Patents

Literature

124results about How to "Guarantee internal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A low-cost precision casting method for titanium alloy and titanium-aluminum alloy

InactiveCN102294436AIncrease contentControl quality costFoundry mouldsFoundry coresPolyvinyl alcoholTitanium alloy

The invention relates to a method for precisely casting a titanium alloy and a titanium aluminum alloy with low cost, which relates to a method for precisely casting the titanium alloy and the titanium aluminum alloy, and solves the technical problem that cast pieces have low surface quality and internal quality in the conventional method for lowering the cost of precisely casting the titanium alloy and the titanium aluminum alloy by using electrically-fused alumina and silica sol. The method comprises the following steps of: preparing a surface layer binder from zirconium sol, silica sol, a wetting agent JFC, n-octyl alcohol, polyvinyl alcohol and latex; adding calcium carbonate, alumina, titanium dioxide and zirconia to prepare a surface layer coating; preparing a shell surface layer; preparing a shell back layer by a universal method for precisely casting the titanium alloy; dewaxing and sintering to obtain a shell; and casting the titanium alloy or the titanium aluminum alloy by using the shell so as to obtain a titanium alloy cast piece or a titanium aluminum alloy cast piece. Compared with a precise casting method by purely using a zirconium-based binder and a zirconia fireproof material, the method has the advantage that raw material cost is lowered by 30 to 70 percent and the method can be used for civil titanium alloy cast pieces and titanium aluminum alloy cast pieces for common aviation.

Owner:HARBIN SHITAI NEW MATERIAL TECH & DEV

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

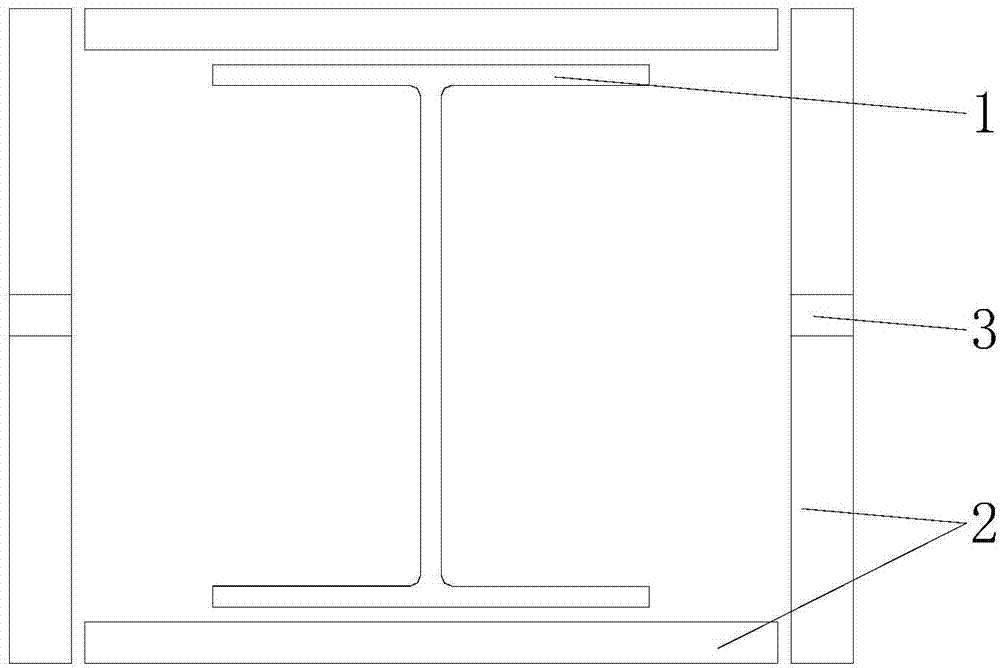

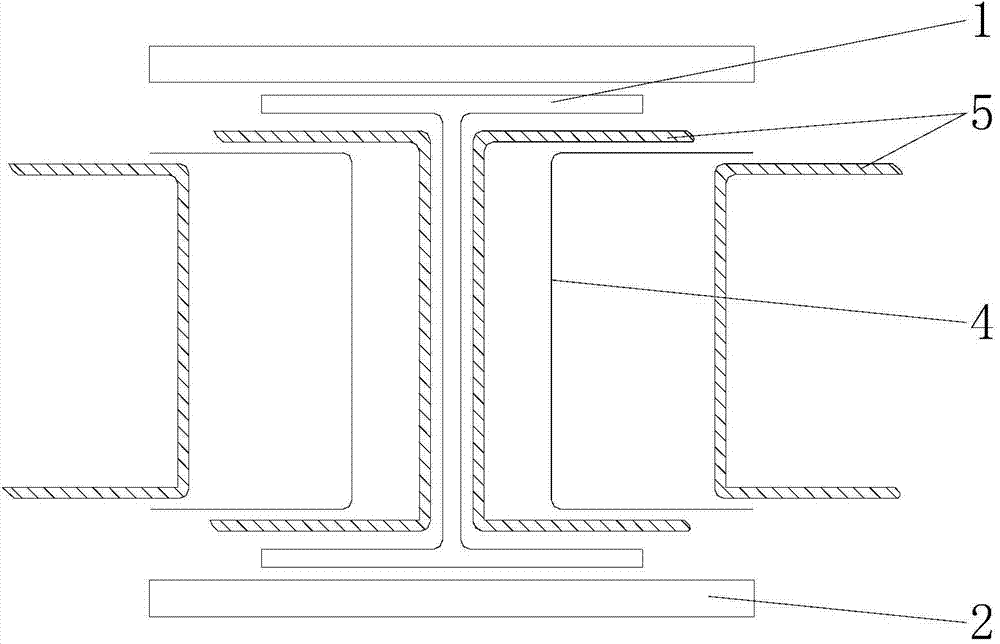

Molding method for composite material structural member with I-shaped section

The invention discloses a molding method for a composite material structural member with an I-shaped section. The composite material structural member is molded by taking a metal fake member and a molding mould to mould a glass fiber enhanced silicone rubber airbag and taking the airbag as a core mould to be combined with the molding mould. The molding method has the advantages that with the adoption of a silicone rubber airbag molded structural member, firstly, the wall of the airbag is thin, the heat transferring performance is good, the temperature gradient of the structural member and the edge is small, and the inner quality of the molded structural member is guaranteed; secondly, silicone rubber on the surface of the airbag is elastic so as to have the effect of a pressure equalizing cushion; the surface quality of a molded part is good; thirdly, the silicone rubber airbag is combined with a box-shaped structure of the airbag; meanwhile, the two ends of the I-shaped structural member are connected by the silicone rubber, the structural rigidity of the airbag is great and the molding position and the size precision of a web are guaranteed; fourthly, the airbag can be used repeatedly and can be manufactured conveniently again so that the production cost is reduced effectively; the whole molding method can uniformly apply a pressure to the web and an edge strip of the structural member and the pressure is equal to a tank pressure.

Owner:航天海鹰(镇江)特种材料有限公司

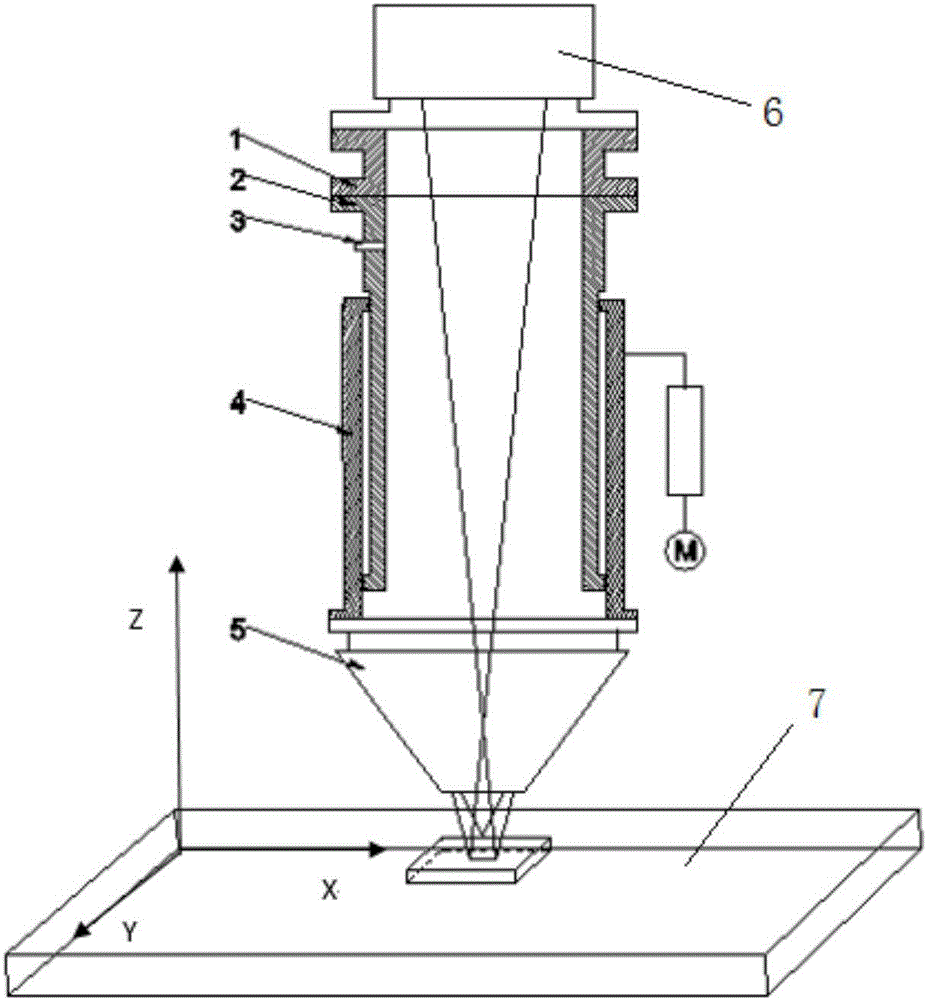

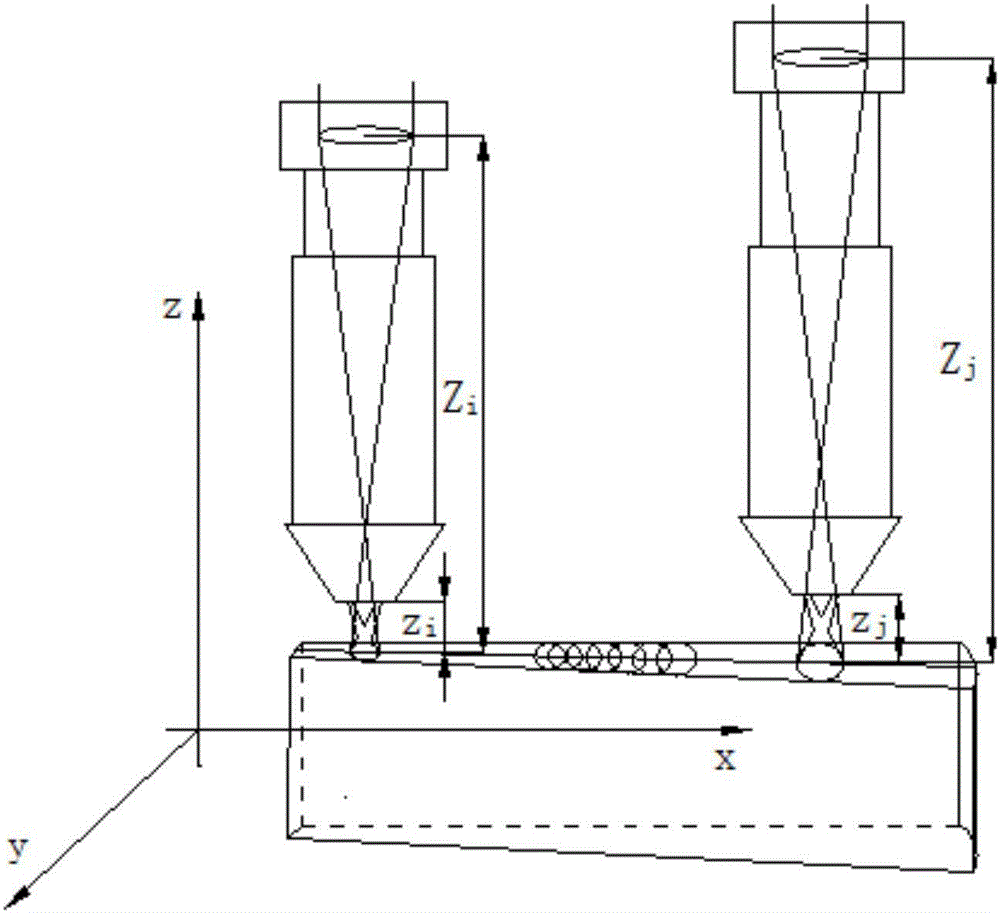

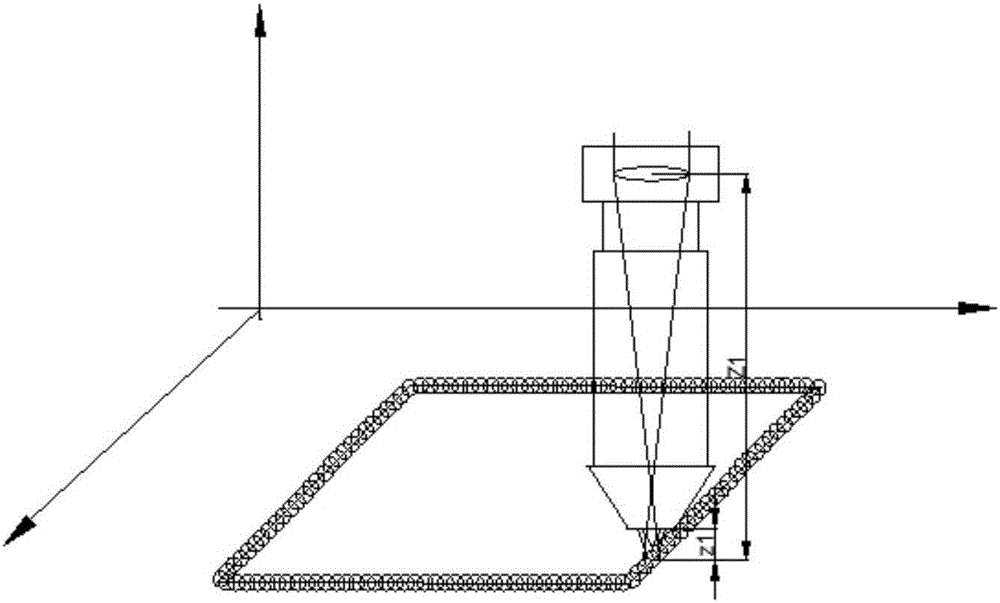

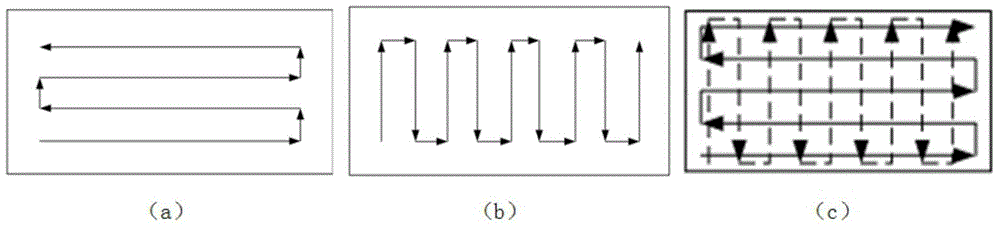

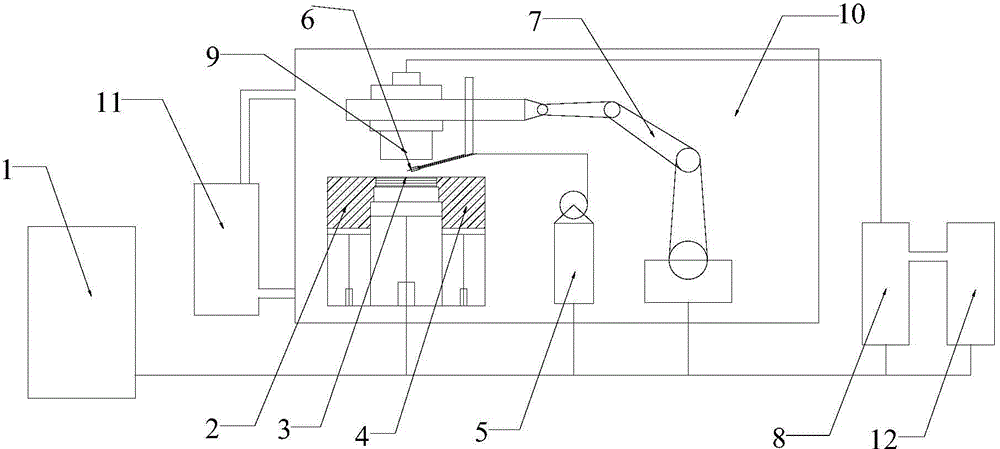

Light spot and powder spot automatic collaboration controlled laser metal added material manufacturing device and method

