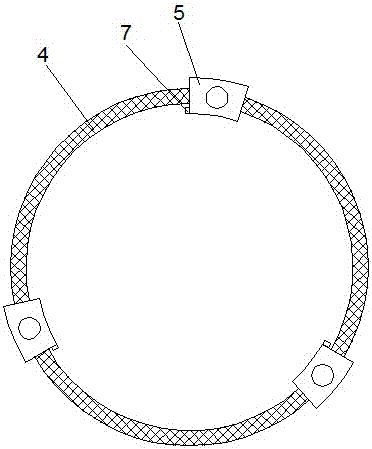

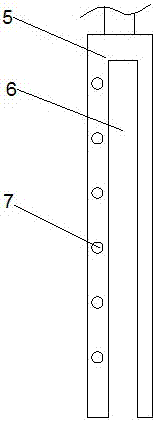

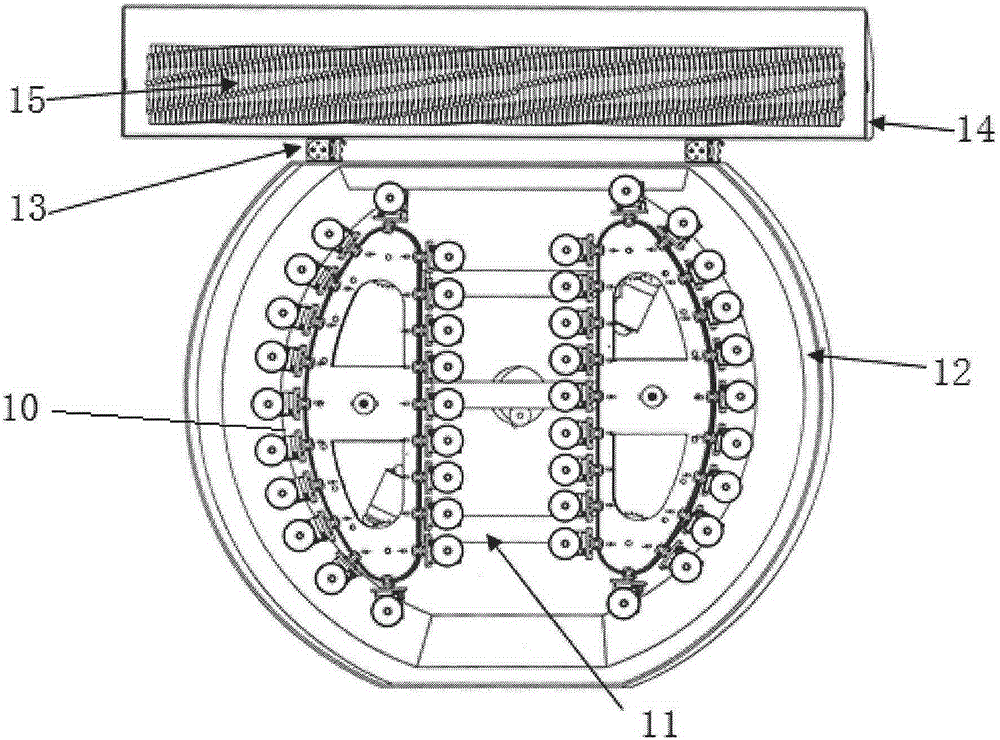

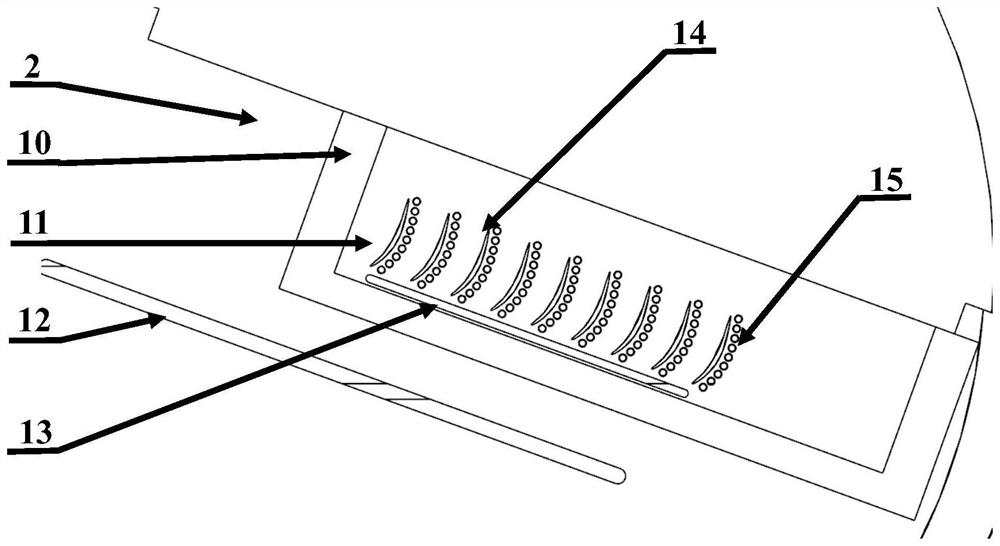

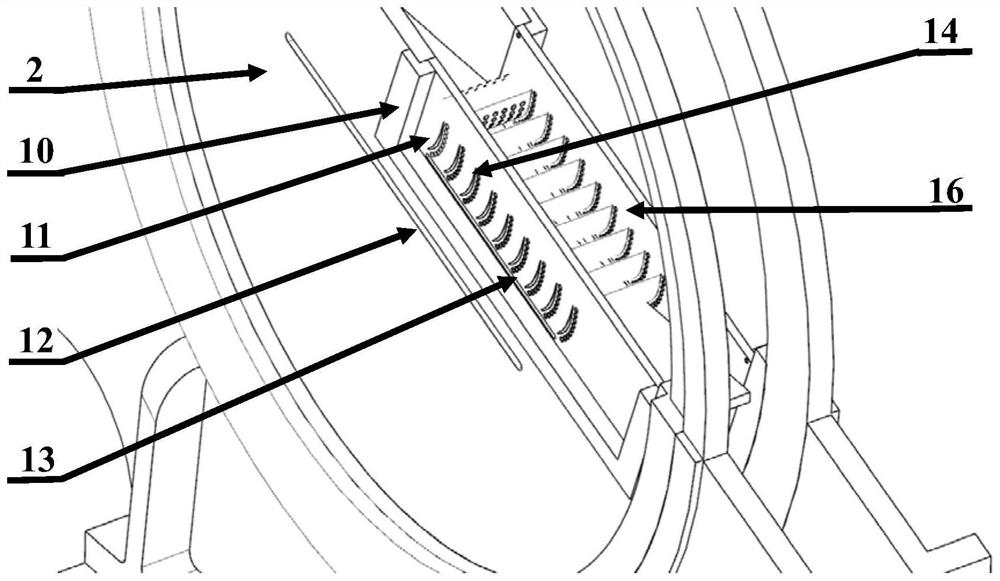

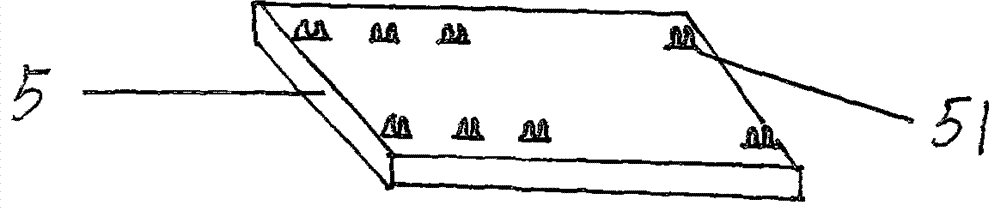

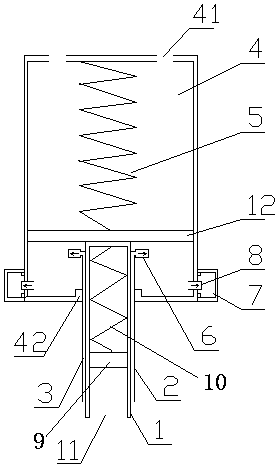

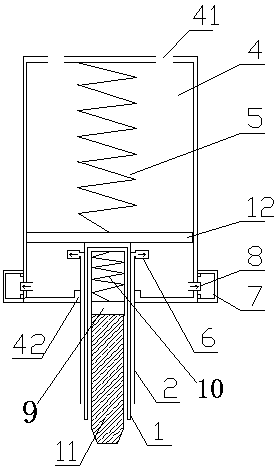

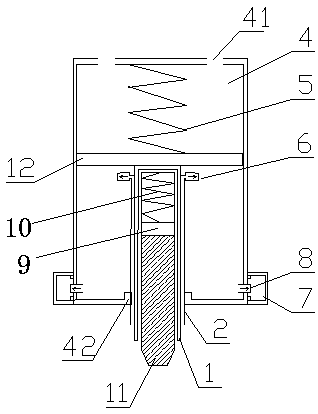

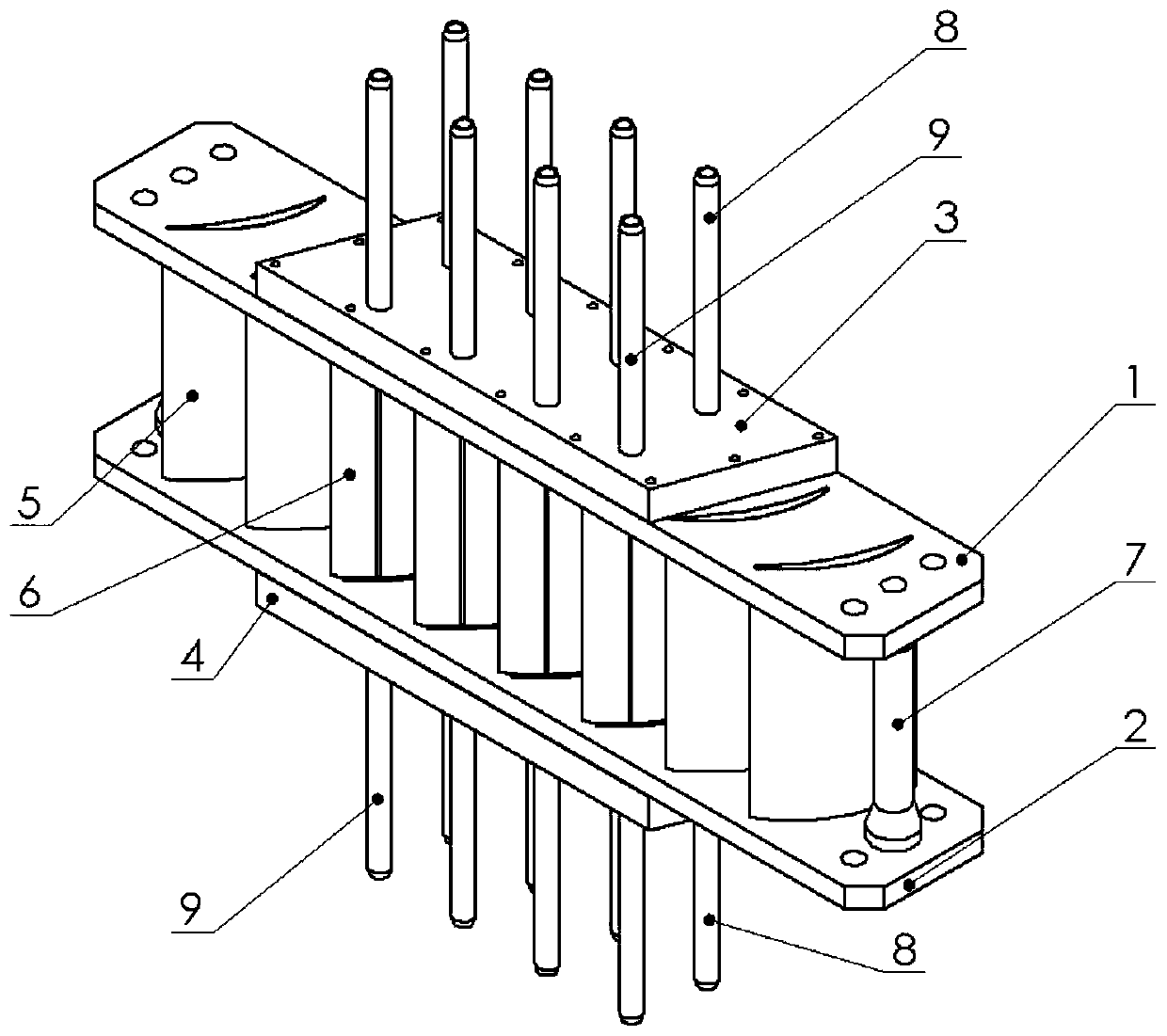

Combined suction type plane cascade experimental device

InactiveCN109826817AIndependent control of suction flowMeet matching experimental needsPump controlNon-positive displacement fluid enginesEngineeringWall suction

The invention discloses a combined suction type plane cascade experimental device which comprises a first grid plate, a second grid plate, a first suction hood, a second suction hood, a non-suction blade, a suction blade, a grid plate rod, a suction surface suction rod and an end wall suction rod, wherein the first suction hood and the second suction hood are of two platy structures in mirror symmetry and are fixed in the centers of the outer end faces of the first grid plate and the second grid plate separately; a plurality of end wall suction cavities are formed between the first suction hood and the first grid plate; a plurality of suction surface suction cavities are formed between the second suction hood and the second grid plate; and the end wall suction rod and the suction surface suction rod at the mounting outer ends are adopted to guide boundary layer low-energy fluid out. The combined suction type plane cascade experimental device overcomes the difficulty in the prior art that end wall suction and suction surface suction cannot be carried out simultaneously, realizes the purpose of independently controlling the suction flow rate of the end wall and the blade suction surface, meets the experimental demand of flow matching of two suction grooves under different working conditions, and can fully and completely suck the low-energy fluid in the end wall boundary layer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

