Patents

Literature

513results about How to "Reduce suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

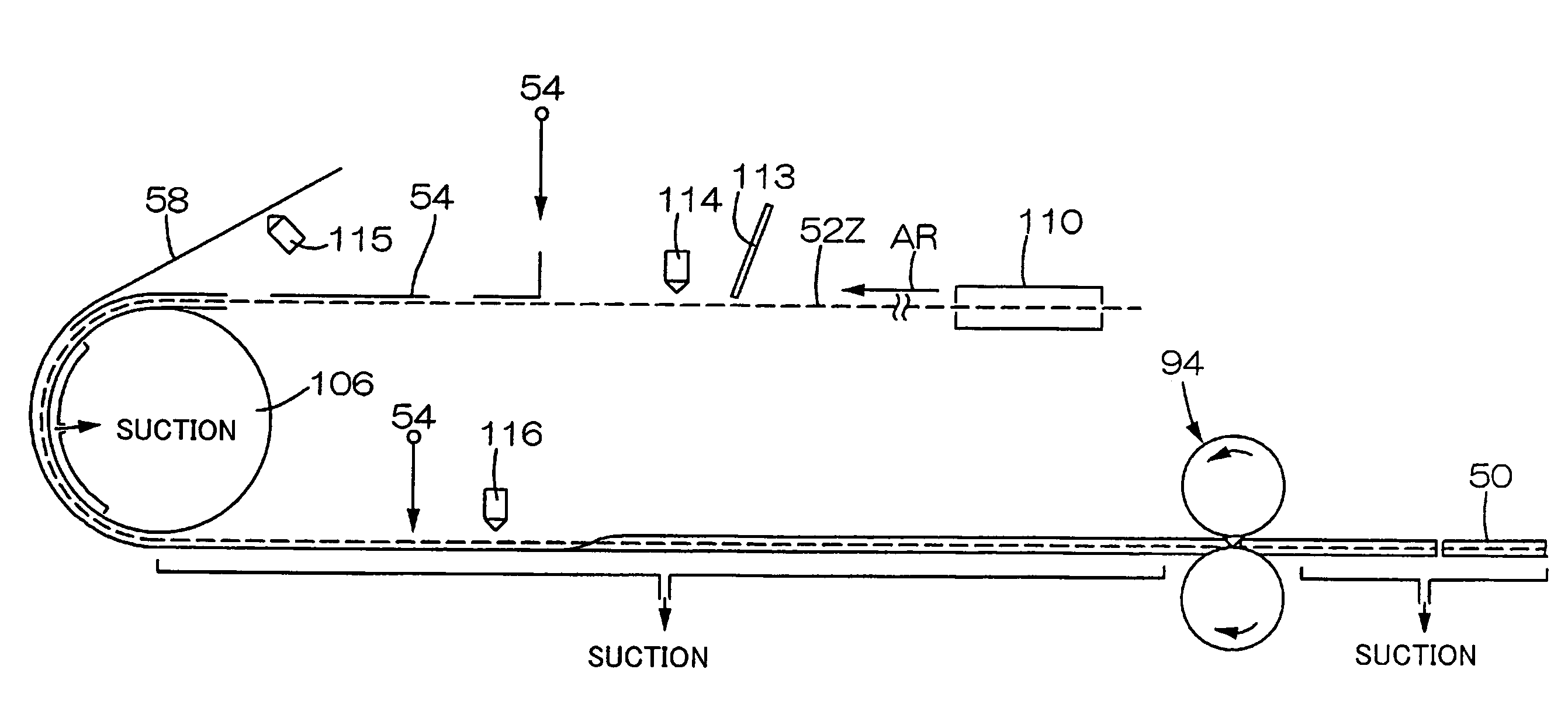

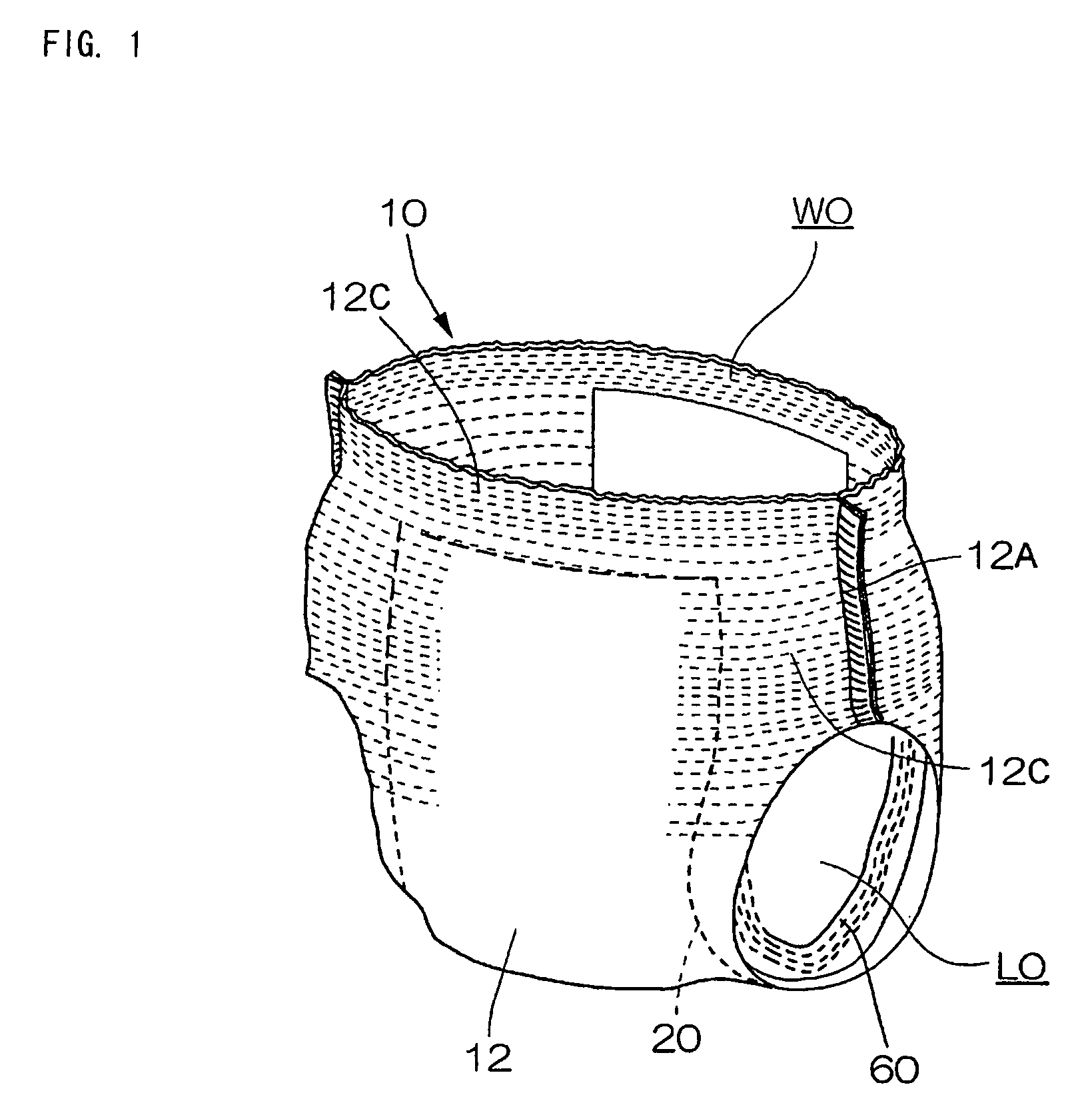

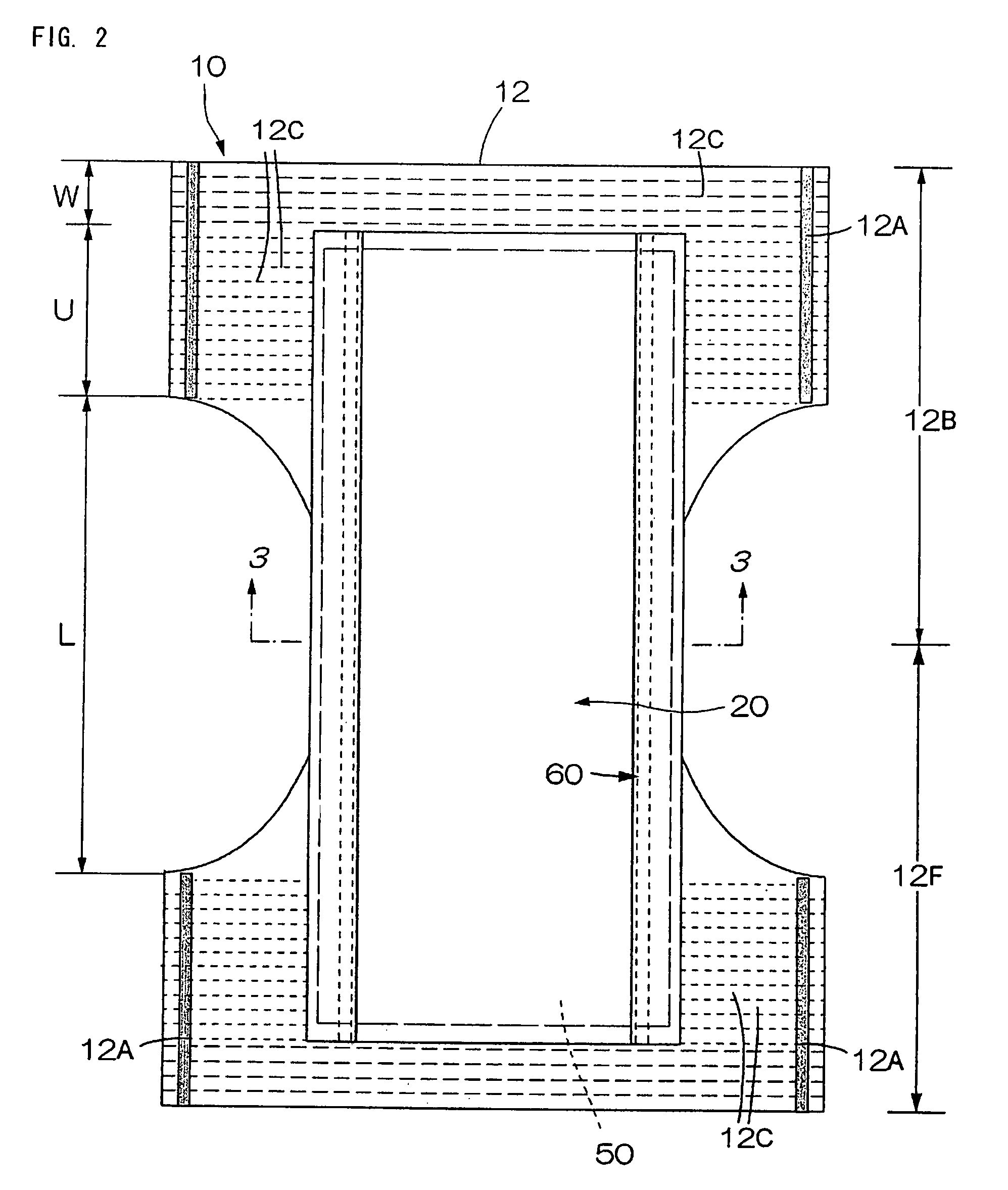

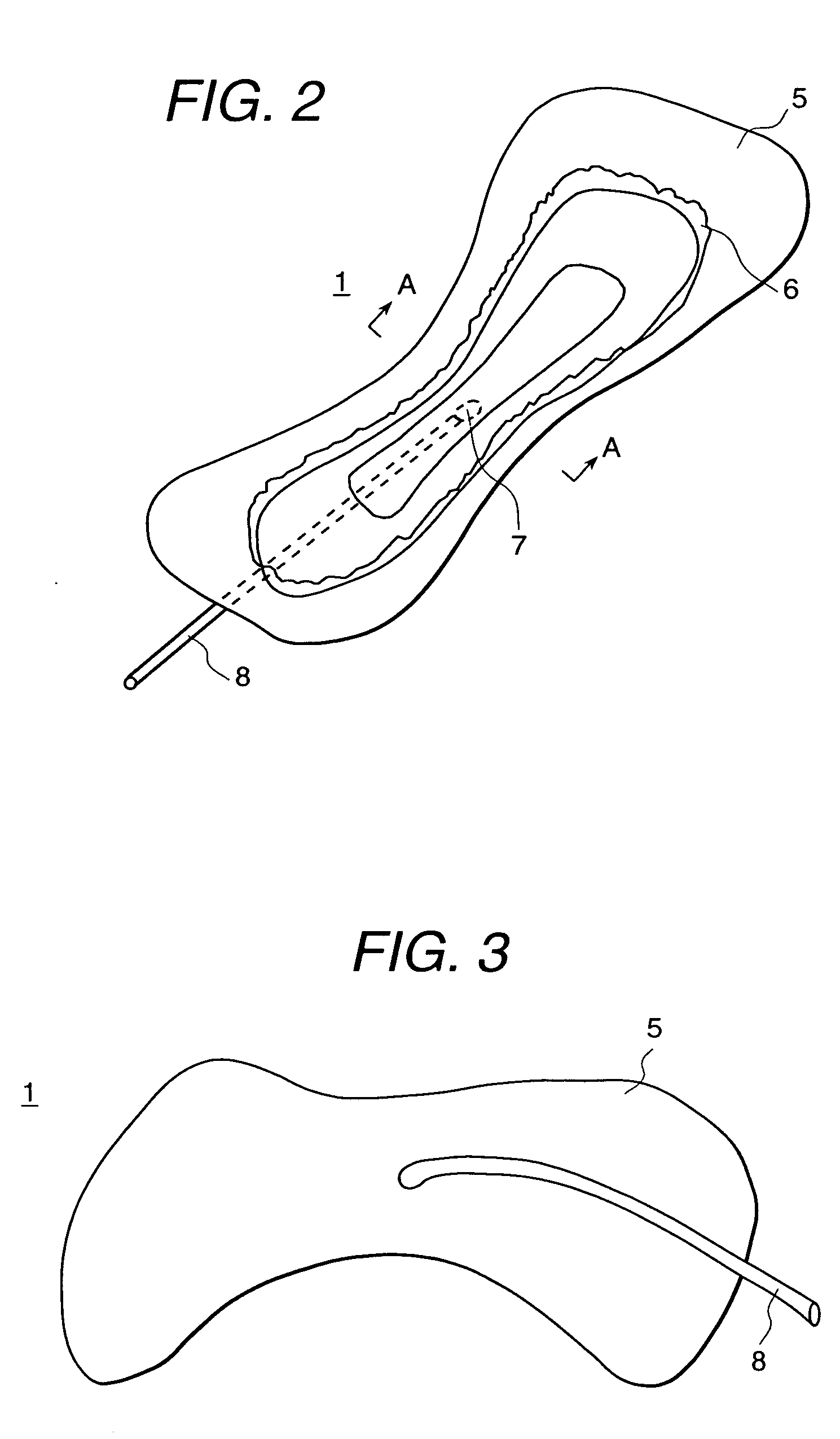

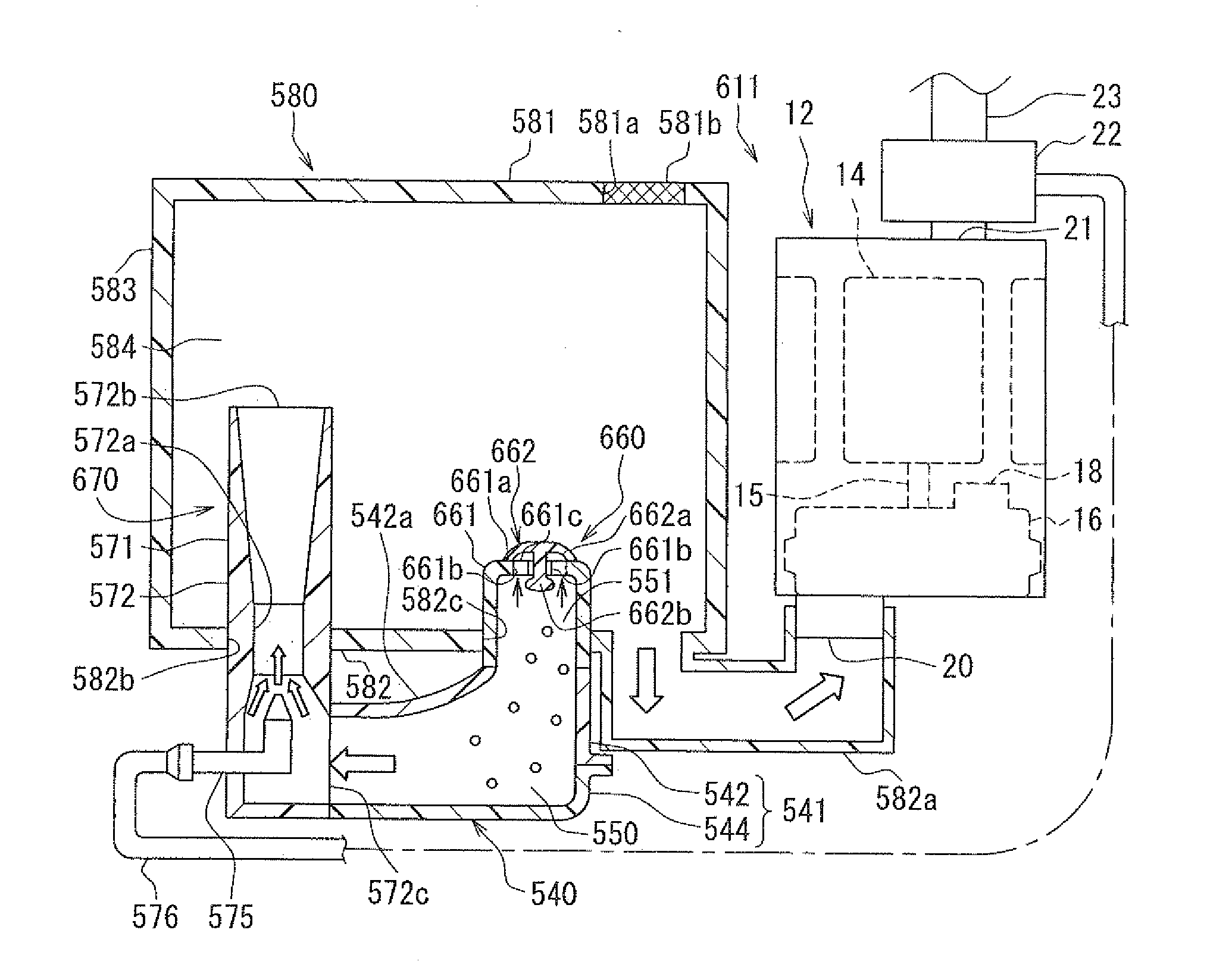

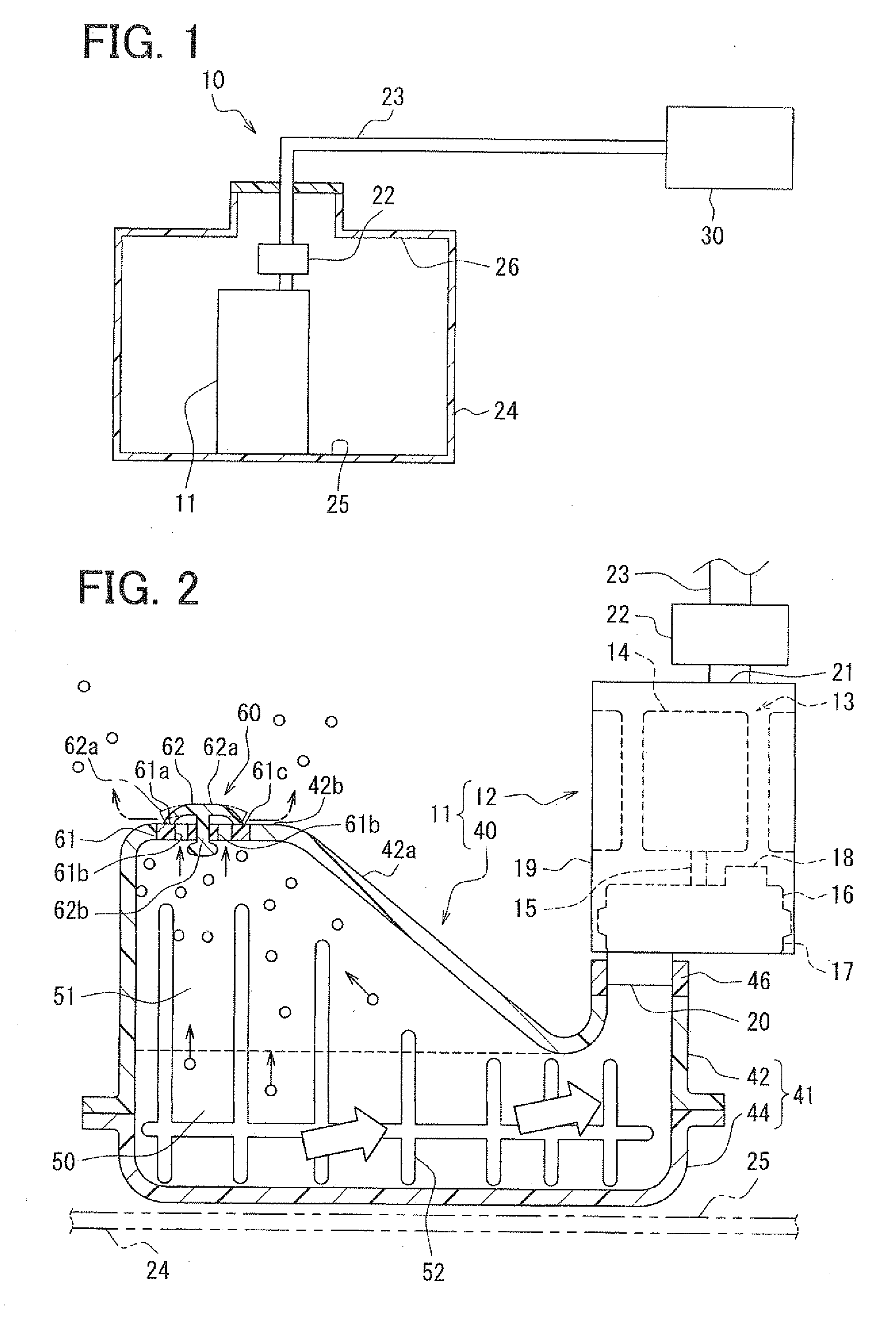

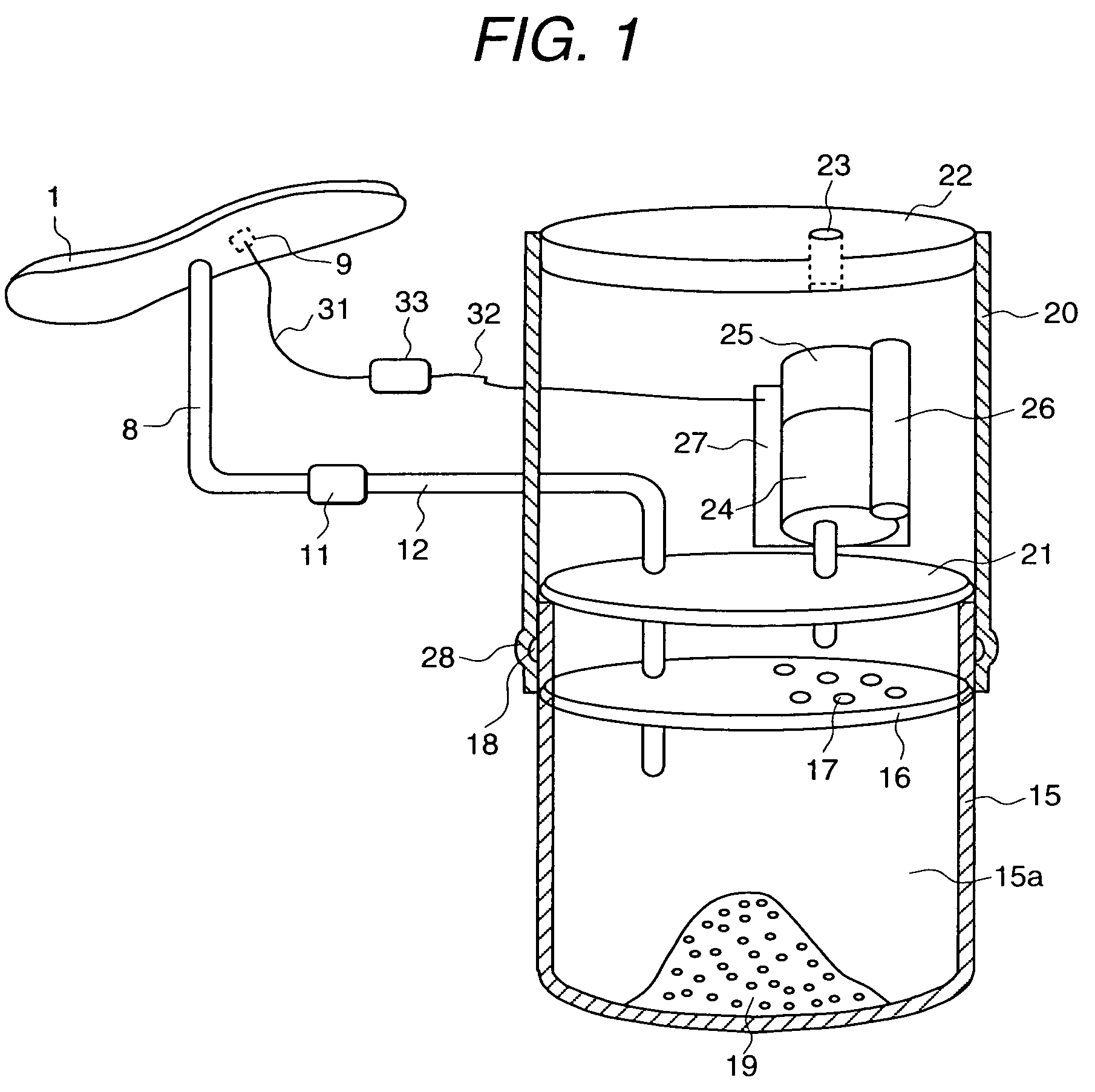

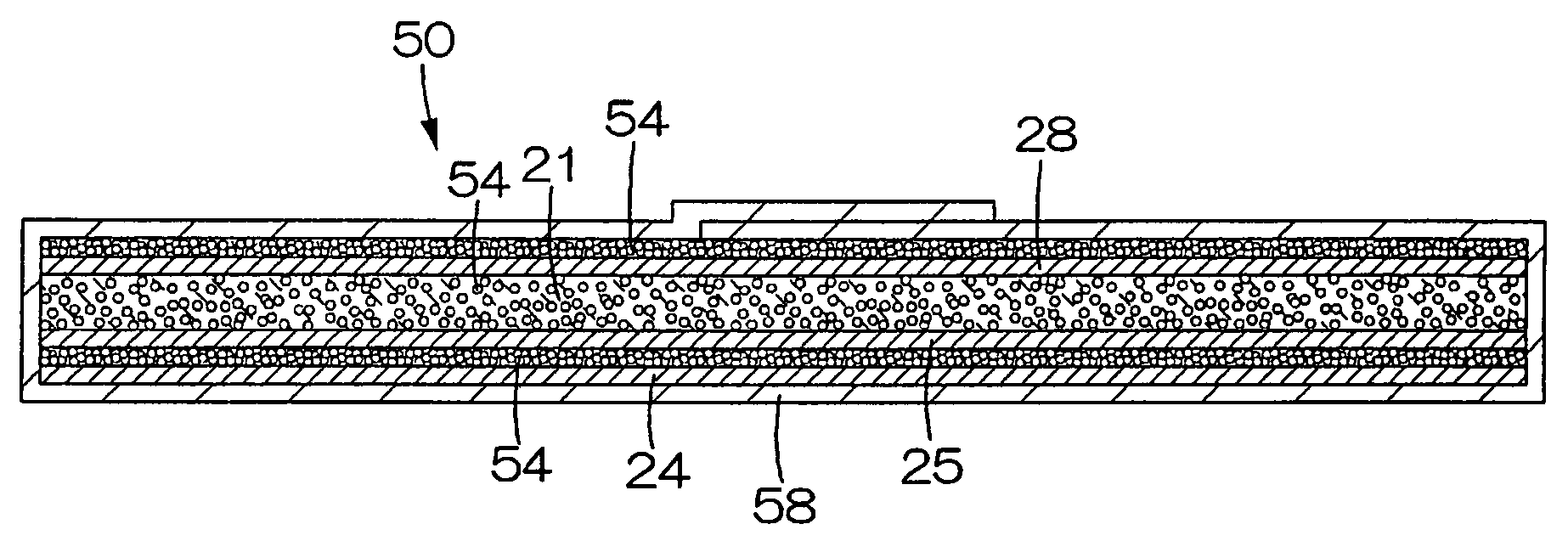

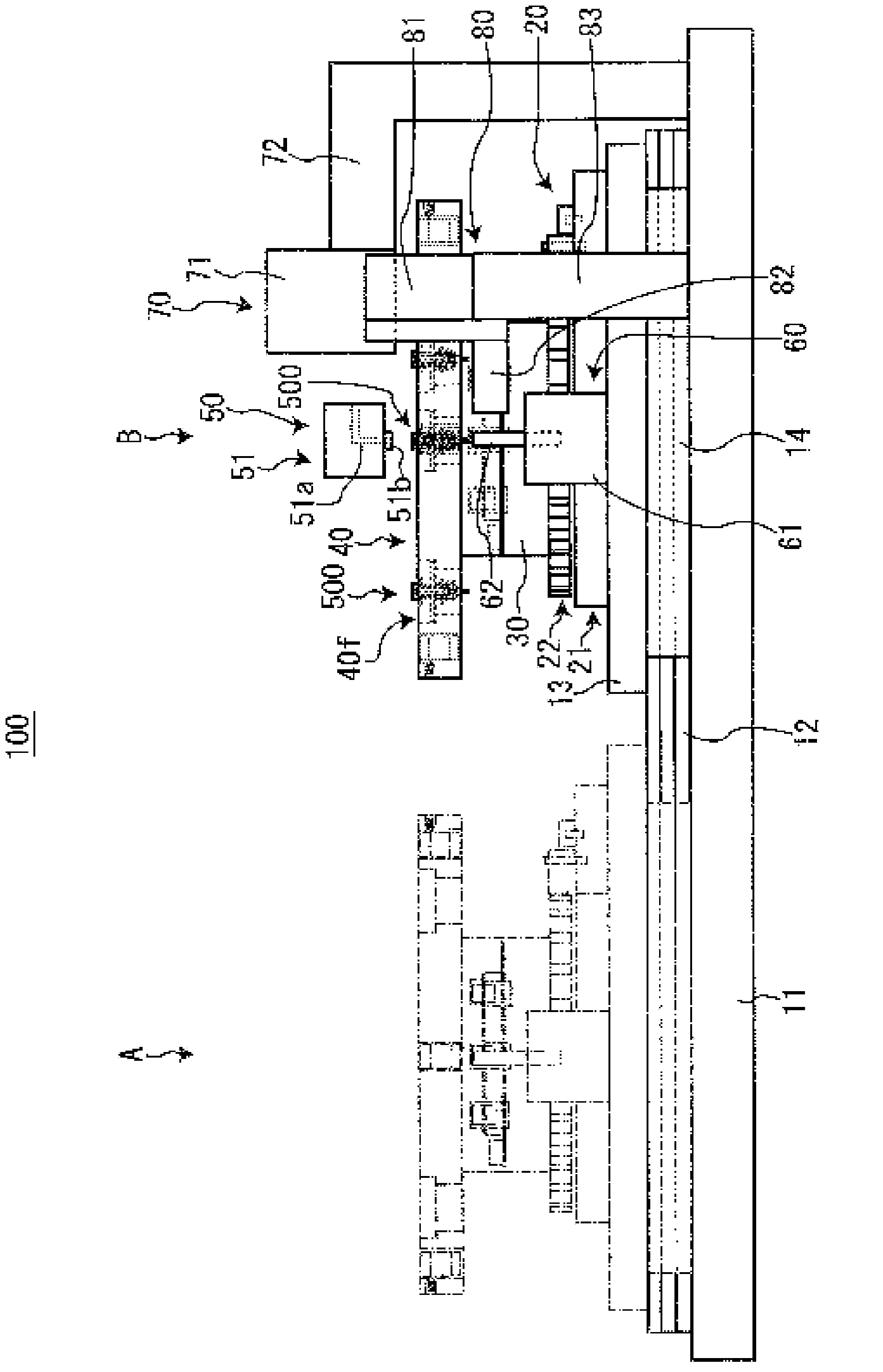

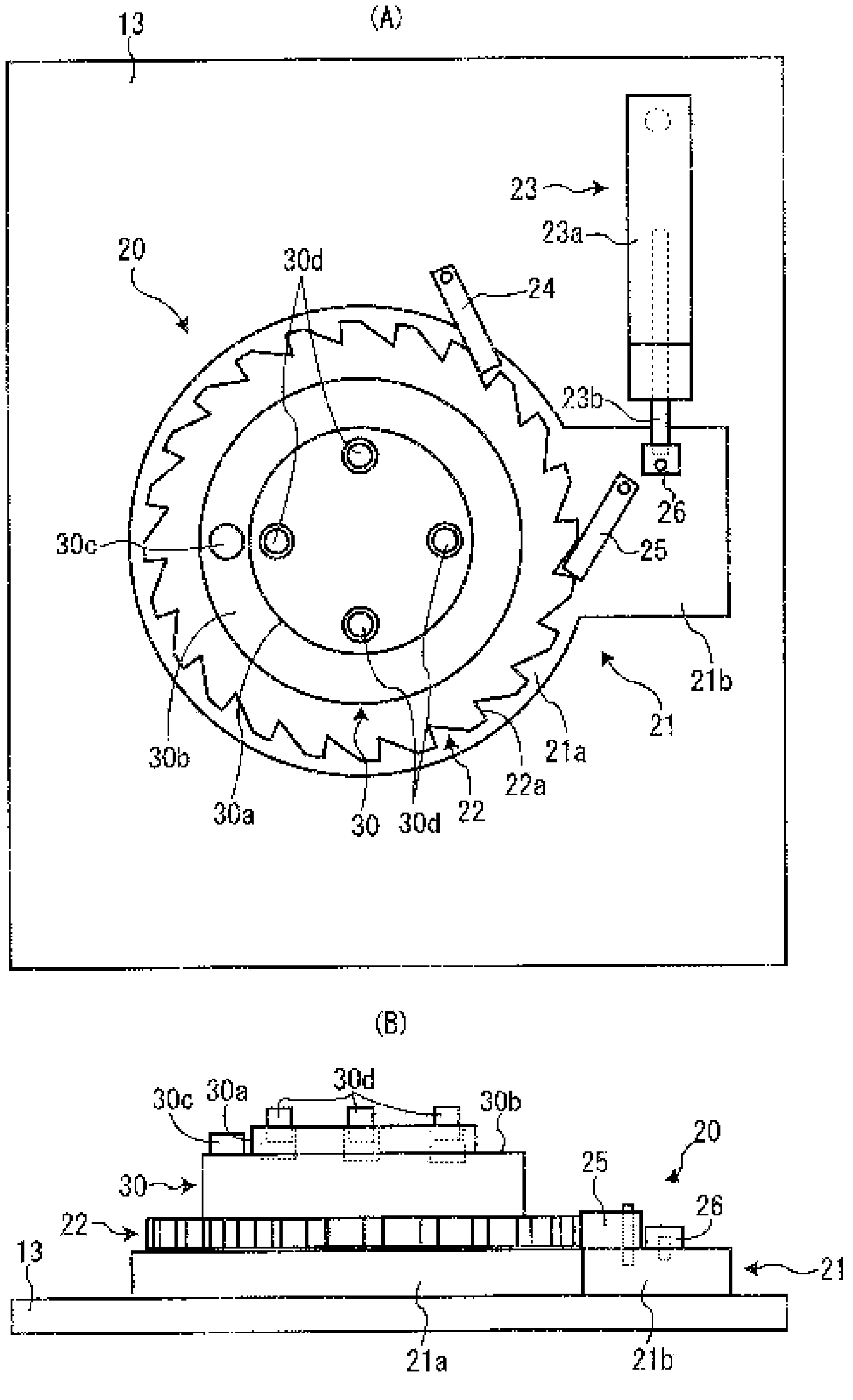

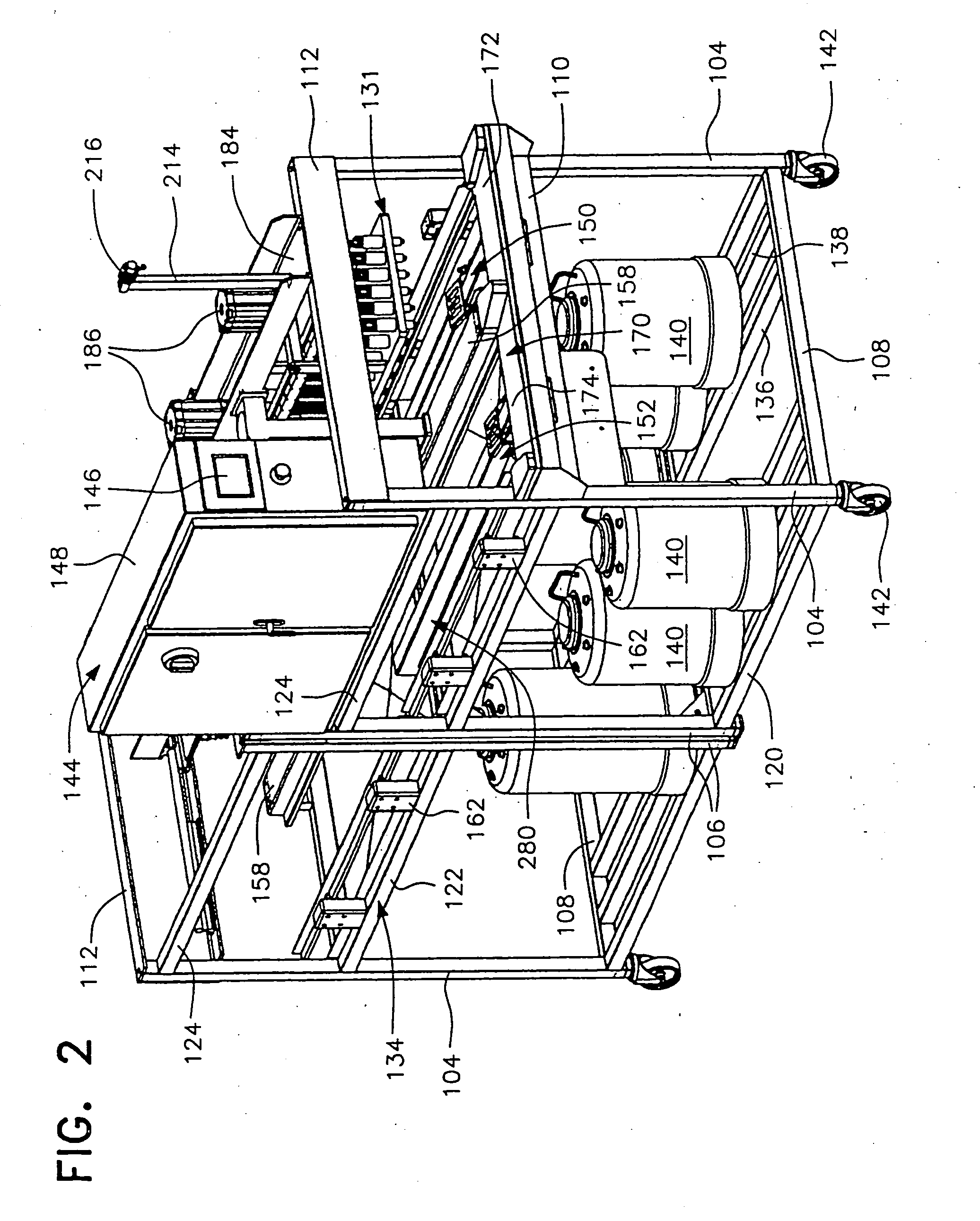

Manufacturing facility of absorbent body, absorbent body and absorbent article

ActiveUS7717150B2Prevent characteristicsDifficult to moveLamination ancillary operationsManual label dispensersFiber bundleSuper absorbent

A shuffling hand feeling and unwanted non-uniform absorption characteristics in the case of using a tow (fiber bundle) are prevented.An absorbent body includes a fiber aggregate 21 formed by opening the tow, a super absorbent polymer 54, and a sheet covering these components; and includesthe super absorbent polymer 54 bonded to the sheet 58 with an adhesive that is applied in a continuous plane to the entire surface or the substantially entire surface of at least the portion to be provided with the super absorbent polymer 54 in this sheet 58.

