Suction nozzle inspection device

A technology for inspection devices and photographing devices, applied to electrical components, electrical components, etc., can solve the problems of reduced suction force of electronic components, difficulty in visually confirming nozzle holes, etc., and achieve good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

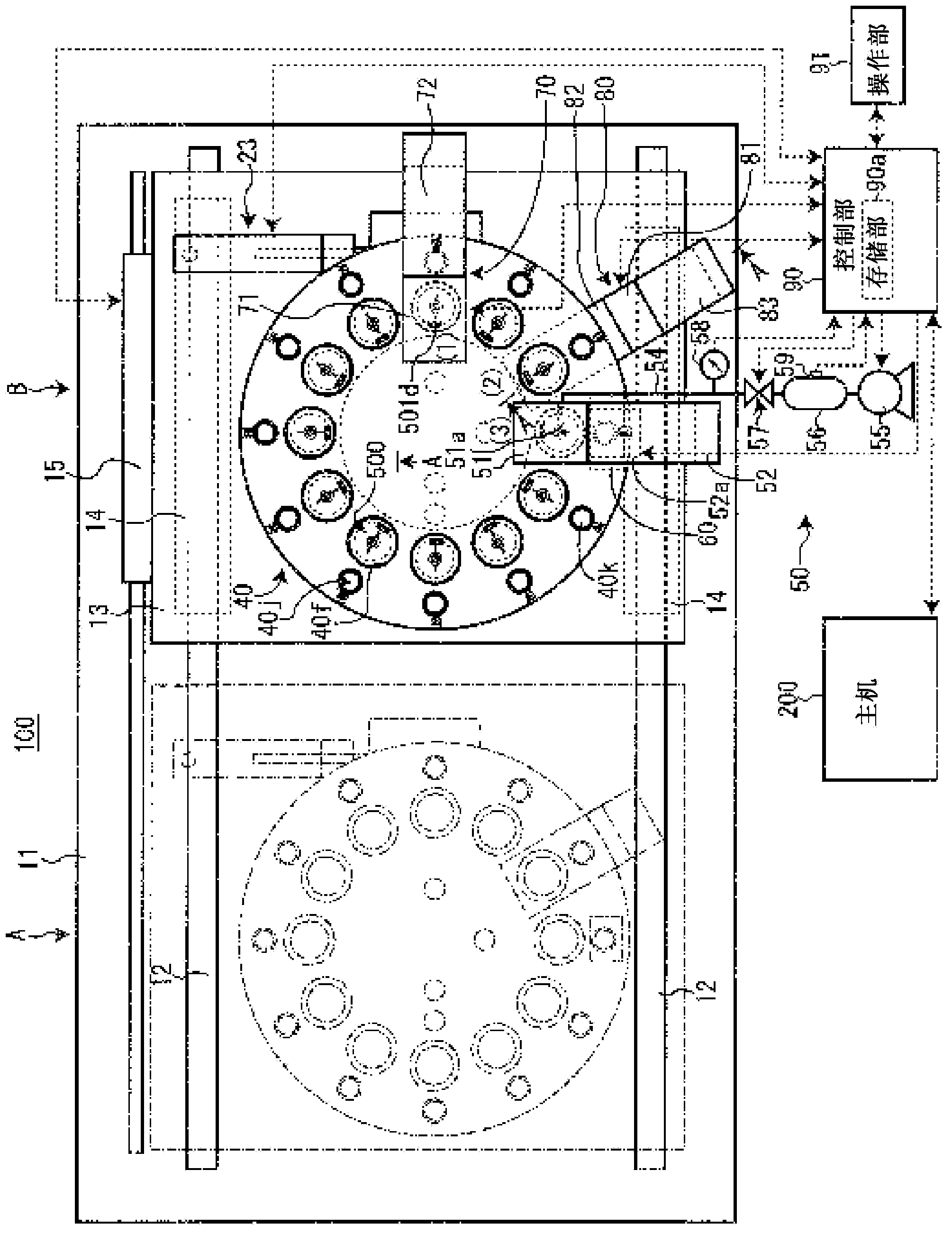

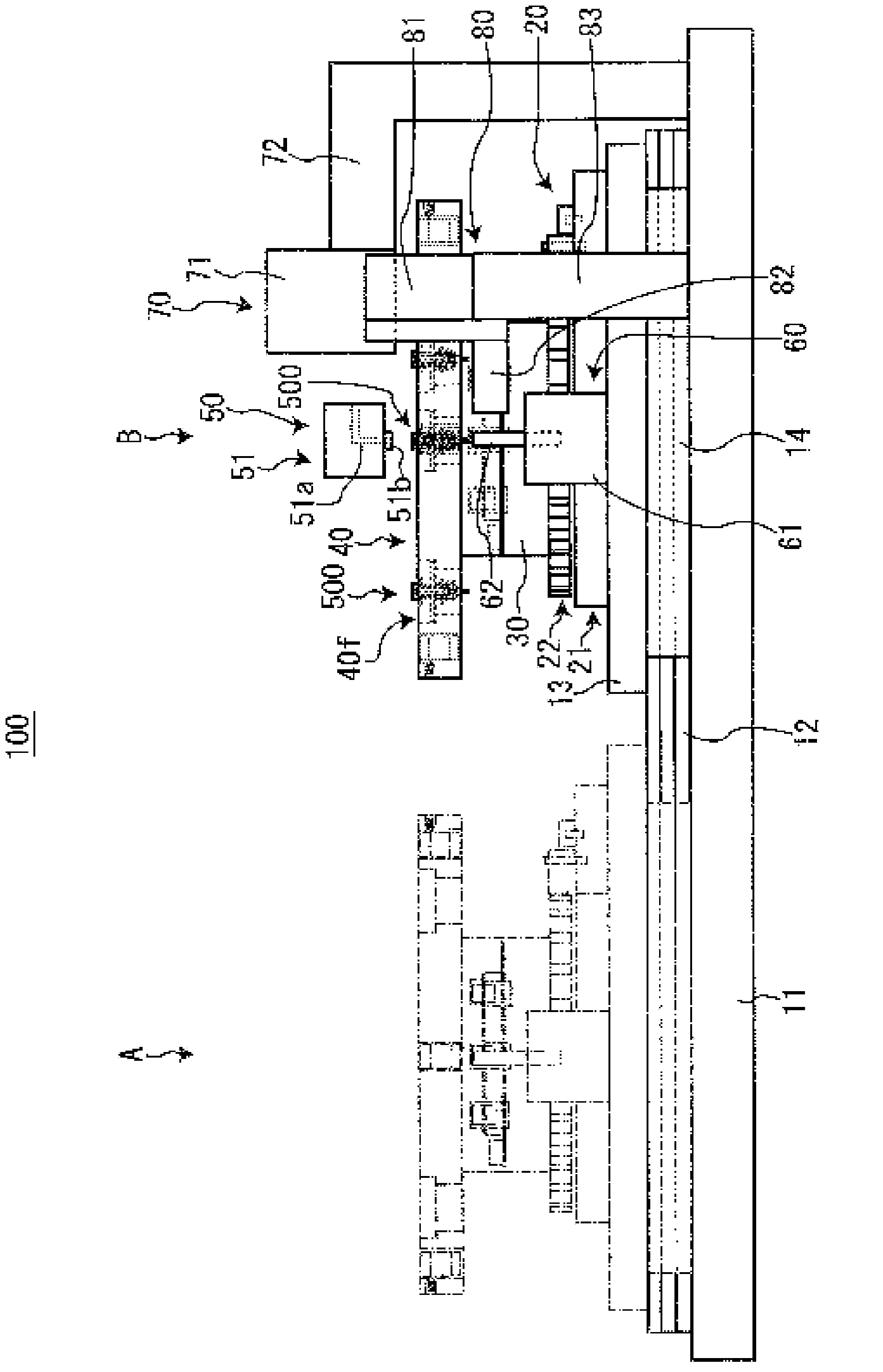

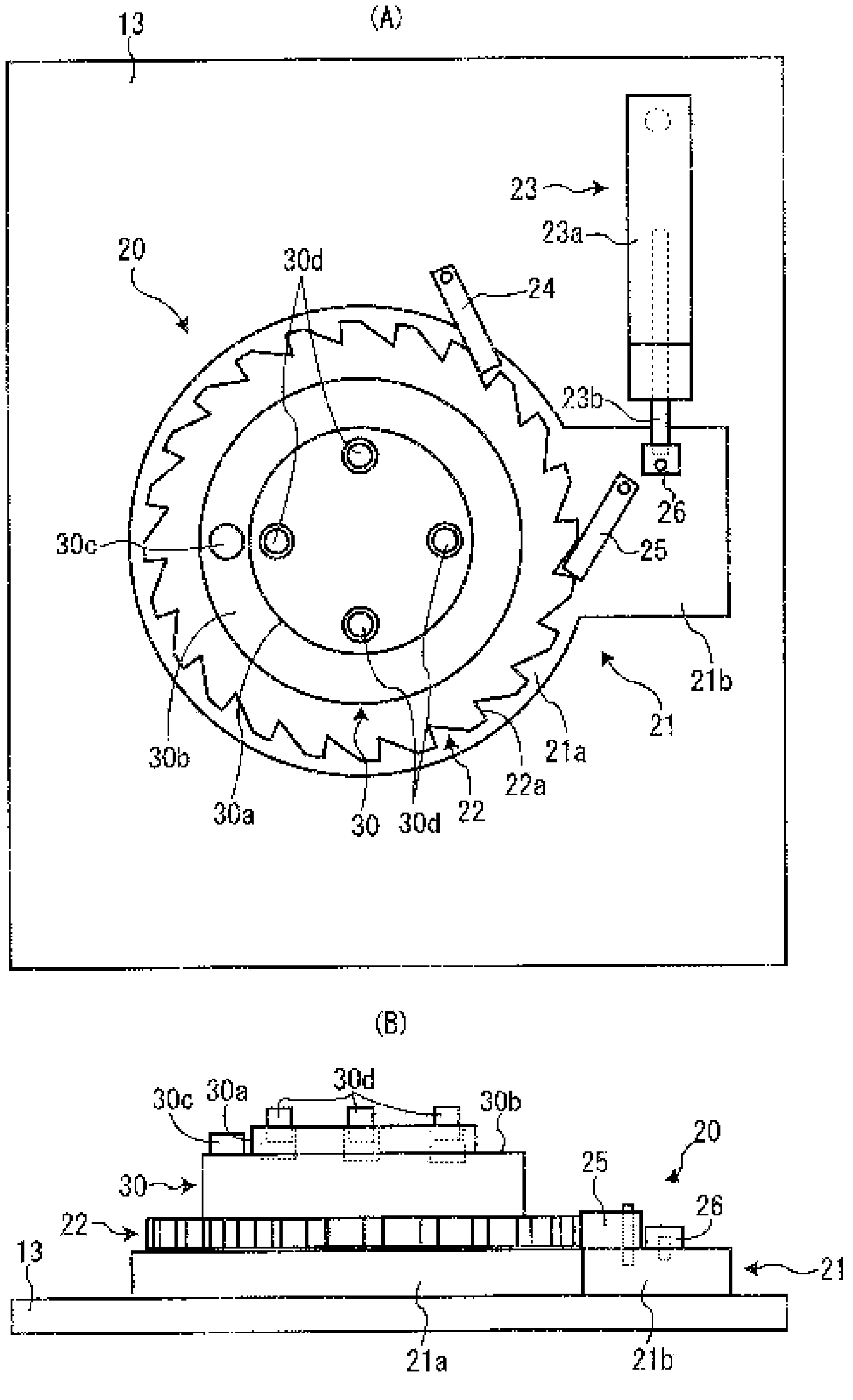

Image

Examples

Embodiment approach )

[0120] In addition, in the embodiment described above, the pump 55 supplies air to the air passage 51 a of the nozzle connection portion 51 , and the flow rate detection sensor 58 detects the flow rate of the air supplied to the nozzle hole 502 f through the pump 55 through the nozzle connection portion 51 . The control unit 90 determines the cleaning state of the nozzle hole 502f based on the flow rate of the air detected by the flow rate detection sensor 58 . However, an embodiment is also possible in which the pump 55 sucks air from the air passage 51a of the nozzle connection portion 51, and the flow rate detection sensor 58 detects the flow rate of the air sucked by the pump 55 through the nozzle connection portion 51 from the nozzle hole 502f. As for the flow rate, the control unit 90 determines the cleaning state of the nozzle hole 502 f based on the flow rate of the air detected by the flow rate detection sensor 58 .

[0121] In addition, in the embodiment described ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com