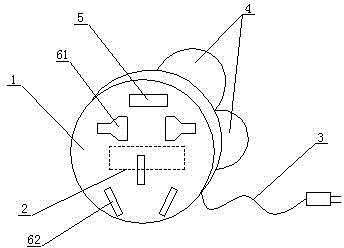

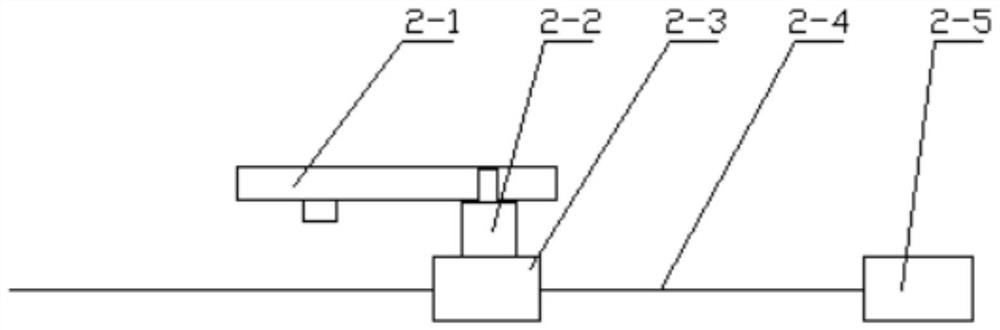

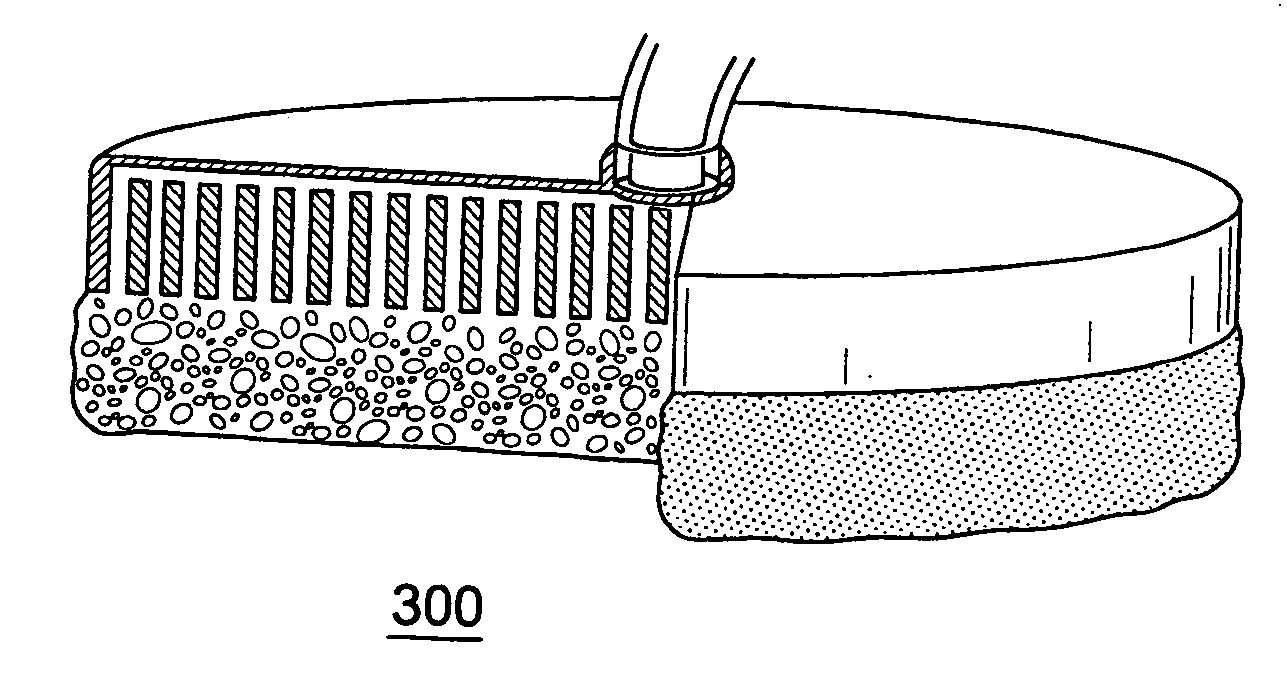

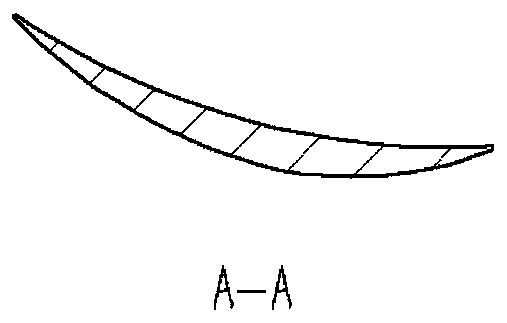

[Khan Orotracheal Suction System]

This abstract describes our product which is in the class of suction catheter systems. Our product is specifically designed for treating acute airway obstruction. Our system comprises a reservoir which is attached on one end to the wall suction vacuum using standard sump tubing. The other end is attached, via an adapter, to 15French suction tubing. This tubing is hooked to the suction catheters which the healthcare provider passes through an endotracheal tube into the trachea. A proximal balloon port is inflated with a 10 cc air filled syringe which inflates a distal cuff on the catheter. The distal cuff, which is 5 mm from the end of the catheter, creates a distal seal in the trachea which allows for the targeted suction force to remove the obstruction.

Owner:KHAN DR IFTIKHAR

Active aerodynamics mitigation and power production system for buildings and other structures

ActiveUS9951752B2Facilitate paradigm shiftReduce suctionWind energy with electric storageWind motor supports/mountsWind damageEngineering

The current invention provides apparatuses and methods for protecting buildings / structures from wind damage and simultaneously harvesting energy from wind. The apparatuses of the current invention comprise horizontal axial wind turbines integrated to the roof-edge of the buildings / structures in an aerodynamically conducive and structurally viable configuration to reduce roof suction. The apparatuses of the current invention can further comprise aerodynamic roof gutter and structural supports / connections to alleviate wind-induced suction (negative pressures) on building roofs generated by separated flows and vortices. The apparatuses of the current invention can also comprise vertical axial wind turbines integrated to the wall-edge of the structures / buildings in an aerodynamically conducive and structurally viable configuration to reduce wind induced wall suction generated by separated flows and vortices.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

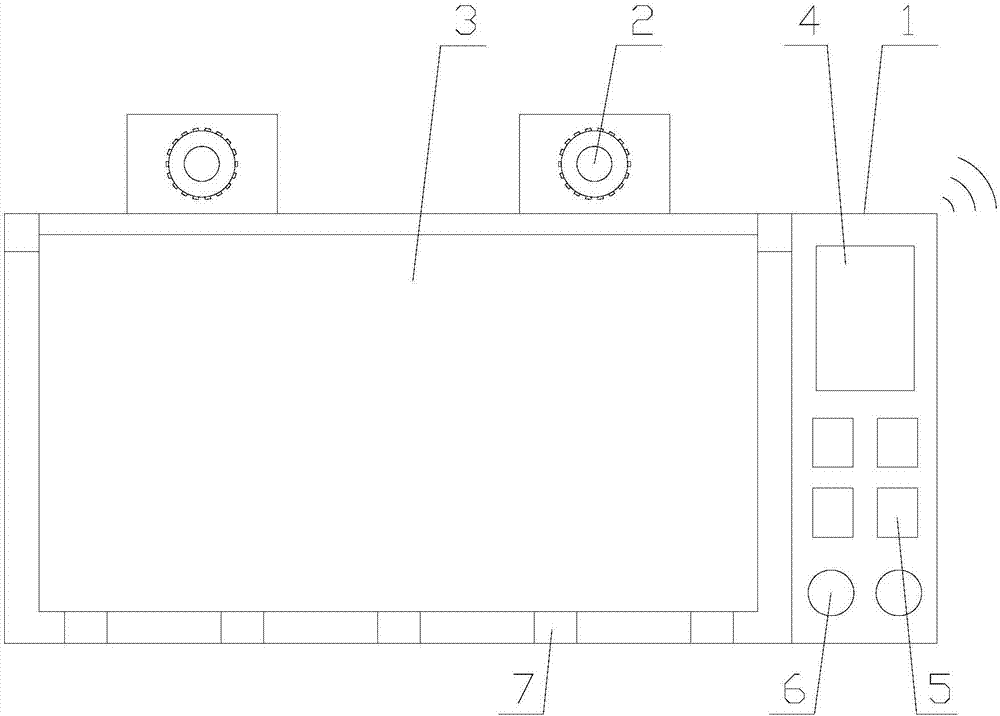

Wall suction type multifunctional power supply conversion socket

The invention relates to a wall suction type multifunctional power supply conversion socket which comprises a socket body, a circuit board arranged in the socket body, a power supply connecting wire penetrating out of the socket body and connected with the circuit board, and a jack set formed in the socket body and electrically connected with the circuit board, wherein two suction discs are longitudinally arranged on a back surface of the socket body. According to the wall suction type multifunctional power supply conversion socket, the suction discs are designed on the socket body, so that the socket body can be sucked on a wall surface and the socket is more convenient to use; a USB (universal serial bus) interface is designed on the socket body, so that an electronic product provided with the USB interface can be charged and the socket is multifunctional.

Owner:XIAN YIMU SOFTWARE TECH

Rotary mobile rescue device

InactiveCN112624005AReduce harmReduce suctionSafety devices for lifting equipmentsMarine engineeringStructural engineering

The invention discloses a rotary mobile rescue device. The device comprises a left frame assembly and a right frame assembly, a wall suction shaft assembly is arranged between the left frame assembly and the right frame assembly and close to the upper end and the lower end of the left frame assembly and the right frame assembly correspondingly, and a first suction cup assembly is arranged on the side, close to a wall, of each wall suction shaft assembly; and a manned box assembly is arranged at the position, close to the middle, between the left frame assembly and the right frame assembly, the left frame assembly and the right frame assembly are each provided with a frame rotation driving mechanism, a second suction cup assembly is arranged on the side, close to the wall, of each frame rotation driving mechanism, and the distance between the second suction cup assembly and the wall is smaller than the distance between the first suction cup assembly and the wall. The device is convenient and fast to use, relatively low in cost and efficient, timely and safe in rescue process, rescue and evacuation can be conducted at the first time after disasters are found, and property losses and personnel injuries caused by the disasters are reduced to the maximum extent.

