Polyvinyl chloride plastic/rubber inking roller and preparation method thereof

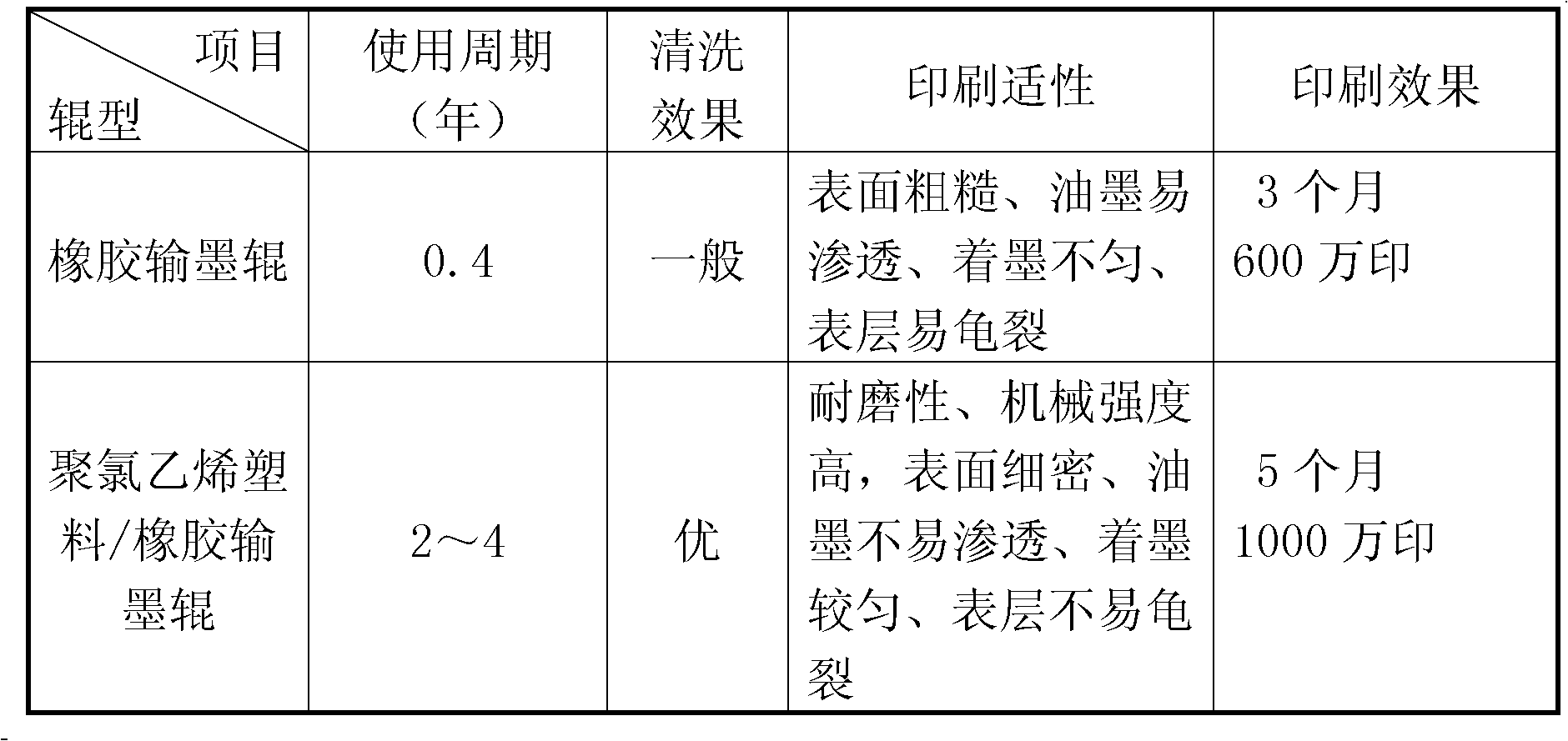

A polyvinyl chloride and inking roller technology, which is applied in the directions of adhesives, epoxy resin glue, and printing press roller jackets, etc., can solve the problems of rough surface of the inking roller, easy cracking of the rubber surface, easy ink penetration, etc. Good wear resistance, good printing adaptability, not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