Owner:DAIO PAPER CORP

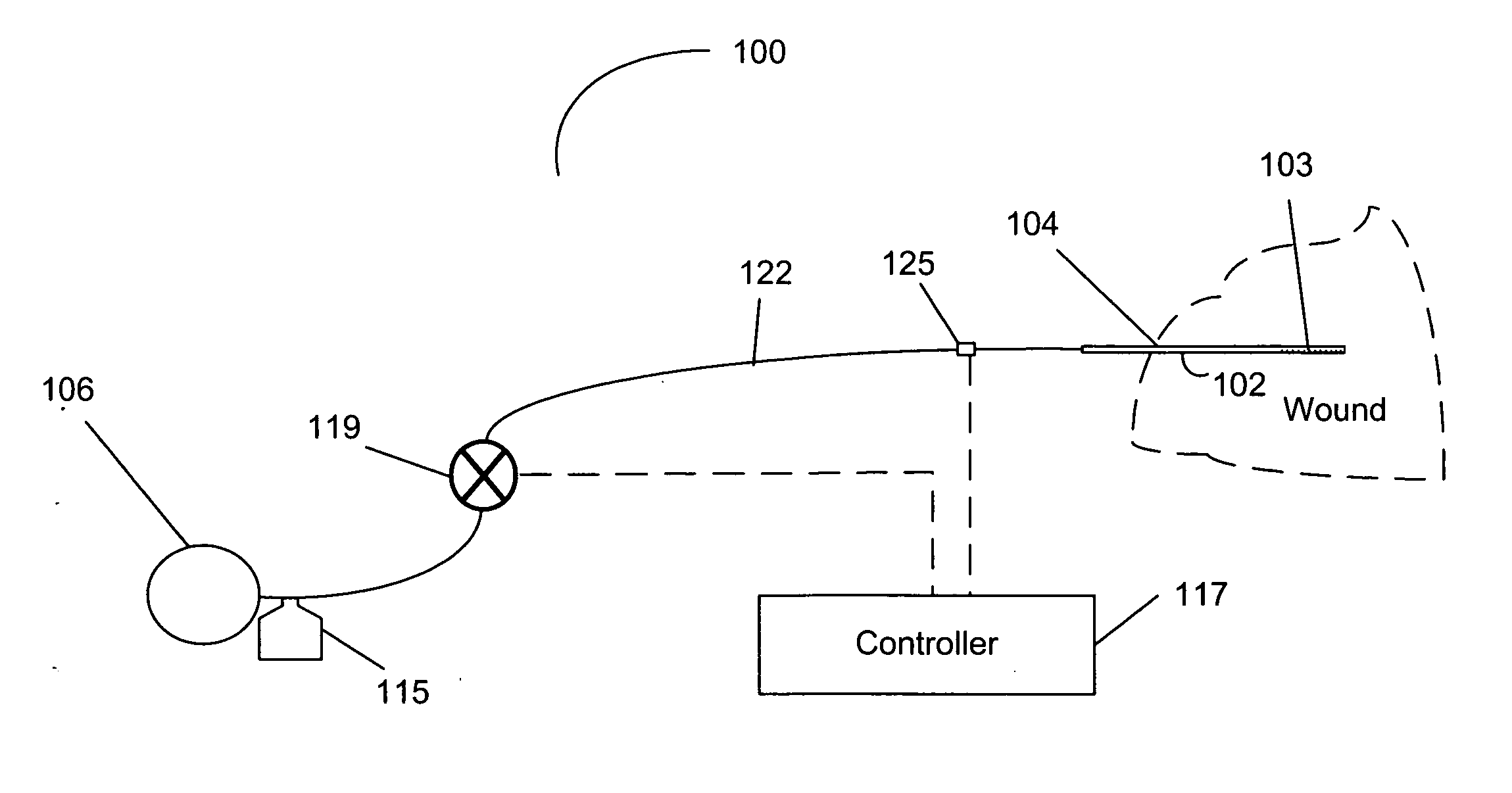

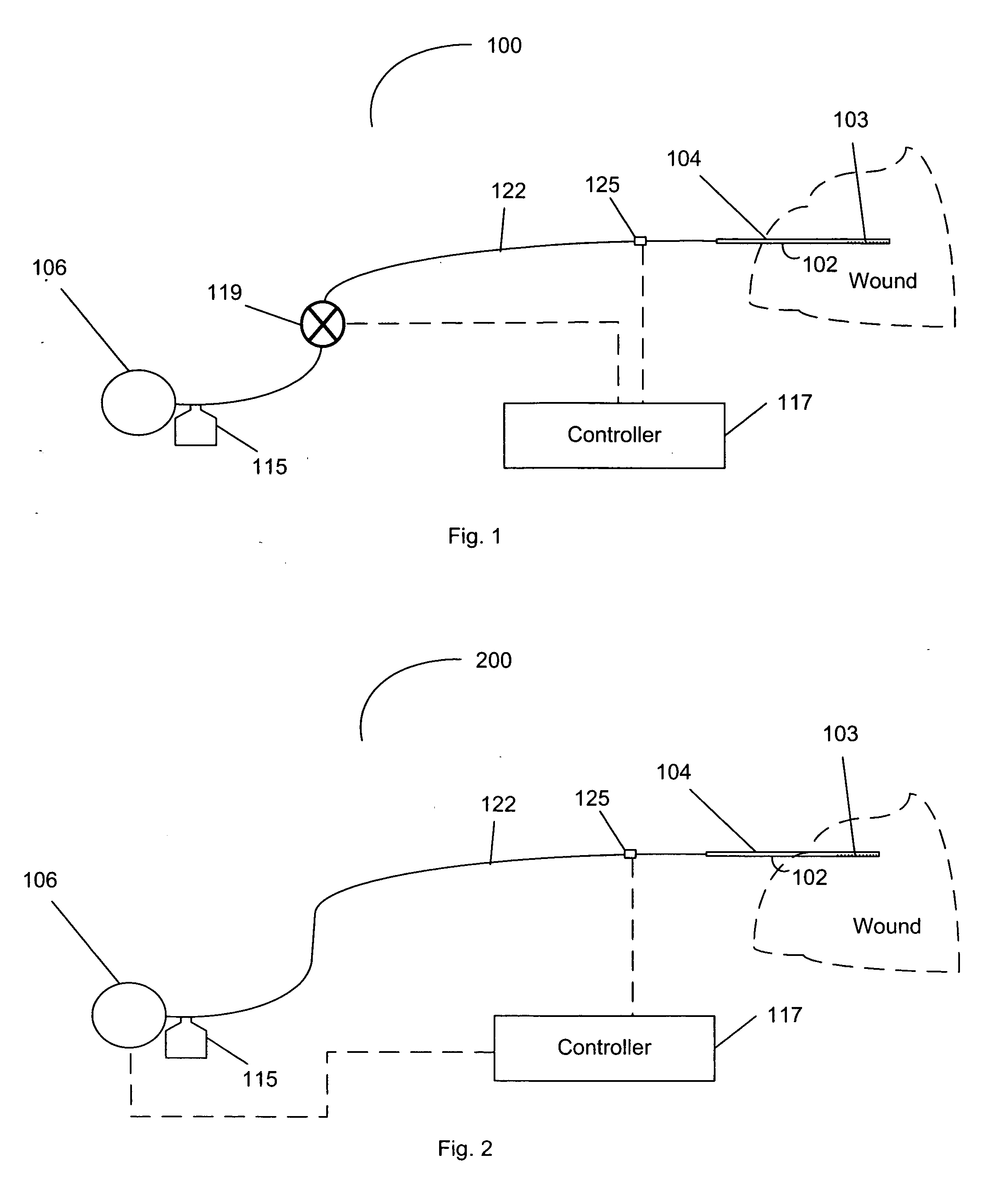

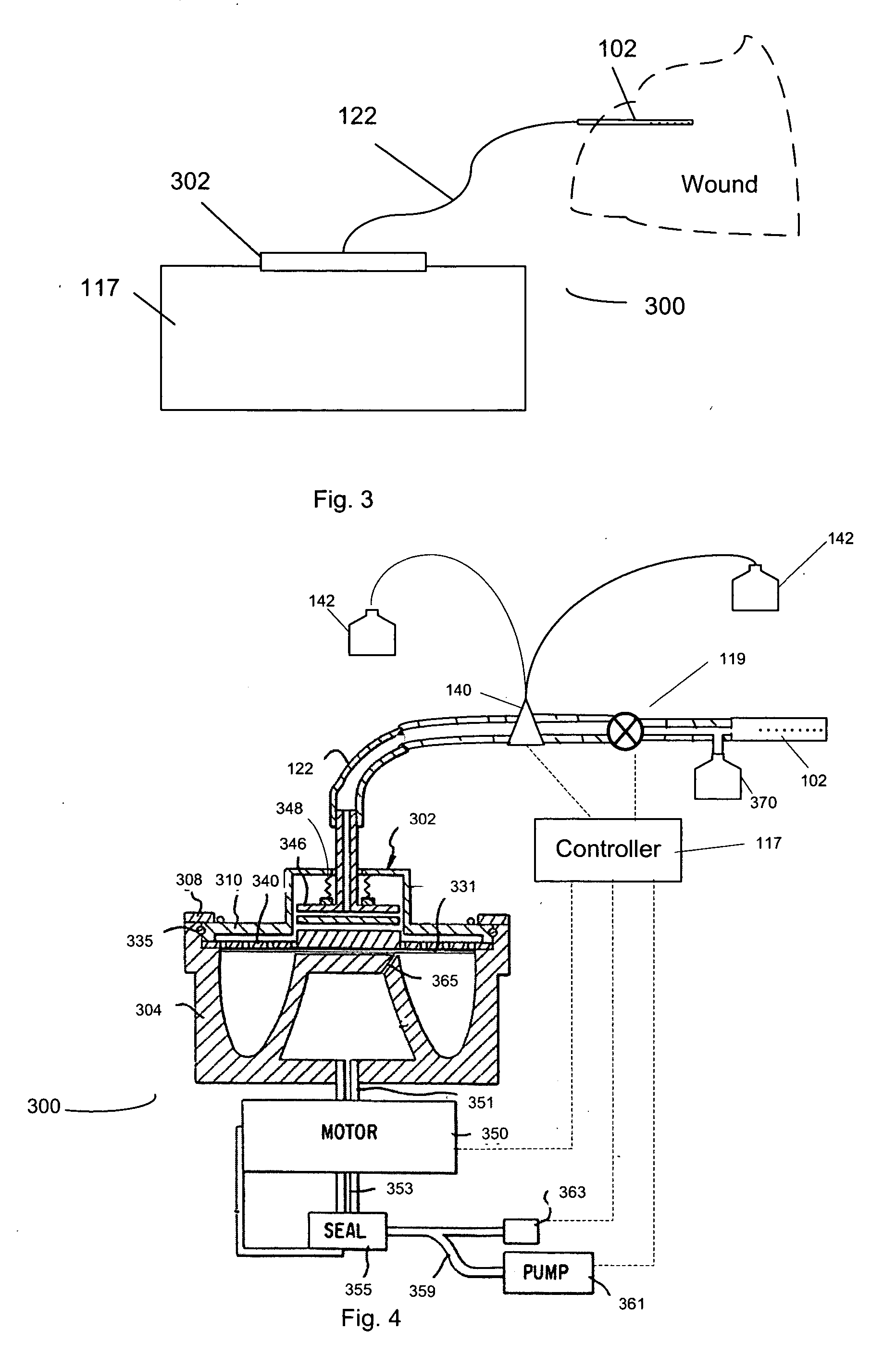

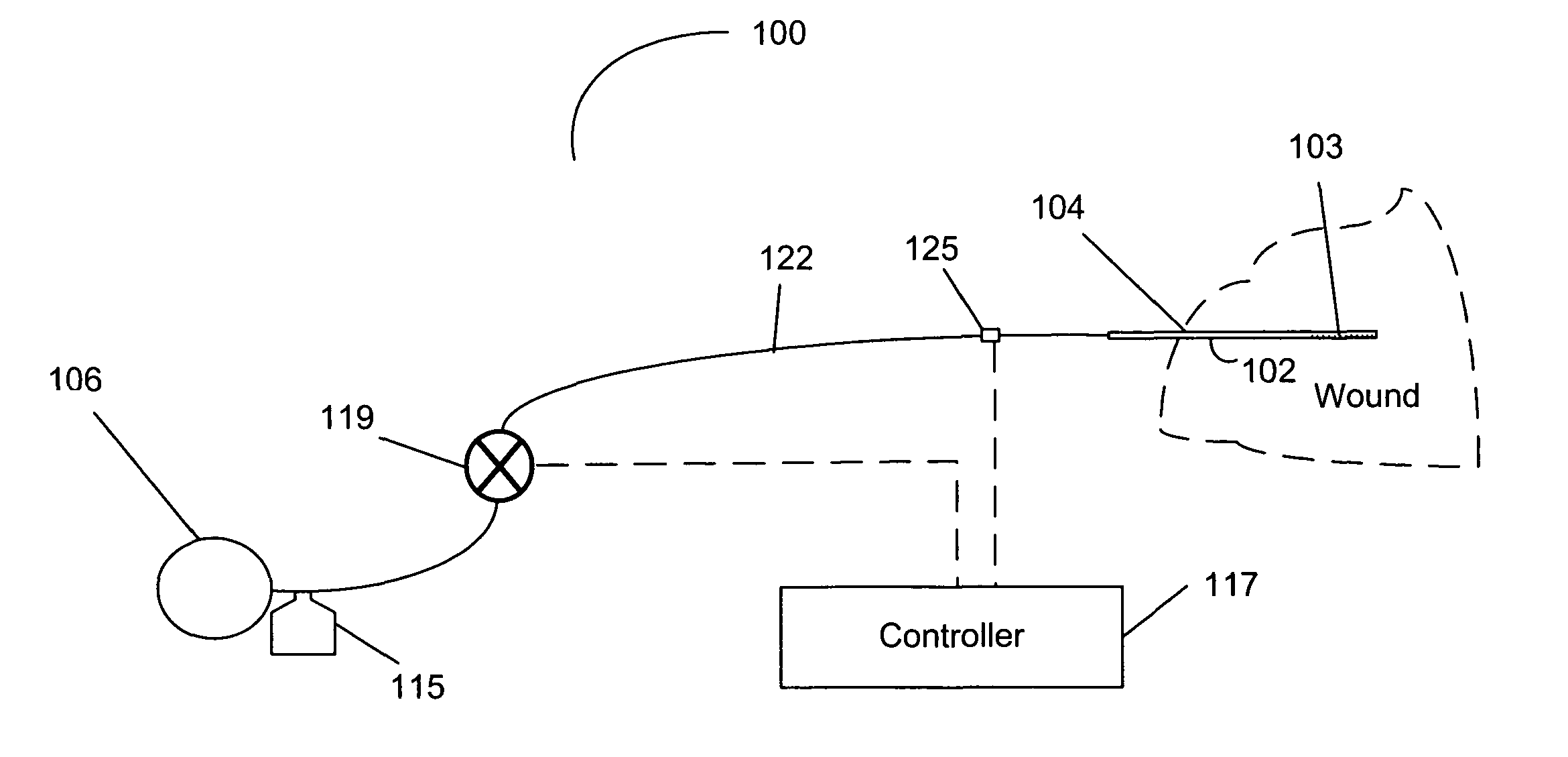

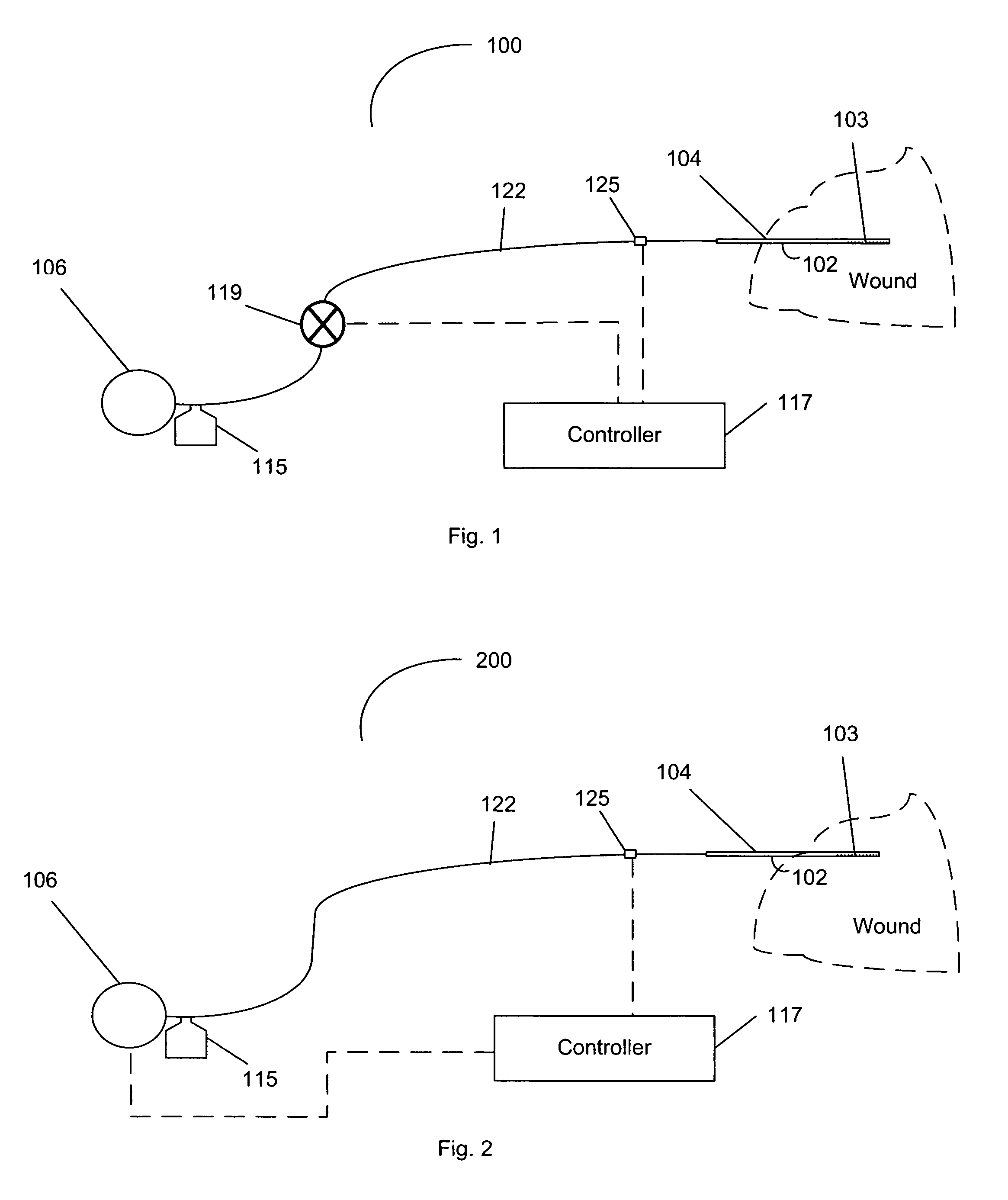

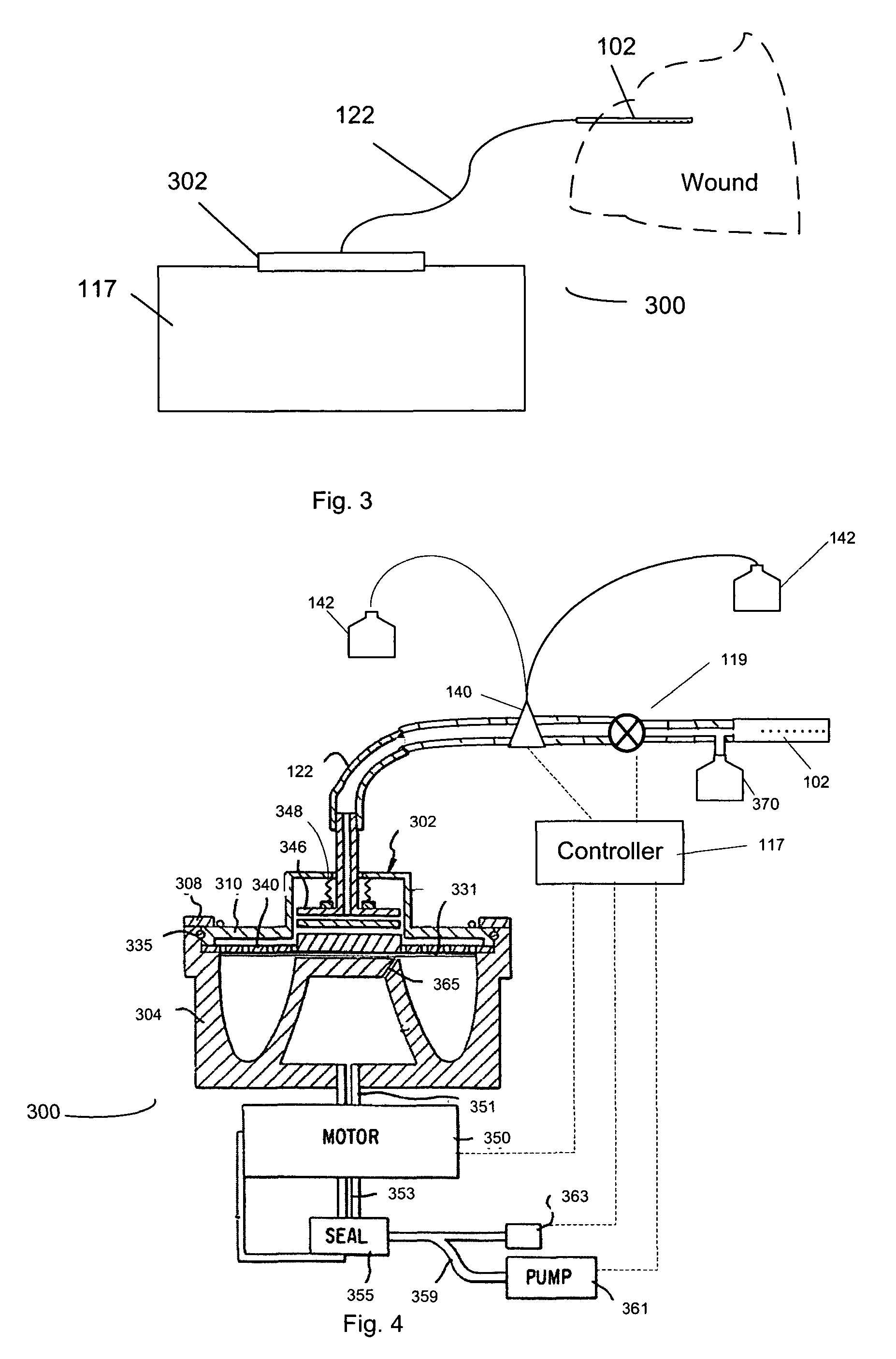

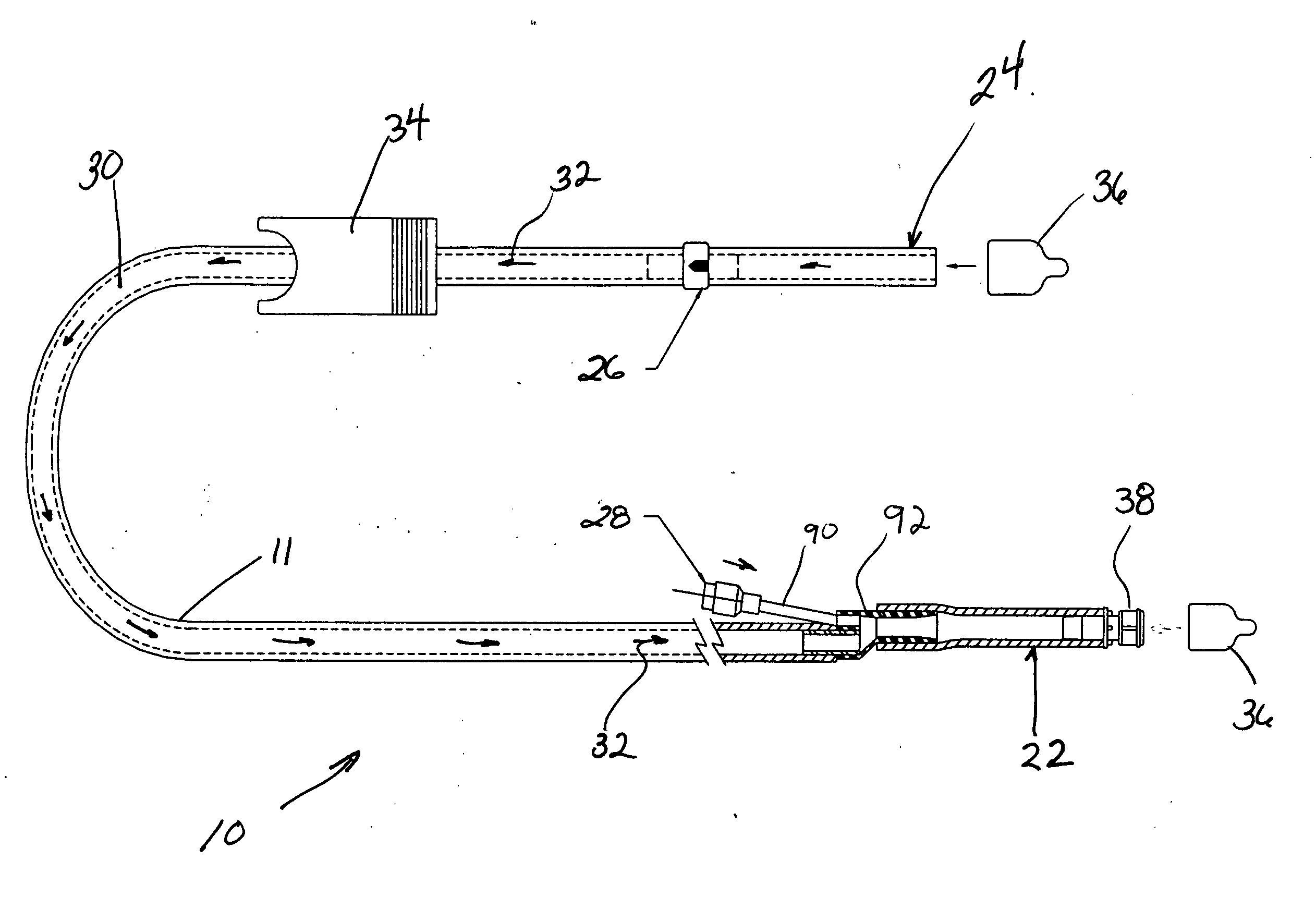

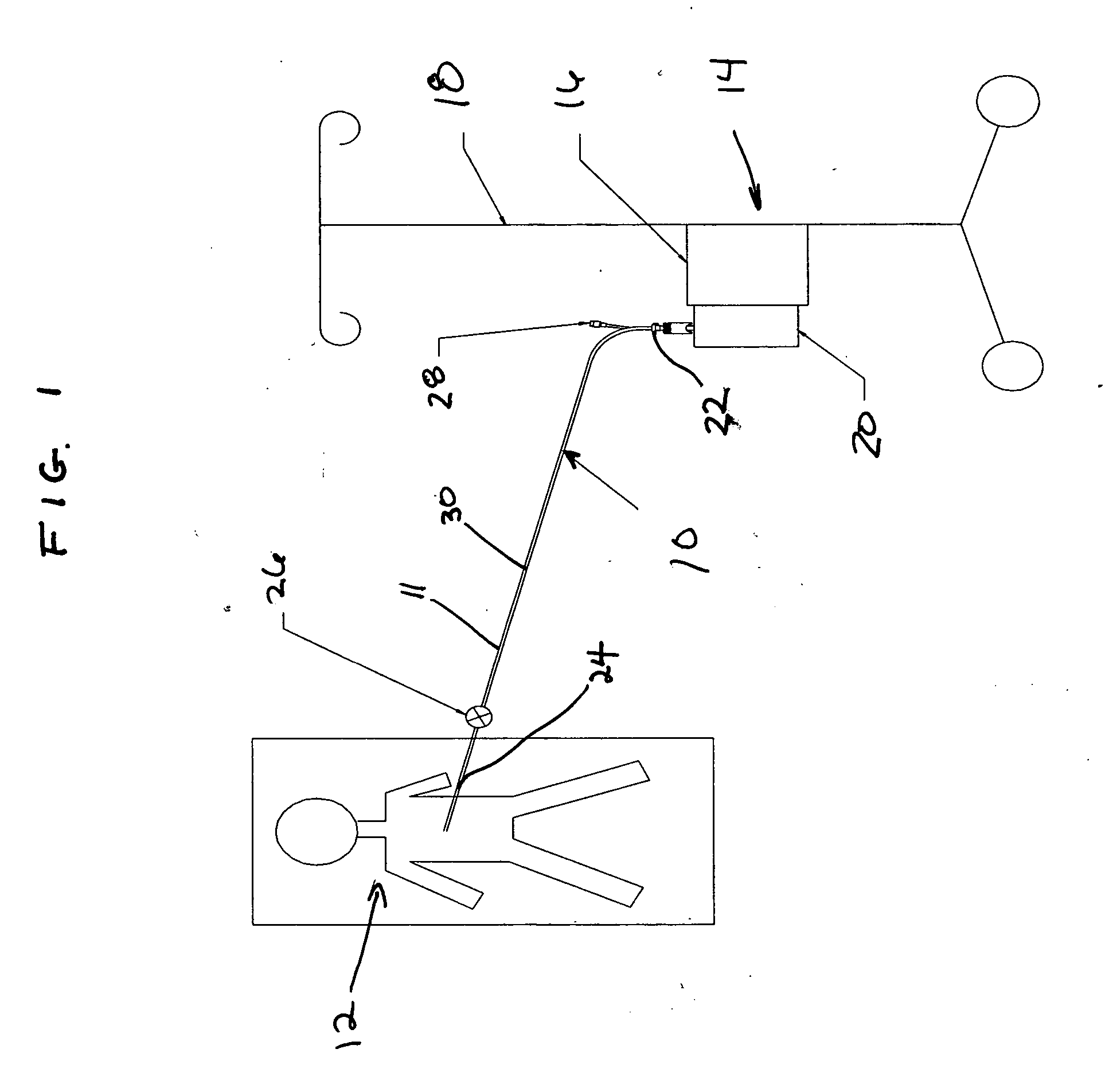

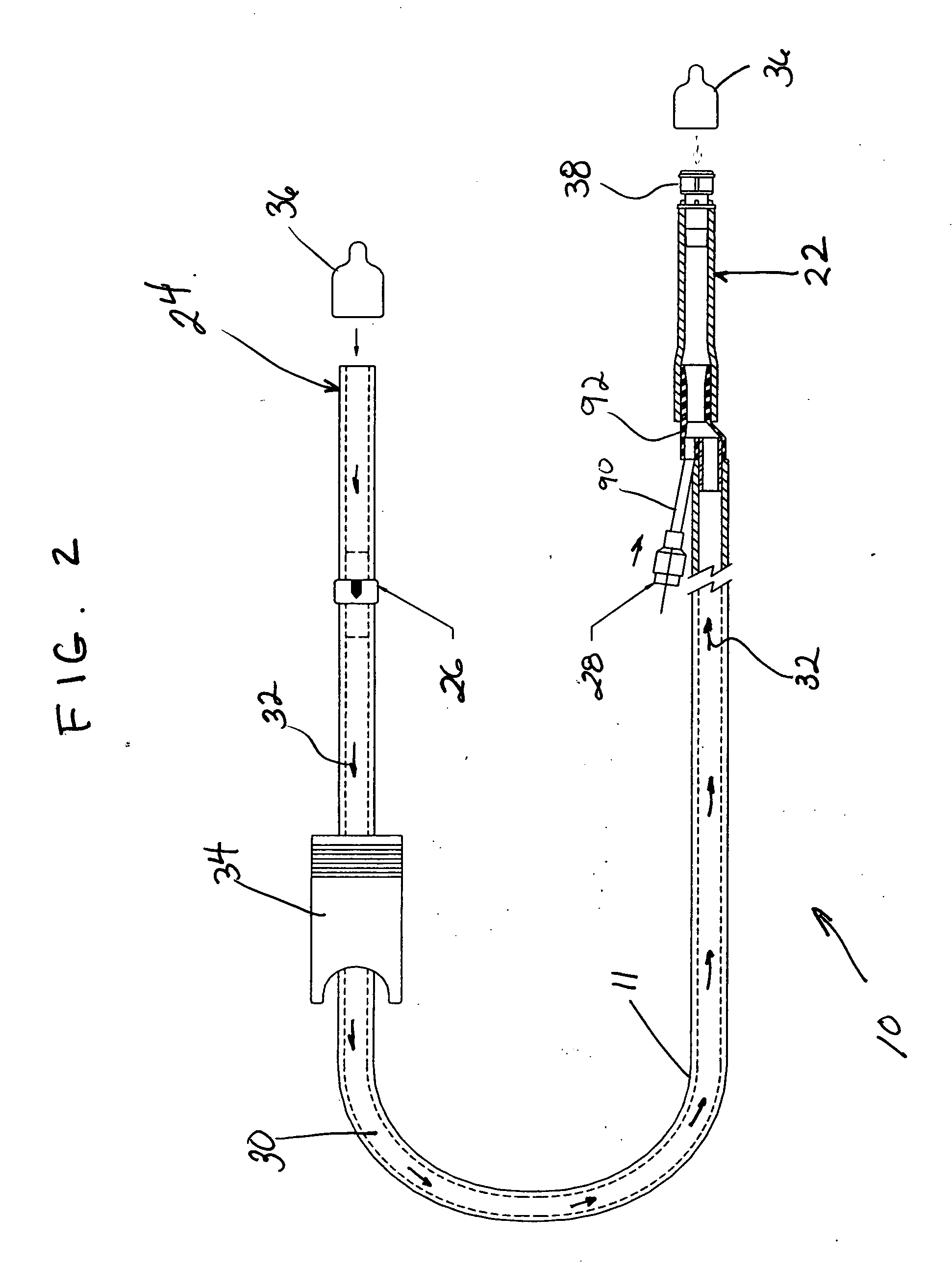

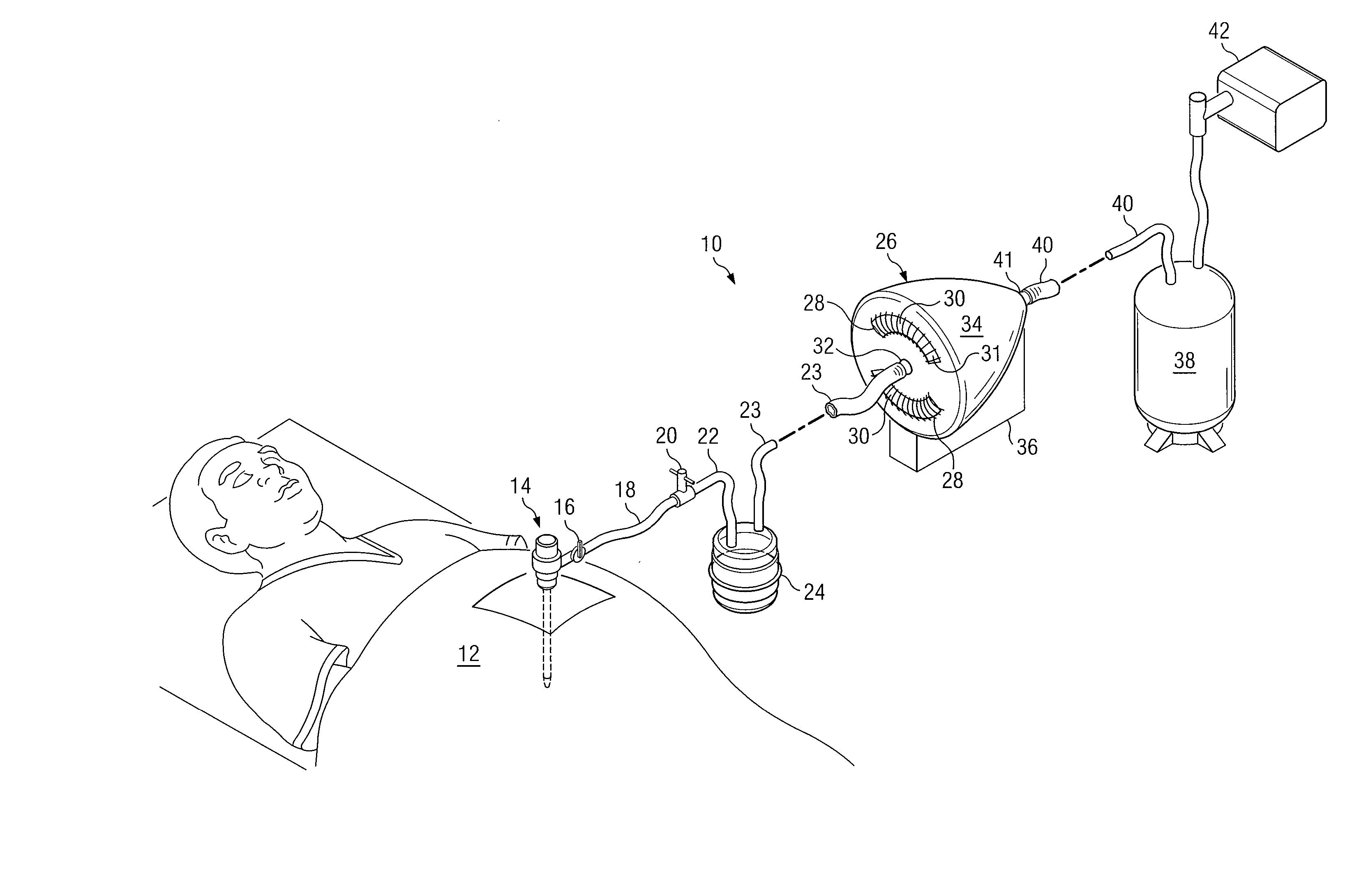

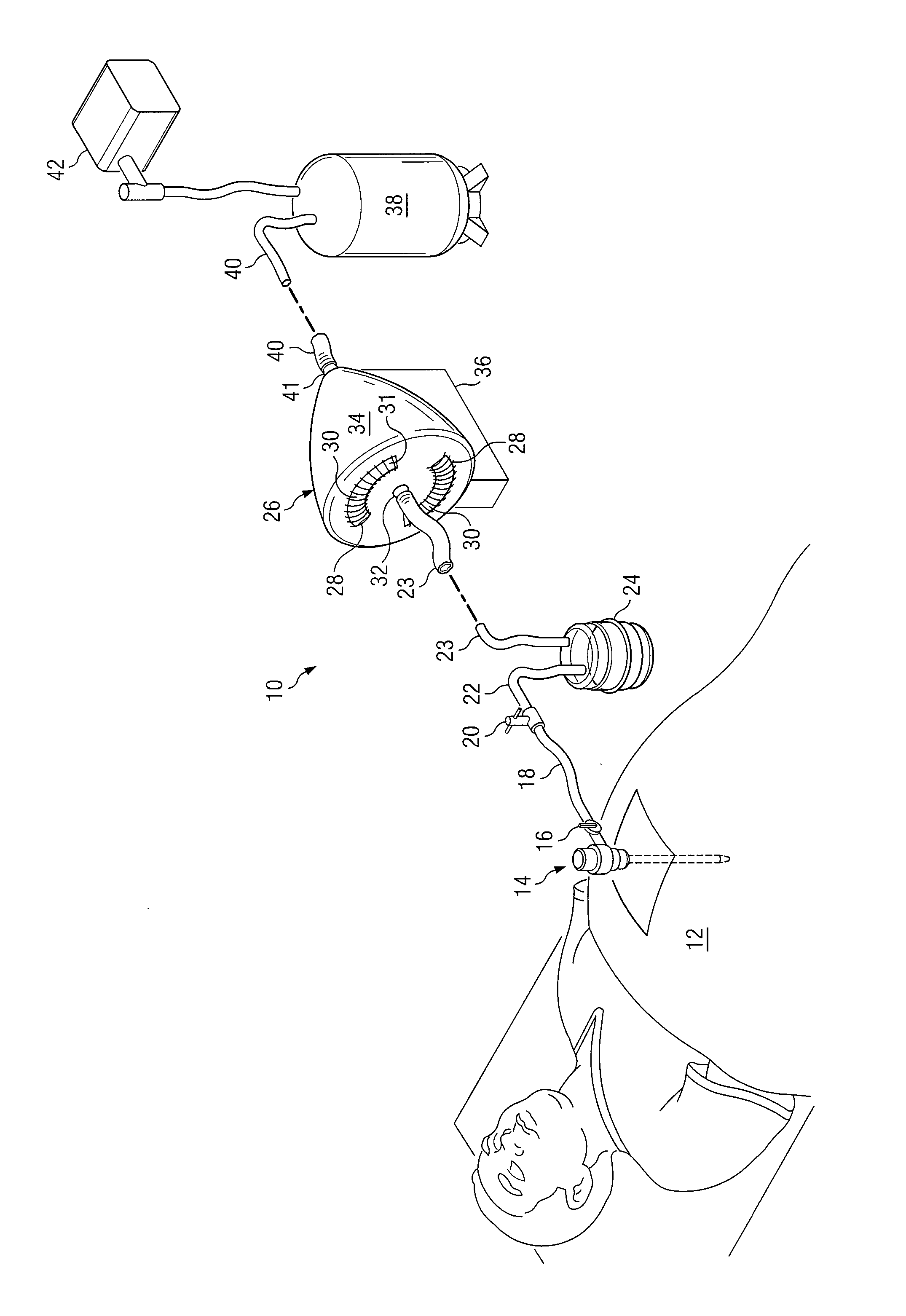

Wound drainage suction relief

InactiveUS20050192548A1Avoid obstructionReduce suctionElectrotherapyOther blood circulation devicesDrainage cathetersWound drainage

In accordance with one embodiment of the invention, there is provided a wound drainage system for draining fluid from a wound of a patient. The system includes a drain catheter. A suction means applies suction at the drain catheter such that fluid is drawn from the wound. While drawing fluid from the wound, a controller periodically increases and decreases the application of suction at the drain catheter. This allows the tissue surrounding the wound drain to relax, thus preventing obstruction of the drain catheter.

