Patents

Literature

176results about "Printing roller shells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

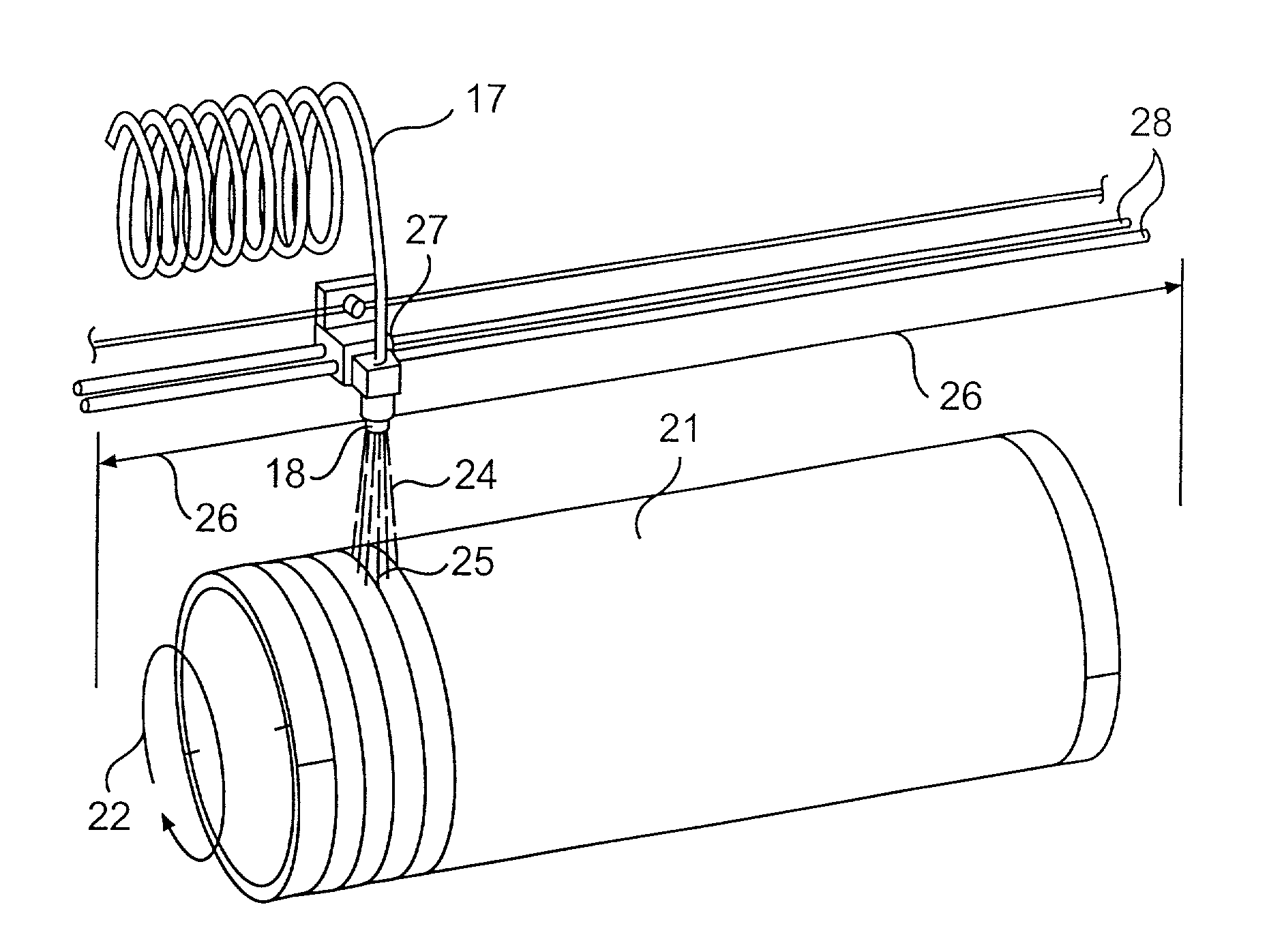

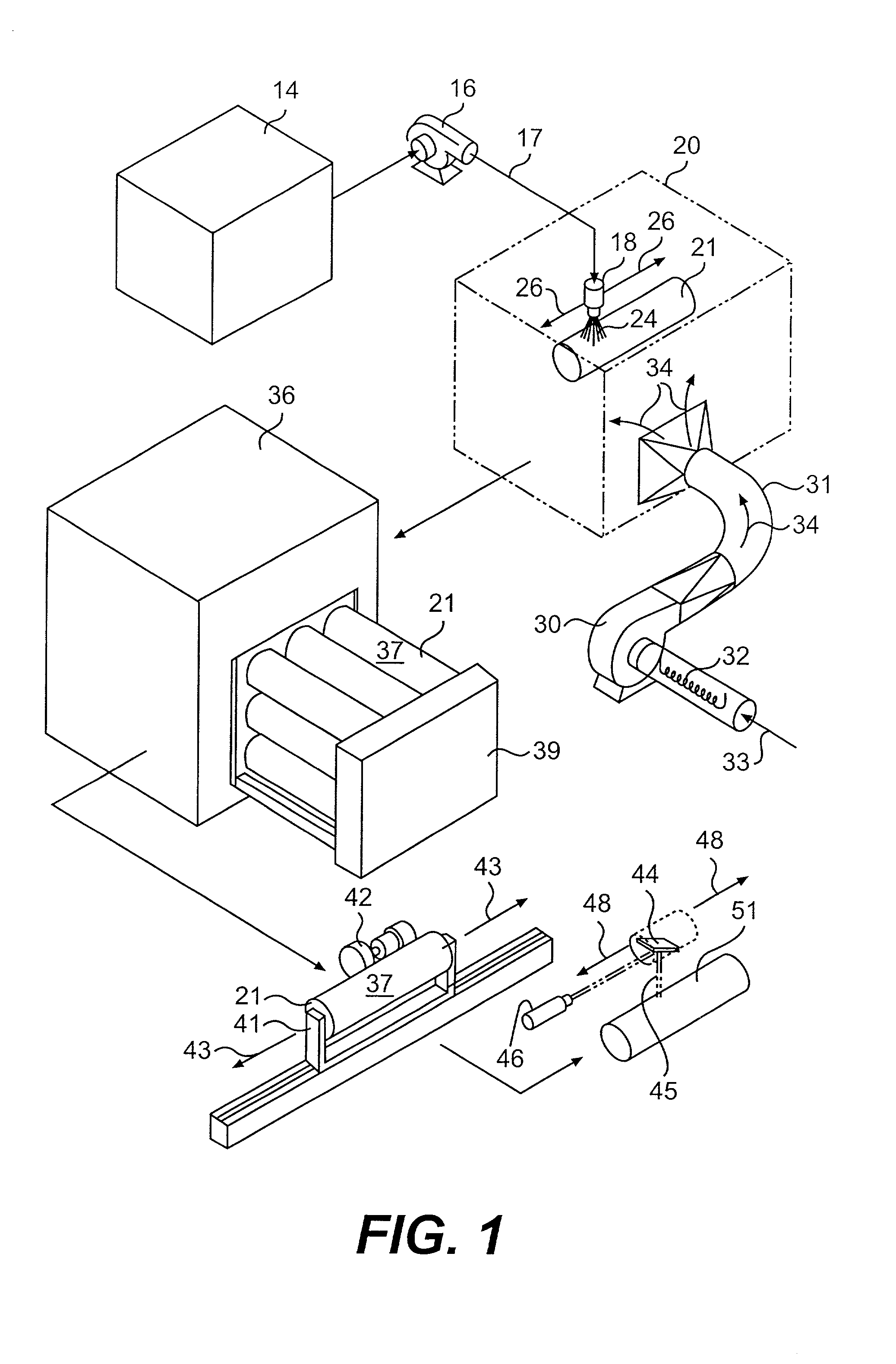

Printing sleeves and cylinders applied with a photopolymer composition

A method of forming a photopolymer layer on a printing substrate (e.g., flexographic printing sleeves and cylinders) is provided. The method includes providing a photopolymer composition that contains a photopolymer and at least one monomer bonded to the photopolymer. The monomer can help reduce the hardness of the resulting photopolymer composition. In addition, the method also includes spraying the photopolymer composition onto a rotating generally cylindrical surface of the printing substrate. In one embodiment, the sprayed photopolymer composition is then cured. The resulting photopolymer layer is seamless and continuous and, in some embodiments, has a hardness of between about 50 to about 70 Shore A.

Owner:ROSSINI SPA

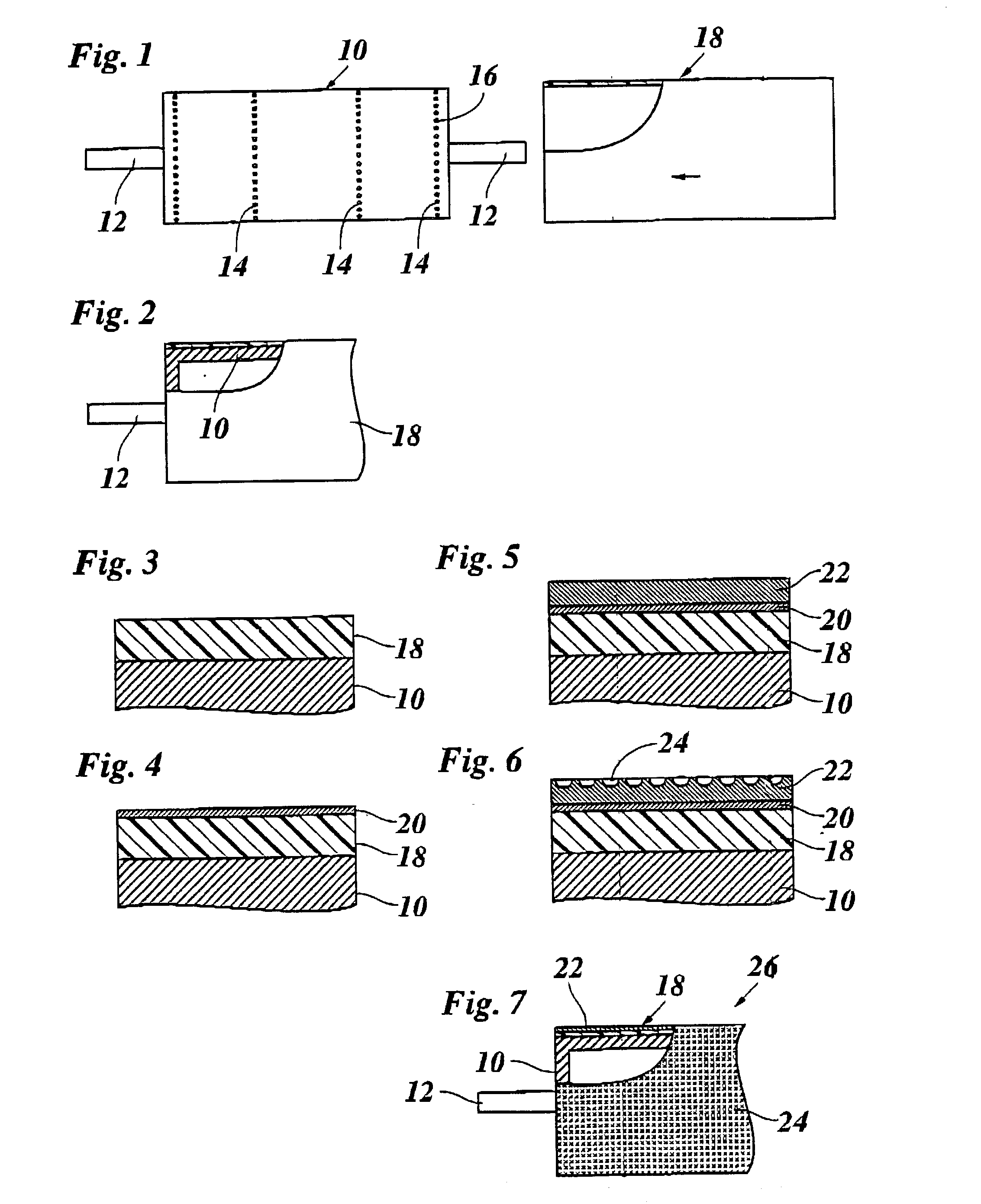

Abrasion-resistant rubber roll cover with polyurethane coating

ActiveUS20070111871A1Improve propertiesImprove toughnessMechanical working/deformationShaft and bearingsEngineeringWear resistance

An industrial roll includes: a substantially cylindrical metallic core; a rubber base layer that is adhered to and circumferentially overlies the core; a rubber top stock layer that circumferentially overlies the base layer; and a polyurethane coating that circumferentially overlies the top stock layer. In this configuration, the roll can provide improved abrasion-resistance, sheet release properties, and / or toughness compared to a roll with a rubber cover, but may provide these properties in a cover that is softer than a typical polyurethane cover.

Owner:STOWE WOODWARD

Process for producing a chemical-resistant protective layer for a rotary body having a base body made from fiber-reinforced plastic

A fiber-reinforced plastic base body is first of all provided with a coating of hard rubber or thermoplastic having a dispersed metal or ceramic content of 5% by volume to 80% by volume, and the coating is ground down to provide a smooth surface In a further step a layer of metal and / or ceramic, which has a printing function, is applied to the smooth surface, preferably by thermal spraying.