Owner:杜慎之

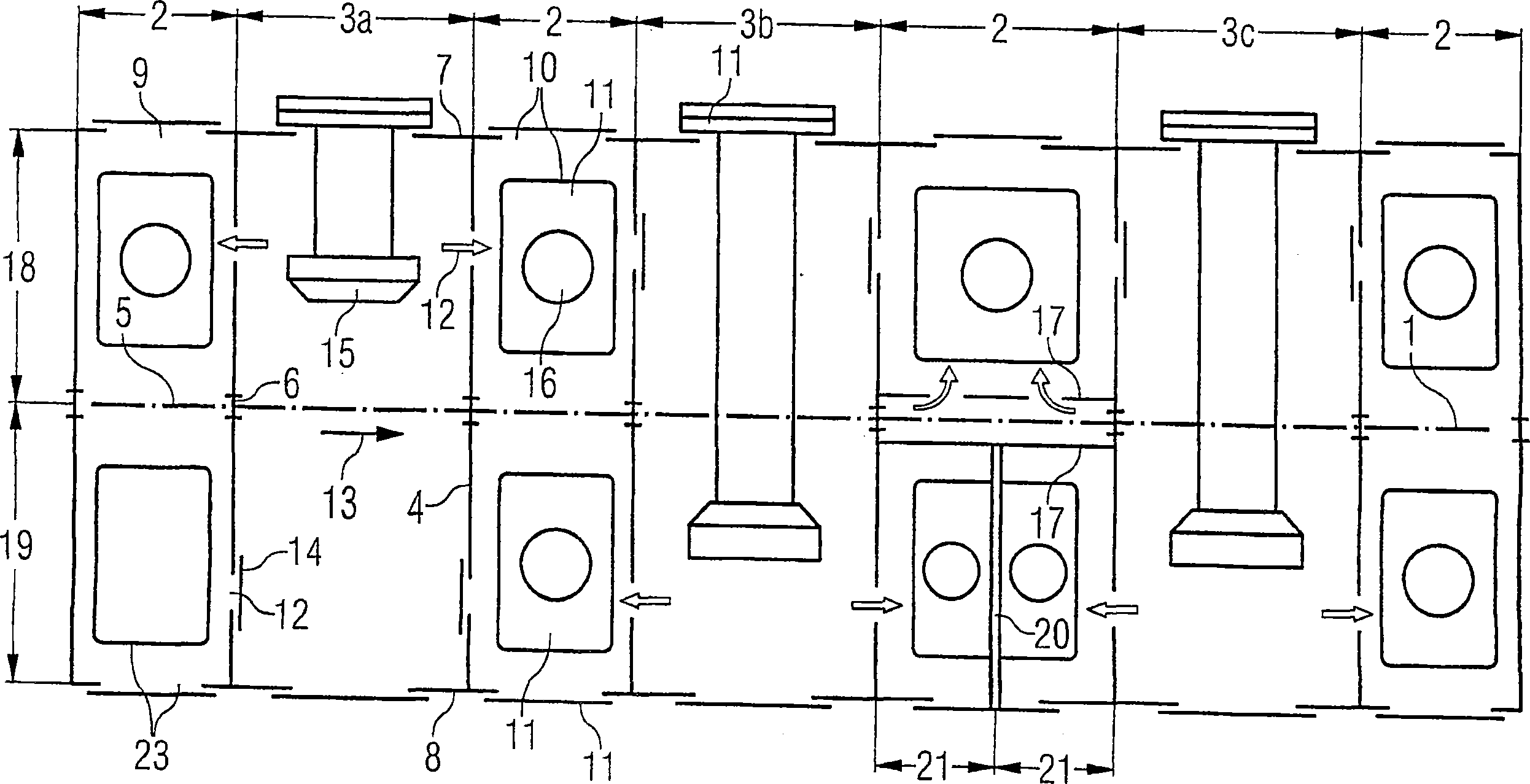

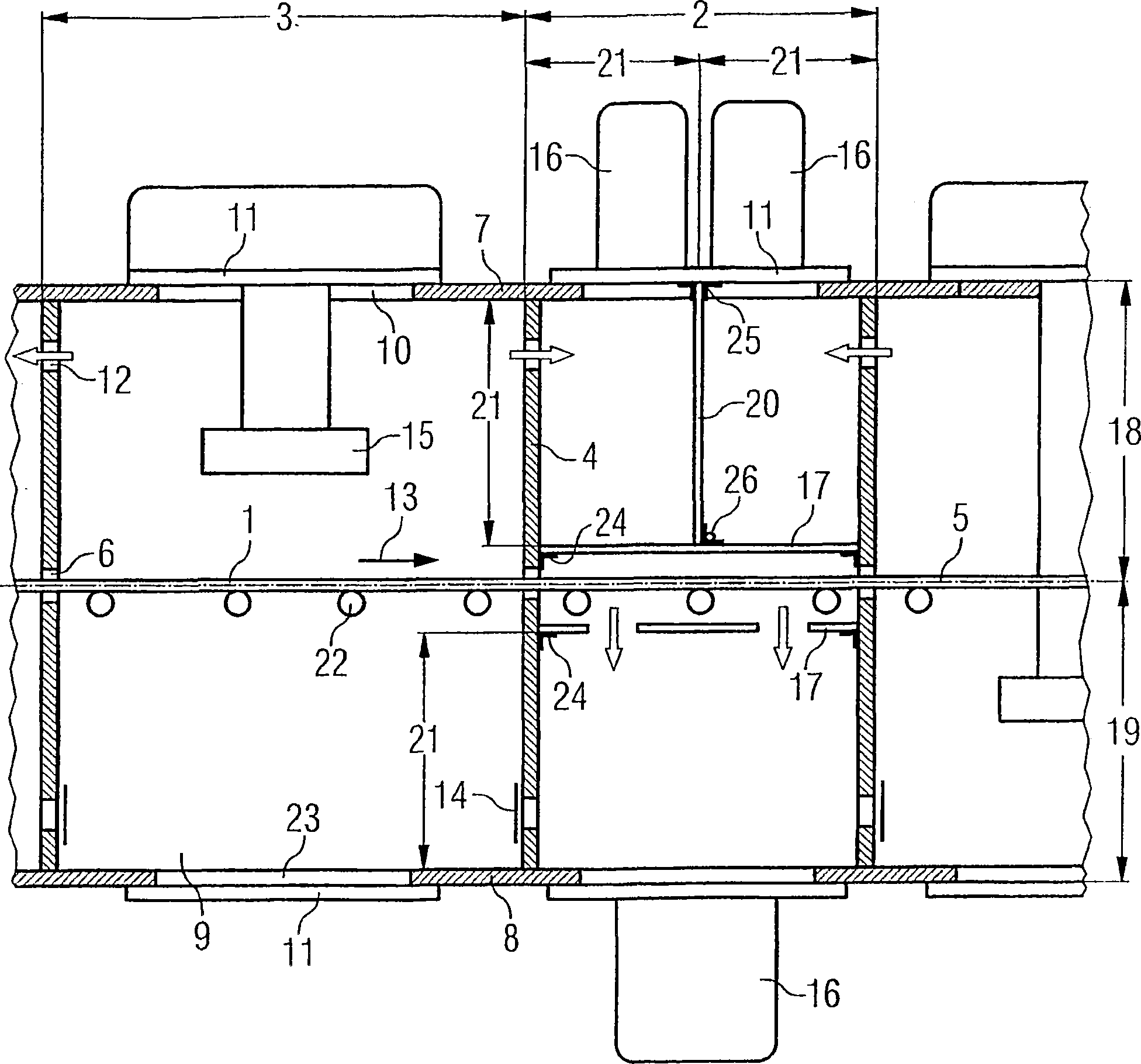

Elongate vacuum system for coating one or both sides of a flat substrate

InactiveCN1902336AFine-tuned emptying managementSputtering parameter optimizationVacuum evaporation coatingSputtering coatingProcess optimizationEngineering

The present invention relates to an elongated vacuum system for coating one or both sides of a flat substrate which is moved by the system. The vacuum system comprises at least one magnetron with a region around the magnetron and is divided into successive compartments by sealable partition walls along the conveying direction of the substrate. The compartment can be evacuated directly via a vacuum port located on the compartment, or indirectly via a suction opening in the partition wall. The at least one compartment includes an upper partial compartment located above the base, the partial compartment including a sealable upper opening in at least one outer wall thereof. The object of the present invention is to produce an elongated vacuum system for flexible application according to the requirements of different one-side and two-side coating processes and to carry out this process within said system which ensures stability, differentiation and process optimization sputtering atmosphere. This object is achieved by the fact that in at least one of the upper partial compartments horizontal and / or vertical elements can be installed for dividing said upper partial compartment into several sub-compartments.

Owner:冯·阿德纳设备有限公司

Building outer wall automatic crawling laser cleaning device

ActiveCN114016759AImprove accuracyAvoid angular deviationBuilding repairsEngineeringMechanical engineering

The invention provides a building outer wall automatic crawling laser cleaning device which comprises laser cleaning equipment, a moving device, a shell, a wall climbing device, a driving device and a wall suction device, and the laser cleaning equipment is installed at one end of the moving device and used for generating laser beams needed by cleaning; the moving device is installed on the upper portion of the shell, the wall climbing devices are installed on the two sides of the shell, and the driving device is installed in the shell and used for driving the wall climbing devices to move; a wall suction device is installed on the shell and used for being sucked to the wall face. The wall-climbing robot carrying the laser cleaning machine is used for conducting full-automatic cleaning on the building coating of the building outer wall, and therefore the function of cleaning the surface of the building outer wall is achieved.

