Patents

Literature

37results about How to "Good quality and performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

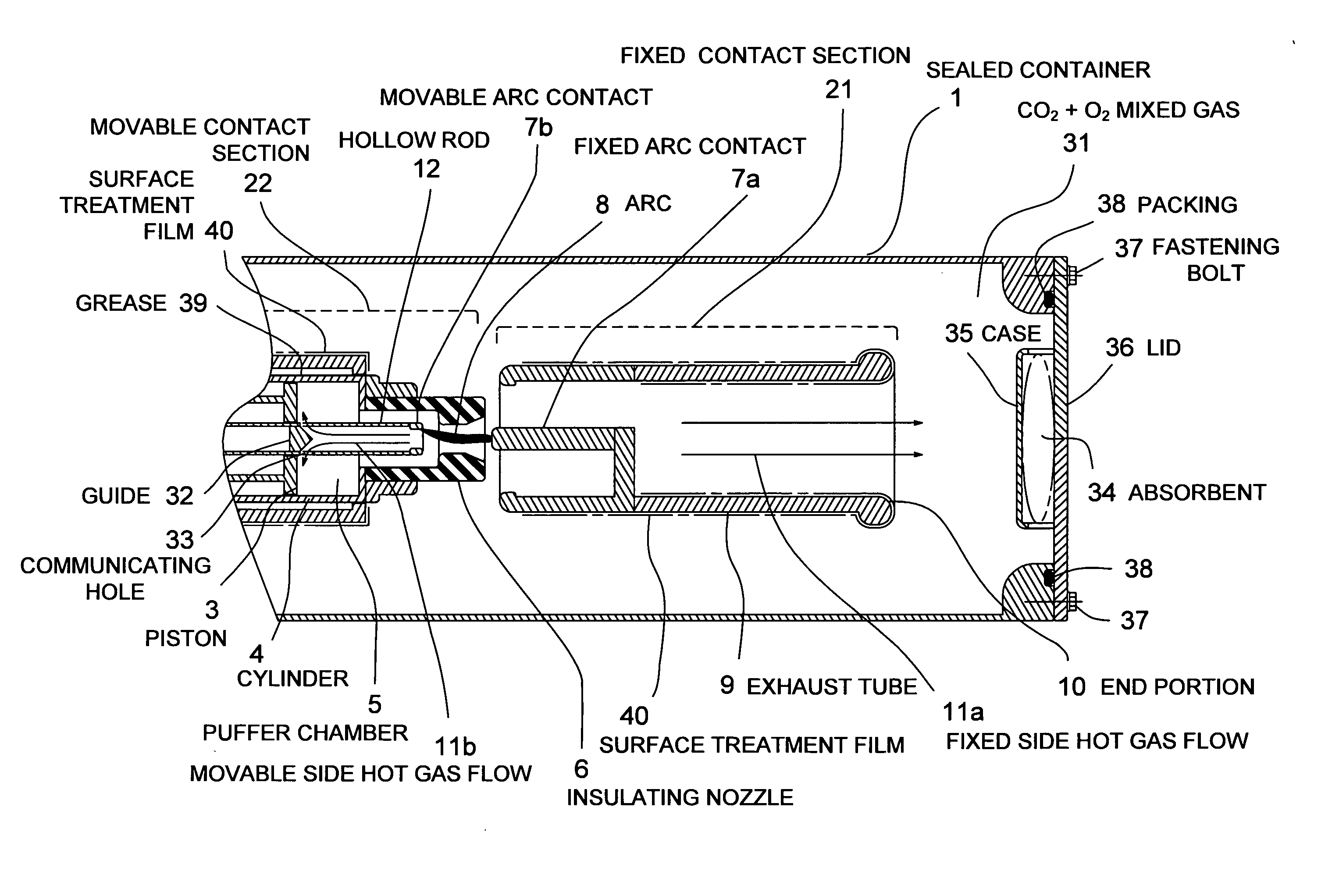

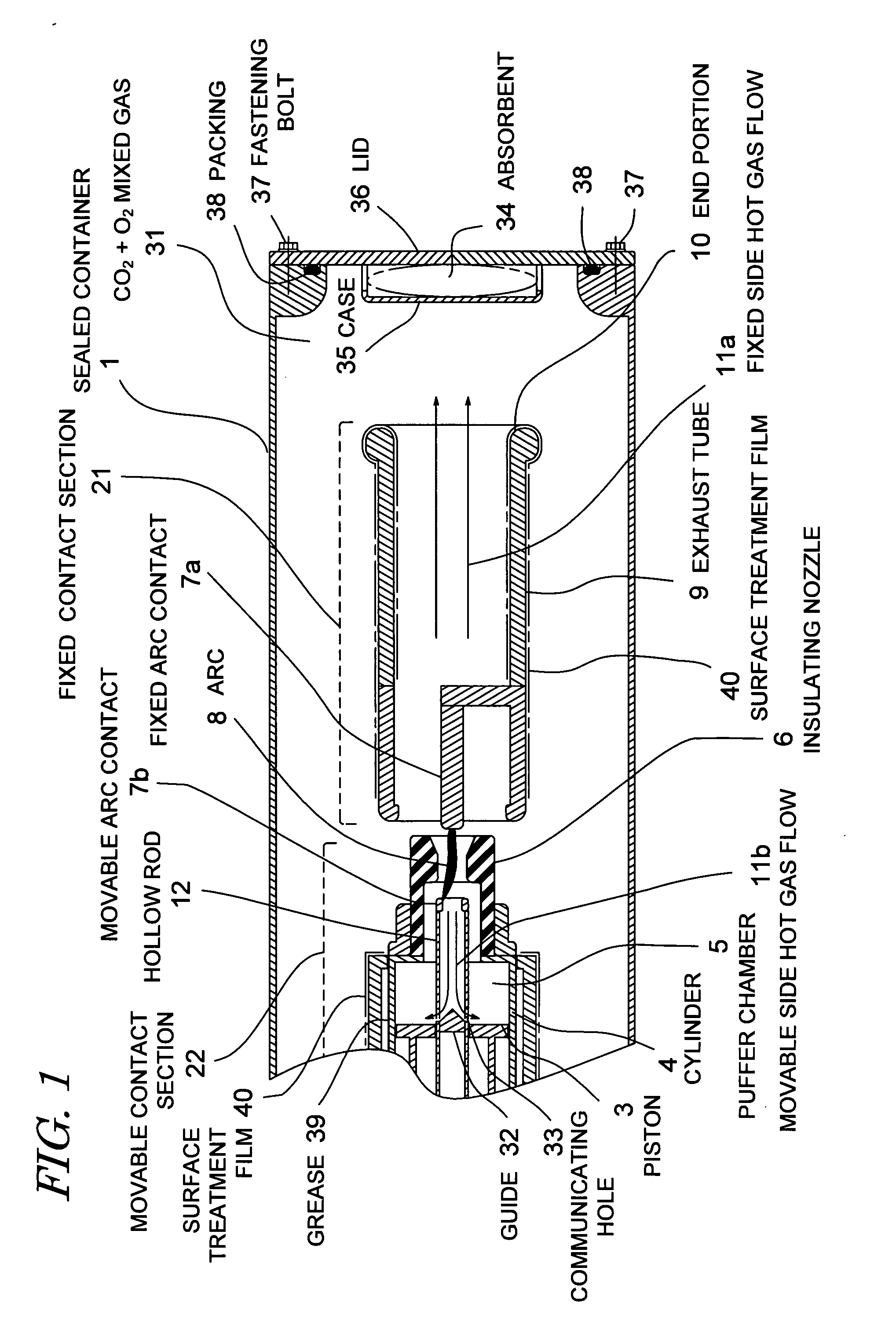

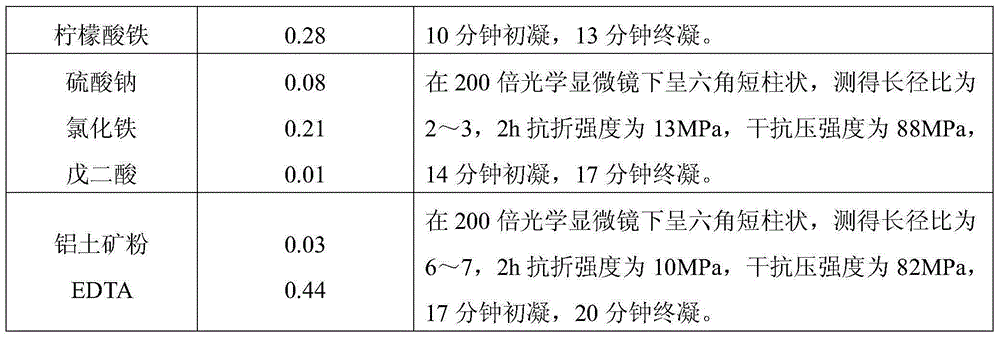

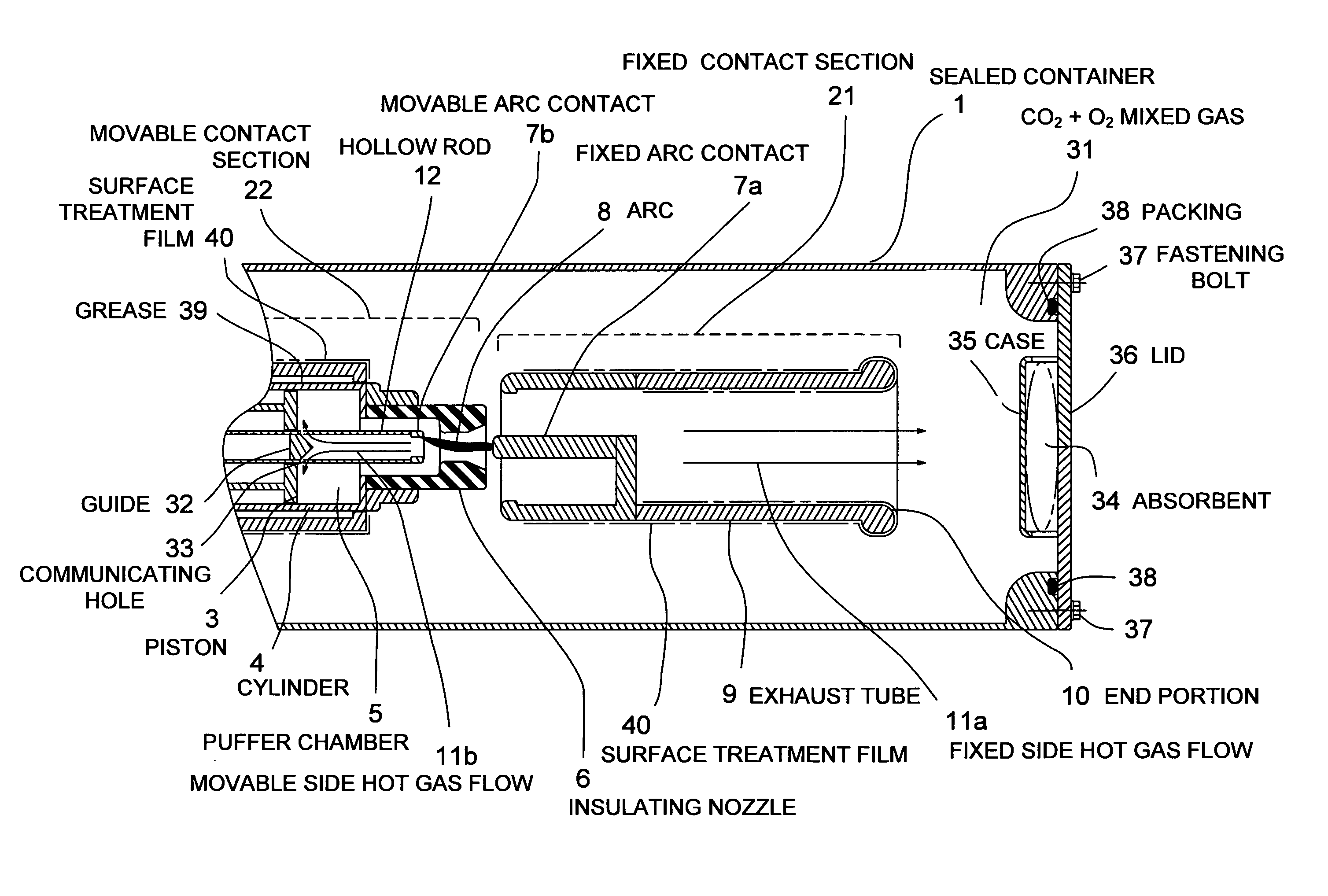

Gas insulated switchgear

ActiveUS20070221626A1Improve performanceReduce impactHigh-tension/heavy-dress switchesAir-break switchesThermal energyEngineering

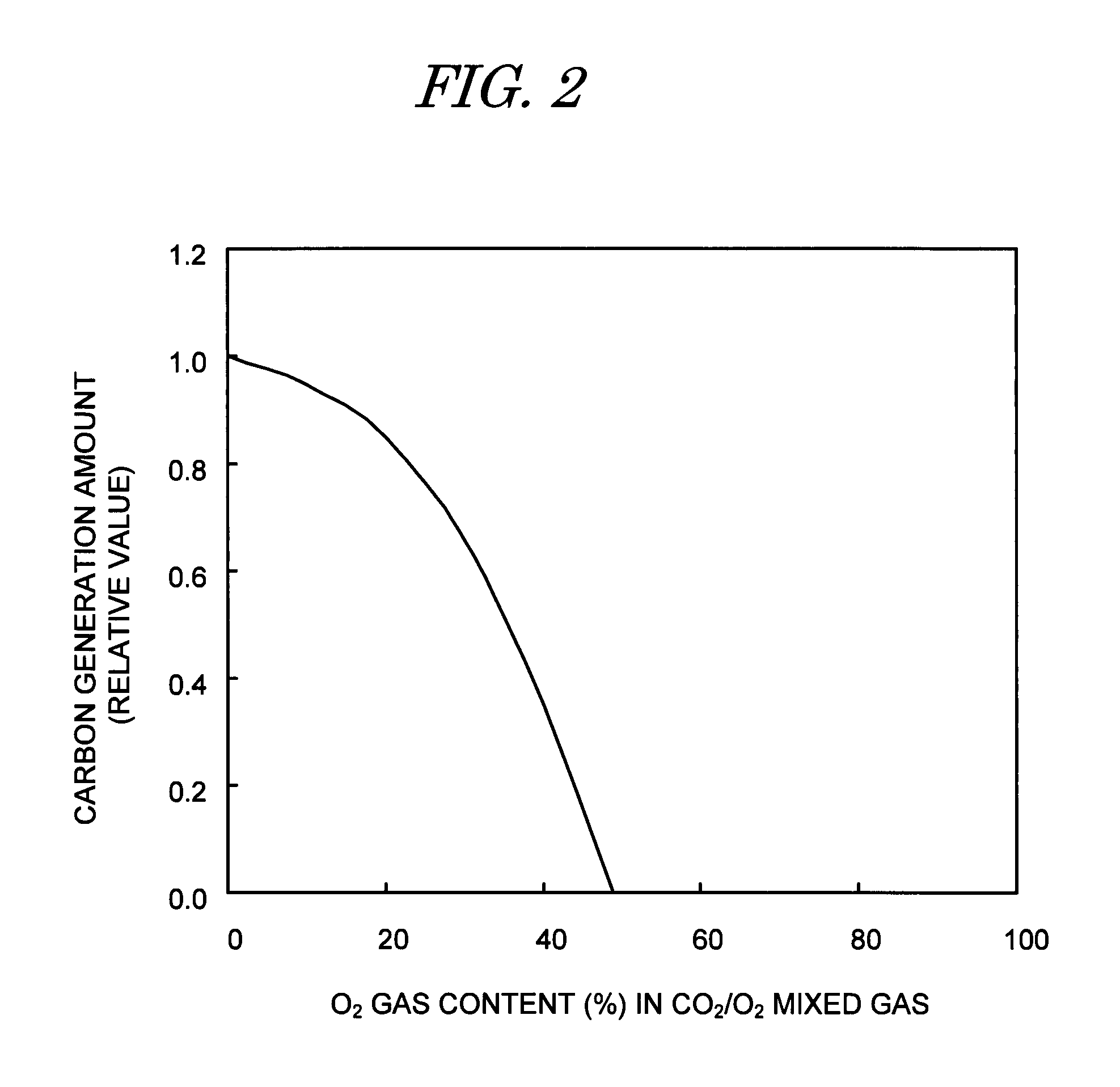

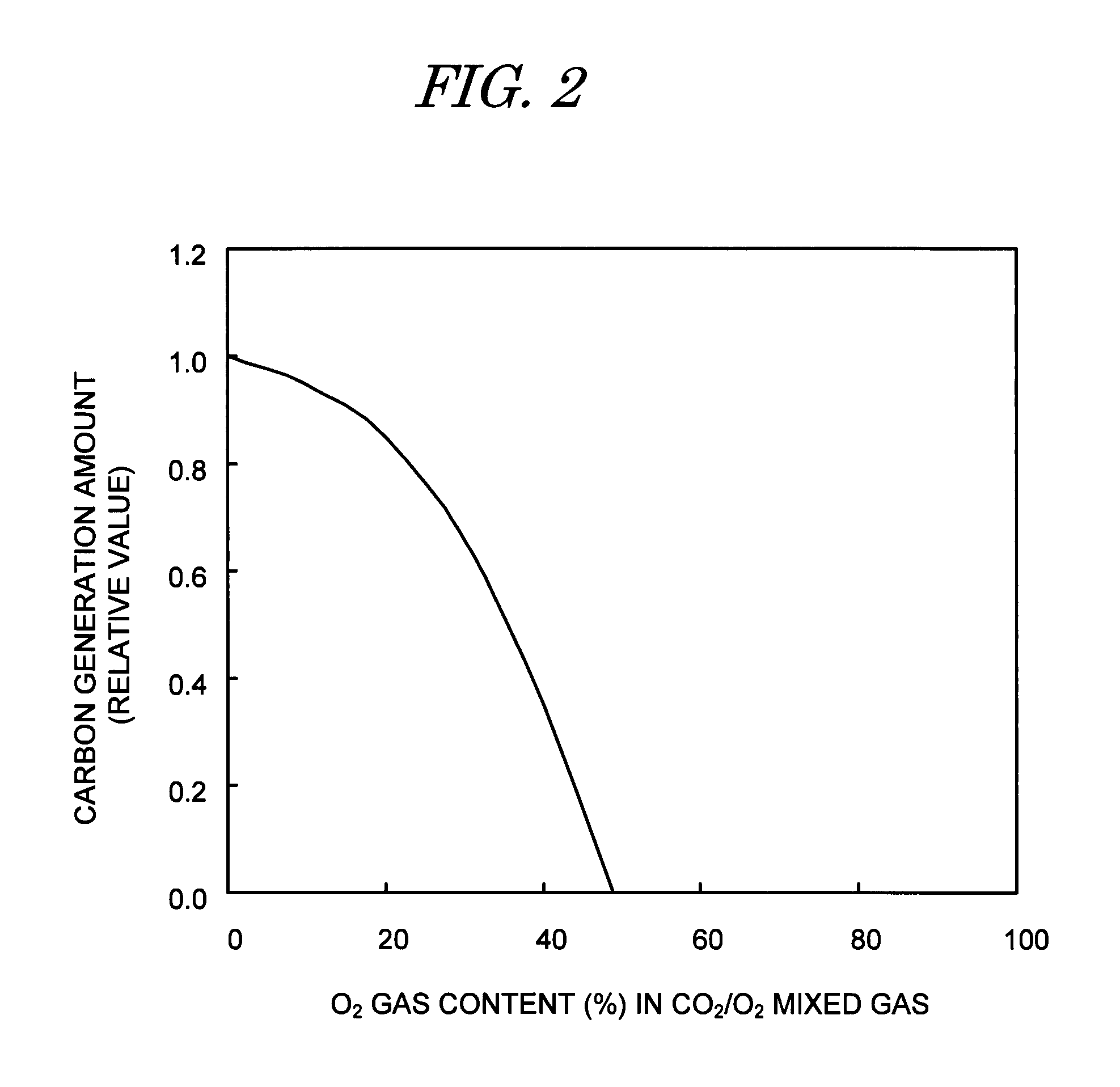

The invention secures superior performance by restraining carbon generation also when using as an arc extinguishing medium a gas comprising the element C and having a global warming potential lower than that of SF6 gas. A fixed contact section and a movable contact section are arranged opposite each other inside a sealed container filled with an insulating gas. A fixed arc contact and a movable arc contact are provided in the fixed contact section and the movable contact section. The insulating gas used as the arc extinguishing medium is a mixed gas of a gas comprising the element C, as the main constituent, and other gases. The presence of O2 gas in the mixed gas has the effect of restraining the amount of carbon generated as a result of current interruption. Adding to the mixed gas H2 gas, which possesses an extraordinary arc extinguishing performance, has the effect of enhancing arc extinguishing performance, compensating for the diminished performance derived from not using actively the thermal energy of the arc. An absorbent having a function of absorbing water, O3 or CO is arranged inside the sealed container.