Owner:MANROLANAD AG

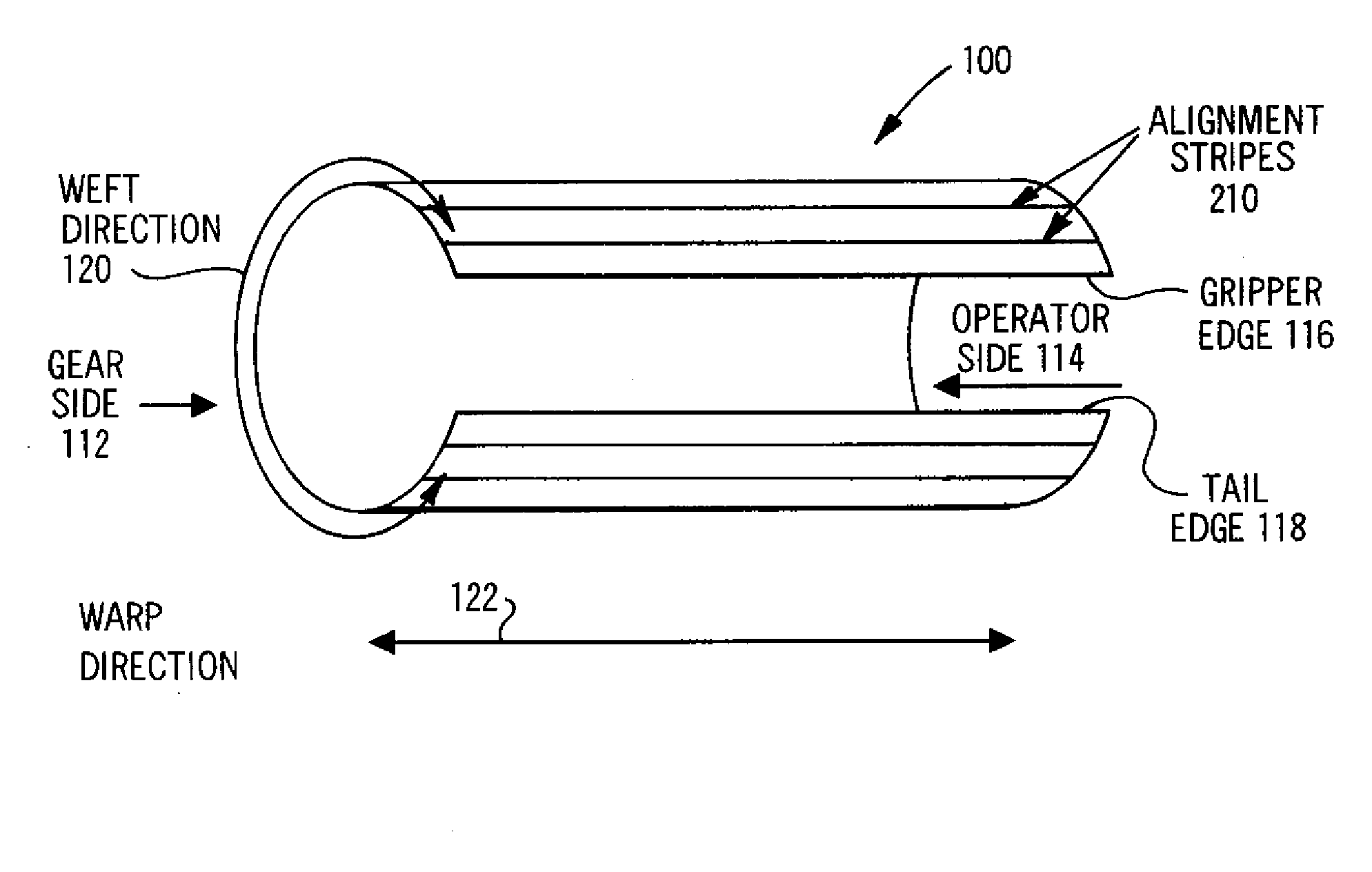

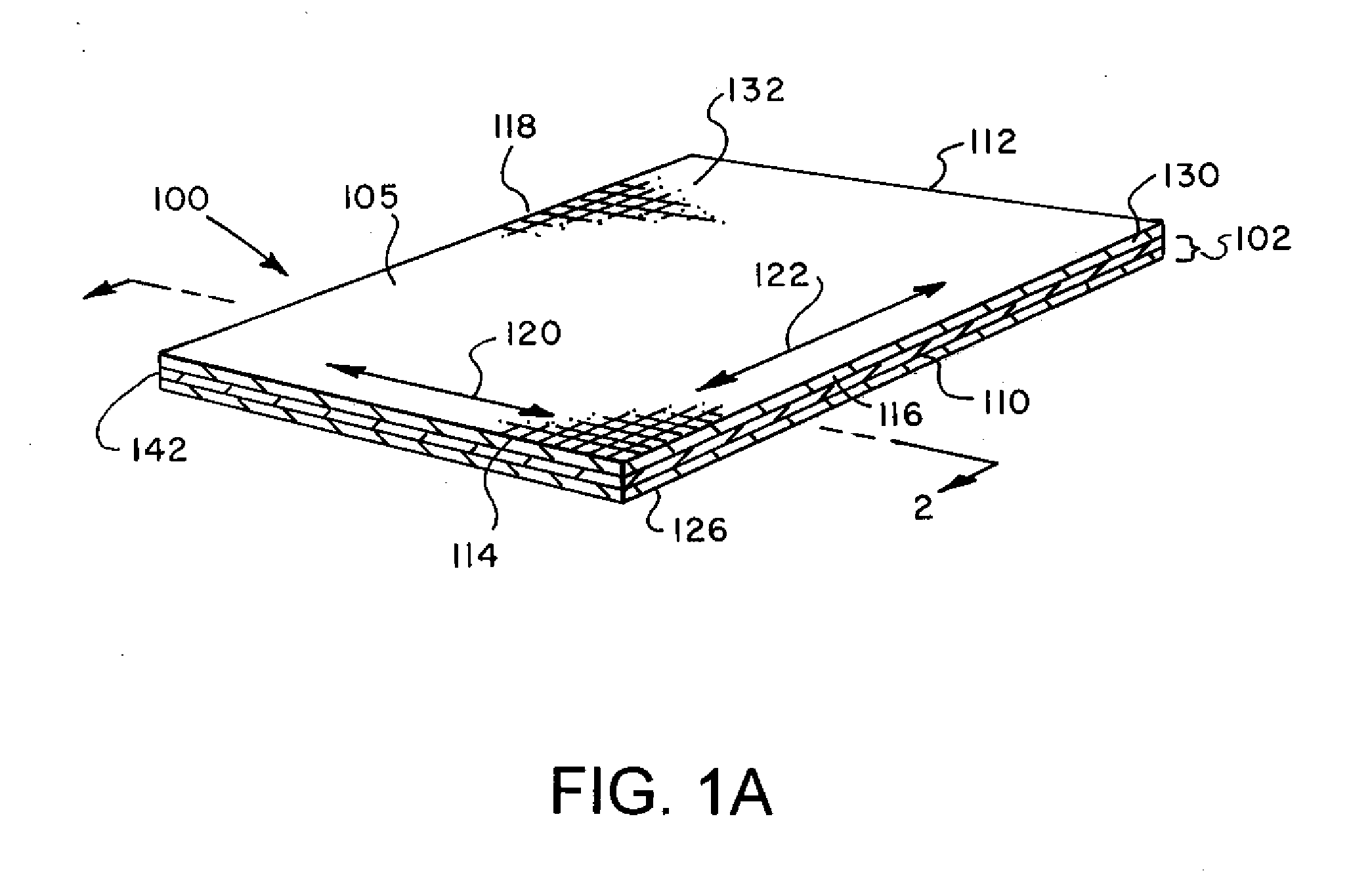

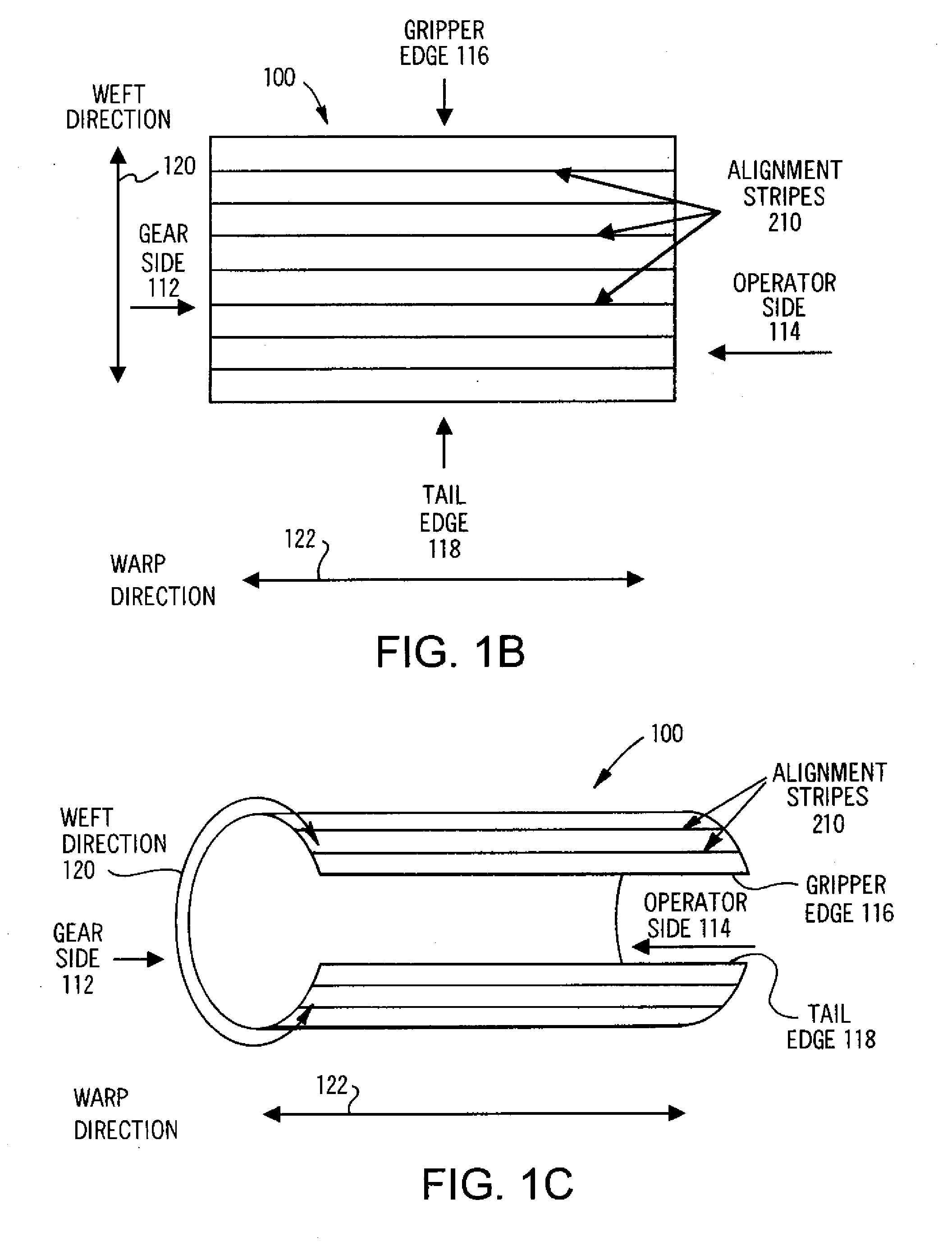

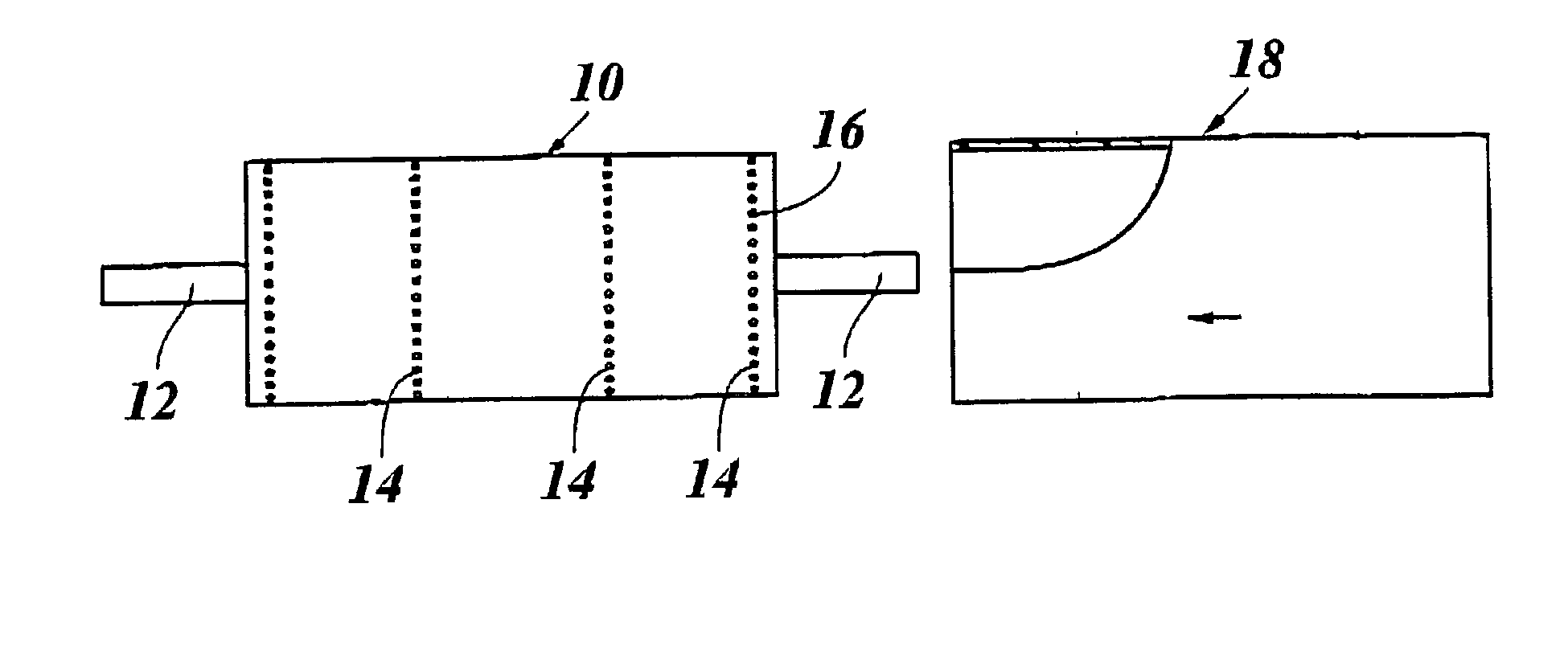

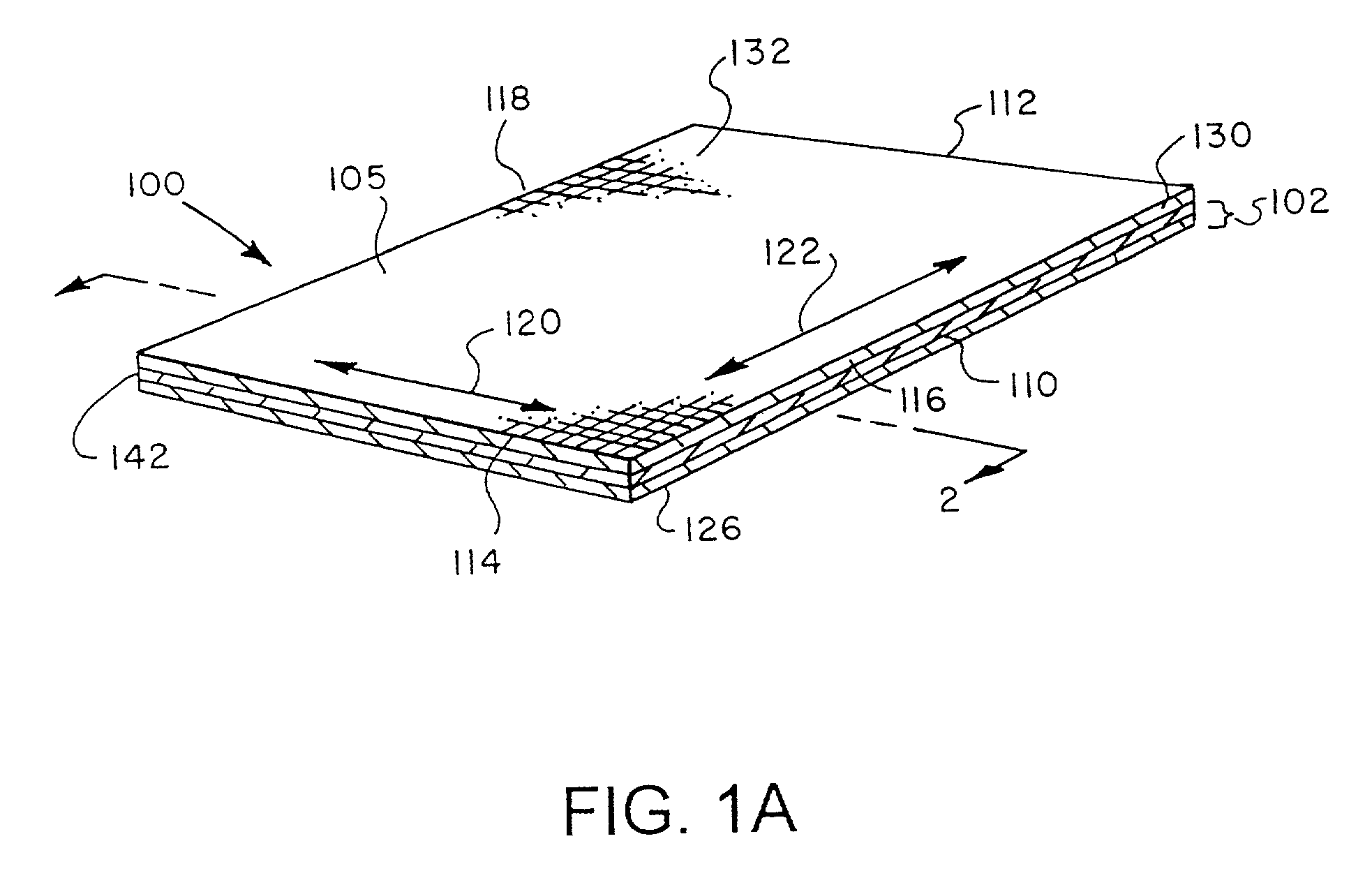

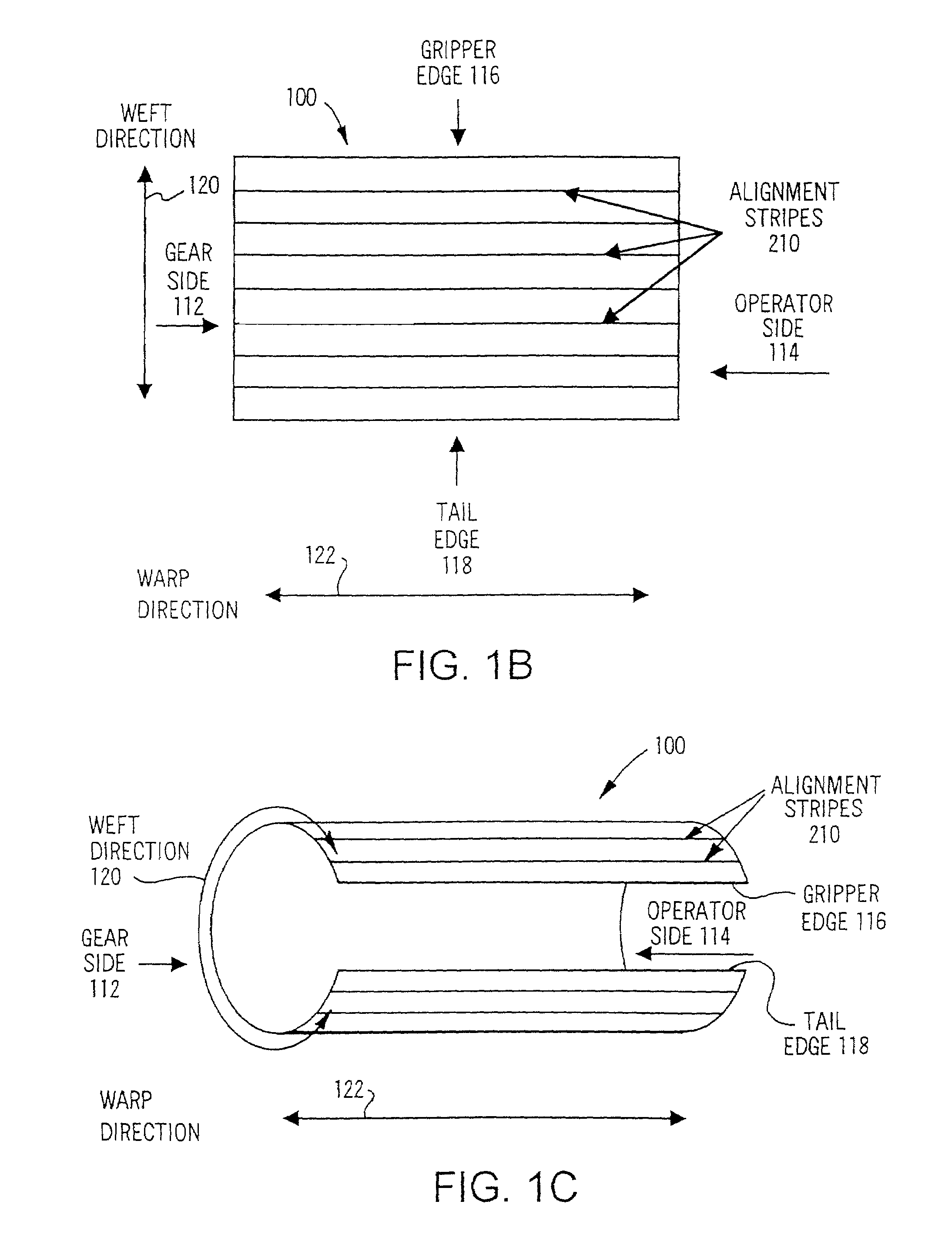

Anti-static, anti-smearing pre-stretched and pressed flat, precision-cut striped flexible coverings for transfer cylinders

InactiveUSRE39305E1Build-up of electrostatic charges on the movable, flexible jacket covering is preventedAvoid chargingCylinder pressesPlaten pressesFrictional coefficientConductive materials

Freshly printed sheets are transferred from one printing unit to another by transfer cylinders each having an ink repellent, electrically conductive, striped flexible jacket covering that is movable relative to the sheet support surface of the transfer cylinder. The jacket covering is made of a flexible fabric material that is pre-stretched, pressed flat, cut to size and treated with an ink repellent compound and is also treated with an anti-static ionic compound or is otherwise rendered electrically conductive by one or more conductive strands. Electrostatic charges carried by the freshly printed sheets are discharged through the ink repellent, electrically conductive, flexible jacket covering into the grounded transfer cylinder. A low friction, electrically conductive cylinder base covering that includes center alignment marks is secured to the transfer cylinder for engaging the flexible jacket