Owner:JIANGSU UNIV

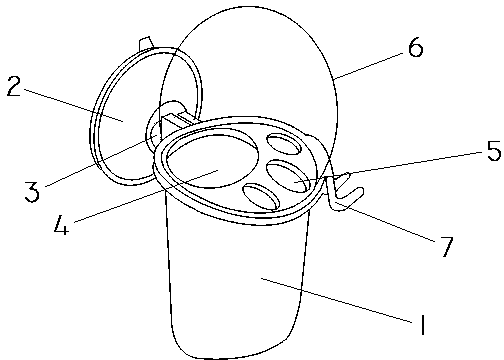

Wall suction toothbrush barrel

InactiveCN103610416AAvoid breakingDoes not take up spaceHolders and dispensersToothpasteStructural engineering

The invention discloses a wall suction toothbrush barrel. The wall suction toothbrush barrel comprises a toothbrush barrel body, a wall suction sucker is arranged on one side of the toothbrush barrel body and connected with the side wall of the top of the toothbrush barrel body through a movable rotary shaft, a toothpaste placement hole and a toothbrush placement hole are formed in the toothbrush barrel body, a hook is further arranged on the side wall of the top of the toothbrush barrel body, and a dust cover is further installed on the upper portion of the toothbrush barrel body. The wall suction toothbrush barrel can be sucked onto the wall, the space of a washing table is not occupied, and thus the wall suction toothbrush barrel is convenient to use and effectively prevented from being dropped and broken; because the dust cover is arranged, a toothbrush and toothpaste which are placed on the toothbrush barrel are made cleaner; the wall suction toothbrush barrel is simple in structure and easy to obtain and has good application prospects.

Owner:赵立军

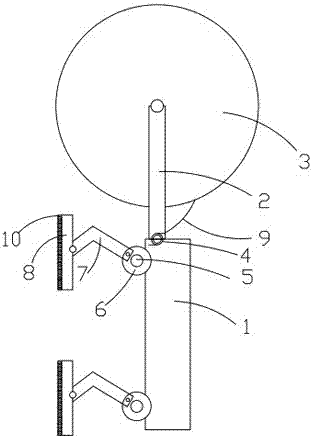

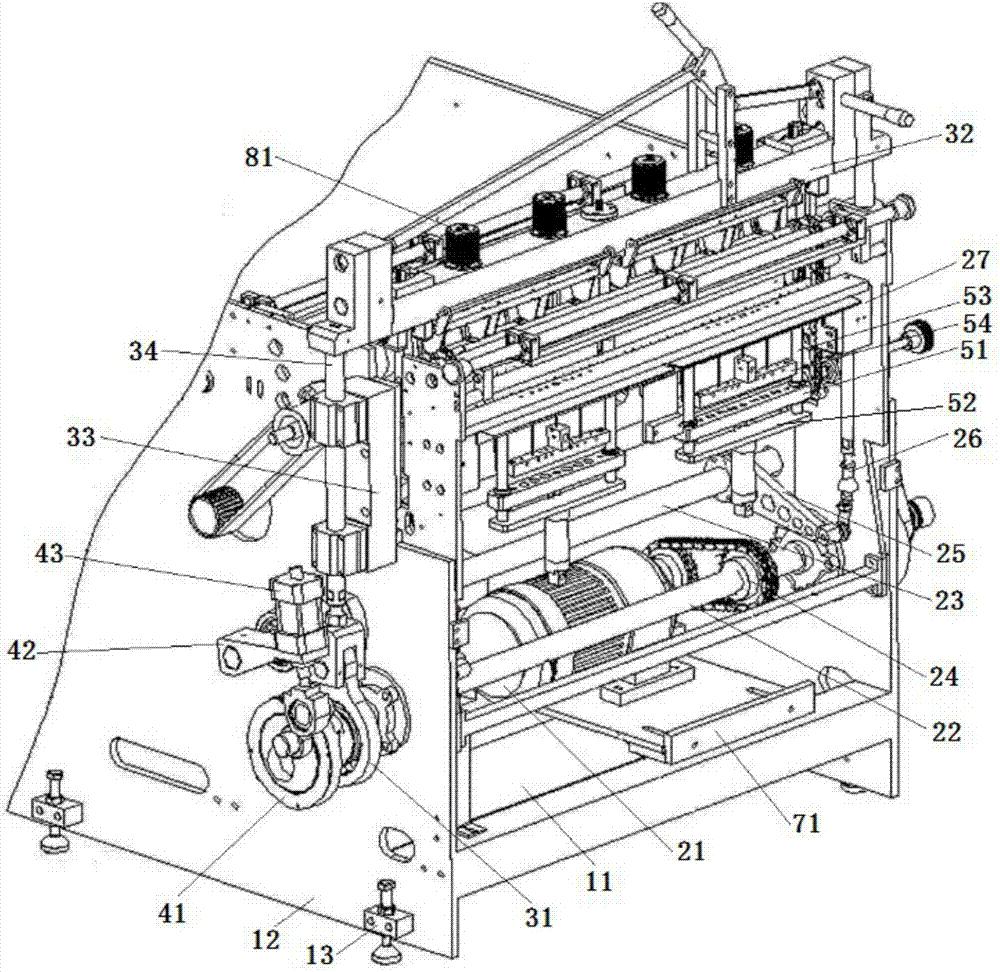

Exterior Wall Cleaning Machine

The invention provides an external wall cleaning machine which comprises a machine frame, a cleaning mechanism, a walking mechanism and a wall suction mechanism. The cleaning mechanism comprises two support rods rotationally arranged at the front end of the machine frame. An installation shaft is arranged between the support rods on the two sides. A cleaning brush roller is arranged on the installation shaft. Torsional springs for compressing the cleaning brush roller on the external wall are arranged between the machine frame and the support rods. The walking mechanism comprises driving shafts rotationally arranged at the front and rear portions of the bottom of the machine frame, eccentric shaft sleeves arranged at the two ends of the driving shafts in a sleeving mode, L-shaped walking legs and a positioning panel rotationally arranged between the walking legs on the two sides, wherein one end of each L-shaped walking leg is rotationally connected with the eccentric shaft sleeve. The two driving shafts are driven by two motors to rotate. The wall suction mechanism comprises a plurality of negative pressure adsorption holes formed in the surface of the positioning panel. The positioning panel is provided with a cavity communicated with the negative pressure adsorption holes. Air passes through a flexible air pipe to be connected with a vacuum pump, the efficiency is high, and the cleaning effect is good.

Owner:涡阳量子信息科技有限公司

Intelligent toothbrush sterilizing device

InactiveCN107019809AImprove reliabilityExhausted completelyLavatory sanitorySuction cupsComputer modulePower circuits

The invention relates to an intelligent toothbrush sterilizing device, which includes a box body, a fixing mechanism, a central control mechanism and a box cover. The fixing mechanism includes a fixing block, a knob, a suction cup and a fixing assembly. In the bacterial device, when the user rotates the knob, the connecting rod moves relative to the fixed block, and the push block will push the suction cup to the wall, extrude the air inside the suction cup, and suck the suction cup to the wall. The block discharges the air in the suction cup more thoroughly, thereby further improving the reliability of the suction cup and the device; not only that, by controlling the conduction of the first triode, the first power supply circuit is realized At the same time, by controlling the conduction of the second triode, the stable output of the second power supply is realized, thereby realizing two stable outputs of the working power supply circuit, thereby improving the practicability of the device.

Owner:封开县烁源电子技术有限公司

Manufacturing method for cylinder body of offshore wind power large-diameter thin-wall suction cylinder

InactiveCN114083242ASuccessful pairingGuaranteed structural strengthWelding/cutting auxillary devicesAuxillary welding devicesSuction forceStructural engineering

The invention discloses a manufacturing method of a cylinder body of an offshore wind power large-diameter thin-wall suction cylinder, and relates to the technical field of offshore wind power manufacturing. The manufacturing method specifically comprises the following steps: S1, a cylinder body is divided into eight sections, and all the sections are manufactured respectively; S2, each section is manufactured; S3, the interior of a single circle is strengthened; S4, vertical welding splicing is carried out; and S5, the rest of the cylinder body sections are assembled. The manufacturing method has the advantages that aiming at manufacturing of the cylinder body of the large-diameter thin-wall suction cylinder, the cylinder body is divided into eight sections to be manufactured respectively, the cylinder body sections at the end parts are internally reinforced, the structural strength is ensured, and smooth assembling, hoisting, transferring, turning over and other procedures of the cylinder body are ensured; and the vertical welding splicing is firstly carried out, and then the rest of the cylinder body sections are sequentially assembled, so that the manufacturing process is optimized, the production efficiency is improved, the assembly precision is improved, the safe construction is facilitated, and the quality stability is improved.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

