Hardened and tempered steel plate production method

A production method, the technology of quenched and tempered steel plate, applied in the field of steelmaking, can solve the problem that the mechanical properties of steel are difficult to meet high requirements, and achieve the effect of uniform impact performance and large margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention is further described below in conjunction with the embodiments.

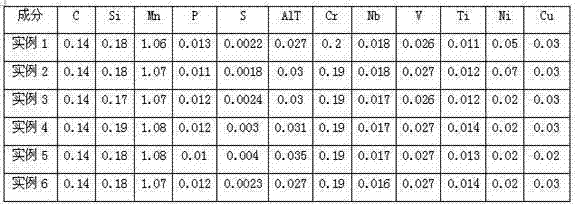

[0017] The production method of quenched and tempered steel plate, the chemical composition mass percentage of steel is C=0.08~0.24, Si=0.20~0.50, Mn=0.80~1.30, P≤0.018, S≤0.005, Als≤0.020~0.050, Cr≤0.25, Mo≤0.08, Cu≤0.25, Ni≤0.25, the others are Fe and residual elements. Including the following process steps:

[0018] a. Converter smelting: control C≥0.05%, P≤0.015%, tapping temperature ≥1650°C, and spot blowing times ≤2 times to avoid slag during the tapping process;

[0019] b. LF refining: use a large amount of slag to make slag to ensure that the retention time of white slag is controlled at more than 15min;

[0020] c. Vacuum refining: refining under the pressure of ≤67Pa, holding time ≥ 25min;

[0021] d. Casting: The normal liquid level depth of tundish ladle casting is ≥1m, and the tundish is protected by covering agent;

[0022] e. Heating: The heat prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com