ActiveCN106513676AImprove matchThe cladding process is stableAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlAdditive layer manufacturing

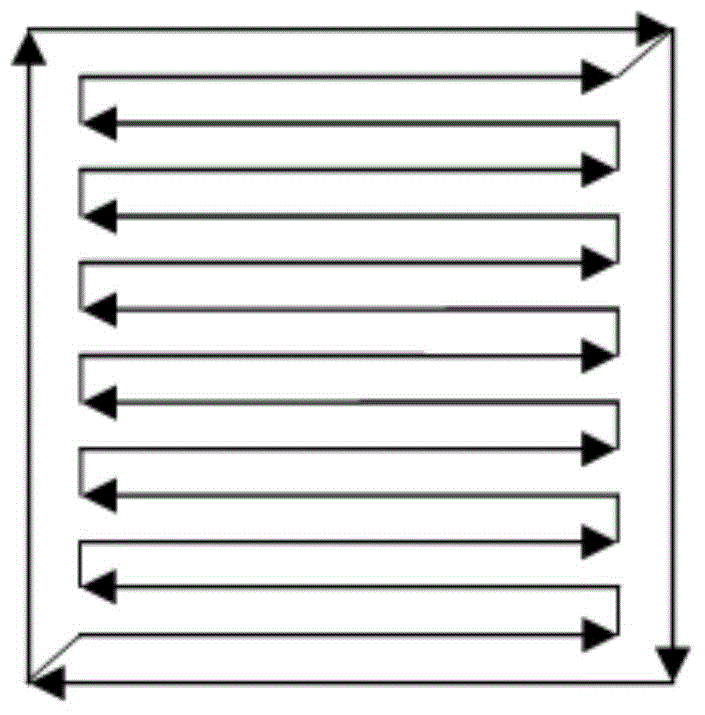

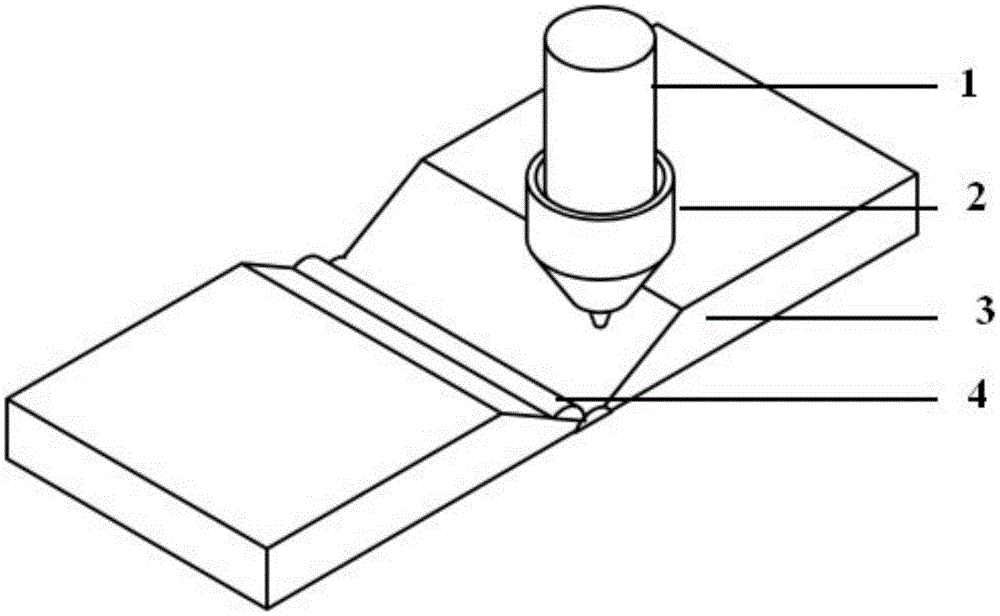

The invention discloses a light spot and powder spot automatic collaboration controlled laser metal added material manufacturing device and a method. The device comprises a connecting joint, a laser focusing head and a sleeve respectively fixed at the upper end and the lower end of the connecting joint, a mobile sleeve slidingly coating the sleeve, a powder feeding nozzle fixed at the lower end of the mobile sleeve, and a numerical control worktable for placing workpieces; the laser focusing head is used for forming light spots on workpiece machined surfaces of a focusing mirror; the powder feeding nozzle is used for gathering powder currents to feed in a machining position to form powder spots on the workpiece machined surfaces; the centers of the light spots and the powder spots are overlapped always; the numerical control worktable is used for driving the workpieces to perform the space movement corresponding to the focusing mirror to control the out-of-focus distance; and a driving device is arranged on the mobile sleeve for driving the powder feeding nozzle to move up and down through the mobile sleeve to control the sizes of the powder spots. When the method forms thick and large workpieces with the cladding layer sizes exceeding the adjusting range, the profile scanning and filling scanning combined path formation is adopted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

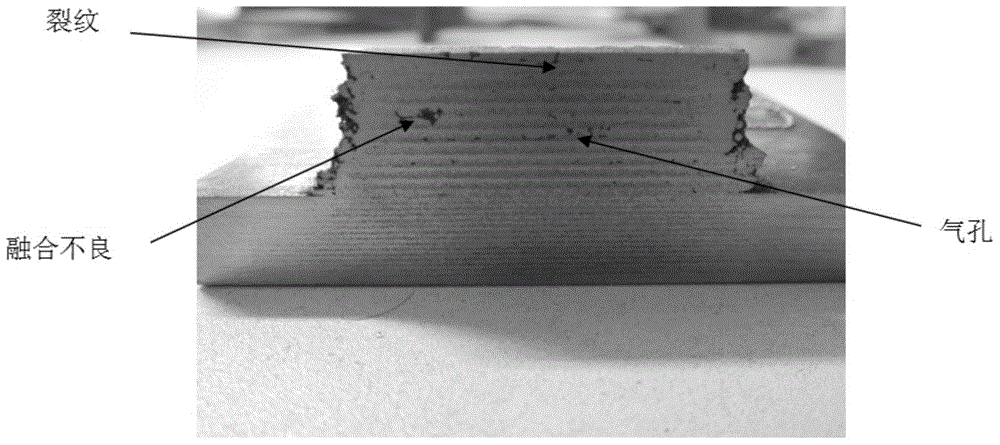

Laser additive manufacturing technology of high-temperature alloy parts

InactiveCN104785778AImplement defect controlControl internal defectsIncreasing energy efficiencyManufacturing technologyLaser scanning

The invention discloses a laser additive manufacturing technology of high-temperature alloy parts, and belongs to the technical field of laser additive manufacturing of metal powder. According to the invention, the technological parameter ranges of different high-temperature alloy materials are determined through basic technological experiments, and then additive manufacturing is carried out by adopting specific laser scanning paths and related internal defect control methods in the manufacturing process. The parts manufactured through the technology have the advantages that the forming efficiency is high, the cost is low, the internal quality is high, the automation degree is high and operation is easy. The high-temperature alloy parts capable of being applied industrially can be directly manufactured by adopting the technology, so that a new approach for manufacturing the high-temperature alloy parts is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

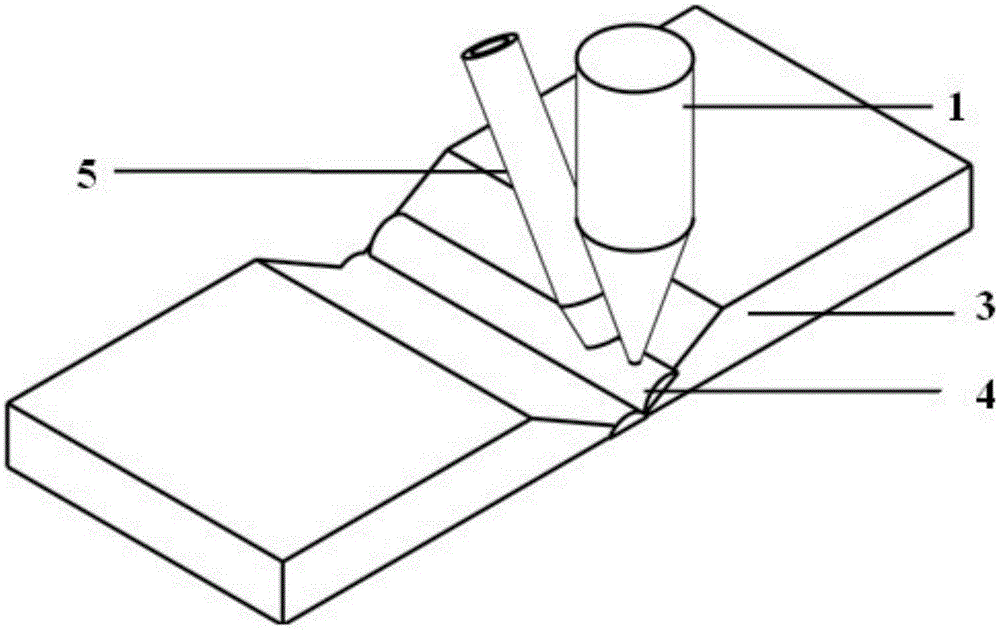

Laser connection method based on laser material additive manufacturing technology

InactiveCN105414762AImprove performanceControl deficienciesLaser beam welding apparatusManufacturing technologyWeld seam

A laser connection method based on the laser material additive manufacturing technology relates to a welded connection method of a special material. According to the laser material additive manufacturing principle, and by utilizing the laser depositing method and the layer-by-layer piling method, a new material shaped like the welding seam between two base materials is formed between the welding seam of two connecting materials and the formed new material is further utilized to connect the two base materials. According to the laser connection method based on the laser material additive manufacturing technology, provided by the invention, the metallurgical composition of the welding seam and the joint performance are improved, near-net forming connection is realized, materials are greatly saved, the cost is reduced, weld defects are controlled, the degree of automation is high, and the operation is easy; besides, a fiber laser, a YAG solid laser, a semiconductor laser or CO2 laser are taken as the core, and a powder feed device, a protective gas system and a cooling system are taken as auxiliary appliances, therefore the overall system is high in automation level, can realize whole-process computer control, and is simple in operation processes and further easy to implement.

Owner:HARBIN INST OF TECH

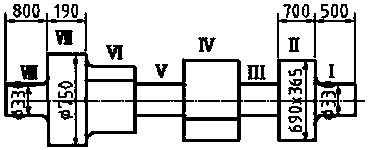

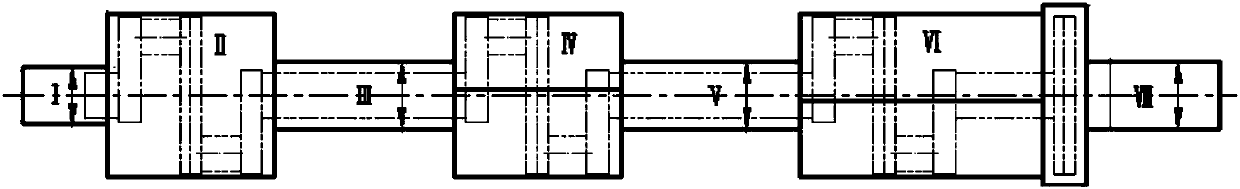

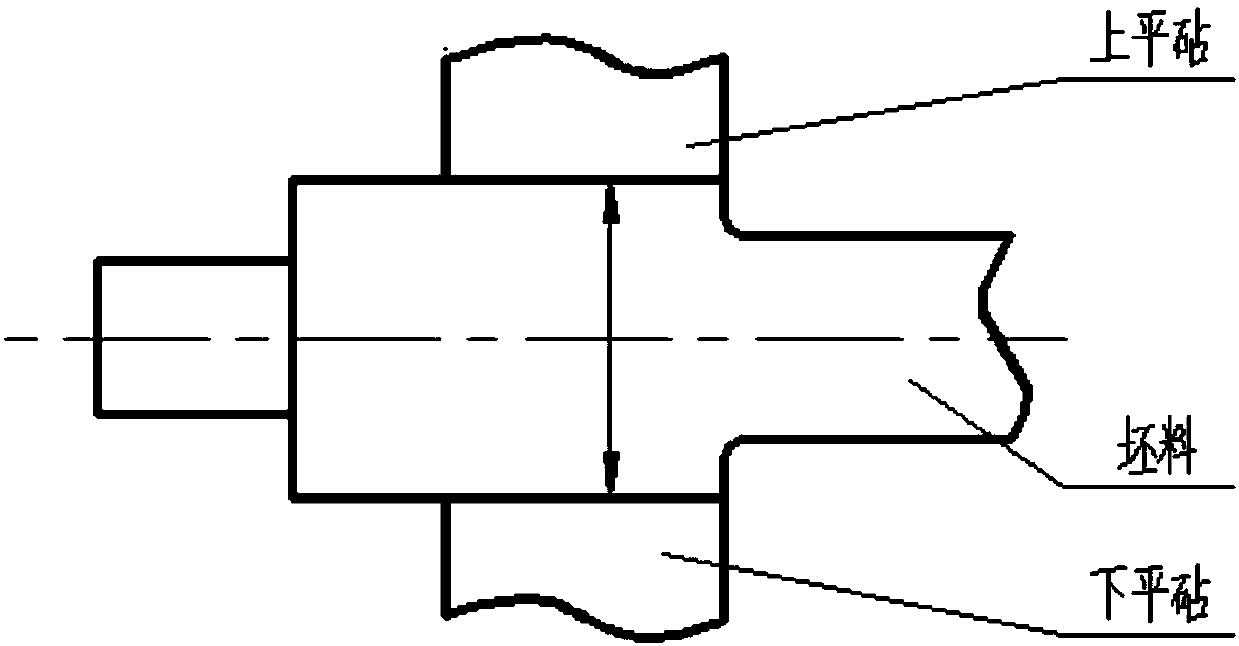

Forging forming process of heteromorphic transition section of super large pressure vessel

The invention relates to a forging process of super large workpieces and provides a forging forming process of a heteromorphic transition section of a super large pressure vessel. The process comprises the following steps of: 1) punching; 2) drawing out; and 3) reaming with a special lower reaming anvil by adopting free forging, wherein the forming surface of the special lower reaming anvil is raised along the low and middle parts of the two axial ends of a forging stock; aiming at forming of each indexing region of the forging stock, firstly the two axial ends of the indexing region are deformed through forging and pressing and are matched with the middle raise of the special lower reaming anvil to form bidirectional axial limits; and after reaming, the inner circumferential surface of the forging stock comprises an inner concave surface formed through the middle raise of the special lower reaming anvil. The process has the following beneficial effects that: through the final inner concave surface of the inner circumferential surface of the forging stock, the dressing metals are saved, the raw material consumption can be reduced, the machining allowance is reduced, the metal flow lines are prevented from being cut off and the forging block quality is improved; and the process is suitable for manufacturing the heteromorphic transition section forging of the super large pressure vessel.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

