Novel switch base wiring cassette material and preparation method thereof

A technology of cassettes and switches, applied in the field of wiring cassettes, can solve the problems affecting the performance and life of cassettes, the tensile strength of materials, the flexibility of flexural modulus materials, the stability of flame retardancy and moisture absorption, and the difficulty in achieving the best balance of cost and so on. problems, achieve low cost, easy promotion and application, good environmental protection and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

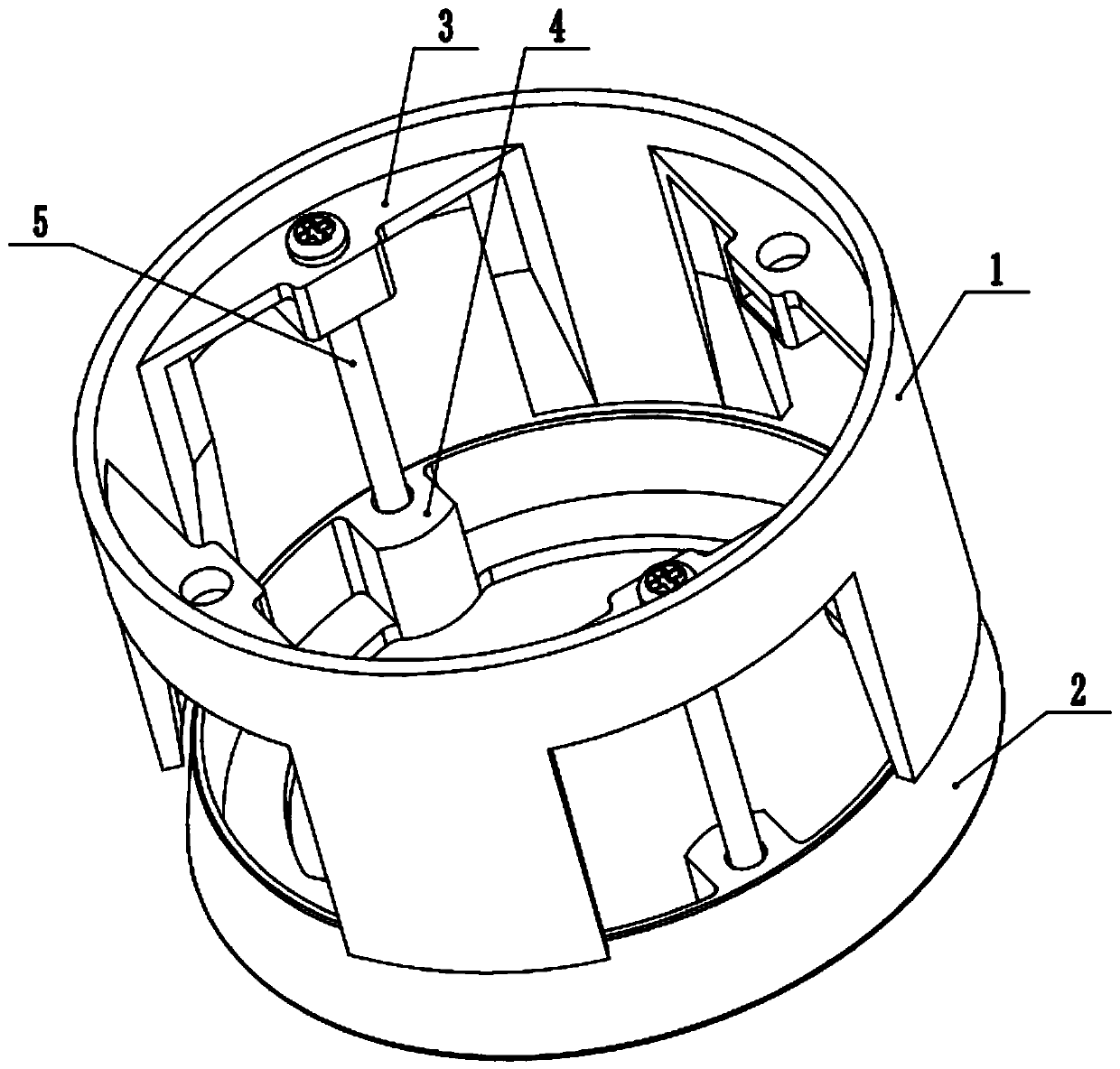

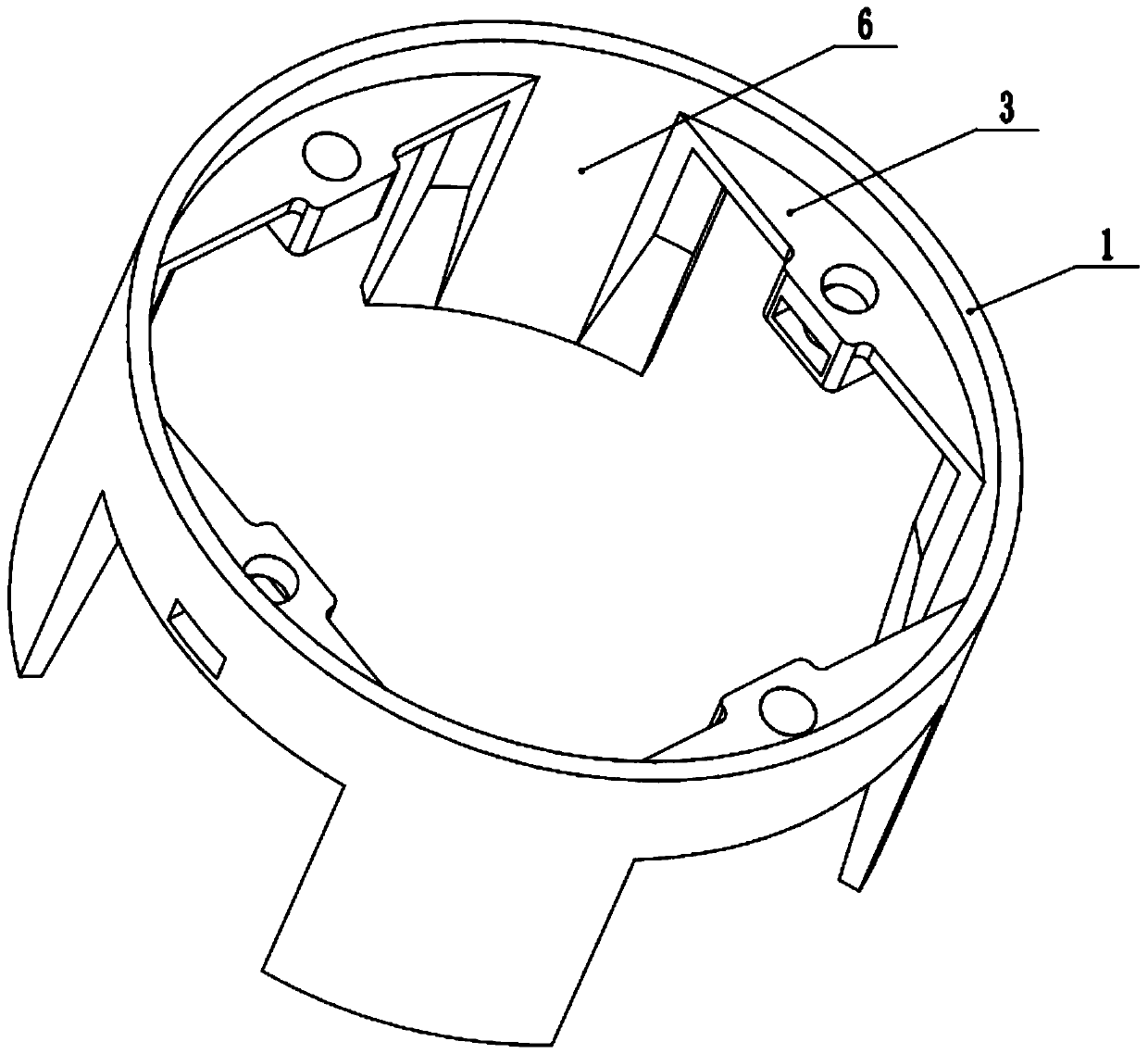

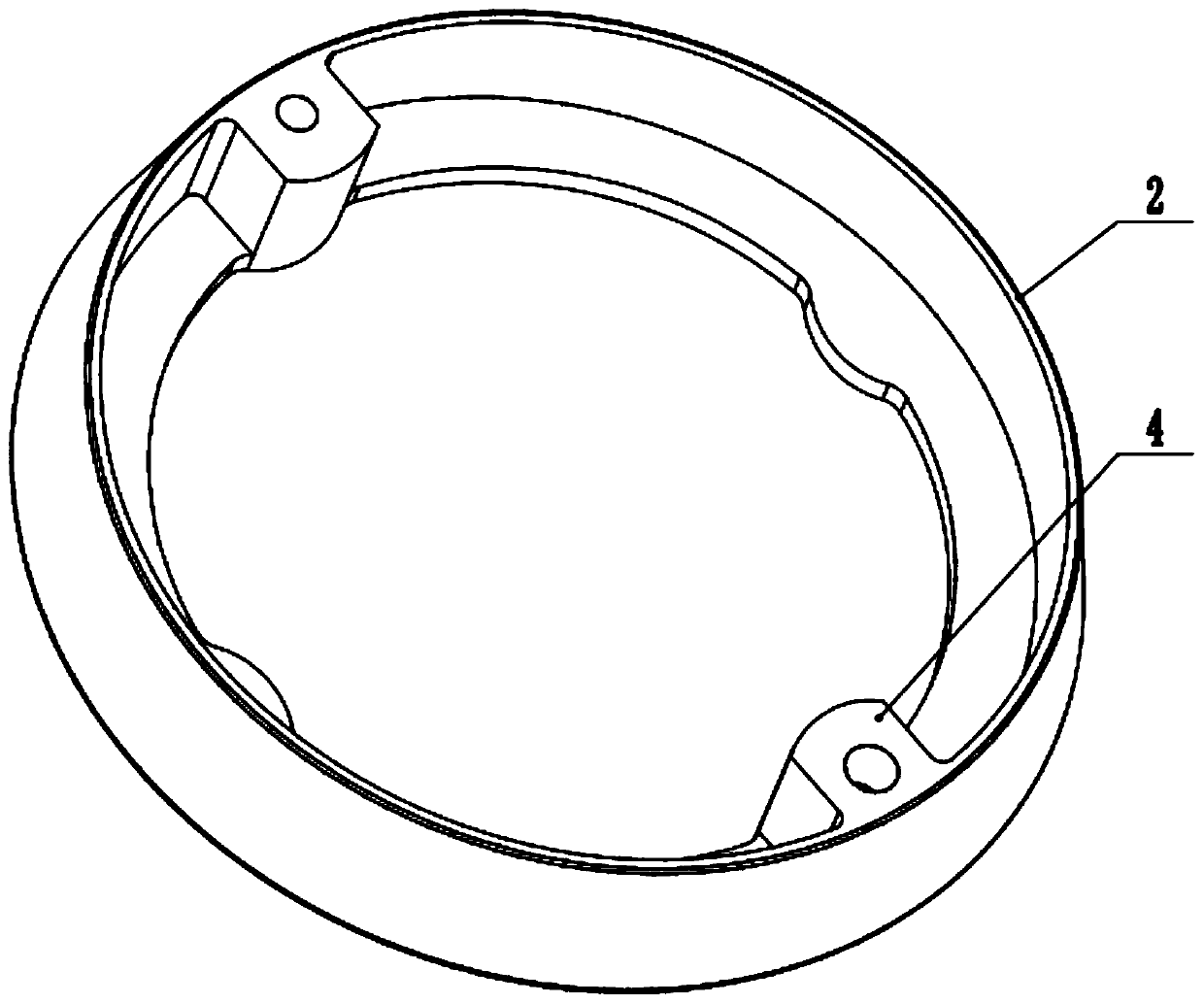

Image

Examples

Embodiment 1

[0024] A new type of switch base junction cassette material, calculated by percentage, includes the following ingredients: PBT resin: 35%, PA66 resin: 33%, glass fiber: 13%, toughening agent: 3%, flame retardant: TR-02- B15%, antioxidant 626: 0.4%, coupling agent: 0.4%, dispersant: 0.2%.

[0025] The model of the glass fiber is E2400, the model of the toughening agent is Dingxin DX-1001, the model of the flame retardant is Tengxinyuan TR-02-B, and the model of the dispersant is BYK-P4102 .

