Connector, conducting connecting structure and method

A connector and conduction technology, which is applied in the field of connectors with concave terminals, can solve the problems of difficult coating of conductive adhesives, high price of conductive adhesives, and rising production costs, and achieve easy and reliable embedding. Cooperative work, good workability, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

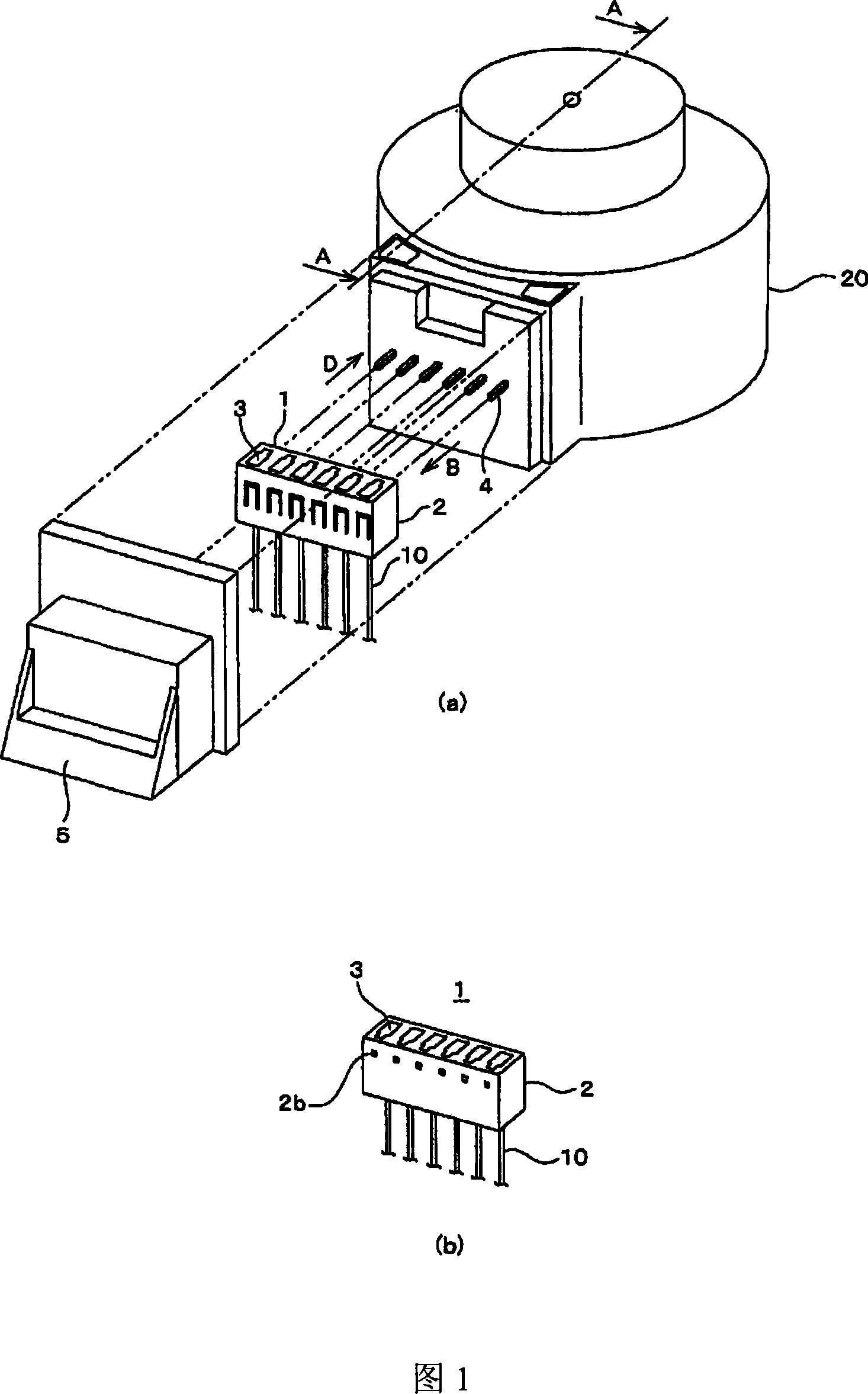

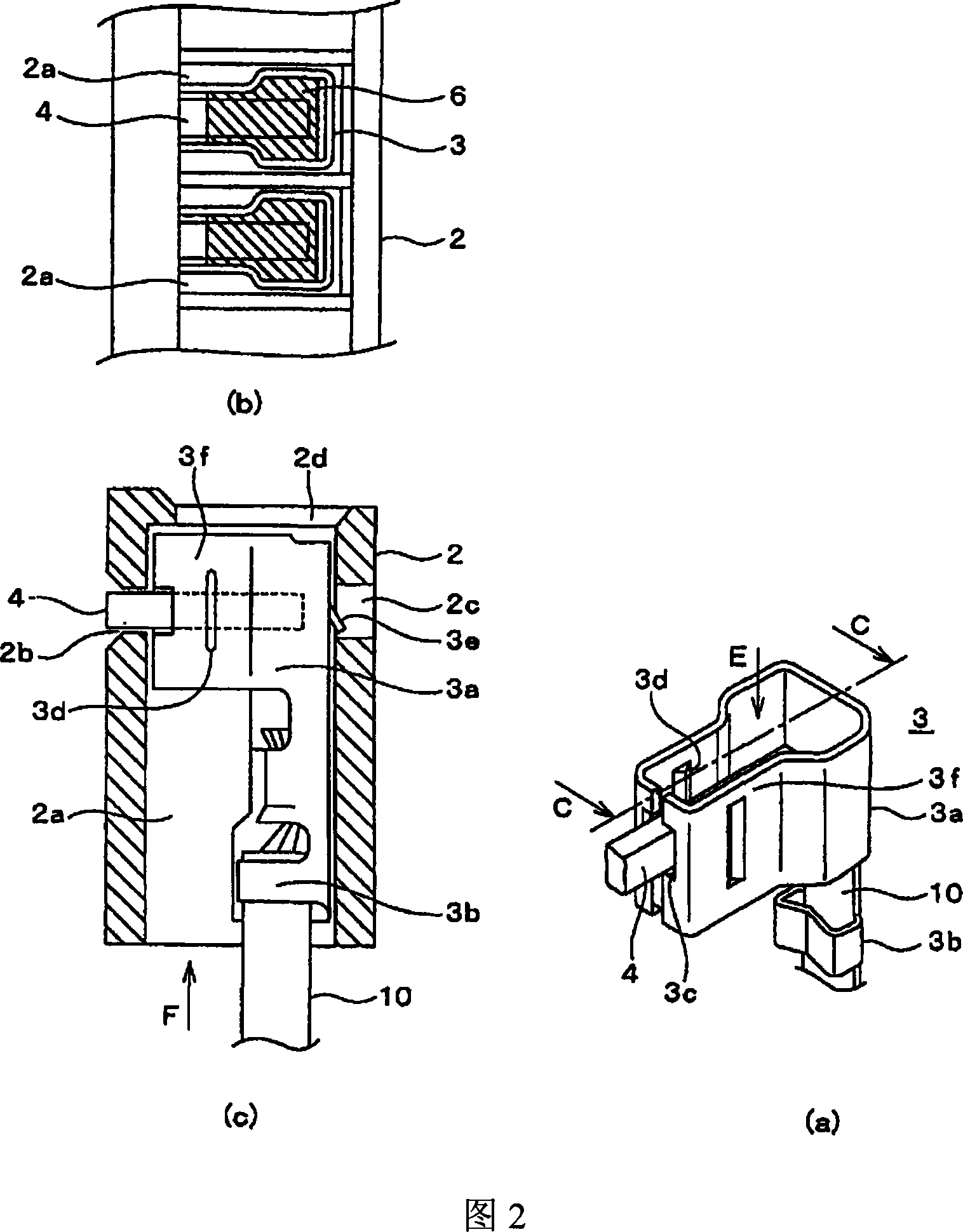

