Free forging forming method for large six throw crankshaft

A six-turn crankshaft, forging molding technology, applied in the field of forging, can solve the problems of improper control of the molding process, disconnection, difficult manufacturing, etc., and achieve the effects of good popularization and application value, accurate angle and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

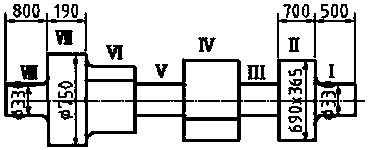

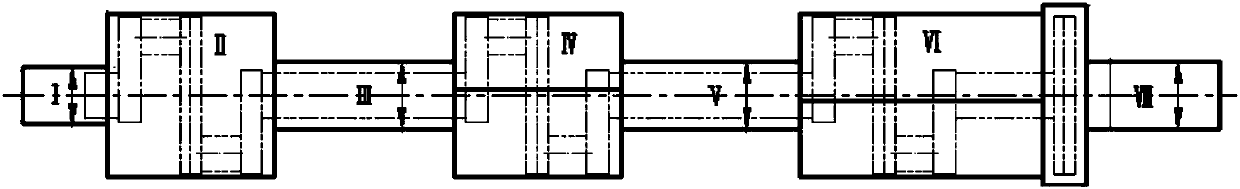

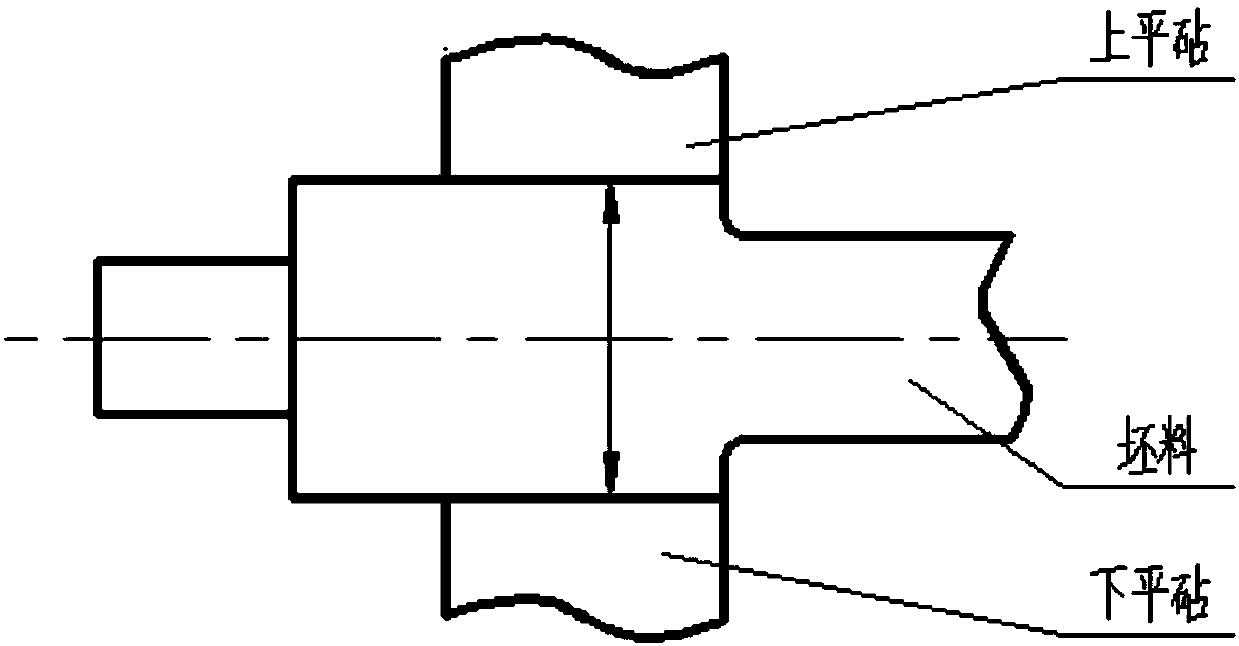

[0020] Attached below Figure 1-7 The present invention is described in detail.

[0021] A free forging method for a large six-turn crankshaft. The angle preset method is used to forge a large six-turn crankshaft as a whole, which can ensure that the angles between the three curved plates at 120° are accurate. After upsetting the steel ingot, it is flattened and squared. The method of reduction and extension, as well as the control of the longitudinal anvil width ratio, transverse material width ratio and reduction rate during the forging process can ensure that the internal quality of large six-turn crankshaft forgings meets the requirements of ultrasonic flaw detection; the longitudinal anvil width ratio and The two instantaneous deformation parameters of the lateral material width ratio are effectively controlled to ensure the internal quality of the forging; forging forming method, the parts I and II, parts III and IV, and parts V and VI are respectively pressed into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com