Owner:KK TOSHIBA

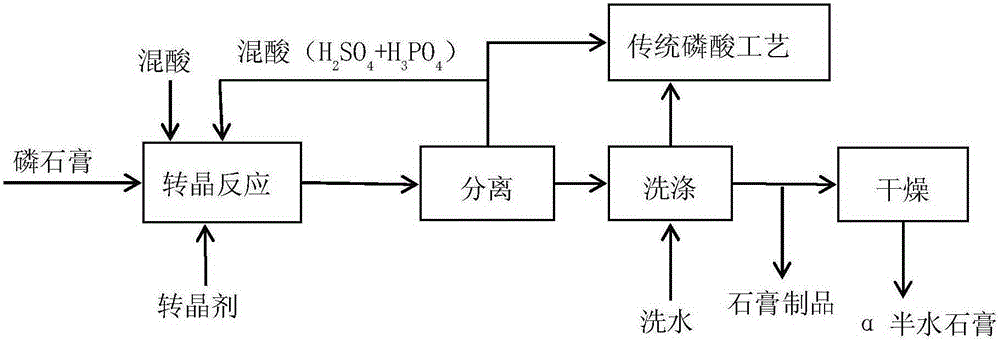

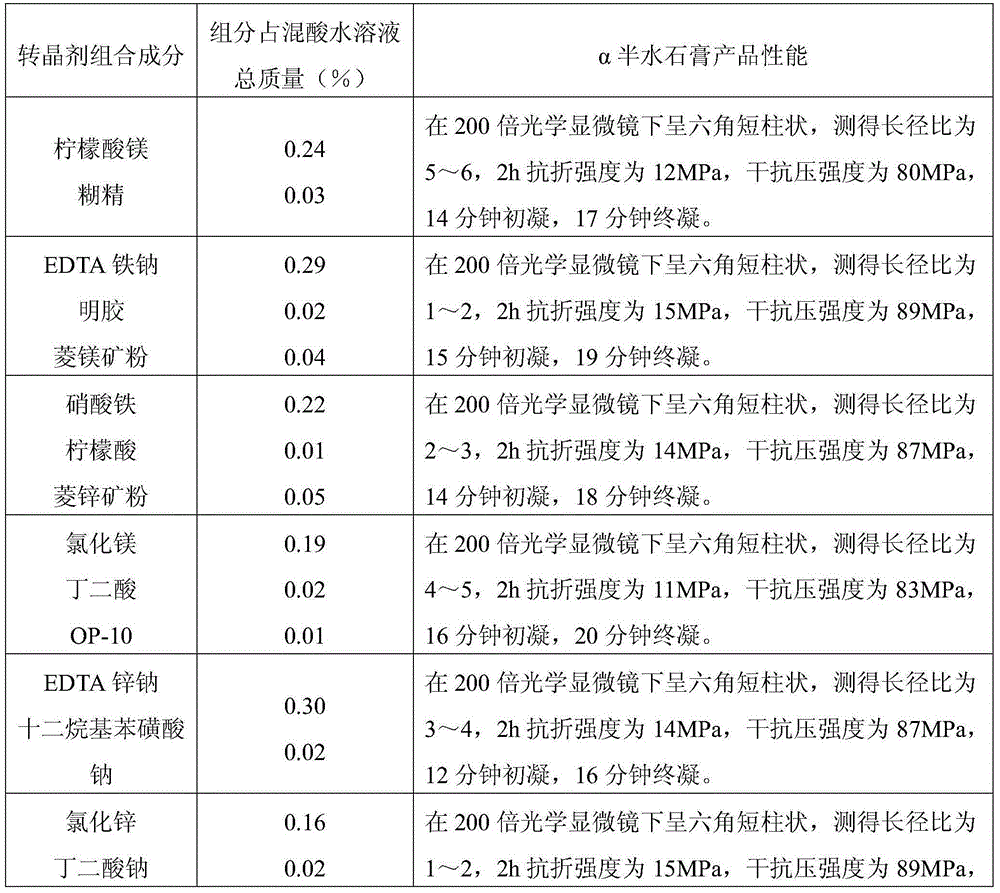

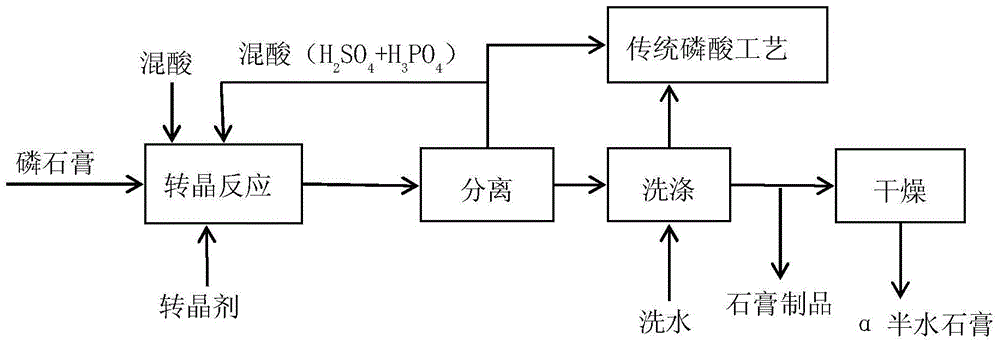

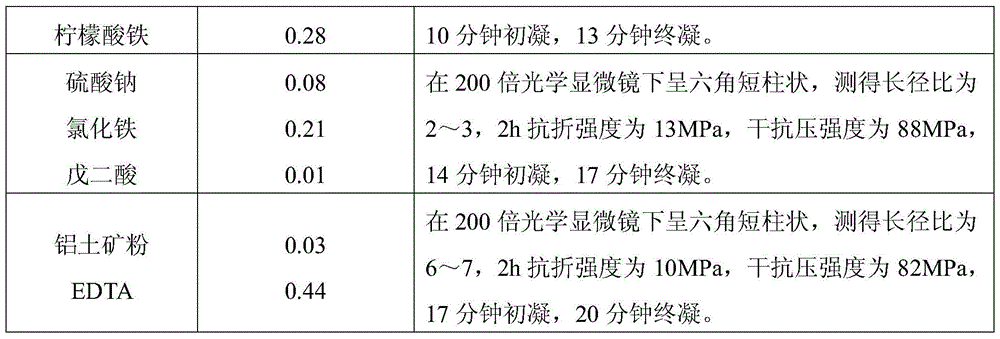

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

Gas insulated switchgear

ActiveUS7816618B2Improve performanceReduce impactHigh-tension/heavy-dress switchesAir-break switchesThermal energyEngineering

The invention secures superior performance by restraining carbon generation also when using as an arc extinguishing medium a gas comprising the element C and having a global warming potential lower than that of SF6 gas. A fixed contact section and a movable contact section are arranged opposite each other inside a sealed container filled with an insulating gas. A fixed arc contact and a movable arc contact are provided in the fixed contact section and the movable contact section. The insulating gas is a mixed gas of a gas comprising the element C, as the main constituent, and other gases. The presence of O2 gas in the mixed gas has the effect of restraining the amount of carbon generated. Adding H2 to the mixed gas has the effect of enhancing arc extinguishing performance, compensating for the diminished performance derived from not using actively the thermal energy of the arc.

Owner:KK TOSHIBA

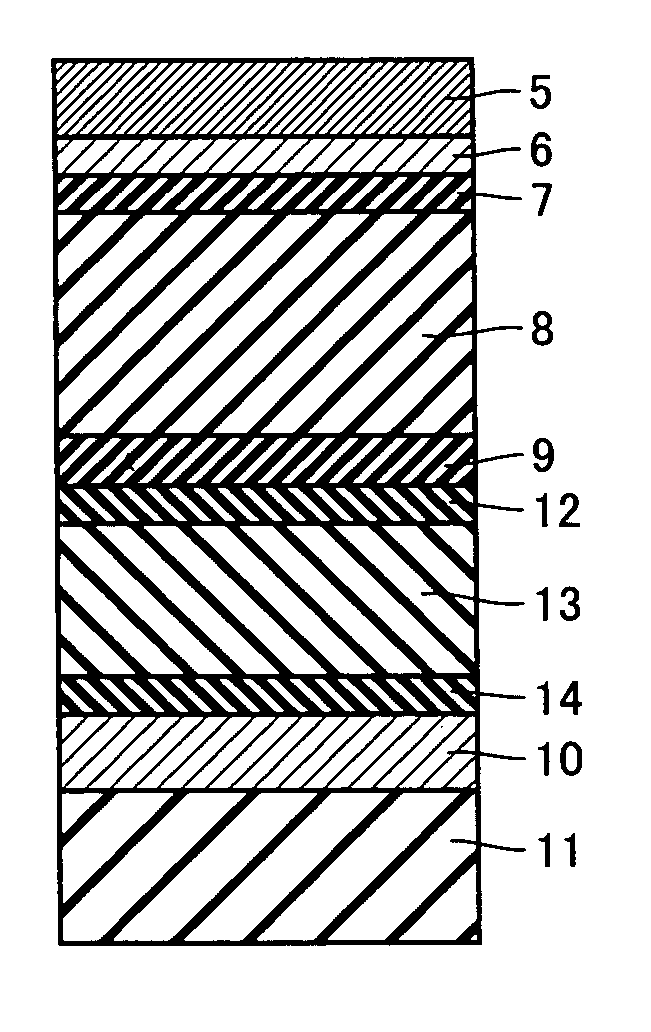

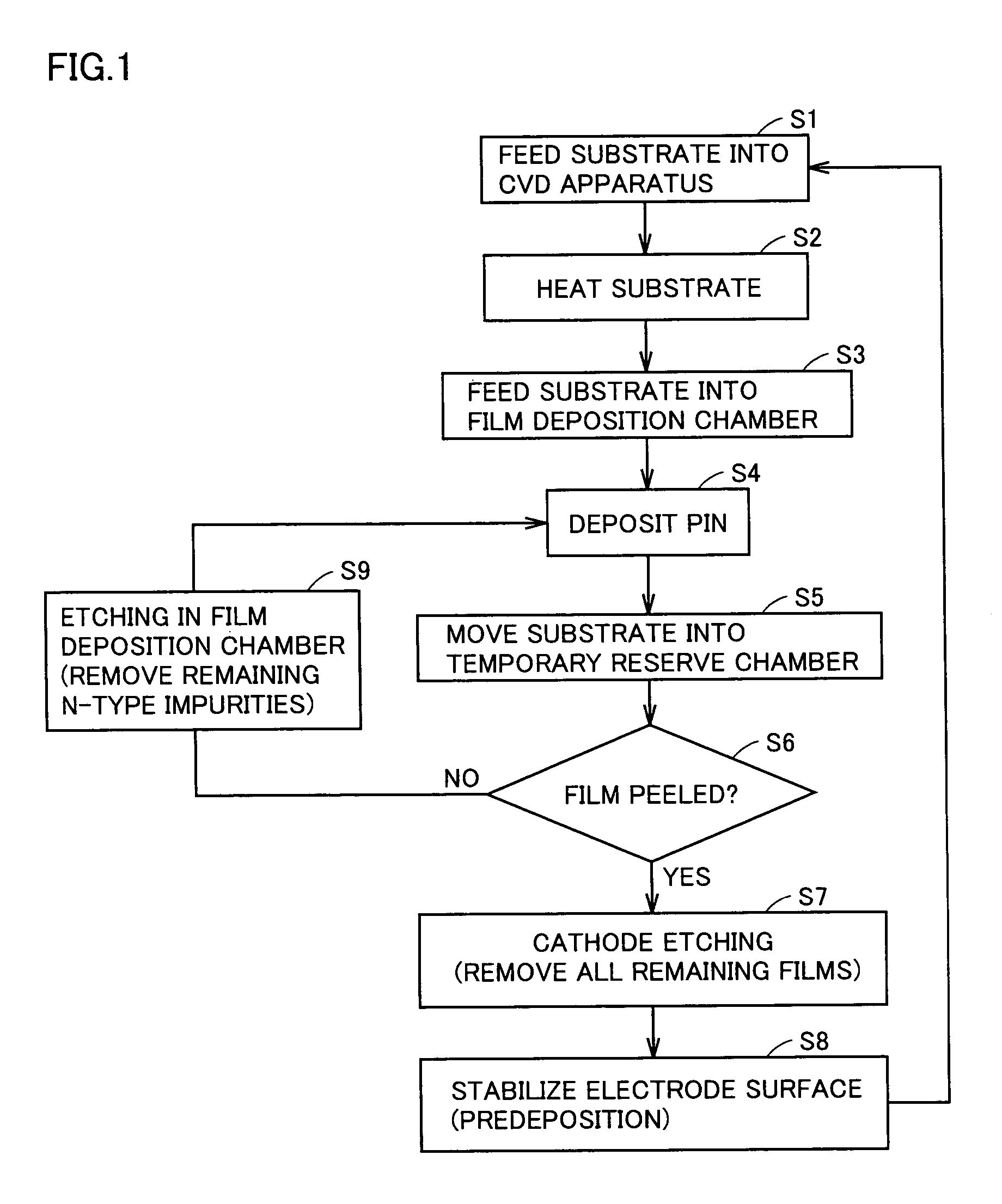

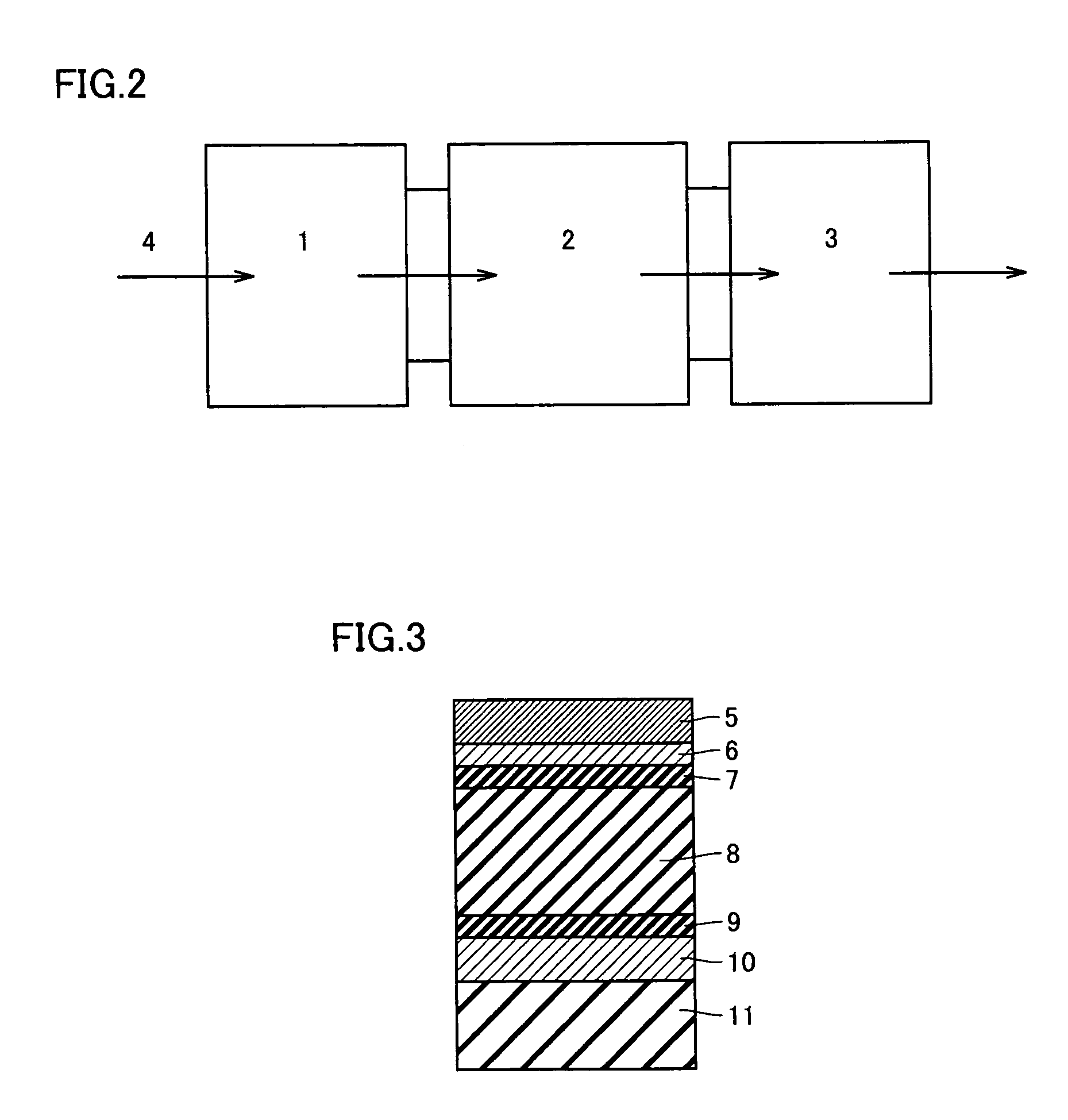

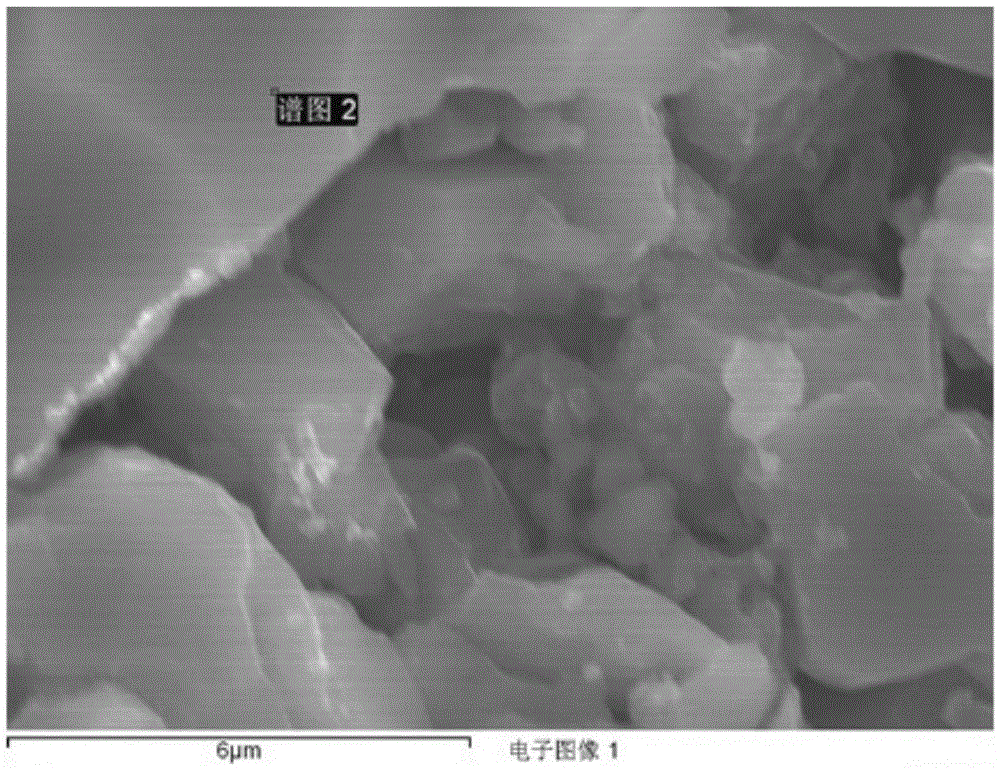

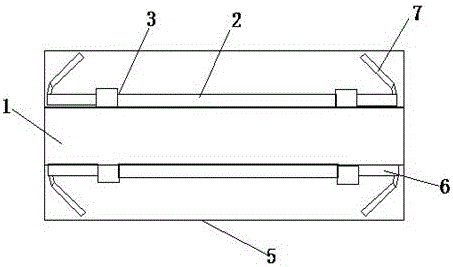

Silicon-based thin-film photoelectric conversion device and method of manufacturing thereof

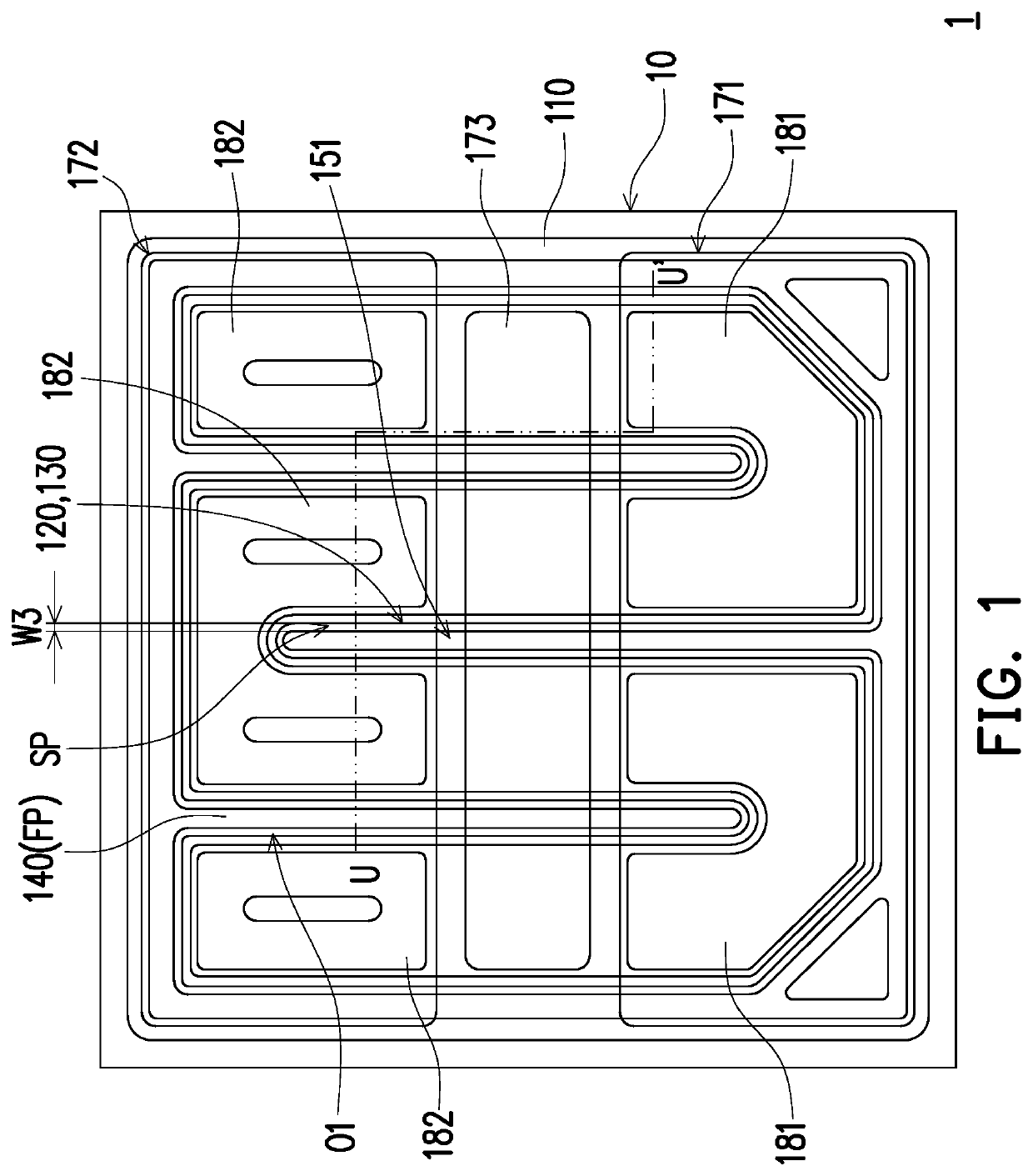

InactiveUS20050085003A1Improve performanceQuality improvementFinal product manufactureSemiconductor/solid-state device manufacturingPlasma depositionEngineering