covering. The ink repellent, electrically conductive flexible jacket covering is provided with alignment center marks and alignment stripes so that the flexible jacket covering can be precisely aligned with ease and secured over the gripper edge, tail edge and side edges of the transfer cylinder. The low frictional coefficient of the conductive cylinder base covering is further reduced by nodes and / or openings.

Owner:DEMOORE HOWARD WARREN +1

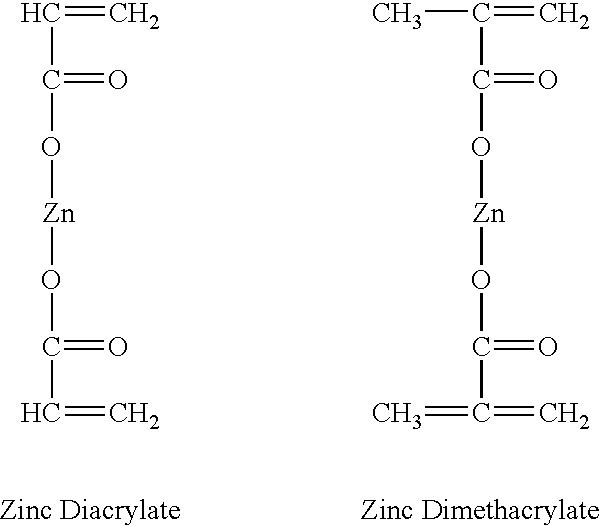

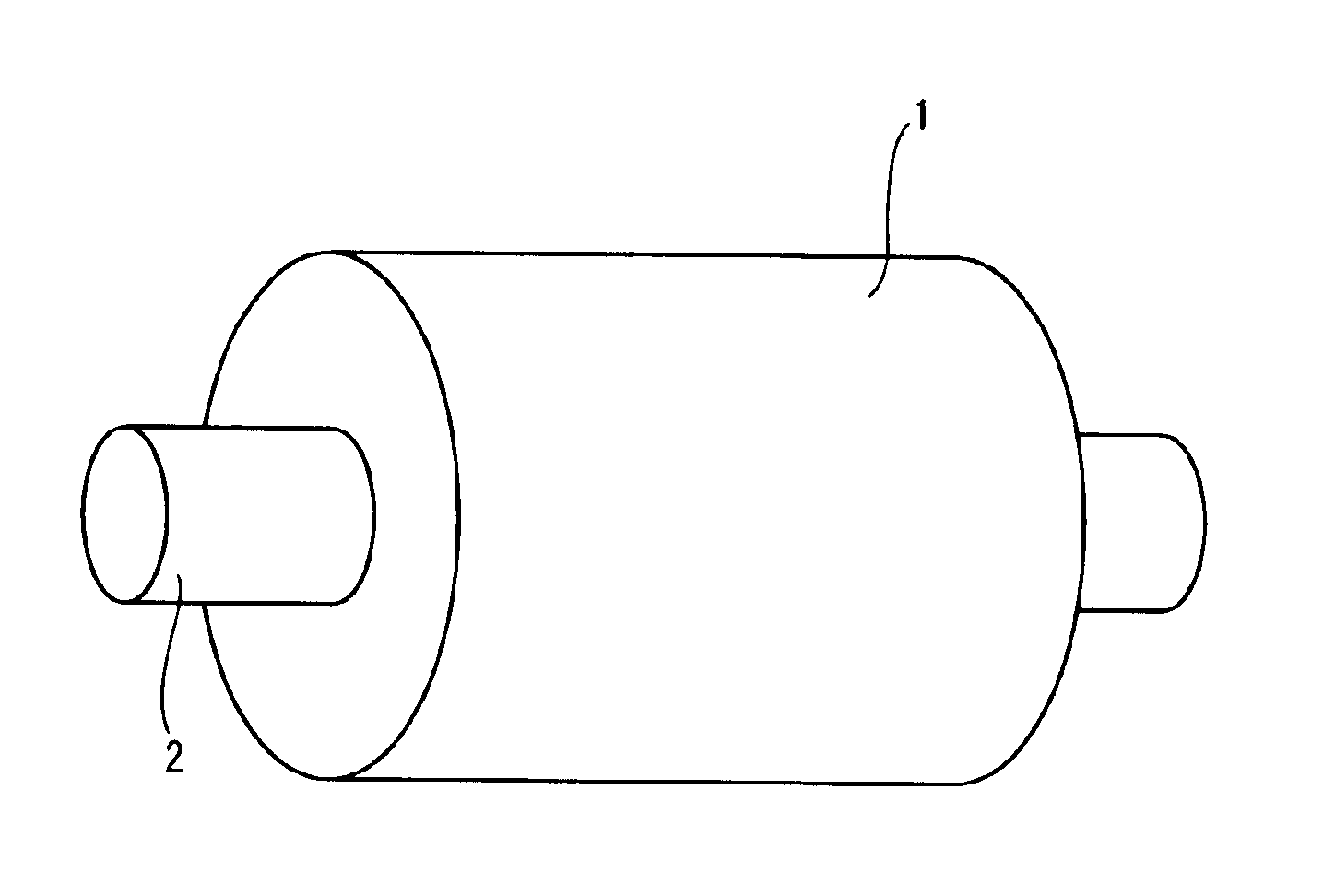

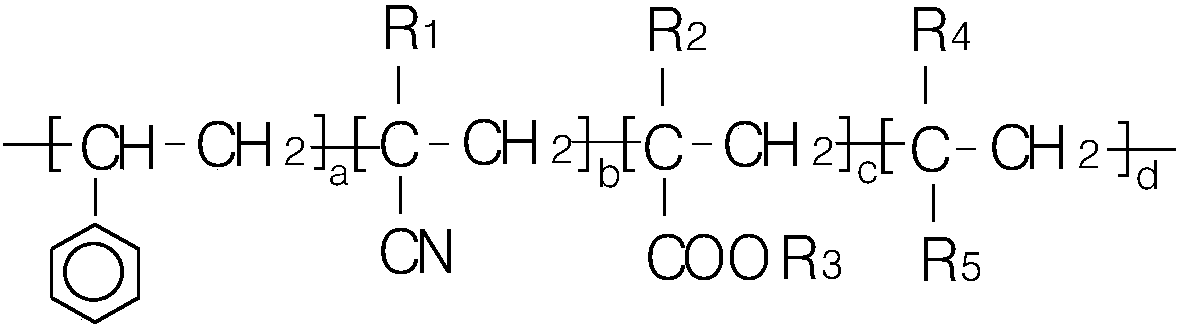

Elastomer composition and rubber roller composed thereof

ActiveUS6919401B2Superior in abilitySuperior in resistanceShaft and bearingsPrinting roller shellsElastomerPolymer science

A rubber roller formed by molding an elastomer composition not less than 250 μs nor more than 400 μs in a T2 relaxation time (spin-spin relaxation) of a bound rubber formed between a rubber and / or a thermoplastic elastomer and a reinforcing filler. EPDM can be used as the rubber and / or the thermoplastic elastomer, carbon black as the reinforcing filler, and an organic peroxide as a crosslinking agent. The T2 relaxation time (spin-spin relaxation) of the bound rubber formed between the rubber and / or thermoplastic elastomer and the reinforcing filler is more than a T2 relaxation time of a bound rubber of the rubber and / or thermoplastic elastomer to which the reinforcing filler is not added by not less than 150% nor more than 300%.