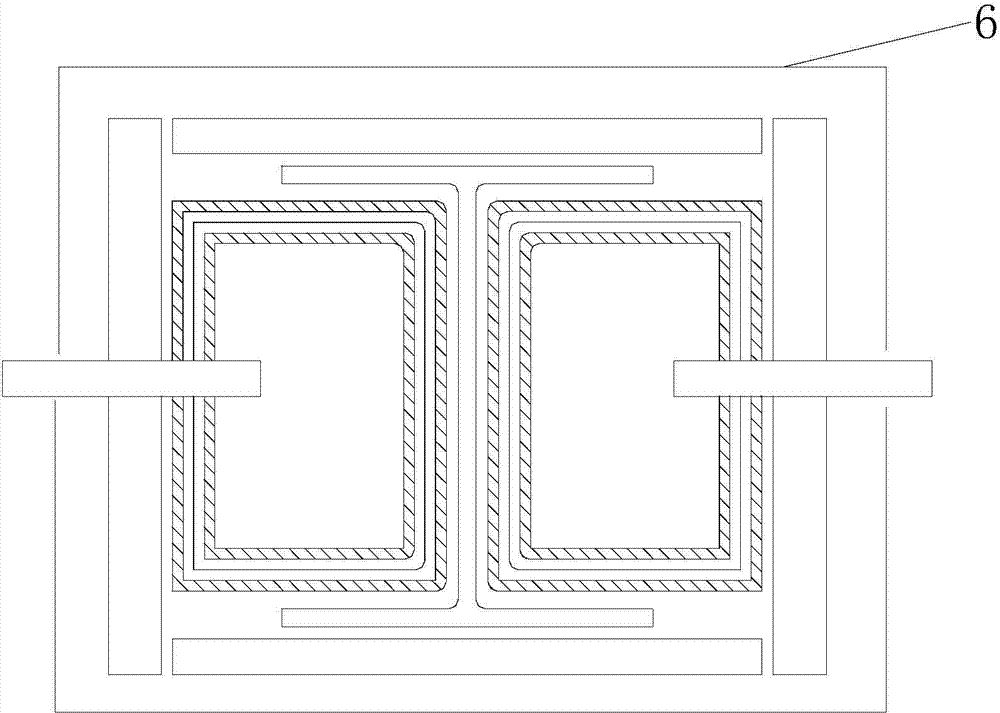

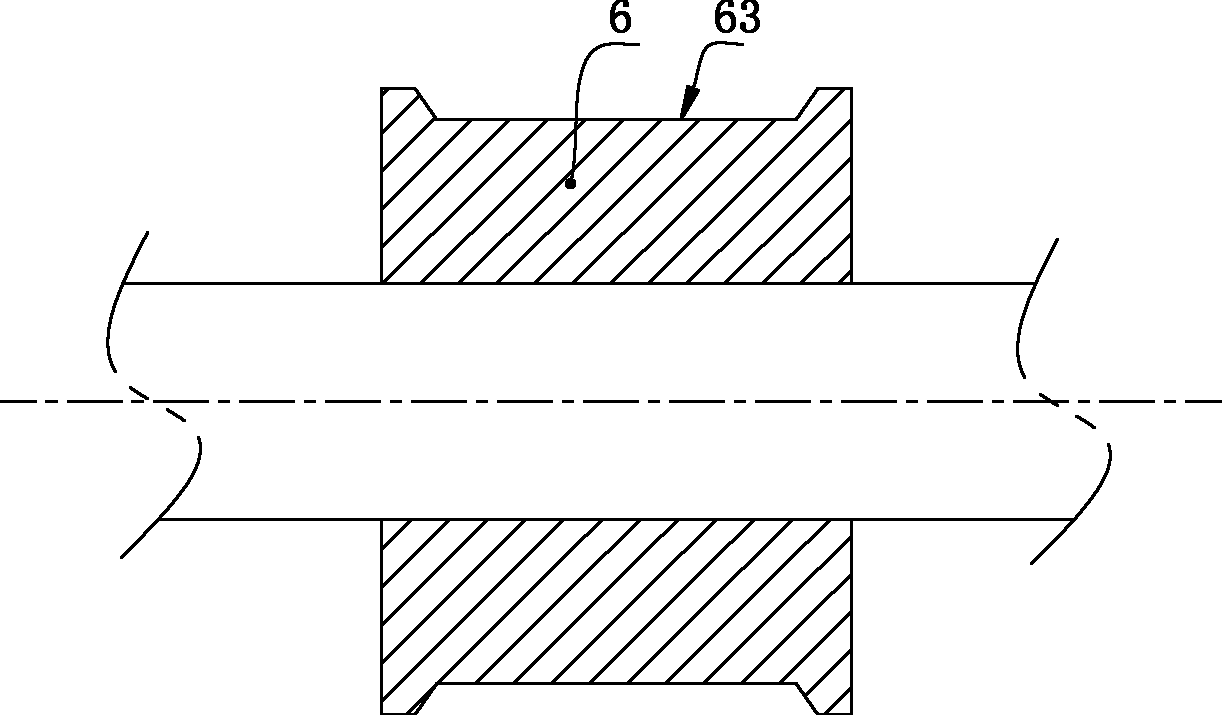

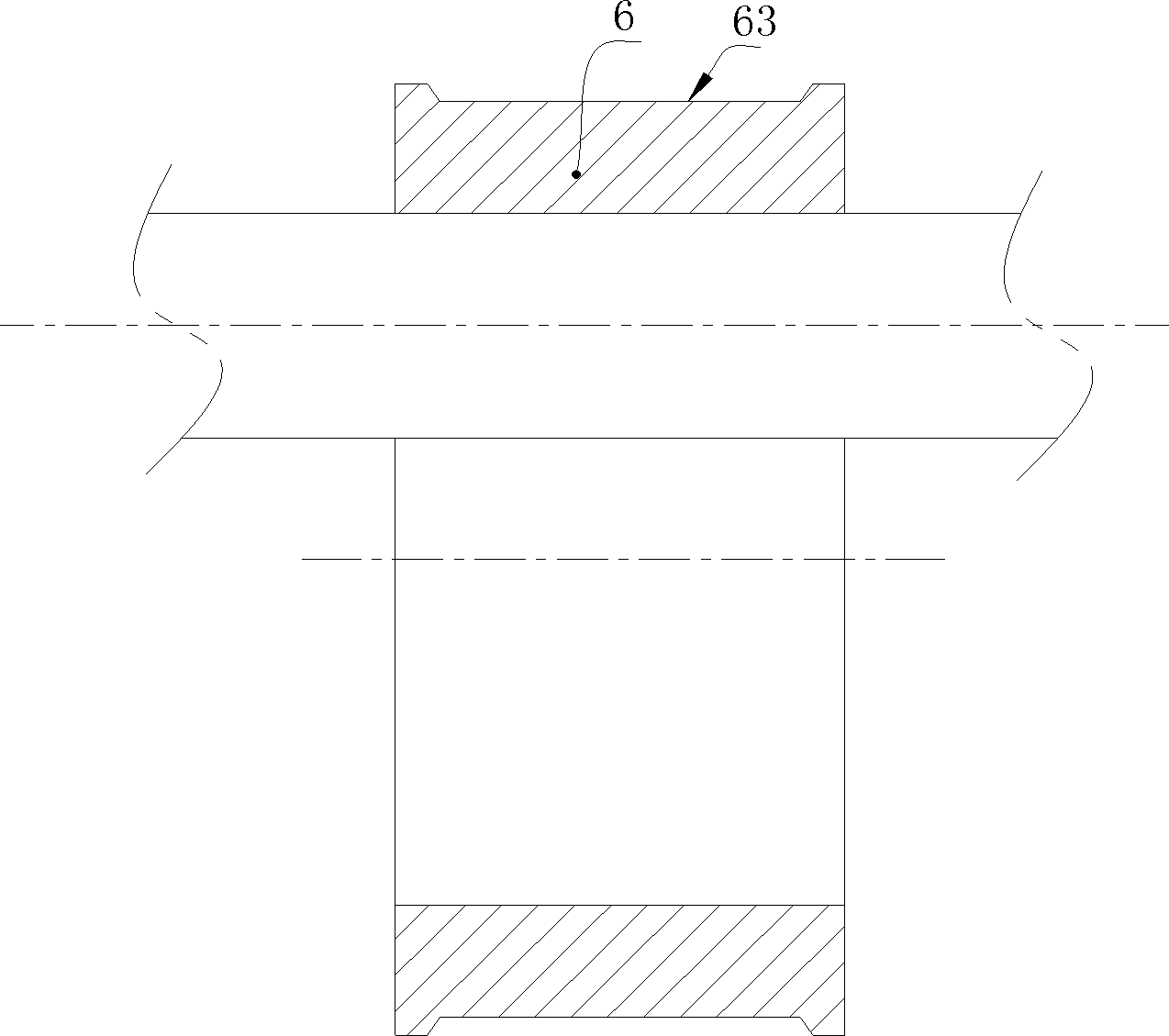

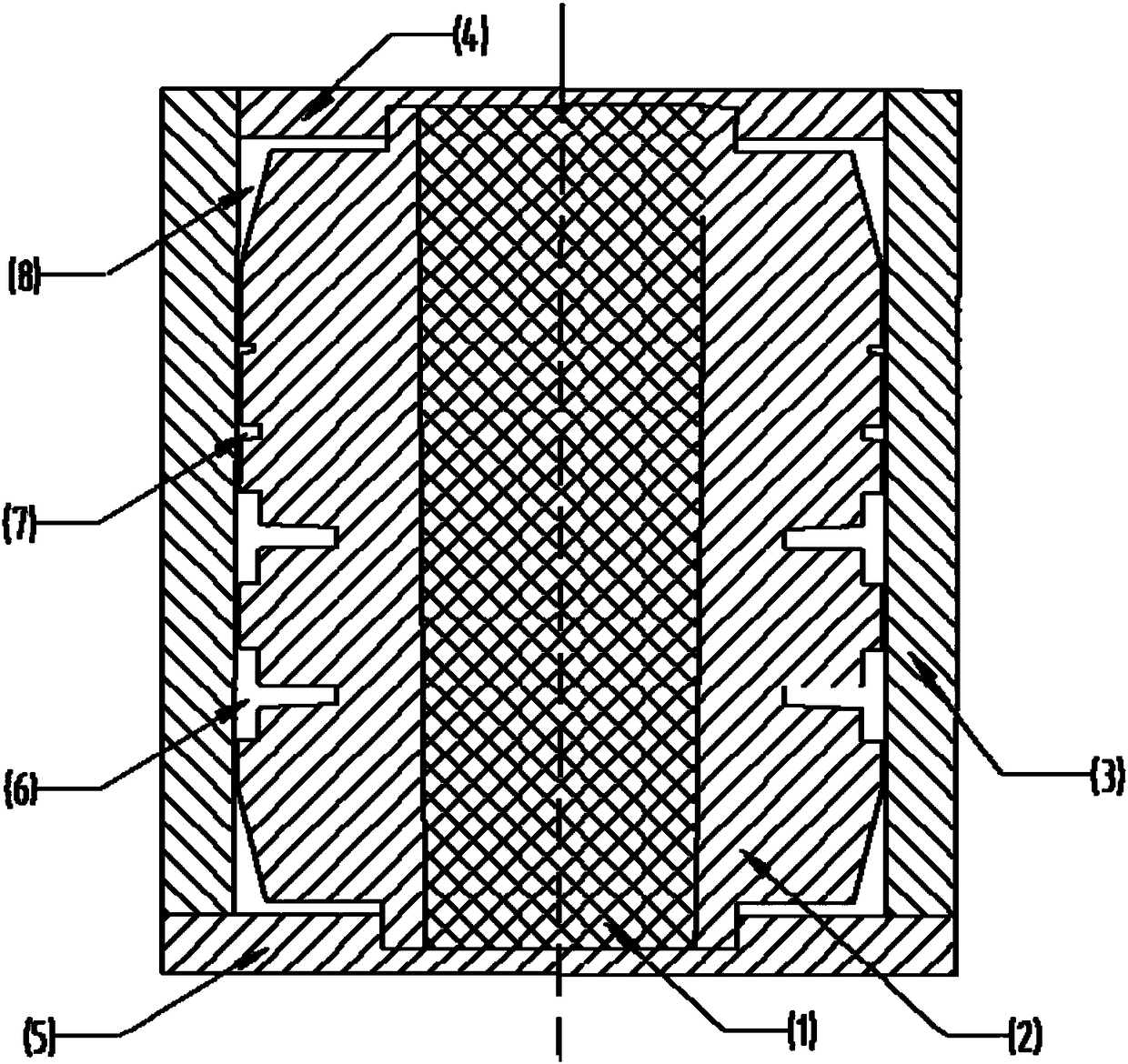

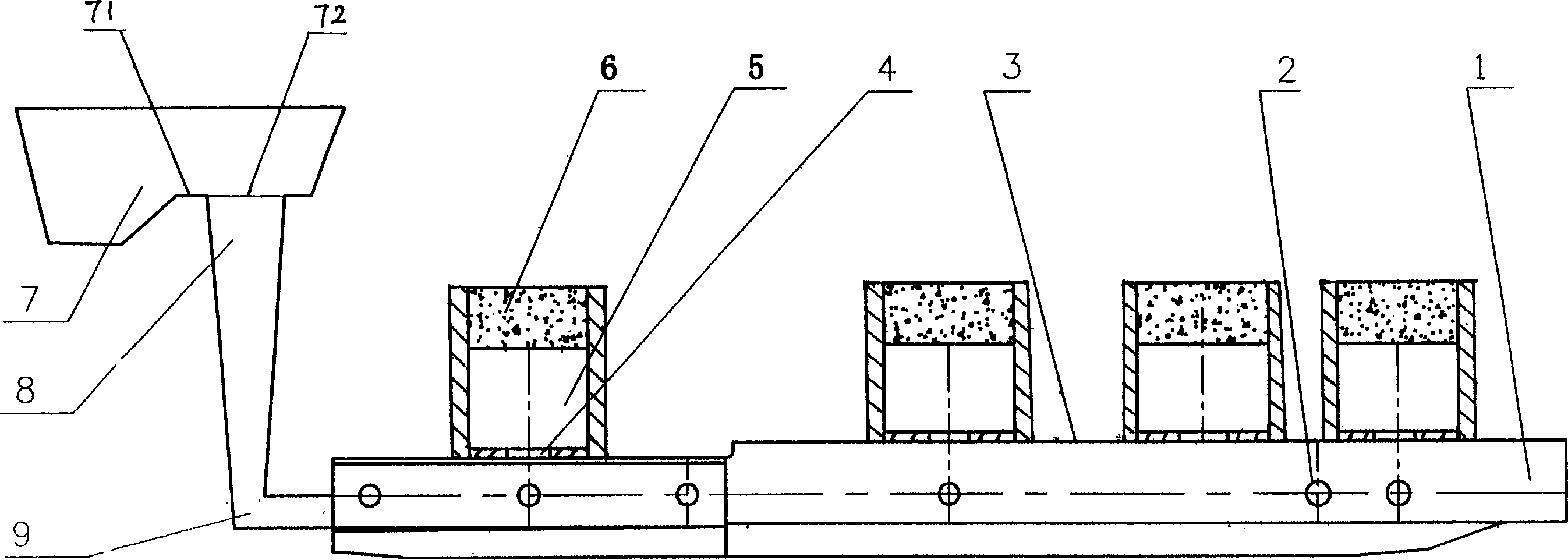

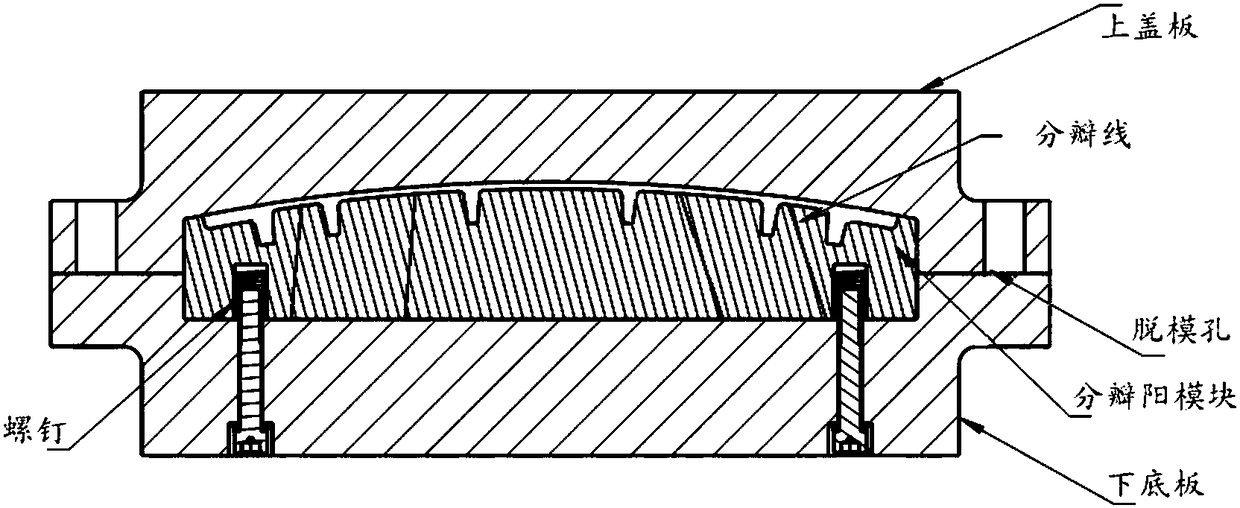

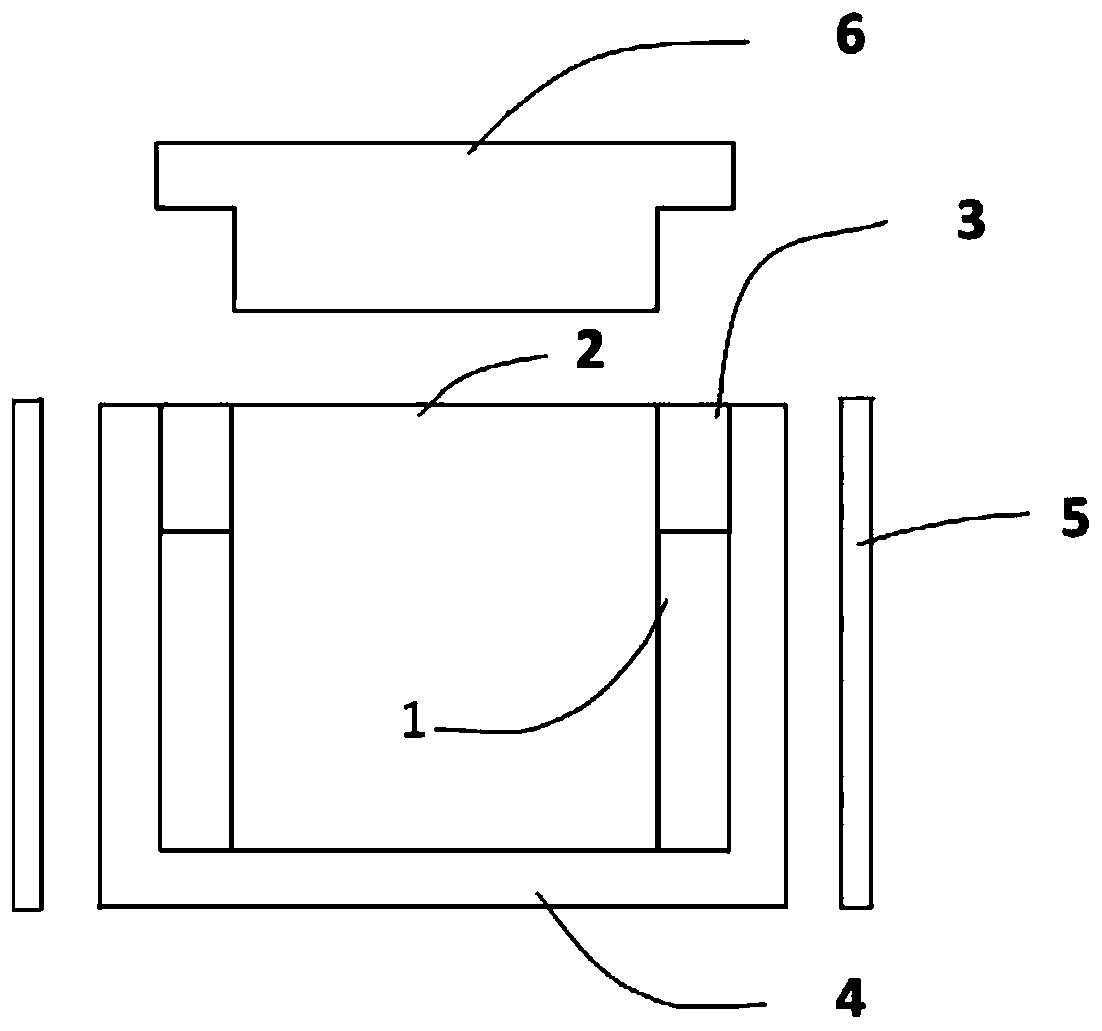

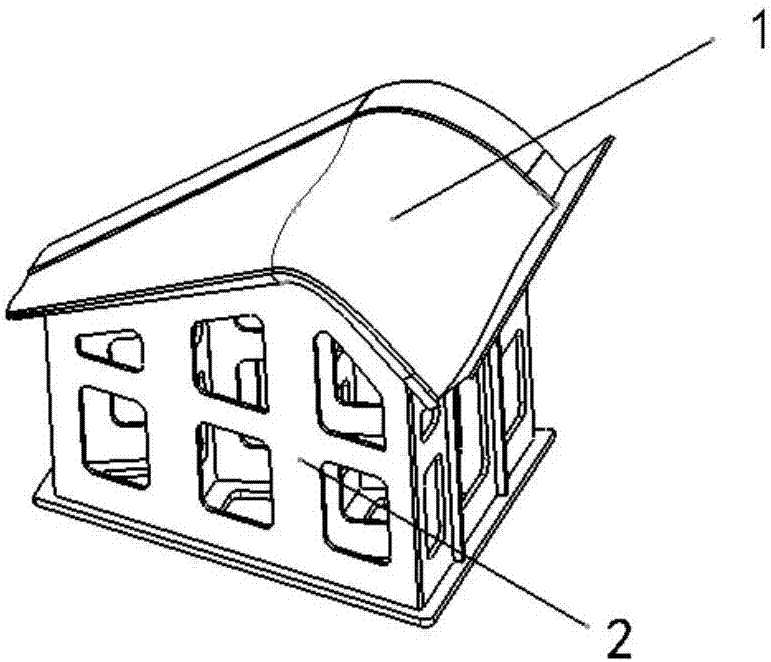

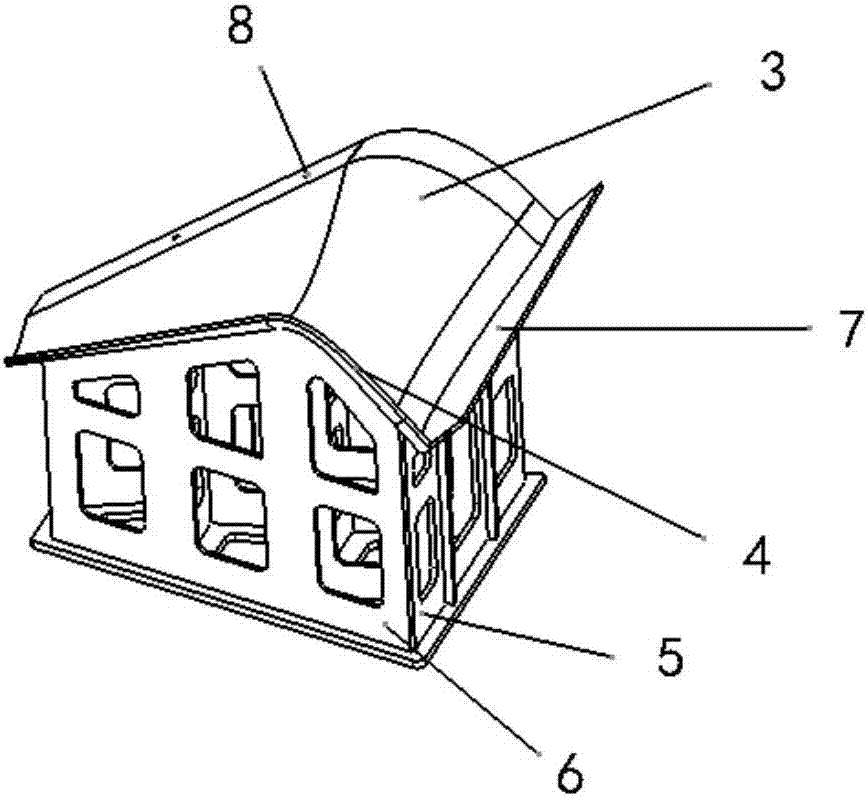

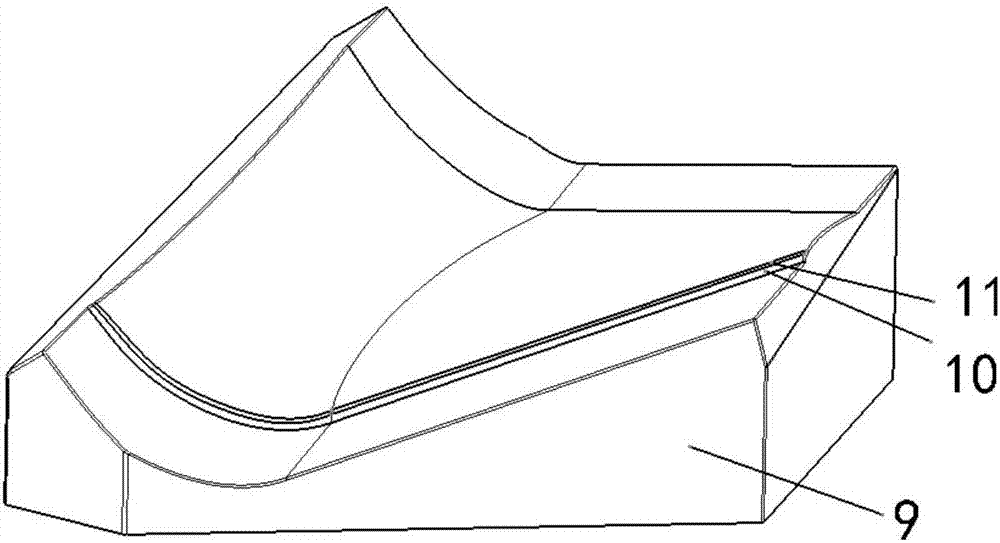

High-precision forming mold and method for thickly-laid composite material boxes

The invention relates to a composite material forming technology and specifically relates to a high-precision forming mold and method for thickly-laid composite material boxes. The high-precision forming mold for thickly-laid composite material boxes is designed in the present invention and comprises a box bottom female die (1), a box body sidewall pressure transfer block (2), a knockout plate (3), a box sidewall female die (4), a male die (5) and a bottom plate (6). On the basis of the high-precision forming mold for thickly-laid composite material boxes, box prepreg layers of a composite material are laid one by one on the male die (5); every two to three prepreg layers are vacuumized and pre-compacted, and a plurality of times of vacuumizing and pre-compacting are carried out until the prepregs are completely fitted with the die; subsequently, more than three times of pre-pressing by using a press are carried out, followed by a process of opening the mold to supplement materials and shaping, and hot press molding. The accuracy of inner and outer molded surfaces of a composite material box formed by using the mold and the method of the present invention can be above + / -mm, and therefore, the composite material box can be glued in an aerospace part as a force-bearing part and may meet later assembly requirements.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