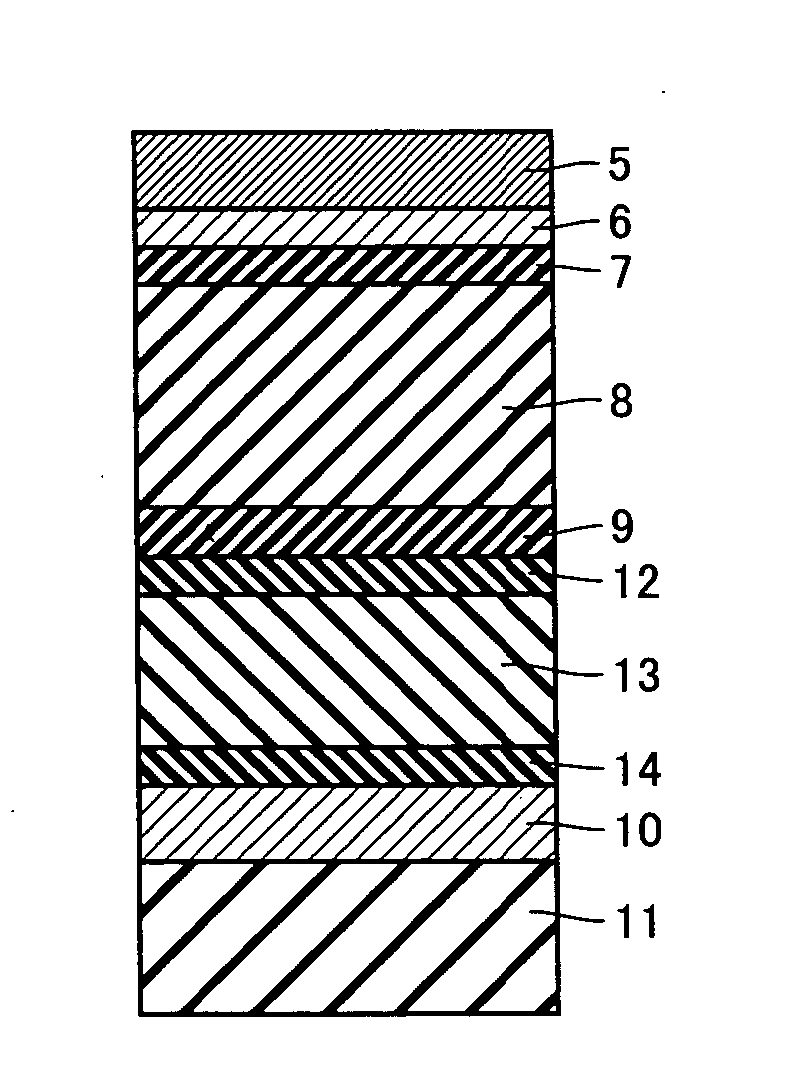

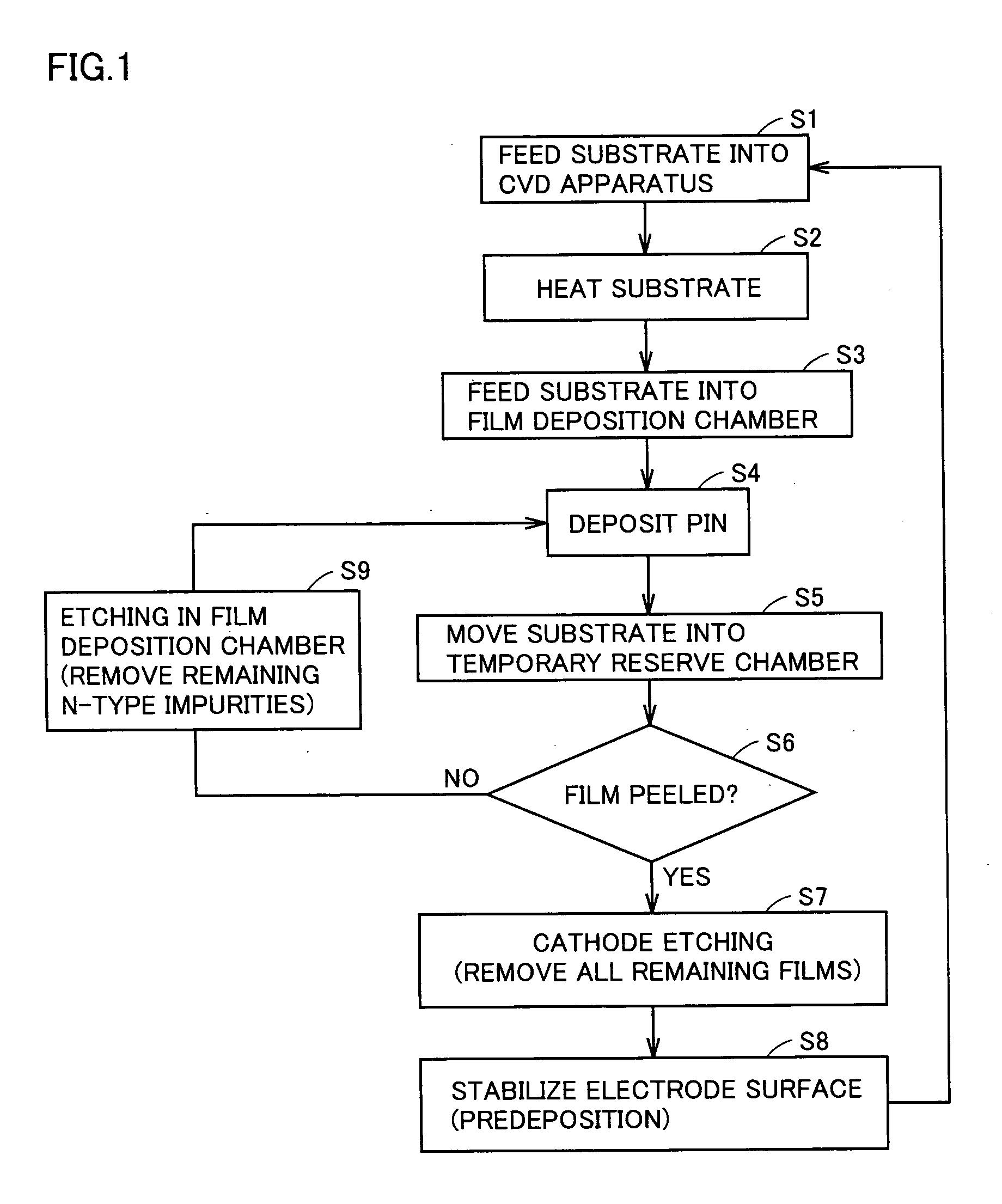

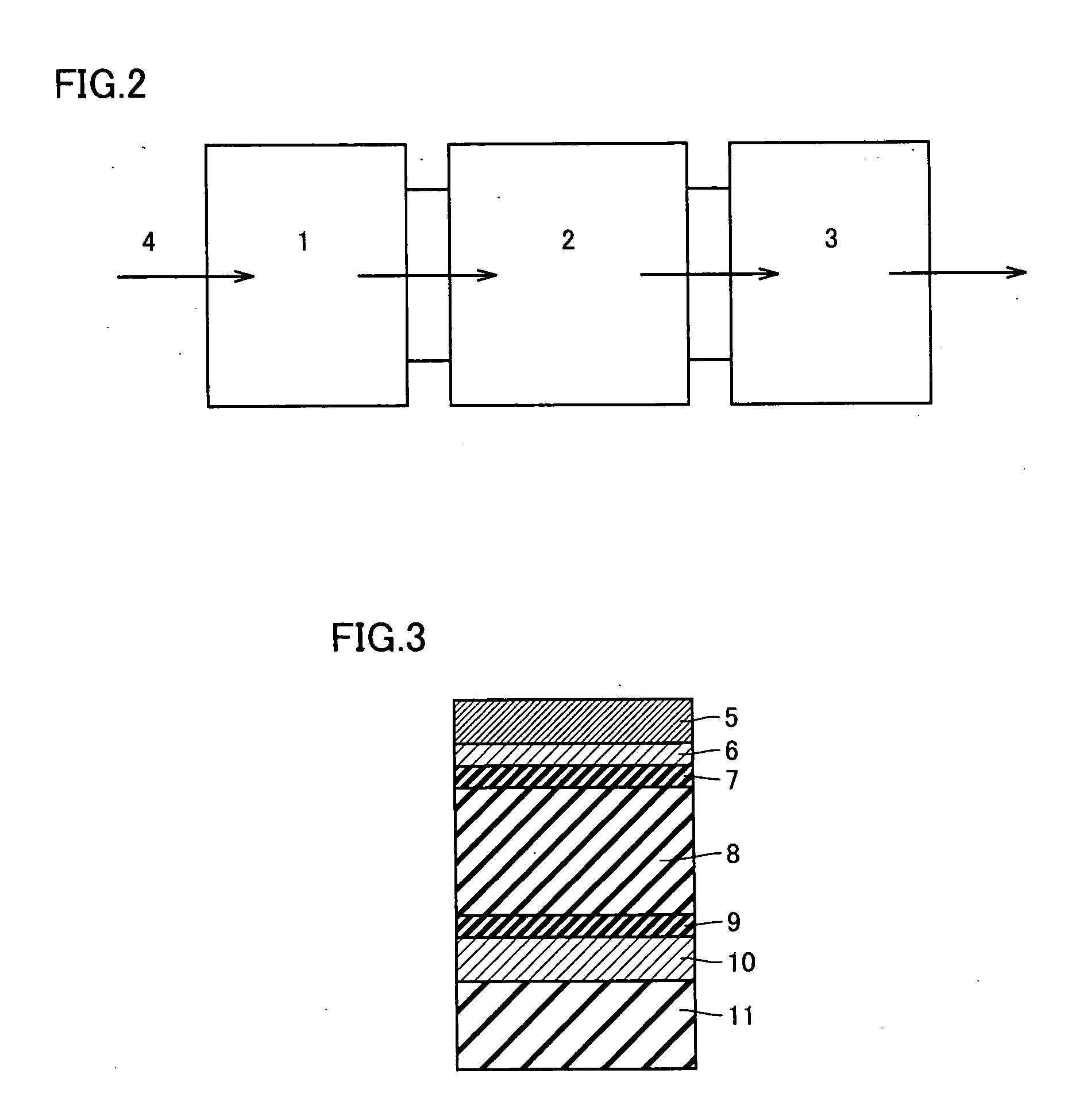

An excellent silicon-based thin-film photoelectric conversion device is manufactured simply and efficiently at a low cost. Specifically, a method of manufacturing the silicon-based thin-film photoelectric conversion device including a p-type semiconductor layer, an i-type microcrystalline silicon-based photoelectric conversion layer and an n-type semiconductor layer deposited by plasma CVD includes the steps of: successively depositing the p-type semiconductor layer, the i-type microcrystalline silicon-based photoelectric conversion layer and the n-type semiconductor layer on a substrate within the same plasma CVD film deposition chamber; transferring the substrate out of the film deposition chamber; and subsequently to the step of depositing the p-type semiconductor layer, the i-type microcrystalline silicon-based photoelectric conversion layer and the n-type semiconductor layer, eliminating influences of remaining n-type impurities on a cathode and / or within the film deposition chamber.

Owner:SHARP KK

Silicon-based thin-film photoelectric conversion device and method of manufacturing thereof

InactiveUS6979589B2Good quality and performanceSimple preparation equipmentFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringPhotoelectric conversion

Owner:SHARP KK

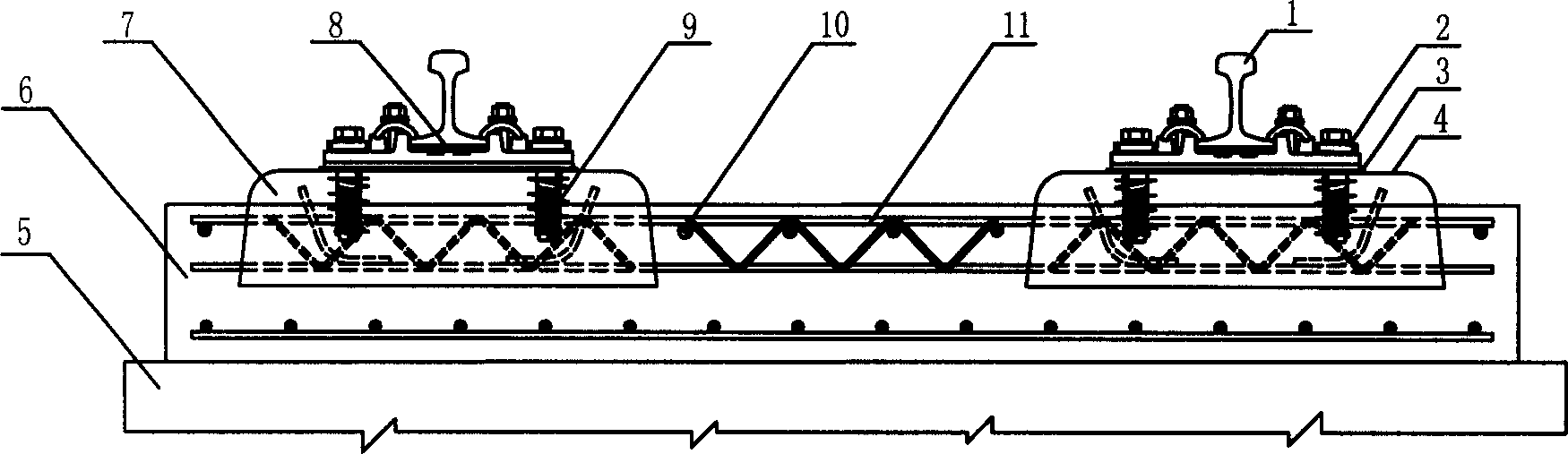

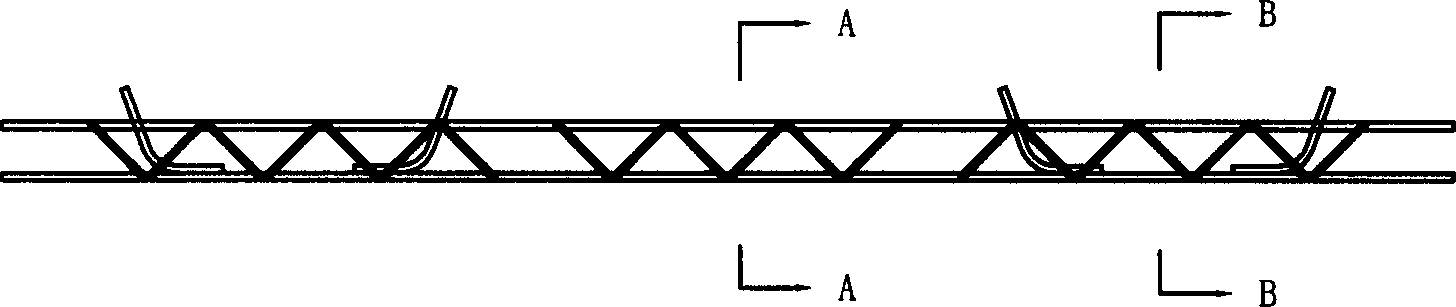

Double-blocked rail without ballast

InactiveCN1818213AImprove insulation performanceImprove riding performanceRailway tracksEngineeringRebar

A railway of double block rail bearings includes a concrete base and a rail bed board fastened to the base. All joints of up and down steel frameworks in the rail bed board are insulated by insulation sleeve. The double block rail bearings are concreted into the rail bed board. Rails are fastened to the double block rail bearings by fasteners and in between the fasteners and the rail bearings has insulation buffering backing plate. The two concrete blocks to the two ends of the rail bearings are connected by steel frameworks, which are made by non-recycle placing of reinforcement and with insulation sleeve inside.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

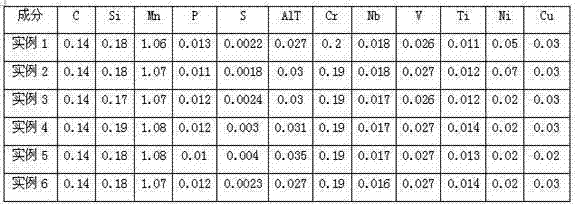

Hardened and tempered steel plate production method

The invention discloses a hardened and tempered steel plate production method. Chemical components of steel include, by mass, 0.08% to 0.24% of C, 0.20% to 0.50% of Si, 0.80% to 1.30% of Mn, smaller than or equal to 0.018% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.020% or smaller than or equal to 0.050% of Als, smaller than or equal to 0.25% of Cr, smaller than or equal to 0.08% of Mo, smaller than or equal to 0.25% of Cu, smaller than or equal to 0.25% of Ni, and the balance Fe and remaining elements. The method includes the following processing steps of converter smelting, refining, vacuum refining, casting, heating, rolling, slow cooling and thermal treatment. Through continuous casting blank production, the internal quality of blanks is guaranteed, the low-cost chemical components only with Nb, V and Ti alloy added are selected and used for design, the cleanliness of steel is guaranteed through an LF and VD process, and the sum of the levels of various impurities does not exceed 2.0; through rolling control and normalizing treatment, the grain size of the steel reaches more than 8.0; through the effective implementation of the technical measures, steel plates for a carbon-manganese-silicon pressure container and steel plates guaranteeing flaw detection, the mechanical performance and the plate shape for the carbon-manganese-silicon pressure container are successfully produced.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