Owner:HAEMONETICS

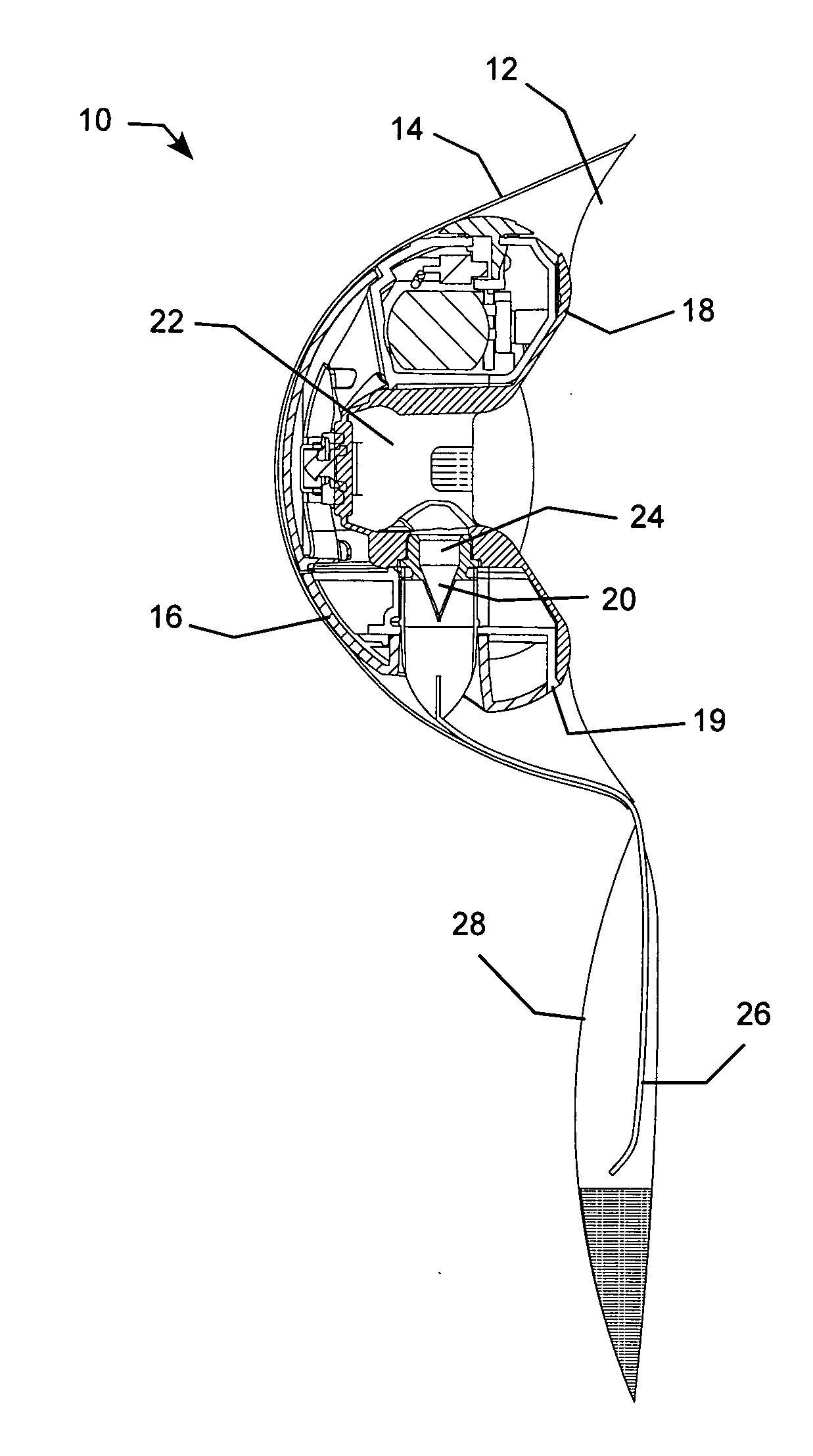

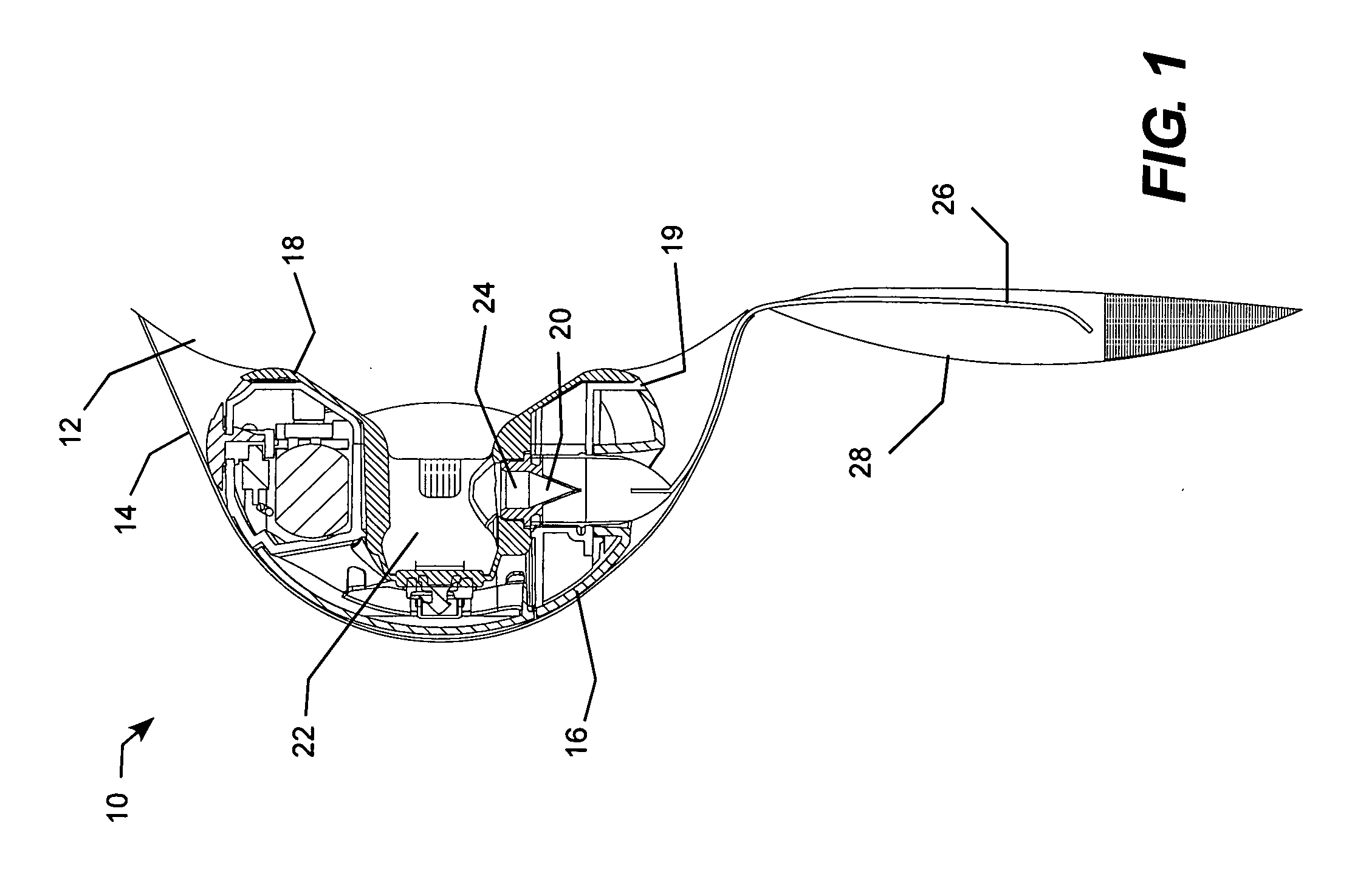

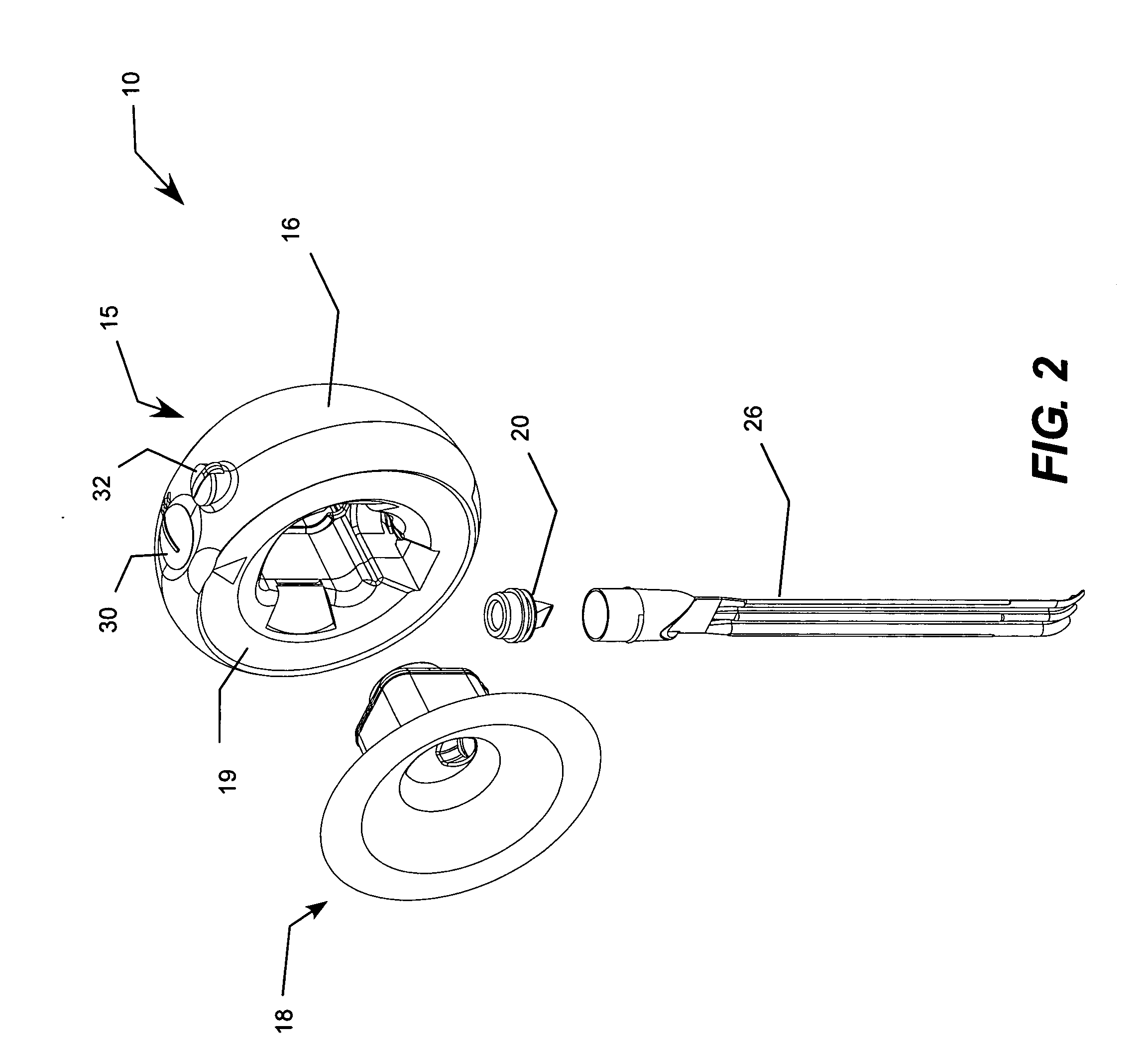

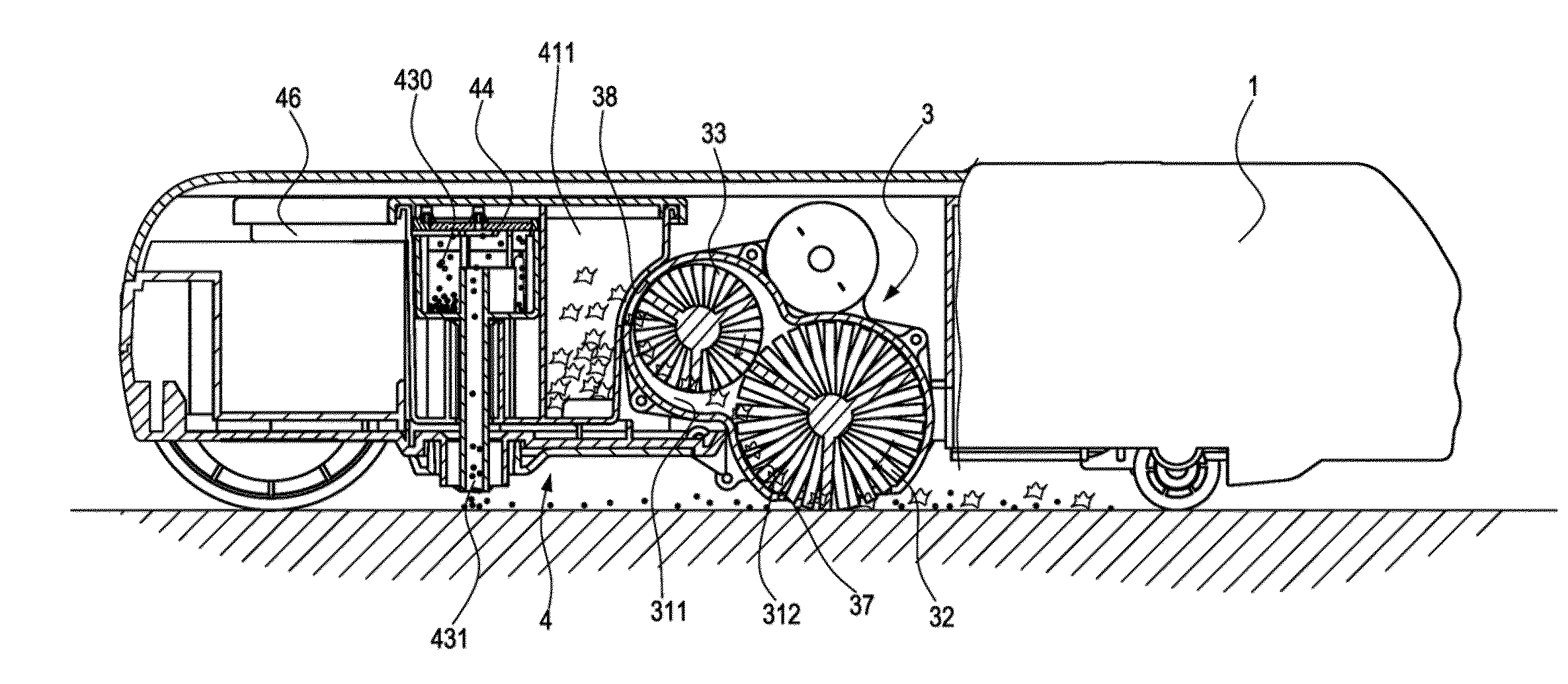

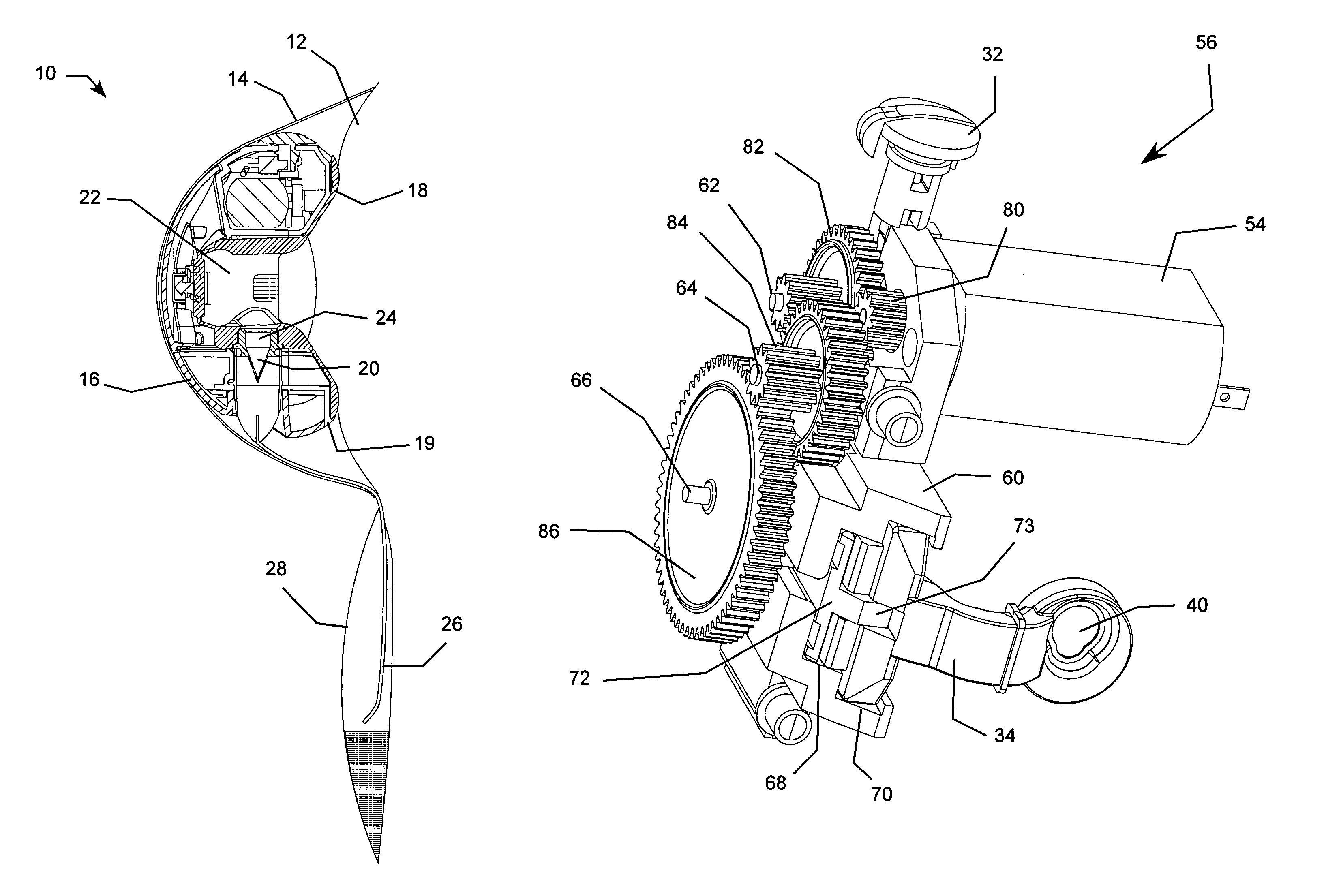

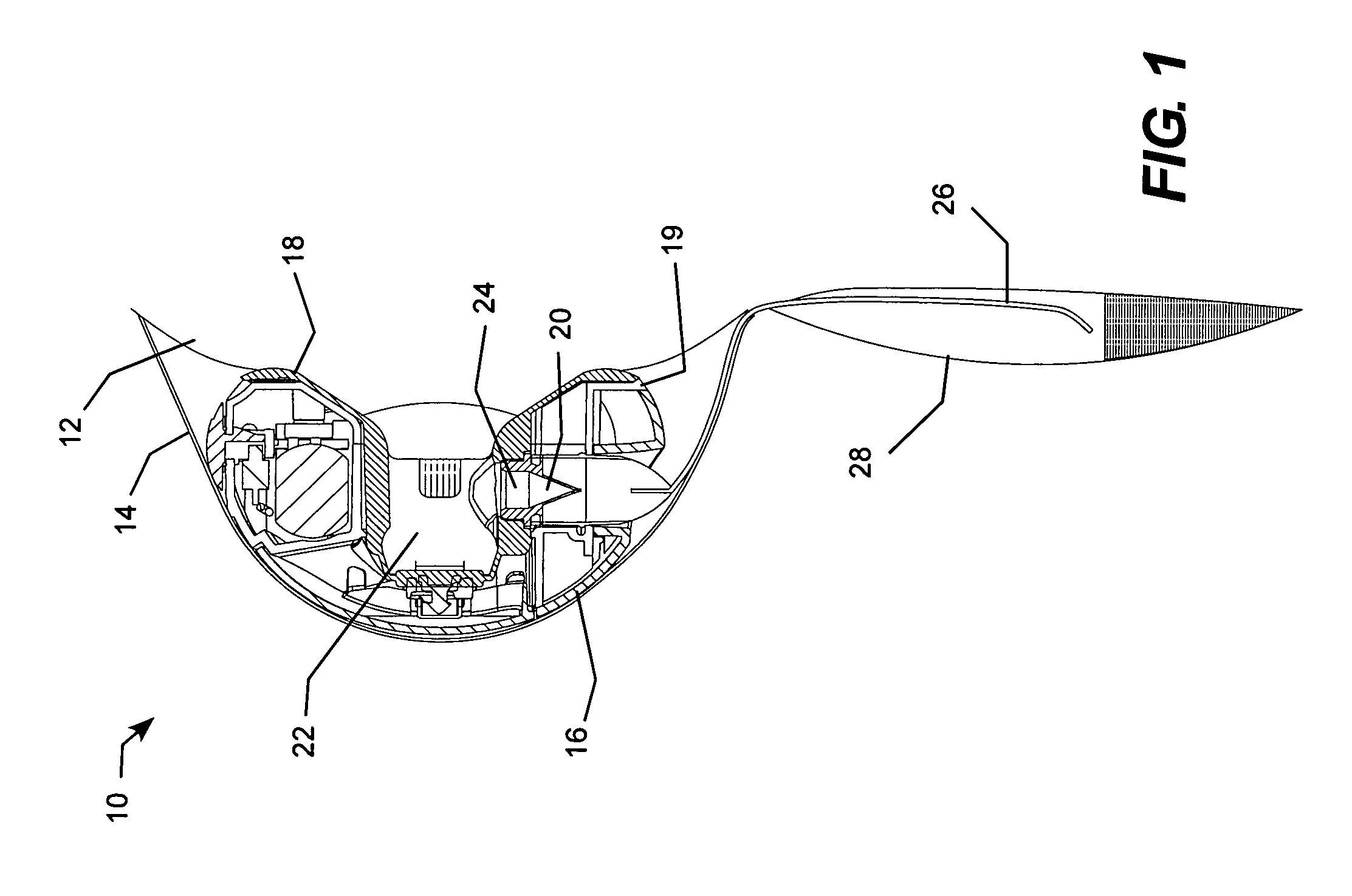

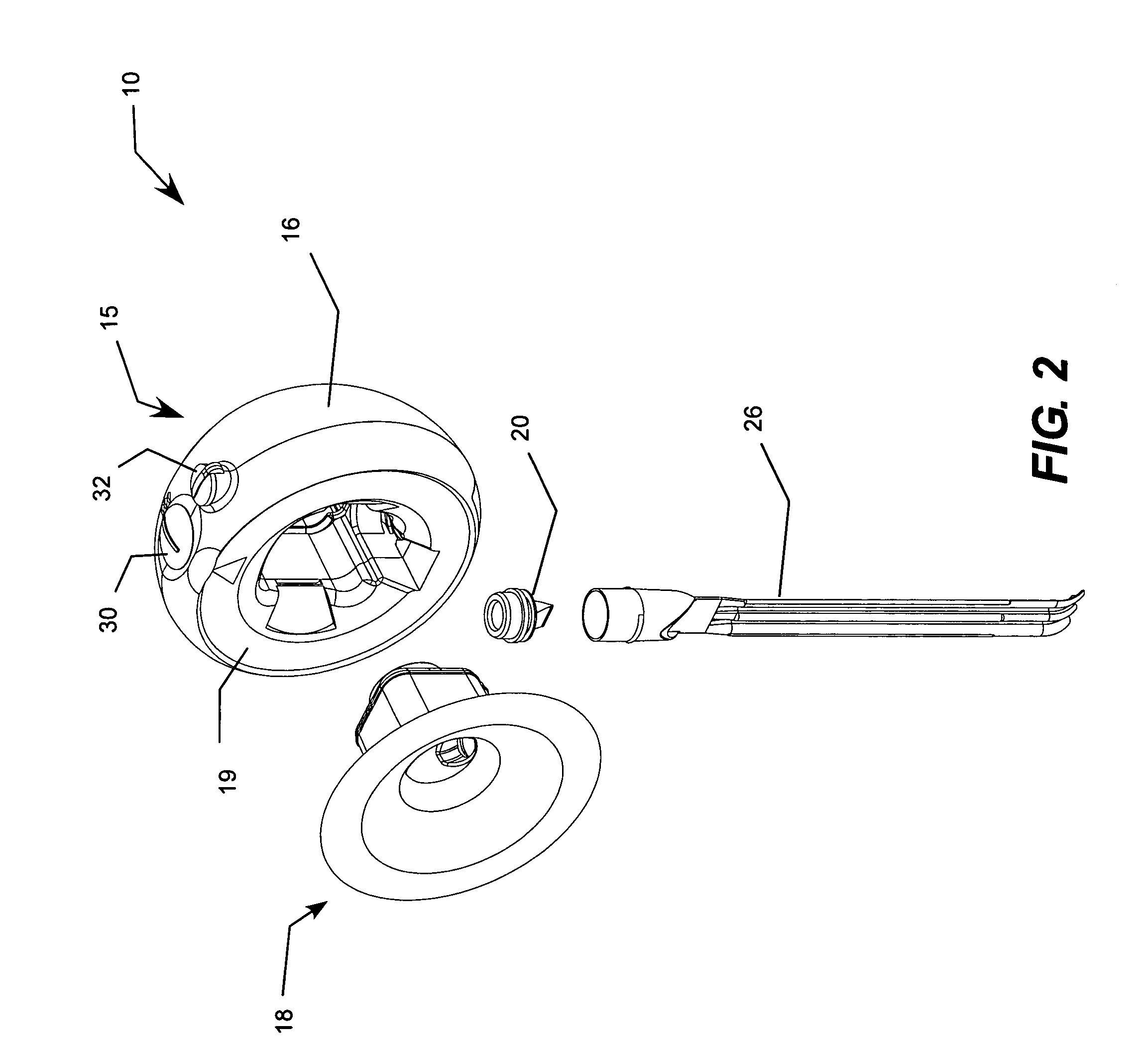

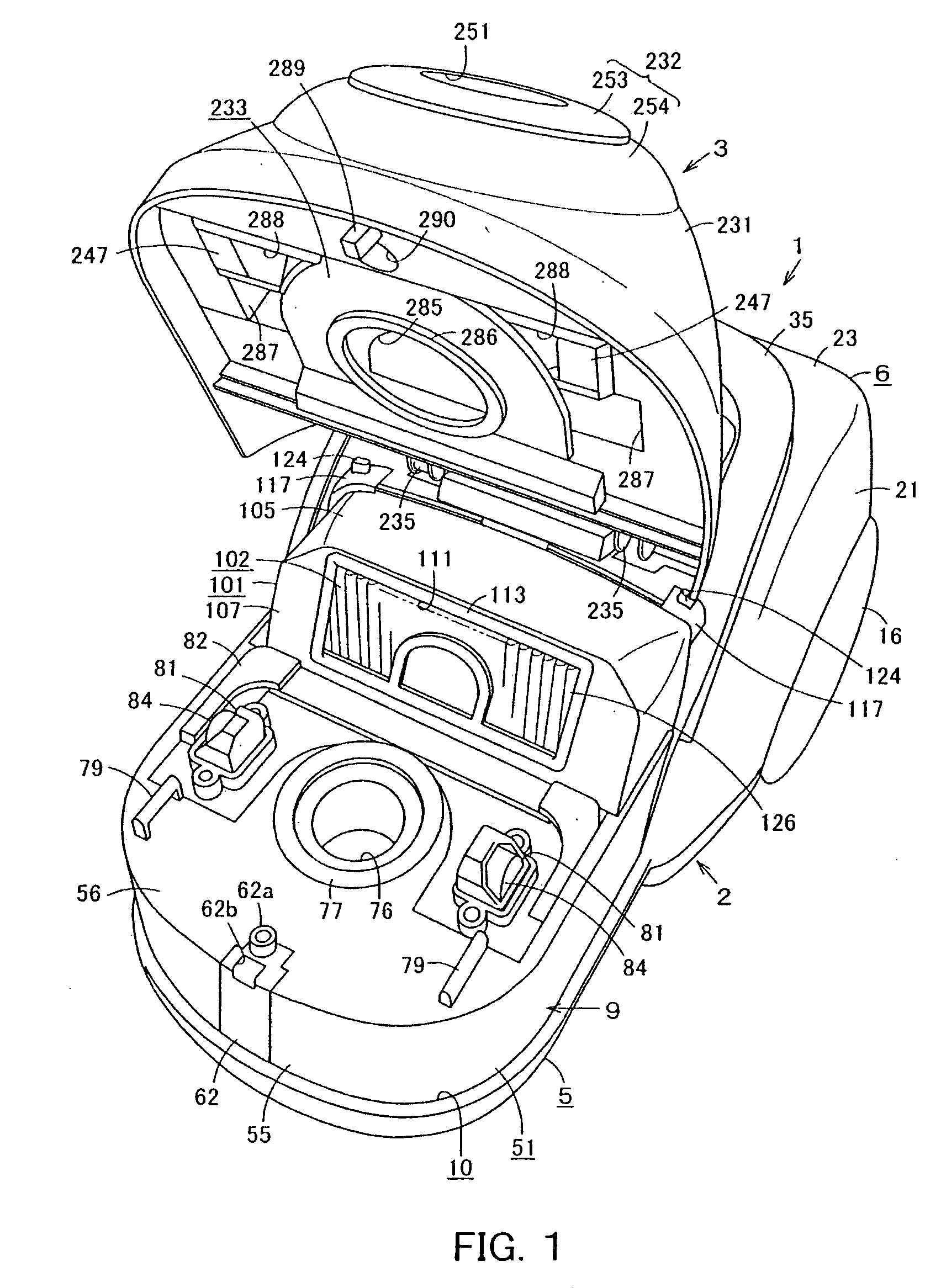

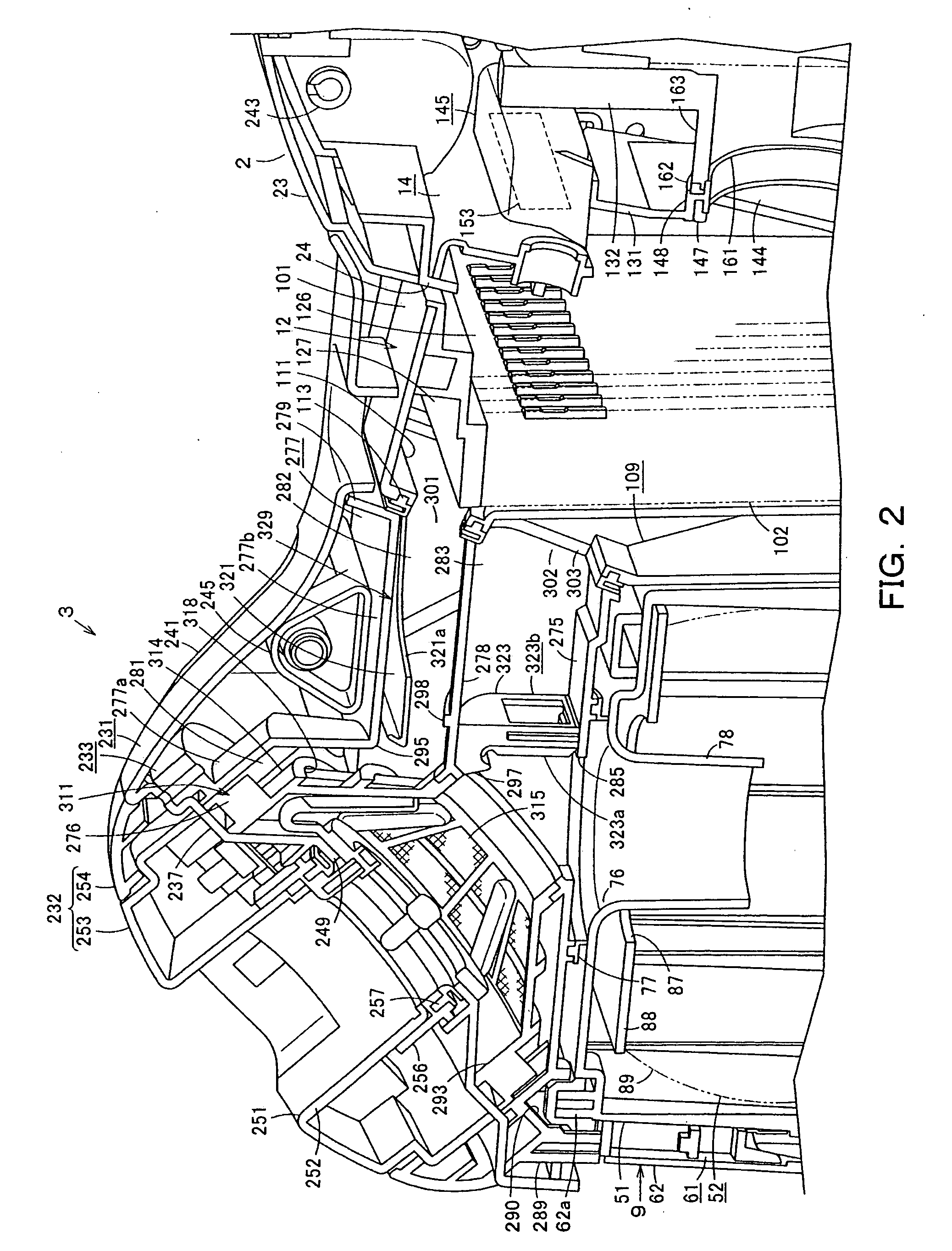

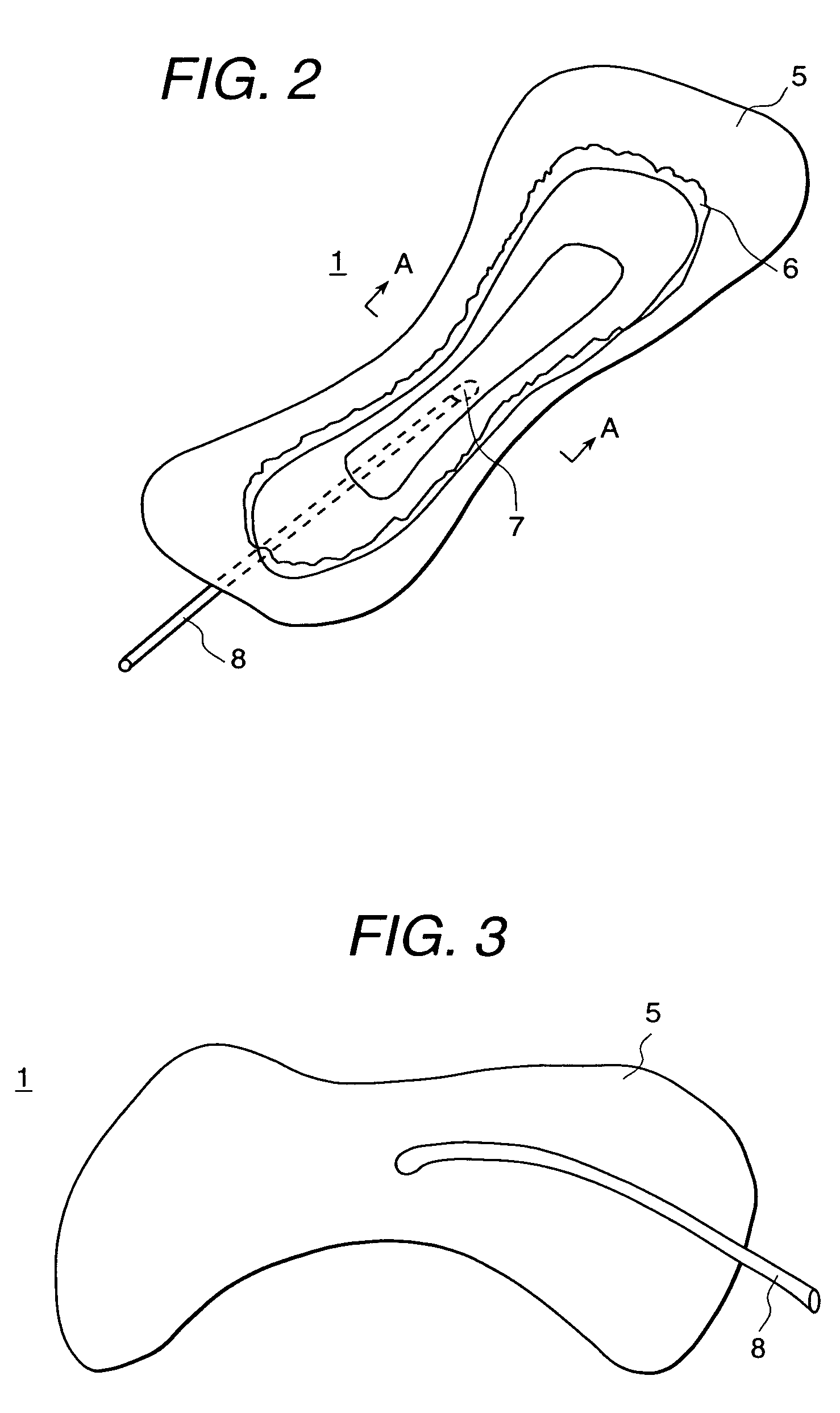

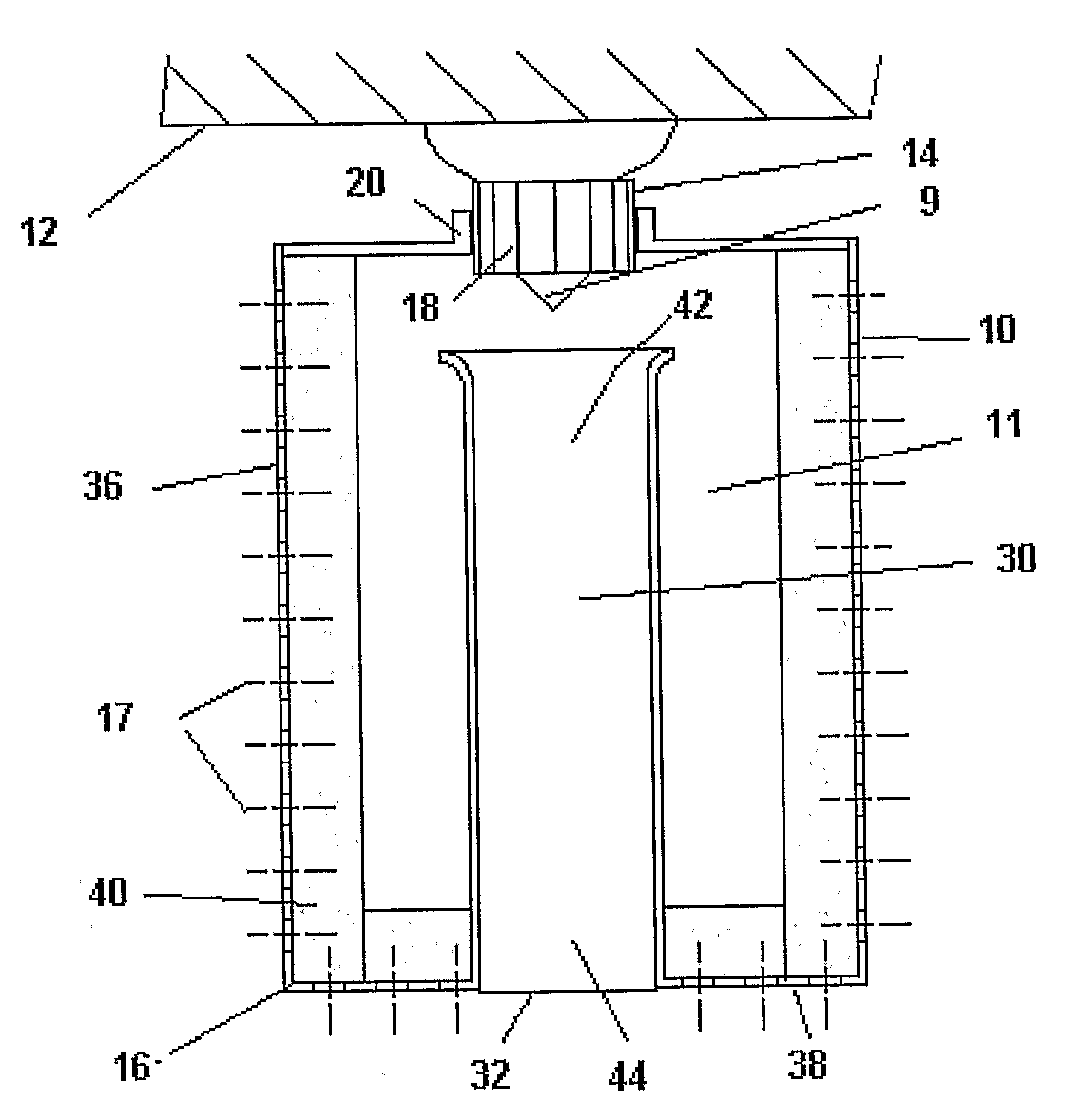

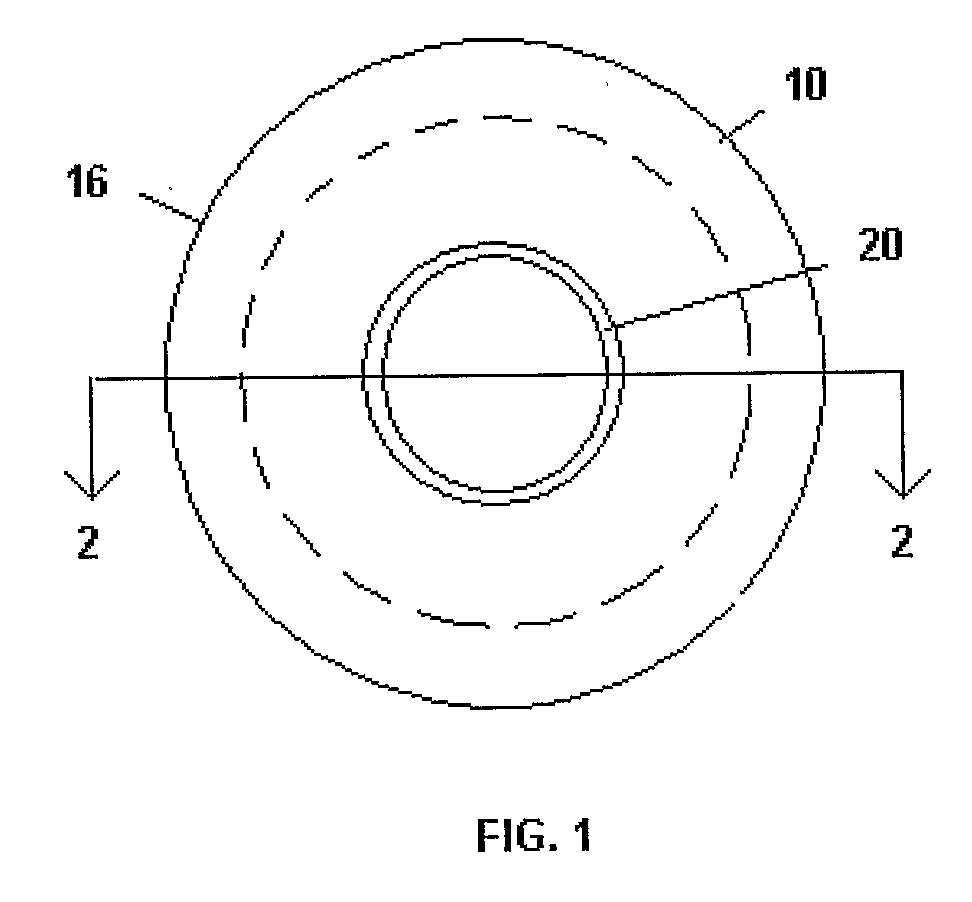

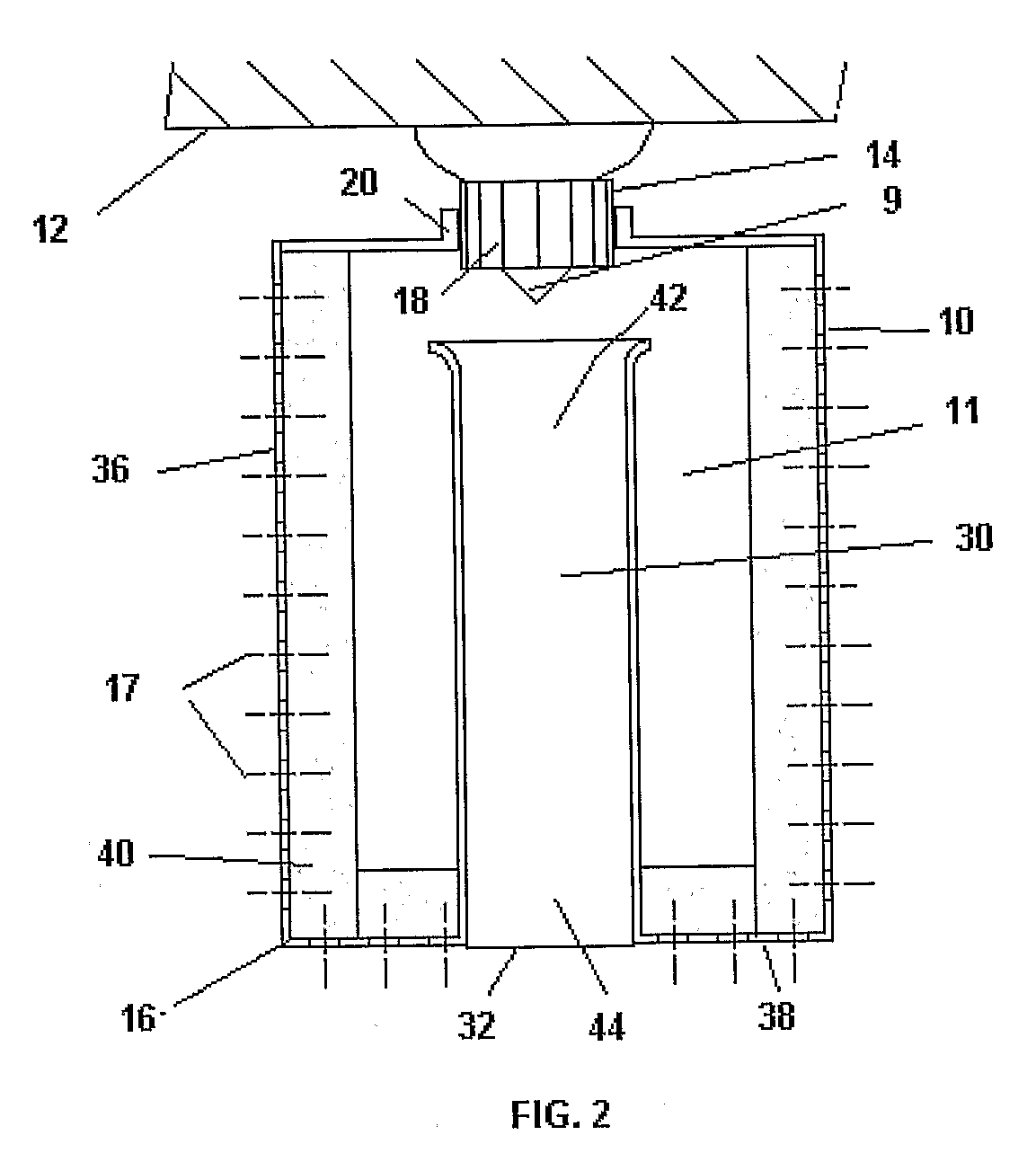

Hands-free breast pump with balanced reciprocating drive

ActiveUS20080275386A1Lower the volumeTotal current dropMilking pumpMedical devicesPush pullHands free

A hands-free breast pump that includes a balanced push-pull reciprocating drive system that applies pumping force to a vacuum chamber formed by a breast interface cup during inward and outward pump strokes. The breast pump includes a breast cup that has a resilient bellows structure that partially collapses the volume of the vacuum chamber during the inward stroke and recovers the volume of the vacuum chamber during the outward stroke. The pump mechanism includes a cam drive system that translates rotary electric motor power into reciprocating linear action of an actuator arm that drives the bellows structure. The bellows structure acts like a spring that charges (resists the pump force) during the inward stroke and discharges (assists the pump force) during the outward stroke, and the shape of the cam track is designed to produce a desired operating profile for the pump.

Owner:MEDELA HLDG AG

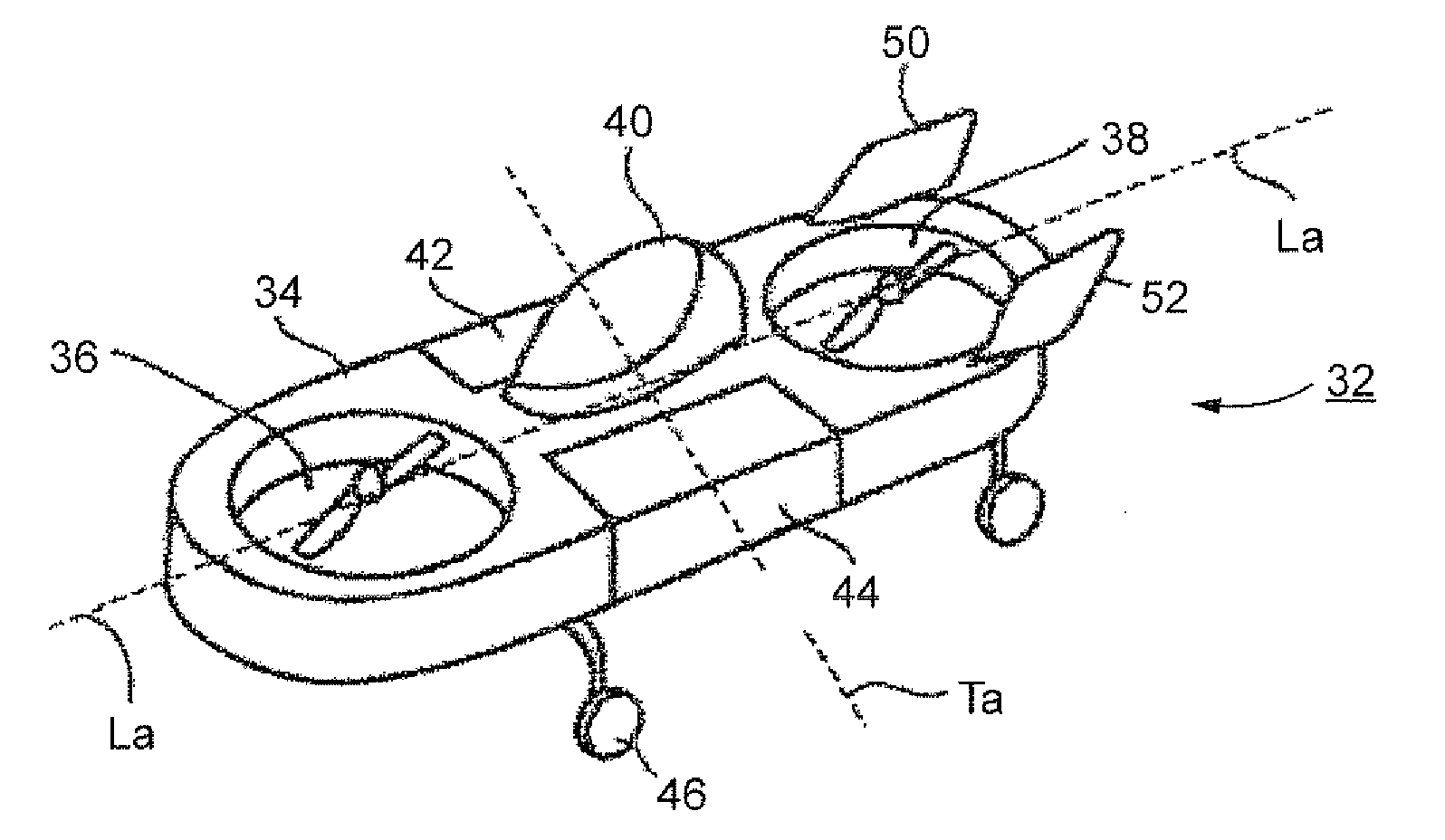

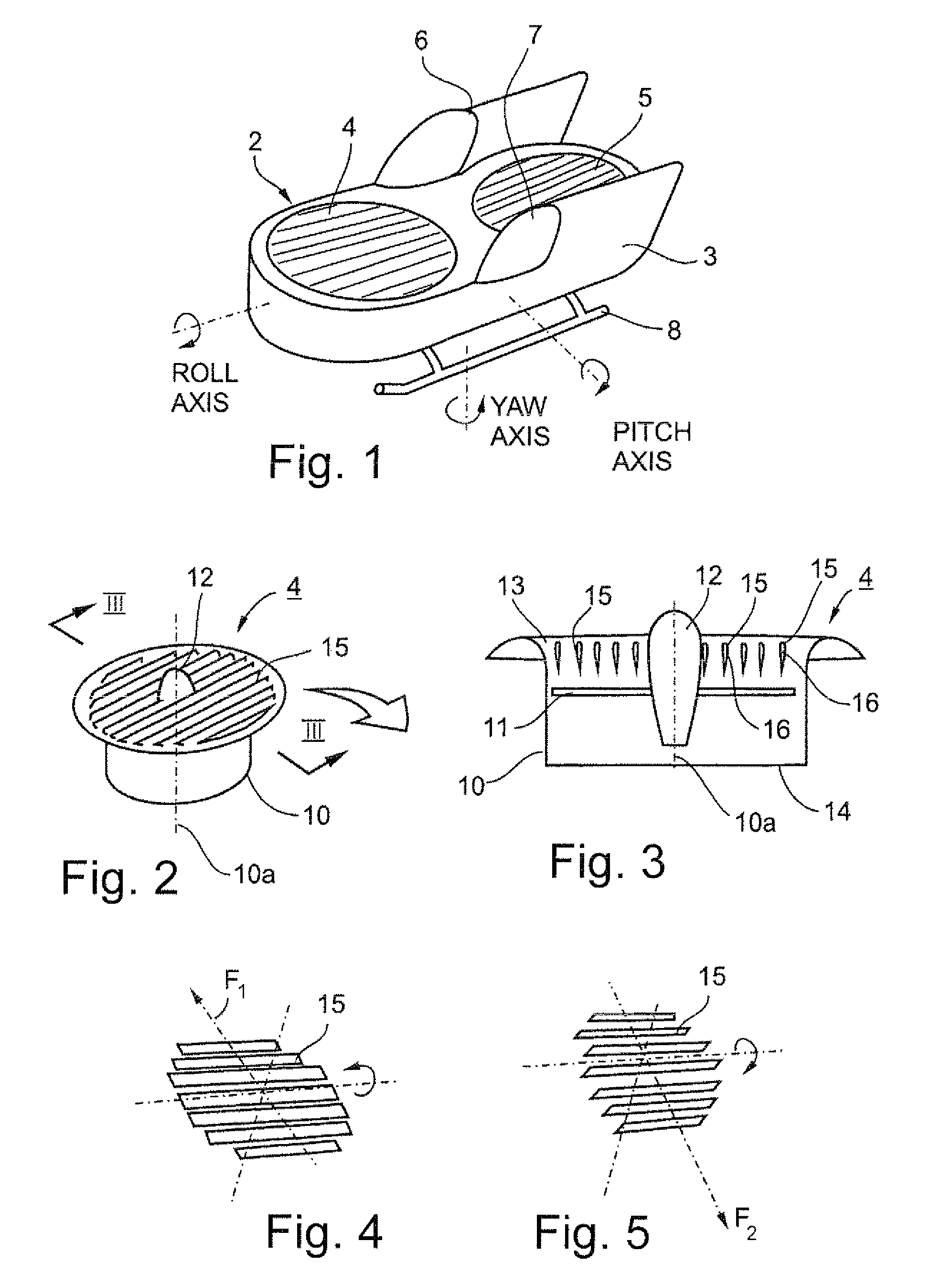

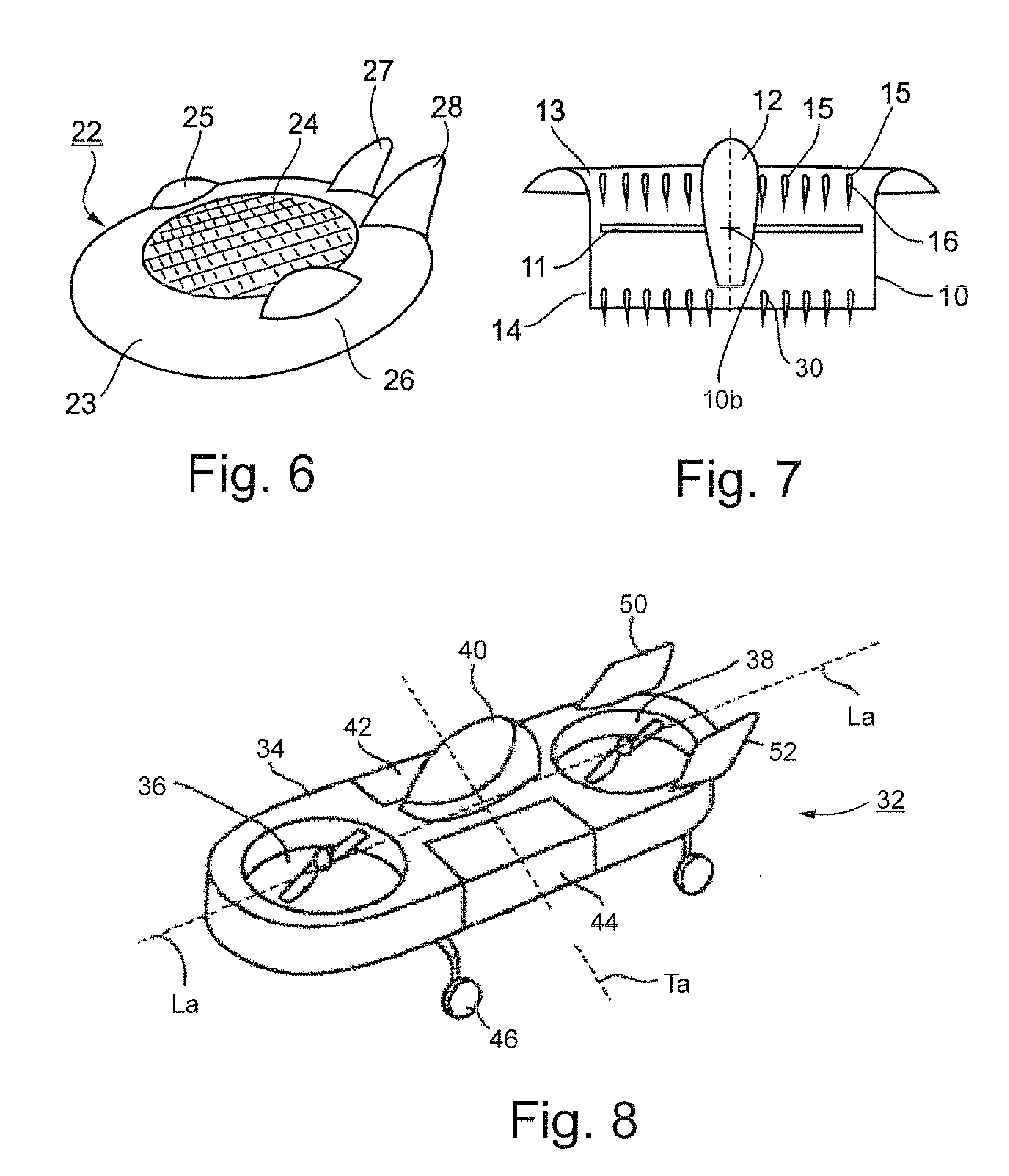

Redundancies and flows in vehicles

InactiveUS20100270419A1Efficient flightReduce suctionSynchronous generatorsAircraft navigation controlControl powerIn vehicle

A control system for a vehicle having plural control elements actuated at a single actuation point including a redundant electric actuator assembly including a control rod moveable linearly in two opposite directions mounting n electric motors, each motor having a controller and a feedback sensor for controlling linear movement of said rod, each motor contributing approximately 1 / n of total control power required for adjusting one or more of said plural control elements, such that failure of any of said motors controllers or feedback sensors leaves sufficient predetermined minimum control power available for operating said control system.

Owner:URBAN AERONAUTICS

Wound drainage suction relief

InactiveUS8157792B2Avoid obstructionReduce suctionElectrotherapyOther blood circulation devicesWound drainage bagCatheter