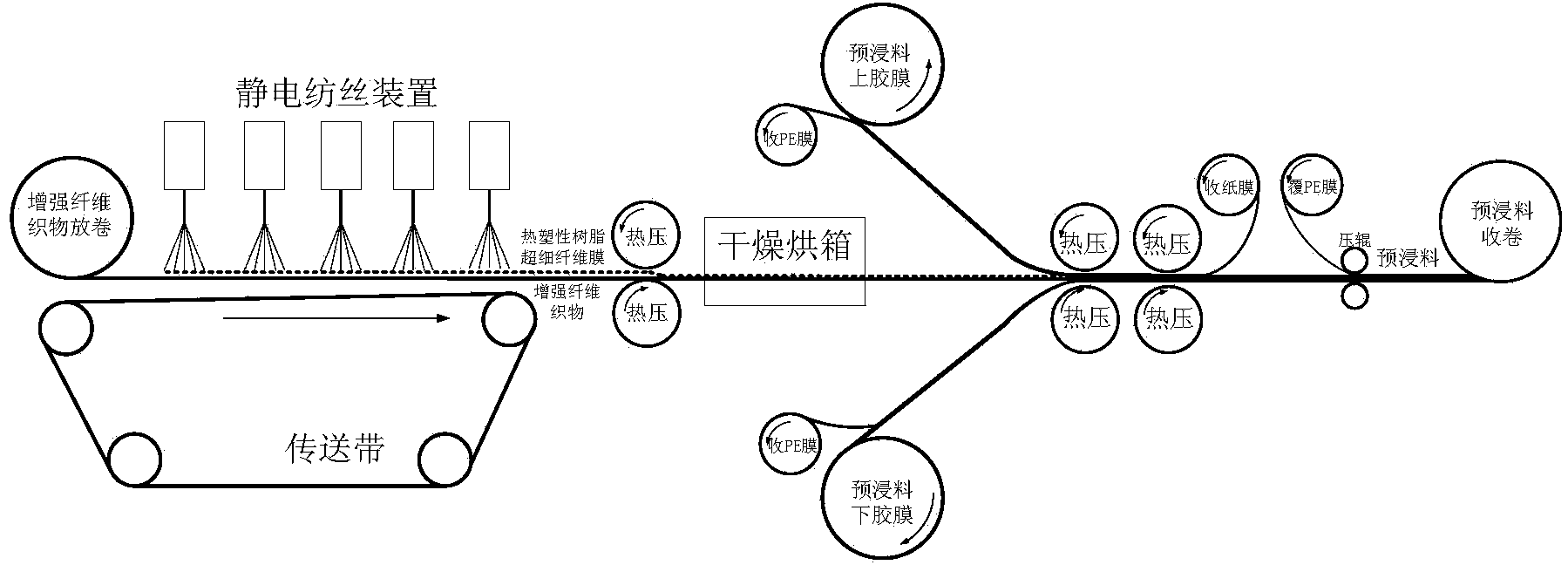

Preparation method of ultrafine fibrous membrane-toughened prepreg of thermoplastic resin

ActiveCN103552331ARedistribution has little effectDoes not affect stickinessSynthetic resin layered productsLaminationFiberPolymer science

The invention belongs to the field of preparation of composite materials, and relates to a preparation method of ultrafine fibrous membrane-toughened prepreg of thermoplastic resin with a toughening function. The method comprises the following steps: electrostatically spinning a toughening agent of thermoplastic resin to obtain ultrafine fibers of the thermoplastic resin with diameter of 100-5000nm, and directly spraying the fibers on the surface of a reinforced fiber fabric so as to form a toughening layer consisting of thermoplastic resin fibers which are distributed irregularly and are uniform in surface density on the surface of the fiber fabric; attaching the toughening layer with the fiber fabric to form a whole through a hot rolling process; and then, compounding the fiber fabric product with the toughening function and a prepreg resin base body to prepare the ultrafine fibrous membrane-toughened prepreg product of thermoplastic resin. The preparation method provided by the invention is simple in technical process and easy to implement, and can realize continuous production of high toughness prepreg, thereby greatly improving the production efficiency.

Owner:AVIC COMPOSITES

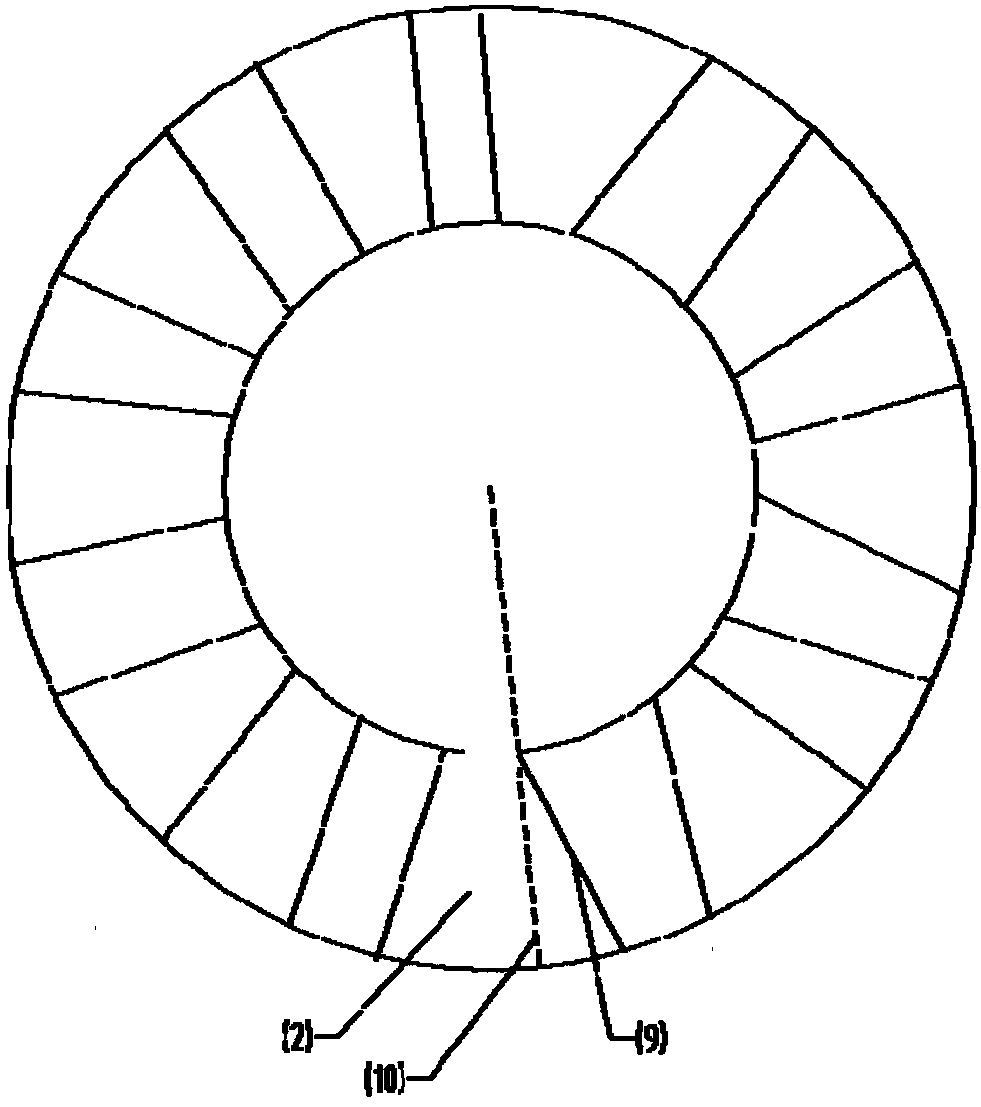

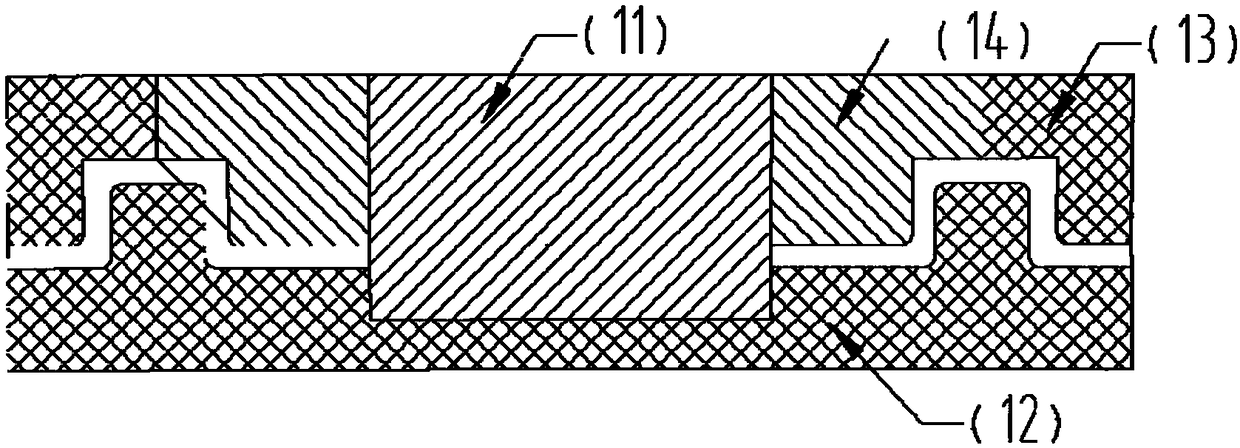

Composite material casing containing inward-flanging windows, forming die and forming method