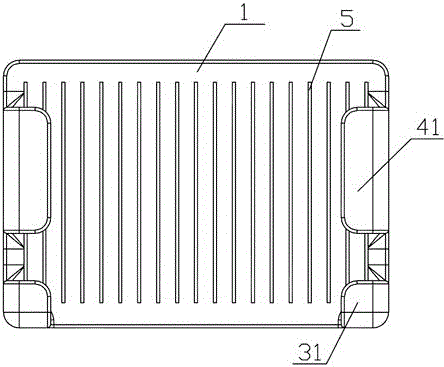

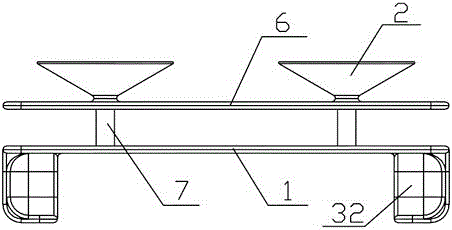

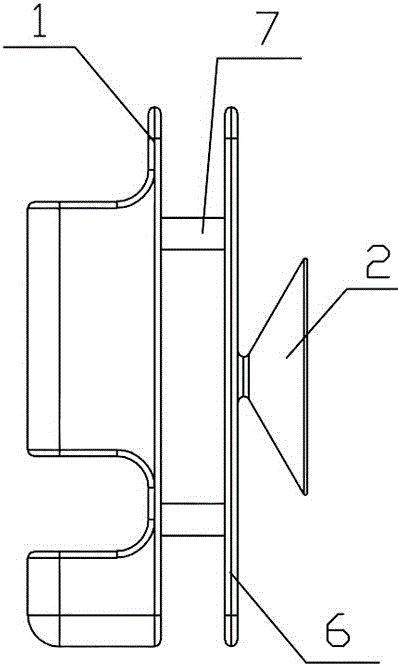

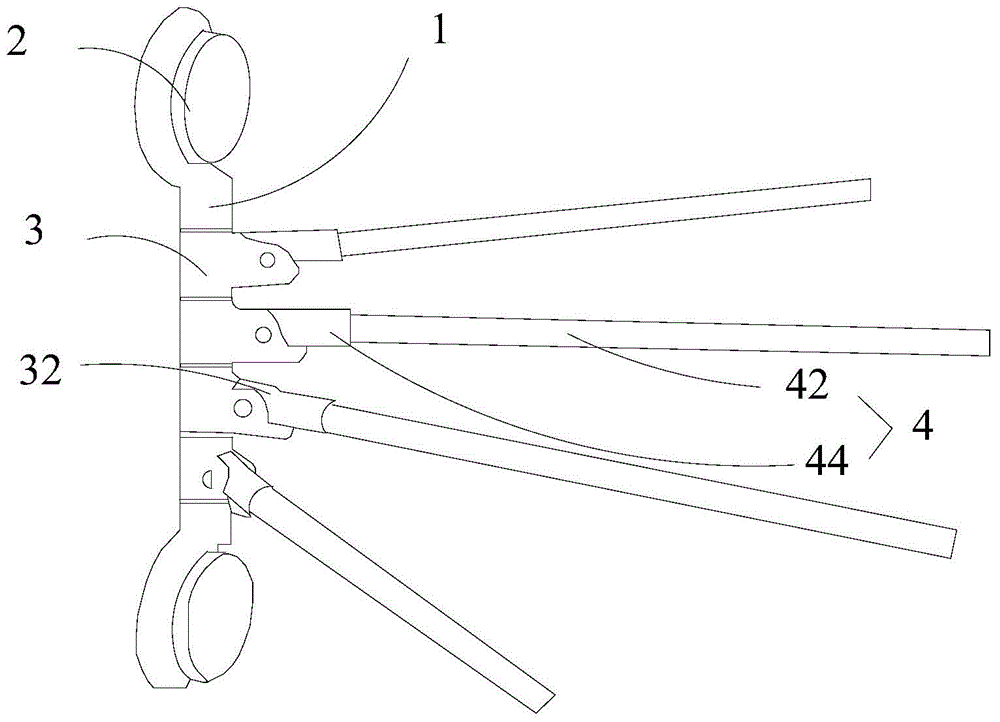

Wall-suction type router bracket

PendingCN106658233ASo as not to damageImprove stabilitySelection arrangementsEngineeringWall suction

The invention discloses a wall-suction type router bracket, comprising a support frame body (1), wherein more than one suckers (2) for adsorbing the whole bracket on the wall surface are arranged at the back surface of the support frame body (1), a supporting plate (3) for providing upward support force for the router is respectively arranged at two right angles at the lower end of the support frame body (1), and a baffle (4) which is used for preventing the router from moving in the horizontal direction and is provided with an L-shaped cross section is respectively arranged on two sides of the front part of the support frame body (1). The wall-suction type router bracket disclosed by the invention has the following beneficial effects: according to the router bracket, the router is arranged on the bracket and cannot generate displacement in any direction without applying external force manually, and thus relatively good stability can be achieved; and the router bracket is adsorbed on the wall surface through the sucker, and thus the wall surface cannot be damaged.

Owner:MORAL ELECTRICAL APPLIANCE KUNSHAN

Wall suction type rotating towel frame

The invention discloses a wall suction type rotating towel frame which comprises a supporting vertical rod, suckers, pivotal sleeves and hanging rods. The suckers are arranged at the upper end and the lower end of the supporting vertical rod and are used for being sucked to ceramic tile glass or marble. The position, located between the two suckers, of the supporting vertical rod is provided with a plurality of pivotal sleeves. The pivotal sleeves are provided with supporting grooves in the horizontal direction in an extending mode. One ends of the hanging rods are fixedly arranged in the supporting grooves in the pivotal sleeves, and the other ends of the hanging rods are free ends. The wall suction type rotating towel frame has the advantages that a plurality of towels can be hung at the same time and are hung separately, and meanwhile the using space is smaller.