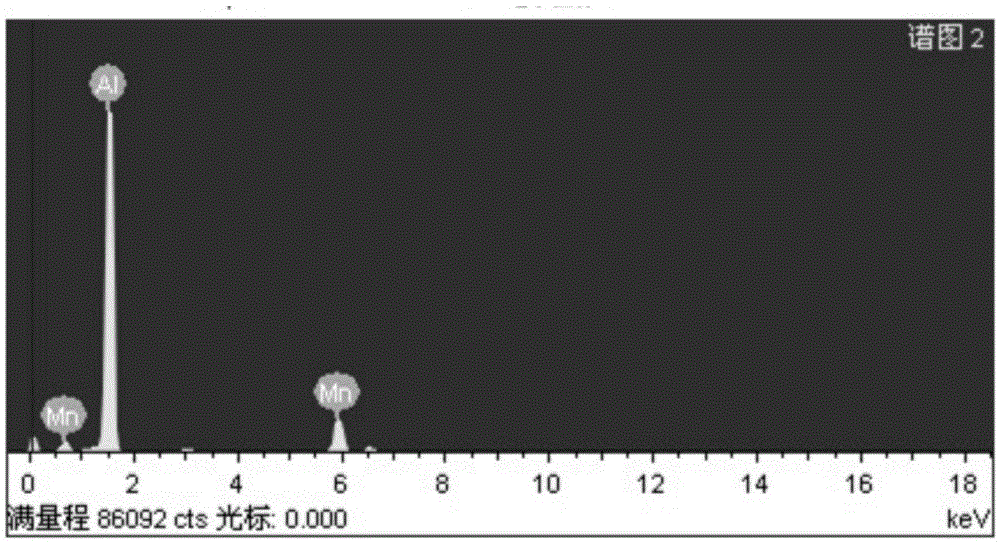

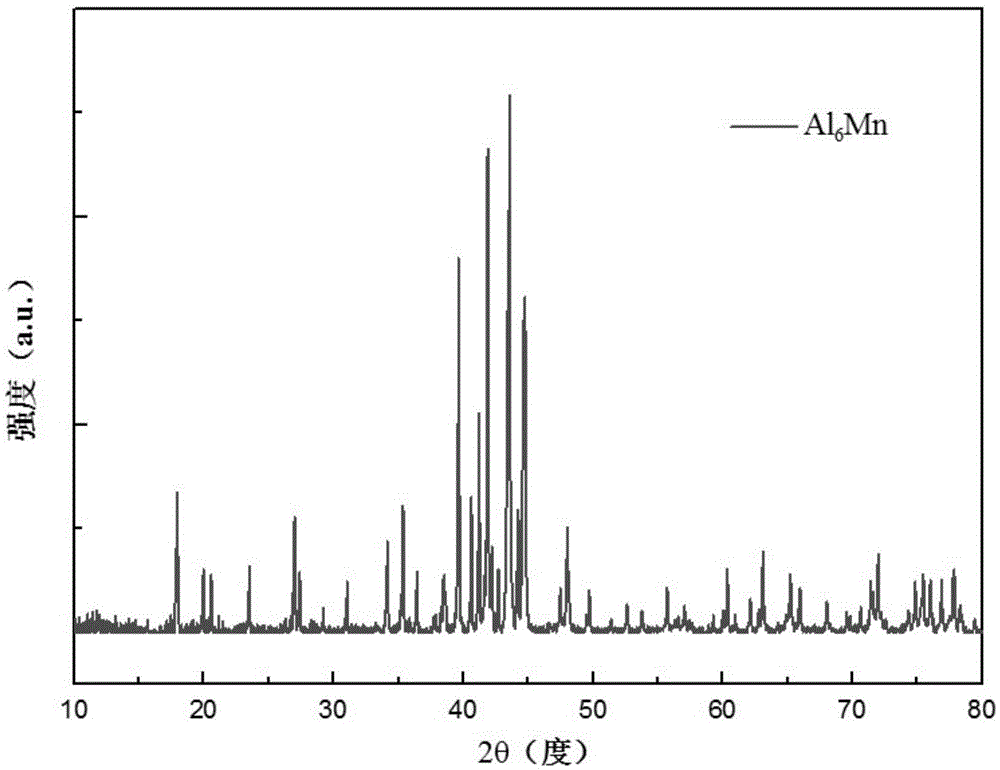

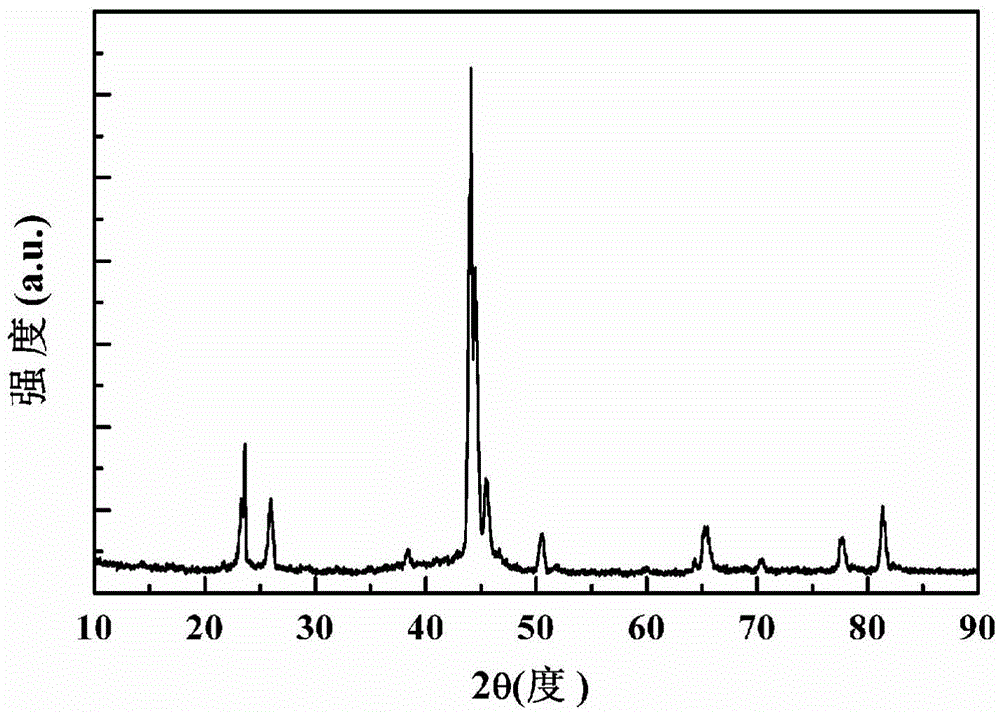

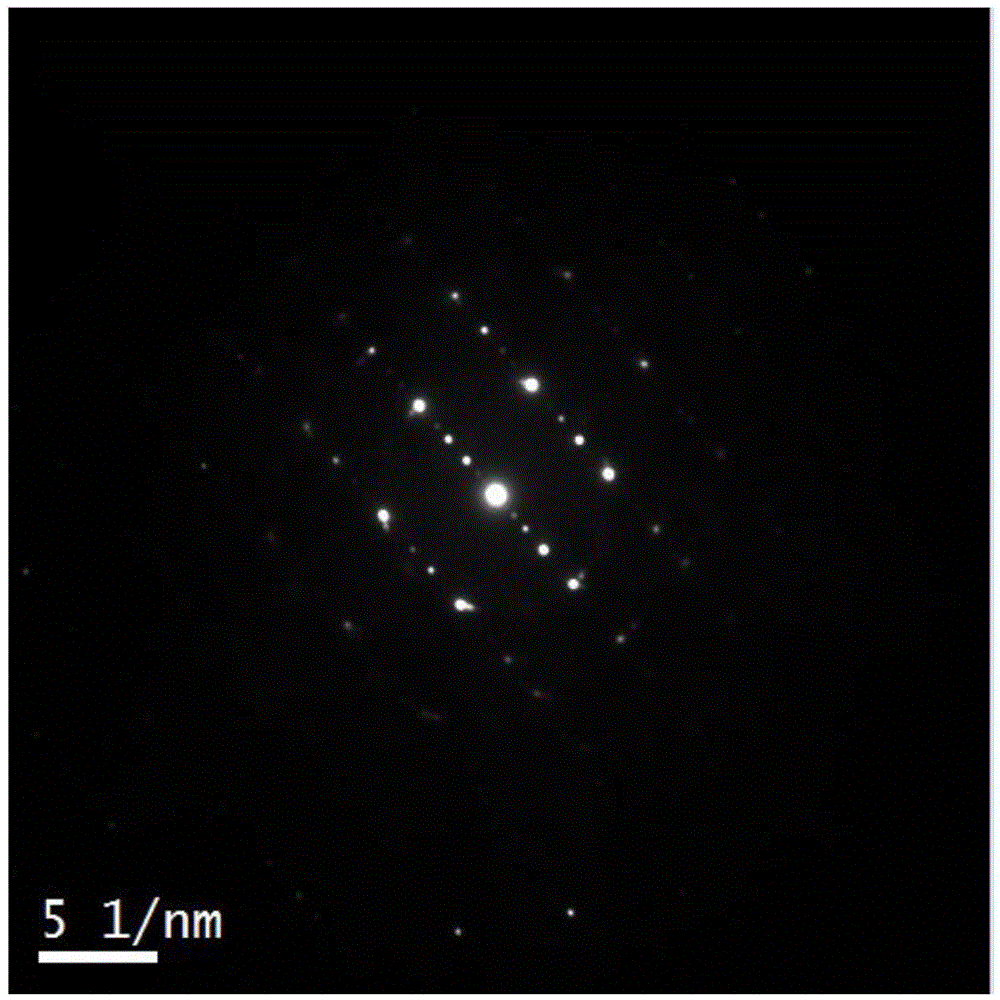

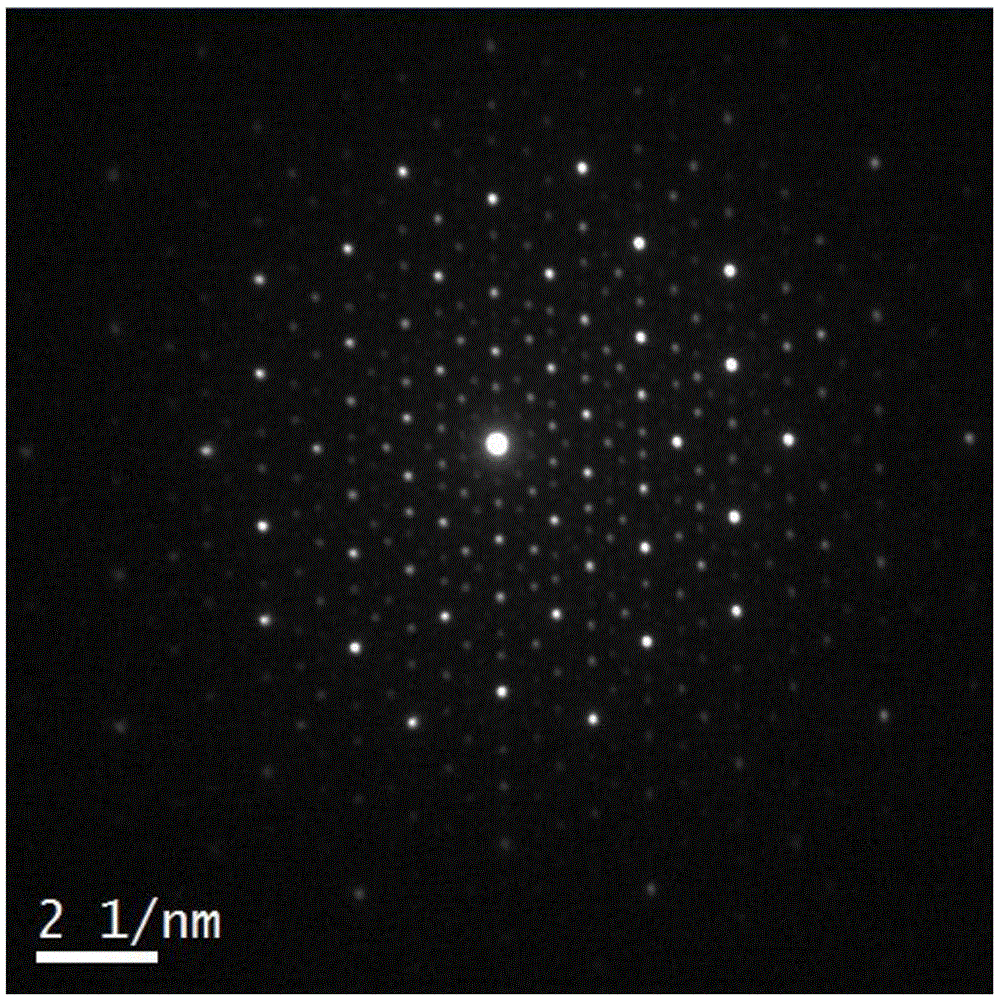

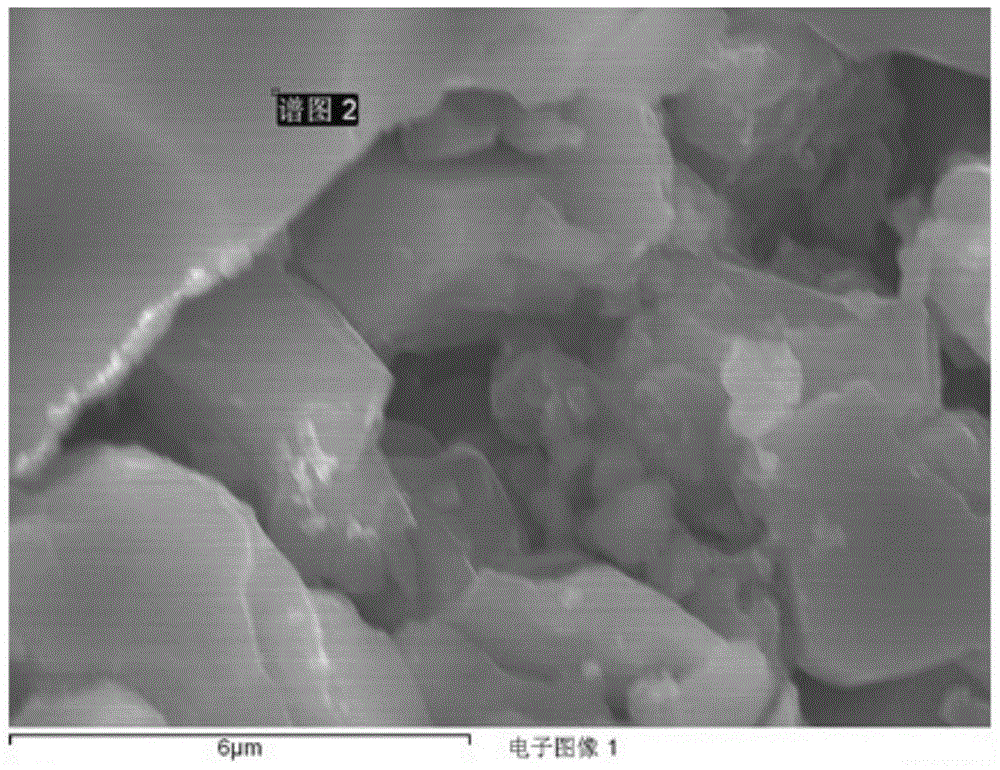

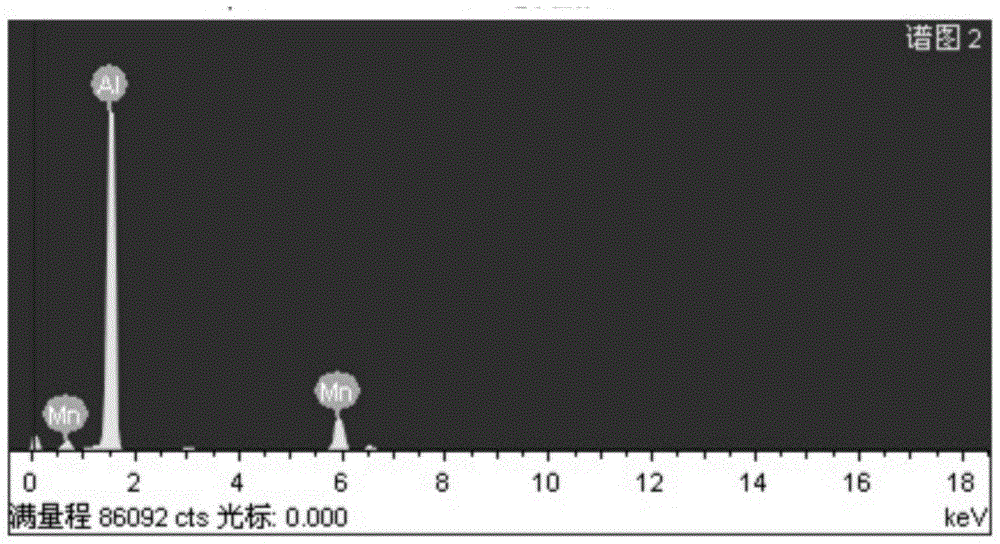

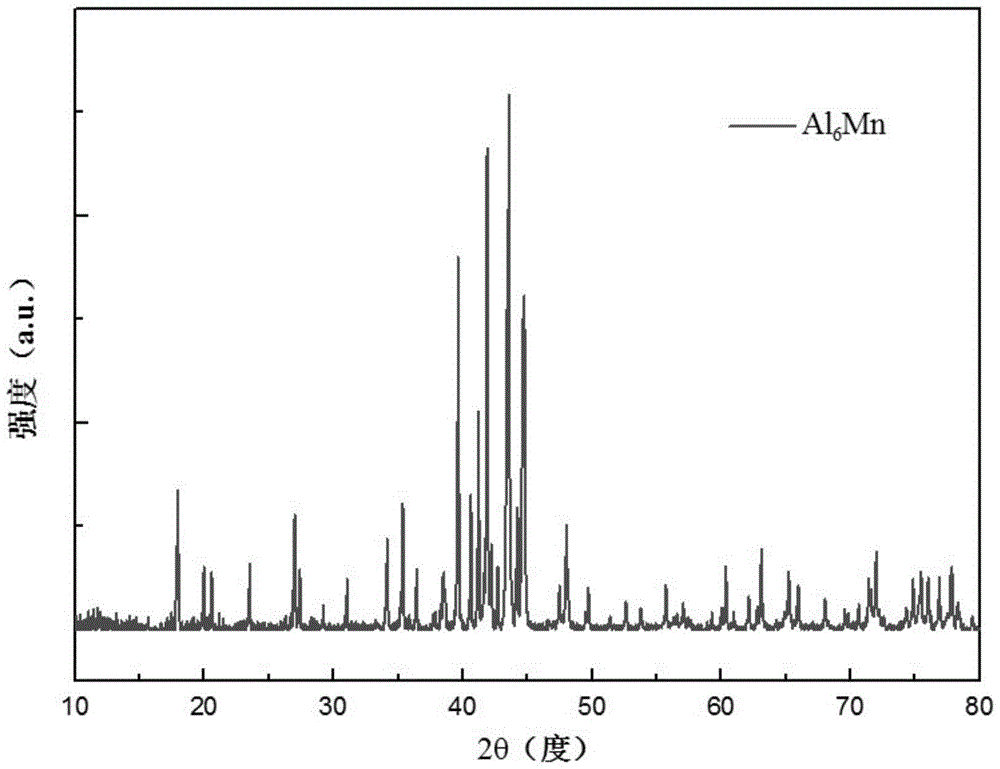

Preparation method for Al6Mn quasicrystal

The invention relates to a preparation method for a Al6Mn quasicrystal. The method mainly includes the steps that pure Al powder and pure Mn powder are evenly mixed according to the atomic ratio of 6:1, arranged into a hard alloy mould, and pressed in a hydraulic tablet press to obtain a reserved block; the reserved block is mounted into a boron nitride crucible, a pre-dried tubular graphite oven body, the boron nitride crucible, a boron nitride piece, a pyrophyllite piece and a graphite piece are assembled and placed in an ultrahigh-pressure environment, the setting pressure is controlled to be the isostatic pressure ranging from 3 GPa to 5 GPa, and the temperature is controlled to rise to 700-850 DEG C and kept for 30-60 minutes; and the temperature is decreased to 480-580 DEG C and kept for 1-3 hours. The preparation method is simple in process, low in energy consumption and high in efficiency, and the content of prepared quasicrystal is high.

Owner:YANSHAN UNIV

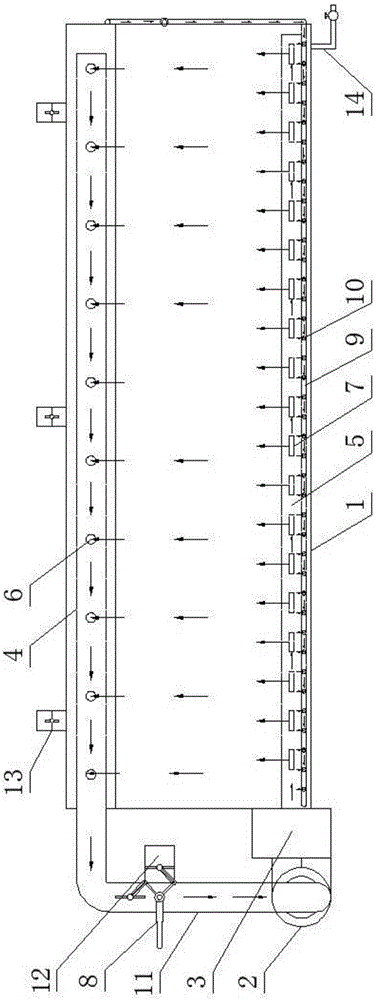

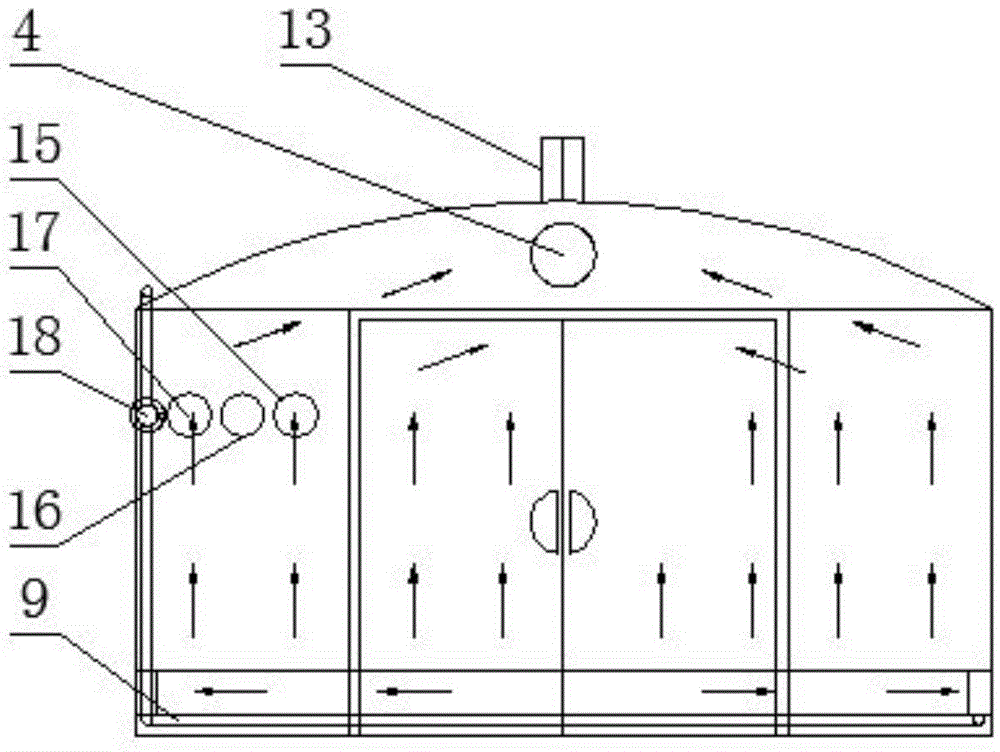

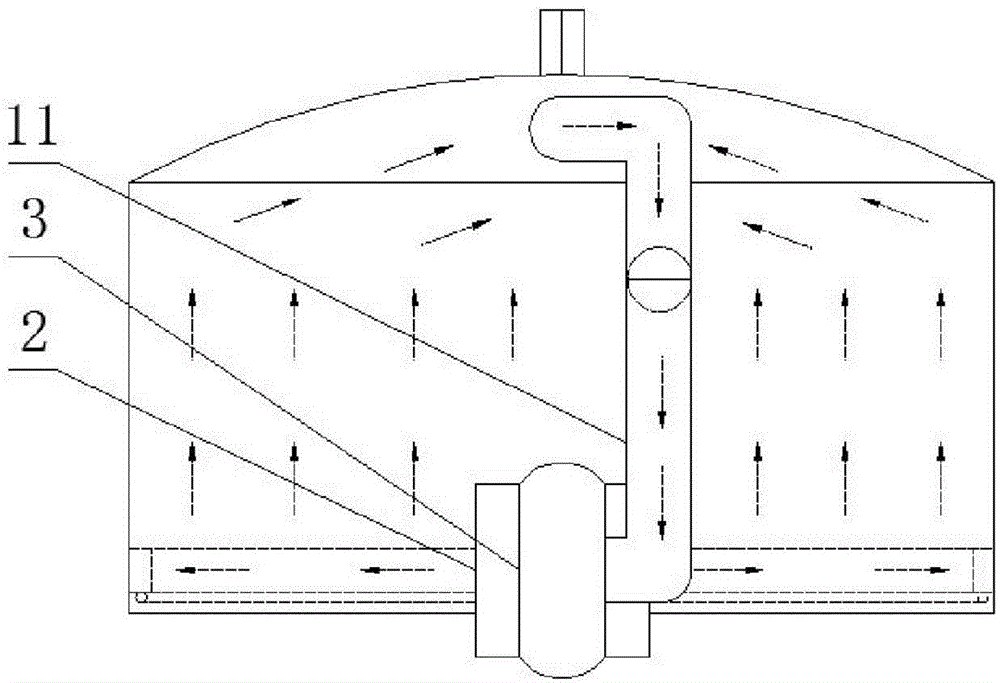

Storage battery electrode plate curing chamber with automatic temperature control

InactiveCN105322139APhysicochemically stableGood quality and performanceLead-acid accumulator electrodesFrequency changerTemperature control

The invention provides a storage battery electrode plate curing chamber with automatic temperature control. The storage battery electrode plate curing chamber comprises a curing chamber body, a circulating fan and a steam warming box, wherein an air outlet of the circulating fan is connected with the steam warming box; a humidity controller, a circulating fan frequency changer and a circulating air temperature setter are arranged at one side of the curing chamber body; a plurality of drying exhaust holes are transversely and evenly formed in the top of the curing chamber body; a drain pipe is arranged at the bottom of the curing chamber body; a circulating air inlet pipeline is transversely arranged at the center part of the top in the curing chamber body; circulating air outlet pipelines are transversely arranged at two sides of the inner bottom in the curing chamber body; the air inlet of the circulating fan is connected with the circulating air inlet pipeline through a pipeline; a drying air inlet hole is also formed in the middle and upper part of the pipeline; the steam warming box is connected with the circulating air outlet pipelines; and steam pipelines which are connected with an external steam generation device of the curing chamber body are also arranged at two sides of the bottom of the curing chamber body. The storage battery electrode plate curing chamber has the beneficial effects that the upper part and the lower part of the curing chamber body are consistent in temperature; and the physical and chemical properties of the cured and dried electrode plate are stable.