ActiveCN108501398AGood for weight lossHigh structural efficiencyDomestic articlesMicrowaveEngineering

The invention relates to a composite material casing containing inward-flanging windows, a forming die and a forming method. The whole casing is of a cylindrical or conical rib-skin structure, and ischaracterized in that the skins at the upper side and lower side of the structure are flanged inwards along the radial direction to form an upper end framework and a lower end framework of the casing;the side surface of the structure is provided with an even number of windows towards the interior of the cylinder, and the inner walls of windows are in a step shape; every two windows are symmetrically distributed along the center of circle at the circumference; the casing is of an integrated forming structure. The composite material casing has the advantages that the inward-flanging windows andthe composite material casing with the rib-skin structure are integrally formed, so that the weight of the composite material member is reduced, and the structure efficiency is improved; the composite material casing is suitable for manufacturing the composite material member of the rib-skin structure containing the inward-flanging windows; by adopting the integrated structure, the weight is light, the strength is high, and a microwave absorbing and transmitting unit can be formed after a functional material is introduced into the integrated window; by adopting the structure type, the wide application prospect in the fields of anti-counterfeiting, hiding and the like of aircrafts is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High manganese steel railway assembled frog centre rail casting process

A technology for casing the high-Mn steel frog of combined switch for railway features that the ferrochromium sand is used as surficial sand and core sand, the alkaline Mg sand powder paint is coated on the surfaces of moulding cavity and core, and an easily cutting plate is added under the insulating siser head. It includes such steps as applying the insulating and heat generating agent to the surface of riser head, horizontal pouring, cutting off the riser head, burying it is sand, and heat treating.

Owner:中科西王特钢有限公司

Welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes

InactiveCN103111731AGuaranteed surface forming qualityGuarantee internal qualityArc welding apparatusPorosityHydrogen Nitrate

The invention discloses a welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes. Firstly, grooves are formed in to-be-welded portions of parts, cleaned mechanically and then subjected to chemical cleaning through a solution of sodium hydroxide (NaOH) and a solution of hydrogen nitrate (HNO3); and then a gas metal arc welding (GMAW) process is carried out, and welding parameters include current, voltage, current polarity, protective gas, the flow rate of the protective gas, backing gas, and the flow rate of the backing gas, wherein the current is 65-95 amperes, the voltage is 18+ / -3 volts, the current polarity is alternating current, the protective gas is argon gas with purity more than or equal to 99.99%, the flow rate of the protective gas is 16+ / -3 liters per minute, the backing gas is argon gas with purity more than or equal to 99.99%, and the flow rate of the backing gas is 16+ / -3 liters per minute. Through the welding method for the longitudinal butt joint of the thin-wall aluminum alloy non-profile long pipes, the surface forming quality and the inside quality of a double-sided welded joint can be guaranteed, welding defects such as bad shape, lack of penetration, porosity, incomplete fusion, burning-through, collapse and inclusions are avoided, production efficiency is improved, the repair rate is lowered, and quality of products is guaranteed.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

Method for controlling center segregation of large-section heavy rail steel slab

InactiveCN105215309AControl center segregationGuarantee internal qualityMolten steelUltimate tensile strength

The invention relates to a method for controlling center segregation of a large-section heavy rail steel slab and belongs to the field of ferrous metallurgy. According to the technical scheme, during the pouring process, the degree of superheat of poured molten steel is 25-35 DEG C, the pulling rate is 0.65 m / min-0.75 m / min, and the solidification tail end of the steel slab is pressed down by 10-14 mm; during the continuous casting process, the electromagnetic stirring strength at a crystallizer is 350-450 A, the stirring frequency is 2.3-2.5 Hz, the electromagnetic stirring strength at the solidification tail end is set to 350-450 A, and the stirring frequency is 6.8-7.2 Hz. According to the method, through controlling the degree of superheat, the pouring rate and the solidification tail end pressing of the poured molten steel, and by combining reasonable selection of the electric stirring mode and the electric stirring parameter, the center segregation of the large-section heavy rail steel slab is effectively controlled, and the rest inner quality of the steel slab is effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

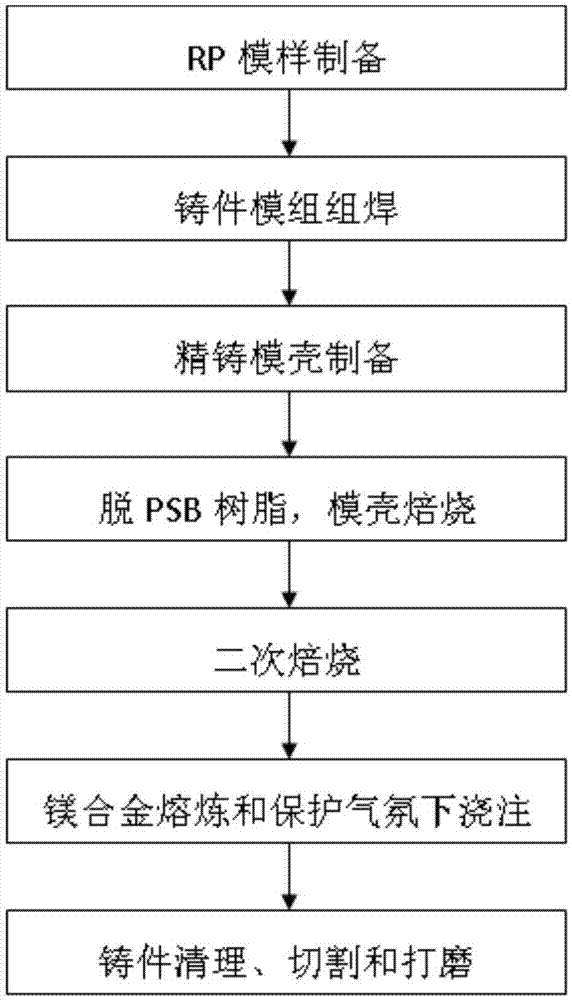

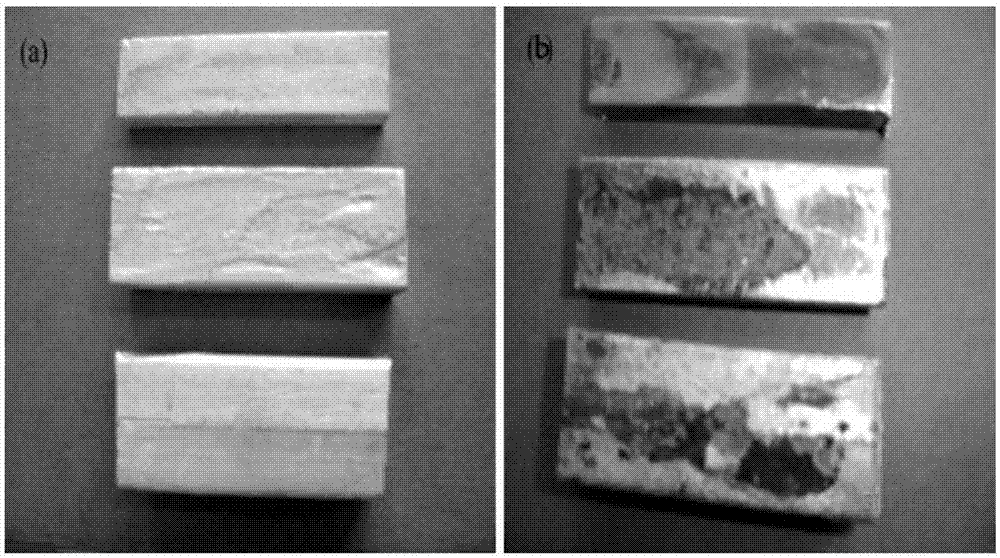

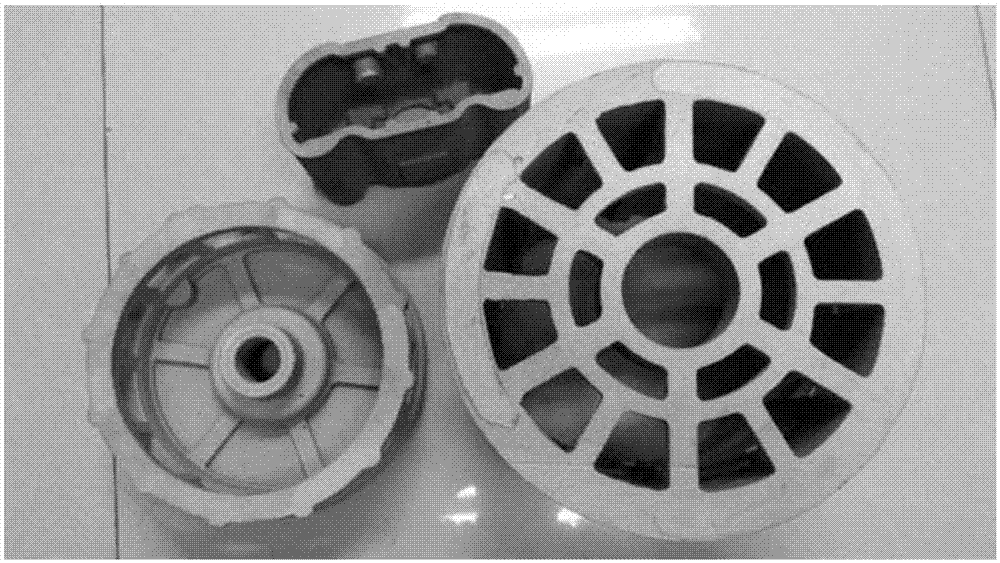

Precision investment casting method for magnesium alloy

The invention discloses a precision investment casting method for magnesium alloy, which is used for solving the technical problem that the conventional investment casting method is poor in oxidization prevention measures. According to the technical scheme, the method comprises the following steps: preparing a wax mould by adopting 3D laser printing, using ZrO2 as a surface layer and second layer sand material, and desorbing resin by using a roasting method to be sufficiently burned; after roasting, immersing a mould shell cavity in a hot saturated boric acid aqueous solution with the temperature being 90-100 DEG C; before pouring, introducing mixed protection gas with the volume fraction ratio of HFC134a to Ar being 30 to 70; in the pouring process, uninterruptedly sprinkling appropriate sulfur to the magnesium alloy ladle pouring liquid level and a riser, and thus effectively preventing magnesium alloy oxidation and burning. As the wax mould is prepared by adopting 3D laser printing, the dimensional precision and the surface smoothness of magnesium alloy casts are ensured. ZrO2 is used to prevent magnesium alloy melt from reacting with a casting mould. The resin is desorbed by using the roasting method to be sufficiently burned, ash content and slag are not left, and the surface smoothness and the internal quality of the magnesium alloy casts are ensured.

Owner:宝鸡金航华颢新材料技术研究院有限公司

Mass concrete cracking proof construction technology

ActiveCN104264678AAvoid crackingReduce water consumptionFoundation engineeringProof constructionTemperature difference

The invention discloses a mass concrete cracking proof construction technology which can prevent the concrete from cracking and improve the concrete pouring quality. The mass concrete cracking proof construction technology comprises the following steps of firstly building a steel reinforcement framework and a template, then selecting the type and the ratio of the concrete, pouring the concrete, regulating the internal and external temperature difference and the maximum temperature of the concrete after concrete pouring is achieved; cooling the concrete by water-passing cooling, when the internal and external temperature difference of the concrete cannot be smaller than 25 DEG C by the water-passing cooling, reducing the internal and external temperature difference of the concrete by rising the temperature of the exterior of the concrete and maintaining naturally concrete temperature reducing when the internal and external temperature difference is smaller than 25 DEG C and the internal maximum temperature is smaller than 50 DEG C; removing the template when the concrete temperature is not changed to achieve construction of the concrete. According to the mass concrete cracking proof construction technology, cracking during a solidification process of the concrete is effectively avoided and the concrete quality is improved.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

Toughened intermetallic compound, preparation method of toughened intermetallic compound and apparatus

ActiveCN104985180AGuarantee internal qualityReduce development costsAdditive manufacturing apparatusMetal fibersIntermetallic

The invention provides a toughened intermetallic compound, a preparation method of the toughened intermetallic compound and an apparatus. The method includes the following steps that: intermetallic compound powder and toughening metal wires are selected as raw materials; and the intermetallic compound powder and the toughening metal wires are laid on a substrate alternately layer by layer, and are melted, so that the toughened intermetallic compound can be obtained, and preferably, the diameter of the metal wires ranges from 0.01 to 2mm. According to the invention, a metal fiber toughened intermetallic compound concept is put forward, and the power bed-based wire / power additive preparation method is provided. According to the preparation method, the metal wires are melt discretely layer by layer in each inner layer, so that metal fibers can be waved, and any metal fibers can be designed, and metal fiber toughened intermetallic compound materials or complex abnormally-shaped components thereof can be prepared directly through deposition.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

