Ultra-germination accelerating system and ultra- cultivation accelerating system

A technology that promotes cultivation and cultivation of soil. It is applied in greenhouse cultivation, botany equipment and methods, and agricultural machinery and equipment. It can solve the problems of difficult and economical temperature management and poor workability, and achieve good workability and energy The effect of less loss and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

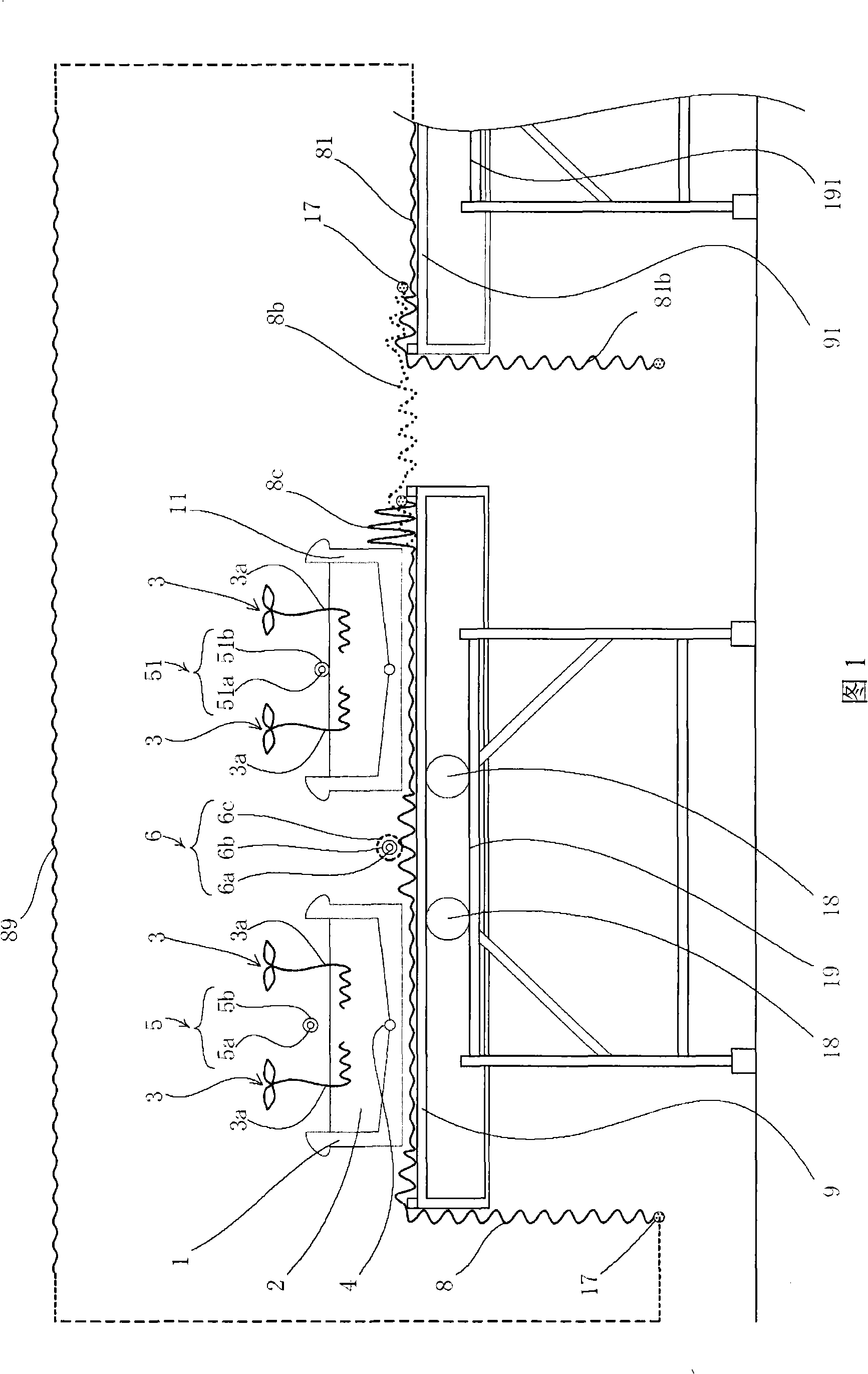

[0045] Referring to Fig. 1, the cultivation soil 2 is accommodated in two seedbed containers 1, 11 respectively, and the seedlings 3 and 3 of the cultivated plants are planted in the cultivation soil 2 of the seedbed containers in two rows.

[0046] The first heat radiation pipes 5, 51 are provided in the seedbed containers 1, 11, respectively.

[0047] The 1st radiating pipe 5,51 is positioned in the middle of two rows of seedlings 3,3. In this embodiment, for the convenience of introduction, it is shown that the 1st radiating pipe 5,51 is arranged on the position close to the top of the cultivation soil respectively, and is arranged in the same position as the cultivation soil. The position where the soil contacts. Usually, however, the first heat radiation pipes 5 and 51 can be installed at the same position.