Owner:SUMITOMO RUBBER IND LTD

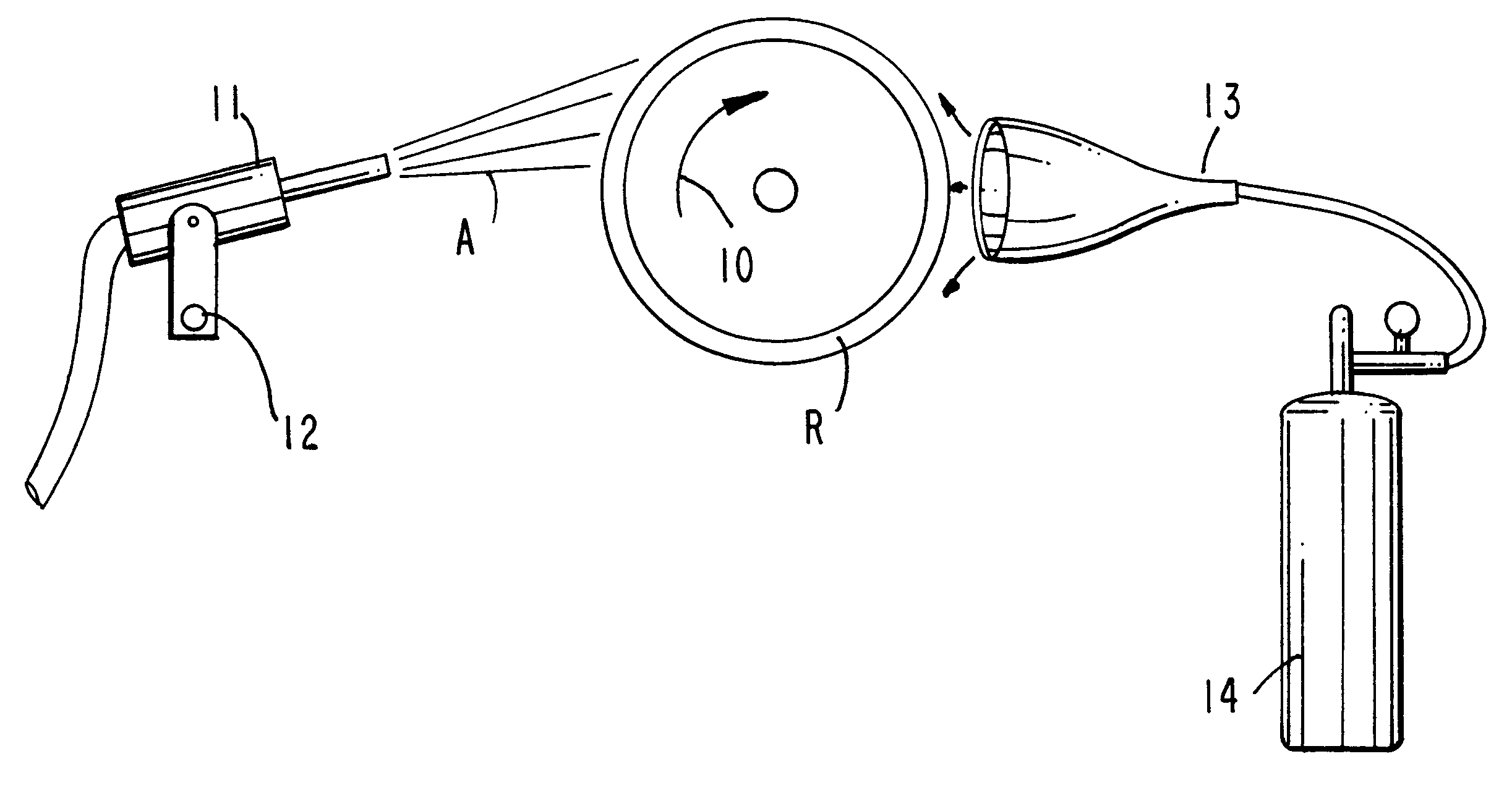

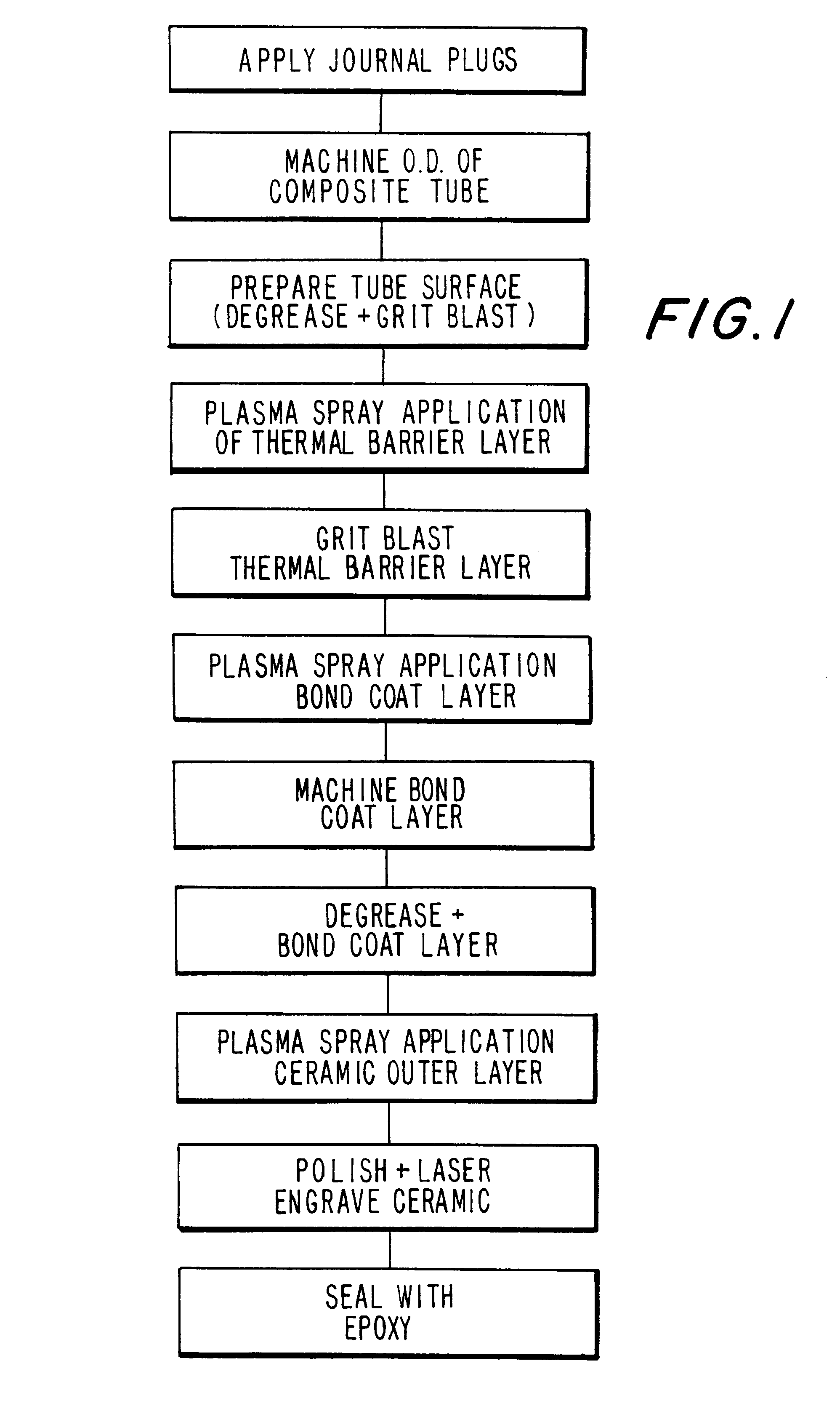

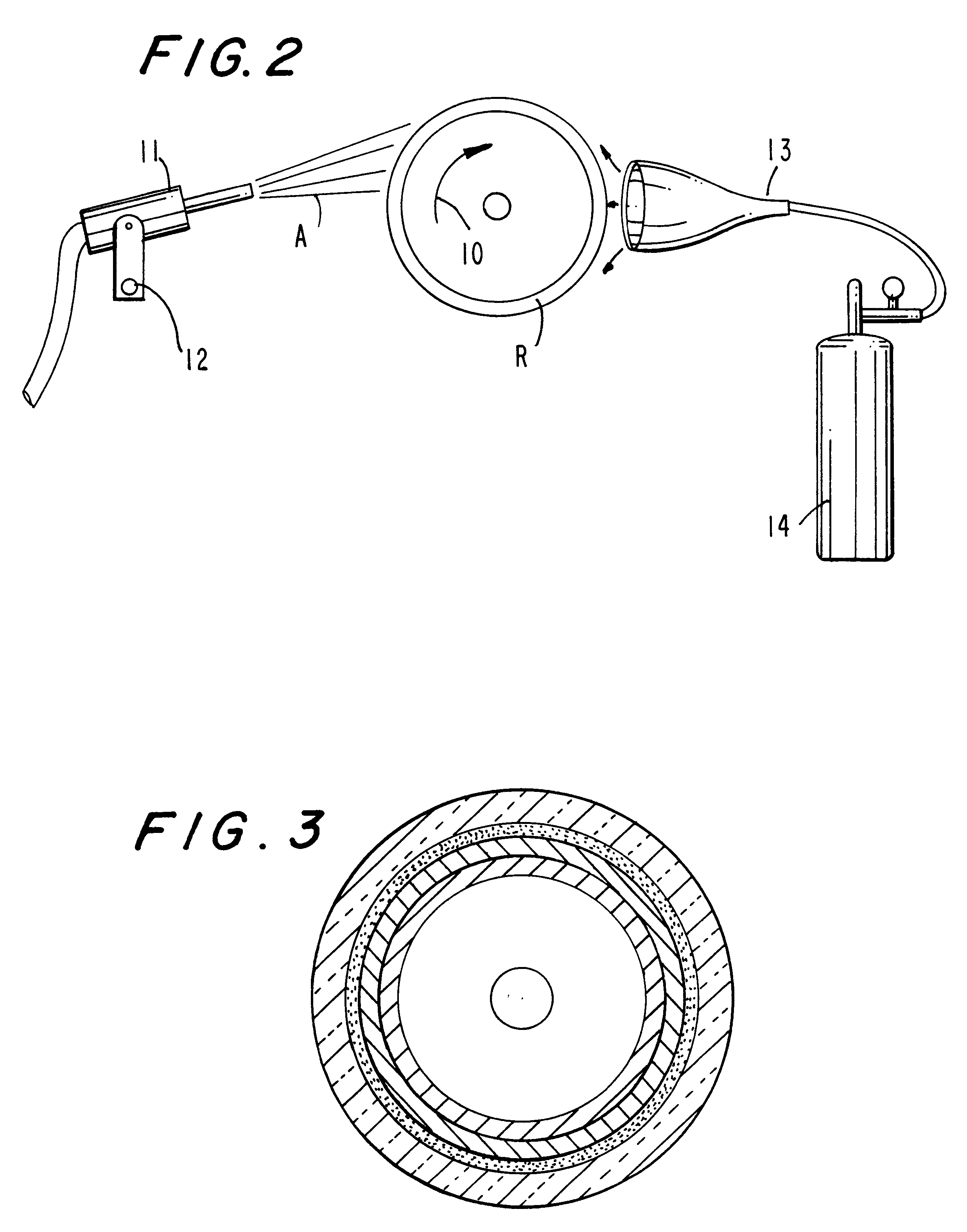

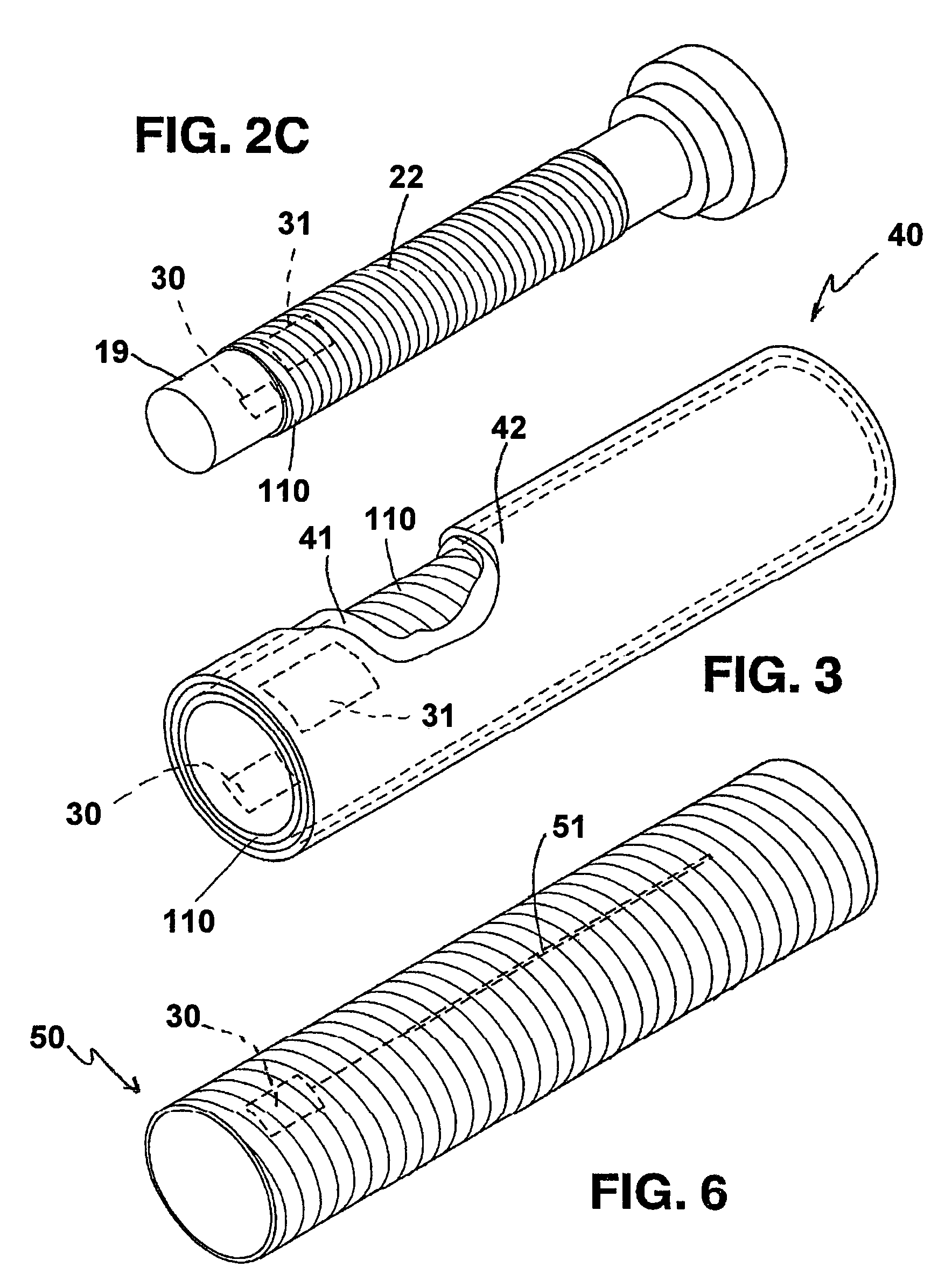

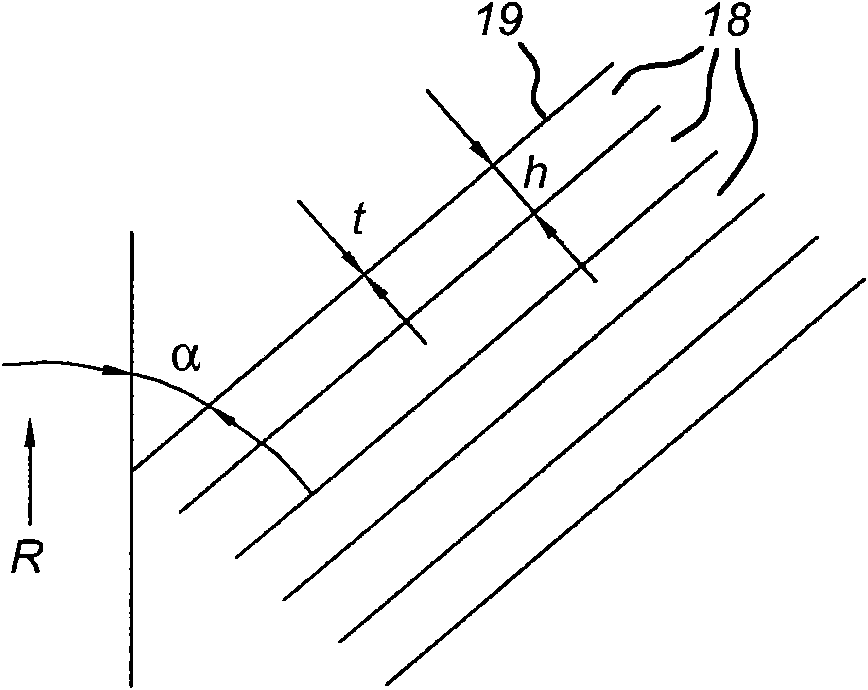

Fluid metering roll and method of making the same

A fluid metering roll such as an anilox roll is comprised of a tubular carbon fiber composition core having one or more metallic layers intervening between the core and a surface layer comprised of ceramic, the ceramic having outwardly opening fluid metering cells. The method of forming the roll includes steps of thermal spray applying one or more layers comprised of metal over the roll surface the layers intervening between the roll and an external ceramic coating. Characterizing features of the application method reside in each of the thermal spray applied layers being directed toward the core at a negative rake angle of from about 11½ to about 13½ and preferably 12½°, the core and layers which receive the thermal spray being simultaneously cooled to about 110° Centigrade or less during application of the thermal spray. The method and article are further characterized in that the coefficient of thermal expansion of the layers intervening between the core and the outermost ceramic layer form a progression whereby the intermediate layers have thermal characteristics which progressively become smaller in the outward direction.