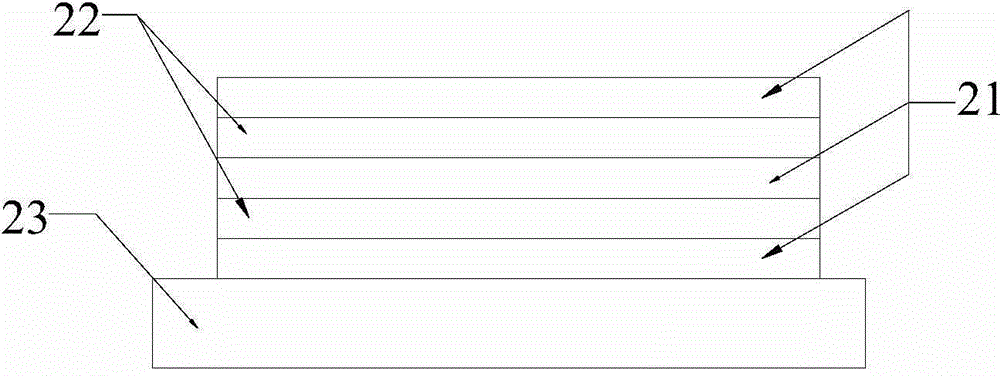

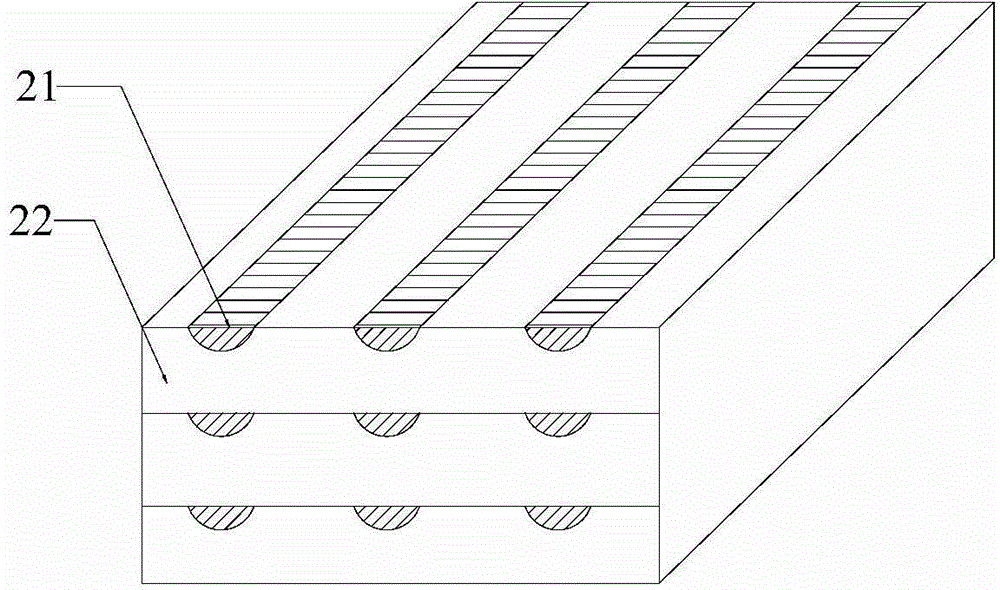

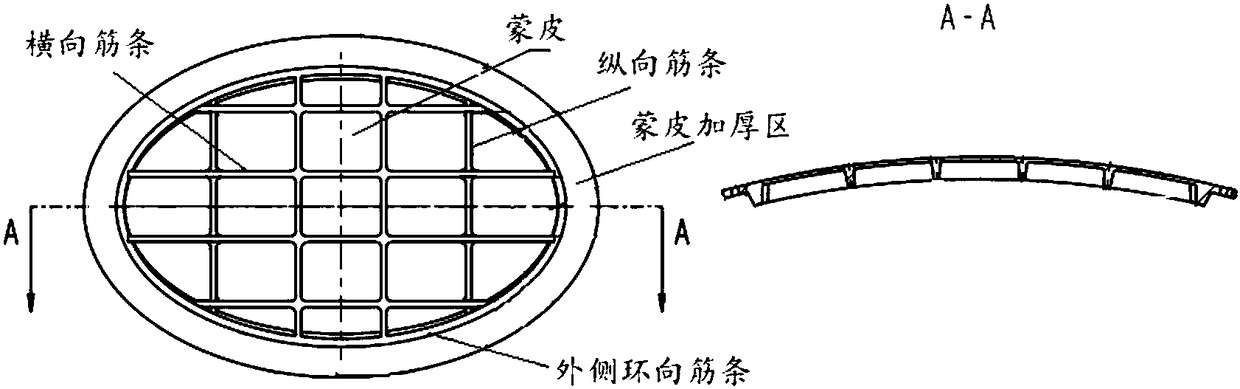

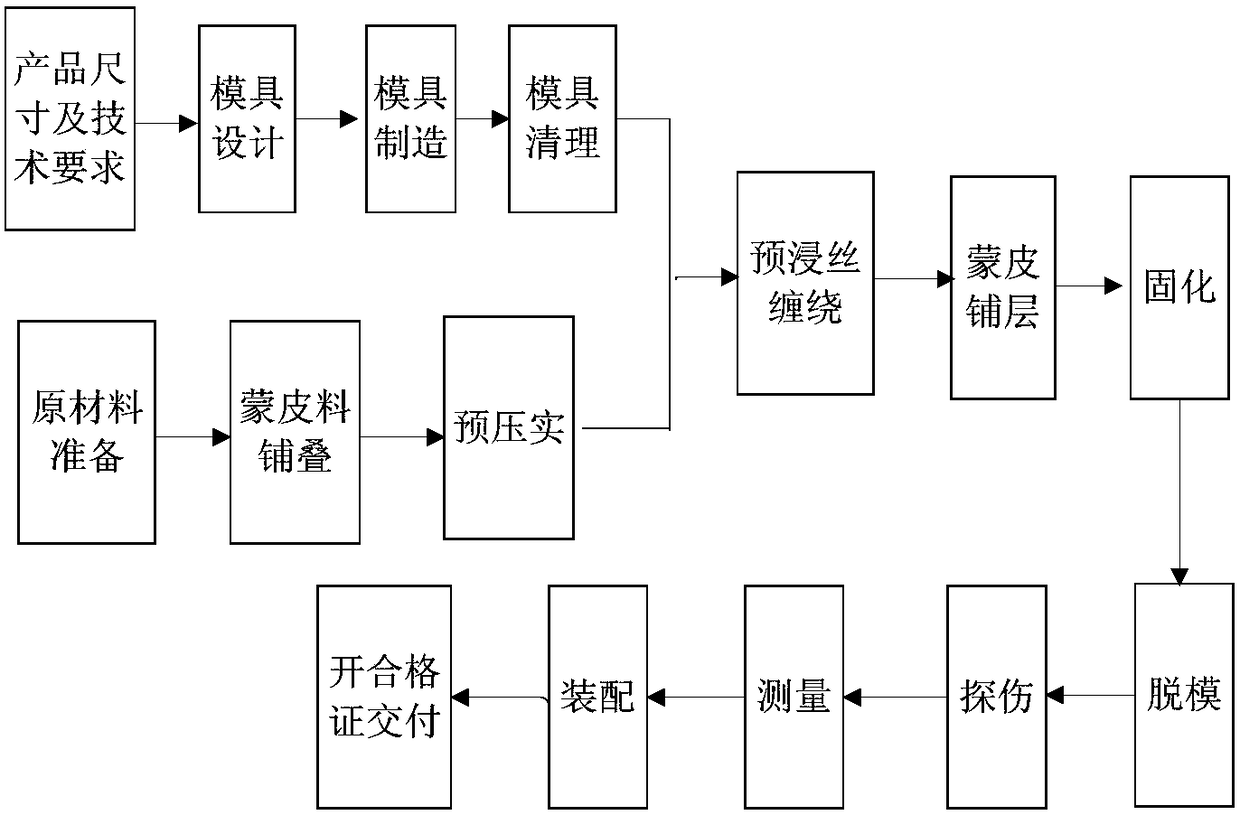

Composite material grid skin structure part die compression molding forming method

ActiveCN108407332AUniform thicknessGood internal and external qualityCompression moldingSkin structure

The invention relates to a composite material grid skin structure part die compression molding forming method, and belongs to the technical field of composite material forming. A set of control measures suitable for skin grid structure part die compression molding forming technology are found through reasonable rib winding and skin laying technological design, one-time integral forming of a composite material skin grid structure part is achieved, product deformation is small, the thickness is uniform, the operation efficiency is high, and rib winding and skin layer laying for the composite material skin grid structure part can be completed only through one day.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Super-strength armour plate and manufacturing method thereof

The invention provides a super-strength armour plate and a manufacturing method thereof and relates to manufacturing of armour plates to solve the problems that an existing armour plate is poor in yield strength and tensile strength. The method comprises the steps that steel-making materials are prepared according to the weight percentage of chemical element compositions; the steel-making materials are added into an electric furnace to be smelted into molten steel; the molten steel is fed into an LF furnace for refining; the refined molten steel is then fed into a VD furnace for vacuum refining; the molten steel is poured into a steel ingot; the steel ingot is put into an annealing furnace for annealing; electroslag remelting is performed on the steel ingot, and an electroslag slab ingot are generated; the electroslag slab ingot is rolled into a middle blank; the middle blank is subjected to annealing; the middle blank is rolled into a steel plate; and the steel plate is subjected to heat treatment, and the super-strength armour plate is manufactured. According to the super-strength armour plate, the yield strength is 1,370 MPa or above, the tensile strength is 1,620 MPa or above, and the tensile strength index can reach 2,200-2,350 MPa after quenching and tempering are carried out; and the armour plate is applied to an armoured car, and the using requirement for defending weapons and bullets can be met.

Owner:宝武特种冶金有限公司

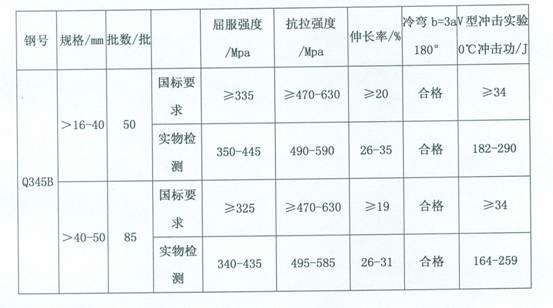

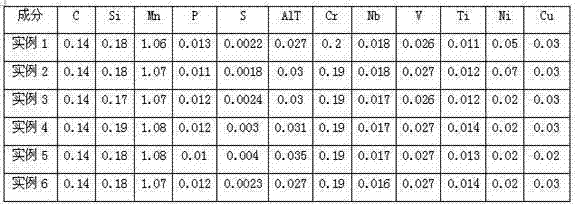

Q345B protected flaw detection steel plate and production method thereof

InactiveCN102041431AGuaranteed mechanical propertiesQuality assuranceProcess efficiency improvementSteel platesSheet steel

The invention discloses a low-alloy series Q345B protected flaw detection steel plate with thickness specification of less than 50 millimeters and a production method thereof. The steel plate comprises the following chemical components in percentage by mass: less than or equal to 0.18 percent of C, less than or equal to 0.45 percent of Si, less than or equal to 1.40 percent of Mn, less than or equal to 0.018 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.020 percent of Ti, less than or equal to 0.015 percent of Als, and the balance of Fe and residual elements. The production method comprises molten iron pretreatment, converter smelting, ladle furnace (LF) refining, continuous steel casting, casting blank heat transfer to a steel mill, casting blank heating, rolling, cold control, stacking and slow cooling. Because the technical scheme is adopted, compared with the prior art, the production method has the advantages of short production period, energy conservation and yield improvement.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Method for manufacturing steel-copper composite shaft sleeve

InactiveCN101701603ASimple production processIncrease productivityBearing componentsLubricationSurface smoothness

The invention relates to a method for manufacturing a steel-copper composite shaft sleeve, and the method comprises the following steps: (1) sealing one end of a steel shaft sleeve, thereby accommodating copper alloy liquid; (2) carrying out centrifuge rotation on the steel shaft sleeve with the copper alloy liquid, thereby combining the copper alloy liquid in the steel shaft sleeve on an inner surface of the steel shaft sleeve under the action of centrifugal force; and (3) carrying out machining on the steel shaft sleeve after the step (2) for obtaining the steel-copper composite shaft sleeve with the required specification. The method has the advantages of simple production technology, high production efficiency and low cost and is applicable to producing a variety of the steel-cooper composite shaft sleeves; in addition, a copper layer surface obtained by applying the method has the advantages of compact structure, high mechanical performances, good surface smoothness, good self-lubrication, good wear resistance and the like.

Owner:WUJIANG RONGSHUN PRECISION CASTING

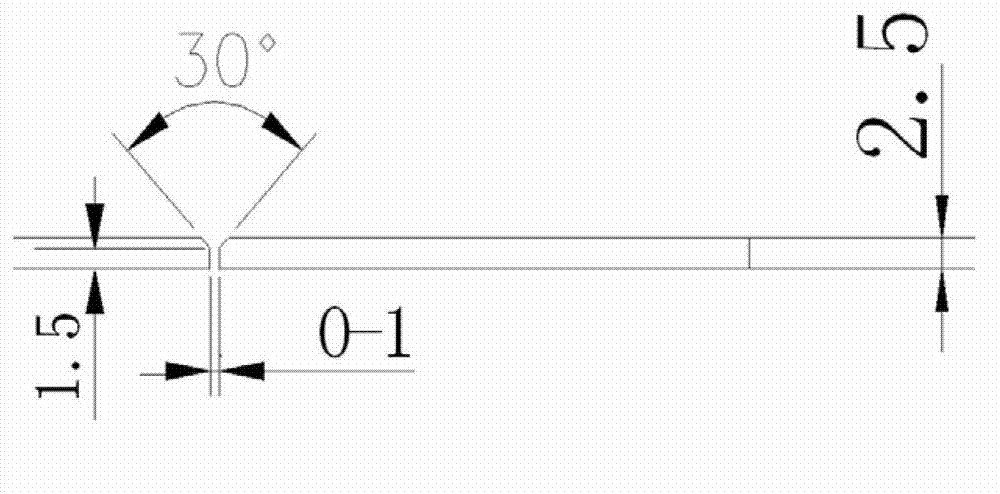

5A06/ZL114A dissimilar aluminum alloy part butt joint laser swing welding method

ActiveCN110539078AGuarantee internal qualityEliminate undercutWelding/soldering/cutting articlesLaser beam welding apparatusButt jointAlloy

The invention provides a 5A06 / ZL114A dissimilar aluminum alloy part butt joint laser swing welding method, and belongs to the technical field of welding. The method comprises the following steps thata 5A06 aluminum alloy part and a ZL114A aluminum alloy part are placed in a butt joint mode to form a structure to be welded, wherein the welding depth of the structure to be welded is 3-5 mm; the structure to be welded is welded through adopting a laser swing welding process to obtain an initial welding part; during welding, an incident angle of a laser beam is 90 degrees, the laser power is 4500-5000W, the welding speed is 1500-1800 mm / min, the light spot diameter is 0.2-0.3 mm, the defocusing amount is -1-1 mm, the swing frequency is 100-300 Hz, and the swing amplitude is 1-3 mm; laser swing welding is carried out on the initial welding part again to obtain a final product; and during welding, the incident angle of the laser beam is 80-85 degrees, the laser power is 1000-2000W, the welding speed is 2000-2200 mm / min, the light spot diameter is 0.1-0.2 mm, the defocusing amount is 3-6 mm, the swing frequency is 200-300 Hz, and the swing amplitude is 2.5-3 mm. A weld joint obtained bythe method has no undercut, no pits, no salient points, and no air holes at the surface or the near surface, the internal quality meets the GB / T 22085.2-2008 standard strict B-level requirement, and no internal cracks or no air holes exist.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

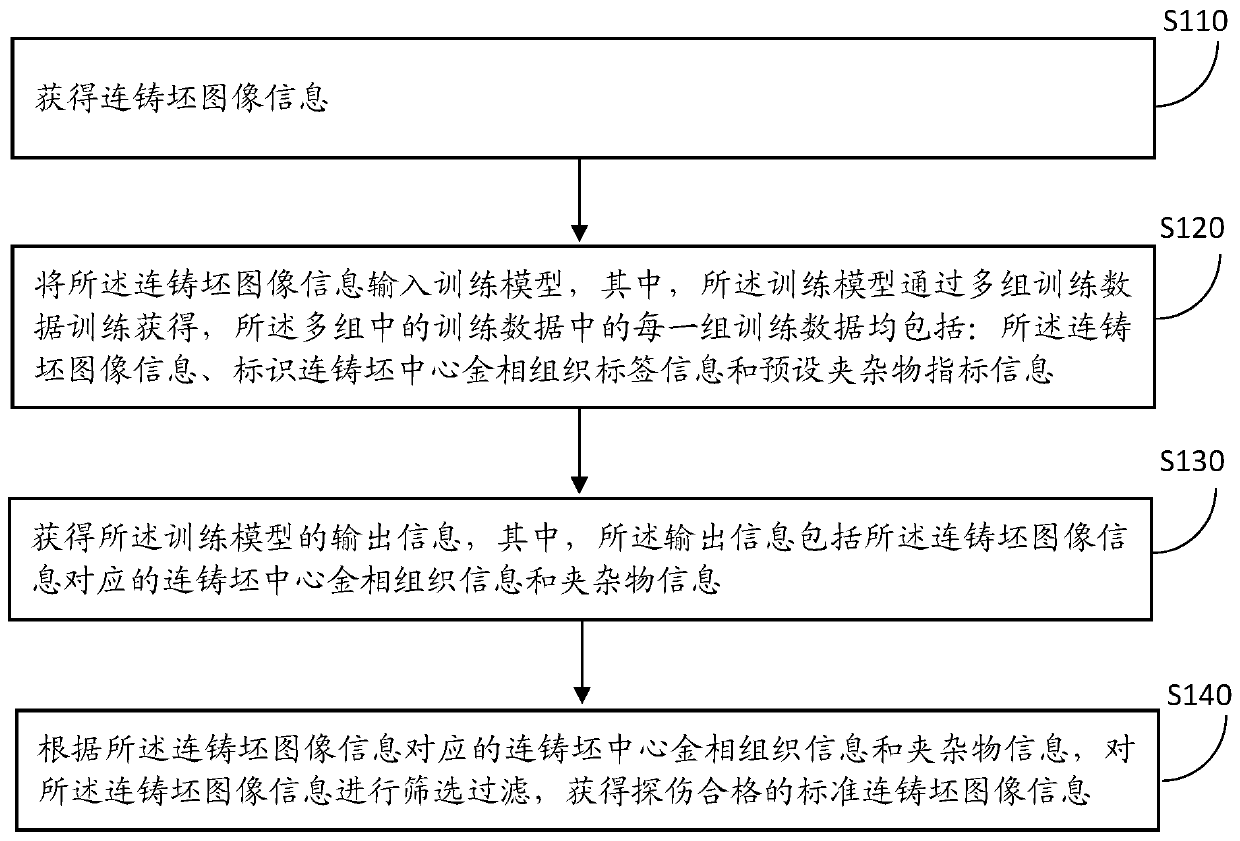

Method and device for improving continuous casting flaw detection qualification rate