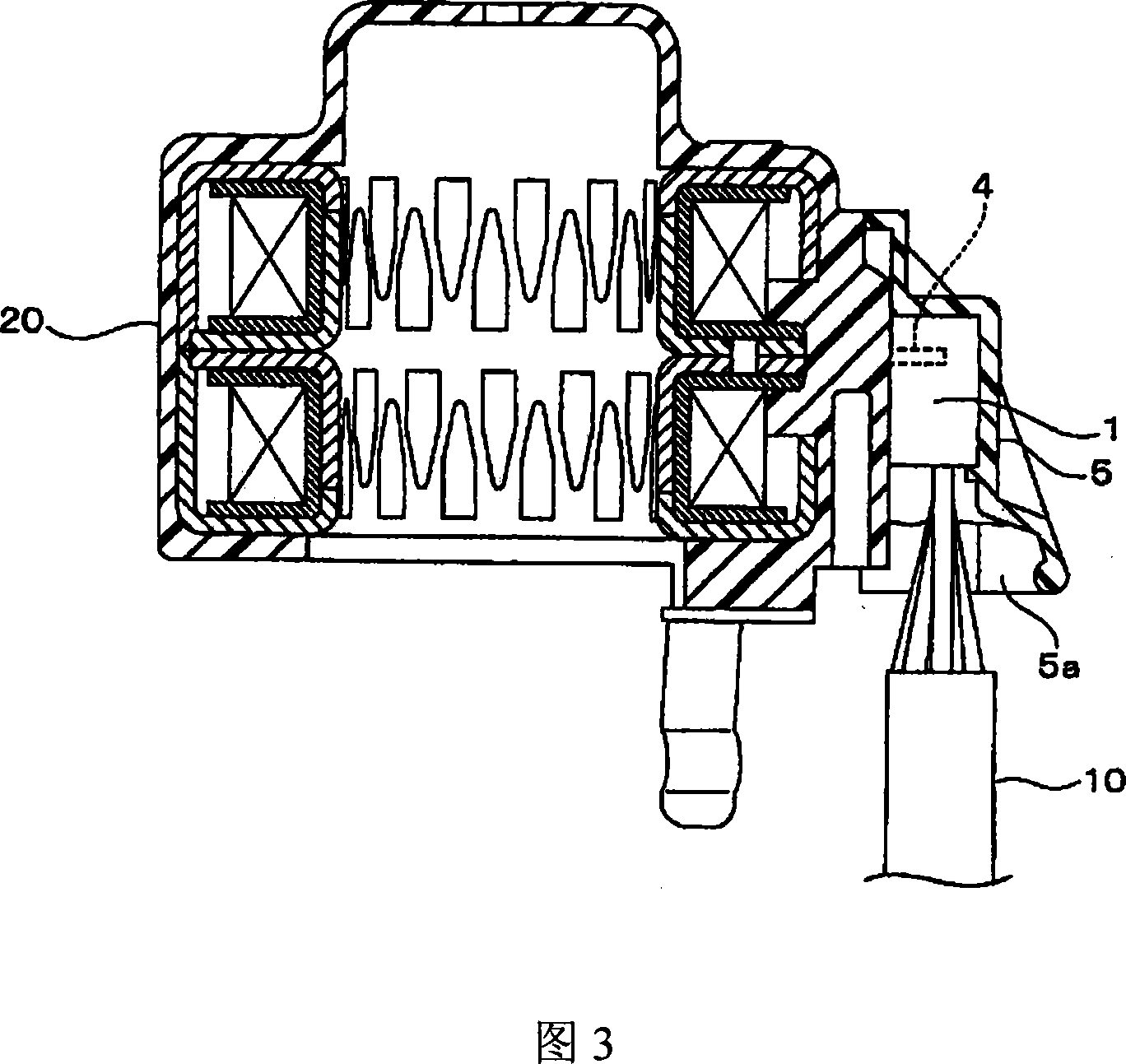

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, the connector of this invention is demonstrated taking the case where it is used for the conduction connection between a stepping motor and the lead wire for electric conduction as an example.

[0021] As shown in FIG. 1 , the connector 1 of the present invention includes a housing 2 and a plurality of female terminals 3 arranged side by side in a row on the housing 2 .

[0022] Housing 2 is made of synthetic resin, as shown in Figure 1 and Figure 2, housing 2 has: a plurality of accommodating parts 2a for accommodating a plurality of female terminals 3; The opening part 2b of the female terminal 3 is engaged with the engaging protrusion 3e of the female terminal 3 so that the female terminal 3 is locked in the housing part 2a by the locking hole part 2c. The entire housing 2 is preferably made of nylon or the like containing ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com