Owner:TIANJIN CHANGDA TECH DEV

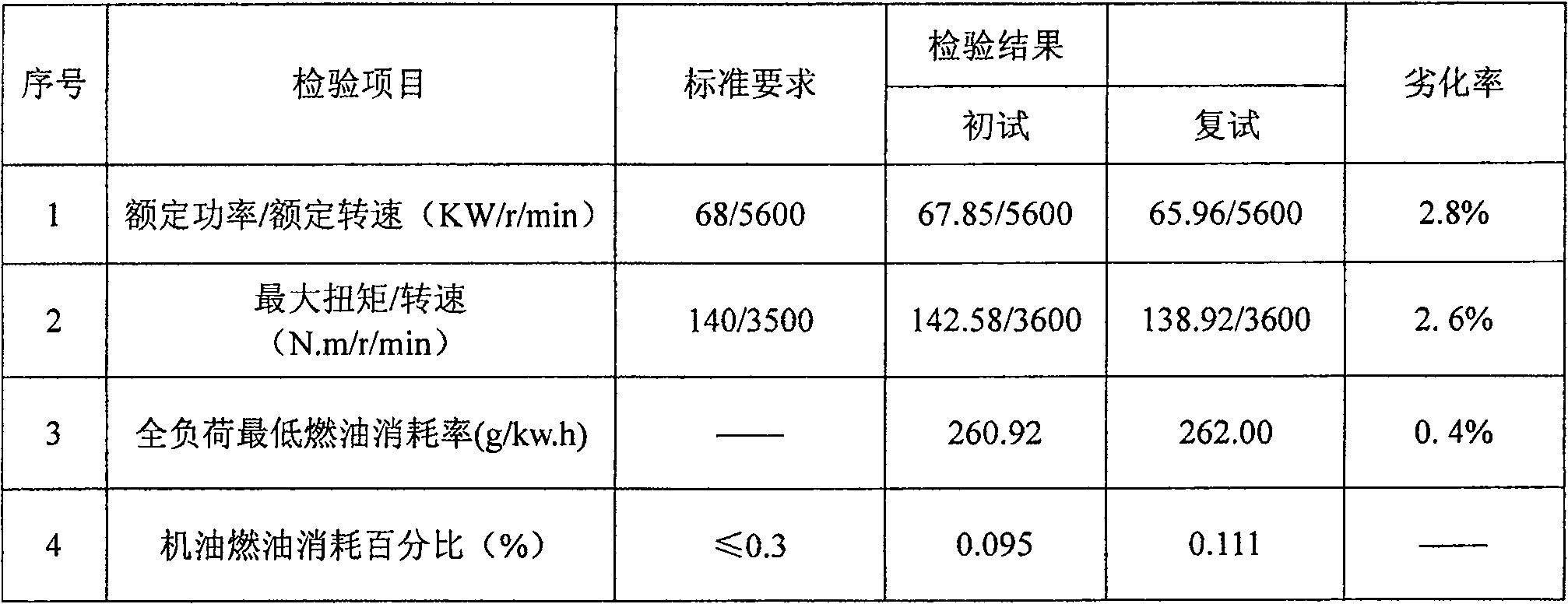

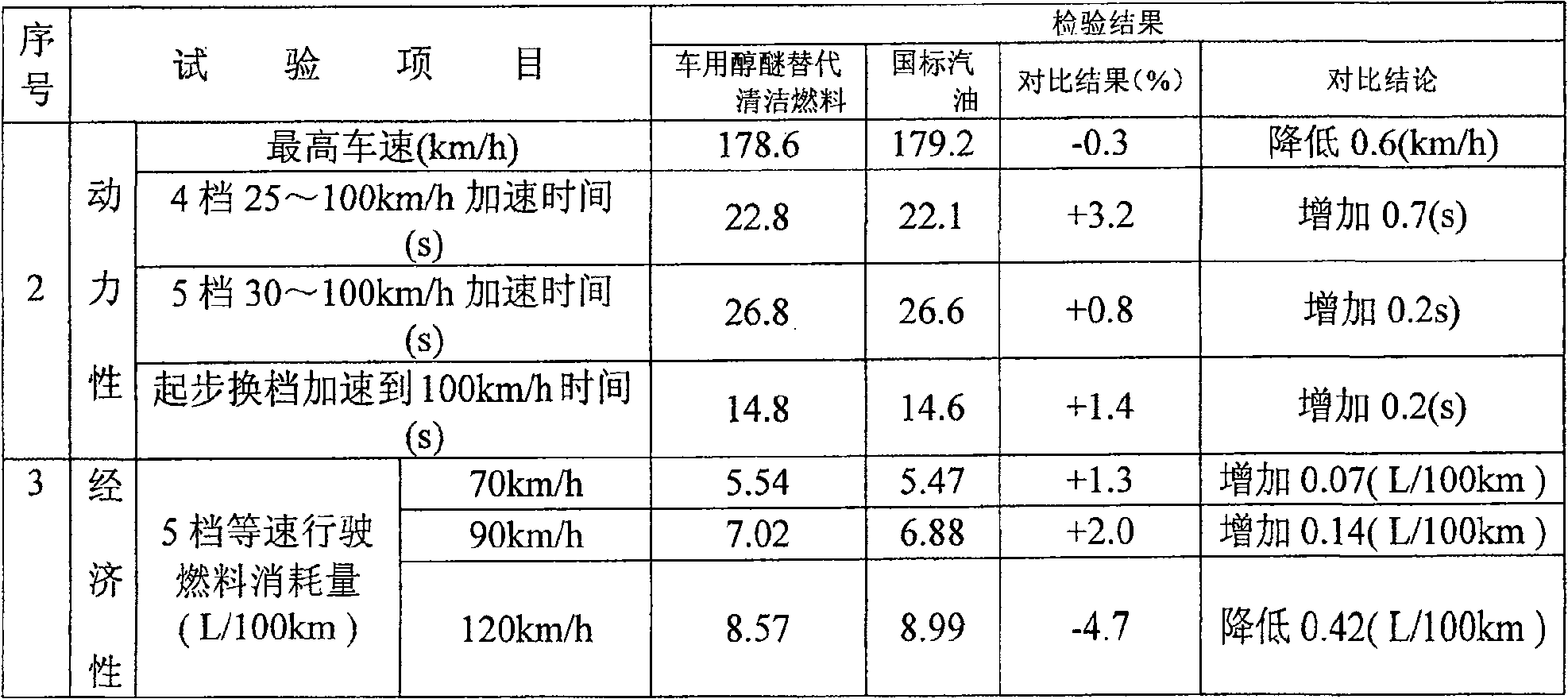

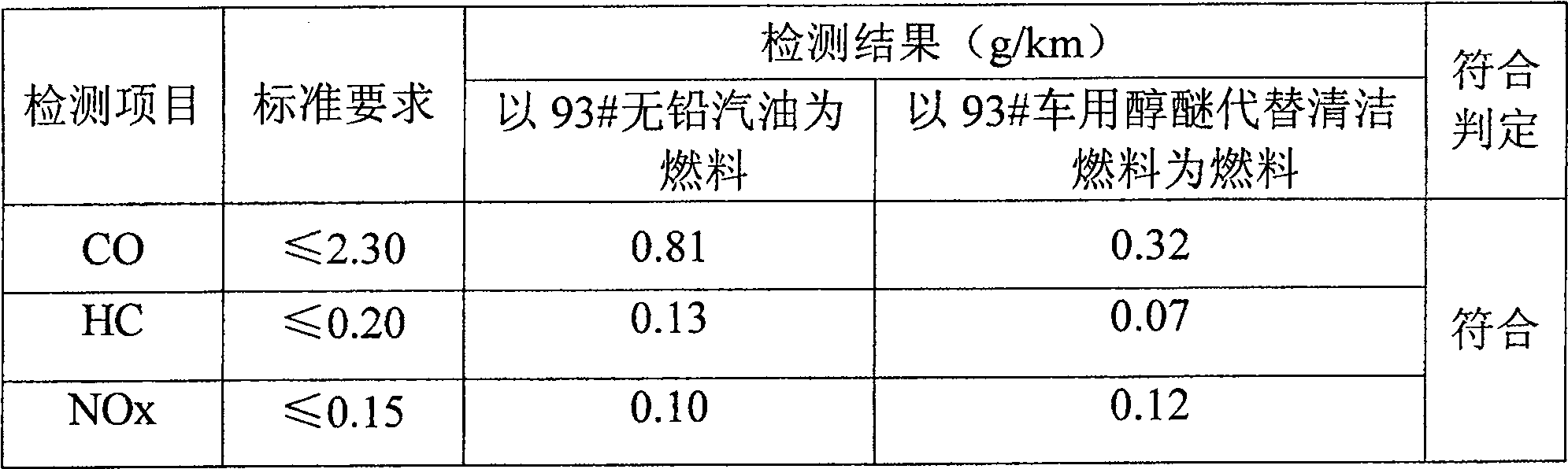

Alcohol ether substituted clean fuel for automobile

ActiveCN101195772AExcellent quality inspection indexGood quality and performanceLiquid carbonaceous fuelsBodies oilPhosphate

The invention discloses alcohol ether replaced clean fuel material used for vehicles, which takes methanol, methylic tertiary butyl ether, ethanol, 190 <NUMBER> -200 <NUMBER> solvent naphtha and heat bodied oil as raw material, under the normal temperature and the normal pressure, sodium perchlorate and potassium permanganate are firstly mixed and prepared by the weight ratio of 1:2, and then filled up into the methanol to be modified, and methylic tertiary butyl ether, ethanol, 190 <NUMBER> -200 <NUMBER> solvent naphtha and heat bodied oil are added in sequence, at last, mixed benzene, light aromatics, methylethyl ketone, sulfurated alkyl phenicate, ialkyl dithiozinc phosphate salt, ethylene glycol monomethyl ether, phosphate ester and Beta- naphthylamine, alkenyl succinic acid and alkylphenol polyoxyethylene are added to prepare a kind of petrous energy source replaced liquid fuel material which resists low temperature, has good mutual solubility, is corrosion proof, has good dynamic performance, low energy consumption and obvious environmental protection effect.

Owner:北京雄韬伟业能源科技发展有限公司

Large-scale resource utilization method for engineering residue soil

The invention relates to the technical field of muck utilization, in particular to an engineering muck large-scale resource utilization method which comprises the following steps: S1, classifying and dewatering engineering muck; s2, separating, crushing and screening the engineering residue soil obtained in the step S1 to obtain semi-finished product residue soil; and S3, mixing and stirring the semi-finished product muck obtained in the step S2 and a curing agent according to the mass percent to obtain a cured muck mixture. The composite material is used for paving a road subgrade or a pavement subbase layer, a reinforced protective layer can be formed, the subgrade below the reinforced protective layer can be protected, a solid foundation is provided for a road pavement structure layer above the reinforced protective layer, and on the basis of not introducing other raw materials such as cement, the regeneration utilization rate of the construction waste is effectively increased; and comprehensive and efficient utilization of building waste resources is promoted.

Owner:上海志昌建设工程有限公司

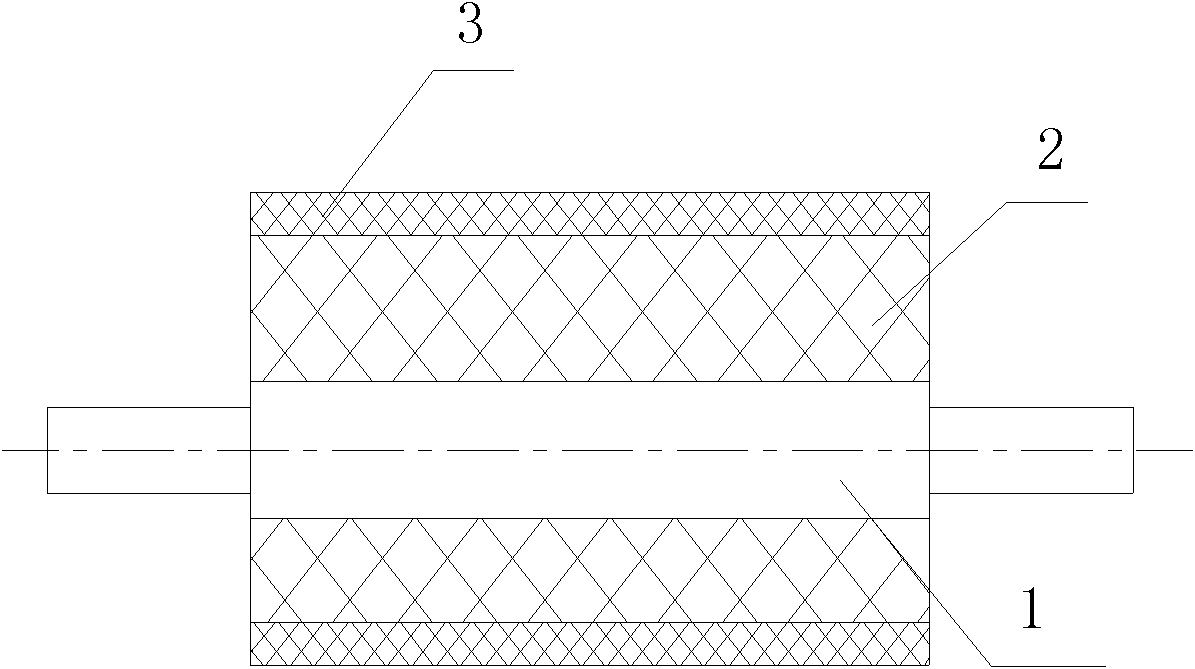

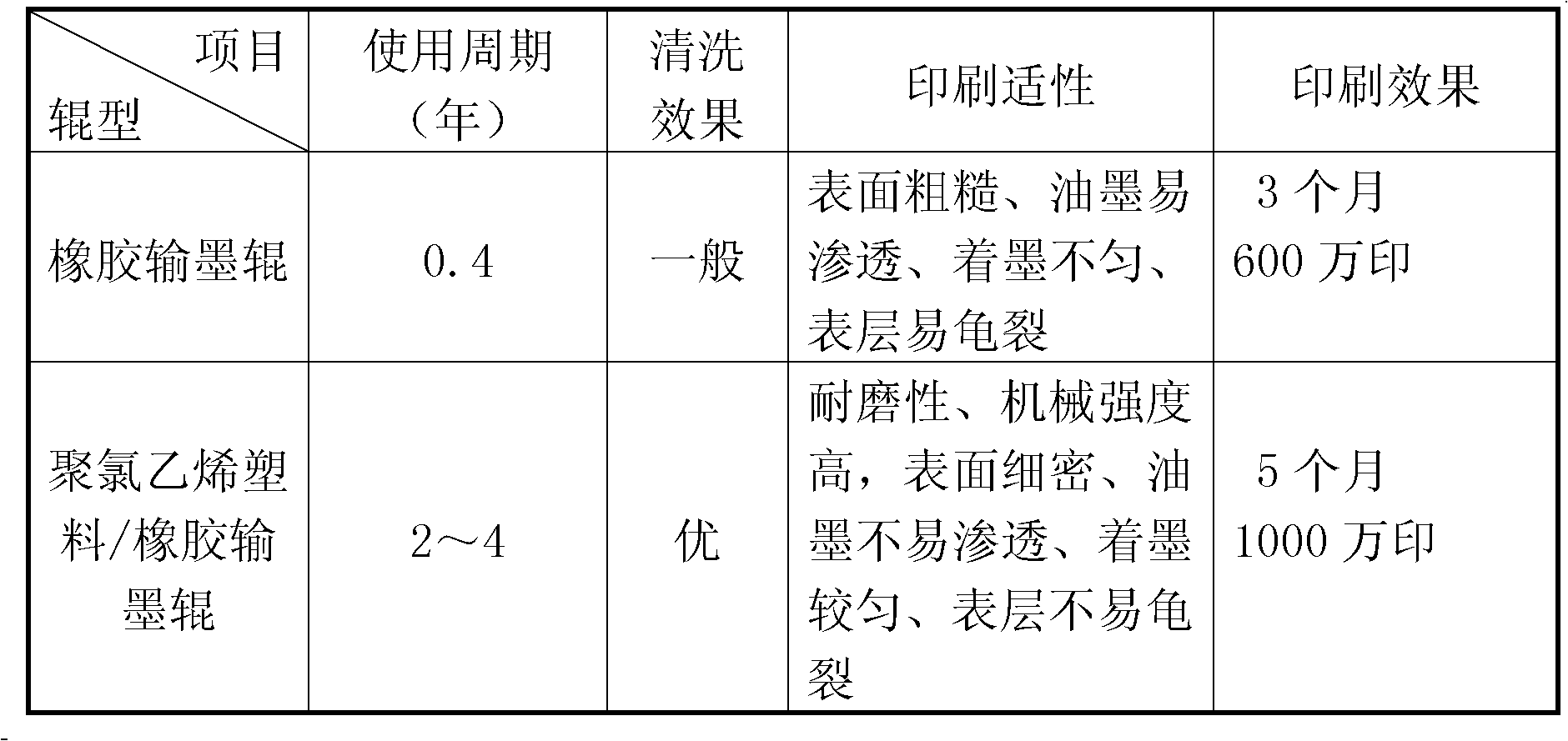

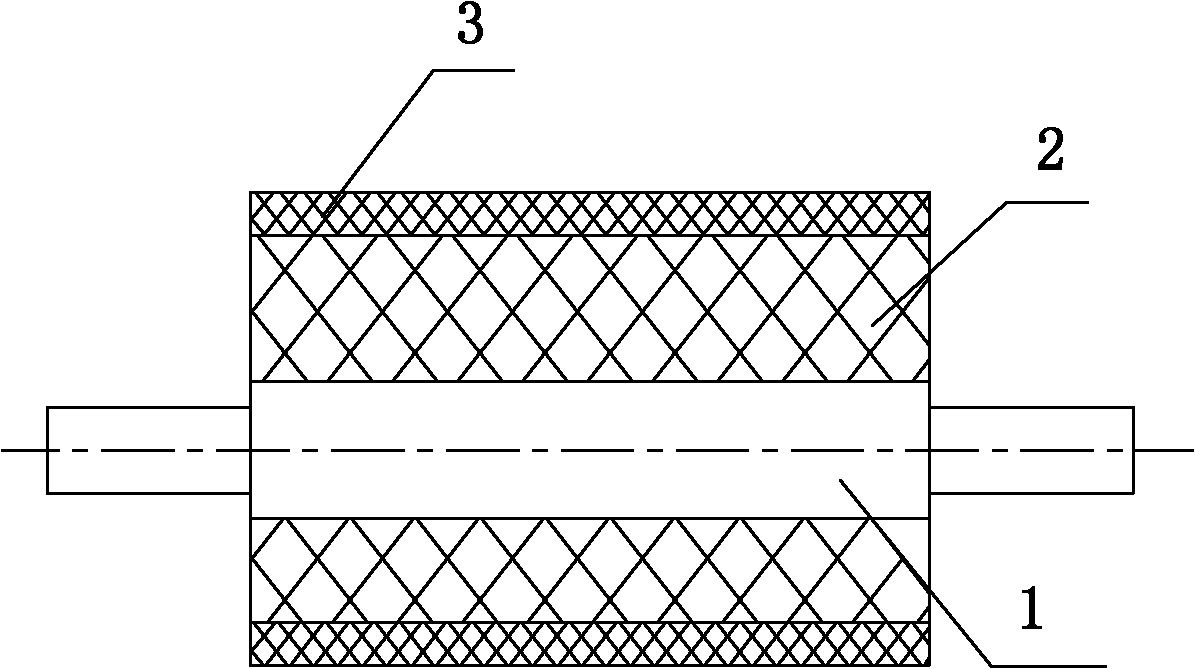

Polyvinyl chloride plastic/rubber inking roller and preparation method thereof

InactiveCN102275381AEasy to cleanImprove wear resistanceLiquid surface applicatorsPrinting roller shellsSurface layerPolyvinyl chloride

