Technological cover plate of combined structure and preparation method

A combined structure and cover plate technology, which is applied in the field of composite material manufacturing, can solve the problems of skin body position mismatch, position mismatch, and high quality requirements on the outer surface, so as to improve the coordination of internal structure activities and reduce the occurrence of flashing Possibility, improve the effect of separation and lapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

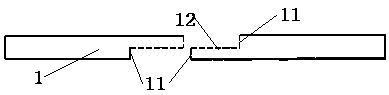

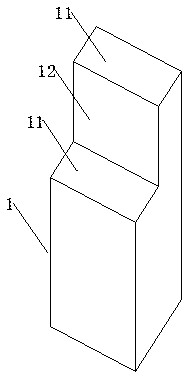

[0035] The present invention is realized through the following technical solutions, as figure 1 As shown, a combined structure process cover plate is used for the manufacture of composite material structures, including a plurality of overlapping split-body shaped panels 1, and the split-body shaped panels 1 include a boundary portion provided with a stepped surface and a The connection part where the boundary part is far away from the end of the stepped surface is connected, and the boundary part and the connection part are solidified and formed at one time. The split shaped panels 1 overlap each other through stepped surfaces.

[0036] It should be noted that, through the above improvements, the stepped surfaces completely contact each other and overlap each other. The coordination of the internal structure of the process cover is improved, the degree of bonding between the process cover and the skin body is optimized, and the internal quality is guaranteed to the greatest e...

Embodiment 2

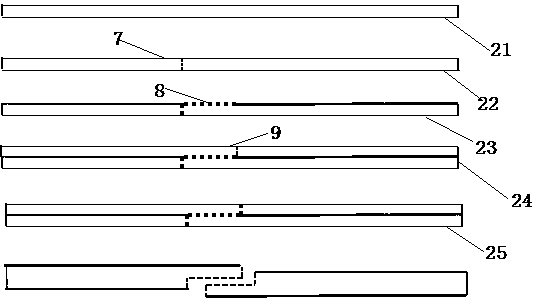

[0039] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the stepped surface includes a middle boundary surface 12 and two edge boundary surfaces 11, the middle boundary surface 12 is parallel to the upper plane / lower plane of the connecting part of the split forming surface, and the two edge boundary surfaces 11 It is perpendicular to the upper plane / lower plane of the connection part of the split panel 1 . Taking the surface perpendicular to the edge boundary surface and the middle boundary surface as the reference surface, the projection on the reference surface of the middle boundary surface 12 is the middle boundary contour line, and the length of the middle boundary contour line is between 0 mm and 10 mm; The projection of the edge boundary surface 11 on the reference surface is an edge contour line, the projection of the connection surface on the reference surface is a connection contour line, and the length of the ed...

Embodiment 3

[0045] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the split shaped panel 1 is made of composite material, the reinforcement includes one or more of carbon fiber, glass fiber, and aramid fiber, and the form of the reinforcement is unidirectional, plain weave, or twill weave , one or more of satin; the resin matrix includes epoxy resin, bismaleimide resin, polyimide resin, polybenzoxazine resin, cyanate resin, phenolic resin, not One or more of saturated resins.

[0046] The reinforcing body is any one of a material composed of carbon fiber material and glass fiber material, a material composed of carbon fiber material and aramid fiber material, a material composed of carbon fiber material, glass fiber material and aramid fiber material.

[0047] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com