Owner:PAMARCO

Apparatus and process for forming a printing form having a cylindrical support

Owner:DUPONT ELECTRONICS INC

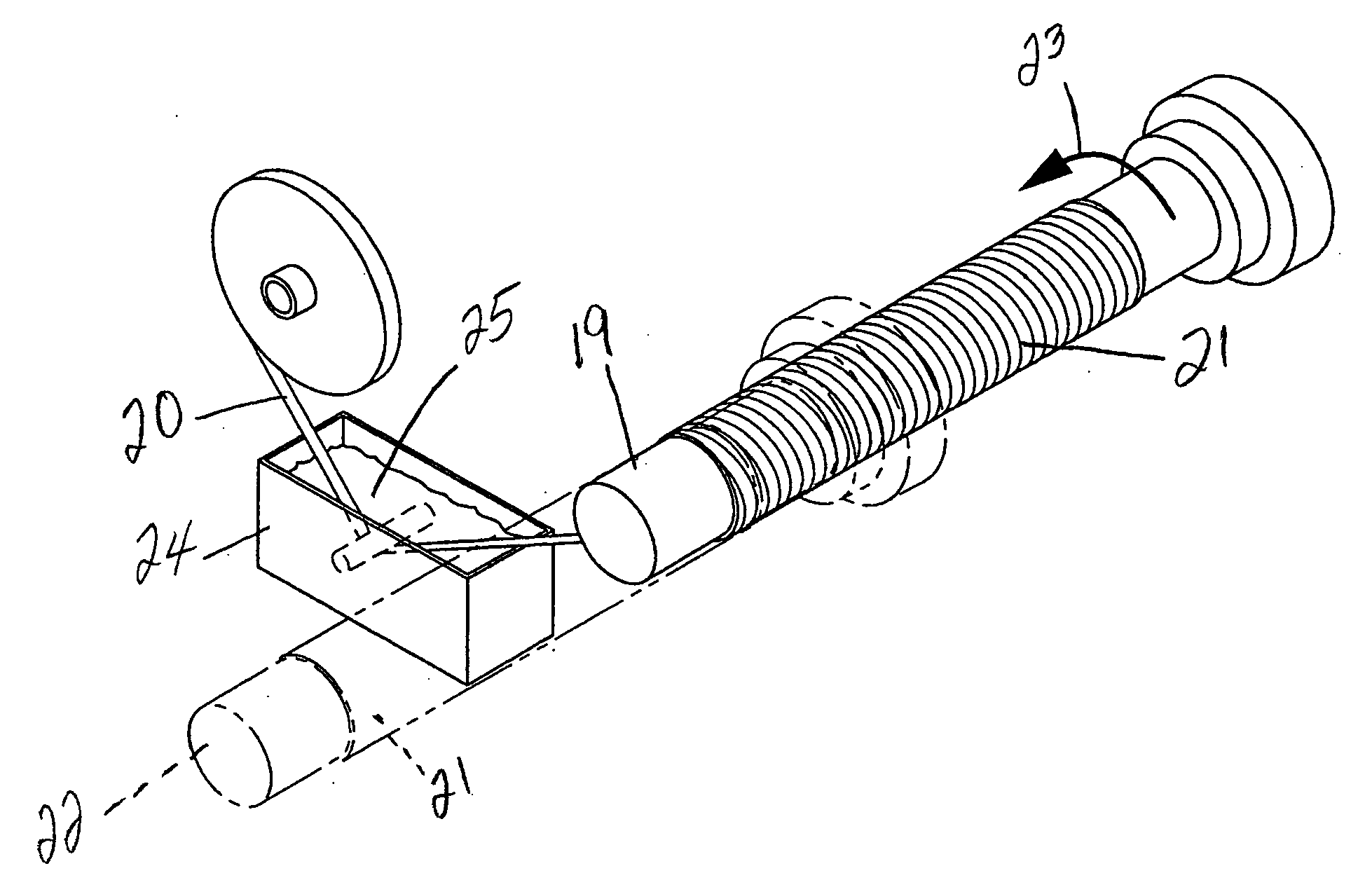

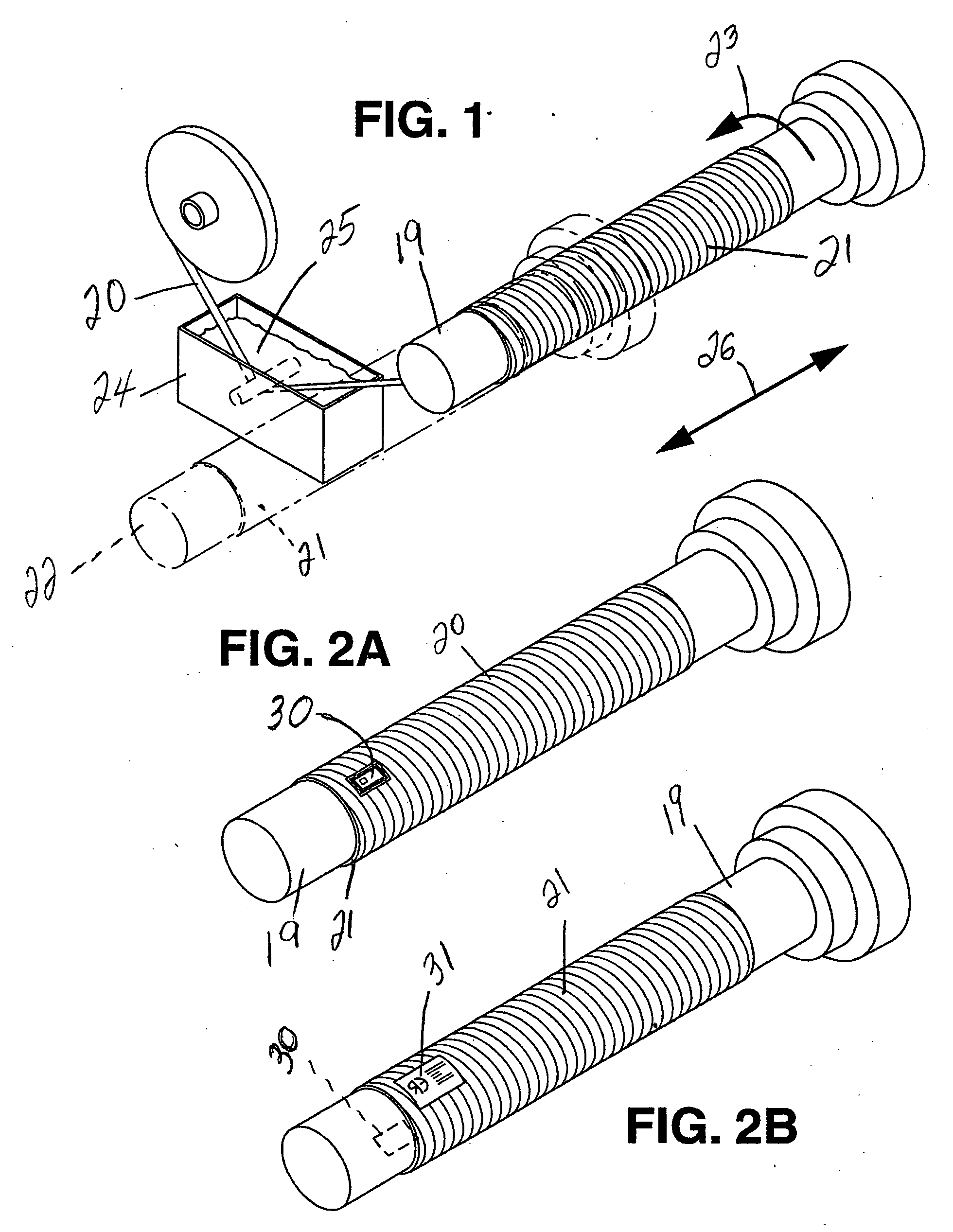

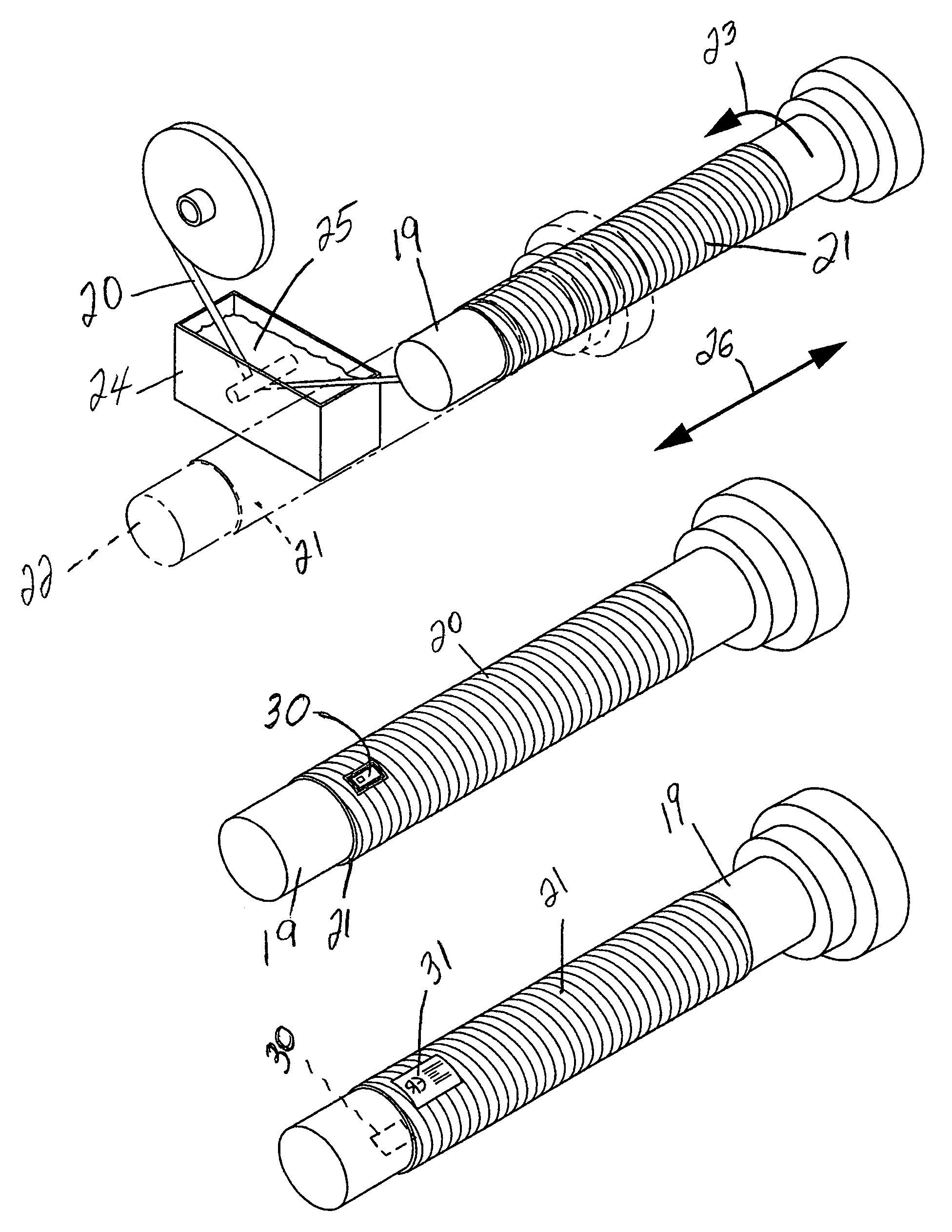

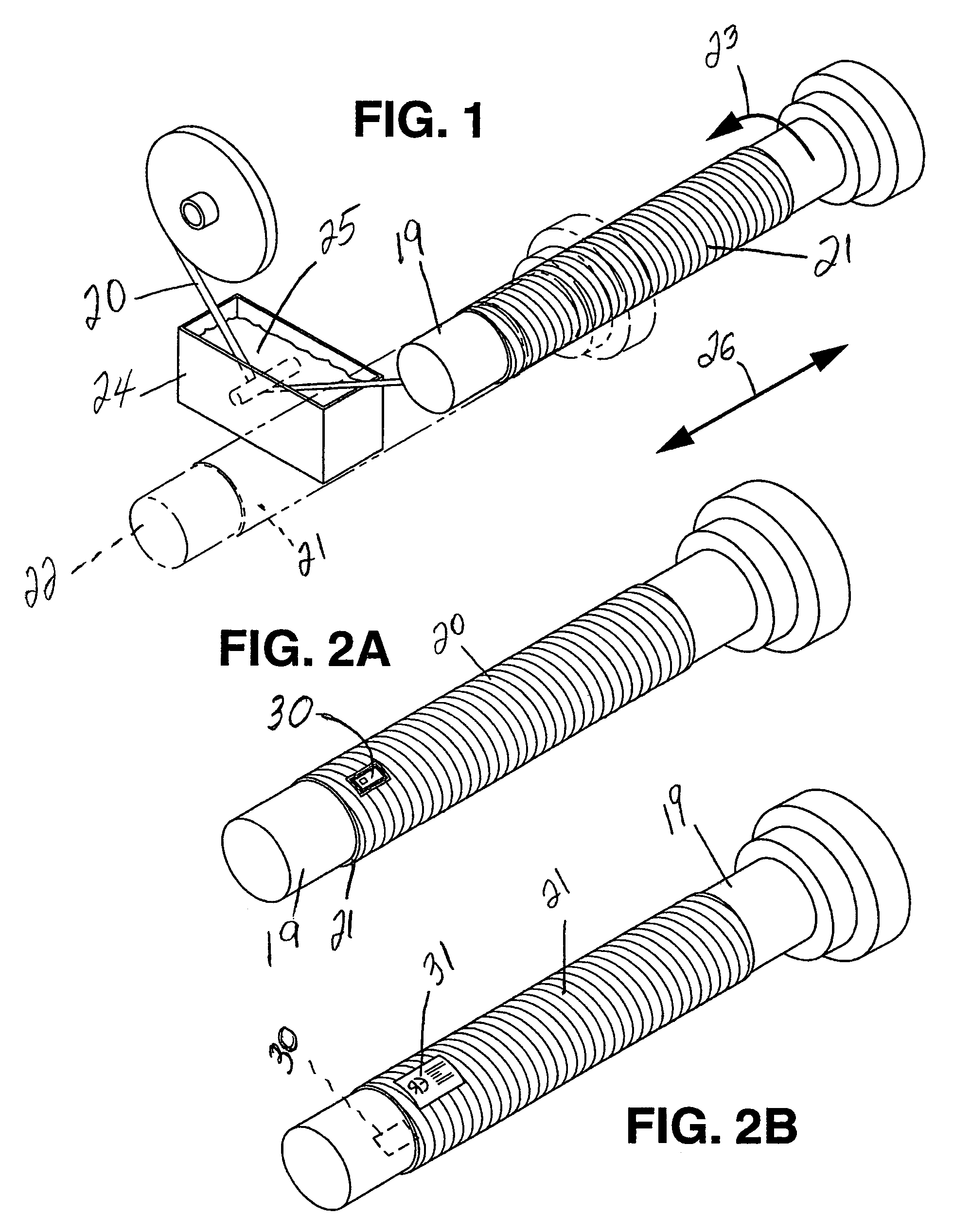

Printing member provided with identification means defined by or connectable to updateable means for recording data relative to the member and useful for its utilization

ActiveUS20050194087A1Easy to readAddressographsPaper/cardboard wound articlesIdentification deviceMetal cylinder

A printing member such as a printing cylinder includes an at least partly metal cylinder, or a sleeve to be mounted on a mandrel rotating about its axis. The printing member comprises a body having a thickness. With the printing member there is associated an activatable signaling device that is connectable to a recording device that is arranged to store data related to at least one characteristic of the printing member or to the use of the printing member. The activatable signaling device can include a transponder such as an RFID.