In accordance with one embodiment of the invention, there is provided a wound drainage system for draining fluid from a wound of a patient. The system includes a drain catheter. A suction means applies suction at the drain catheter such that fluid is drawn from the wound. While drawing fluid from the wound, a controller periodically increases and decreases the application of suction at the drain catheter. This allows the tissue surrounding the wound drain to relax, thus preventing obstruction of the drain catheter.

Owner:HAEMONETICS

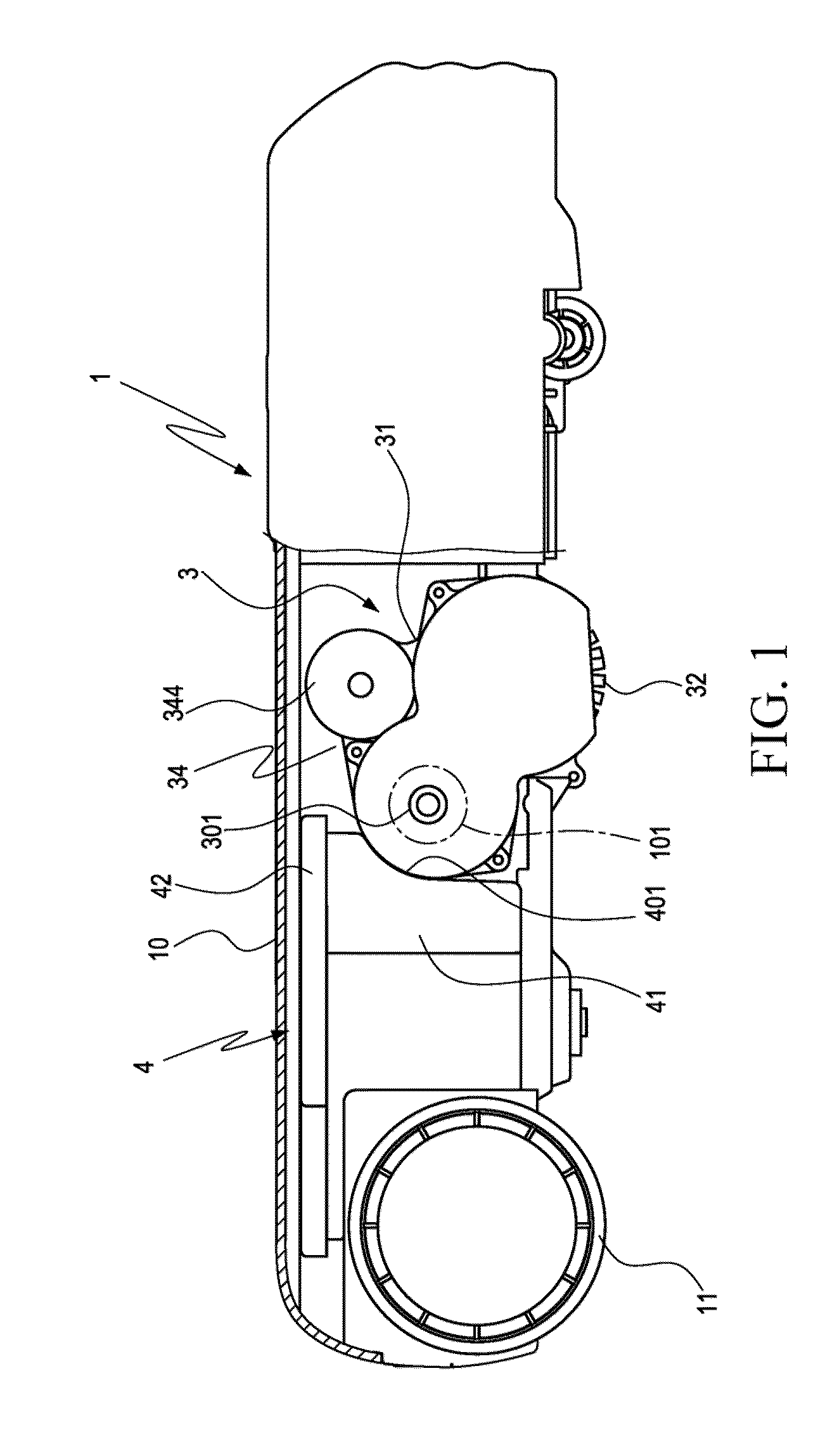

Cleaning device with sweeping and vacuuming functions

ActiveUS7827653B1Reduce suctionReduce noiseCarpet cleanersCleaning action controlPower unitDust collector

A cleaning device with sweeping and vacuuming functions includes a body accommodating a sweep module and a vacuum module. A main brush and an auxiliary brush driven by a power unit are pivoted in the sweep module. The main brush partially extends outside an opening at a bottom of the sweep module and contacts a ground surface. The sweep module has an outlet adjacent to a top of the auxiliary brush, and is pivoted in the body to freely and pivotally swing under weight. A first chamber of a dust collector of the vacuum module has an inlet corresponding to the outlet, and trash removed by the sweep module is collected into the first chamber. An air inlet communicating with an air intake component is formed above a second chamber of the dust collector. A suction port is formed below the second chamber to draw dust into the second chamber.

Owner:MATSUTEK ENTERPRISES

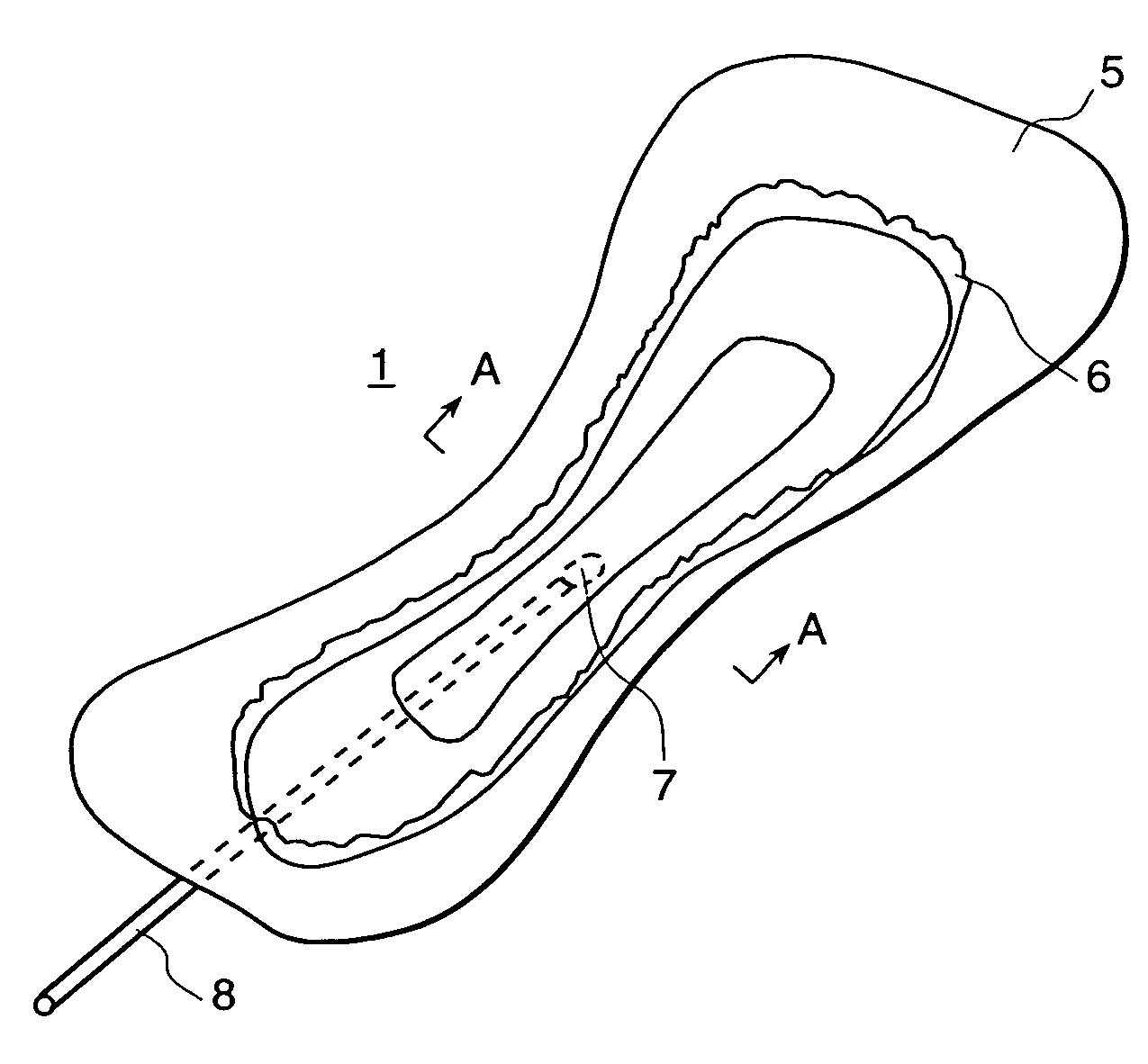

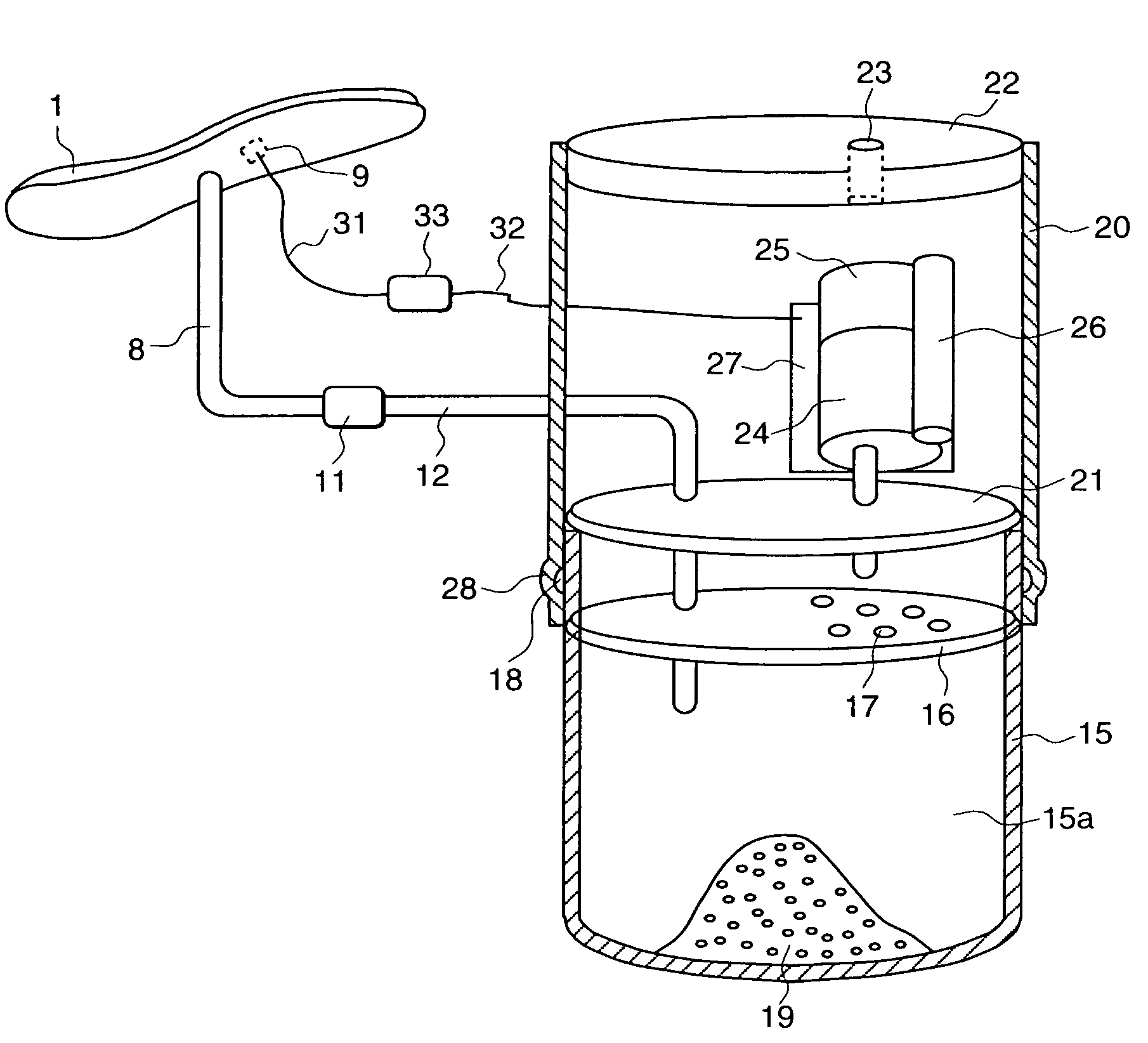

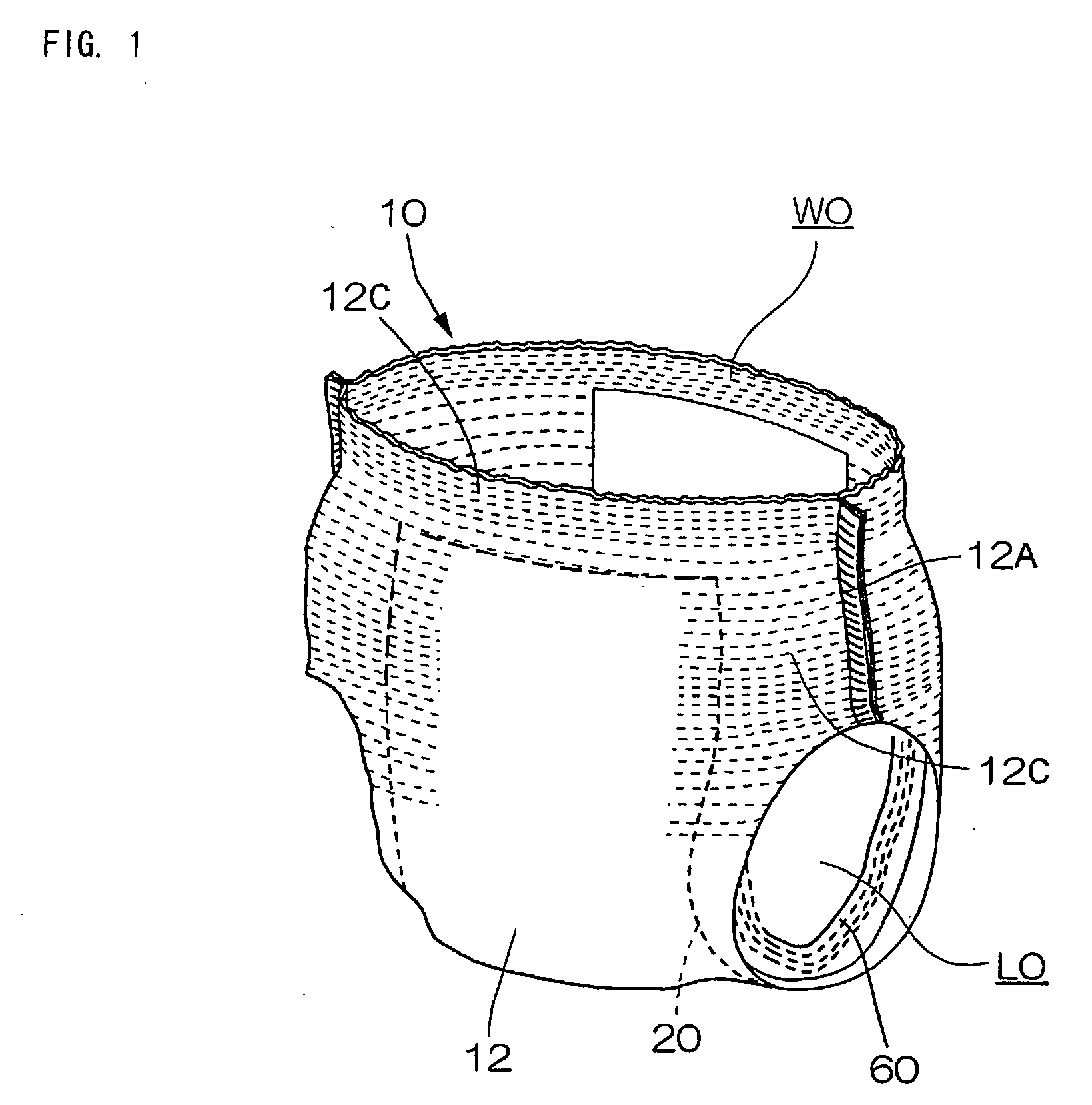

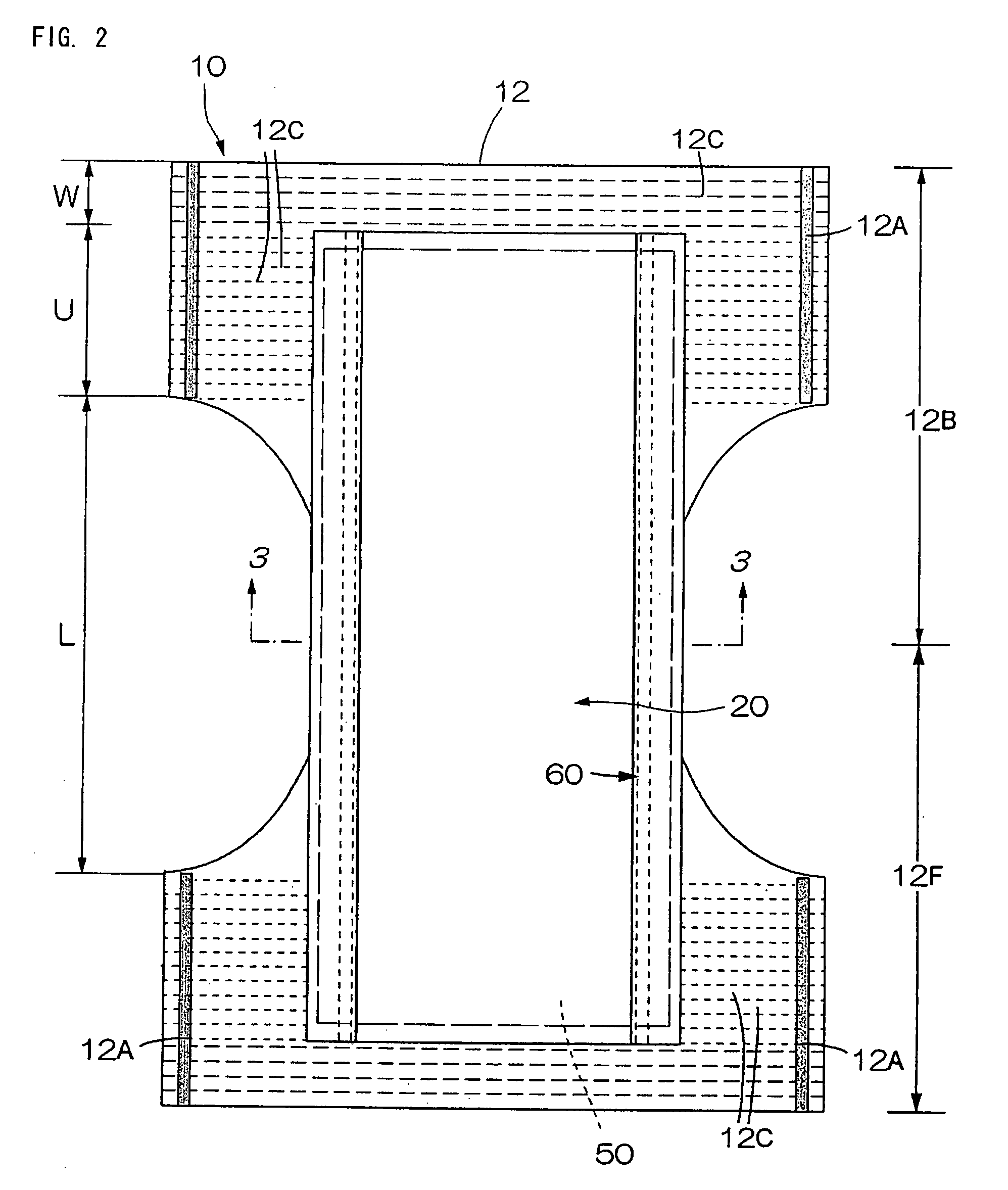

Automatic urine disposal device and urine receptacle used therefor

InactiveUS20050033248A1Increase percentagePercentage of urine collection from the urine collecting padBathroom accessoriesNon-surgical orthopedic devicesUrine productionDrainage tubes

An automatic urine disposal device has a urine collecting pad, vacuum pump, and urine tank. In the urine collecting pad, the top sheet comes in contact with the wearer's skin, the hydrophilic sheet is disposed on the bottom of the top sheet, and the urine absorbent sheet is disposed at the bottom. When discharged urine flows in the top sheet, the hydrophilic sheet widely diffuses urine to saturate its entire surface and then becomes non-breathable. As the vacuum pump vacuums the air from the urine tank, urine is directed from a urine drainage port of the urine collecting pad via a urine drainage tube to the urine tank which is a sealed container.