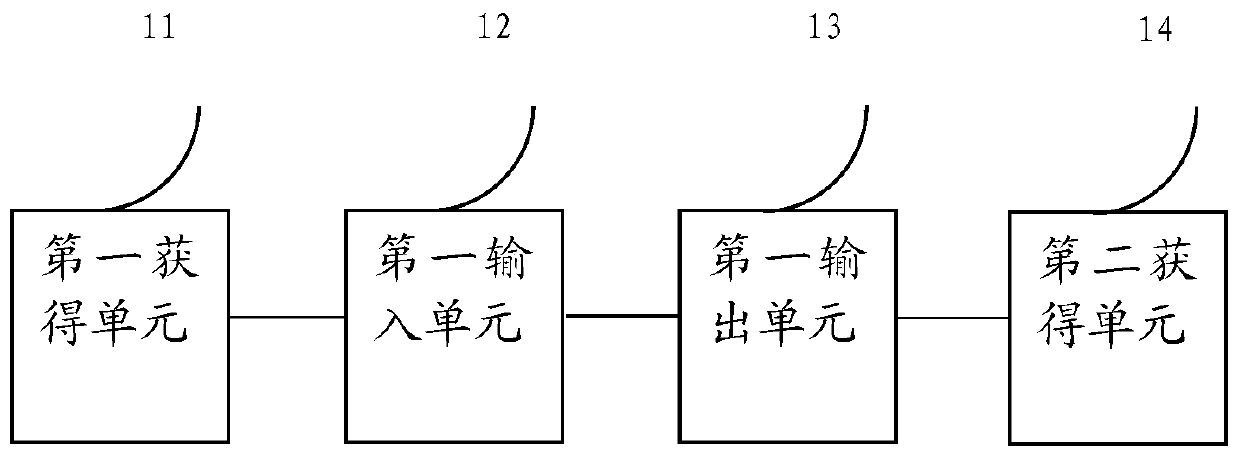

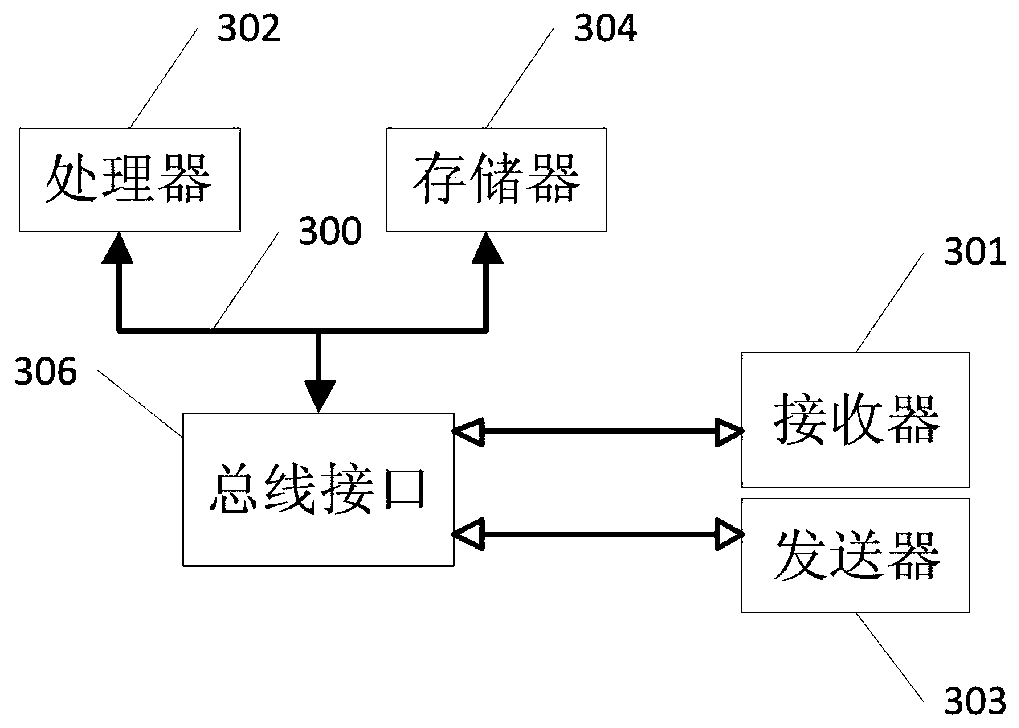

ActiveCN110490862AImprove the qualified rate of flaw detectionGuarantee internal qualityImage enhancementImage analysisComputer scienceContinuous casting

The embodiment of the invention provides a method and device for improving the continuous casting flaw detection qualification rate. The method comprises the steps that obtained continuous casting billet image information is input into a training model, the training model is obtained through training of multiple sets of training data, and each set of training data in the multiple sets of trainingdata comprises the continuous casting billet image information, identification continuous casting billet center metallographic structure label information and preset inclusion index information; output information of the training model is obtained, and the output information comprises continuous casting billet center metallographic structure information and inclusion information corresponding to the continuous casting billet image information; according to the continuous casting billet center metallographic structure information and the inclusion information corresponding to the continuous casting billet image information, the continuous casting billet image information are screened and filtered to obtain standard continuous casting billet image information with qualified flaw detection, thereby achieving the technical effects of improving the flaw detection qualification rate of the continuous casting billet, reducing the inclusion content, ensuring the internal quality of the continuous casting billet and reducing the production cost.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

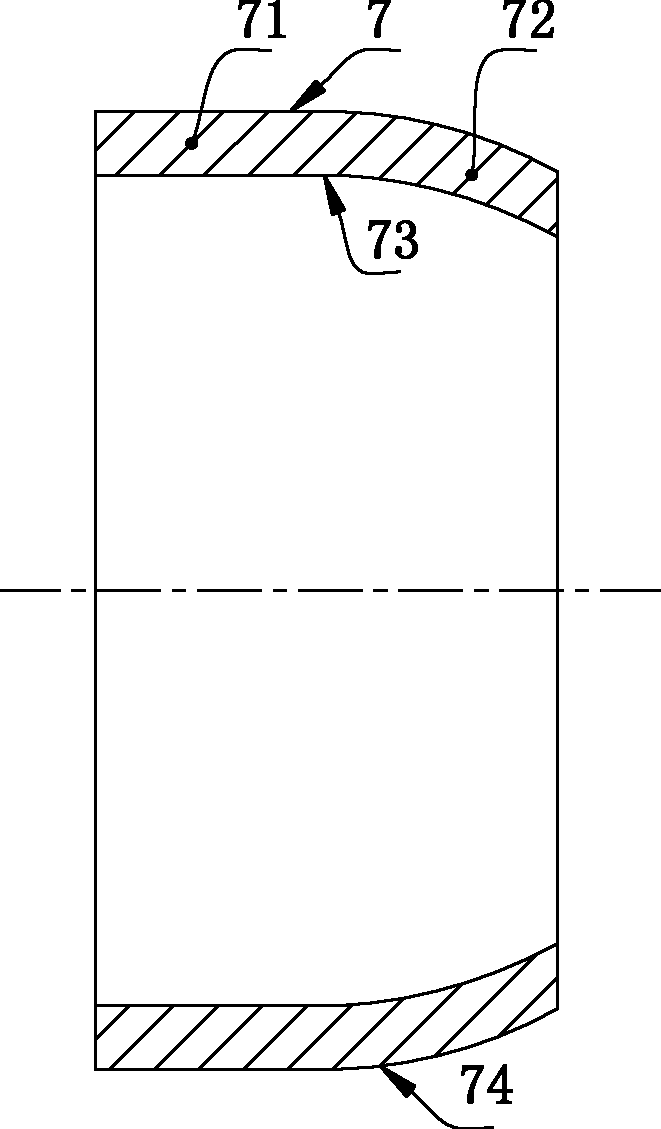

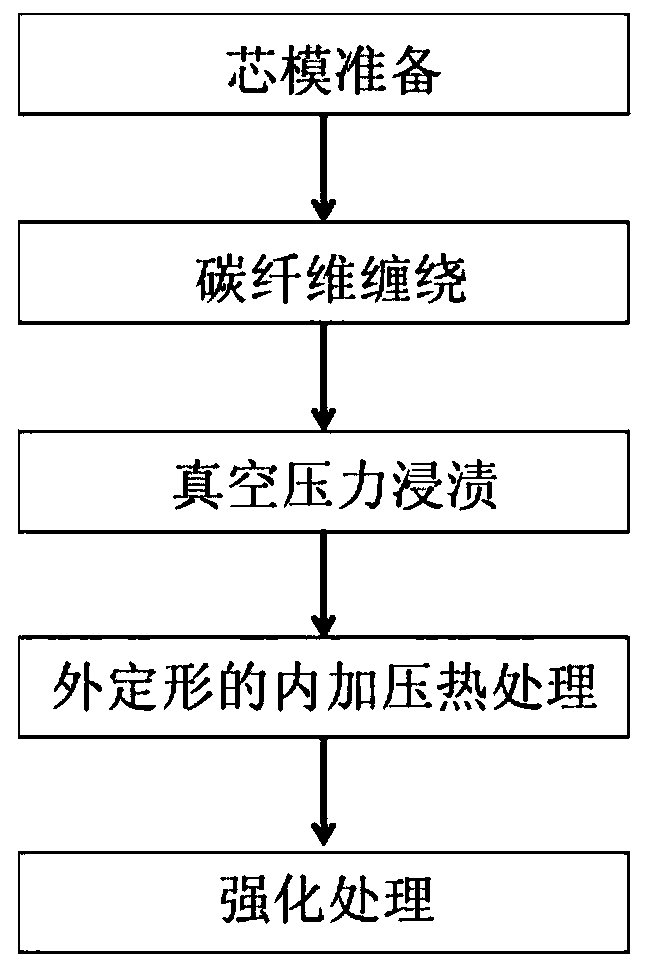

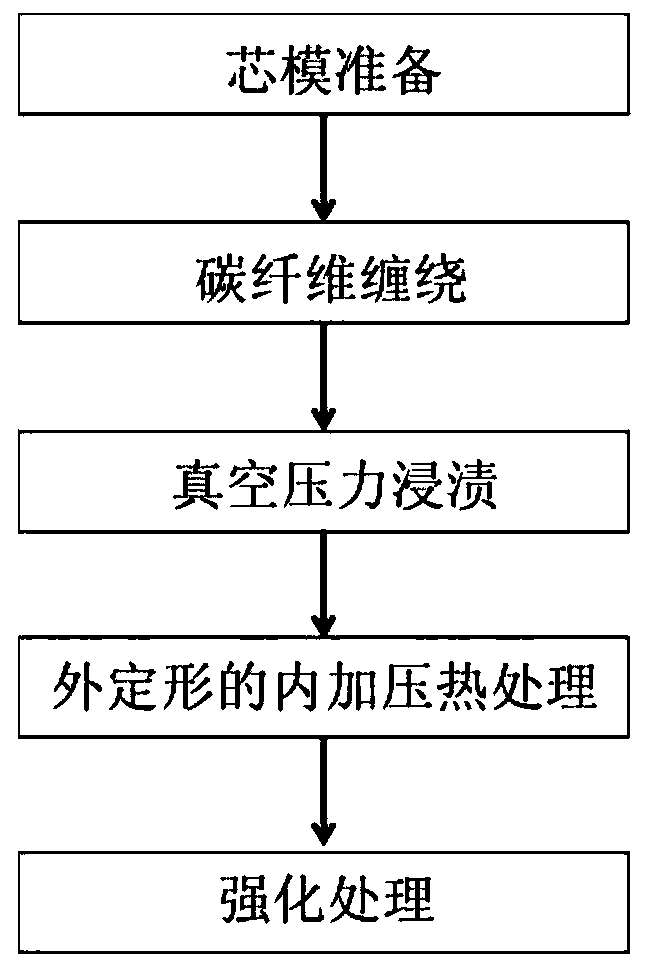

Preparation method of revolved body type carbon/carbon composite material

The invention discloses a preparation method of a revolved body type carbon / carbon composite material. The method comprises the following steps: 1, cleaning a core mold, paving demolding cloth in thecore mold, and brushing the demolding cloth with a release agent; 2, winding continuous carbon fibers on the core mold coated with the release agent to form a wound part; 3, carrying out vacuum pressure impregnation on the wound part, performing demolding, and carrying out machining treatment to obtain an impregnated part; 4, applying a shaping tool to the outer surface of the impregnated part, and carrying out internal-pressurization heat treatment to obtain a green body of the revolved body type carbon / carbon composite material; and 5, strengthening the revolved body type carbon / carbon composite material blank to obtain the revolved body type carbon / carbon composite material. The thickness of the target composite material is achieved by introducing asphalt and adopting an external-shaping internal-pressurization heat treatment process and strengthening treatment; the volume content of carbon fibers in the revolved body type carbon / carbon composite material is increased, the performance of the revolved body type carbon / carbon composite material is improved, a densification period is shortened, and the preparation efficiency of the revolved body type carbon / carbon composite material is improved.

Owner:XIAN CHAOMA SCI TECH

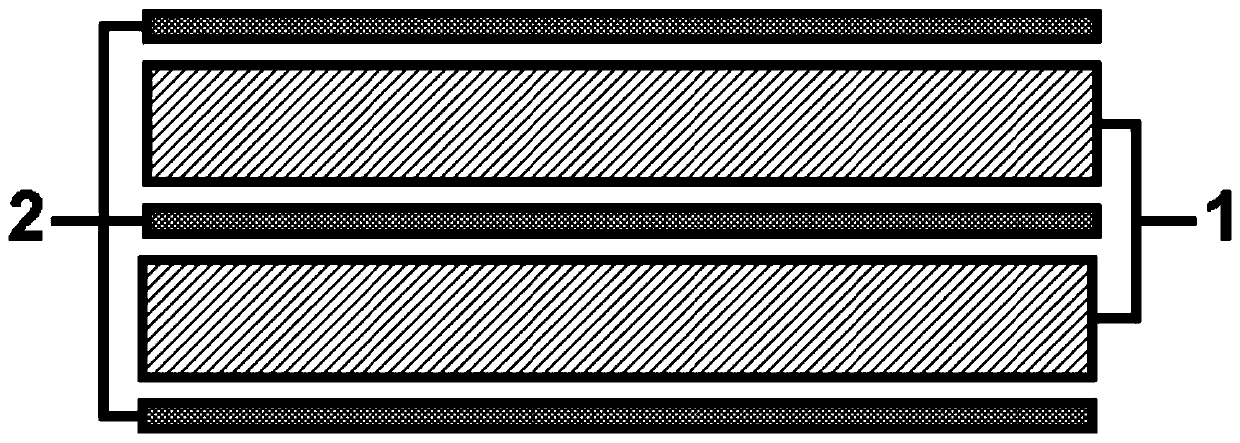

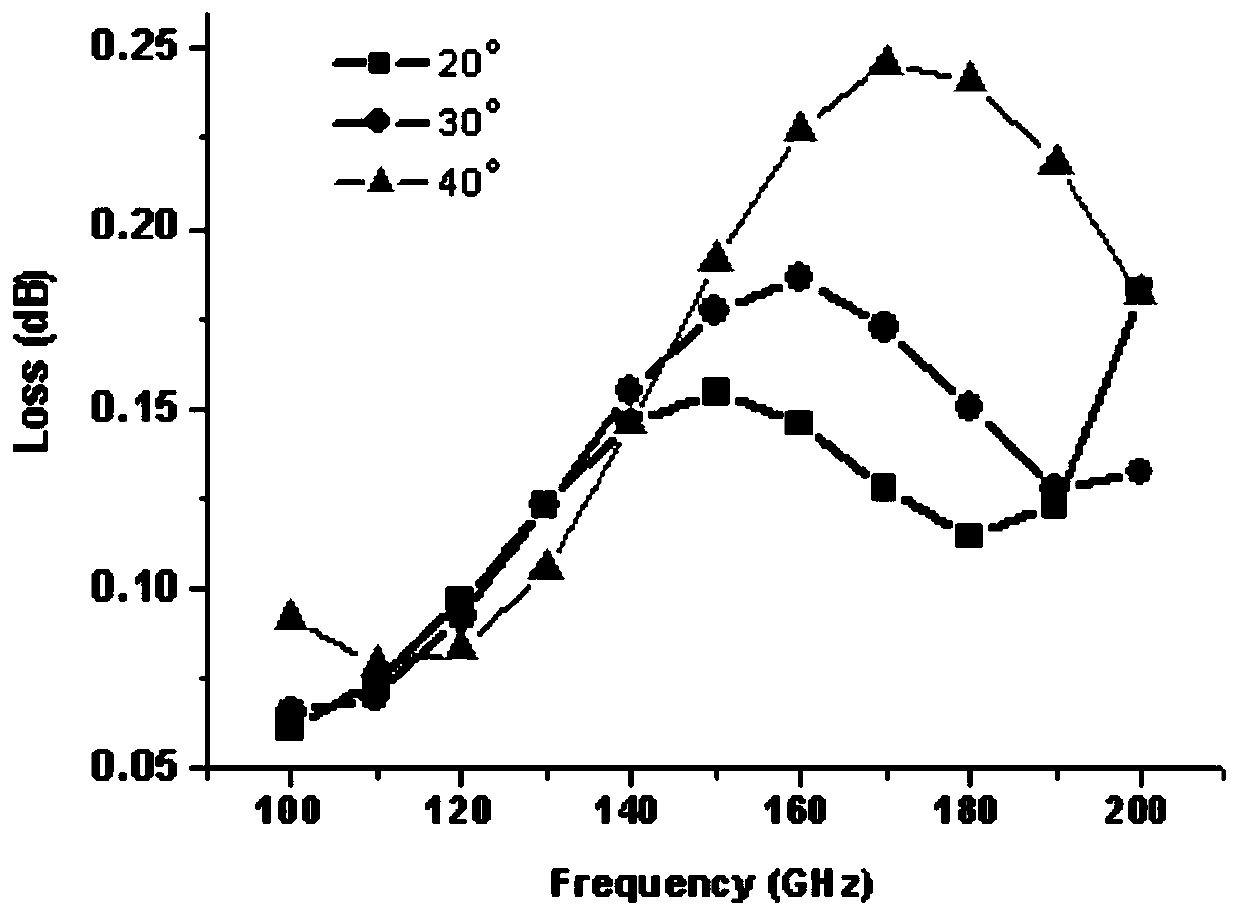

6G radome suitable for terahertz antenna and preparation method thereof

ActiveCN110350317AImprove temperature resistanceLightweightRadiating element housingsMaxillary gingivaBisphenol