Owner:ROSSINI SPA

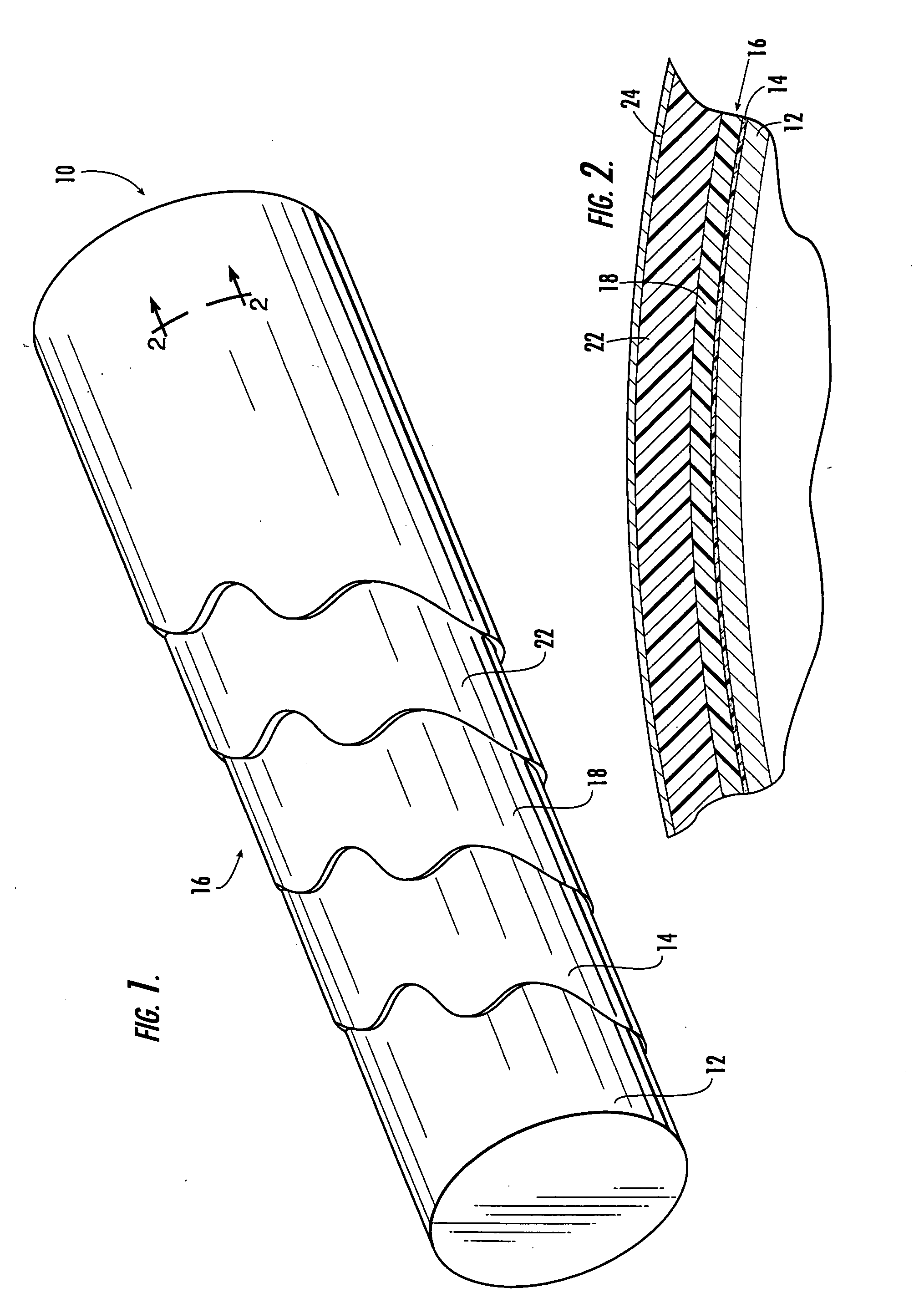

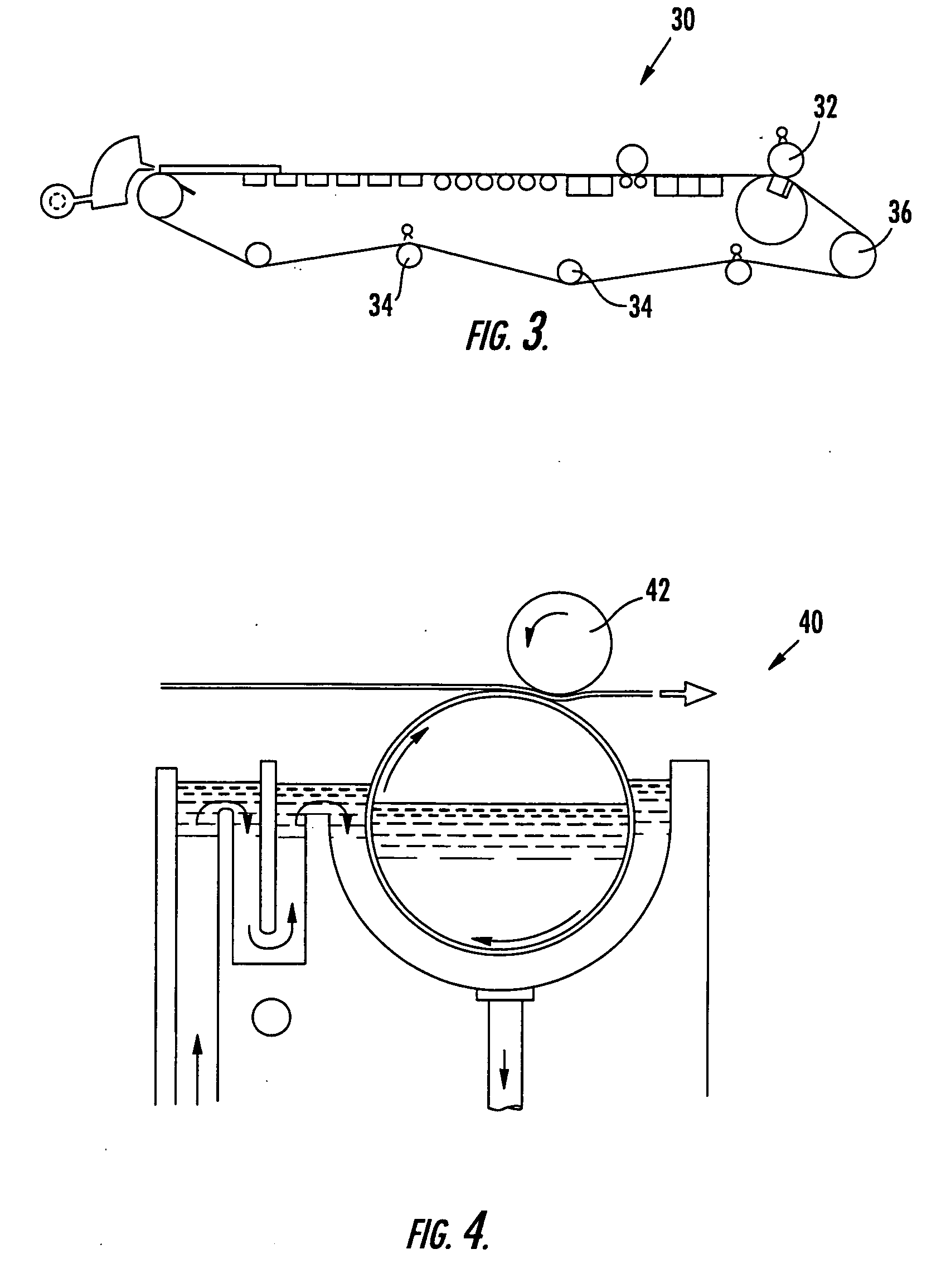

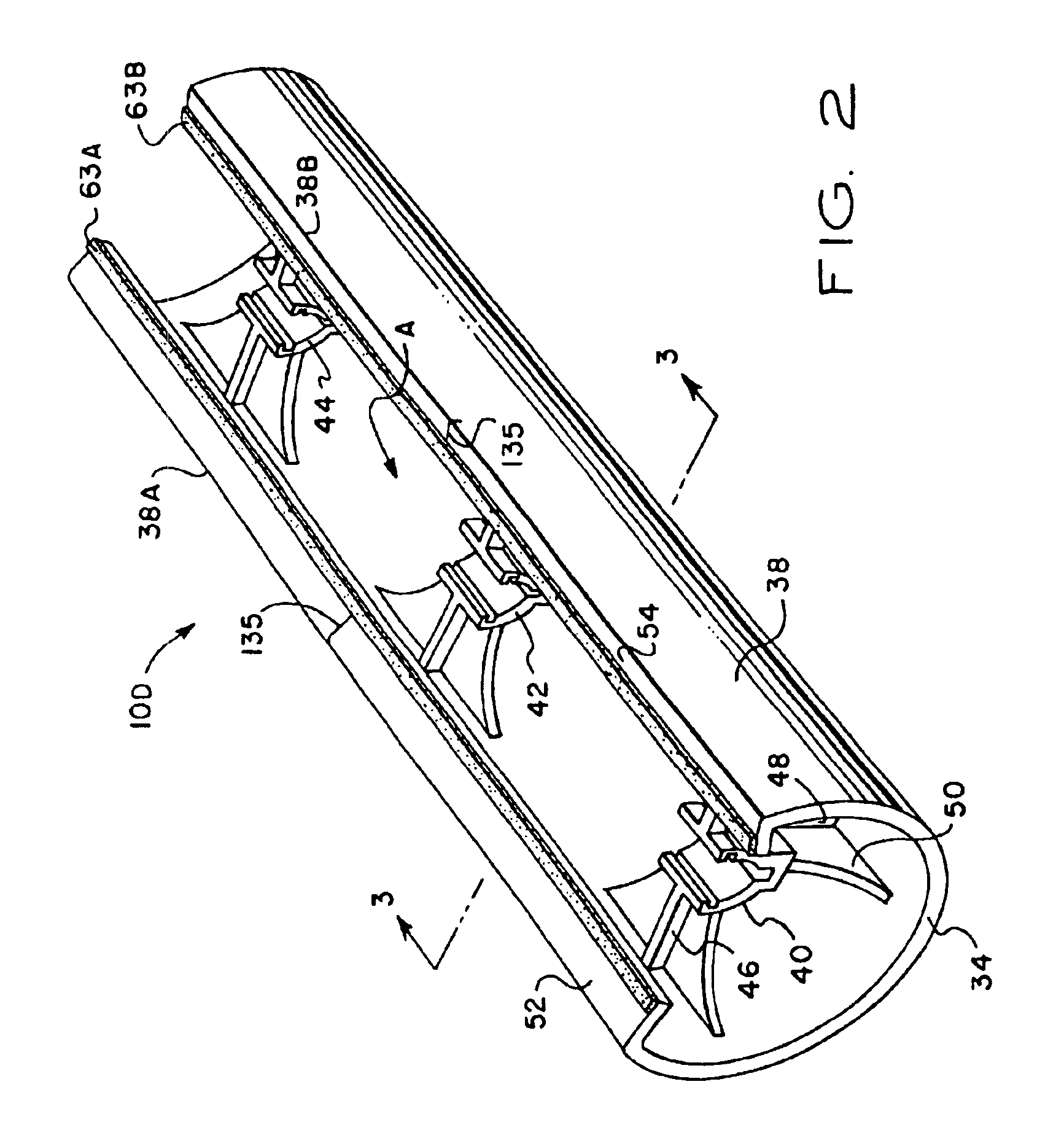

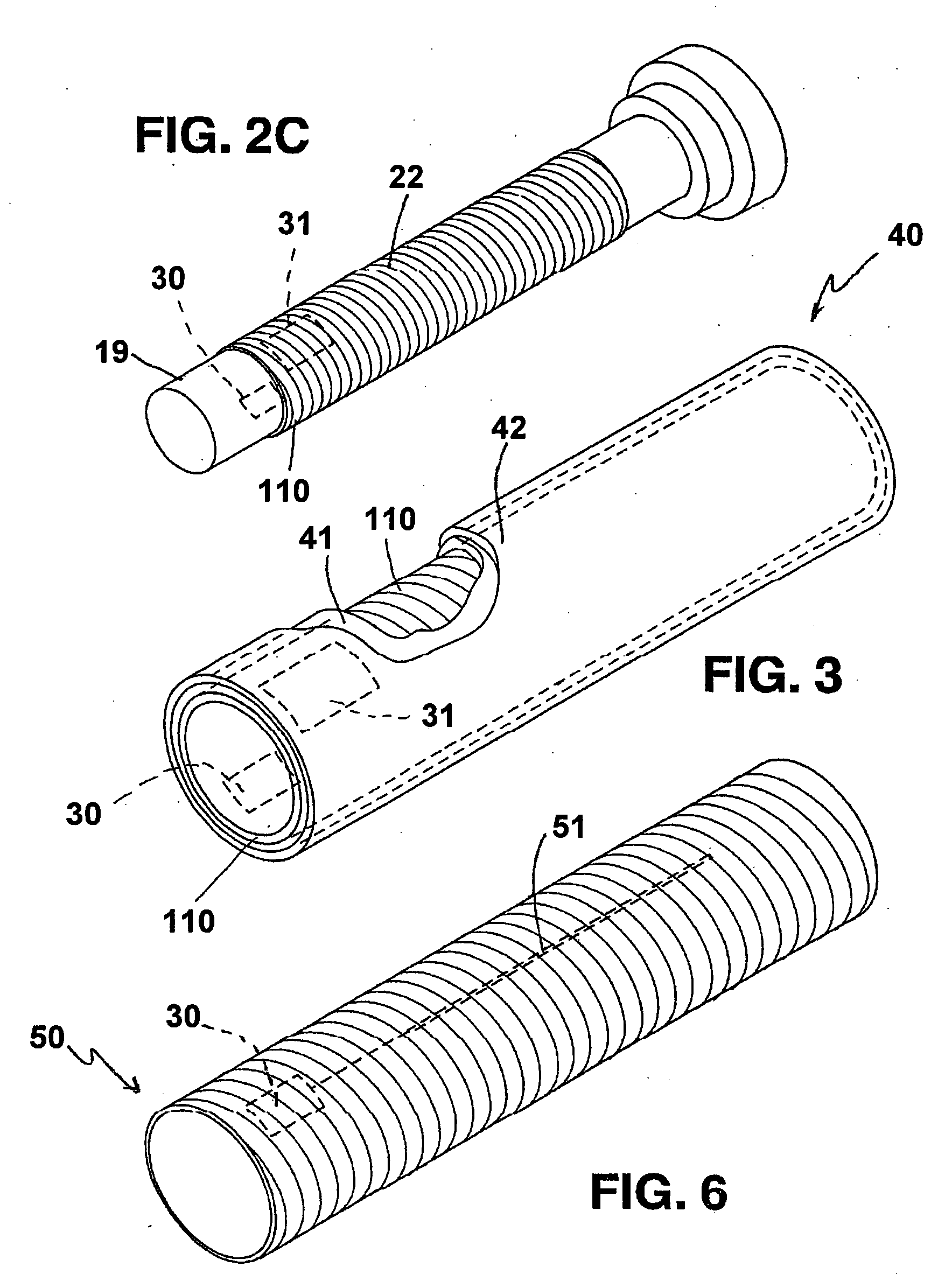

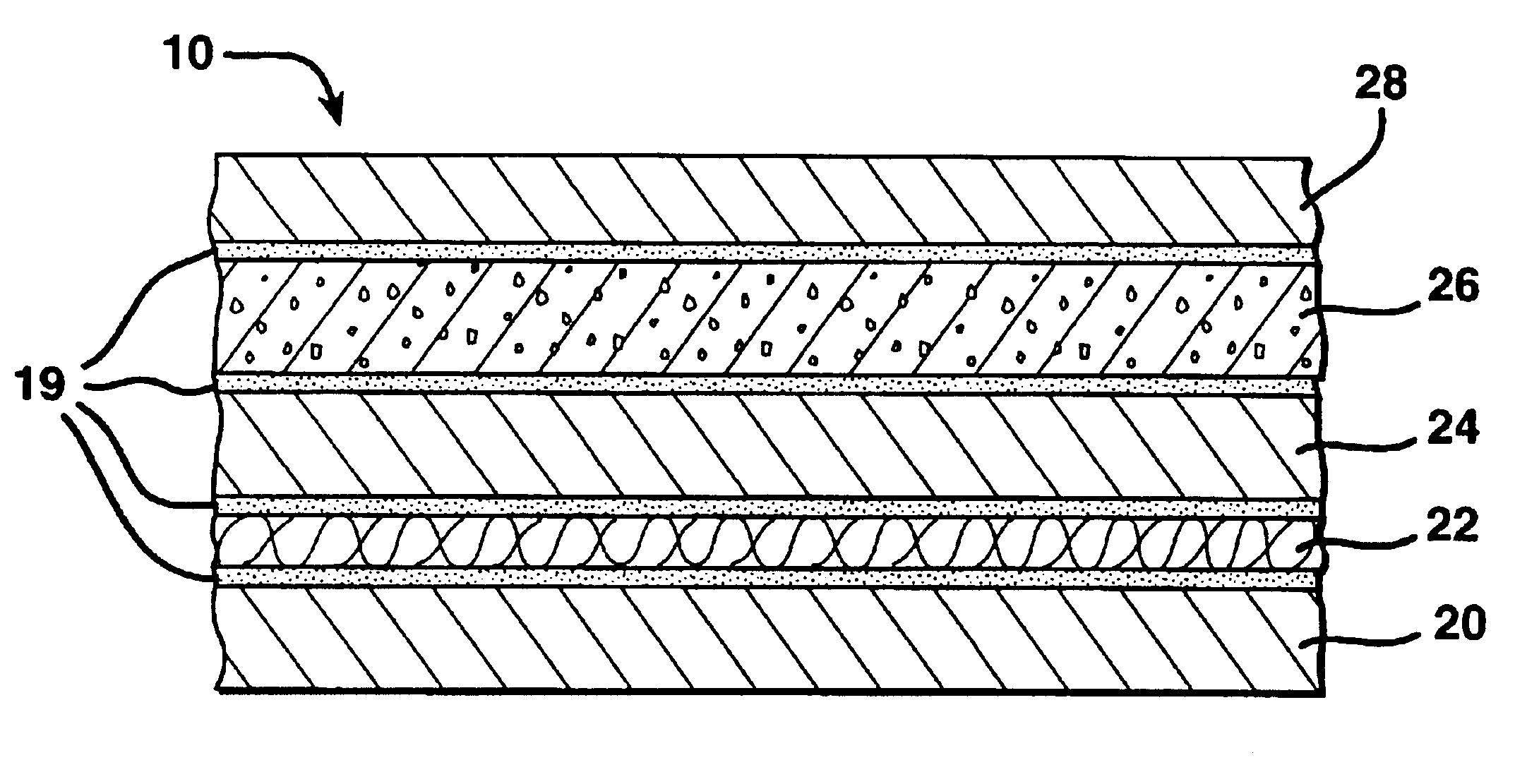

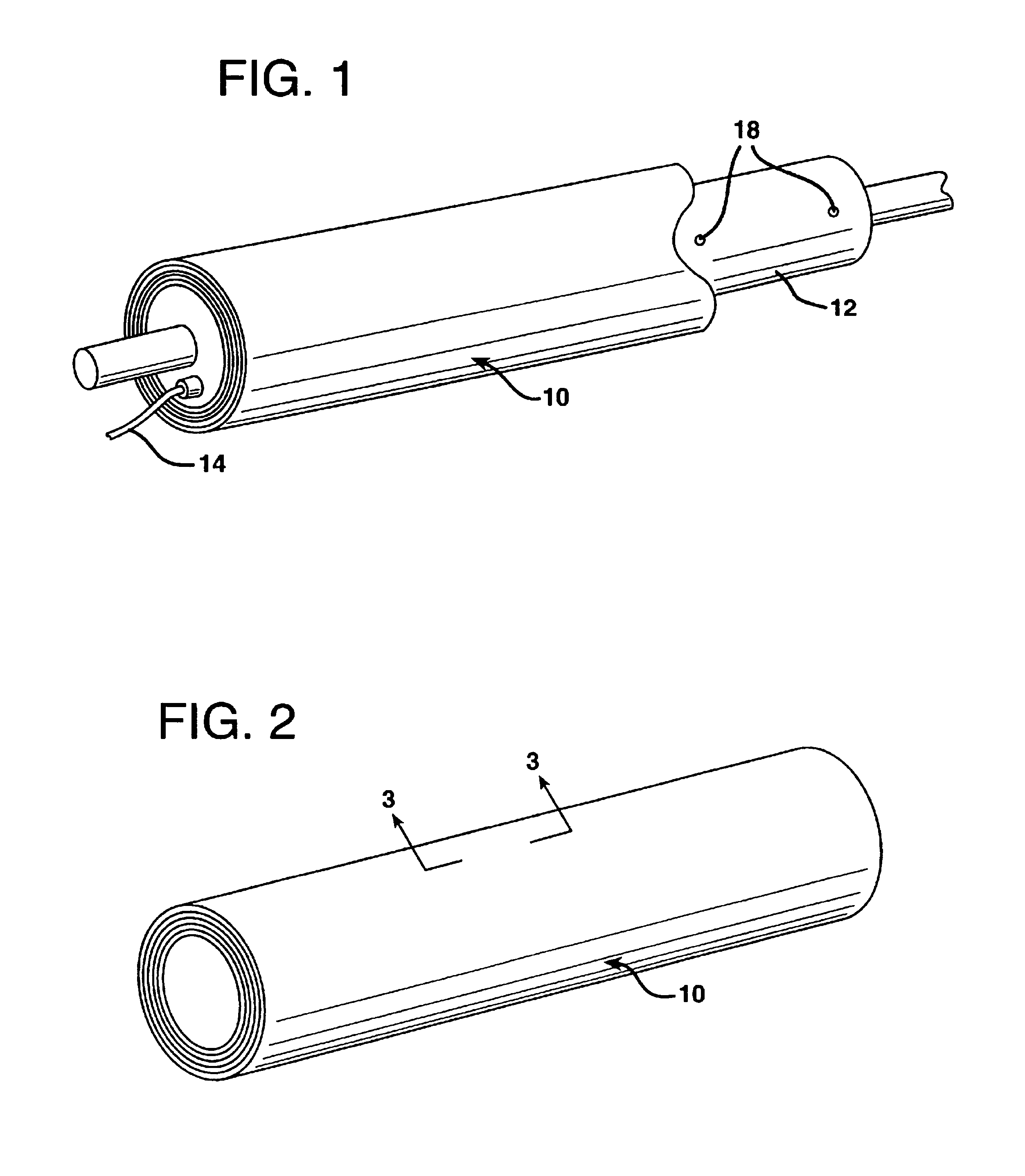

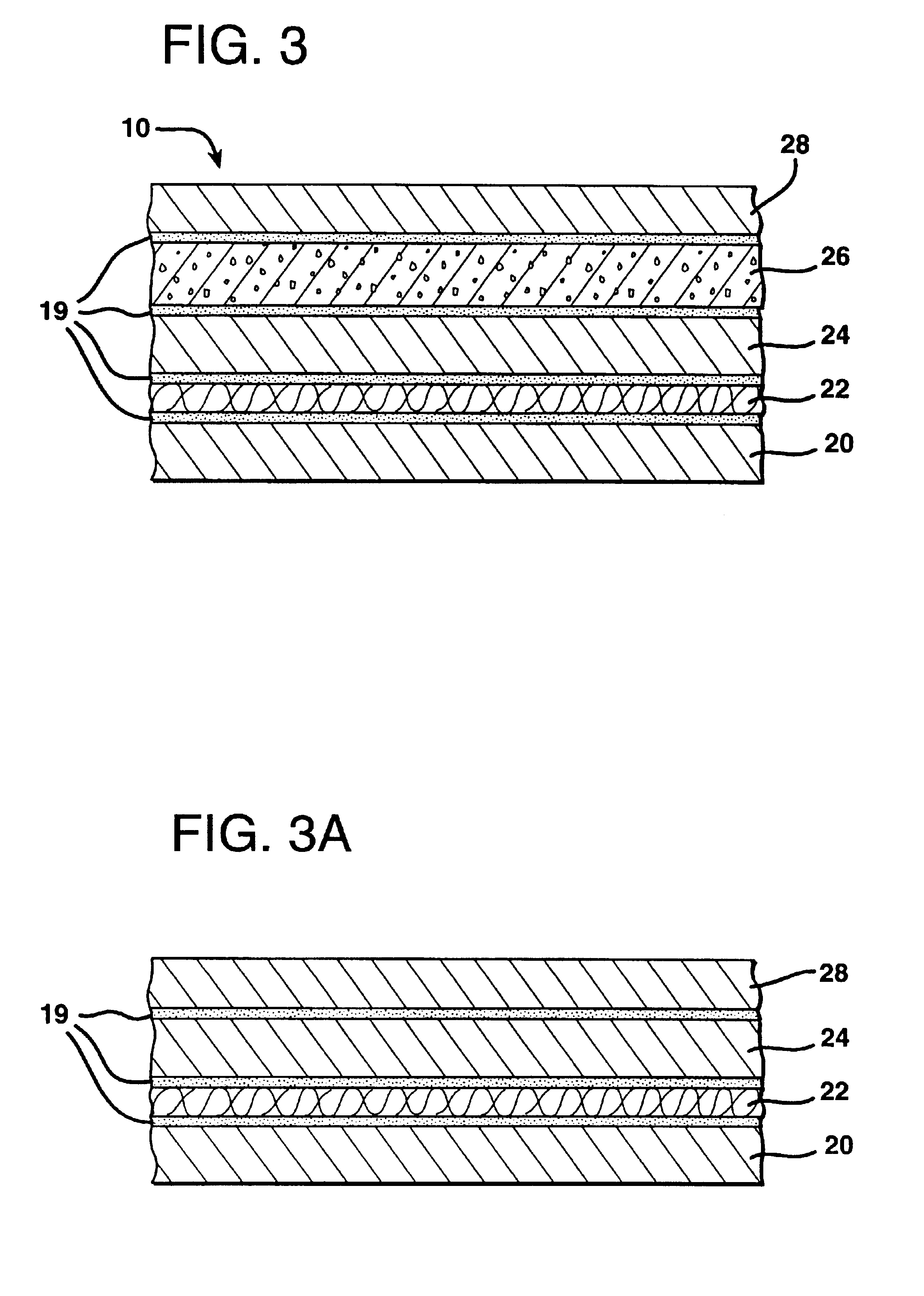

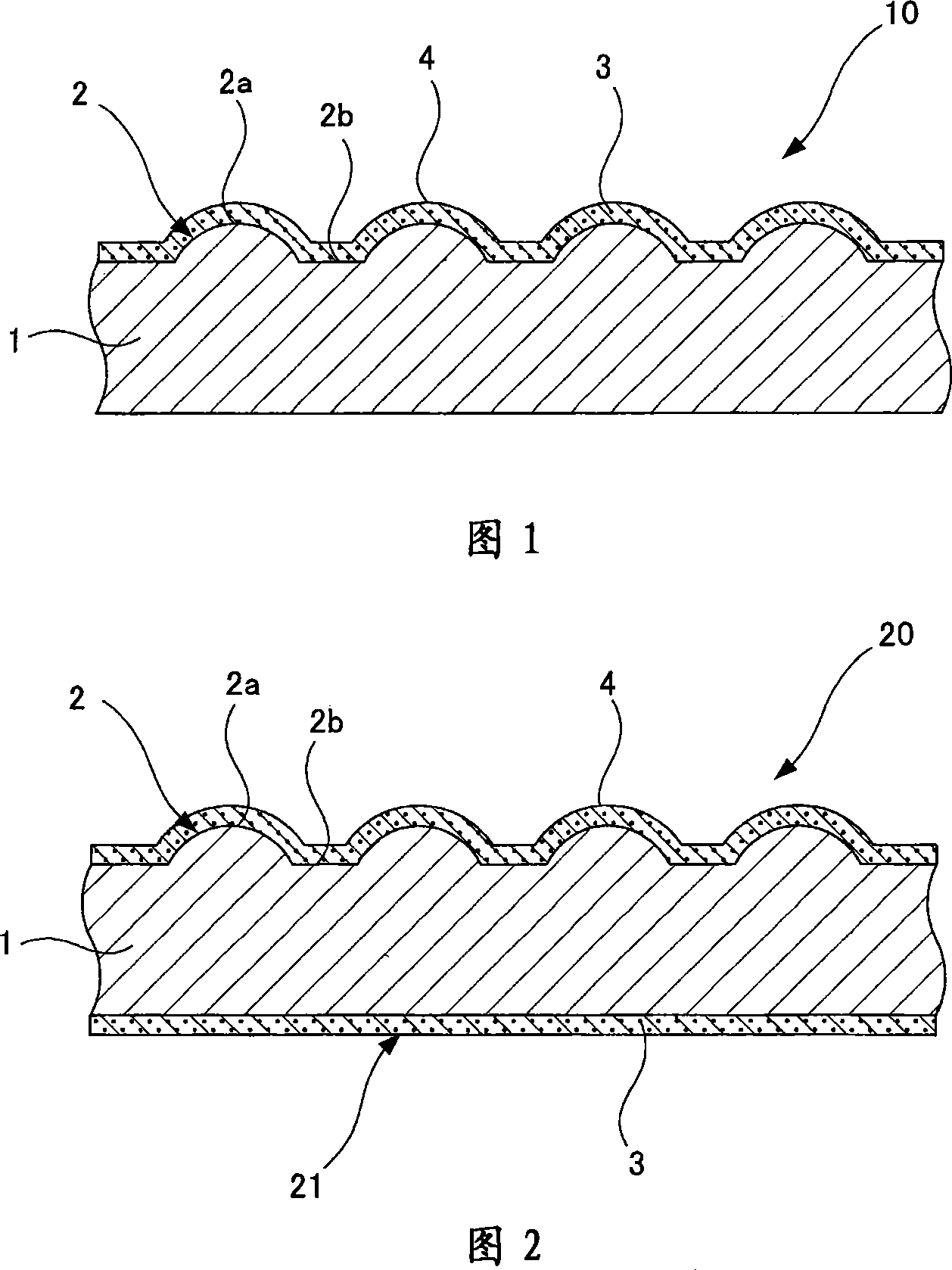

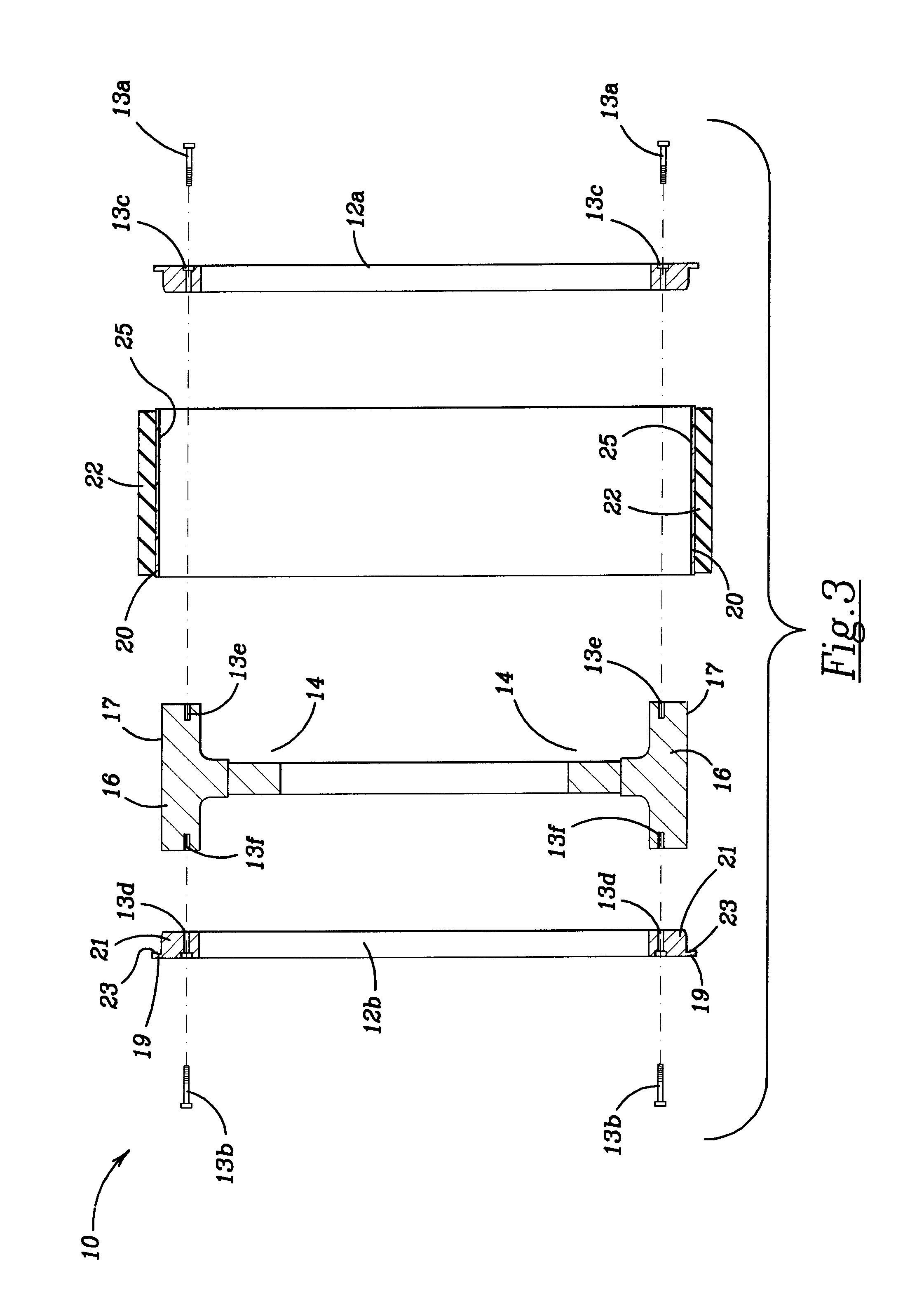

Replaceable sleeve