Owner:HITACHI LTD +1

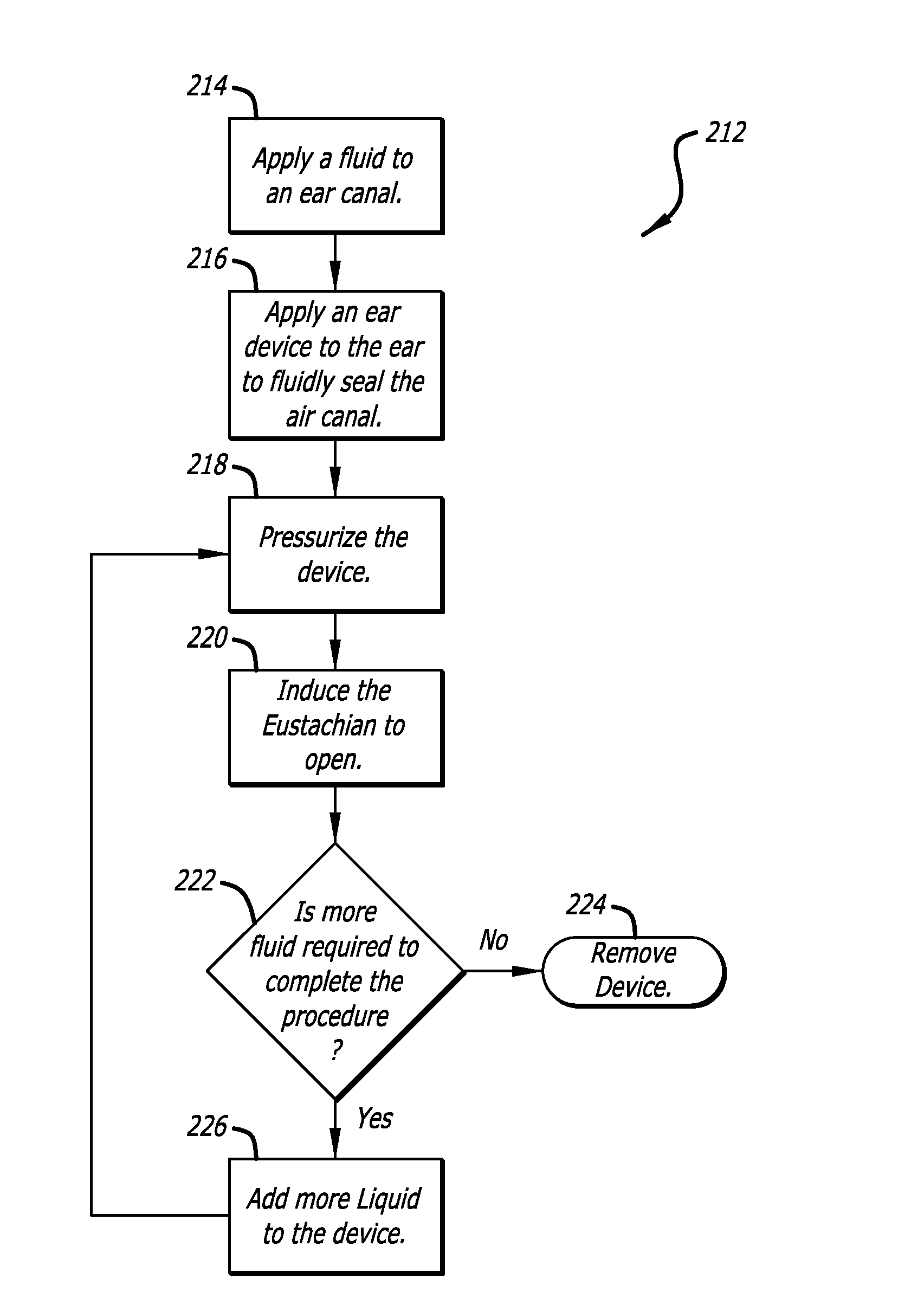

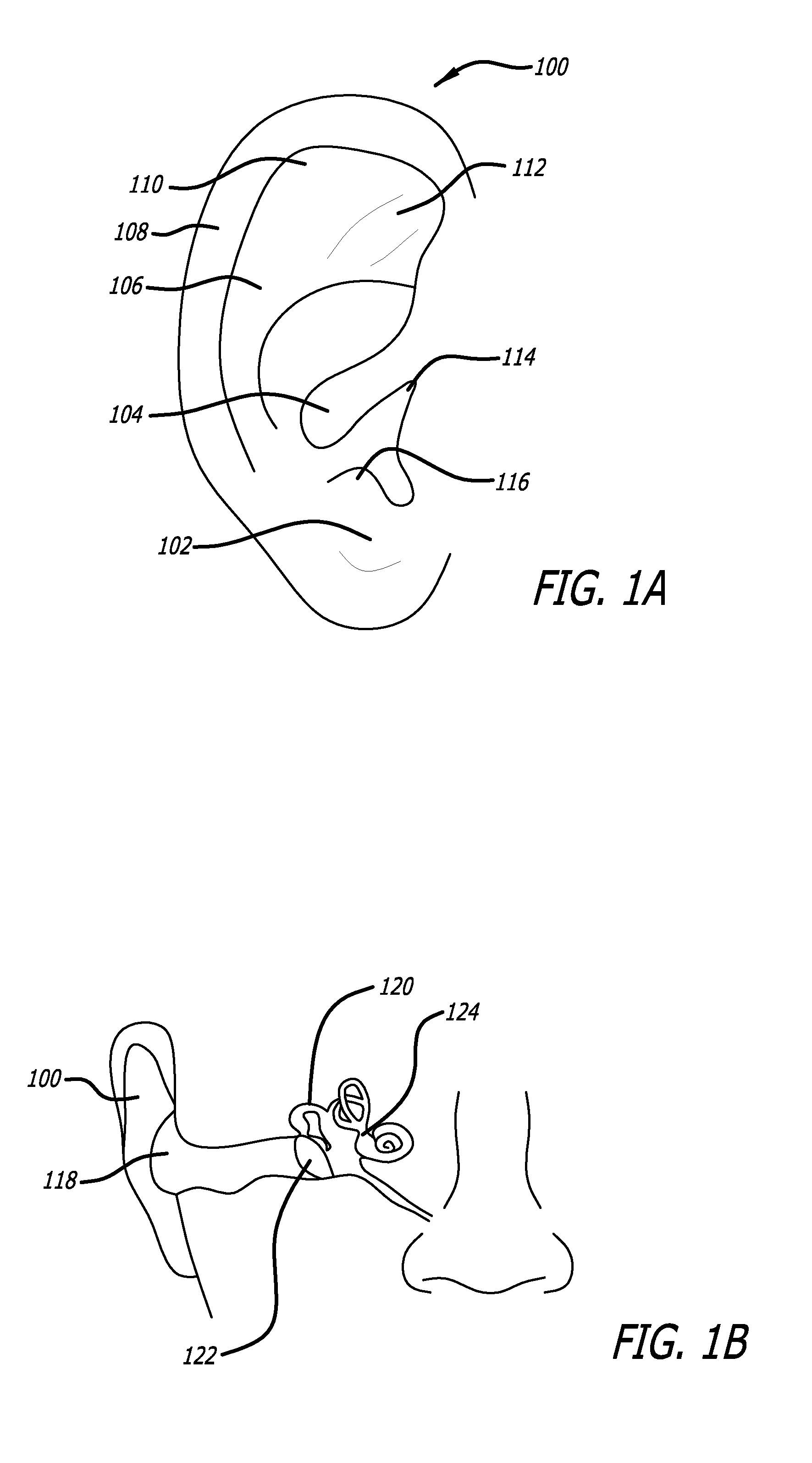

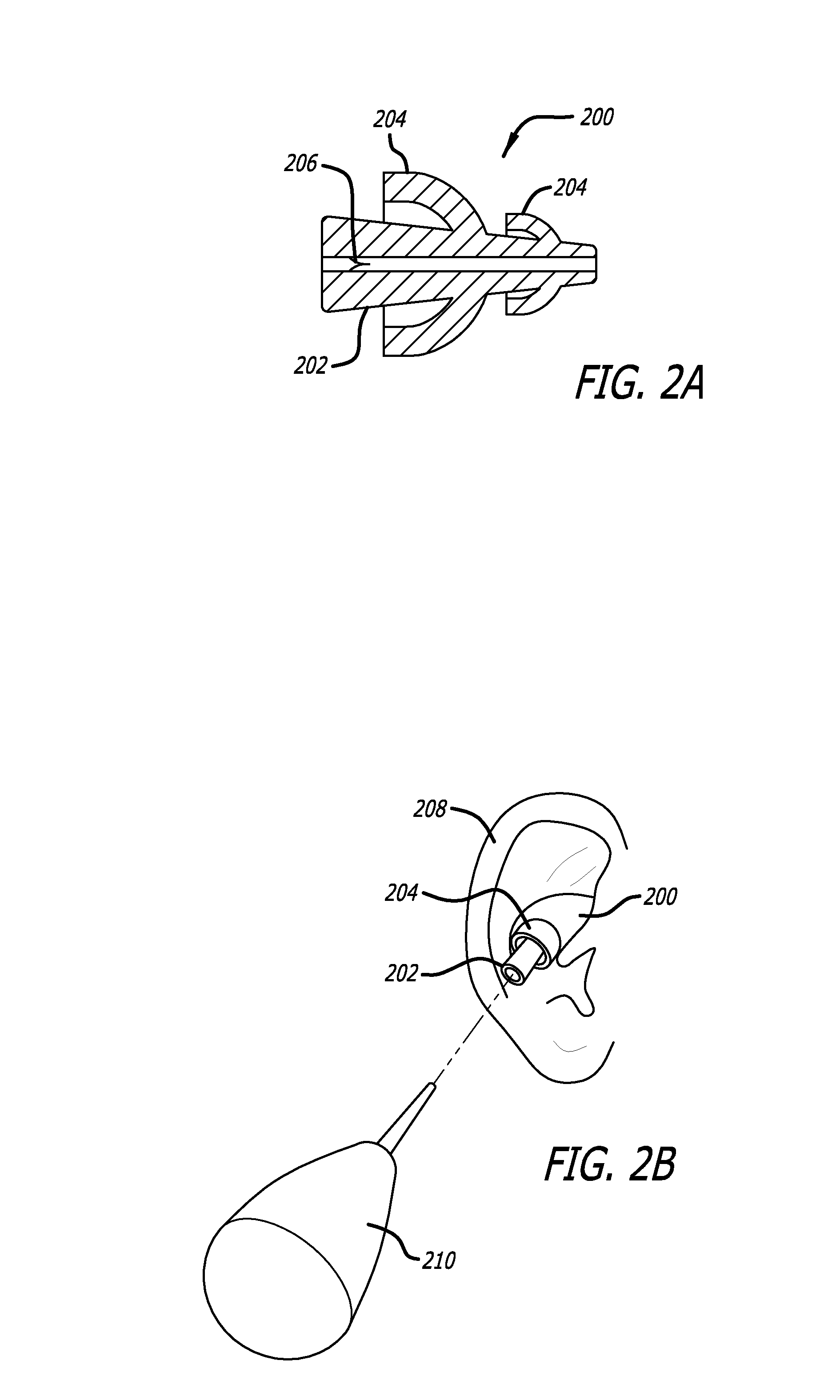

Silent Effusion Removal

ActiveUS20100217296A1Reduce noiseReduce suctionEar treatmentCannulasEffusionPERFORATED TYMPANIC MEMBRANE

A method is disclosed for clearing effusion from an ear. The method may include applying liquid to an ear canal, which is proximal to a perforated tympanic membrane, which is proximal to a middle ear containing effusion, applying an ear device to seal and pressurize the liquid inside the ear canal, the ear device regulating the amount of pressure inside the ear canal, and inducing a Eustachian tube, which is distal to the middle ear, to open, which causes the fluid to displace the effusion into the Eustachian tube.

Owner:ACCLARENT INC

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

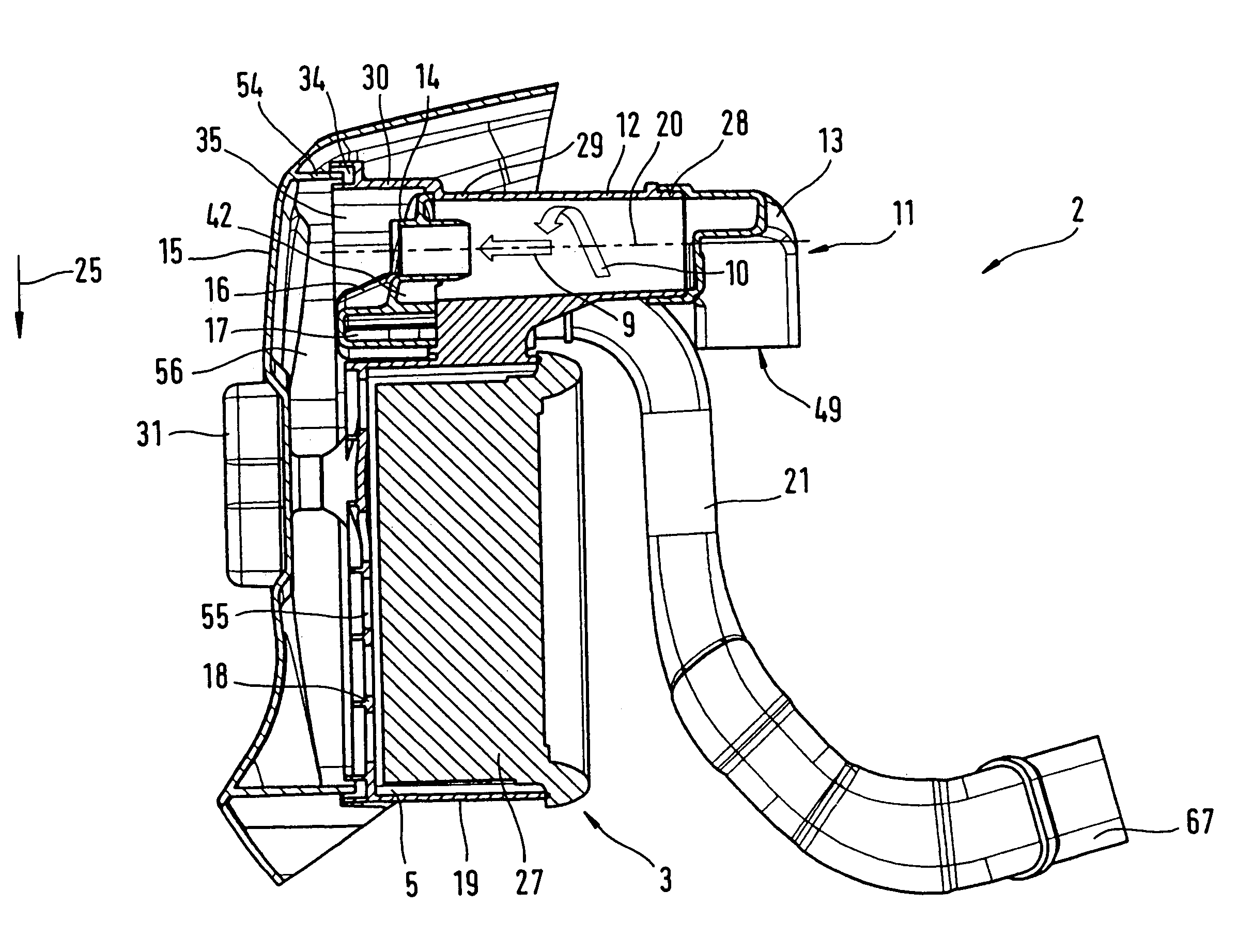

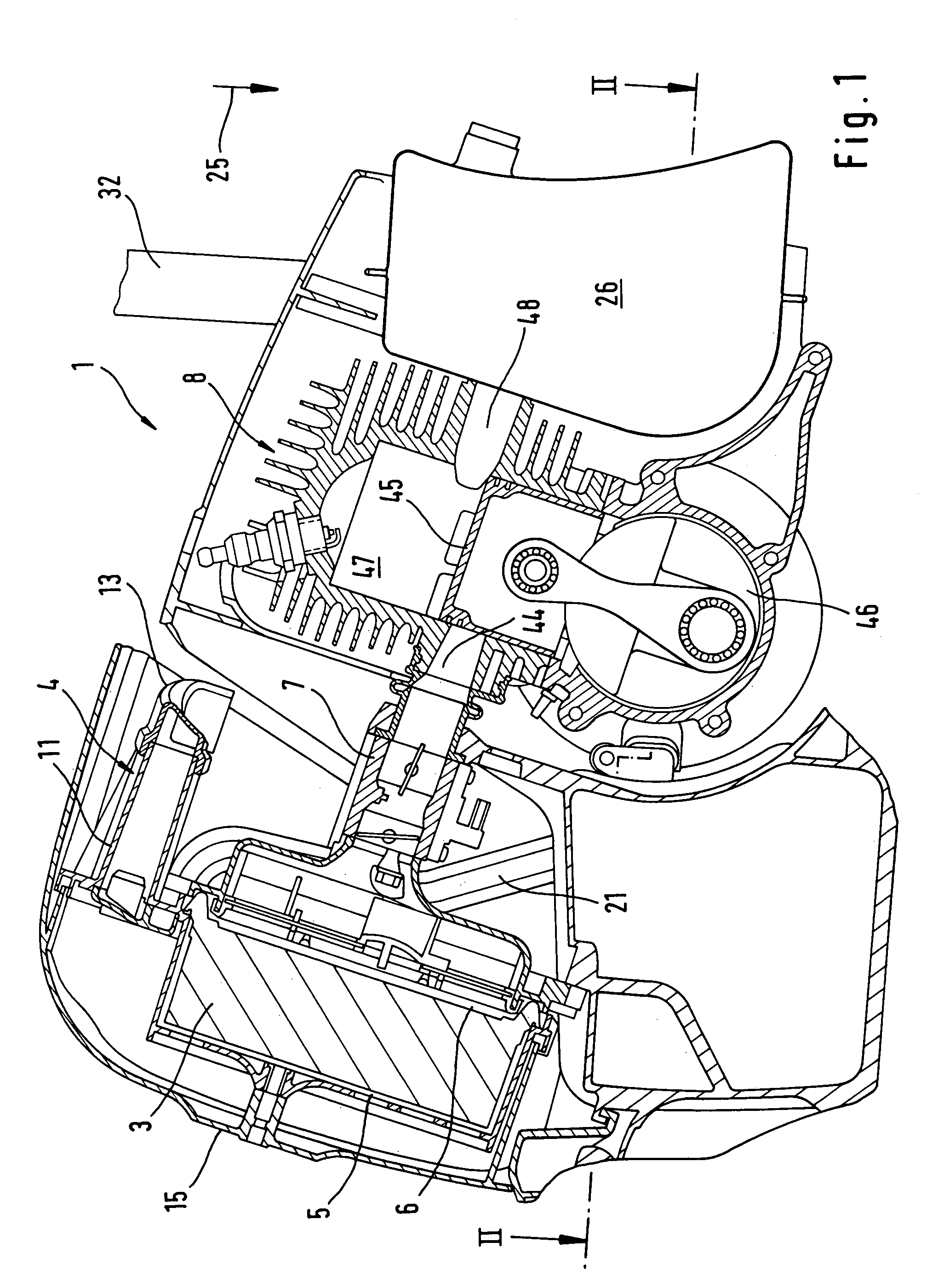

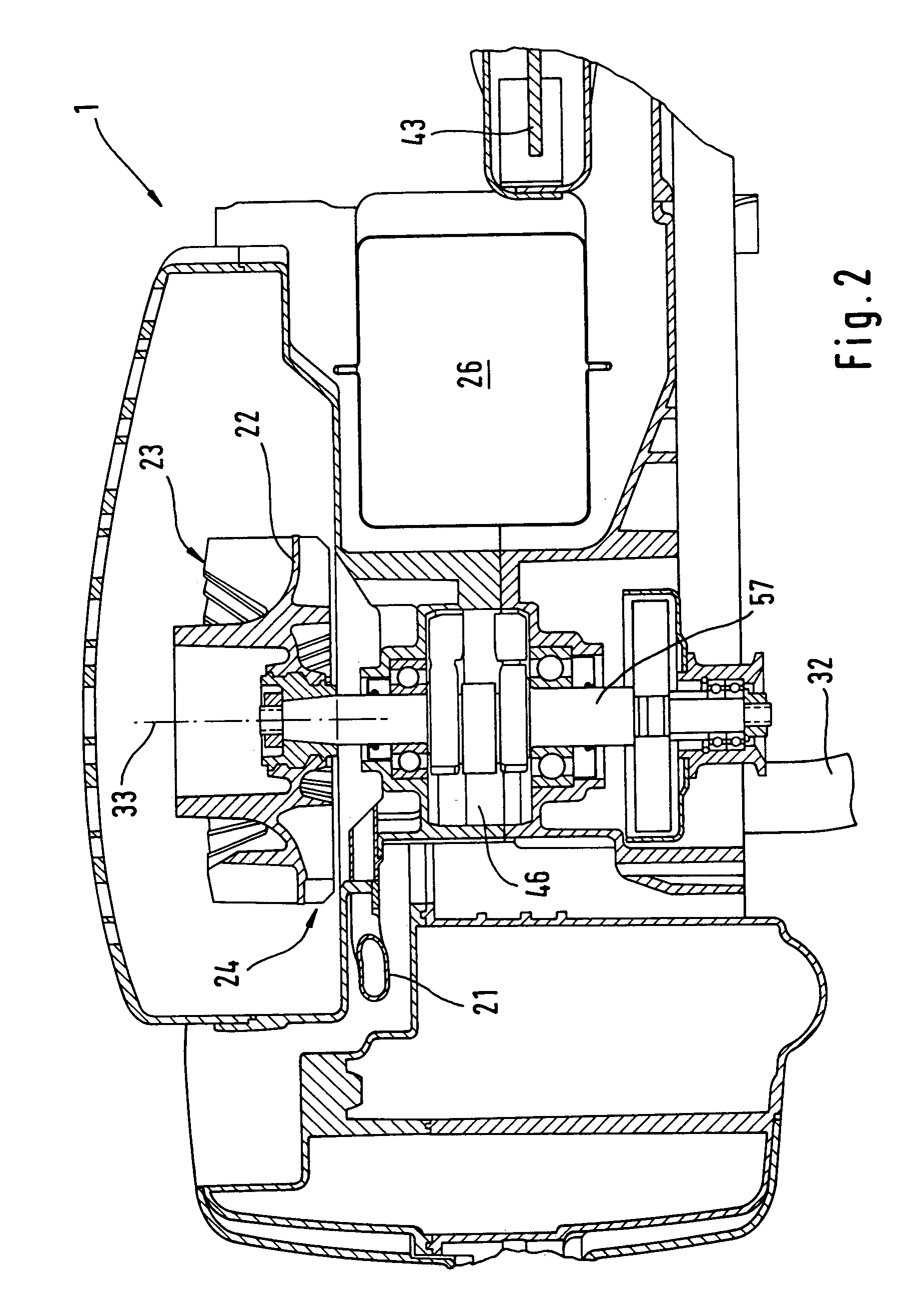

Intake system

An intake system for the combustion air of a motor of a hand held implement is provided. The system includes an air filter and a centrifugal separator. The air filter has a dirt chamber and a clean chamber that is separated therefrom by a filter medium. The clean chamber is fluidically connected with a carburetor of the motor to convey combustion air to the motor. The centrifugal separator splits the air stream into a core flow having low particle density and a peripheral flow having high particle density. The centrifugal separator includes at least two cyclones, wherein the discharged flows from the cyclones are respectively combined in pairs and open out into a common suction tube.

Owner:ANDREAS STIHL AG & CO KG

Hands-free breast pump with balanced reciprocating drive

A hands-free breast pump that includes a balanced push-pull reciprocating drive system that applies pumping force to a vacuum chamber formed by a breast interface cup during inward and outward pump strokes. The breast pump includes a breast cup that has a resilient bellows structure that partially collapses the volume of the vacuum chamber during the inward stroke and recovers the volume of the vacuum chamber during the outward stroke. The pump mechanism includes a cam drive system that translates rotary electric motor power into reciprocating linear action of an actuator arm that drives the bellows structure. The bellows structure acts like a spring that charges (resists the pump force) during the inward stroke and discharges (assists the pump force) during the outward stroke, and the shape of the cam track is designed to produce a desired operating profile for the pump.

Owner:MEDELA HLDG AG

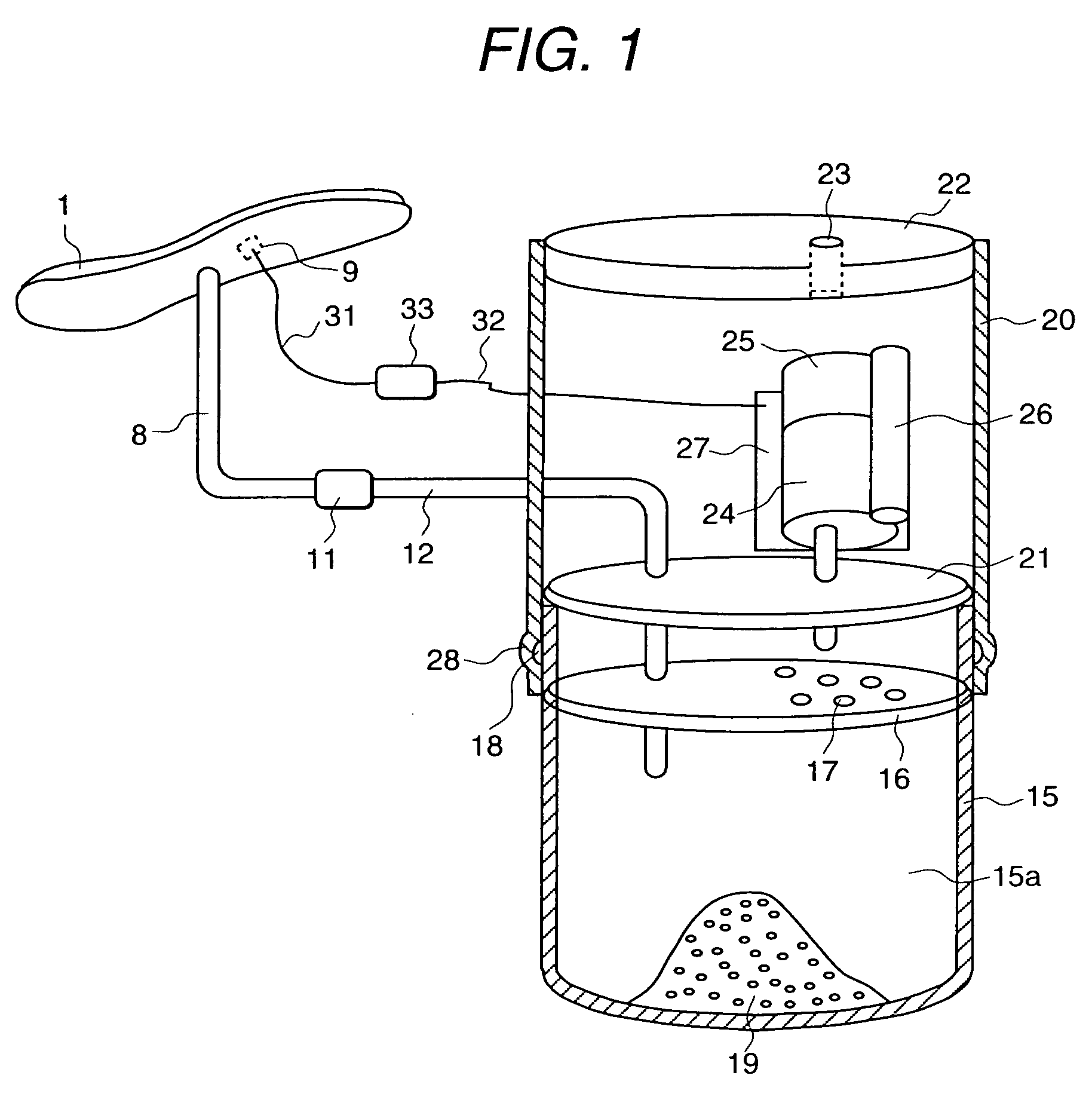

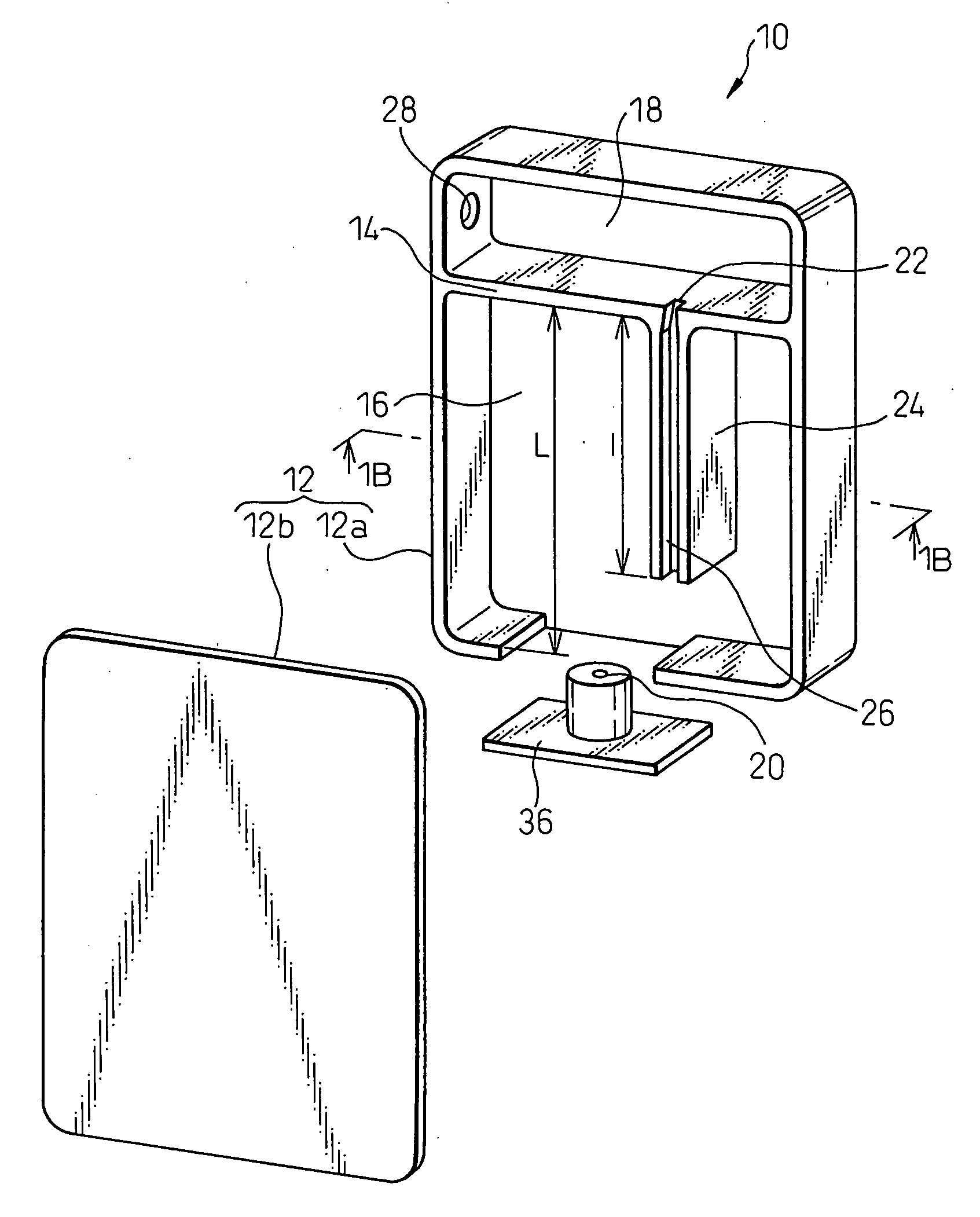

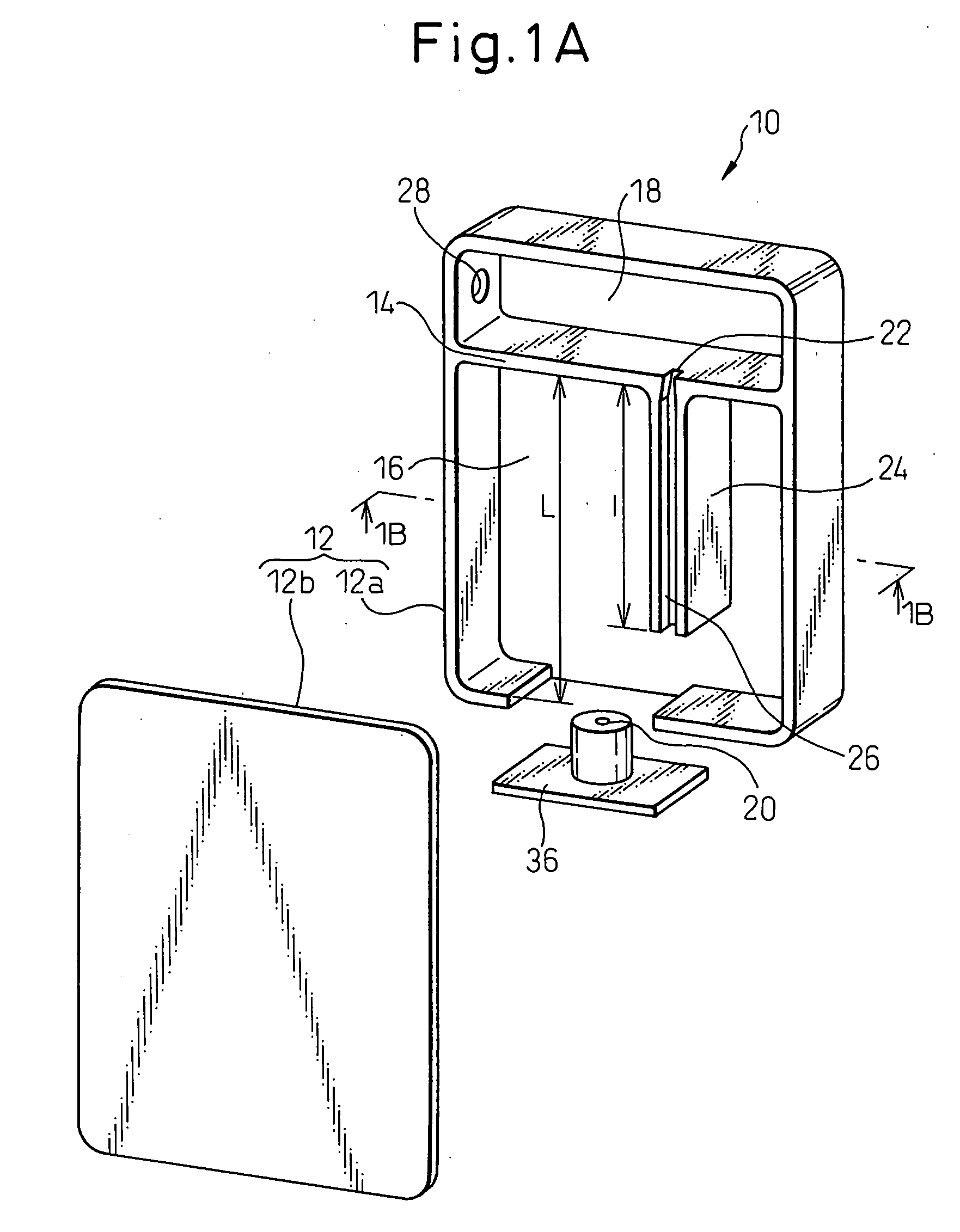

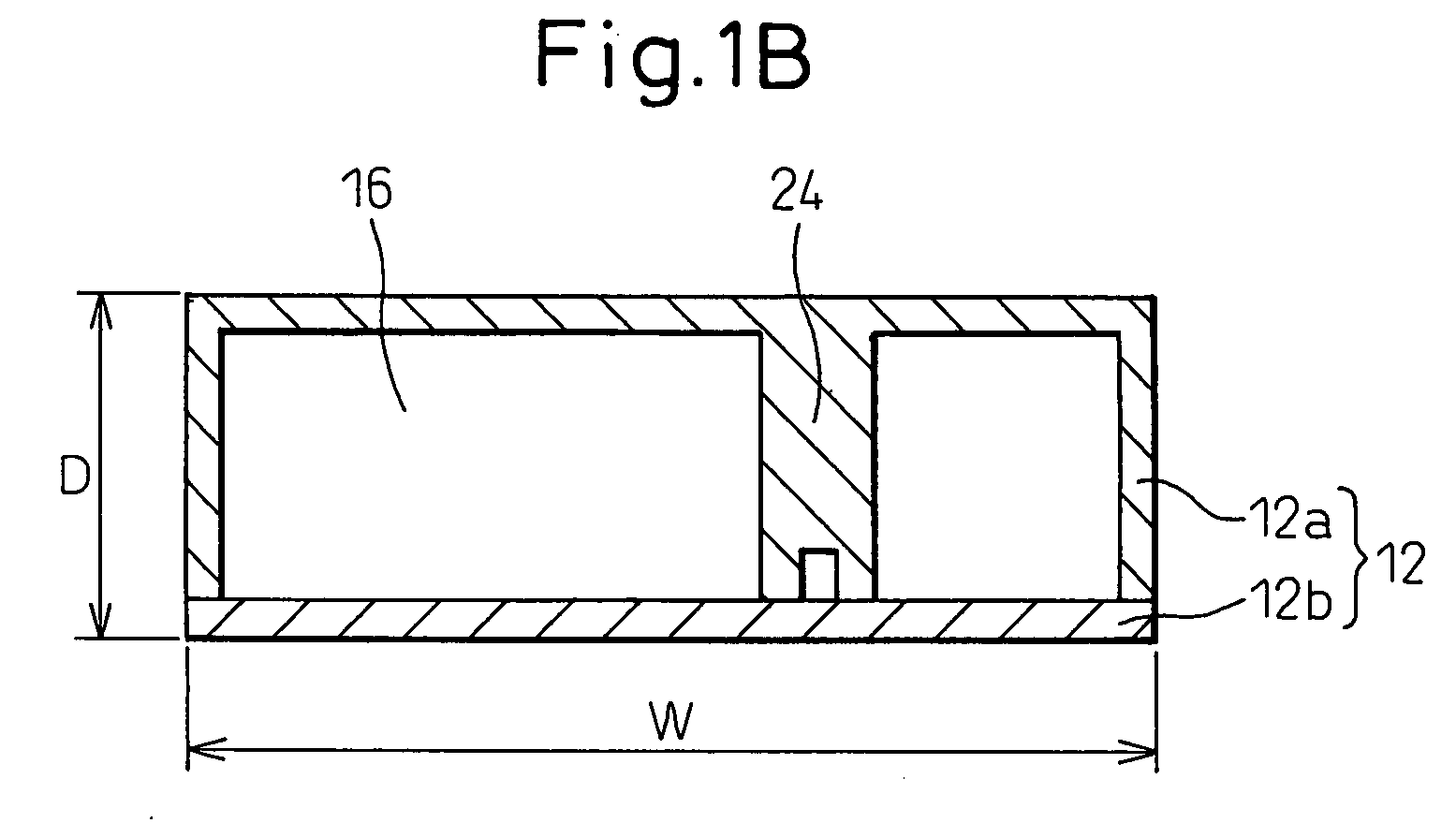

Silencer and oxygen concentrator having silencer

InactiveUS20090025564A1Dead space is minimizedReduce thicknessRespiratorsCombination devicesEngineeringExpansion chamber

Provided are an expansion-type silencer (10) including a substantially rectangular parallelepiped-shaped expansion chamber (16) surrounded by six partition walls and having a suction port (20) and an exhaust port (22) which are formed in the partition walls, and an oxygen concentrator using the expansion-type silencer (10). The expansion-type silencer (10) has a rib (24) extending from one of the partition walls of the expansion chamber (16) formed with the exhaust port (22) toward the interior of the expansion chamber (16) while being in contact with both of a pair of parallel partition walls adjacent to the one of partition walls. The rib (24) is formed with an air passage (26) for providing communication between the exhaust port (22) and the expansion chamber (16).