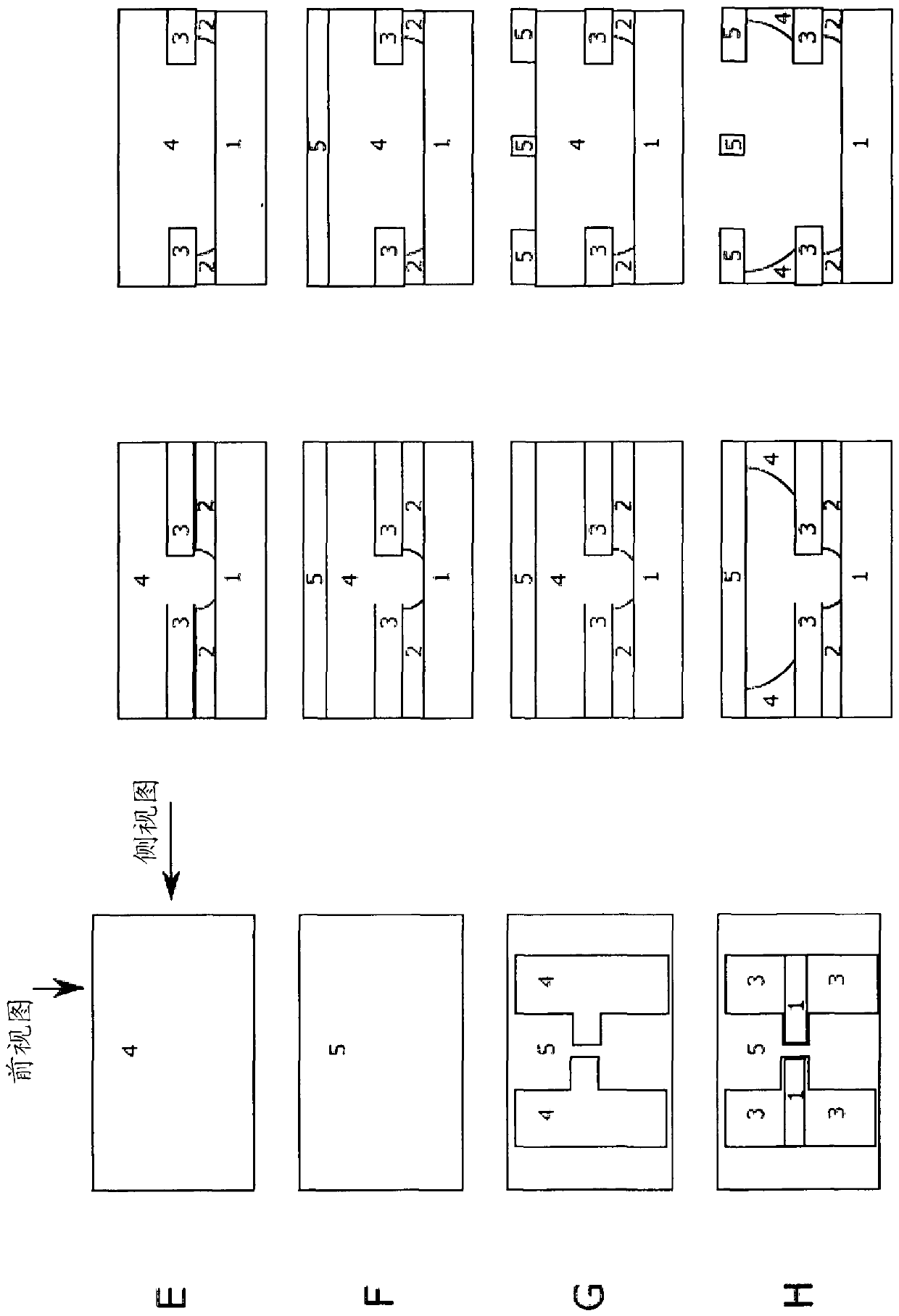

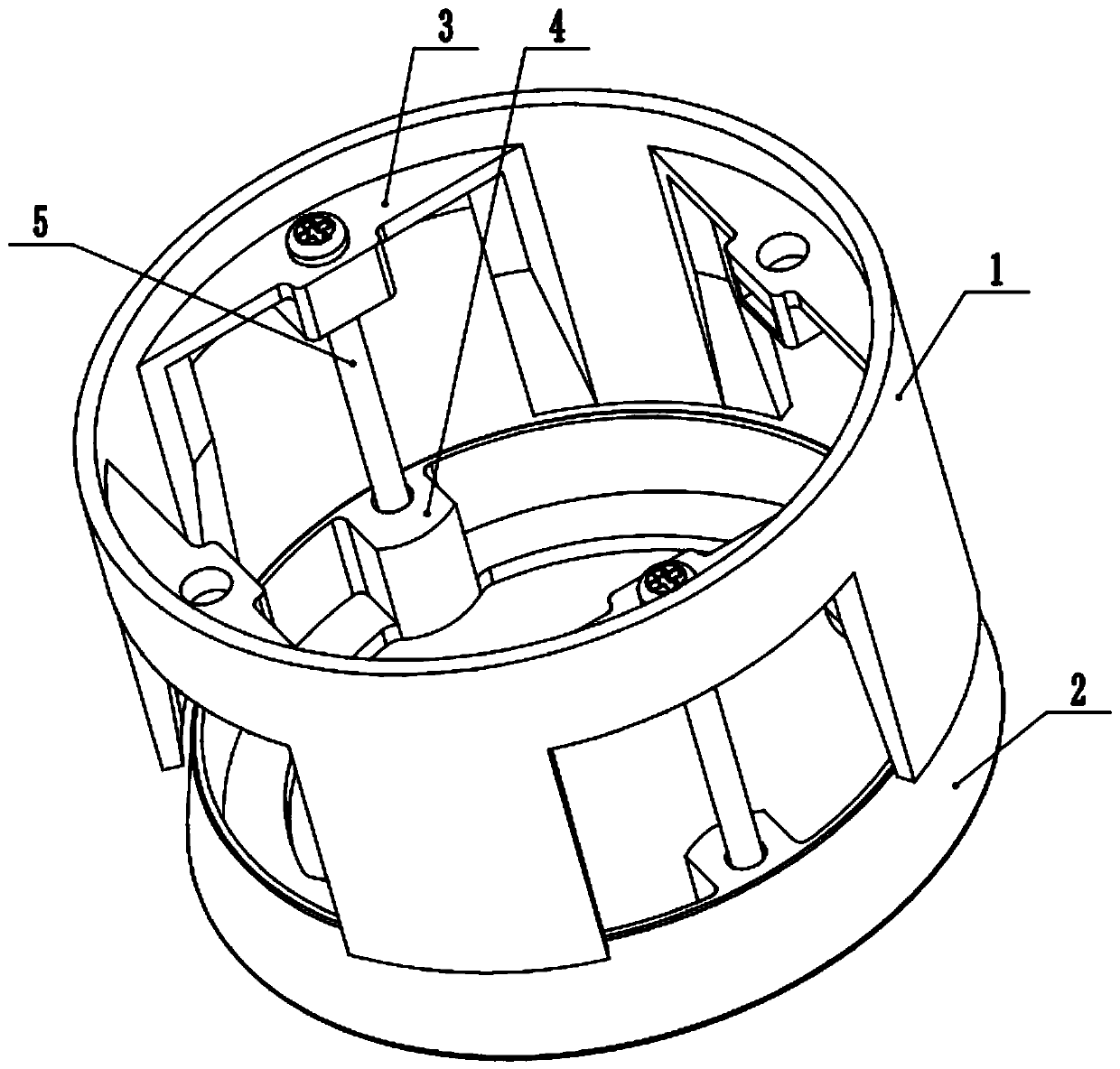

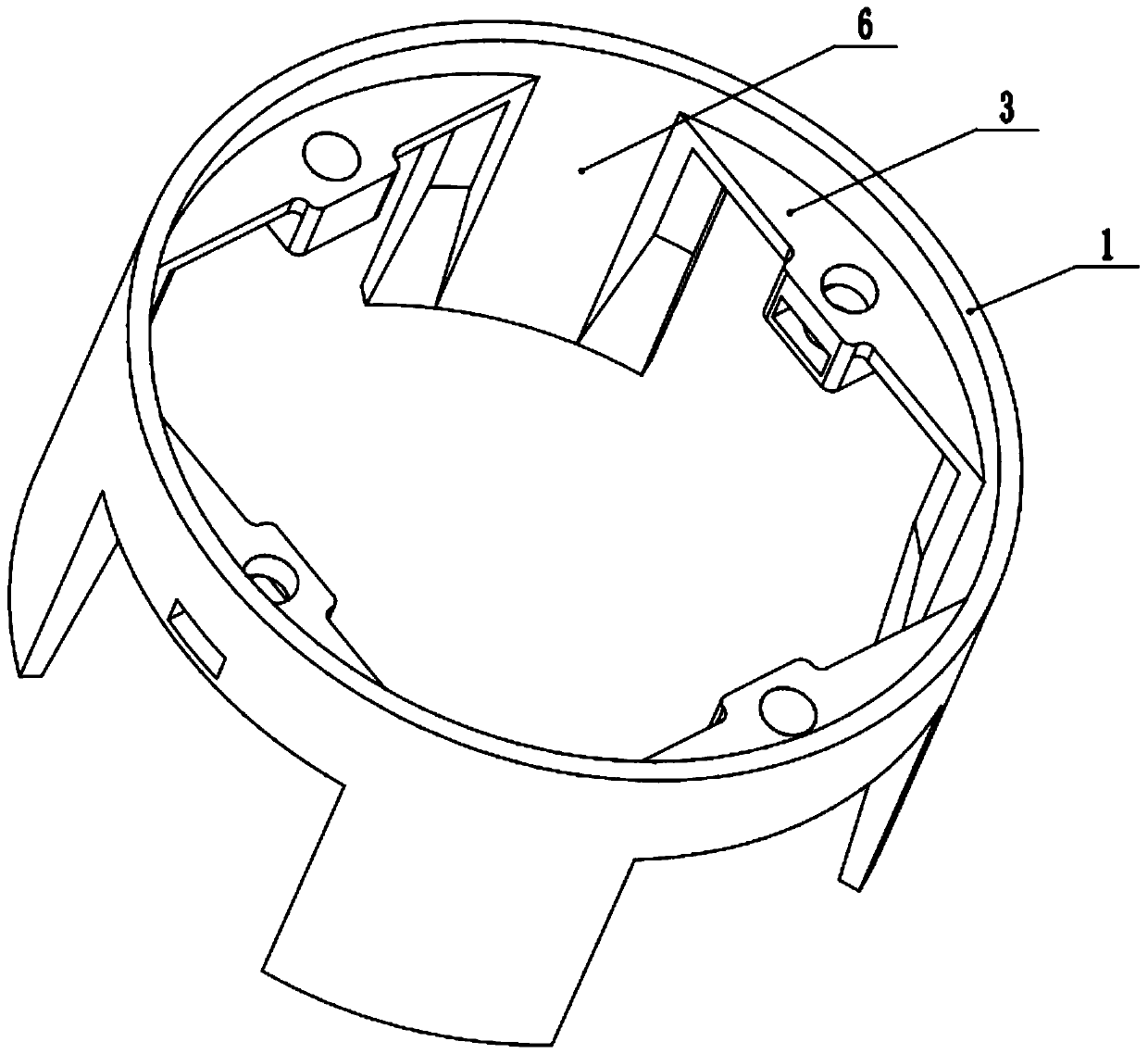

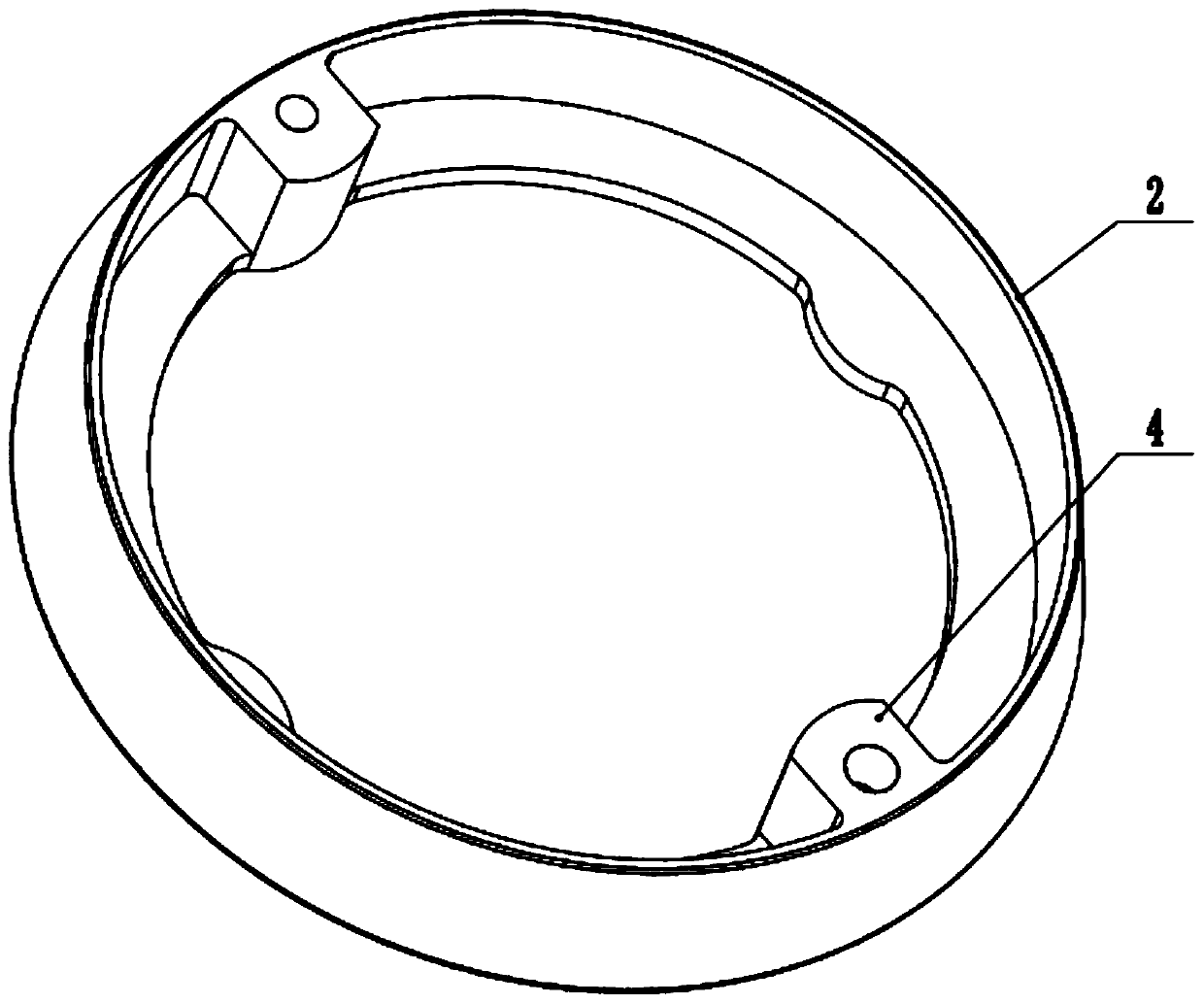

The invention relates to a polyvinyl chloride plastic / rubber inking roller and a preparation method, comprising a metal roller core (1), a rubber layer (2) wrapping the metal roller core (1), and the outer surface of the rubber layer (2) is coated with PVC plastic layer (3). The invention overcomes the technical problems of rough surface of the existing inking roller, easy penetration of ink, uneven inking, difficult to clean, and easy cracking of the rubber surface. A polyvinyl chloride plastic / rubber inking roller whose rubber surface layer is not easy to crack and a preparation method thereof.

Owner:CHINA BANKNOTE PRINTING & MINTING +1

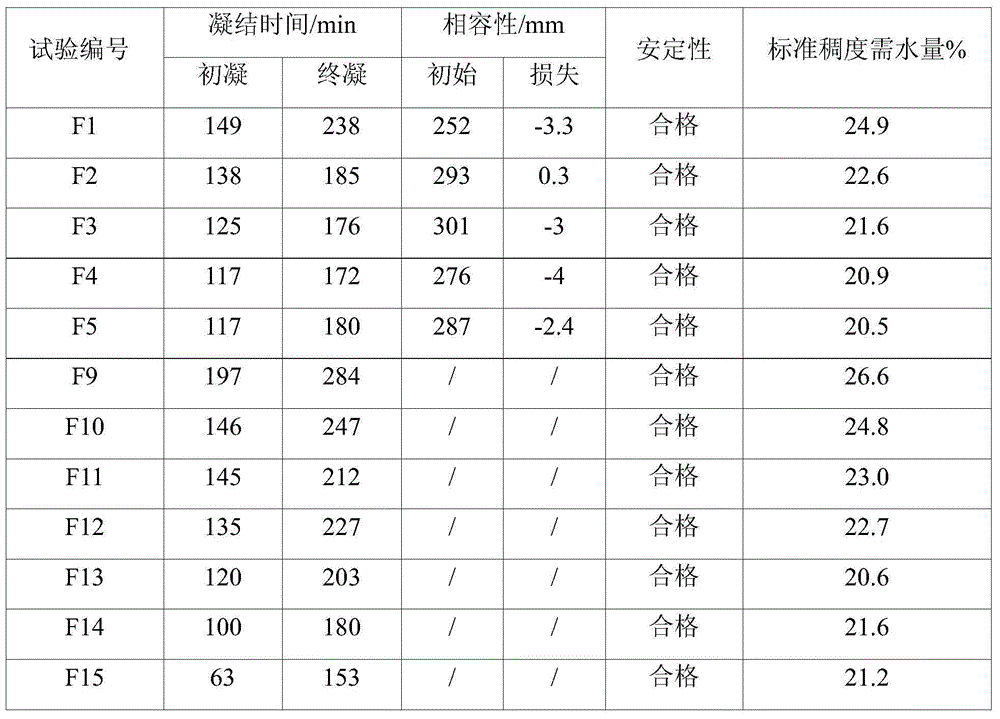

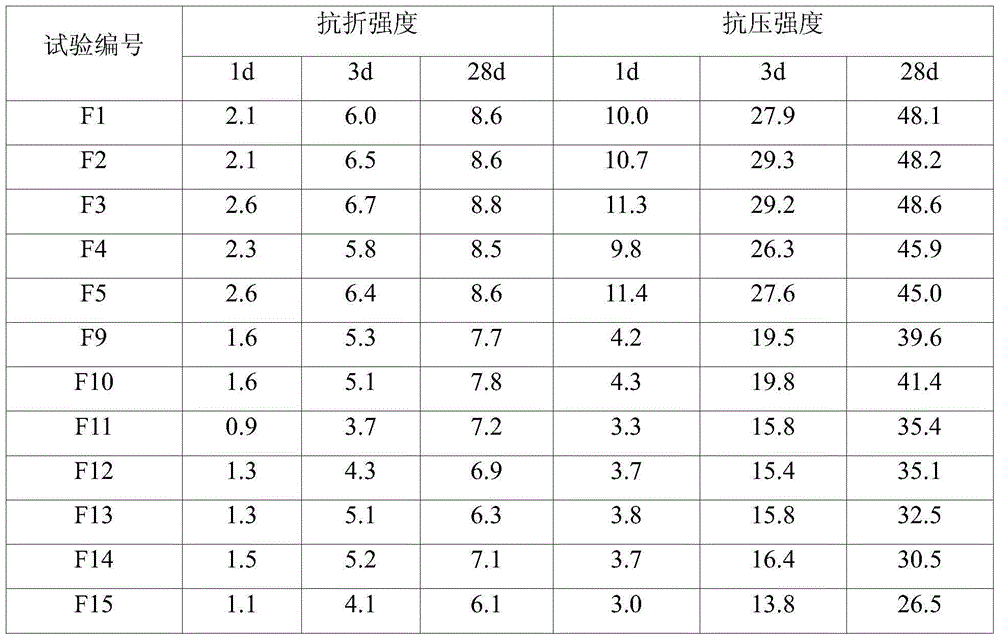

Novel cement admixture, and preparation method and application thereof

The invention belongs to the field of comprehensive utilization of waste residues, and particularly relates to a novel cement admixture, and a preparation method and application thereof. By comprehensively utilizing cement industry high-alkali high-chlorine waste bypass snuffle ash, high-chlorine high-alkali kiln ash and other waste residues, the method can widen the application range of high-chlorine high-alkali raw materials and reduce the environmental pollution caused by industrial wastes; and other industrial wastes are simultaneously added to optimize the cement performance. The invention aims to provide a novel cement admixture which is prepared from the bypass snuffle ash or high-alkali high-chlorine kiln ash used as the raw material and papermaking white clay and carbide slag used as auxiliary materials. The novel cement admixture is prepared from the following components in parts by weight: 1 part of papermaking white clay, 1-2 parts of carbide slag and 0.5-3 parts of bypass snuffle ash. The method achieves the goal of comprehensively utilizing the bypass snuffle ash or high-chlorine high-alkali kiln ash, papermaking white clay, carbide slag and other waste residues.

Owner:QINGSHEN XINTONGLING BUILDING MATERIALS CO LTD

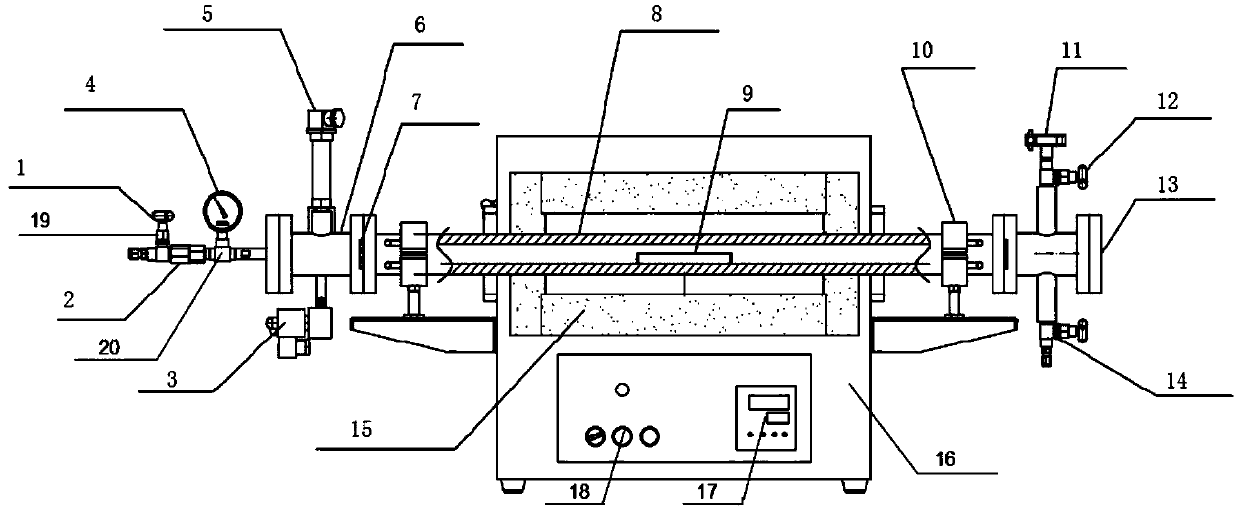

Automatic nanocrystalline metal composite material preparation furnace through reaction under protection of high temperature and high pressure gas

The invention discloses an automatic nanocrystalline metal composite material preparation furnace through reaction under protection of high temperature and high pressure gas. The preparation furnace comprises a double-ferrule gas inlet needle valve, an automatic decompression valve, a pressure gage, a pressure sensor, a first sealing flange, red copper seal rings, a high temperature alloy steel tube, a reaction sample boat, a second sealing flange, a vent valve, a heating furnace hearth and a metal plate furnace body, wherein two water cooling fixed mounts are symmetrically mounted on the twosides of the metal plate furnace body; the heating furnace hearth is arranged in the metal plate furnace body; the high temperature alloy steel tube penetrates through the metal plate furnace body andthe heating furnace hearth; the reaction sample boat is fixedly connected with the interior of the high temperature alloy steel tube; the two ends of the high temperature alloy steel tube are in sealing connection with the first sealing flange and the second sealing flange separately through the red copper seal rings; and the automatic decompression valve is fixedly connected with the bottom of the first sealing flange. According to the automatic nanocrystalline metal composite material preparation furnace through reaction under protection of high temperature and high pressure gas, nano material and metal material have high pressure synthesis reaction under the protection of high temperature and high pressure gas to obtain high-quality composite material.