[0026] A method for preparing a new type of switch base junction cassette material includes the following steps:

[0027] Step 1: Drying treatment: Dry the PBT resin in a blast drying oven at 110 degrees for 8 hours, and dry the PA66 resin in a blast drying oven at 90 degrees for 6 hours;

[0028] Step 2: Prepare the premix: premix the dried PBT resin and PA66 tree with the toughening agent, flame retardant, antioxidant, coupling agent, and dispersant to obtain the premix;

[0029] Step 3: Melt ex...

Embodiment 2

[0034] A new type of switch base junction cassette material, calculated by percentage, includes the following ingredients: PBT resin: 30%, PA66 resin: 35%, glass fiber: 13%, toughening agent: 5%, flame retardant: TR-02- B14.5%, antioxidant 626: 0.5%, coupling agent: 0.5%, dispersant: 1.5%.

[0035] The model of the glass fiber is E2400, the model of the toughening agent is Dingxin DX-1001, the model of the flame retardant is Tengxinyuan TR-02-B, and the model of the dispersant is BYK-P4102 .

[0036] A method for preparing a new type of switch base junction cassette material includes the following steps:

[0037] Step 1: Drying treatment: Dry the PBT resin in a blast drying oven at 110 degrees for 8 hours, and dry the PA66 resin in a blast drying oven at 90 degrees for 6 hours;

[0038] Step 2: Prepare the premix: premix the dried PBT resin and PA66 tree with the toughening agent, flame retardant, antioxidant, coupling agent, and dispersant to obtain the premix;

[0039] Step 3: Melt ...

Embodiment 3

[0044] A new type of switch base junction cassette material, based on percentage, including the following ingredients: PBT resin: 33%, PA66 resin: 33%, glass fiber: 13%, toughening agent: 4.5%, flame retardant: TR-02- B15%, antioxidant 626: 0.35%, coupling agent: 0.35%, dispersant: 0.8%.

[0045] The model of the glass fiber is E2400, the model of the toughening agent is Dingxin DX-1001, the model of the flame retardant is Tengxinyuan TR-02-B, and the model of the dispersant is BYK-P4102 .

[0046] A method for preparing a new type of switch base junction cassette material includes the following steps:

[0047] Step 1: Drying treatment: Dry the PBT resin in a blast drying oven at 110 degrees for 8 hours, and dry the PA66 resin in a blast drying oven at 90 degrees for 6 hours;

[0048] Step 2: Prepare the premix: premix the dried PBT resin and PA66 tree with the toughening agent, flame retardant, antioxidant, coupling agent, and dispersant to obtain the premix;

[0049] Step 3: Melt ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com