Owner:TEIJIN PHARMA CO LTD

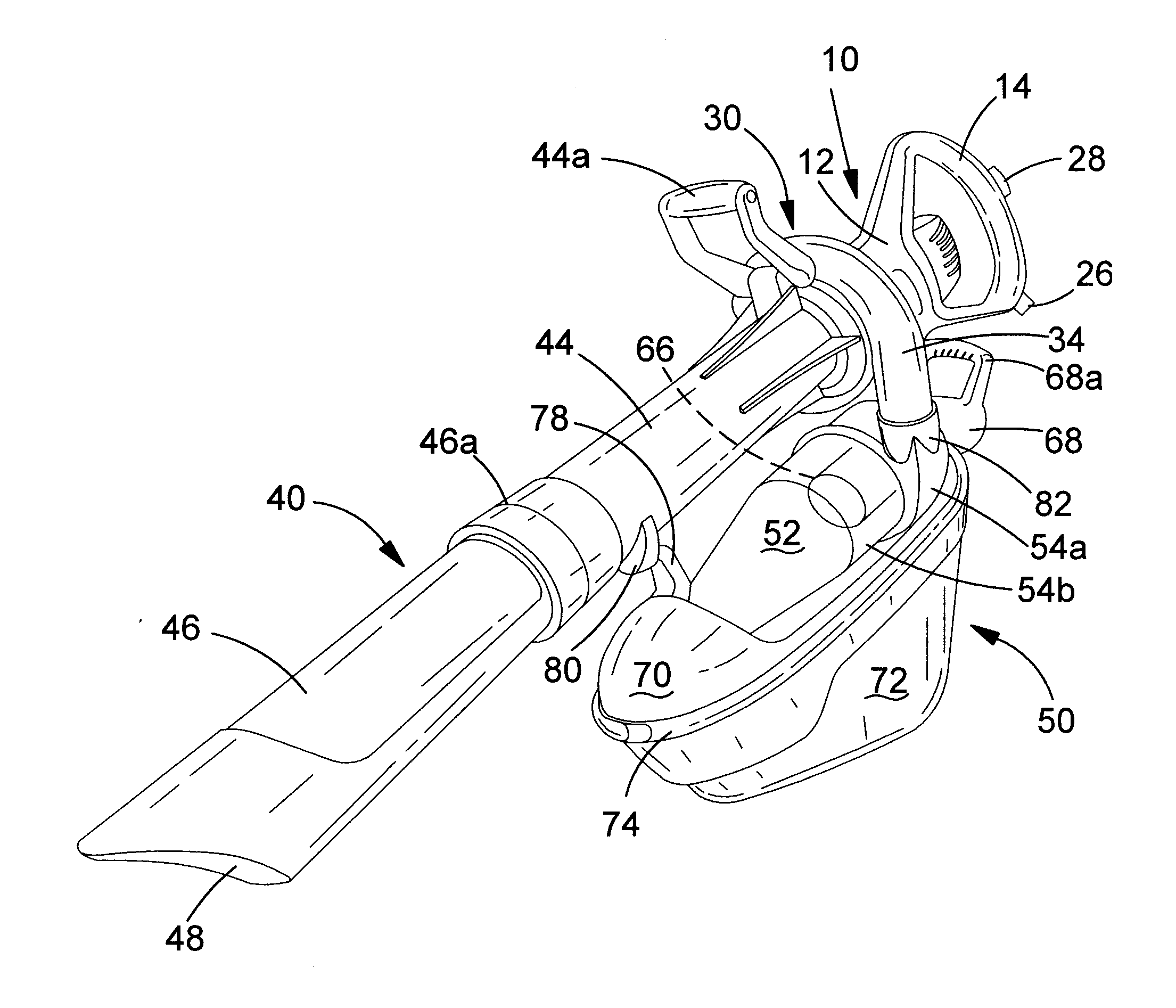

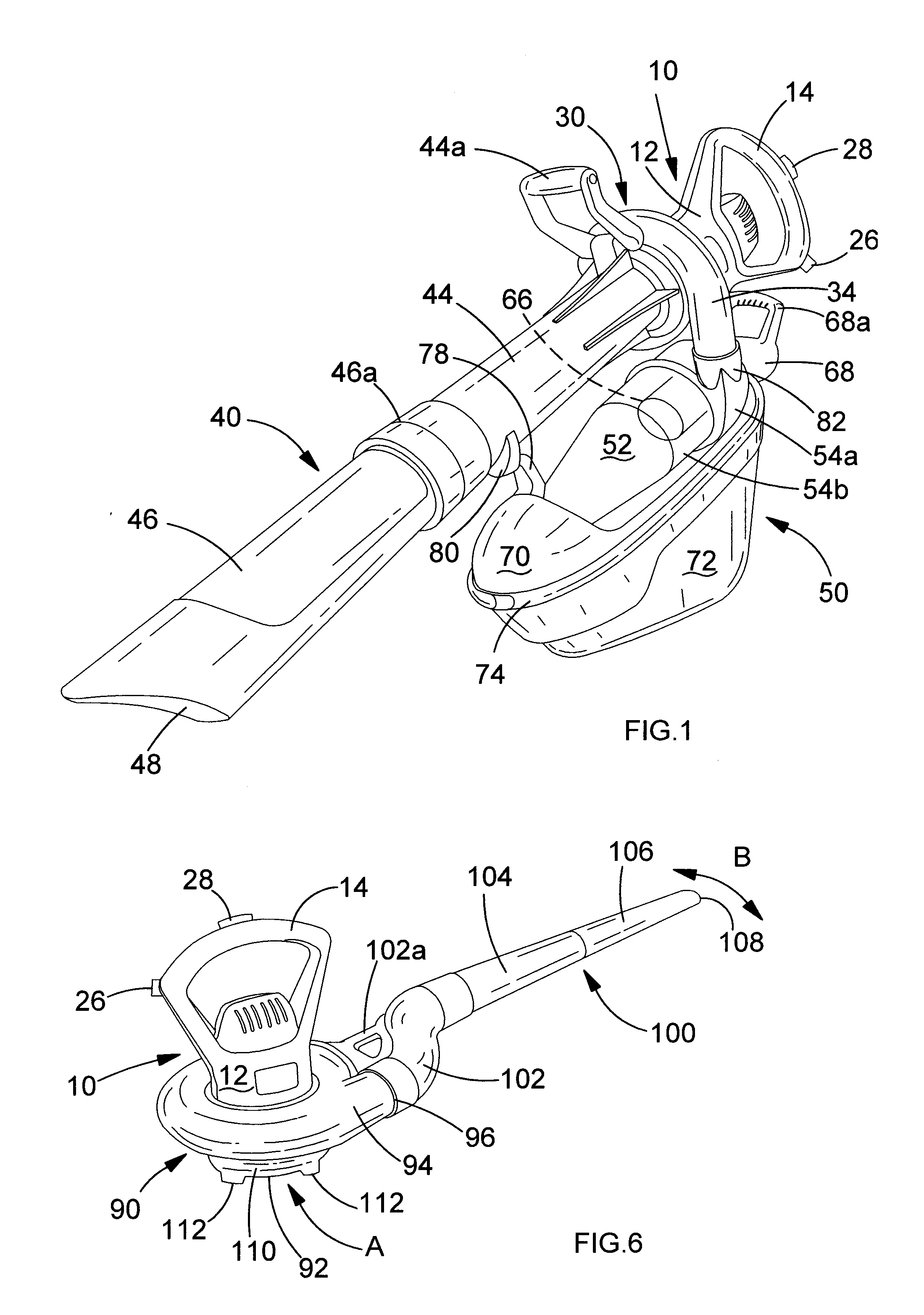

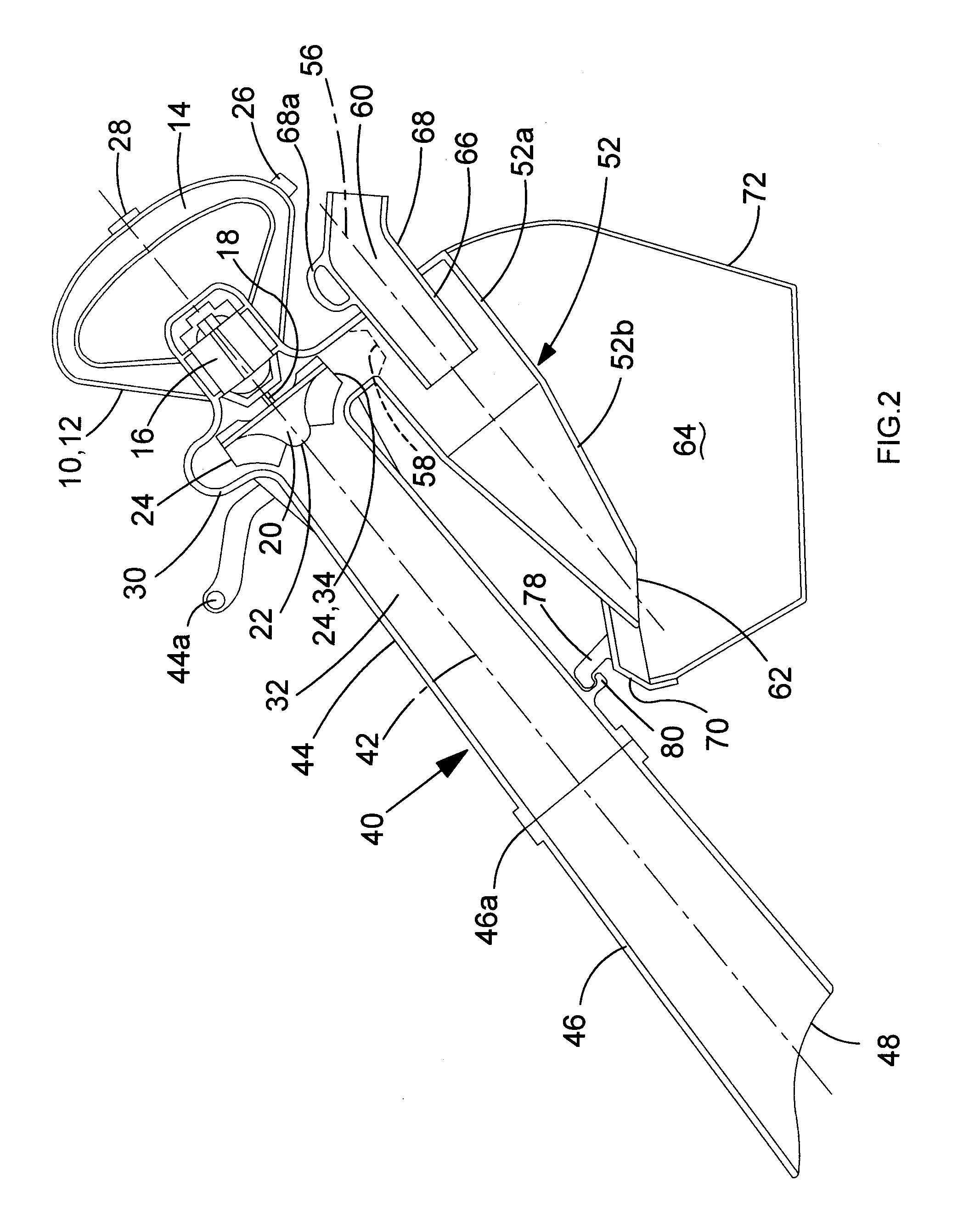

Apparatus for collection of garden waste

ActiveUS20130185892A1Reduce usageHigh energyHops/wine cultivationSuction cleanersImpellerCyclonic separation

An apparatus for collection of garden waste wherein the apparatus has a vacuuming mode of operation and a dirty fan operation in the vacuuming mode of operation thereof, the apparatus comprising: a hand-holdable unit comprising a motor with an output shaft coupled to an impeller for generation of air flow; a volute enclosing the impeller for direction of air flow from an axial air inlet of the volute past the impeller to a tangential air outlet of the volute; a vacuum tube for conducting dirty air flow to the air inlet of the volute in the vacuuming mode of operation; and a cyclonic separation arrangement for receiving dirty air flow from the air outlet of the volute and separating garden waste from said dirty air flow in the vacuuming mode of operation. A blowervac comprising the apparatus for collection of garden waste.

Owner:BLACK & DECKER INC

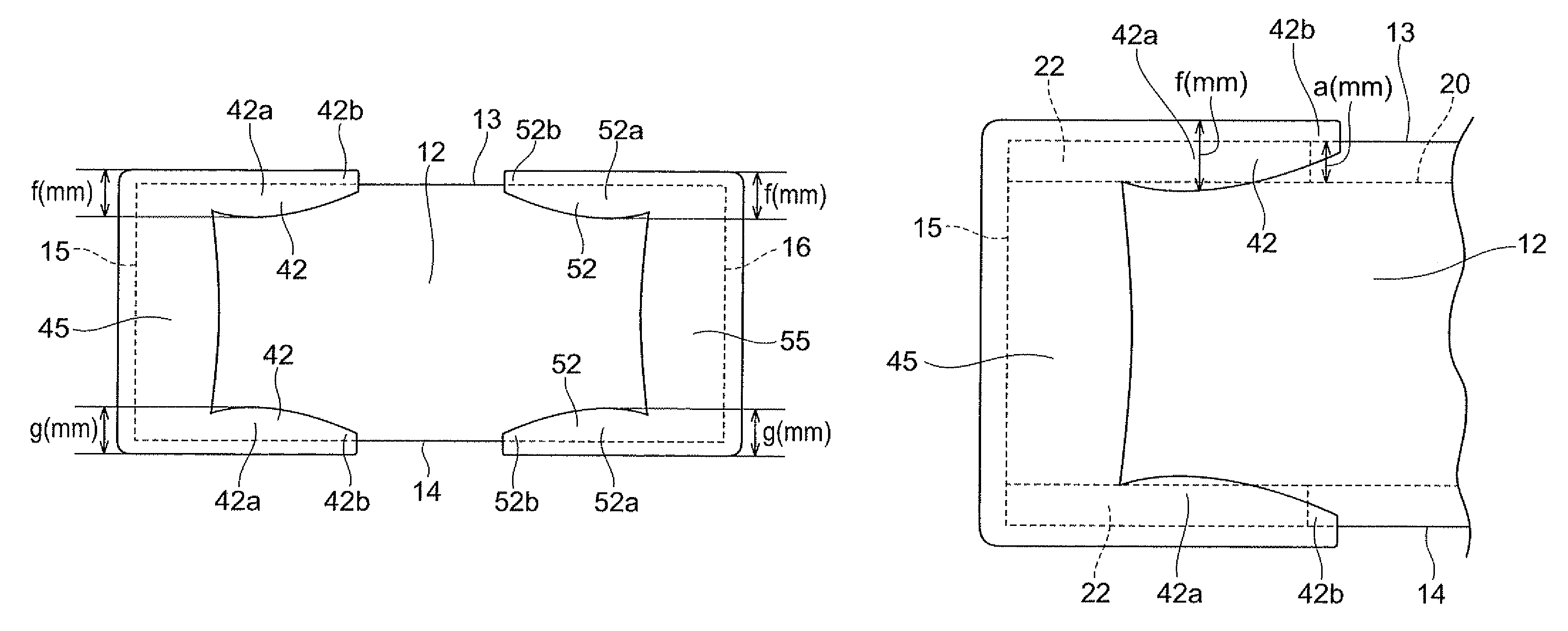

Multilayer capacitor

ActiveUS8107217B2ESL could be reducedInhibitionThin/thick film capacitorFixed capacitor electrodesEngineeringCapacitor

Each of second terminal portions of a first terminal electrode has a wide part a width of which is larger than a first lead width of lead portions in each first internal electrode, and a narrow part a width of which decreases from the wide part toward the second terminal electrode and toward the first or second side face side. In a multilayer capacitor, the wide part causes an electric current to flow in the lead portions of the first internal electrodes in a direction opposite to that of an electric current flowing in the first terminal electrode, so as to cancel magnetic field thereof each other and thereby reduce ESL, and the narrow part prevents a solder bridge from occurring between the first terminal electrode and the second terminal electrode in a work of mounting the terminal electrodes of the multilayer capacitor on a circuit board or the like.

Owner:TDK CORPARATION

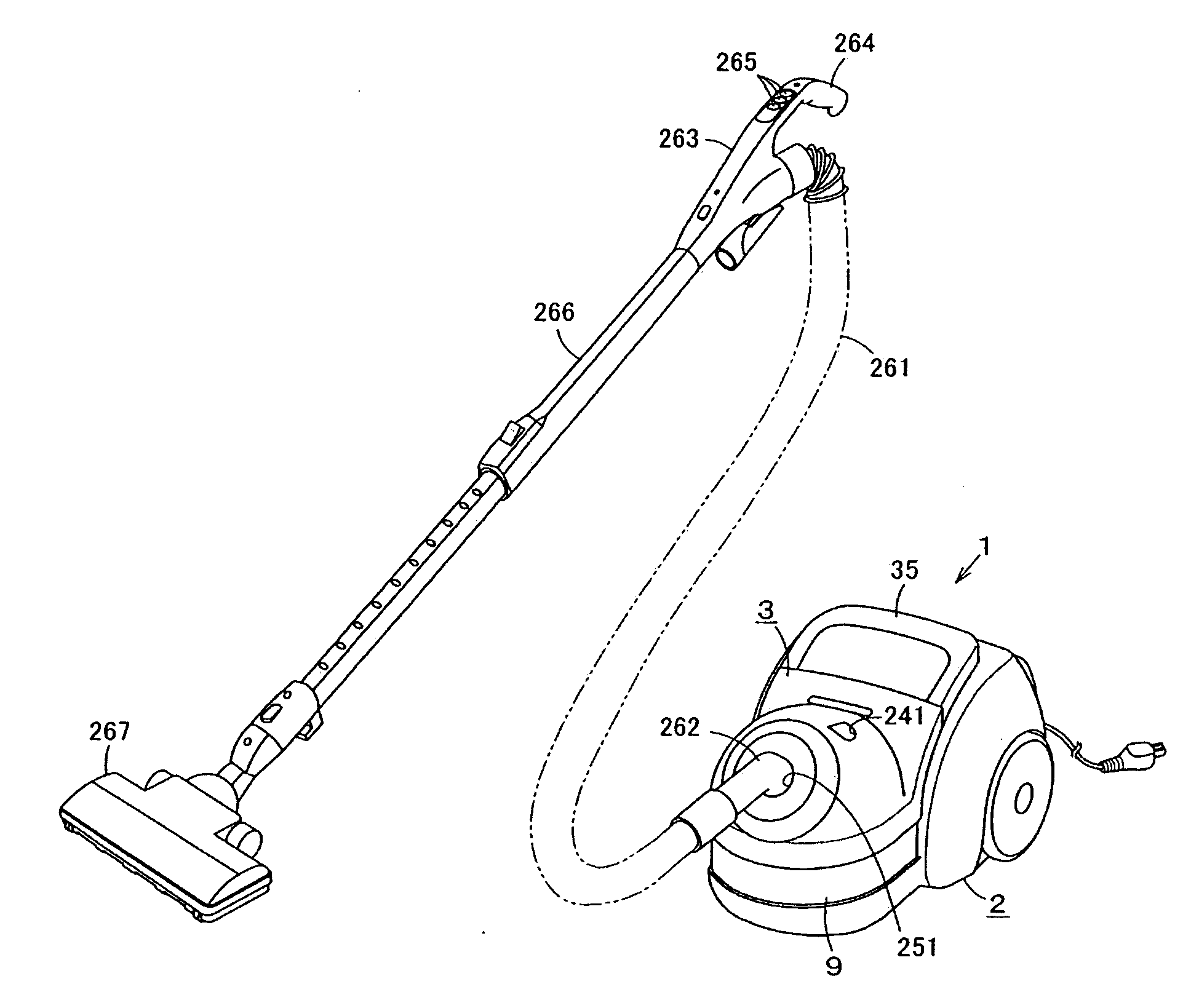

Electric vacuum cleaner

InactiveUS20080235901A1Reduction in suction amount is suppressedIncrease in air passage resistance of air passageCleaning filter meansSuction filtersSuction forcePower over

In a suctioning state, even if the amount of dust trapped in a dust collecting unit in a main air passage is increased, air suctioned from a hose connection port is branched into a first half passage and reduction in the suction air amount can be suppressed. When the suctioning state is switched to a dust moving state by switch means, the dust trapped in a pleated filter is moved to the dust collecting unit, increase in the air passage resistance at the first half passage side caused by clogging of the pleated filter can be suppressed, and reduction in suction power over time can be suppressed. Since an upper air passage and lower air passage are provided in the lid body, the dust collecting unit is exposed with the lid body opened, whereby maintenance performance of the dust collecting unit is improved.

Owner:KK TOSHIBA +2

Fuel pump

InactiveUS20110139278A1Reduce suctionDischarge amount is reducedDomestic plumbingMachines/enginesInternal combustion engineFuel supply

A filter device is connected to a fuel pump for supplying filtered fuel to an internal combustion engine. The filter device has a bag-shaped filter element forming therein a fuel passage, wherein fuel passes through the filter element to enter into the fuel passage. The filter element further forms a vapor pooling chamber above the fuel passage, so that vapors separated from the filtered fuel in the fuel passage are moved toward the vapor pooling chamber. A valve device is provided at a portion of the filter device, which is close to the vapor pooling chamber, so that vapors are discharged from the vapor pooling chamber to an outside of the filter device.

Owner:DENSO CORP

Automatic urine disposal device and urine receptacle used therefor

InactiveUS7390320B2Increase percentagePercentage of urine collection from the urine collecting padBathroom accessoriesNon-surgical orthopedic devicesDrainage tubesUrine flow

An automatic urine disposal device has a urine collecting pad, vacuum pump, and urine tank. In the urine collecting pad, the top sheet comes in contact with the wearer's skin, the hydrophilic sheet is disposed on the bottom of the top sheet, and the urine absorbent sheet is disposed at the bottom. When discharged urine flows in the top sheet, the hydrophilic sheet widely diffuses urine to saturate its entire surface and then becomes non-breathable. As the vacuum pump vacuums the air from the urine tank, urine is directed from a urine drainage port of the urine collecting pad via a urine drainage tube to the urine tank which is a sealed container.

Owner:HITACHI LTD +1

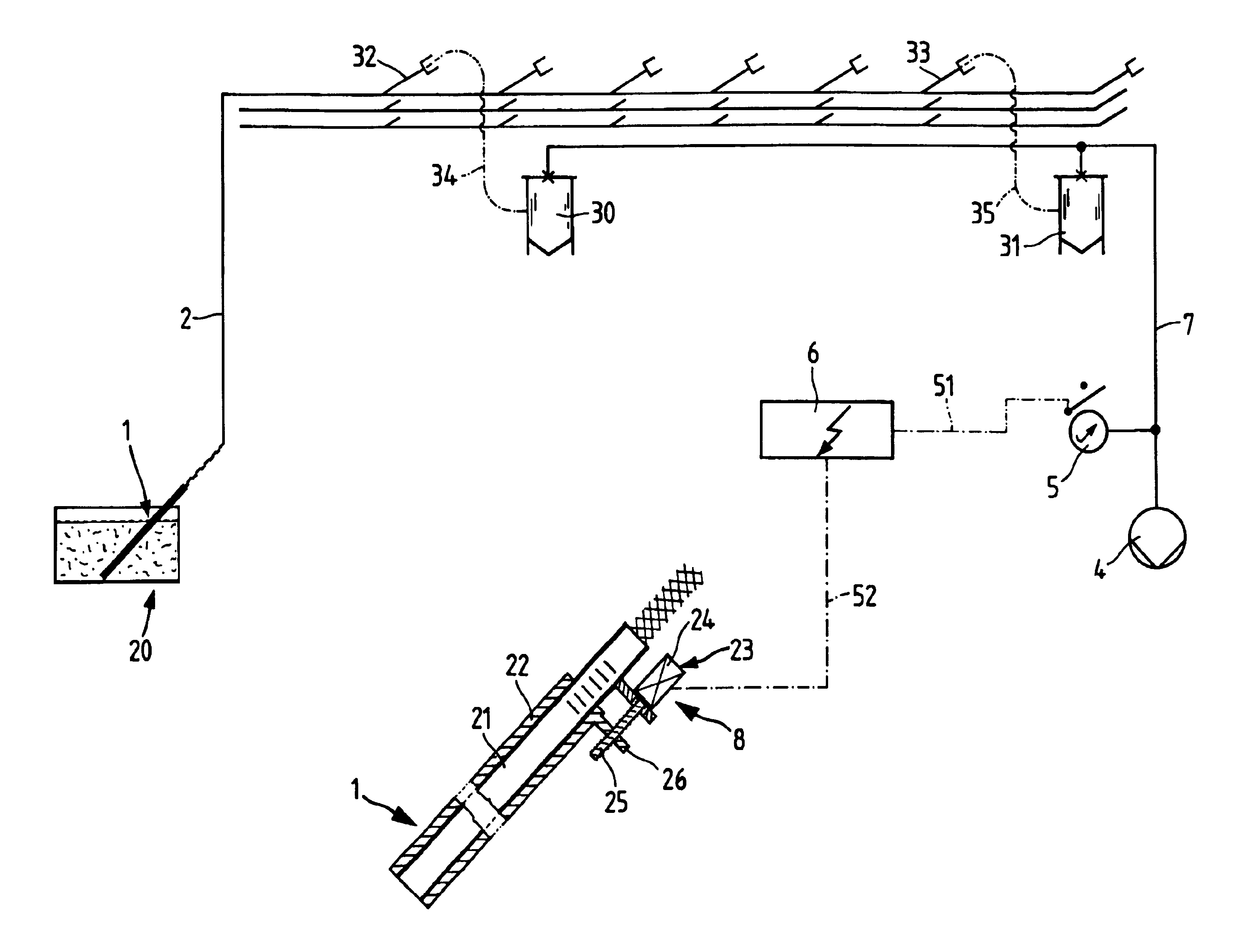

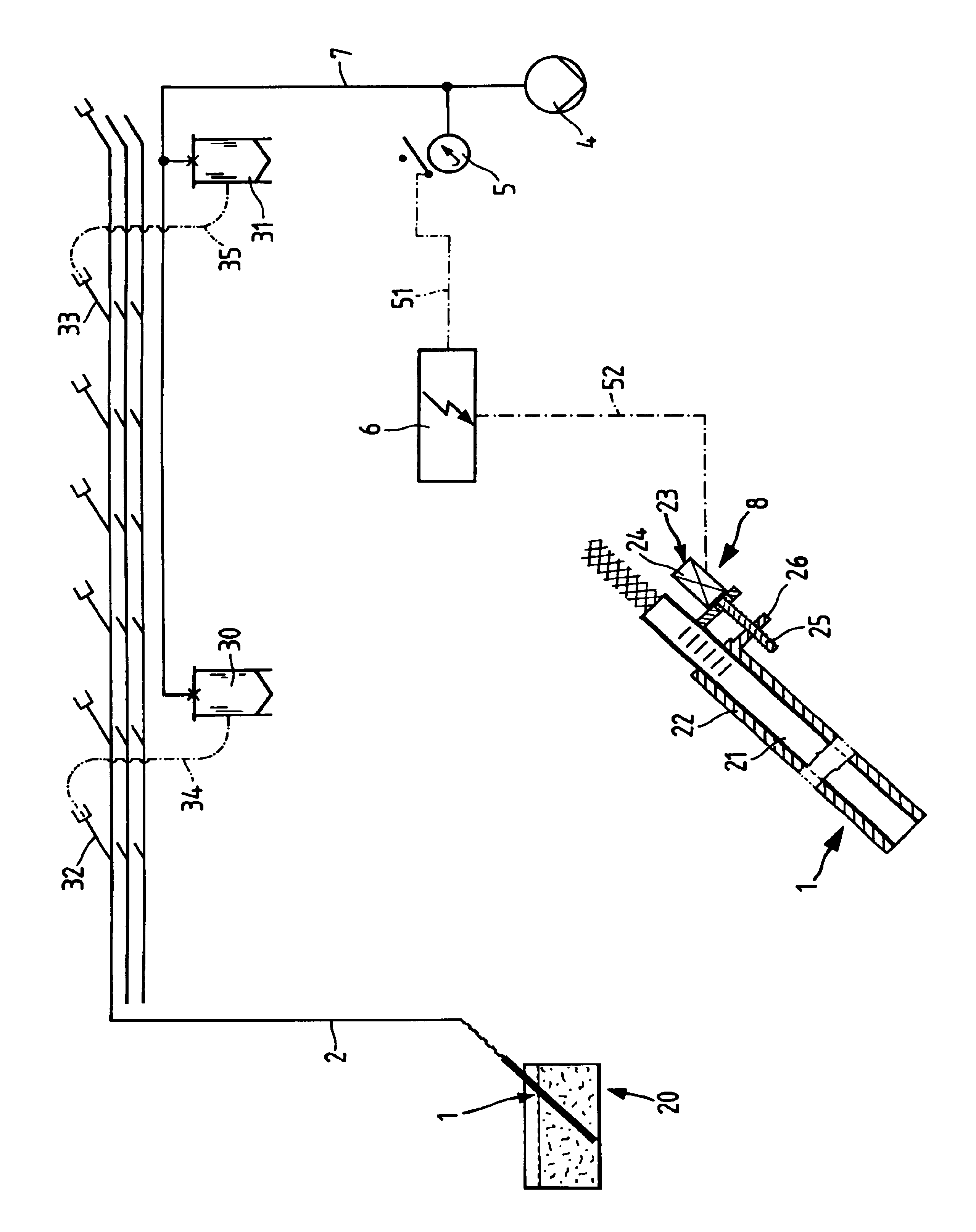

Conveyor device for particulate material

A conveyor apparatus for a particulate material to be conveyed, e.g., a synthetic resin granulate or powder, with a plurality of handling devices (30, 31) for processing the conveyed material, a storage bin (20) for the material to be conveyed, a conveying line (2) provided with a suction probe (1) for withdrawing the material to be conveyed from the storage bin, and a negative pressure source (4) connected to the handling devices via a suction line (7). The handling devices (30, 31) are all connected to a common conveying line (2), and a control member (8) is provided on the suction probe (1) to control the air volume going through the conveying line (2). This control member is controlled by an air pressure sensor (5) disposed on the suction line (7).

Owner:MANN & HUMMEL PROTEC GMBH

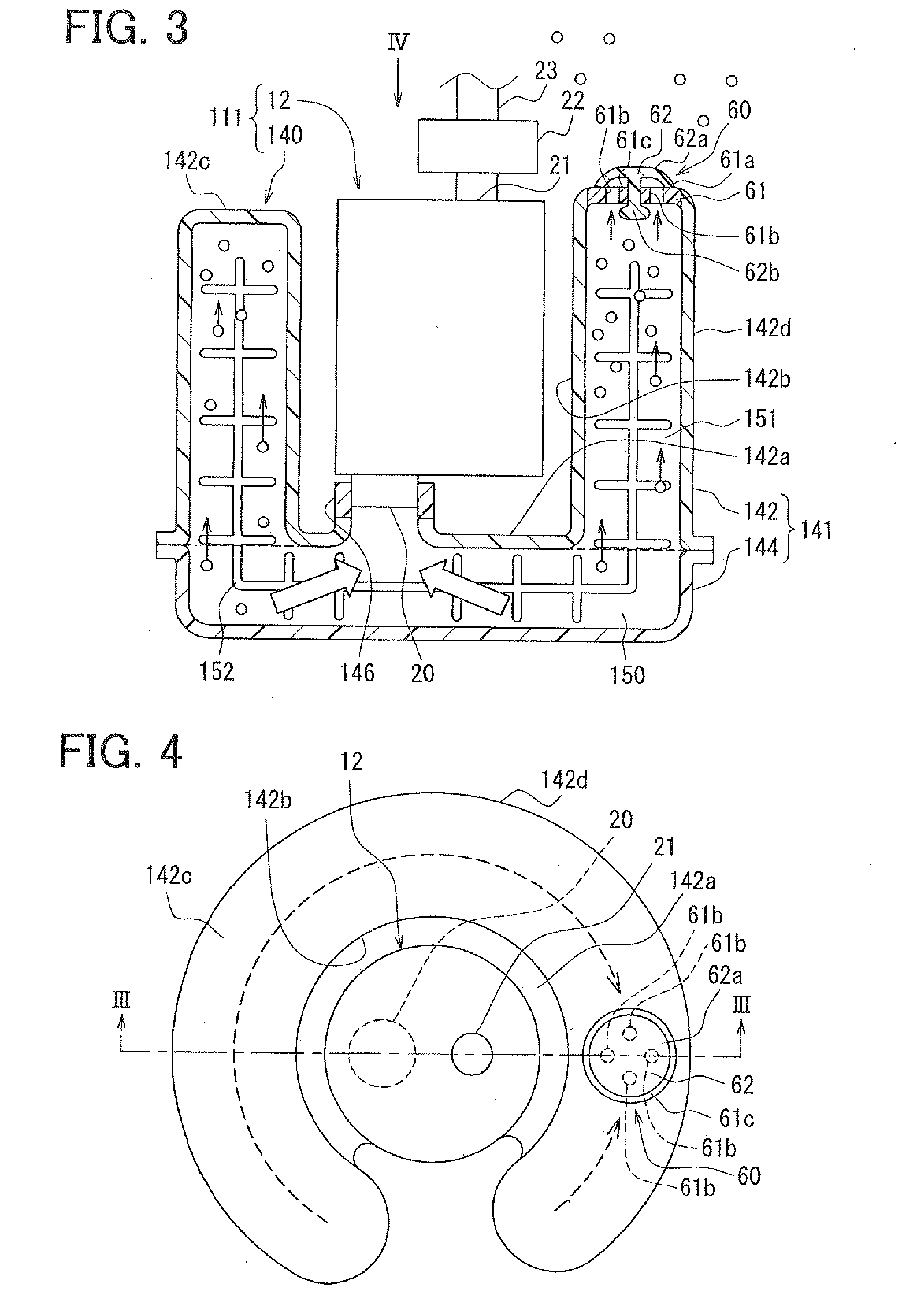

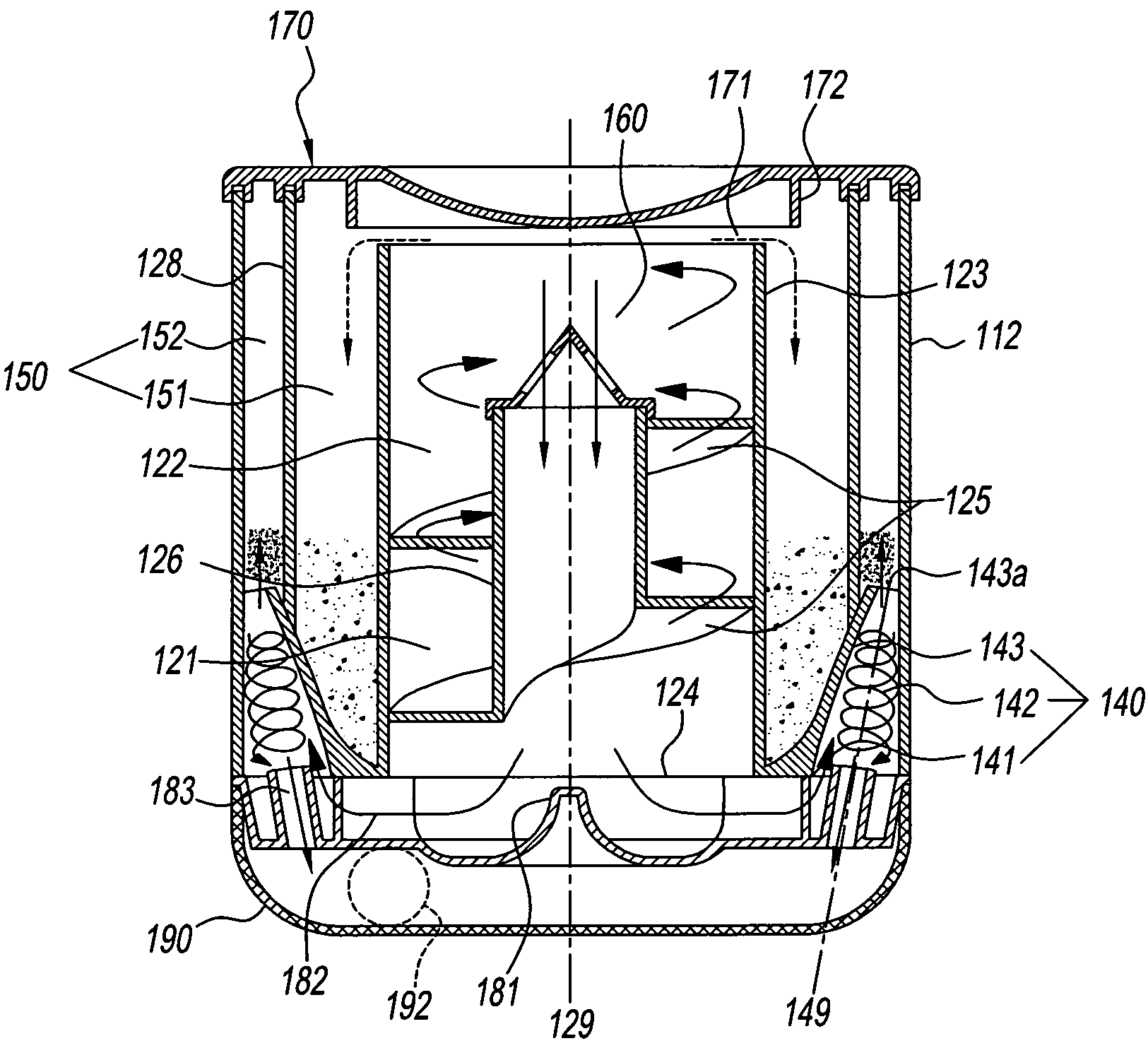

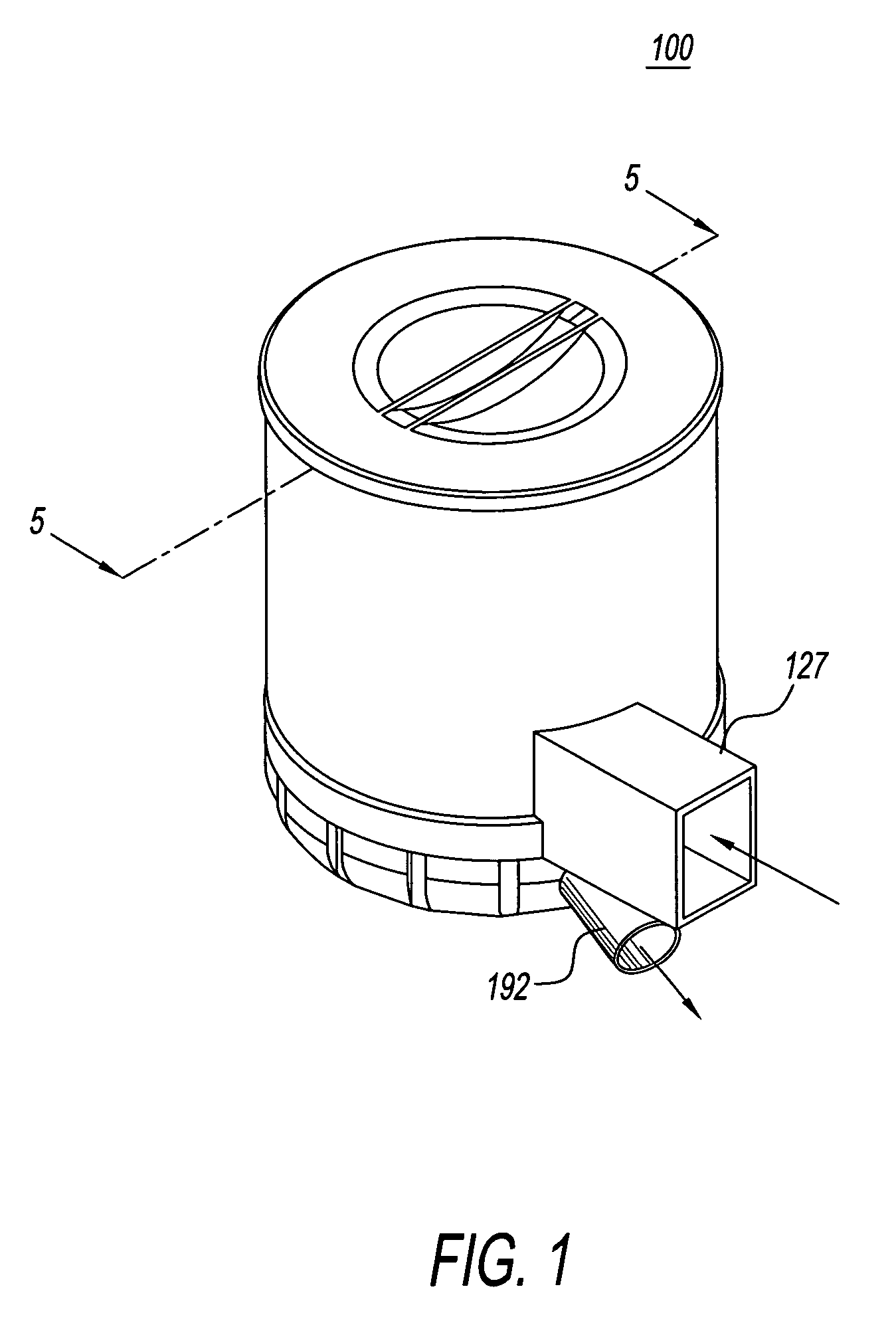

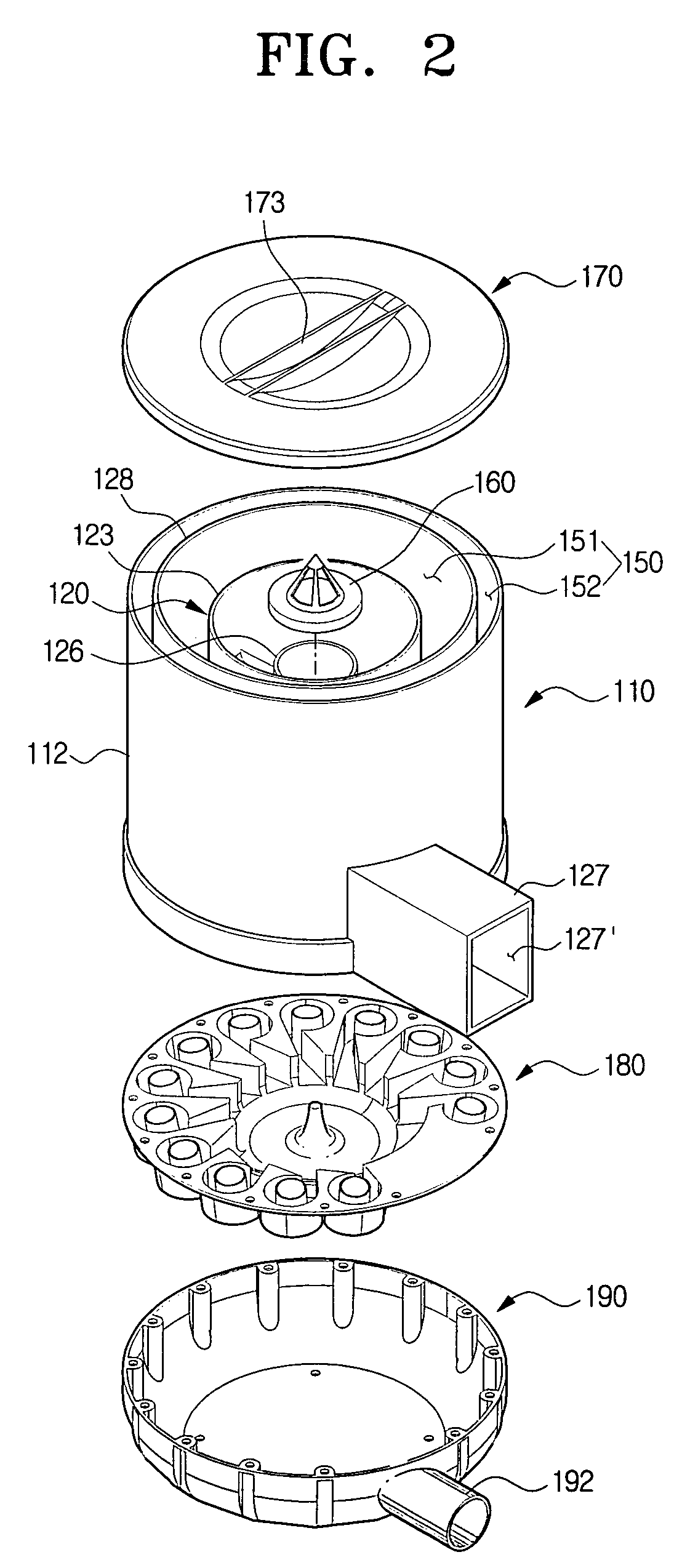

Multi-cyclone dust collection apparatus

InactiveUS7682412B2Shorten the length of the flow pathReduce suctionCleaning filter meansSuction filtersCycloneEngineering