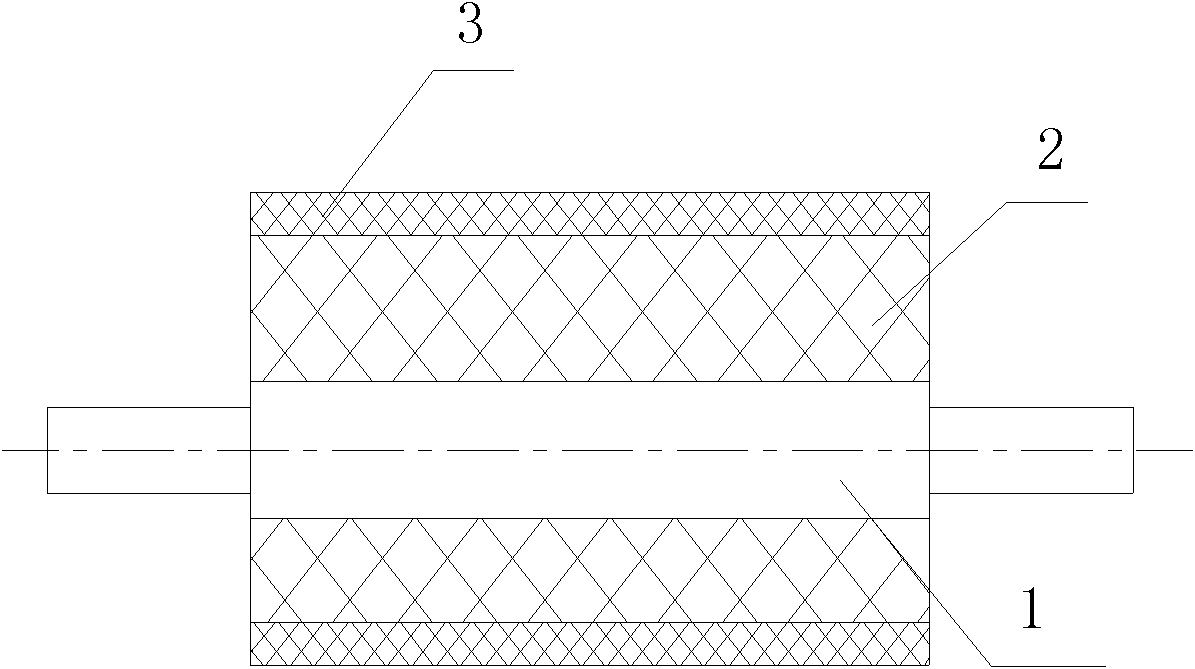

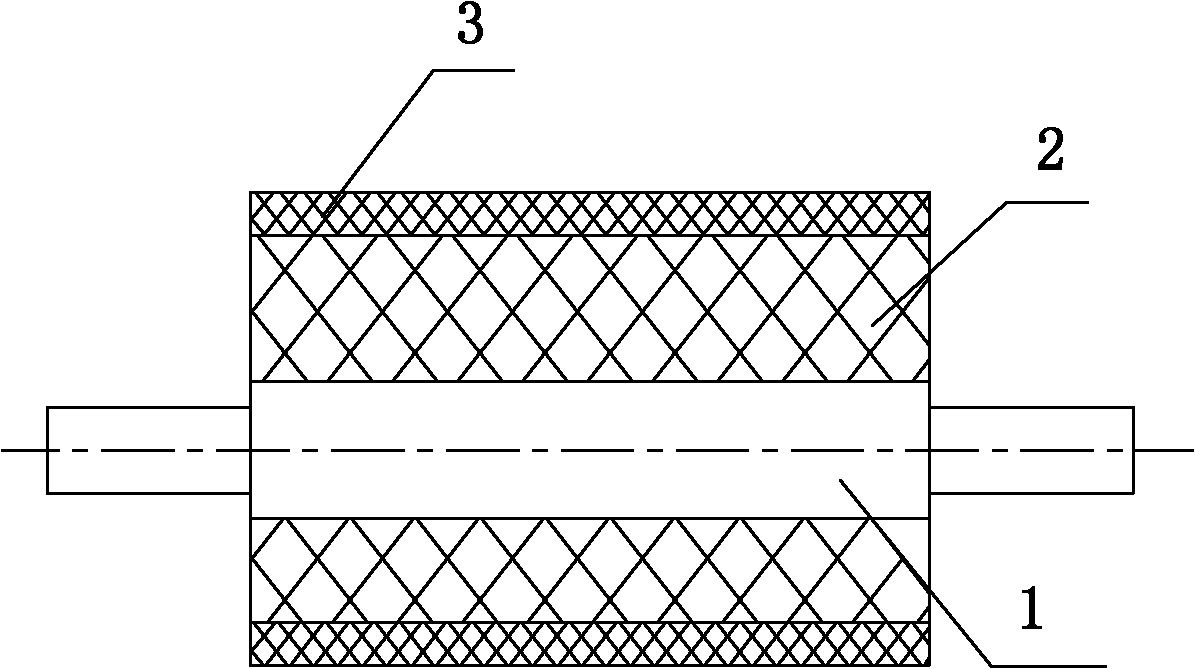

[0030] The existing inking roller is wrapped with a layer of rubber on the outer surface of the metal roller core, and the polyvinyl chloride plastic / rubber inking roller of the present invention is coated with a layer of polyvinyl chloride on the outer surface of the rubber layer of the existing inking roller. plastic layer.

[0031] The preparation method of polyvinyl chloride plastics / rubber inking roller of the present invention is as follows:

[0032] 1] According to the ratio of 80-120 parts of polyvinyl chloride resin, 50-70 parts of plasticizer, 1-3 parts of stabilizer, and 4-6 parts of filler, the raw materials are selected; among them, polyvinyl chloride resin can be selected from polyvinyl chloride resin. Vinyl chloride paste resin PSH-10, R-1069 polyvinyl chloride paste resin, 1345K polyvinyl chloride paste resin or 4472 polyvinyl chloride paste resin, preferably polyvinyl chloride paste resin PSH-10; the plasticizer is phthalic acid di Octyl ester; stabilizer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com