The invention relates to a 6G radome suitable for a terahertz antenna and a preparation method thereof. The radome comprises an outer skin, a foam core layer, a middle skin, a foam core layer and an inner skin. The 6G radome is characterized in that the prepreg formed by combination of fiber reinforcement and resin is used as the skin material. As for the prpreg, the resin is polyphenylene ether modified bisphenol M cyanate ester resin and has the following dielectric properties: dielectric constant is less than or equal to 2. 6 and the loss factor is less than or equal to 0. 004. The fiber reinforcement is quartz fiber braid. The prepreg gum content is 30wt%-44wt%. The hot-pressing pot forming technology is used. The radome has high wave transmittance within the range of 100-200GHz and can meet the transmission performance requirements of the 6G antenna network within the terahertz band.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Large-caliber Gr3 seamless steel tube applied at low temperature and production method thereof

InactiveCN104451381AEnsure dense and uniformCrack suppressionMetal rolling arrangementsImpuritySizing

The invention discloses a large-caliber Gr3 seamless steel tube applied at a low temperature. The large-caliber Gr3 seamless steel tube comprises the following ingredients in percentage by mass: 0.04-0.08 percent of C, 0.29-0.35 percent of Si, 0.45-0.49 percent of Mn, 0.011-0.012 percent of P, 0.0032-0.005 percent of S, 3.45-3.75 percent of Ni, 0.095-0.12 percent of Mo and the balance of Fe and inevitable impurities. The seamless steel tube is produced by adopting a Pilger milling process according to the following steps: blanking a tube blank; perforating the center of tube blank; heating by using an annular furnace; perforating by using a Mannesmann perforator; milling the tube by using a Pilger milling machine; cutting a Pilger head; heating by using a stepping furnace; sizing by using a sizing mill; thermally machining; straightening; cutting by using a saw; machining inner and outer surfaces; inspecting manually; performing automatic combined flaw detection by ultrasonic vortex; re-inspecting manually; and cleaning, identifying, packaging and putting into storage.

Owner:HENGYANG VALIN STEEL TUBE

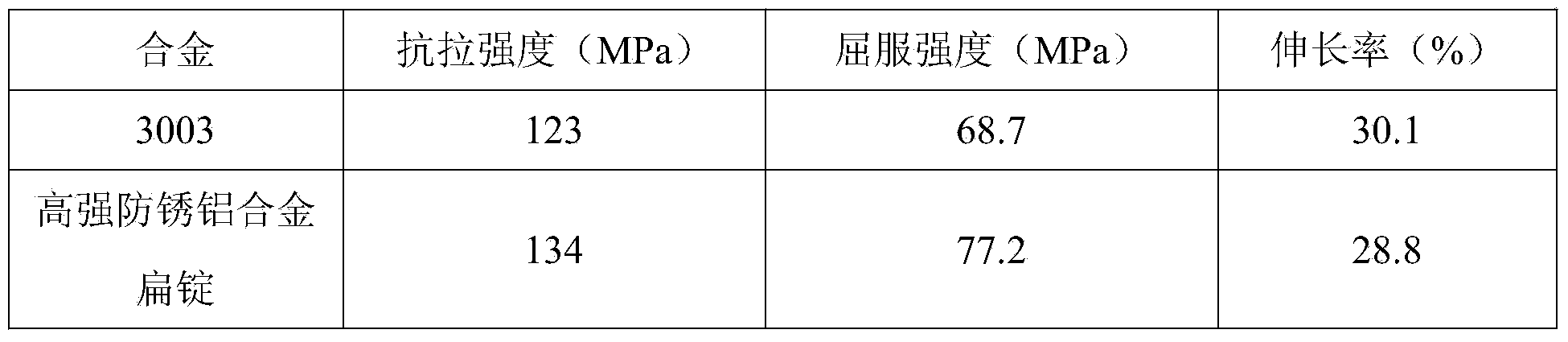

Manufacturing method of high-strength antirust aluminum alloy slab ingot

ActiveCN104264015AIncrease productivityIncrease the degree of diffusionIngotUltimate tensile strength

The invention discloses a manufacturing method of a high-strength antirust aluminum alloy slab ingot and relates to a manufacturing method of an aluminum alloy slab ingot. The manufacturing method solves the problems that a core of an existing composite material is mainly a 3003 alloy, but the 3003 alloy hardly meets the requirements of the current market on the high-performance composite material due to low alloying degree and low strength. The method comprises the following steps: 1, melting, and 2, forming, so that the high-strength antirust aluminum alloy slab ingot is obtained. The manufacturing method is used for manufacturing the high-strength antirust aluminum alloy slab ingot.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Forming tool for winglet of foam sandwich composite structure

The invention belongs to the technical field of composite aviation manufacturing and relates to a forming tool for a winglet of a foam sandwich composite structure. The forming tool is composed of an upper forming mold and a lower forming mold. The upper forming mold is a composite mold and is used for ensuring the outline dimension and the surface quality of the upper molded surface of the winglet in the winglet forming process. The lower forming mold is a composite frame mold and is used for supporting and fixing a whole part and ensuring the outline dimension and the surface quality of the lower molded surface of the winglet in the winglet forming process. The molded surface of the lower forming mold is a variable-thickness composite molded surface. The butt joint area of the front edge of the lower forming mold and the upper forming mold is provided with a thinning area to ensure the uniformity of a pressure field in the large-curvature area of the front edge of the winglet. The forming tool for the winglet of the foam sandwich composite structure is easy to operate, demolding is easy, the problem that large-curvature complex structure parts similar to the winglet are unevenly pressurized is solved, and the internal quality and the surface quality of the parts are well ensured.

Owner:AVIC COMPOSITES

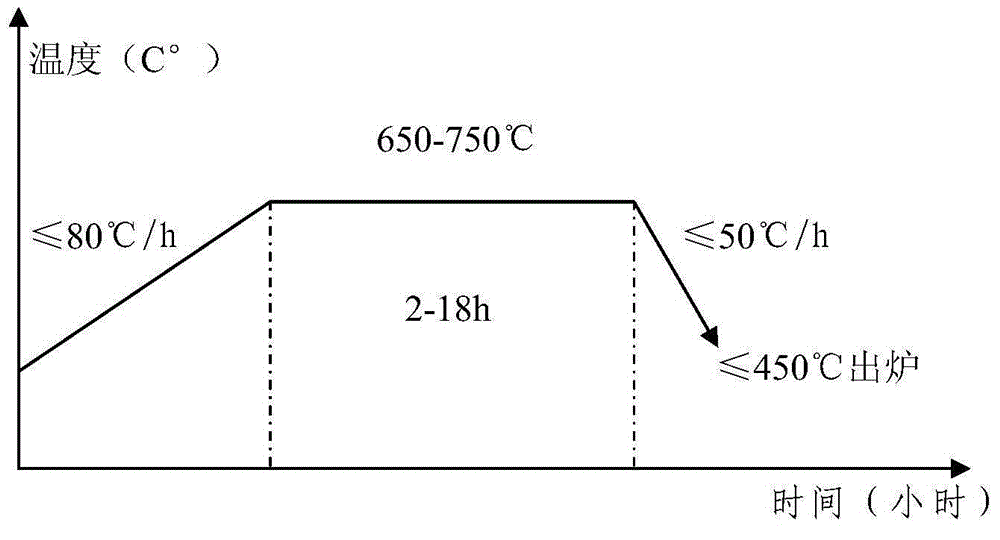

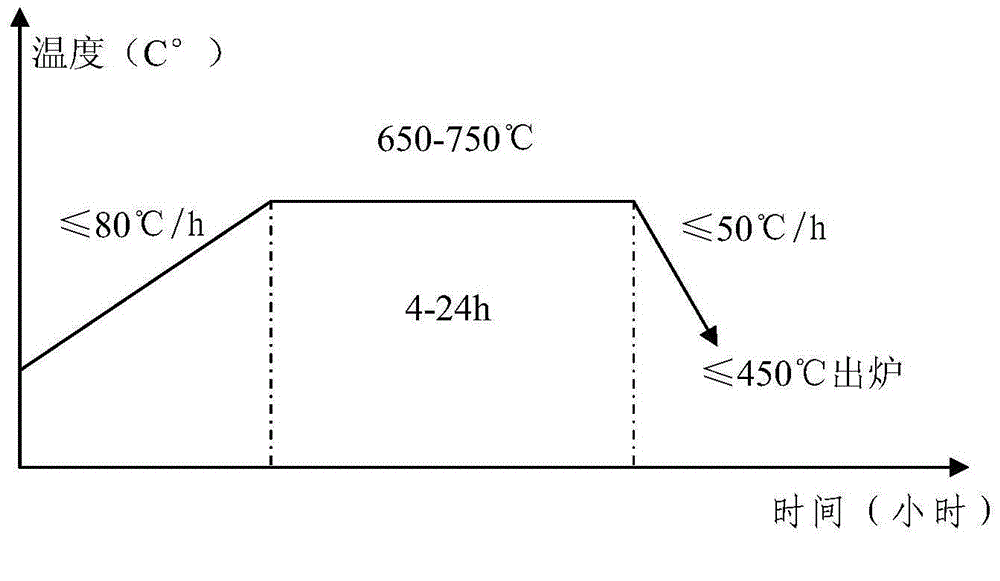

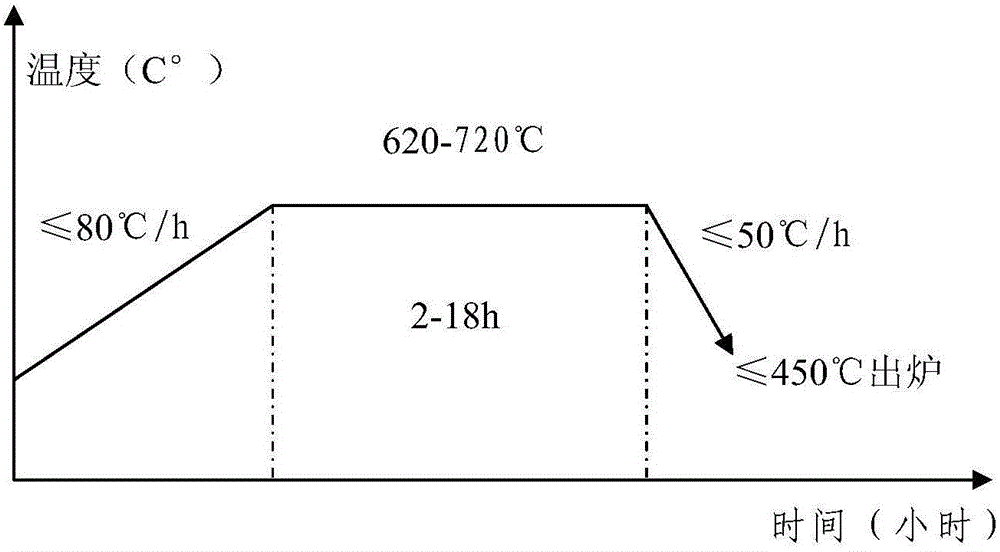

Hardened and tempered steel plate production method

The invention discloses a hardened and tempered steel plate production method. Chemical components of steel include, by mass, 0.08% to 0.24% of C, 0.20% to 0.50% of Si, 0.80% to 1.30% of Mn, smaller than or equal to 0.018% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.020% or smaller than or equal to 0.050% of Als, smaller than or equal to 0.25% of Cr, smaller than or equal to 0.08% of Mo, smaller than or equal to 0.25% of Cu, smaller than or equal to 0.25% of Ni, and the balance Fe and remaining elements. The method includes the following processing steps of converter smelting, refining, vacuum refining, casting, heating, rolling, slow cooling and thermal treatment. Through continuous casting blank production, the internal quality of blanks is guaranteed, the low-cost chemical components only with Nb, V and Ti alloy added are selected and used for design, the cleanliness of steel is guaranteed through an LF and VD process, and the sum of the levels of various impurities does not exceed 2.0; through rolling control and normalizing treatment, the grain size of the steel reaches more than 8.0; through the effective implementation of the technical measures, steel plates for a carbon-manganese-silicon pressure container and steel plates guaranteeing flaw detection, the mechanical performance and the plate shape for the carbon-manganese-silicon pressure container are successfully produced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

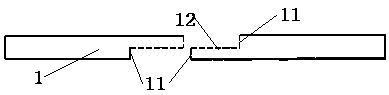

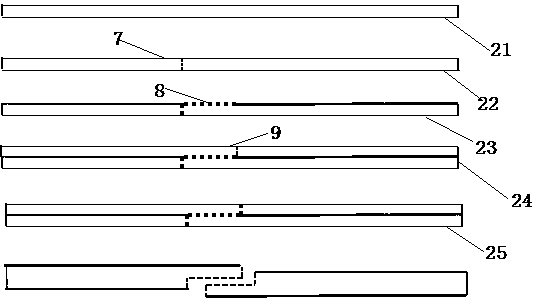

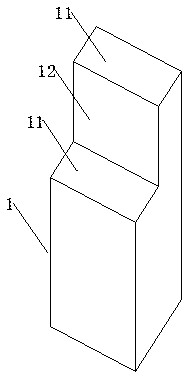

Technological cover plate of combined structure and preparation method

The invention discloses a technological cover plate of a combined structure. The technological cover plate comprises a plurality of split shaped panels in lap joint, and the split shaped panels comprise border parts provided with step surfaces and connecting parts connected with the ends, away from the step surfaces, of the border parts; the border parts and the connecting parts are molded throughone-time curing; and the split shaped panels are in lap joint through the step surfaces. According to the technological cover plate, the border parts with the step surfaces are adopted, motion coordination of internal structures of the technological cover plate is improved, the fitting degree of the technological cover plate and skin green bodies is optimized, and internal quality is guaranteed;lap joint clearances are prevented from being generated, the possibility of the material overflow problem is reduced, even though the material overflow problem occurs, only resin overflows, and overflowed materials can be treated through simple polishing; and the operation program is effectively simplified, the separated lap joint effect of the split shaped panels is improved, the possibility of material overflow at lap joint zones of the split panels is reduced, the structure is unique, the concept is novel, and the prepared technological cover plate of the combined structure has high structure motion coordination of rubber technological cover plates.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Free forging forming method for large six throw crankshaft

InactiveCN107790594AGuarantee internal qualityMeet the requirements of ultrasonic flaw detectionMetal-working apparatusEngine componentsReduction rateIngot

The invention discloses a free forging forming method for a large six throw crankshaft. The large six throw crankshaft is forged overall through an angle presetting method, angle accuracy of three bent plates arranged mutually at the included angles of 120 degrees can be guaranteed, and the novel free forging method is provided. Through the method of flattening-squaring and heavy reduction drawingout after upsetting of steel ingots and control over the longitudinal blank width ratio, the transverse tool width ratio and the reduction rate in the forging process, it is guaranteed that the internal quality of the large six throw crankshaft forged piece meets the ultrasonic flaw detection requirement. Metal fiber of the forged crankshaft is continuous and free of torsion, and the quality of the forged piece is good. Tool accessory investment for the method is small, operation is simple, the cost is low, the quality of the large six throw crankshaft is improved, and the method can be usedfor free forging production of equal-angle multi-throw crankshafts.

Owner:SHENYANG FOUNDRY & FORGING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com