Owner:ANHUI BEQ EQUIP TECH

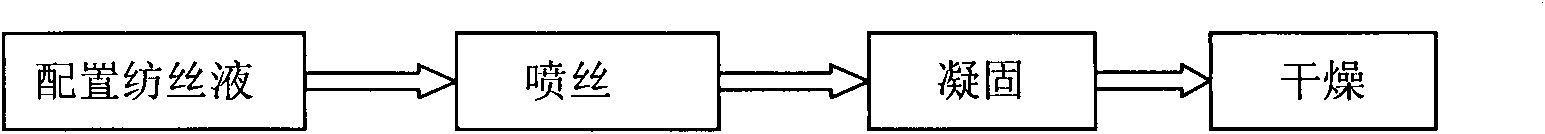

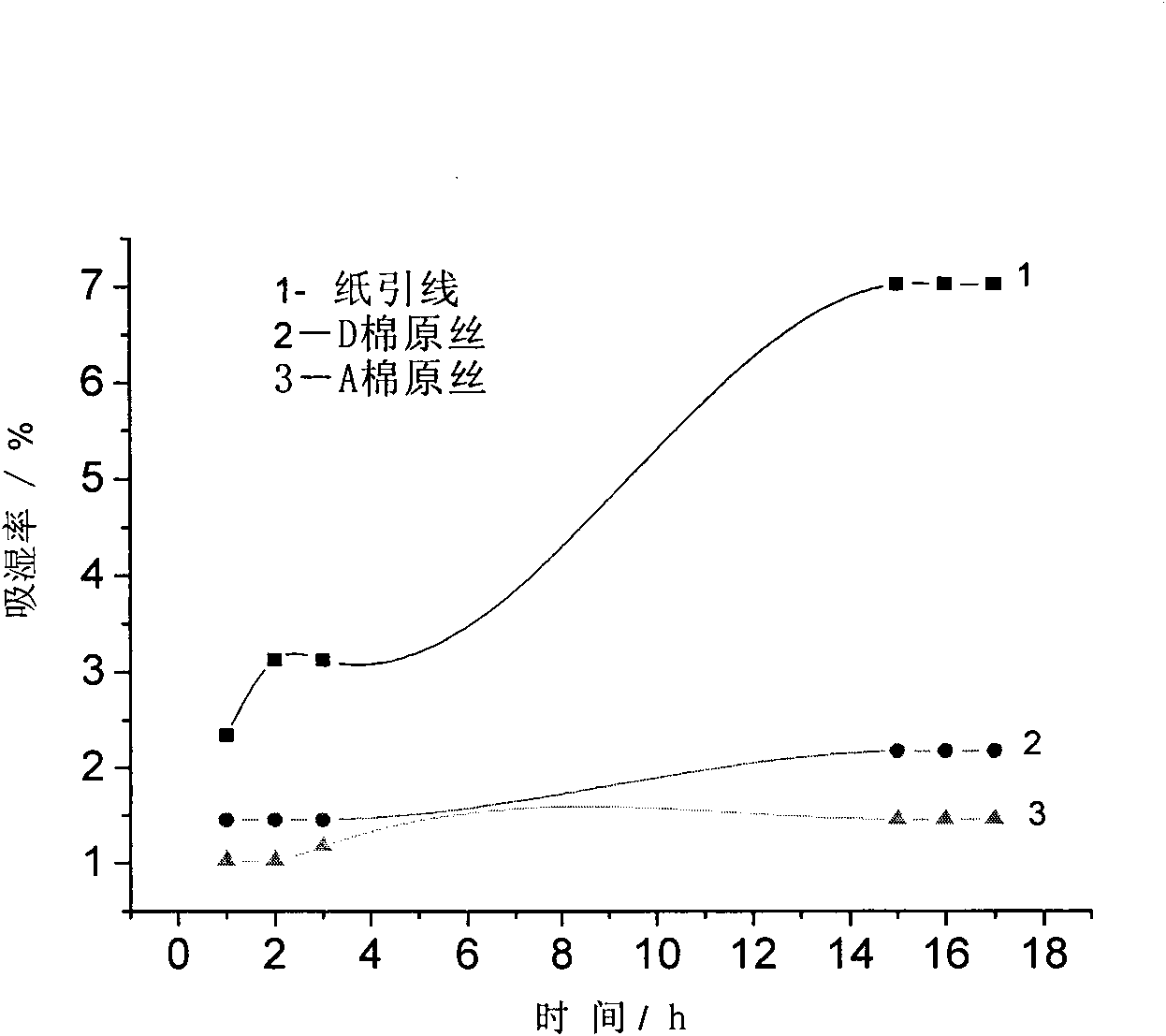

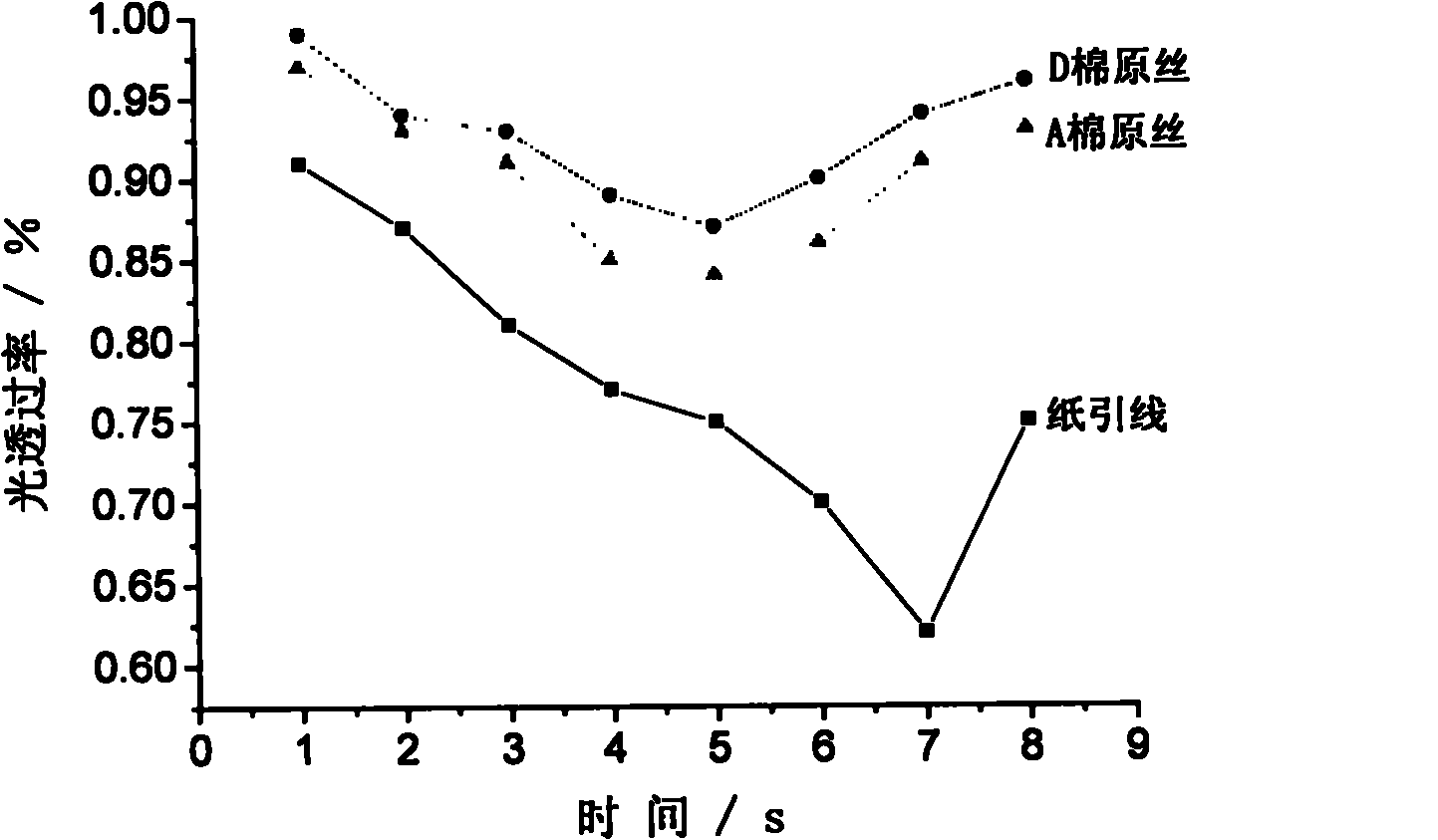

Method for spinning nitro-cotton (NC) and application

InactiveCN101956239ASimple processGood quality and performanceFirecrackersWet spinning methodsSolventProcess engineering

The invention discloses a method for spinning nitro-cotton (NC) and application. The method comprises the following steps of: preparing spinning solution from the NC, a plasticizer and a process solvent and adding the spinning solution into a spinning kettle; extruding the spinning solution from a spinning hole on the spinning kettle under the pressure of pressurized nitrogen or compressed air and stretching the spinning solution on an air layer under the action of gravity so as to form stock solution trickles; allowing the stock solution trickles to enter a coagulating bath and curing the stock solution trickles into nitro-cotton yarns under double-diffusion action; and winding, drying and molding. The nitro-cotton yarns obtained by the method meet technical requirements of a firework lead in the aspects of mechanical property, hygroscopic property, burning rate performance, environment protection of a combustion product and the like so as to replace the application of a paper lead to fireworks and solve the problems of production safety and use environmental protection of the paper lead.

Owner:NANJING UNIV OF SCI & TECH

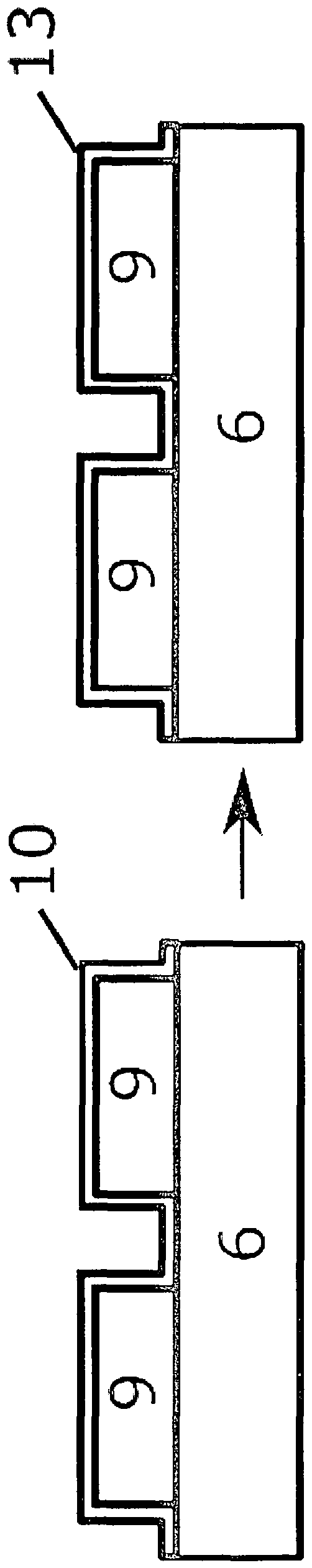

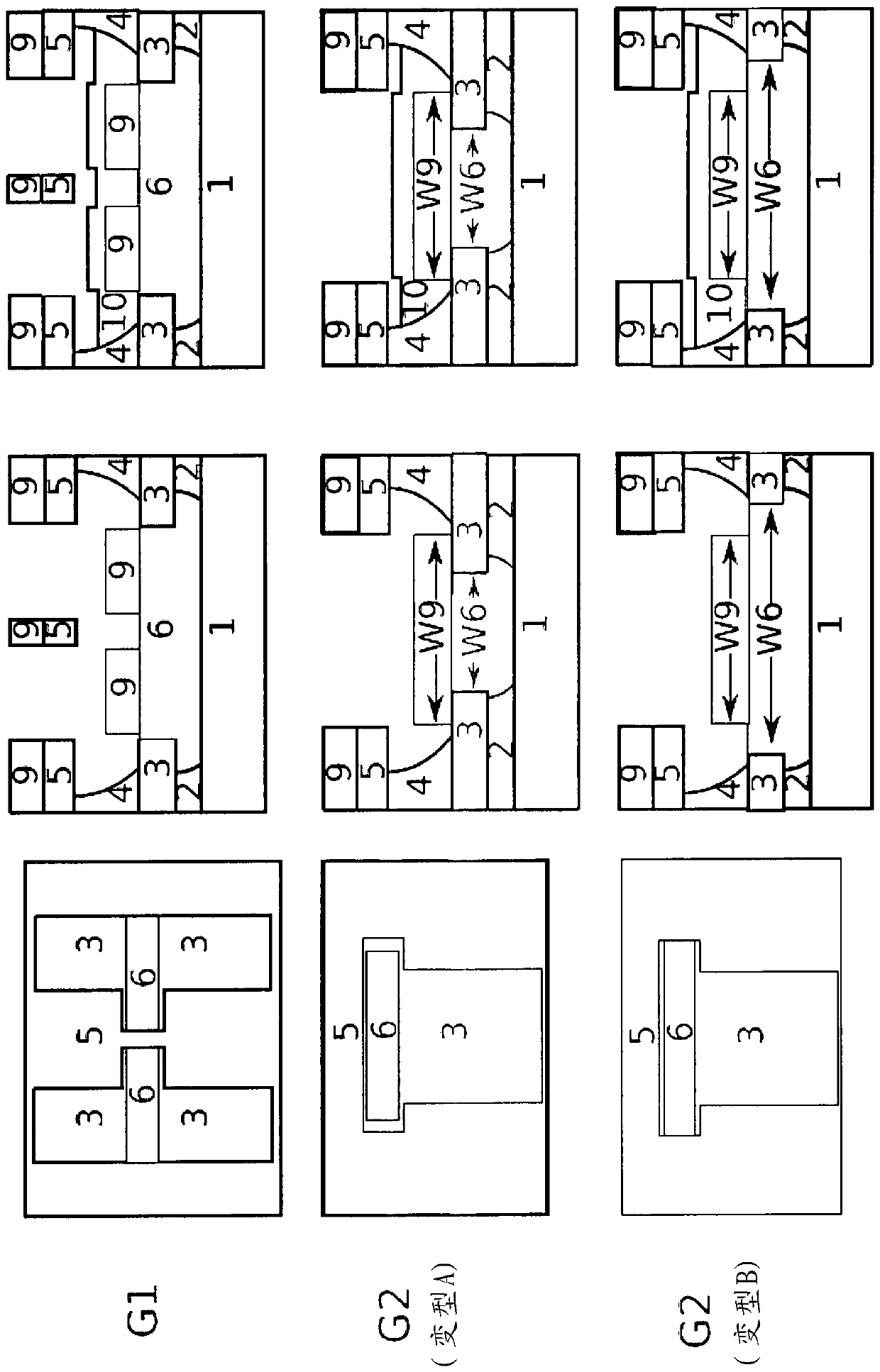

Method for in situ production of majorana material superconductor hybrid networks and hybrid structure produced using the method

PendingCN110291649AGood quality and performanceQuantum computersNanoinformaticsContaminationMAJORANA

The invention relates to a method for producing a Majorana material superconductor hybrid structure. The superconductive material is applied onto the Majorana material using a shadow mask, wherein a first mask (2, 3) for a structured application of the Majorana material (6) and an additional mask (shadow mask) (4, 5) for the structured growth of the superconductive material (7) are first generated on a substrate (1), the masks being aligned relative to each other, and the Majorana material and the superconductive layers are applied without interruption in an inert atmosphere, preferably in a vacuum and particularly preferably in an ultrahigh vacuum. The produced hybrid structure comprises at least one structured Majorana material, at least one superconductive material arranged thereon, and a passivation layer. The structured Majorana material has a wire-type design with a length between 0.1 and 100 [mu]m, a width between 10 and 200 nm, and a layer thickness between 12 and 260 nm, preferably between 15 and 50 nm. The boundary surface between the structured Majorana material and at least one superconductive material arranged thereon is advantageously free of contamination. The surface of the structured Majorana material is completely covered either by a preferably superconductive material or by a passivation layer.

Owner:KERNFORSCHUNGSANLAGE JUELICH GMBH

Preparation method of Al-Co-Ni quasicrystal

The invention discloses a preparation method of an Al-Co-Ni quasicrystal. The chemical component of the Al-Co-Ni quasicrystal comprises 70-74% of Al, 8-11% of Co and 18-21% of Ni. The preparation method mainly comprises the steps that Al powder, Co powder and Ni powder are evenly mixed and placed into a hard alloy die, pressure in a hydraulic tablet machine is 2-4 MPa and maintained for 100-300 s, and a preliminary block is obtained; the prepared preliminary block is placed into a boron nitride and graphite pipe heating furnace, then a pyrophyllite block is added, the product is placed in an isostatic pressing six-surface diamond presser, isostatic pressing is carried out under 3-5 Gpa, the current is switched on for heating and start, the temperature is kept for 30 min after being increased to 1050-1150 DEG C, the temperature is kept for 1-3 h after being decreased to 850-950 DEG C, and the Al72Co9Ni19 quasicrystal is obtained. The preparation method is simple in technology and convenient to operate, the quasicrystal is prepared in one step, and the obtained quasicrystal has the good mechanical property and good quality performance.

Owner:YANSHAN UNIV

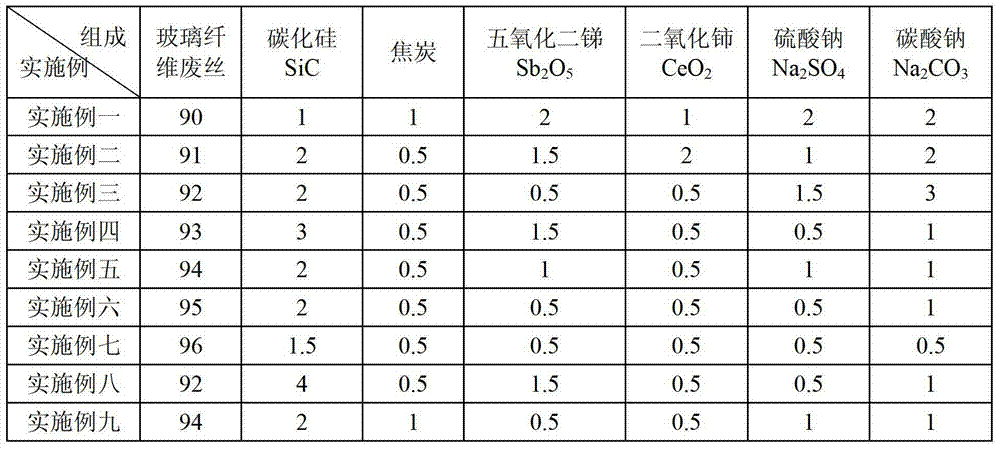

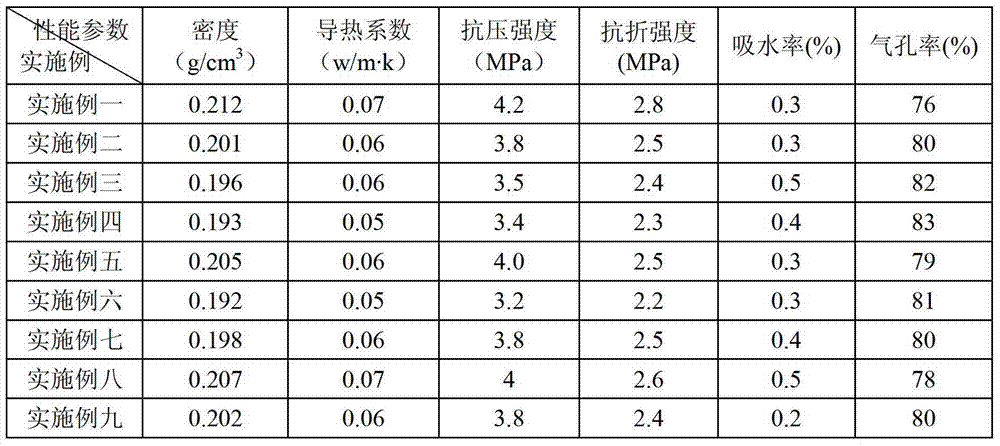

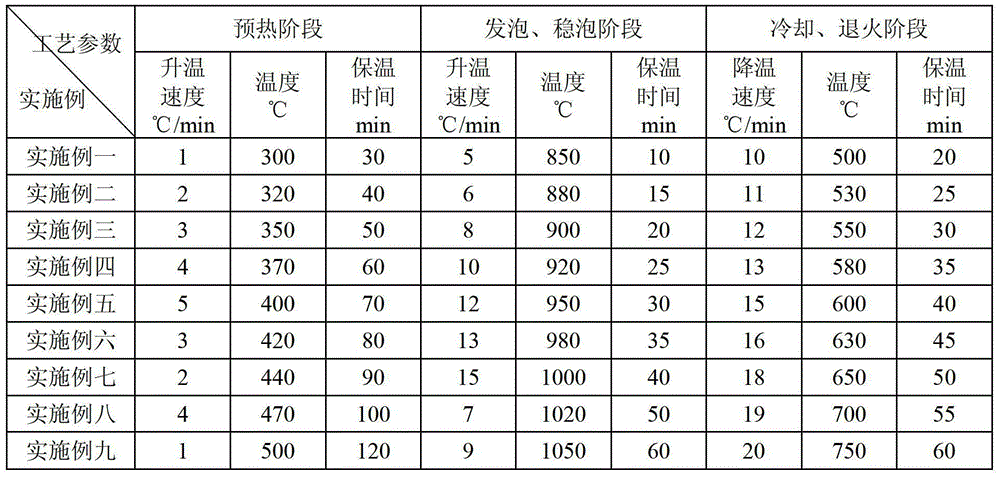

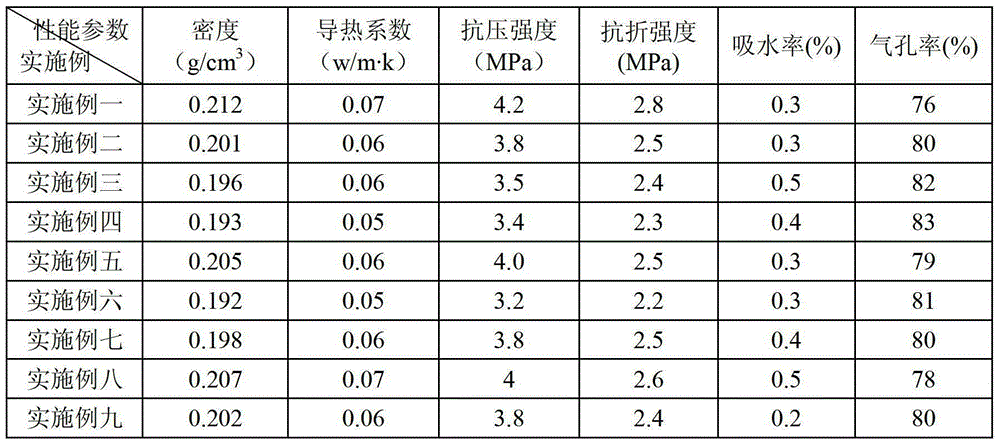

Foam glass prepared from waste high-aluminum alkali-free boron-free glass fiber and manufacturing method thereof

The invention discloses foam glass prepared from waste high-aluminum alkali-free boron-free glass fiber. The foam glass comprises 90-96wt% of waste glass fiber, 0.5-5wt% of SiC, 0.5-5wt% of coke, 0.5-7.5wt% of Sb2O5, 0.5-7.5wt% of CeO2, 0.5-7.5wt% of Na2SO4 and 0.5-7.5wt% of Na2CO3, wherein the waste glass fiber contains not less than 12wt% of Al2O3; and the molar ratio of Na2O / Al2O3 in the composition of the foam glass is more than 1. The invention further discloses a manufacturing method of the foam glass. The foam glass disclosed by the invention has the advantages of low density, high compressive and flexural strength and excellent quality performance, and can not only effectively improve the comprehensive utilization of industrial wastes, but also reduce the manufacturing cost of the foam glass and the environmental harm caused by the foam glass. In addition, the preparation process disclosed by the invention has the advantages of simple process and low production cost, and is suitable for industrial production.