Owner:陈青苹

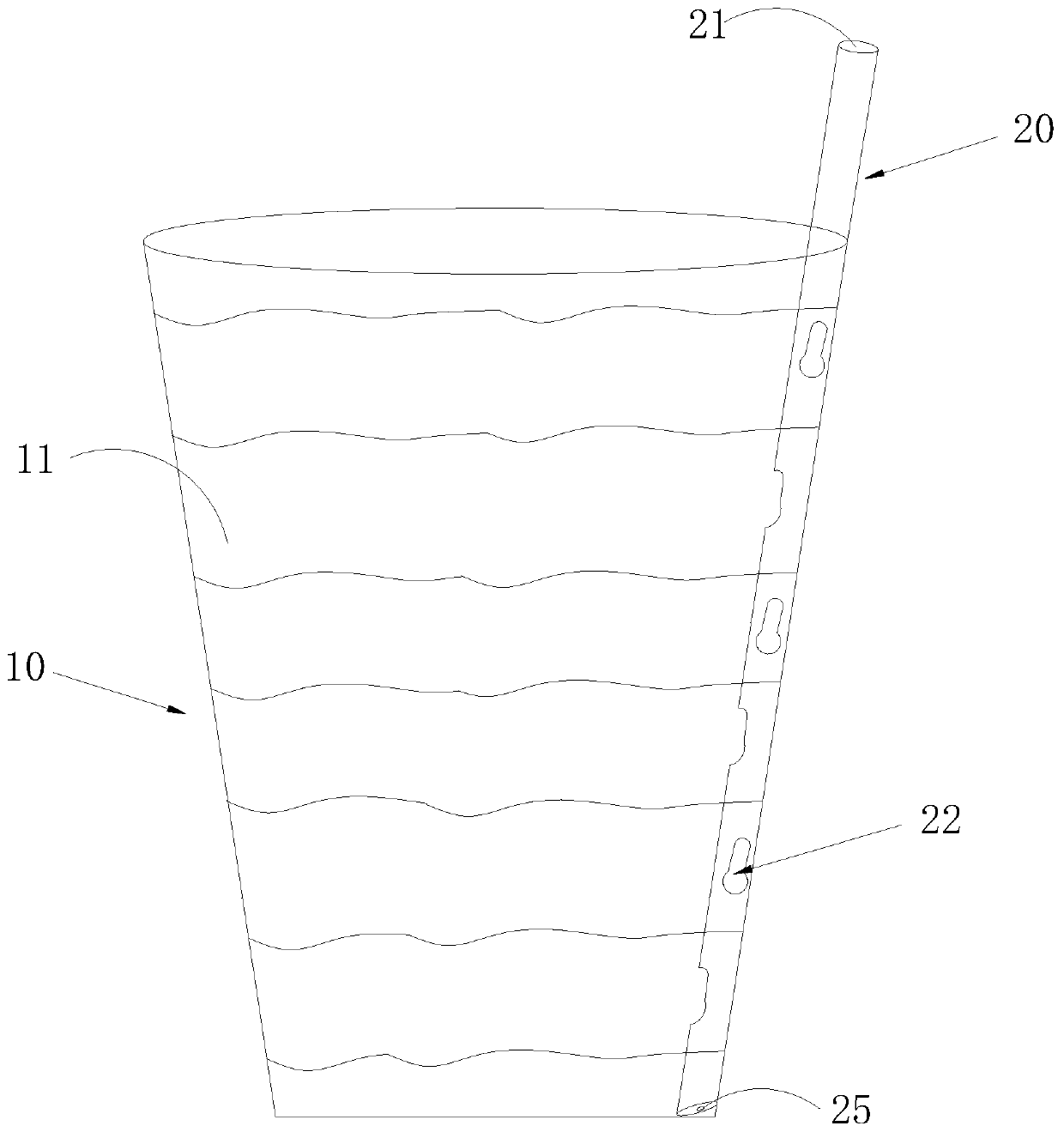

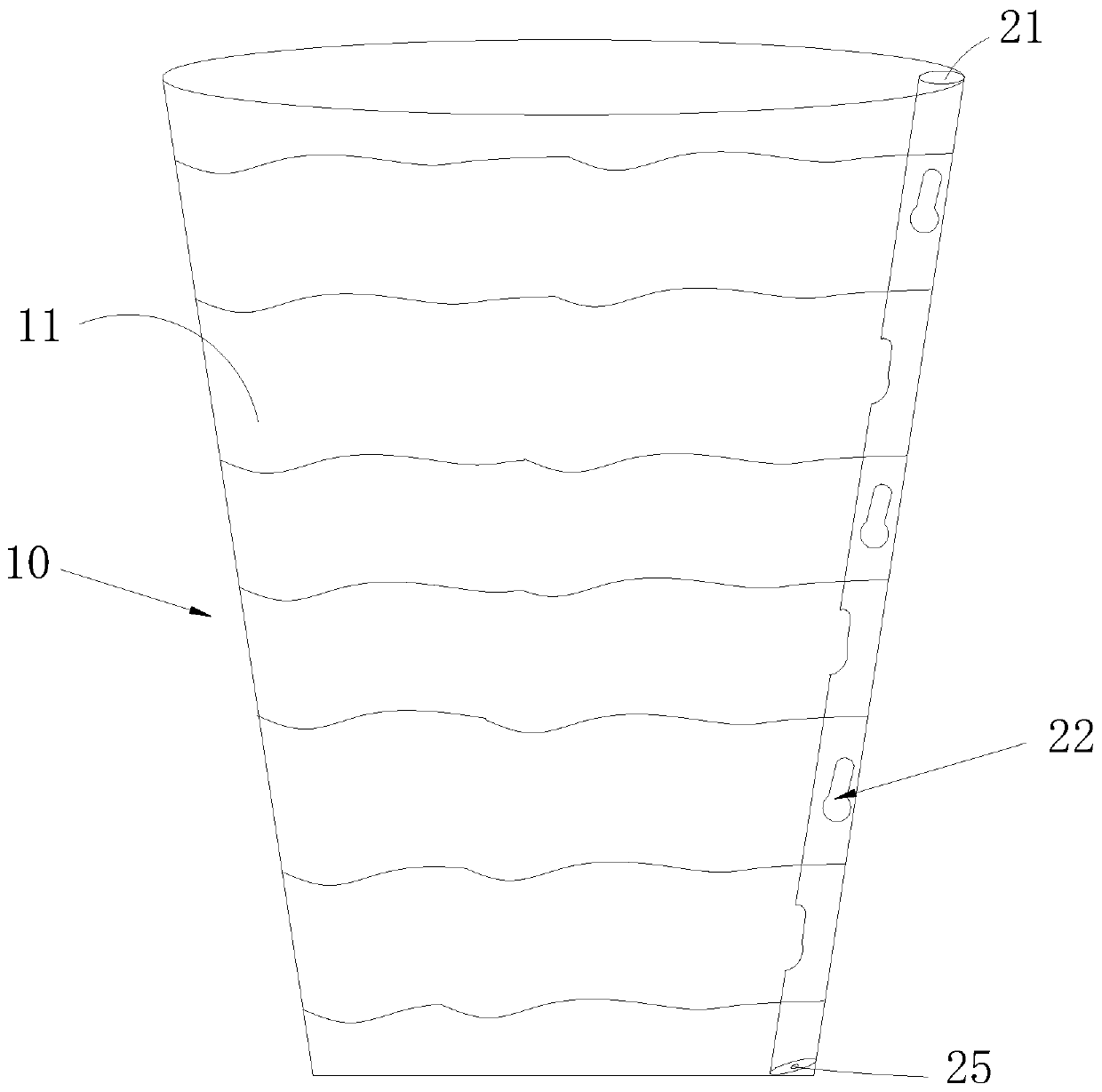

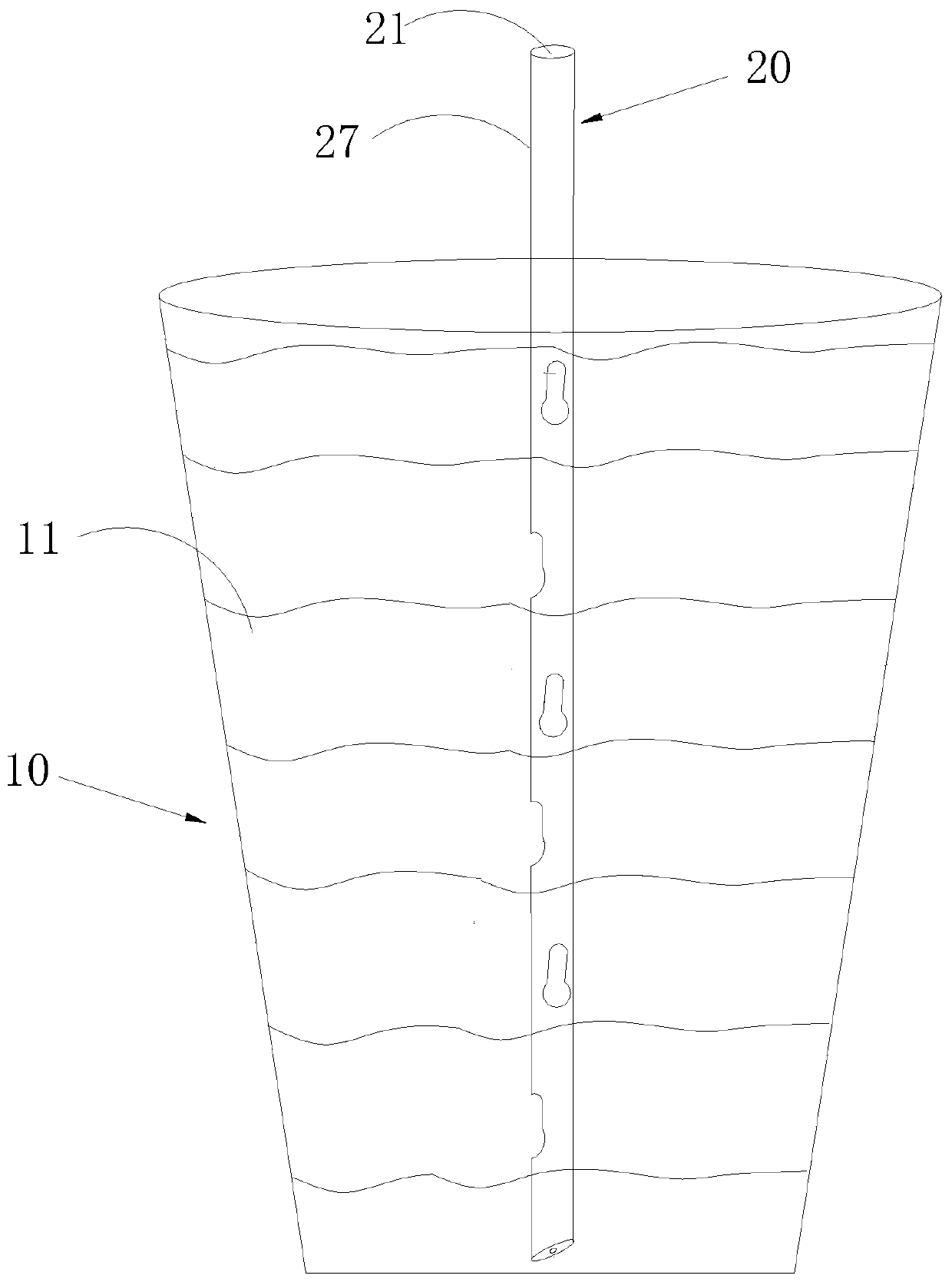

Mixed flavor drinking method of beverages

The invention relates to the technical field of beverages, and discloses a mixed flavor drinking method of beverages. Various kinds of beverages with different specific weight are charged into a cup body; in the height direction of the cup body, the various kinds of beverages are in separation layer type arrangement in the cup body to form a plurality of beverage layers; the beverages in the cup body are sucked through a suction pipe; the suction pipe is provided with a suction opening used for a user to suck the beverages; a plurality of side wall suction holes are formed in the side wall ofthe suction pipe; the beverages with different specific weight are put into the cup body; after a while, the beverages with different specific weight can be divided into a plurality of layers in the height direction of the cup body to form beverage layers with different flavors; the suction pipe is put into the cup; each side wall suction hole respectively corresponds to each beverage layer; eachbeverage layer can be sucked into the suction pipe through each correspondingly communicated side wall suction hole; and the beverages enter the mouth of the user through the suction opening, so thatthe user tastes the beverages with various different flavors.