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

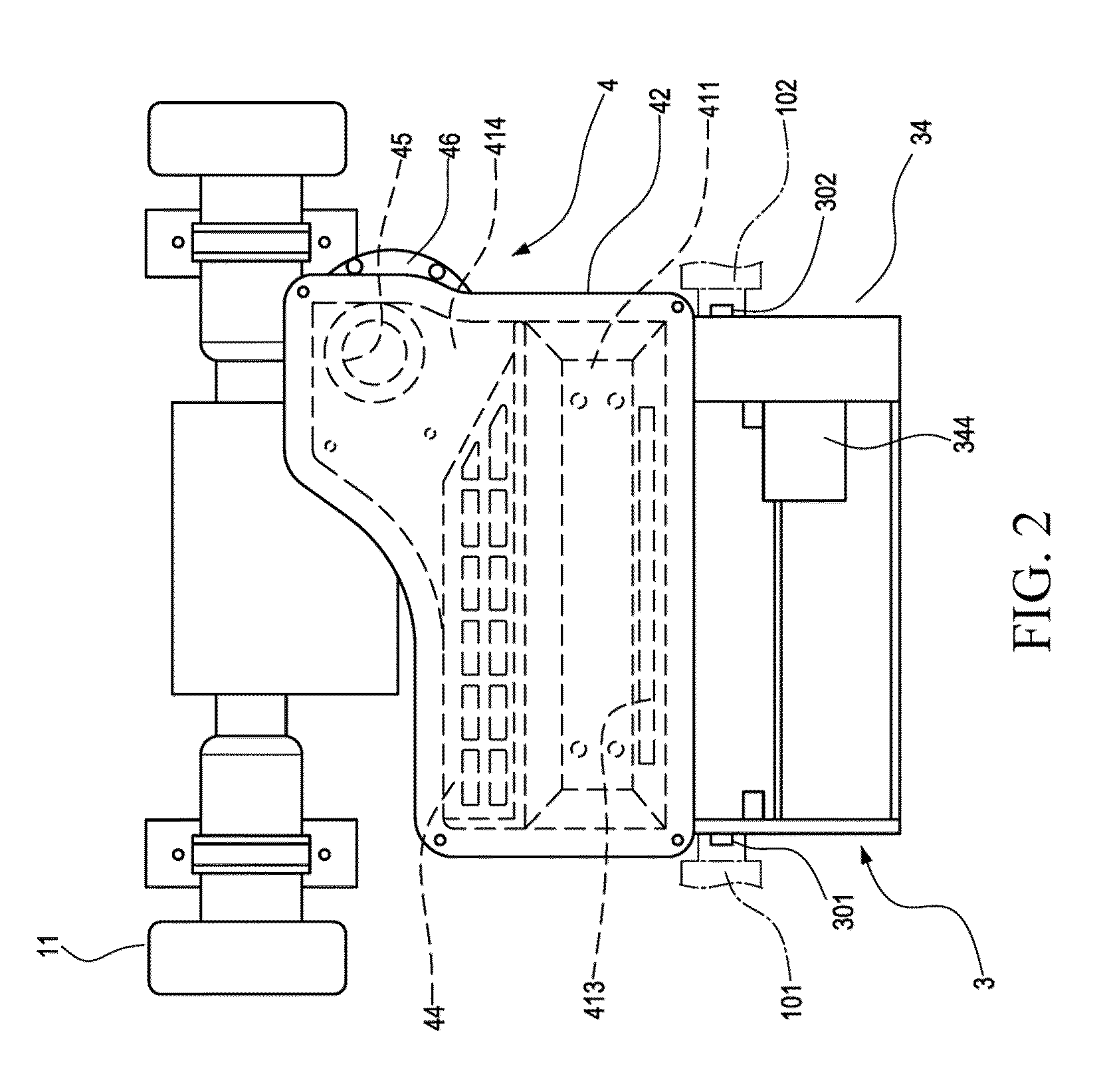

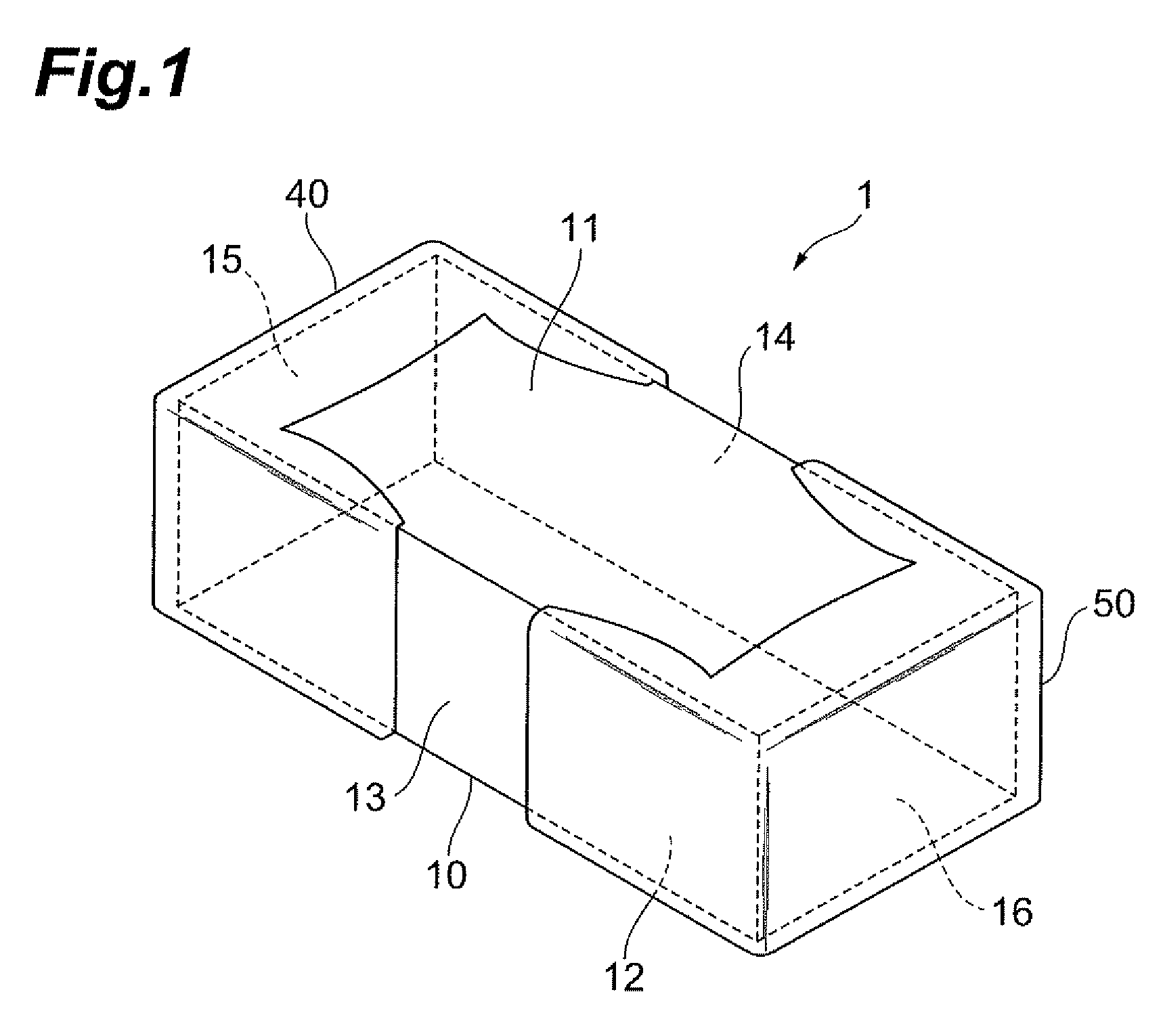

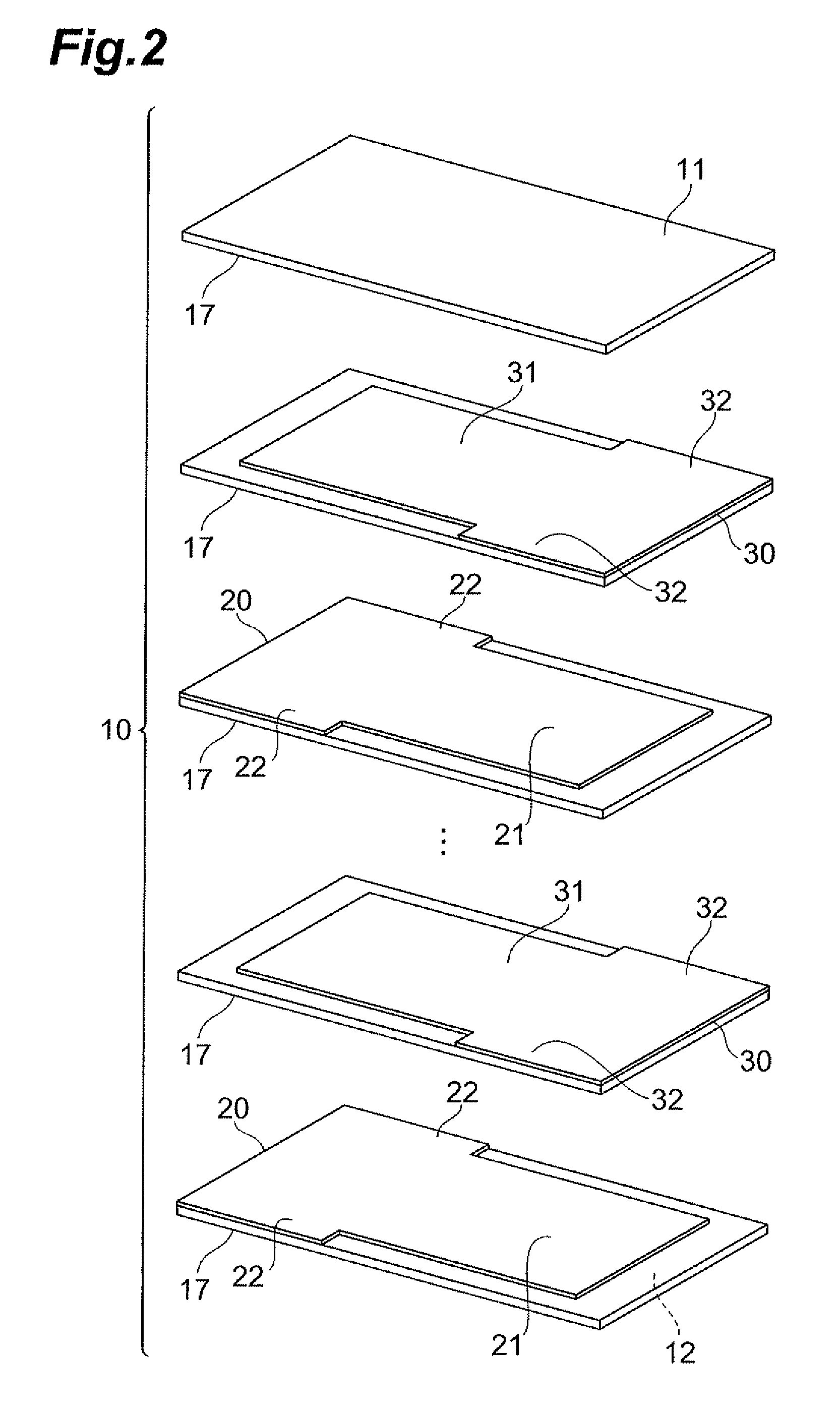

Apparatus For Producing Absorbing Material, Aborbing Material And Absorbent Article

ActiveUS20080038504A1Prevent characteristicsPrevent feelingLamination ancillary operationsManual label dispensersSuper absorbentSuperabsorbent polymer

[Problem to be Solved] A shuffling hand feeling and unwanted non-uniform absorption characteristics in the case of using a tow (fiber bundle) are prevented. [Solution] An absorbent body includes a fiber aggregate 21 formed by opening the tow, a super absorbent polymer 54, and a sheet covering these components; and includes the super absorbent polymer 54 bonded to the sheet 58 with an adhesive that is applied in a continuous plane to the entire surface or the substantially entire surface of at least the portion to be provided with the super absorbent polymer 54 in this sheet 58.

Owner:DAIO PAPER CORP

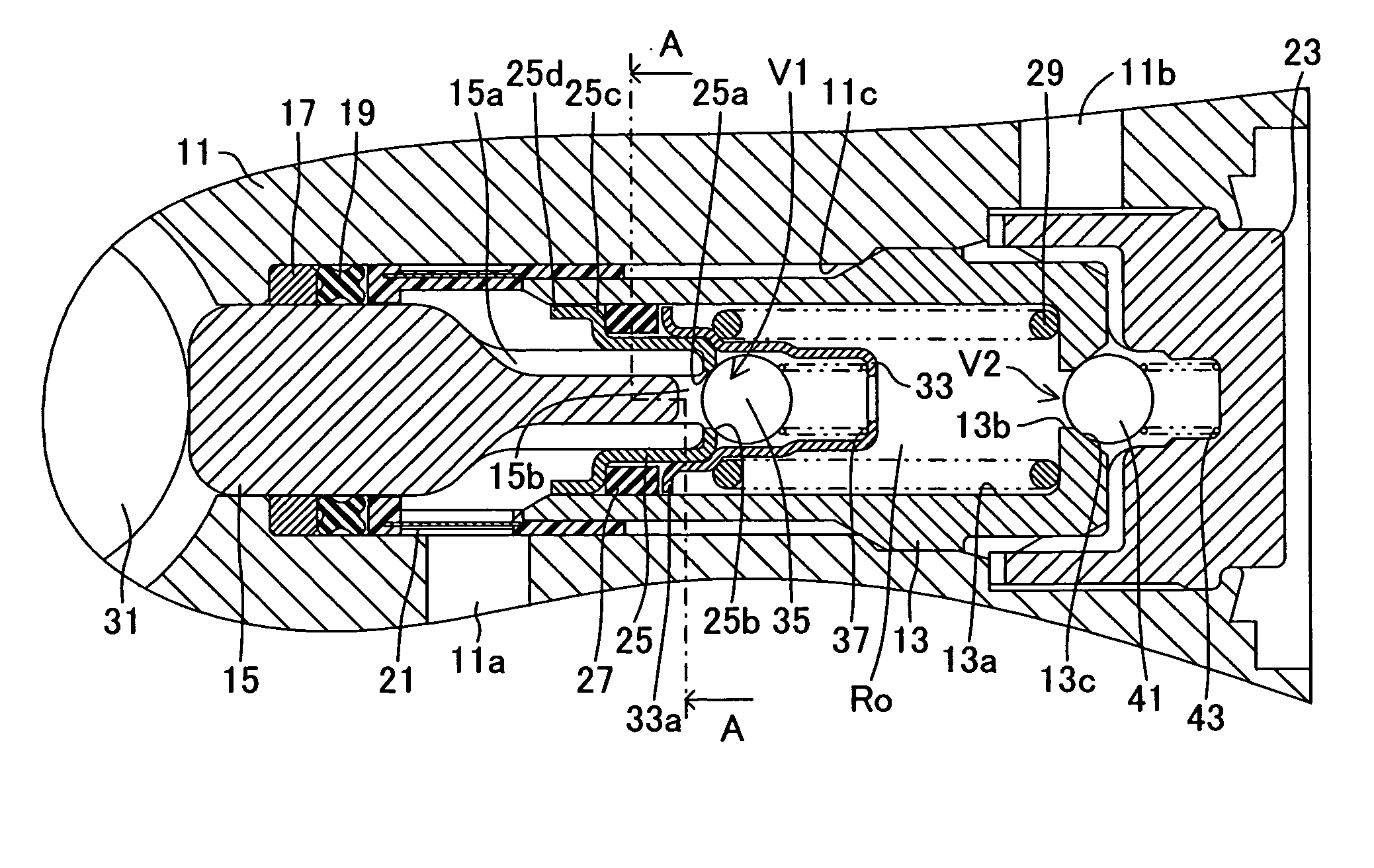

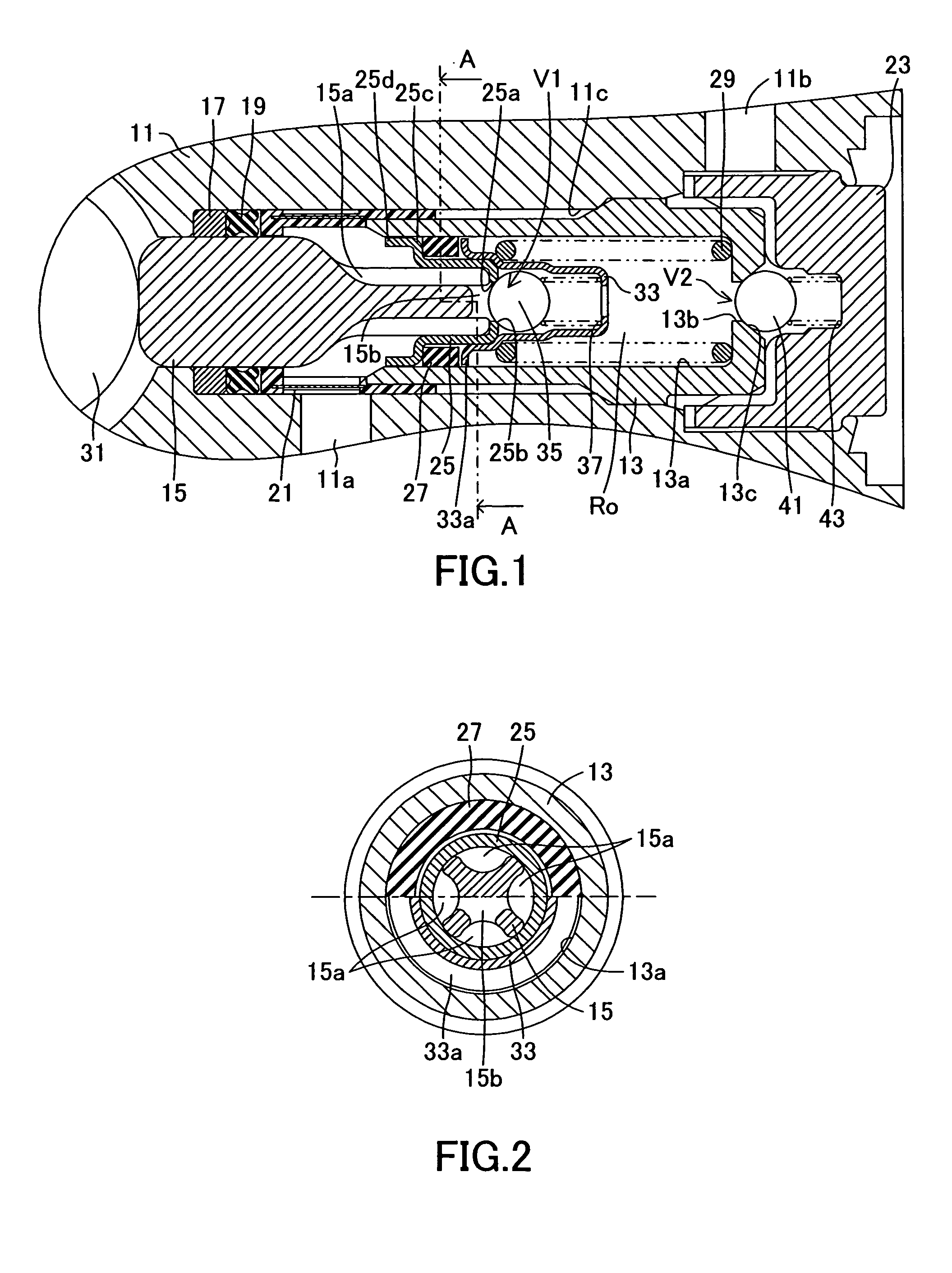

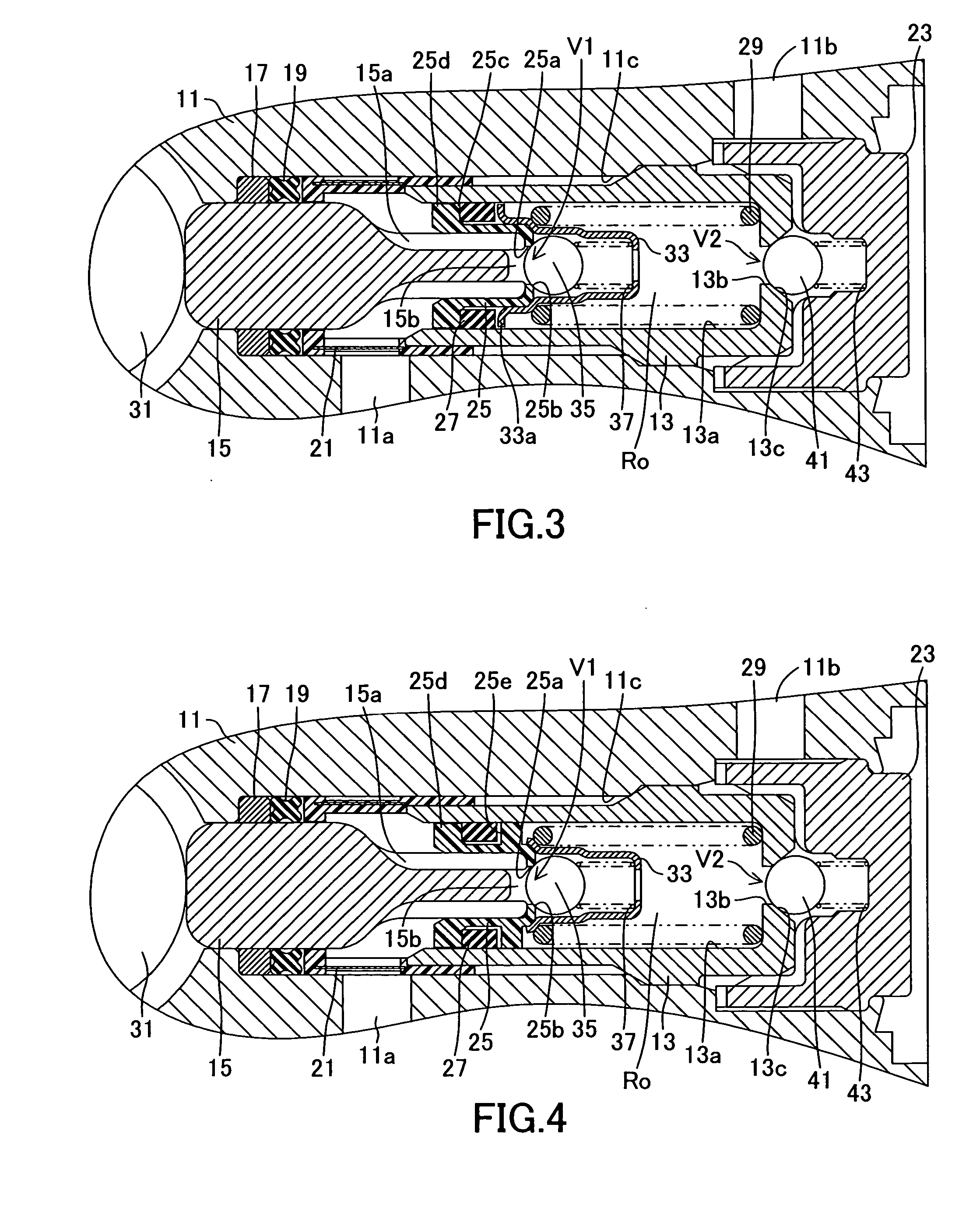

Piston pump

InactiveUS20050063846A1Low costReduce manufacturing costPositive displacement pump componentsPump controlEngineeringPiston pump

A piston pump includes a piston for increasing and decreasing the volume of a pump chamber formed in a cylinder bore of a cylinder member, by means of axially reciprocating movement thereof; a suction valve provided in the piston, and opening and closing when the volume of the pump chamber increases and decreases, respectively; and a discharge valve provided at a discharge side of the pump chamber, and opening and closing when the volume of the pump chamber decreases and increases, respectively. A plurality of mutually communicating, axially extending grooves are formed on an outer circumferential portion of the piston located on the pump-chamber side. A cylindrical seat member is fixedly and externally fitted to the piston in a region of the communicating grooves. A valve port and a valve seat of the suction valve are formed at an end portion of the seat member located on the pump-chamber side.

Owner:ADVICS CO LTD

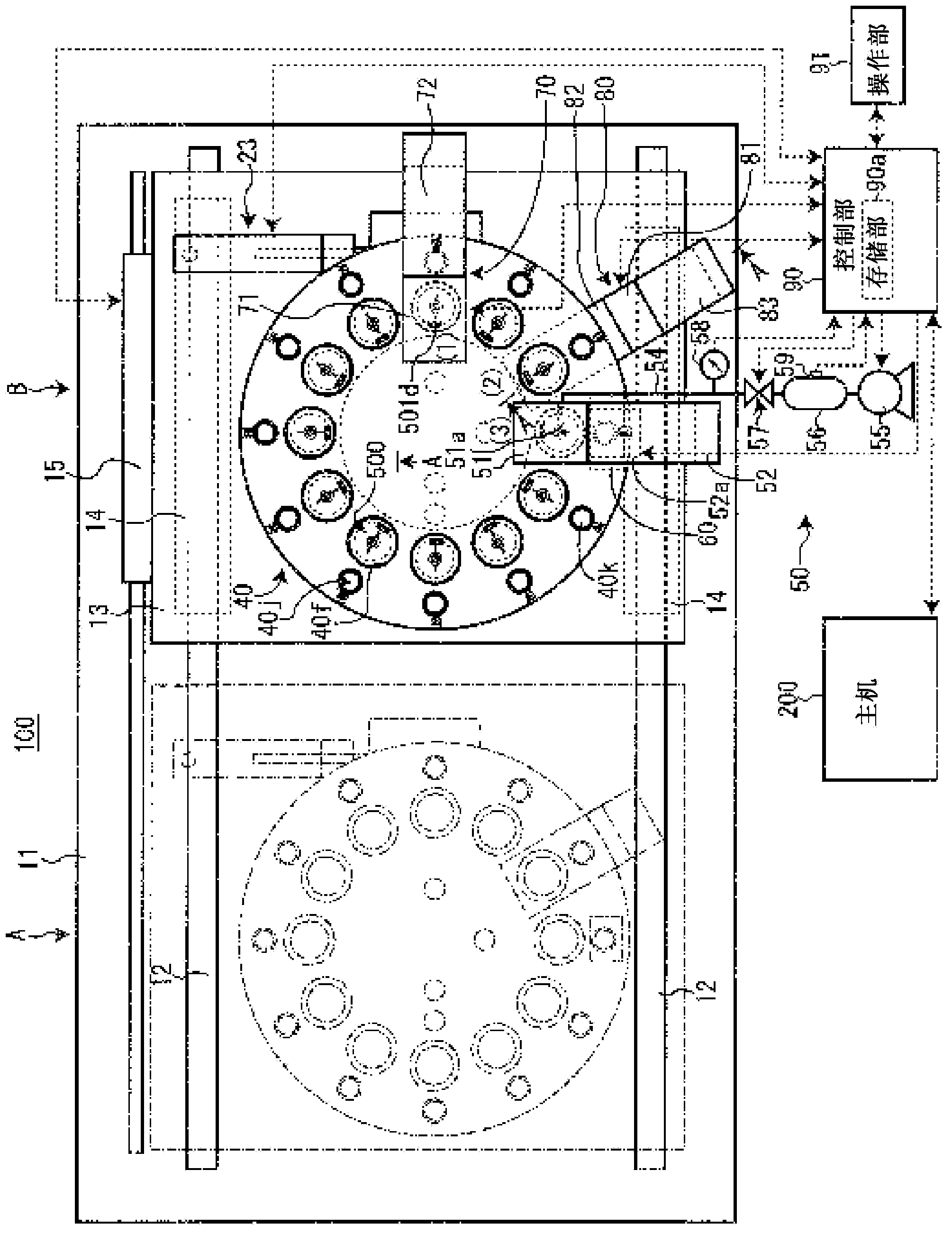

Suction nozzle inspection device

Provided is a suction nozzle inspection device which can inspect the cleaning state of a suction nozzle after cleaning. The suction nozzle inspection device has a rotary device (20), a suction nozzle holding tray (40), a suction nozzle connecting part (51), a pump, a flow detection part and a cleaning state determination part, wherein the rotary device (20) enables a rotary table (30) to rotate by a specified angle, the suction nozzle holding tray (40) is detachably arranged on the rotary table (30) and is provided with plural suction nozzle holding parts (40f) for vertically holding the suction nozzle (500) at equal intervals at the periphery, the suction nozzle connecting part (51) is arranged to move vertically and is connected and communicated with a suction nozzle hole of the suction nozzle (500), the pump supplies air to the suction nozzle connecting part (51), the flow detection part detects the flow of air supplied to the suction nozzle from the suction nozzle connecting part via the pump, and the cleaning state determination part determines the cleaning state of the suction nozzle (500) based on the flow of air detected by the flow detection part.

Owner:FUJI KK

Surgical wound drain tube with flow control safeguards

InactiveUS20050197647A1Promote healingReduce suctionWound drainsIntravenous devicesBlood collectionReflux valve

Flow control safeguards are integrated into a blood collection system on a disposable component such as the post-operative surgical drain tube leading from the patient to the collection device. One aspect of the invention prevents suction levels that are too high for the tissue and organs adjacent at the surgical site by providing a vacuum relief valve integrated into the drain tube. In another aspect of the invention, reverse flow of fluid back to the patient is prevented by integration of an anti-reflux valve into the surgical drain tubing.

Owner:DOLLIVER PHILLIP B +2

Personal environment airflow controller

InactiveUS20090163131A1Reduced pressure suctionIncrease air circulationCombination devicesDucting arrangementsAir contaminantEngineering

Owner:THE BOEING CO +1

System and Method to Vent Gas From a Body Cavity

ActiveUS20080082084A1Improve patient safetyReduce the possibilityRespiratorsSurgical needlesEngineeringEndoscopic Procedure

One aspect of the invention is a method to vent gas from a body cavity during an endoscopic procedure. A body cavity is in fluid communication with an exhaust gas inlet of a vacuum break device. The vacuum break device has a chamber in fluid communication with both the inlet and an outlet. The chamber may comprise one or more openings in fluid communication with the atmosphere. A conduit in fluid communication with the exhaust gas outlet may be connected directly or indirectly to a suction source. The suction source may be activated.

Owner:LEXION MEDICAL LLC

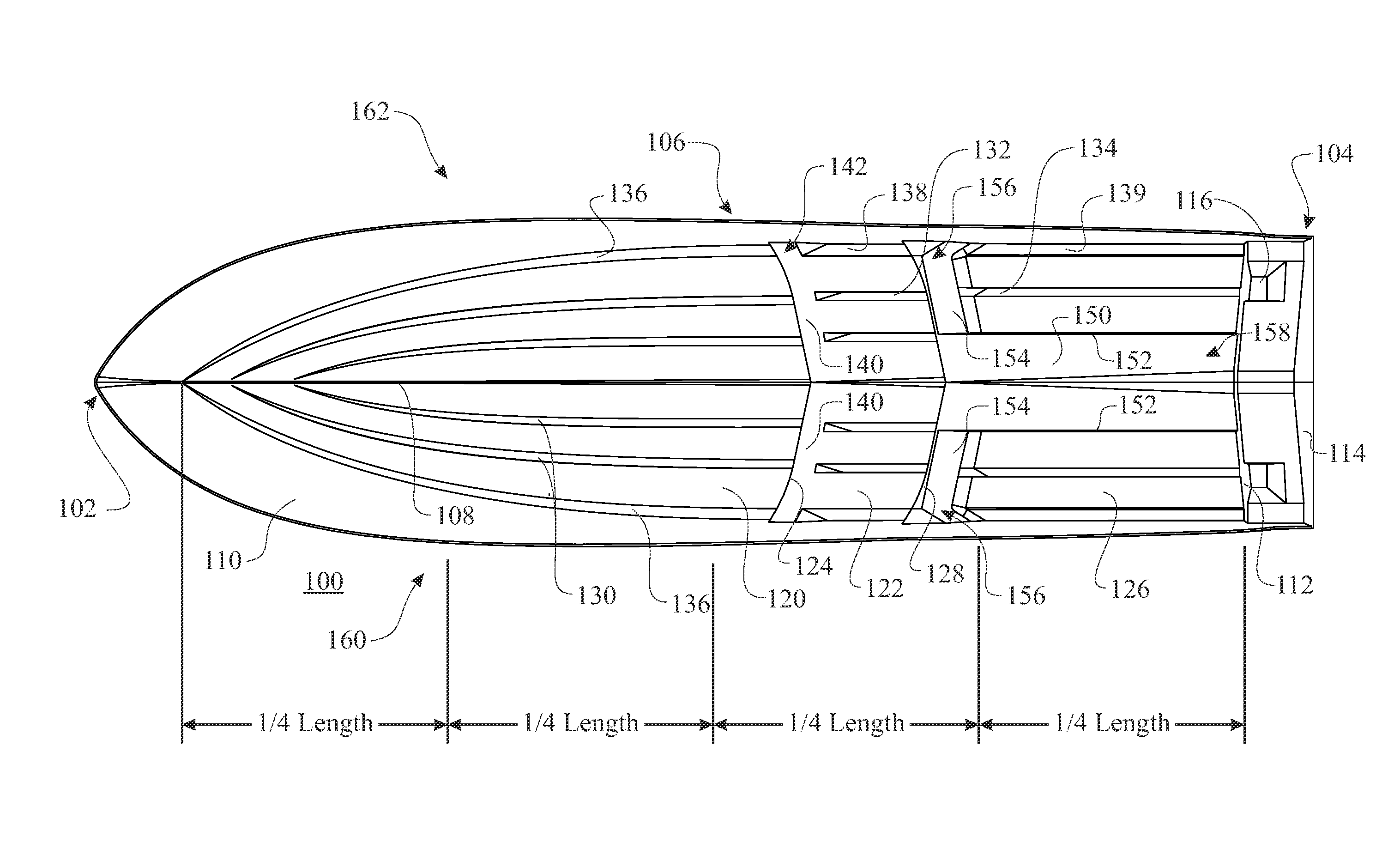

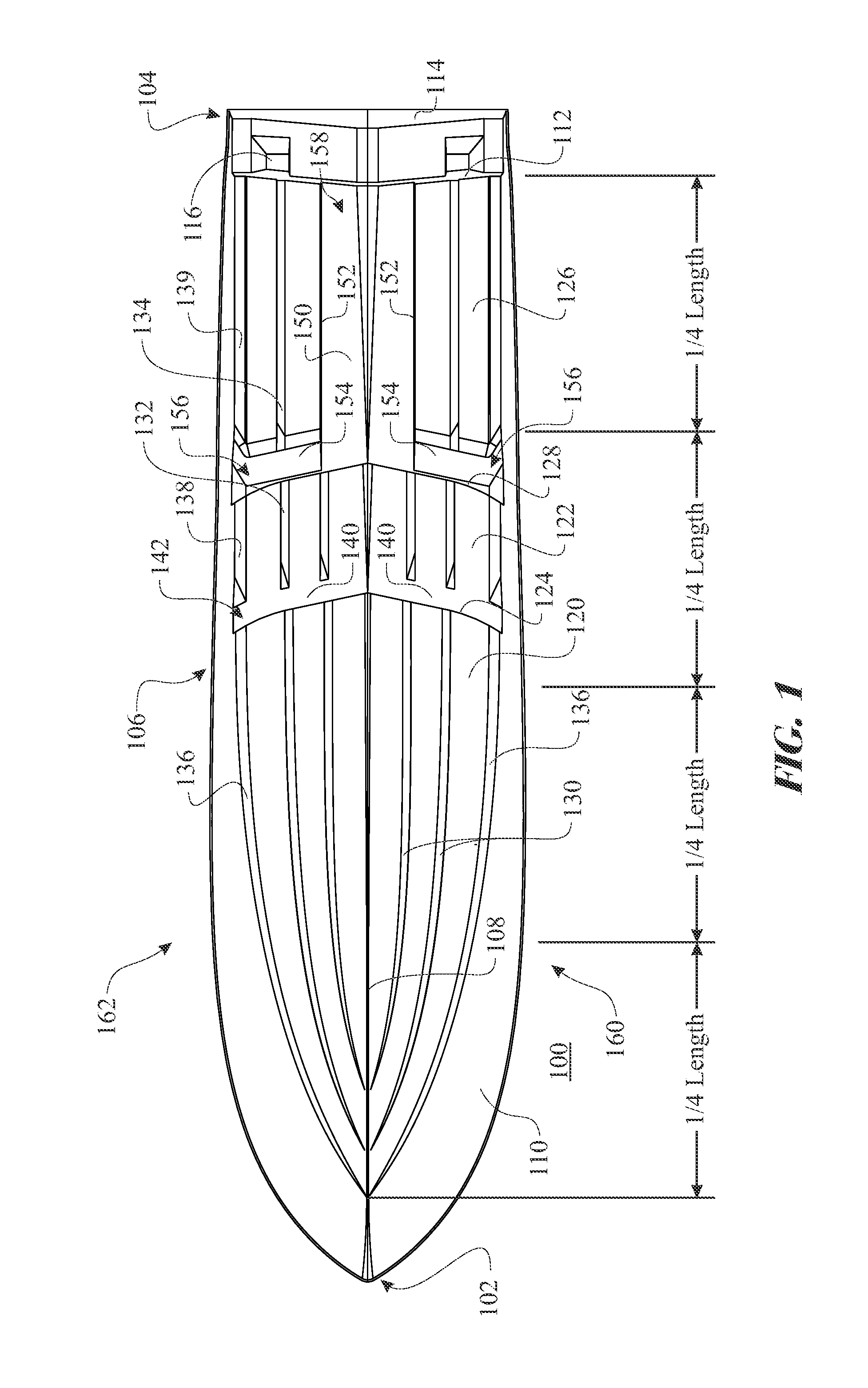

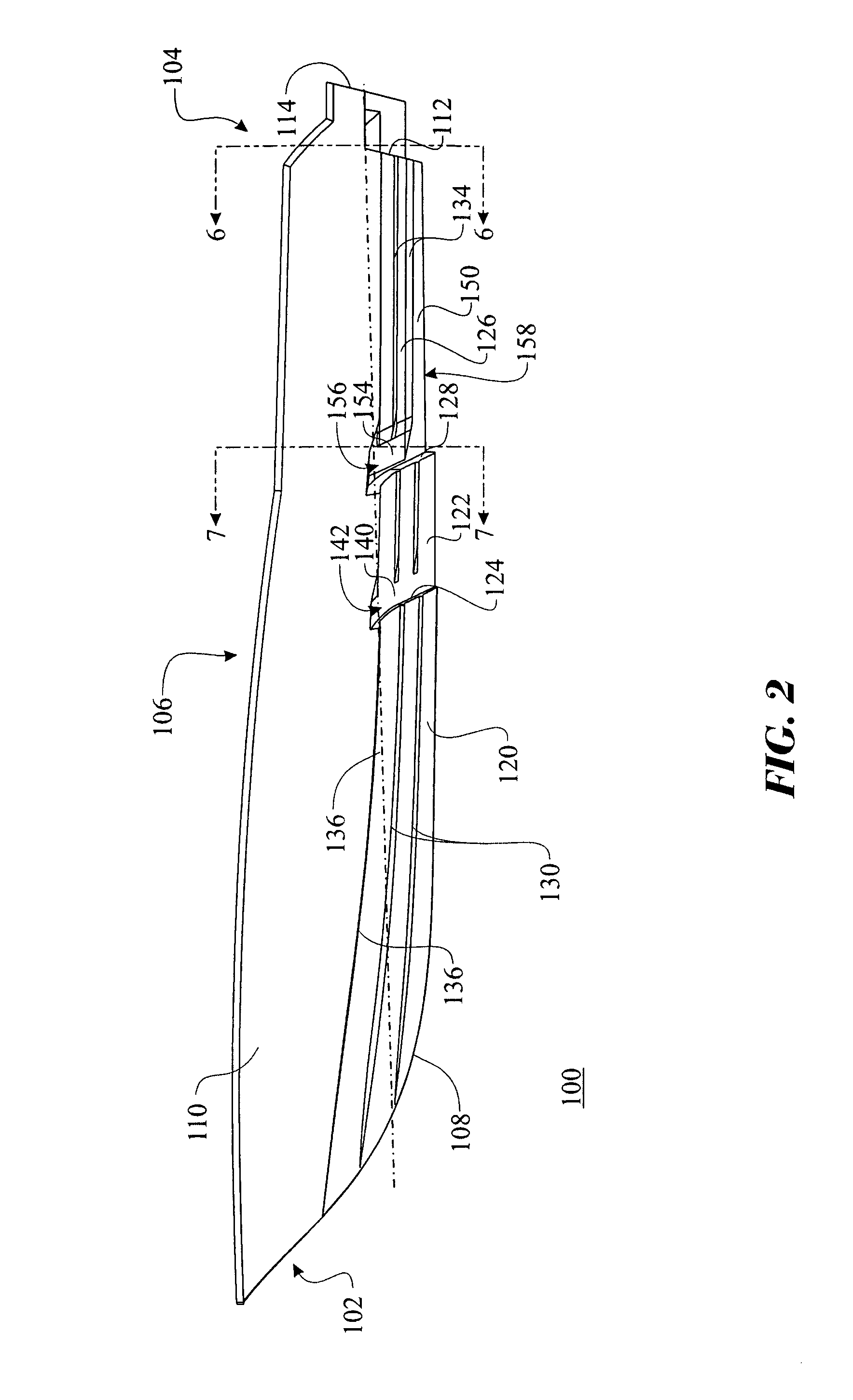

Stabilized step hull utilizing a ventilated tunnel

ActiveUS8291850B1Easy to controlImproved directional stabilityWatercraft hull designFloating buildingsMarine engineeringTunnel ventilation

A high speed powerboat hull (100) incorporating a tunnel ventilation channel (154) spanning between a starboard (160) and port (162) side of the hull (100). The hull (100) has a “V” shaped forward section. The ventilated tunnel (150) is provided as a recess having two substantially vertical sidewalls (152) arranged parallel to each other located along each of the two outer edges of the tunnel (150). The tunnel (150) is disposed longitudinally between the ventilated channel (154) and a transom (112). The ventilated tunnel (150) is in fluid communication with the ventilation channel (154). The hull (100) can further comprise at least one stepped hull section (122, 126).