[0048] The second heat radiation pipe 6 is provided in the middle of the seedbed containers 1,11.

[0049] And at the bottom center of seedbed container 1,11, drai...

Embodiment 2

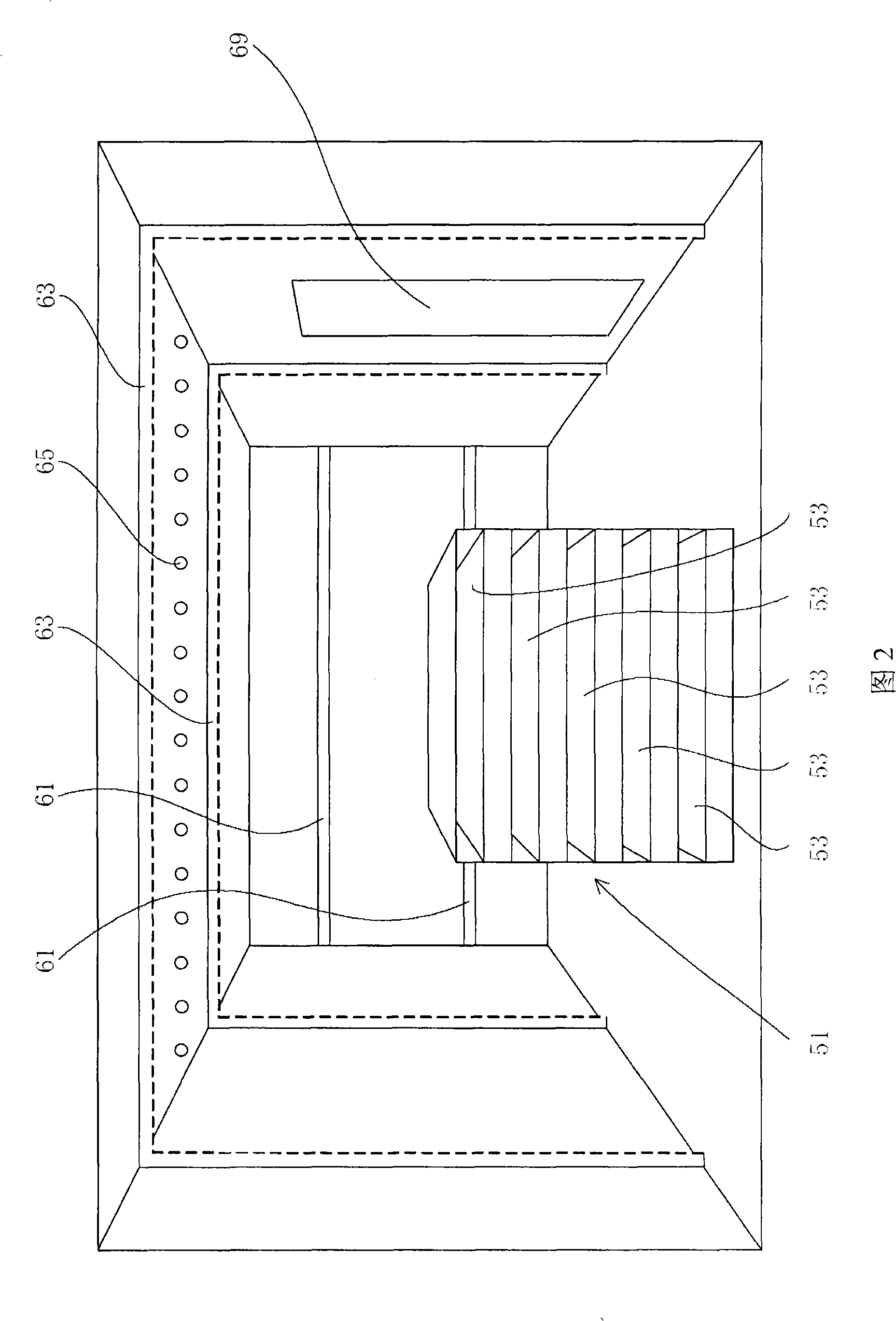

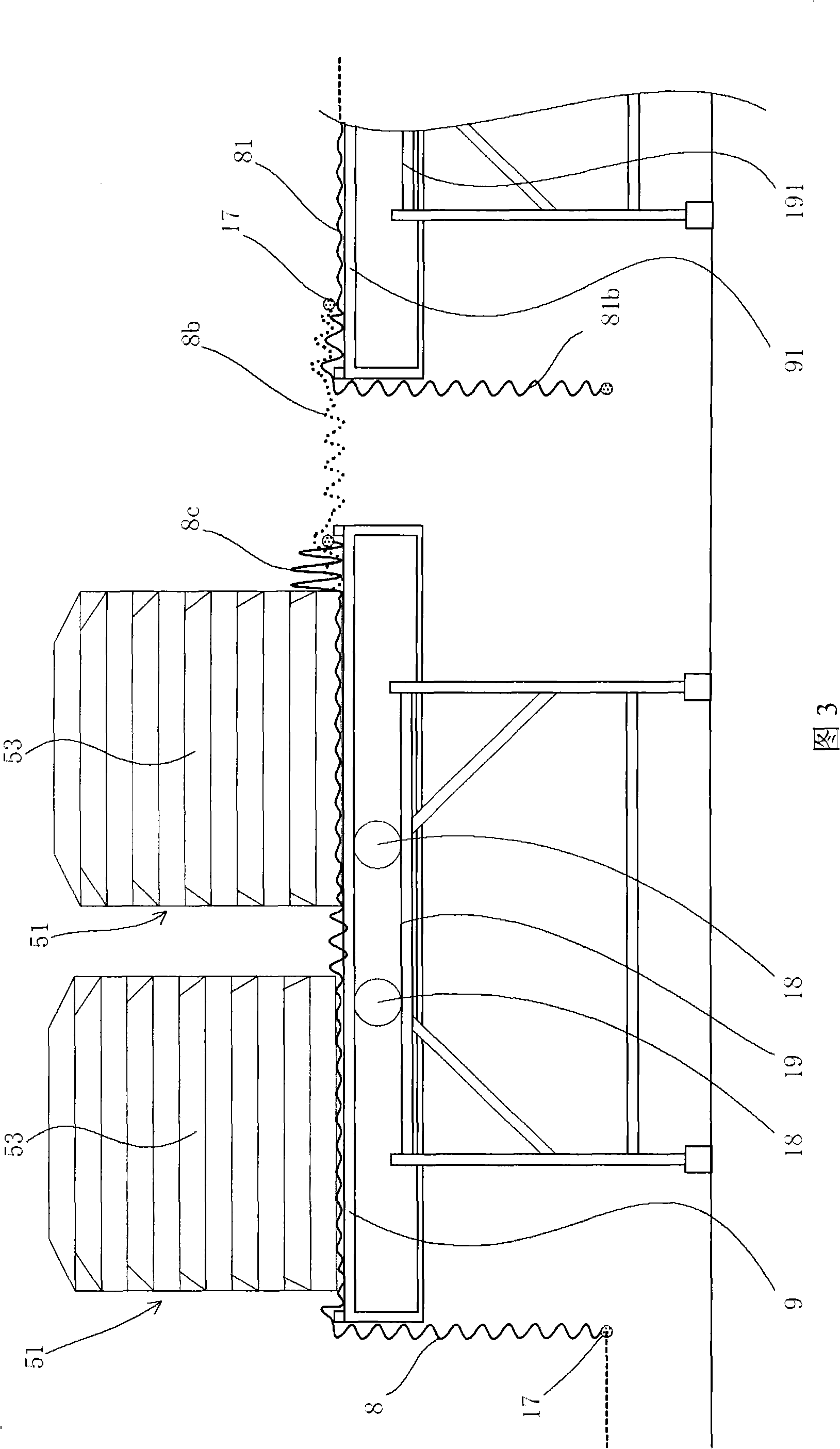

[0054] The seedbed containers 1 and 11 are installed on the support stand 9 covered with the 1st thermal insulation board 8 together with the 2nd heat radiation pipe 6. As shown in FIG.

[0055] Since the support platform 9 is placed on the fixed platform 19 by the wheels 18, 18 and can move relative to the fixed platform, the operator stands between the fixed platform 19 and the adjacent fixed platform 191, and pushes the support platform 9 laterally from the figure. , can easily open the access to the upper part of the figure for work. At this time, on the left side in the figure, the passage not used for work is blocked.

Embodiment 3

[0057] The first insulation board 8 is provided with hammers 17, 17 at both ends in the figure, and the end 8b of the insulation board 8 is generally shown in the dotted line 8b on the right side of the support platform 9 among the figures, straddling the passage with space and spreading on the adjacent On the support platform 91, it is controlled by the hammer 17.

[0058] The end portion 81b of the first heat insulating board 81 on the adjacent supporting table 91 hangs down naturally in this embodiment, but it may be spread on the supporting table 9 so as to overlap with the end portion 8b of the insulating board 8 .

[0059] When the operator pushes the support table 9 to form a passage, the end portion 8b of the thermal insulation board 8 is folded and installed on the support table 9 as shown by the solid line 8c. Or, similarly to the end 81b of the thermal insulation board 81, it hangs down naturally.

[0060] In this way, since it is easy to open the passage for opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com