Owner:广东康道科学研究院有限公司

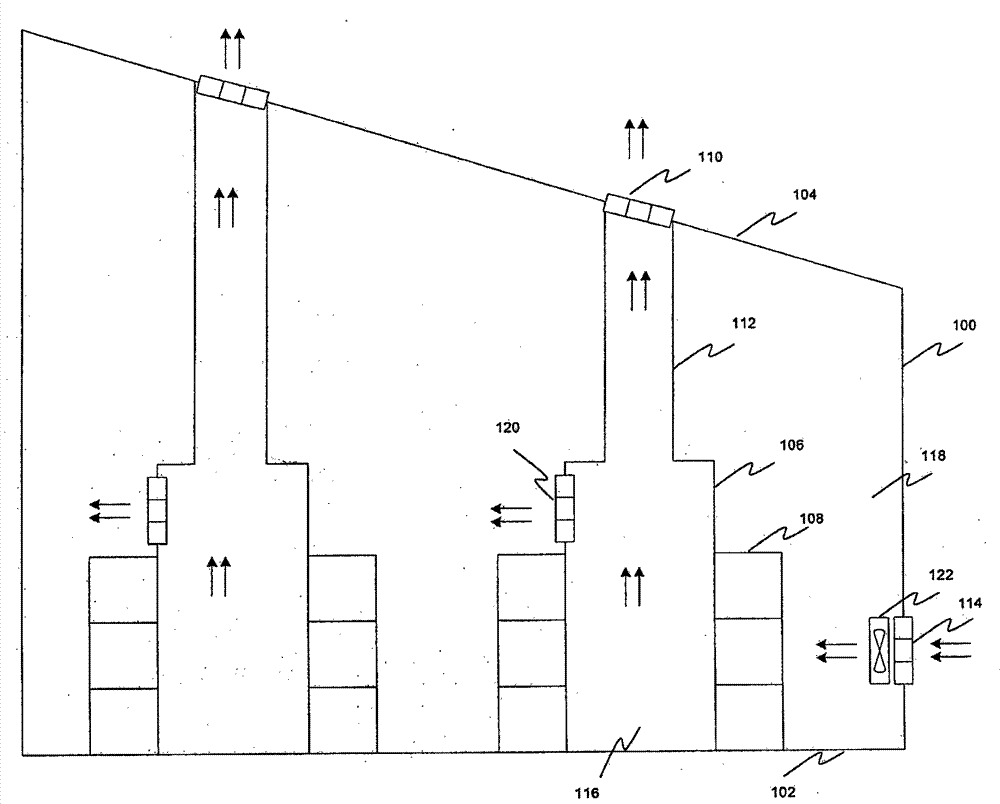

Integrated Building-Based Air Handlers for Server Farm Cooling Systems

InactiveCN102473028BDigital data processing detailsCooling/ventilation/heating modificationsEvaporative coolerData center

The present invention provides apparatus, methods and systems for integrated building-based air handlers for efficient cooling of data centers. Some embodiments of the present invention allow for encapsulation of the heat row through the enclosure and allow one or more cooling fans to be integrally mounted within the rack mount unit for drawing cool air to cool the rack mount mounted in the rack unit and exhaust heated air towards the enclosure wall. In other embodiments, the disclosed system can be used to bring in outside air to cool servers. In some embodiments, in addition to the heat row enclosure, the system also encloses the cold row through the cold row enclosure. The rack-mount unit's cooling fans draw cool air from the cold row enclosure to cool the unit, and expel heated air toward the hot row enclosure. In some embodiments, the control system is used to selectively utilize free cool air to cool the servers. When the outside air is not suitable for cooling purposes, the control system recirculates the heated air from the thermal exhaust enclosure and one or more evaporative coolers are used to cool the heated air.

Owner:EXCALIBUR IP LLC

A combined suction plane cascade experimental device

InactiveCN109826817BIndependent control of suction flowMeet matching experimental needsPump controlNon-positive displacement fluid enginesSuction forceMechanical engineering

The invention discloses a combined suction type plane cascade experimental device which comprises a first grid plate, a second grid plate, a first suction hood, a second suction hood, a non-suction blade, a suction blade, a grid plate rod, a suction surface suction rod and an end wall suction rod, wherein the first suction hood and the second suction hood are of two platy structures in mirror symmetry and are fixed in the centers of the outer end faces of the first grid plate and the second grid plate separately; a plurality of end wall suction cavities are formed between the first suction hood and the first grid plate; a plurality of suction surface suction cavities are formed between the second suction hood and the second grid plate; and the end wall suction rod and the suction surface suction rod at the mounting outer ends are adopted to guide boundary layer low-energy fluid out. The combined suction type plane cascade experimental device overcomes the difficulty in the prior art that end wall suction and suction surface suction cannot be carried out simultaneously, realizes the purpose of independently controlling the suction flow rate of the end wall and the blade suction surface, meets the experimental demand of flow matching of two suction grooves under different working conditions, and can fully and completely suck the low-energy fluid in the end wall boundary layer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A Combined Suction Layout Method for Controlling the Separation of Compressor Stator Corner Areas

The invention relates to a combined suction scheme for controlling compressor stator corner separation. The combined suction scheme is characterized in that a suction groove is formed in an end wall of an axial-flow compressor stator cascade channel circumferentially, a suction groove is formed in a blade suction surface in a blade height direction, a suction groove in the end wall is parallel to a forehead line, the control on different axial positions and different suction groove lengths can be realized, and the suction groove in the end wall and the suction groove in the blade suction surface can also be controlled through different combination forms of positions. Compared with a single suction scheme, the combined suction scheme can combine advantages of suction surface suction and end wall suction, so that the development of boundary layers on the suction surface and the end wall can be prevented more effectively, gathering and mixing of the boundary layers at corners can also be prevented, the corner separation can be inhibited obviously, the total pressure loss can be reduced, and the stability and the efficiency of a compressor can be improved.

Owner:BEIHANG UNIV

Down-feather dust removal device

InactiveCN107881565APlay the role of dialingGood for fallingAnimal fibre deburring machinesState of artEngineering

The invention discloses a feather dedusting device, which comprises a box body, a material storage net box, an anti-adsorption device and a dust collection device; the material storage net box has a net-shaped hollow cylindrical structure; The air outlet pipe that is evenly arranged on the side wall of the material net box, the air inlet pipe connected to the upper end of the air outlet pipe and the fan connected to the air inlet pipe; the inside of the air outlet pipe has a cavity that is arranged in the vertical direction, so The cross-section of the cavity along the horizontal direction is arc-shaped, and it is used for nesting and matching of the material cage; Vacuum cleaner connected to suction hose. The present invention adds an anti-adsorption device on the basis of the prior art, and blows air through the air outlet nozzle attached to the inner wall of the material storage cage, thereby blowing up the down adsorbed on the material storage cage, which is convenient for unloading, and at the same time, the air outlet blows the air. It can also play a role in feeding down, so that the dust on the upper end can fall off and be sucked away by the vacuum cleaner.

Owner:徐州腾宇羽绒制品设备有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[Khan Orotracheal Suction System] [Khan Orotracheal Suction System]](https://images-eureka.patsnap.com/patent_img/278b4c40-b8c6-49f5-b38a-820eb11fe314/US20050020975A1-20050127-D00000.png)

![[Khan Orotracheal Suction System] [Khan Orotracheal Suction System]](https://images-eureka.patsnap.com/patent_img/278b4c40-b8c6-49f5-b38a-820eb11fe314/US20050020975A1-20050127-D00001.png)