Owner:PETERS MICHAEL PAUL

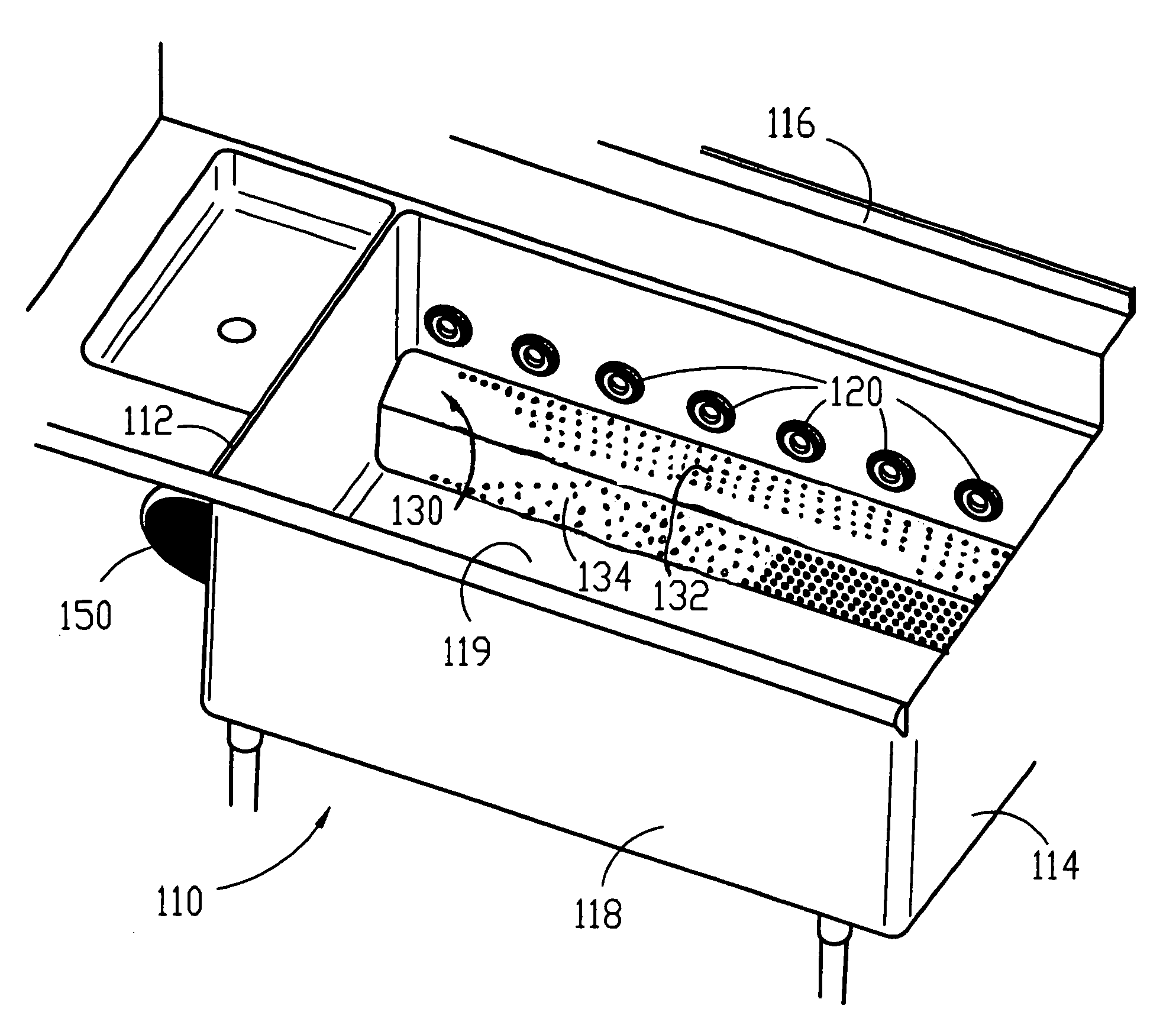

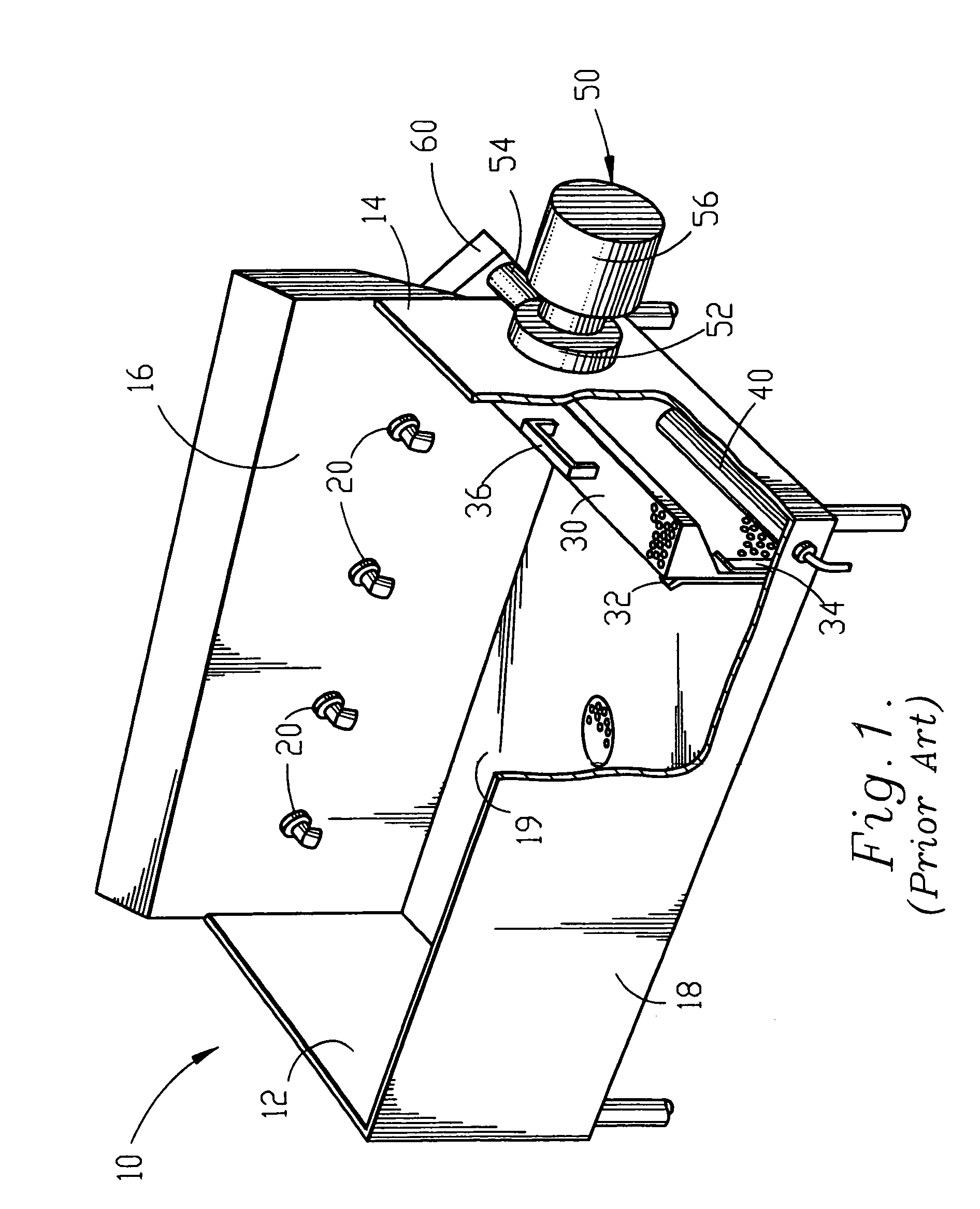

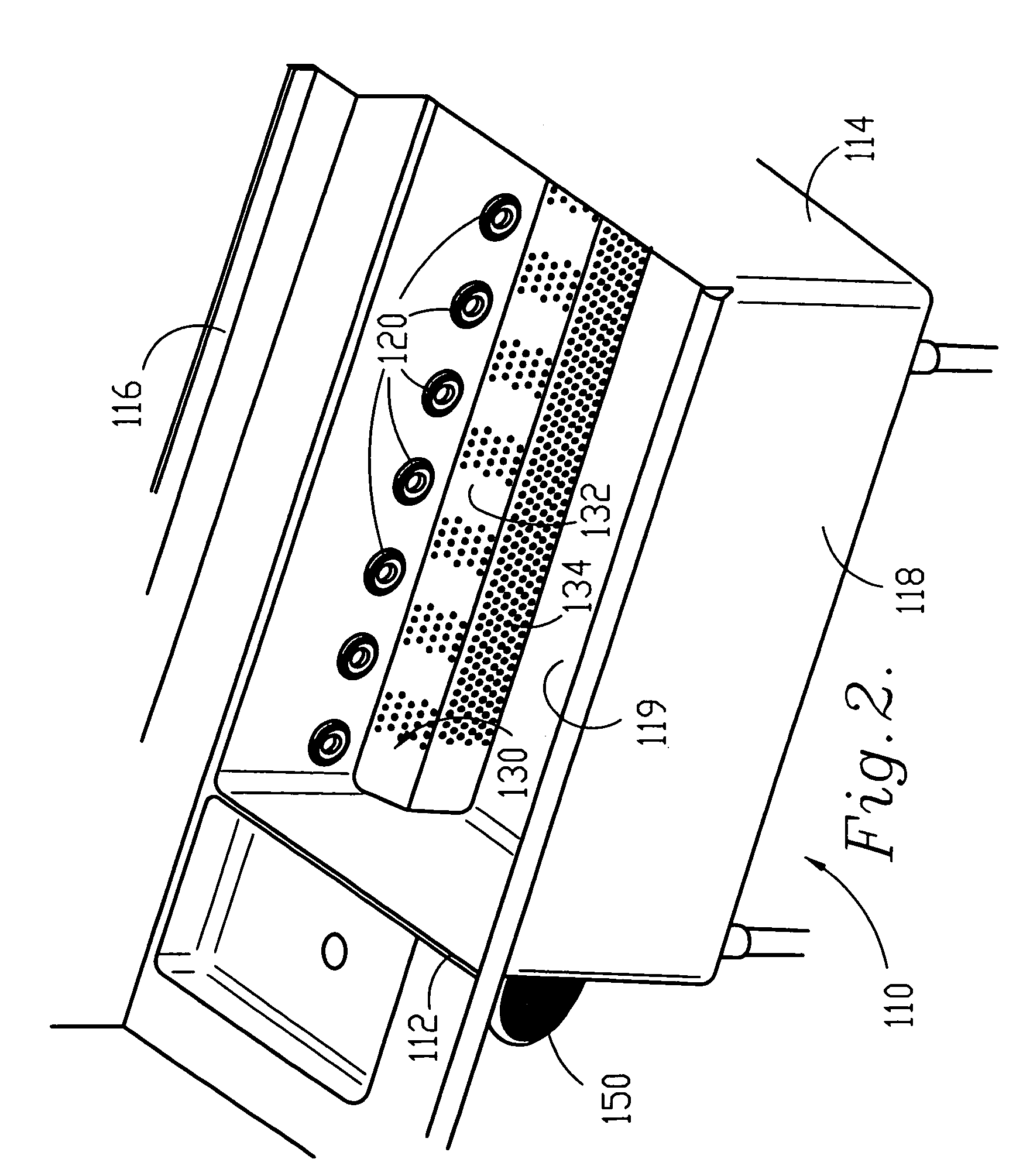

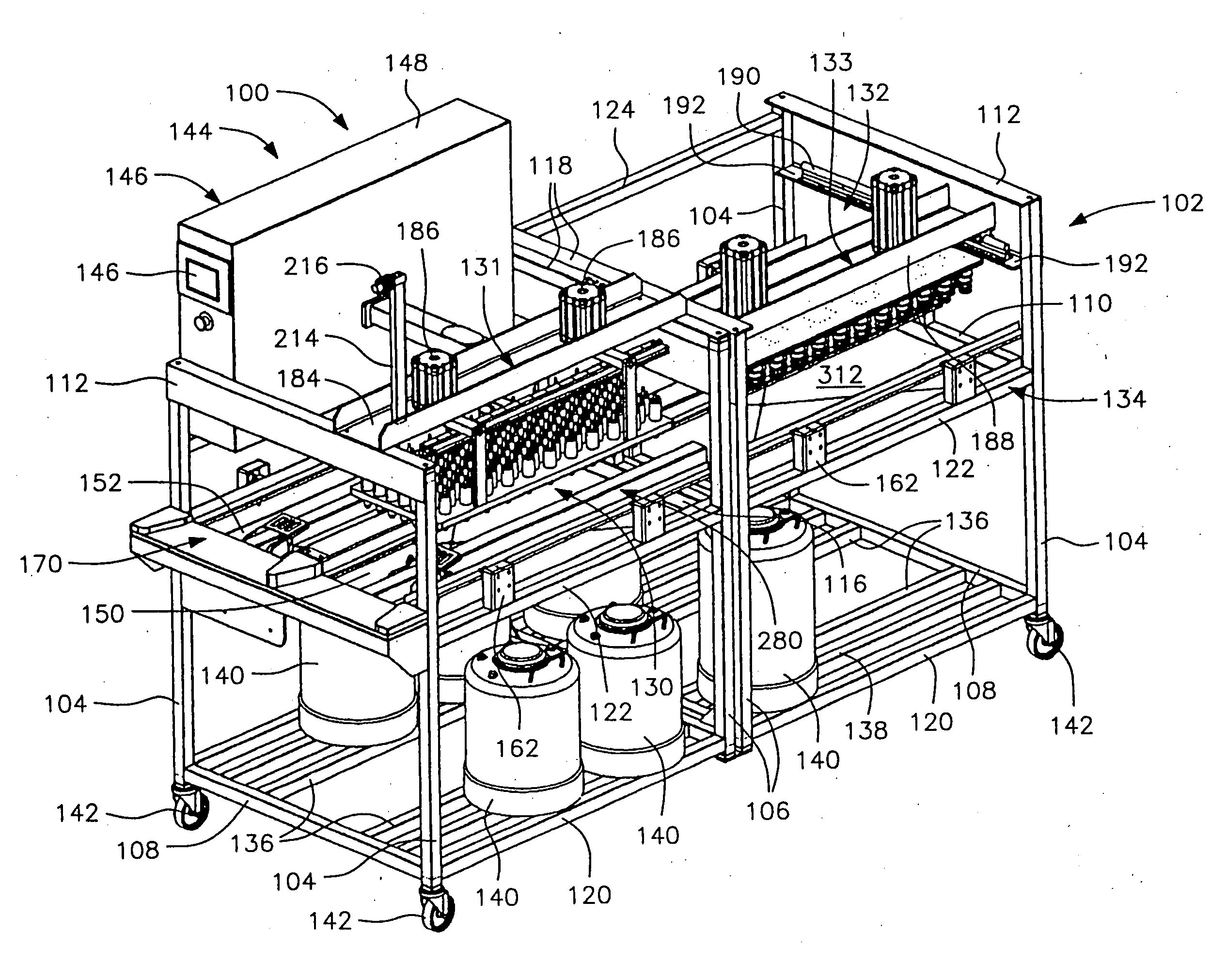

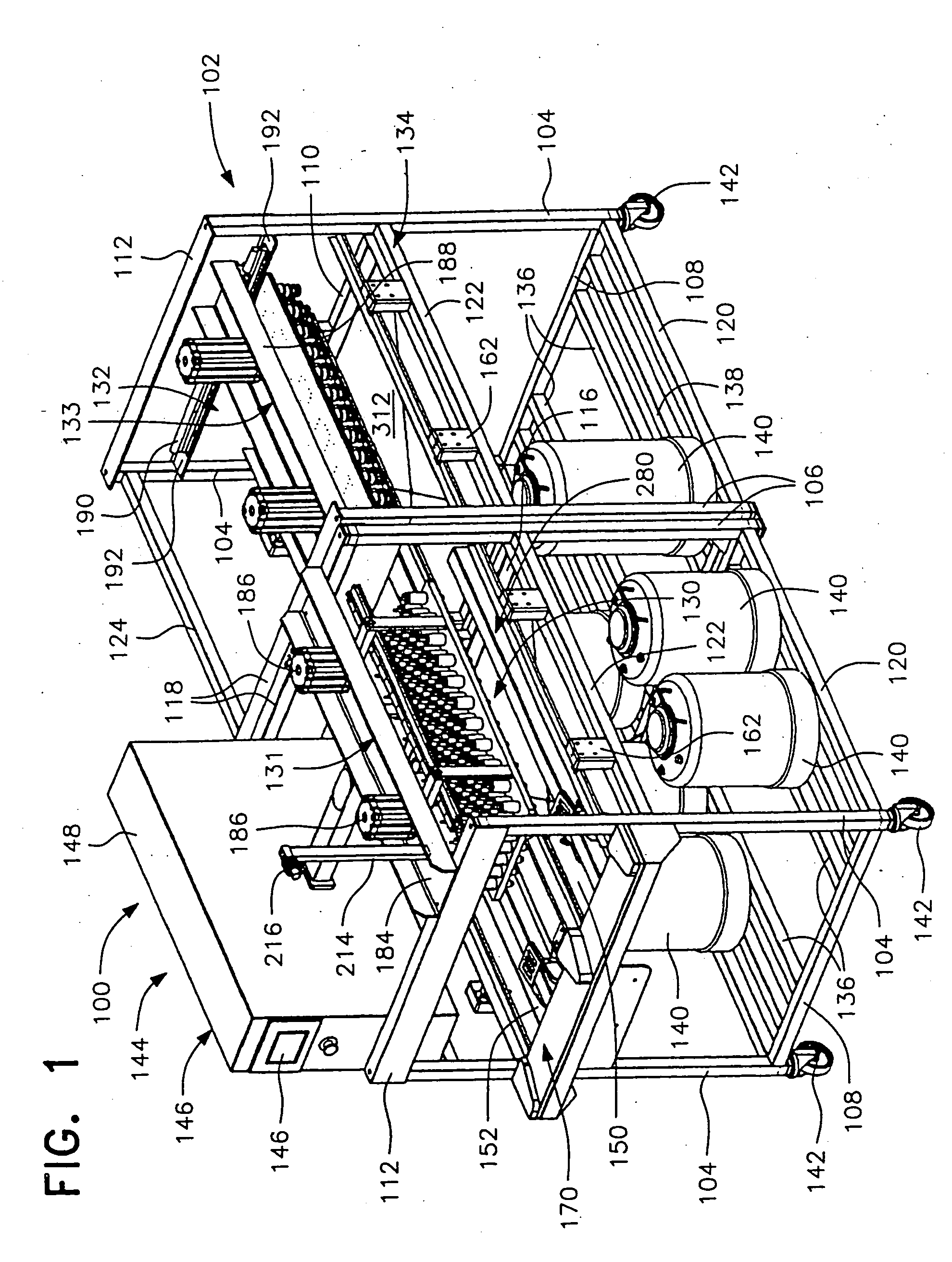

Pot and pan washing machine, components, and methods of washing items

InactiveUS7246624B2Eliminates potentialLess turbulenceTableware washing/rinsing machine detailsPump componentsBiomedical engineeringInlet manifold

An improved pot and pan washing machine is provided including a low suction intake manifold and a partition for capturing a substantial portion of the wash action of the washing machine within a segregated area. The intake manifold of the instant invention includes a plurality of voids having a void concentration that increases as the distance from the source of suction (such as a pump or intake inlet) increases. The partition (or divider) of the instant invention can be removed and repositioned within the wash tank through the use of channels along the walls of the wash tank that receive the partition.

Owner:UNIFIED BRANDS

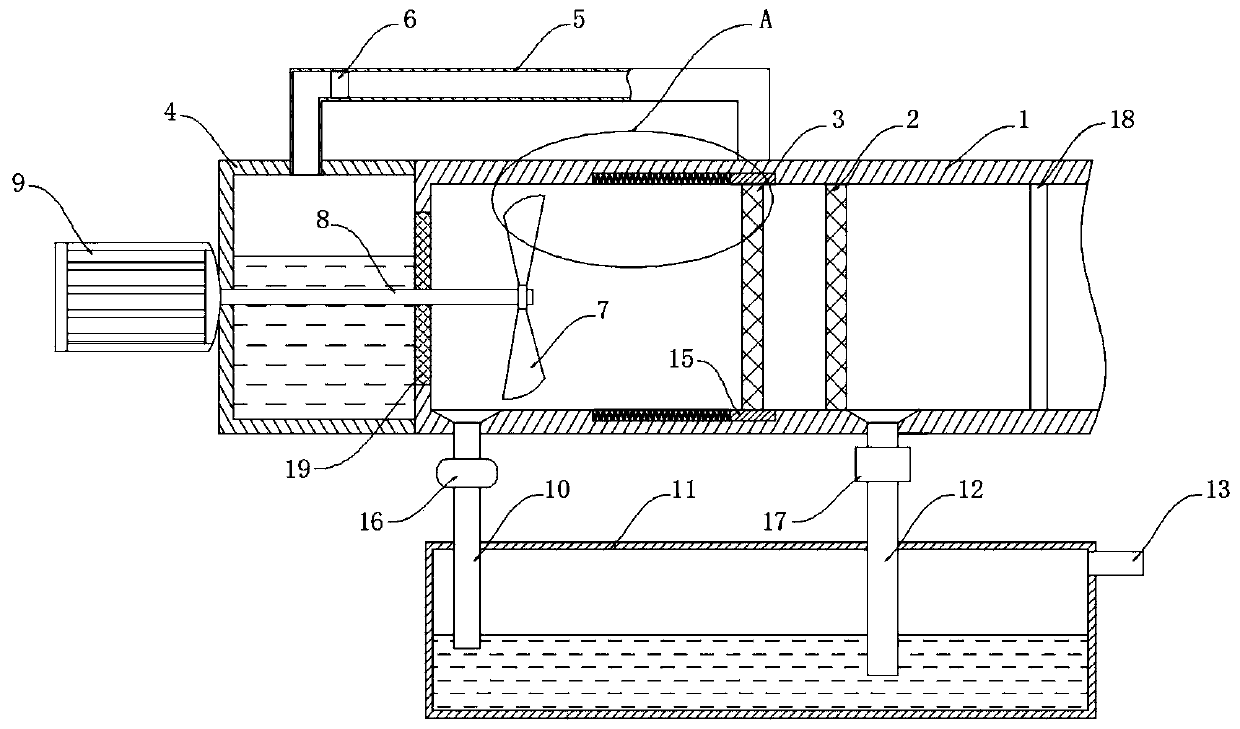

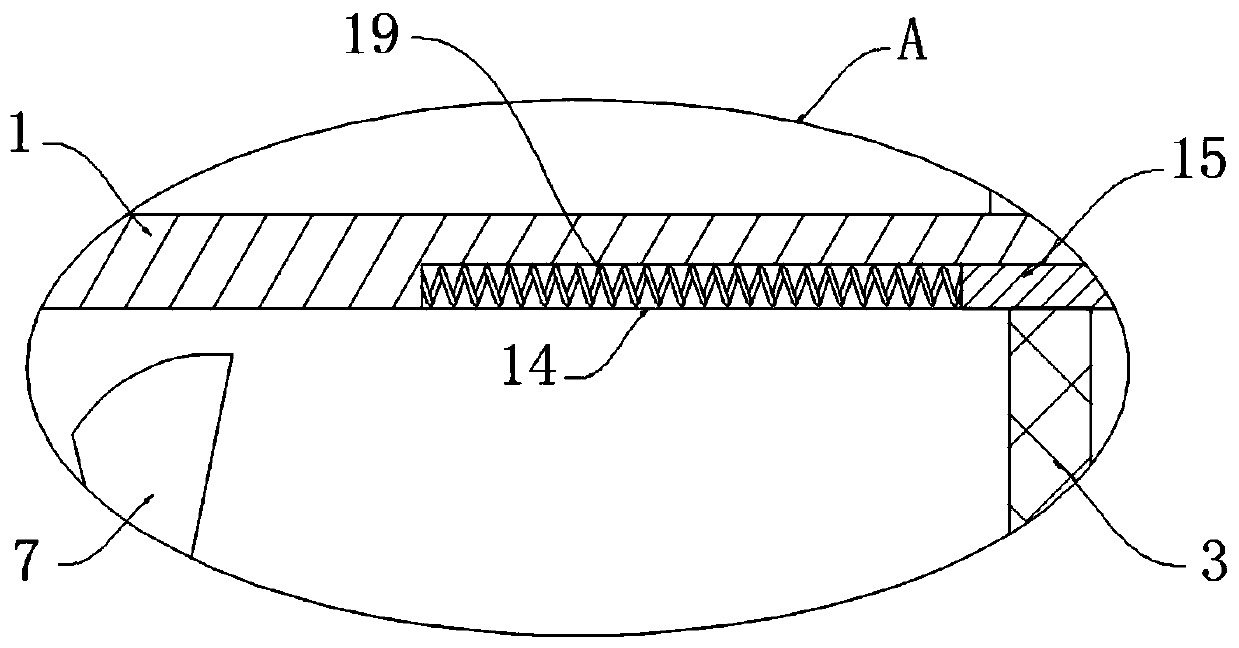

Self-cleaning dust collection filter screen for spinning

The invention discloses a self-cleaning dust collection filter screen for spinning. The self-cleaning dust collection filter screen comprises a dust suction pipe, and a first filter screen and a second filter screen are respectively arranged in the dust suction pipe; the first filter screen is fixedly connected with an inner wall of the dust suction pipe in a sealed mode. A sliding device is connected to the second filter screen, a wind wheel is arranged in the dust suction pipe, a rotating shaft is fixedly connected to the wind wheel, a rotating shaft penetrates the bottom of the dust suctionpipe, a liquid tank is fixedly connected to one side of the dust suction pipe, and the liquid tank and the dust suction pipe are jointly connected and communicated with a ventilation pipe. The self-cleaning dust collection filter screen has the advantages that when the self-cleaning dust collection filter screen is used, evaporated liquid is heated under the action of a large amount of heat generated by idling of a motor, so that a piston pushes gas to backflush the filter screen, the filter screen is automatically cleaned when meshes of the filter screen are blocked, and damage to the motorcaused by idling is reduced while the waste of electric energy is avoided.

Owner:陕西帛宇纺织有限公司

Automated egg injection machine and method

A pneumatically operated egg injection machine includes a sealed frame structure with a pair of in line parallel tracks through an injection section and a transfer section in series. An injection assembly over one parallel track includes a plurality of injectors gripped in a support plate to simultaneously inject vaccine into the same injection region irrespective of egg height and orientation. Fluid delivery systems meter prescribed vaccine dosages to the injecting needles with reduced turbulence, friction, heat and residence time to increase the delivered titer to the injected eggs. A transfer assembly includes a plurality of transfer suction cups which lift the injected eggs by causing a reduced pressure in a ring around the injection hole while maintaining the injection hole at atmospheric pressure, thus avoiding negative pressure in the egg. Once the eggs are lifted, the plate and suction cups move horizontally across the machine over to the other parallel track to deposit the injected eggs. All of the eggs are injected and transferred as a single group. The injection assembly is sprayed with a sanitizing solution at the same time that the injected eggs are moved from the injection section to the transfer section and the transfer assembly can transfer the eggs from the incubating tray to the hatching tray while the eggs in the next incubating tray are injected by the injecting assembly, thus increasing machine speed. The operation of the machine is controlled and monitored by a controller or computer with appropriate visual display monitor.

Owner:SANOVO CAPITAL

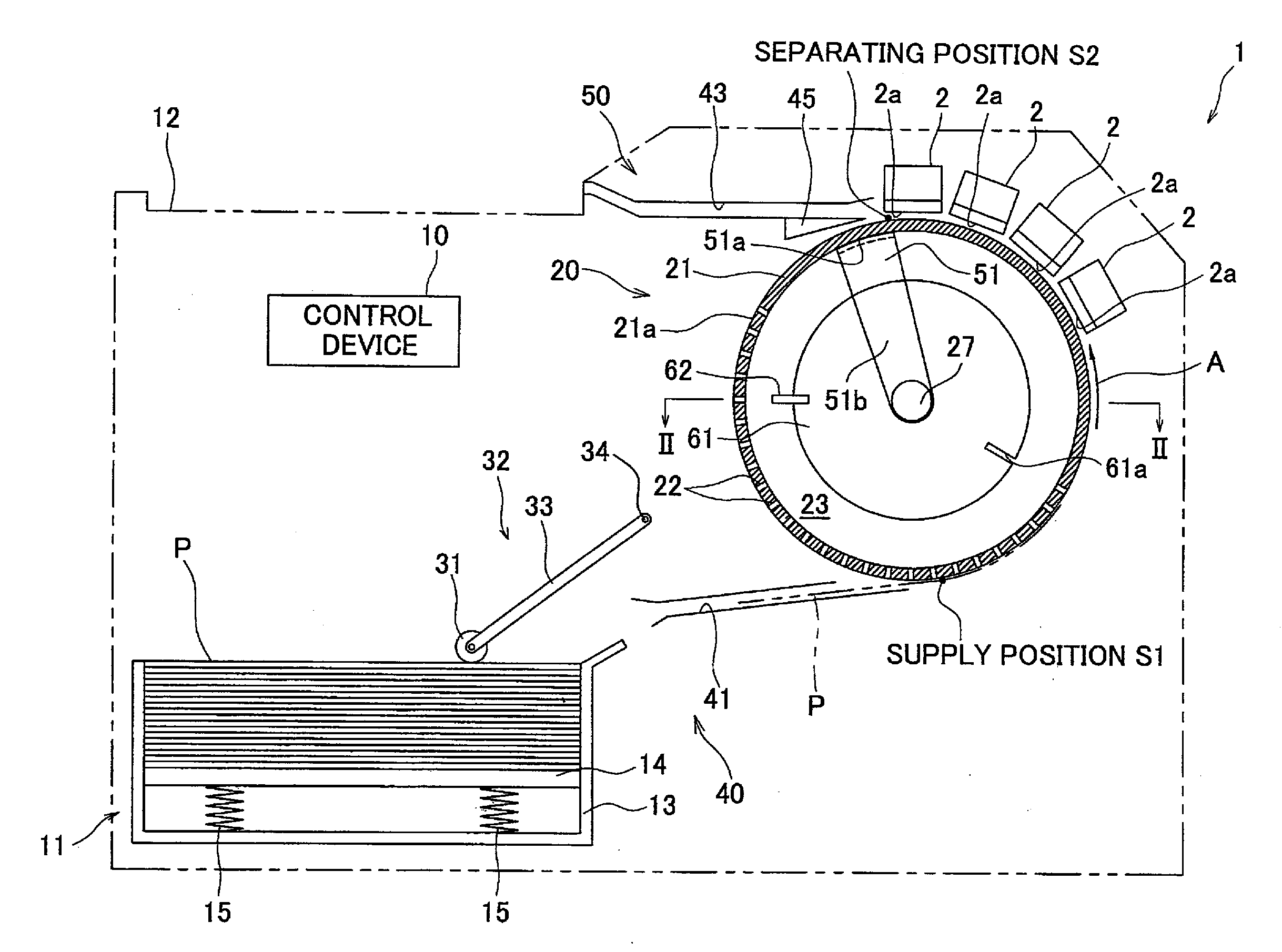

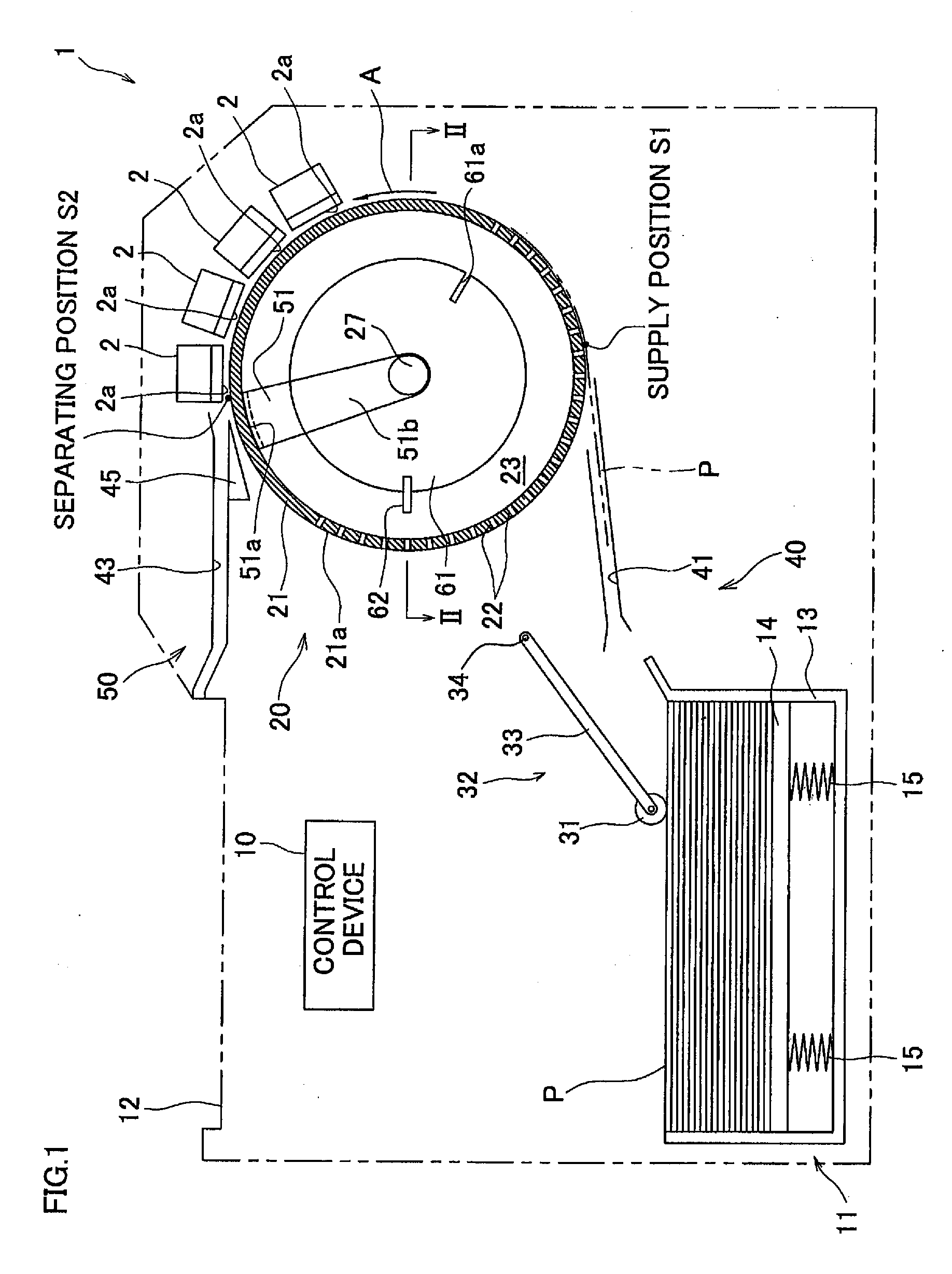

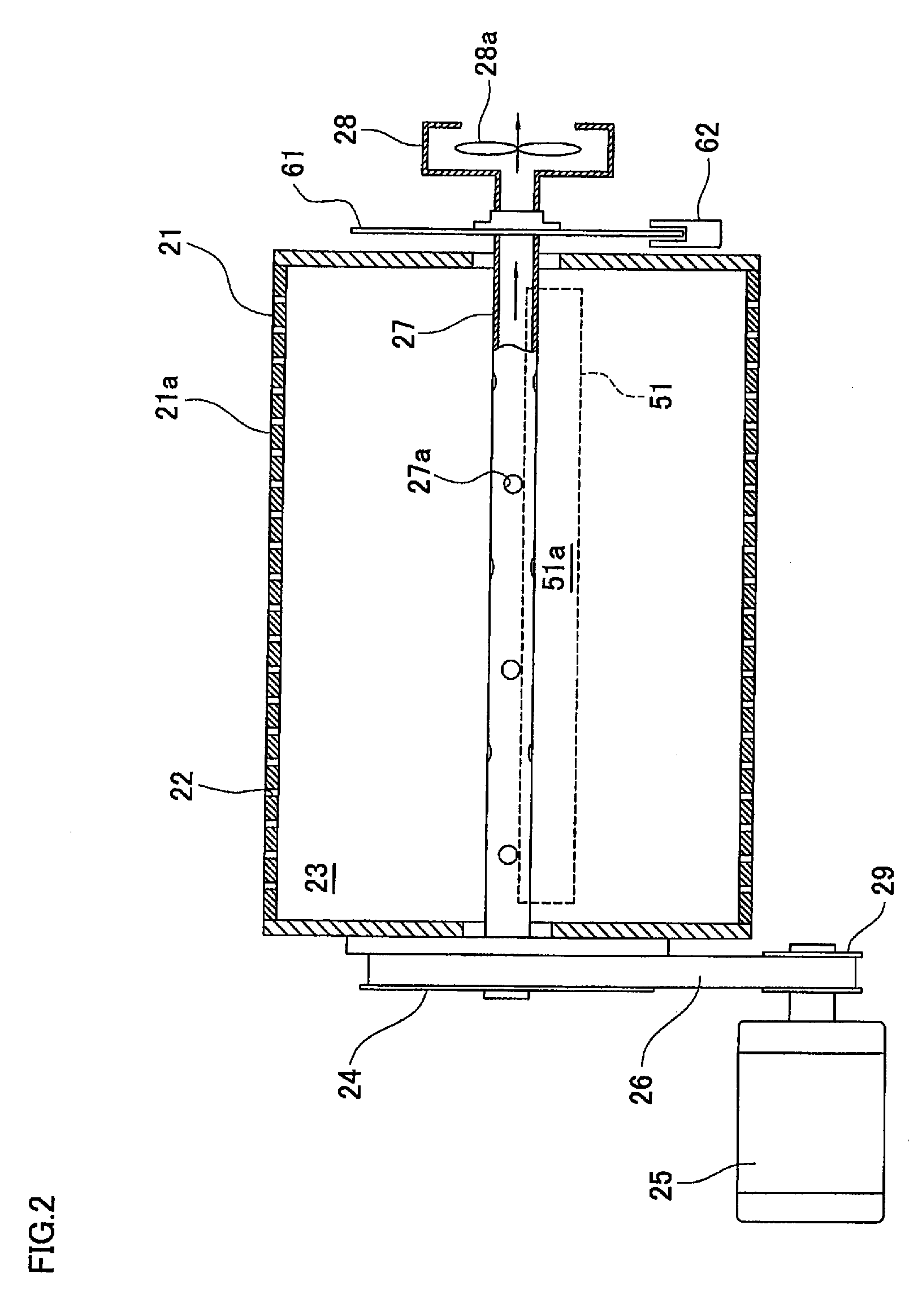

Inkjet recording apparatus

ActiveUS20090051747A1Easy to separateReduce suctionOther printing apparatusArticle feedersInterior spaceImage recording

An image recording apparatus of the present invention includes a conveyance mechanism having a circumferential wall. On the circumferential wall are formed suction holes which communicate an internal space inside the circumferential wall with the outside of the circumferential wall. A recording medium is placed on the outer circumferential surface of the circumferential wall, and is conveyed on the outer circumferential surface in a direction of the rotation of the circumferential wall. A suction unit sucks the air in the internal space to create an air flow from the outside of the circumferential wall to the internal space via the suction holes. A recording medium ejection path branches off from the outer circumferential surface at a separating position which is at the most downstream position of a record head or a position further from the supply position S1 than the most downstream position from the supply position. A blocker positioned in the internal space successively faces an inner opening of at least one of the suction holes having reached the separating position with the movement of the circumferential wall, so as to block the inner opening of the at least one of the suction holes.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com