Owner:JINGDEZHEN CERAMIC INSTITUTE

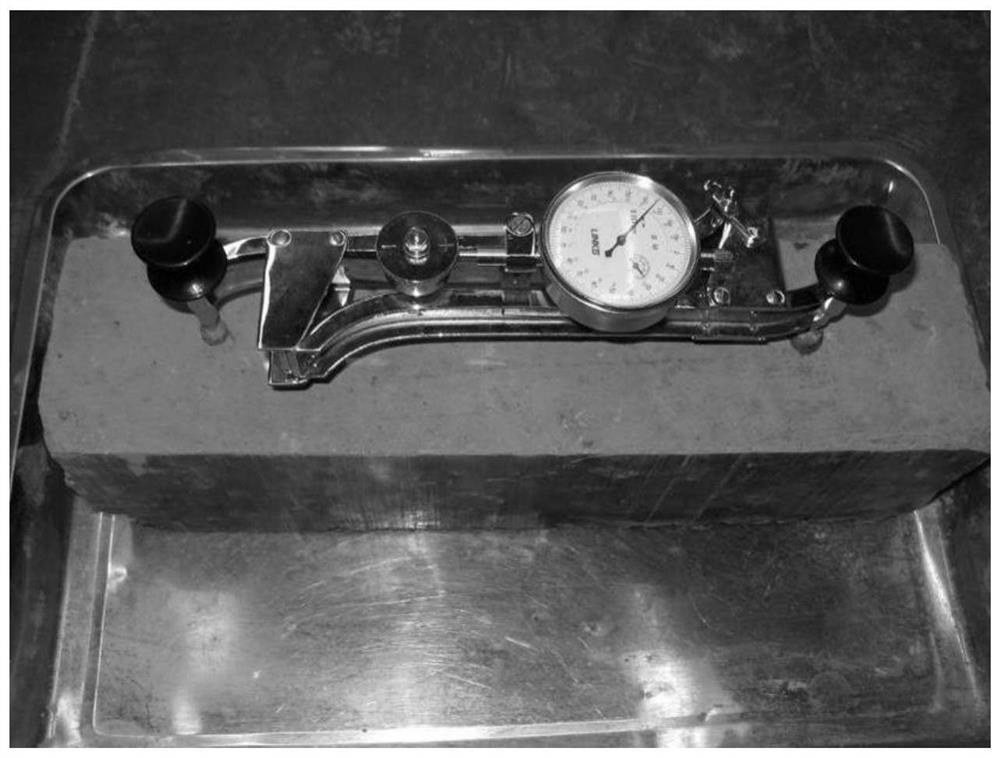

Preparation method of quasicrystal block

InactiveCN102443799ARapid coolingUnlimited sizeMetallic material coating processesMelting tankPolymer science

The invention which relates to a preparation method of a quasicrystal block belongs to the technical field of metal materials. The preparation method of the quasicrystal block is characterized in that: mixed quasicrystal powder or synthetic quasicrystal powder placed in a powder feeder is delivered to a laser melting pool by a powder delivery gas in a rapid laser shaping device, a quasicrystal or quasicrystal composite material coating is obtained after melting and cooling the mixed quasicrystal powder or the synthetic quasicrystal powder, a laser head is risen by the height of a coating, and the quasicrystal or quasicrystal composite material block is prepared through repeatedly coating. The preparation method of the invention, which has the advantages of simple technology, simple operation, feasibility, good mechanical performance, no restriction of the dimension of the block, excellent quality performance, wide application and the like, can satisfy the large scale application of materials like the quasicrystal block as a structural and functional device.

Owner:TIANJIN ENG MACHINERY INST

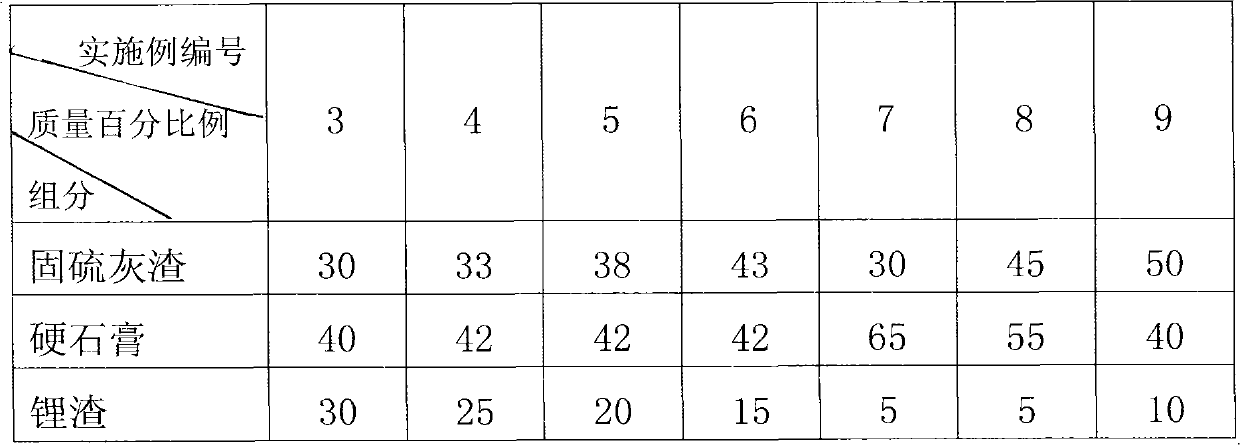

Concrete expansion agent containing circulating fluidized bed combustion coal solid sulfur clinker

The invention discloses a concrete expansion agent containing circulating fluidized bed combustion coal solid sulfur clinker. The concrete expansion agent is characterized by comprising the following components in percentage by mass: 30 to 50 percent of solid sulfur clinker, 40 to 65 percent of anhydrite and 5 to 30 percent of lithium slag. During preparation, after the components are crushed andground, the components are taken according to the proportion and mixed uniformly to obtain a product without calcining. Because industrial wastes such as the solid sulfur clinker, the lithium slag and the like are used as main raw materials, the concrete expansion agent changes the wastes into valuable, has low cost, reduces environmental pollution, has simple production process, low energy consumption and good performance, and has market competitiveness and strong practicability compared with like products.

Owner:SOUTHWEAT UNIV OF SCI & TECH

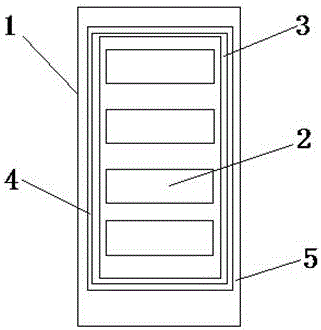

Indicating body construction of traffic warning board

InactiveCN106592458ASimple structureEasy to operateTraffic signalsRoad signsQuality performanceEngineering

The invention discloses an indicating body construction of a traffic warning board. The indicating body construction comprises an indicating body and is characterized in that the indicating body is provided with a plurality of signboard pasting areas; LED luminescent lamp strips are arranged around the signboard pasting areas; and light condensation strips are arranged around the LED luminescent lamp strips. A protective cover is arranged outside the indicating body and is fixed to the indicating body through a screw. The light condensation strips are divided into connectors connected around the pasting areas and reflective faces obliquely arranged on the connectors. The indicating body construction has the beneficial effects that due to the fact that the indicating body of the traffic warning board is provided with the LED luminescent lamp strips and the light condensation strips are arranged around the LED luminescent lamp strips, signs on the warning board can be identified clearly more easily. The structure is simple, operation is convenient, and quality performance is excellent.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

A kind of method that dihydrate gypsum prepares alpha hemihydrate gypsum

ActiveCN105174760BApplicable to different market needsGood quality and performanceAcid waterPhosphoric acid

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

Copper strip production process

The invention discloses a copper strip production process. The copper strip production process specifically comprises the following steps of (1) smelting and continuous casting; (2) surface milling; (3) hot rolling; (4) annealing; (5) acid pickling and cleaning; (6) fine rolling; and (7) shearing, packaging and warehousing. The copper strip production process has the beneficial conditions that after a raw material smelting alloy material is added, the weight of the raw material is controlled and the heating temperature and the heating environment are controlled during hot rolling, the oxidation burning loss of a copper material in a heating furnace can be reduced to a large extent, the yield of a finished product is controlled, a series of quality problems caused by heating oxidation of the copper material are reduced, annealing parameters are controlled, deformation resistance is lowered, the plasticity is restored, and the quality performance of the finished copper strip product produced by a method is good.

Owner:温州铜丰铜业有限公司

Alcohol ether substituted clean fuel for automobile

ActiveCN100577777CExcellent quality inspection indexGood quality and performanceLiquid carbonaceous fuelsBodies oilPhosphate

The invention discloses alcohol ether replaced clean fuel material used for vehicles, which takes methanol, methylic tertiary butyl ether, ethanol, 190 -200 solvent naphtha and heat bodied oil as raw material, under the normal temperature and the normal pressure, sodium perchlorate and potassium permanganate are firstly mixed and prepared by the weight ratio of 1:2, and then filled up into the methanol to be modified, and methylic tertiary butyl ether, ethanol, 190 -200 solvent naphtha and heat bodied oil are added in sequence, at last, mixed benzene, light aromatics, methylethyl ketone, sulfurated alkyl phenicate, ialkyl dithiozinc phosphate salt, ethylene glycol monomethyl ether, phosphate ester and Beta- naphthylamine, alkenyl succinic acid and alkylphenol polyoxyethylene are added to prepare a kind of petrous energy source replaced liquid fuel material which resists low temperature, has good mutual solubility, is corrosion proof, has good dynamic performance, low energy consumption and obvious environmental protection effect.

Owner:北京雄韬伟业能源科技发展有限公司

Novel switch base wiring cassette material and preparation method thereof

InactiveCN110229481ALow costGood environmental protection and flame retardant performanceEngineeringFire retardant

The invention discloses a novel switch base wiring cassette material and relates to the field of wiring cassettes. The material comprises the following ingredients (by weight): 30-35% of PBT resin, 30-35% of PA66 resin, 10-15% of glass fiber, 2-5% of a flexibilizer, 10-15% of a fire retardant TR-02-B, 0.2-0.5% of an antioxidant 626, 0.2-0.5% of a coupling agent, and 0.2-1.5% of a dispersant. A preparation method of the novel switch base wiring cassette material comprises the following steps: drying the PBT resin in an air dry oven for a certain period of time, and drying the PA66 resin in an air dry oven for a certain period of time; premixing the dried PBT resin and PA66 resin with the flexibilizer, the fire retardant, the antioxidant, the coupling agent and the dispersant to obtain a premix; feeding the premix into a double screw extruder and extruding and granulating, and finally processing to obtain a wiring cassette upper body and a wiring cassette lower body. The prepared wiringcassette material has low cost and good environment-friendly flame retardant property, and is convenient for market promotion and application.

Owner:FOSHAN KOER TECH DEV

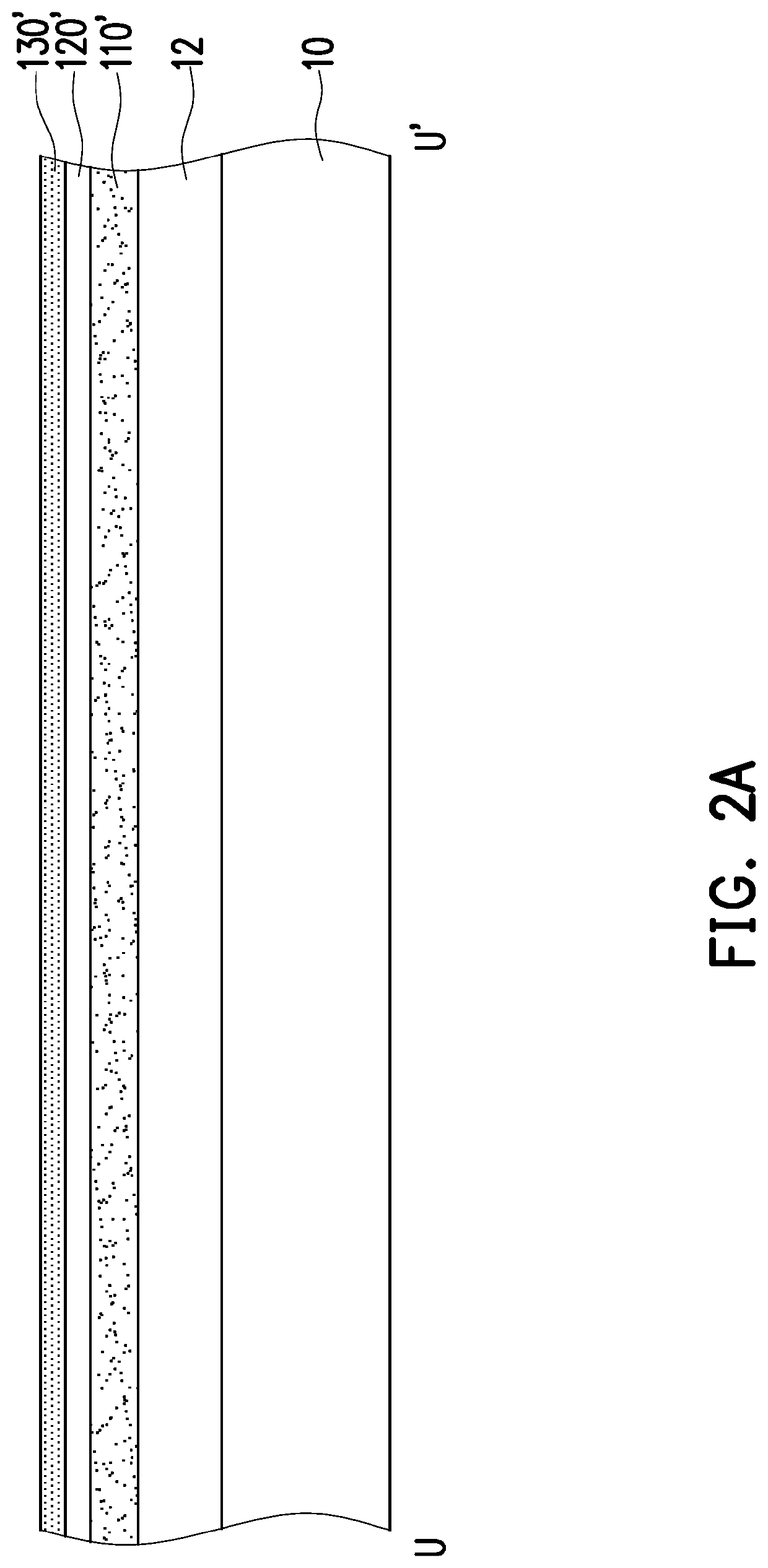

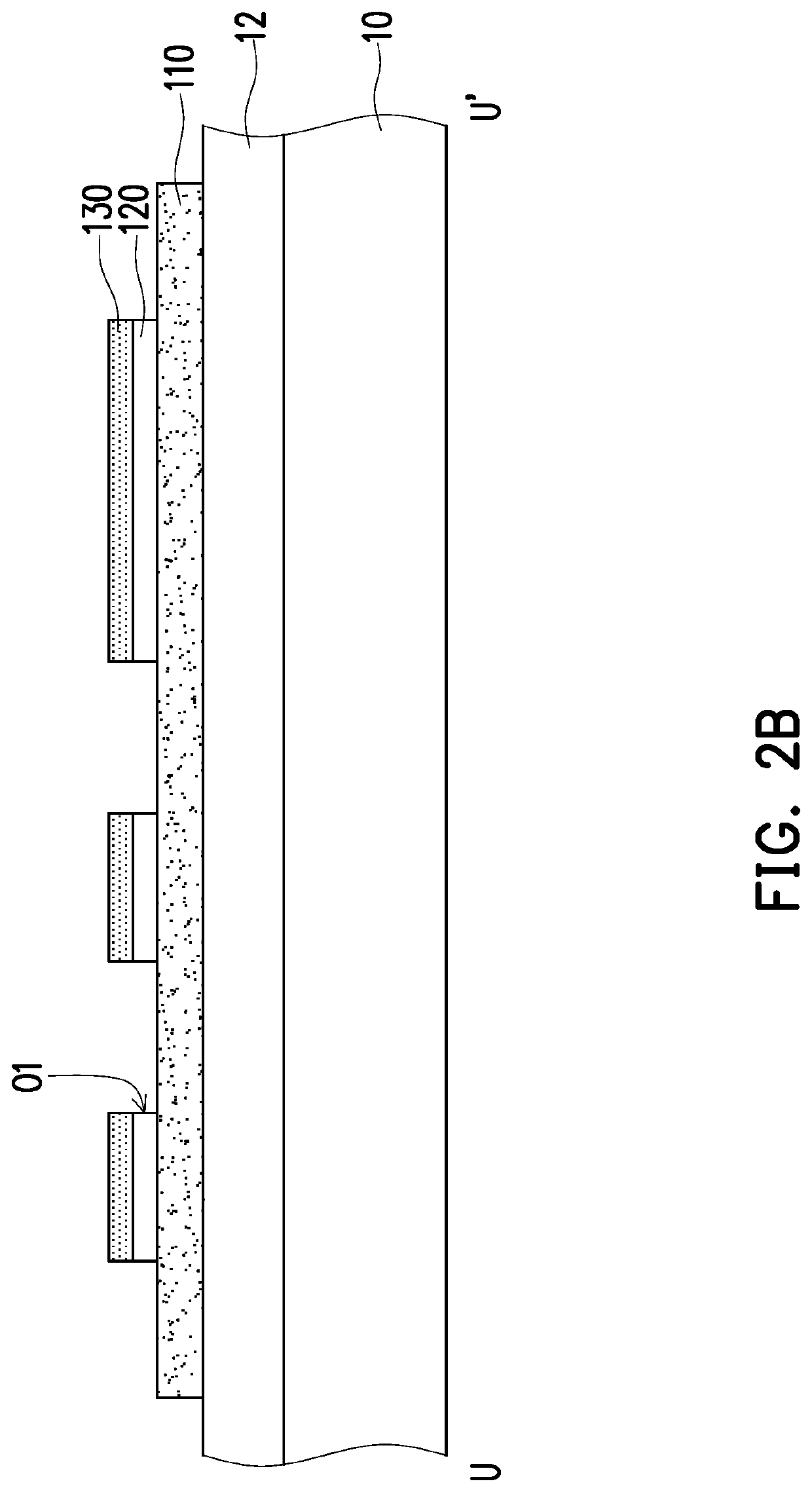

Light emitting device and manufacturing method thereof

InactiveUS20210391519A1Improve performanceLower resistanceSemiconductor devicesElectrical conductorOhmic contact

A light emitting device includes a growth substrate, a light emitting component, a first conductive bump and a second conductive bump. The light emitting component is disposed on the growth substrate, including a first type semiconductor layer, a second type semiconductor layer, a light emitting layer, an ohmic contact layer, a first conductor layer, and a second conductor layer. The light emitting layer and the second type semiconductor layer are penetrated by a trench. The ohmic contact layer is disposed on the first type semiconductor layer and is disposed in the trench. The ohmic contact layer is electrically connected to the first type semiconductor layer. The first conductor layer is disposed on the first type semiconductor layer and is disposed in the trench. The first conductor layer covers the ohmic contact layer. The second conductor layer is disposed on the second type semiconductor layer, and is electrically connected to the second type semiconductor layer. A manufacturing method of the light emitting device is also provided.

Owner:GENESIS PHOTONICS

a kind of al 6 Preparation method of mn quasicrystal

The present invention relates to a kind of preparation method of Al-Mn quasi-crystal, it mainly mixes pure Al powder and Mn powder uniformly and puts into cemented carbide mold according to atomic ratio 6:1, presses in hydraulic pressure tablet machine to obtain Prepare the block, put the above prepared block into the boron nitride crucible and assemble the pre-dried tubular graphite furnace body, boron nitride crucible, boron nitride sheet, pyrophyllite sheet and graphite sheet, and place them in an ultra-high pressure environment , set the pressure at 3‑5GPa isostatic pressure, control the temperature and heat to 700°C‑850°C, keep warm for 30‑60min; when the temperature drops to 480°C‑580°C, keep warm for 1‑3h. The invention has the advantages of simple process, low energy consumption and high efficiency, and the prepared quasi-crystal content is relatively high.

Owner:YANSHAN UNIV

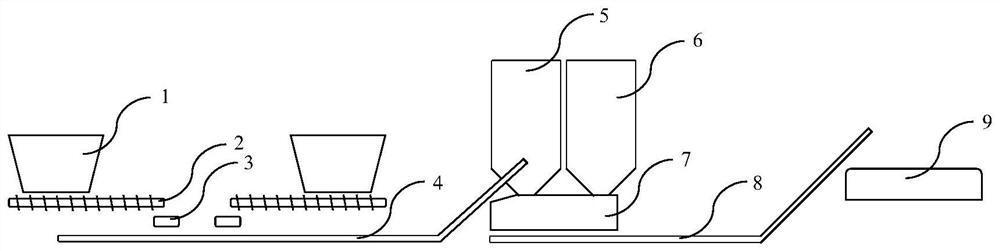

Manufacturing method of self-heat-preservation non-bearing wallboard

InactiveCN113103421AFix instabilityBeautiful appearanceDischarging arrangementFeeding arrangmentsTemperature controlEconomic benefits

The invention discloses a manufacturing method of a self-heat-preservation non-bearing wallboard. The manufacturing method comprises the following steps of ingredient stirring, mold box pouring, upper forming manufacturing, temperature control precuring, demolding and board discharging, and acceptance and warehousing. The manufacturing method solves the problem of instability of traditional foam, reduces the overall construction cost, and has obvious economic benefits; and a wall body is not easy to fall off, the adhesive force of the wall to decorative materials is improved, an inner wall can be decorated, the structural space self-heat-preservation performance is high, the weight is light, manufacturing is easy, materials and energy are saved, and the engineering cost can be greatly reduced.

Owner:JIANGXI XIONGYU GRP

Method for preparing bleached chemi-mechanical pulp for culture paper making by using cotton wood to process remainder

ActiveCN101613975BTake advantage ofEnergy saving and environmental protection in pulping processPretreatment with water/steamPulp bleachingHigh intensityProcessing plants

The invention discloses a method for preparing bleached chemi-mechanical pulp fore culture paper making by using cotton wood to process remainder, which belongs to the field of pulp refining for making paper. The method mainly comprises presteaming, double screw extrusion, chemical impregnation, high-consistency pulp refining by a double-screw fiberizer, adding medicament in the pulp refining process, high-consistency stay, middle-consistency pulp refining and other steps. The pulp refining process adopts single-section double-screw extrusion and single-section alkaline hydrogen peroxide impregnation, has simple process flow and compact equipment, completely adopts home equipment and saves the investment. The chemi-mechanical pulp prepared by processing cotton wood remainder through the method has the characteristics of high bulk, strength, whiteness and the like, and is suitable for pulp to be used for paper making of medium-high grade culture paper. The method achieves the cleannessand high-efficiency utilization of the remainder of the cotton wood processing factories, and is suitable for medium-small paper making enterprises for producing culture paper dependent on outsourcing goods.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

A kind of foam glass prepared by using high-alumina, alkali-free and boron-free glass fiber waste and its manufacturing method

The invention discloses foam glass prepared from waste high-aluminum alkali-free boron-free glass fiber. The foam glass comprises 90-96wt% of waste glass fiber, 0.5-5wt% of SiC, 0.5-5wt% of coke, 0.5-7.5wt% of Sb2O5, 0.5-7.5wt% of CeO2, 0.5-7.5wt% of Na2SO4 and 0.5-7.5wt% of Na2CO3, wherein the waste glass fiber contains not less than 12wt% of Al2O3; and the molar ratio of Na2O / Al2O3 in the composition of the foam glass is more than 1. The invention further discloses a manufacturing method of the foam glass. The foam glass disclosed by the invention has the advantages of low density, high compressive and flexural strength and excellent quality performance, and can not only effectively improve the comprehensive utilization of industrial wastes, but also reduce the manufacturing cost of the foam glass and the environmental harm caused by the foam glass. In addition, the preparation process disclosed by the invention has the advantages of simple process and low production cost, and is suitable for industrial production.

Owner:JINGDEZHEN CERAMIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com