InactiveUSRE38468E1Easy to installEasy to makeShaft and bearingsSynthetic resin layered productsInter layerEngineering

A replaceable sleeve having a working surface is provided which is adapted to be mounted on a carrier. The sleeve includes an inner polymeric layer, a reinforcing layer overlying the inner layer, an intermediate polymeric layer overlying the reinforcing layer, and an outer polymeric layer. The sleeve may include a cushion layer between the intermediate layer and the outer layer. The layers comprising the sleeve are formed around a support and then cured simultaneously in a single step. The resulting sleeve may be used in printing operations or in other applications such as coating, embossing, laminating, calendering and the like.

Owner:DAY INT

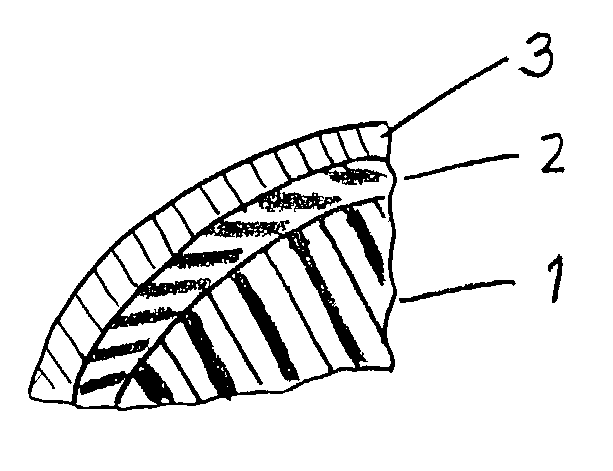

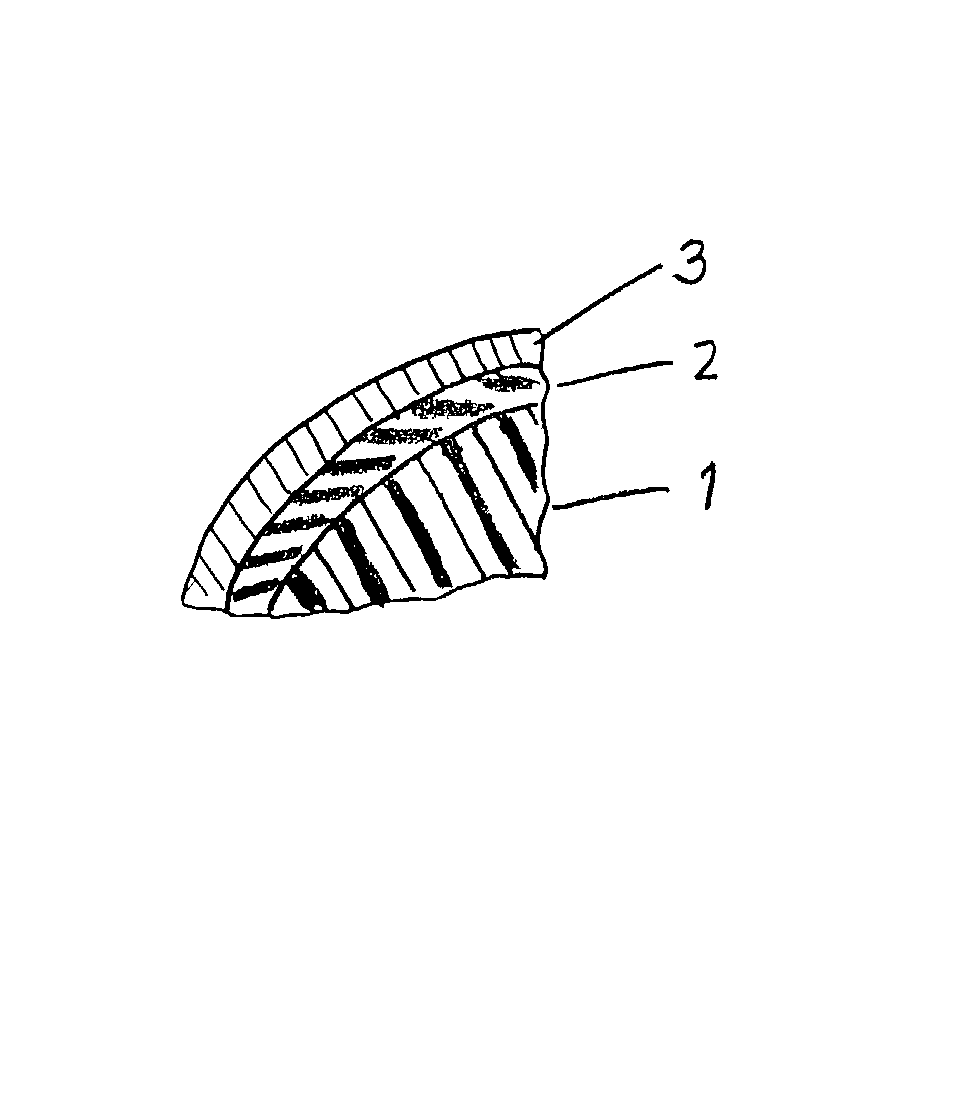

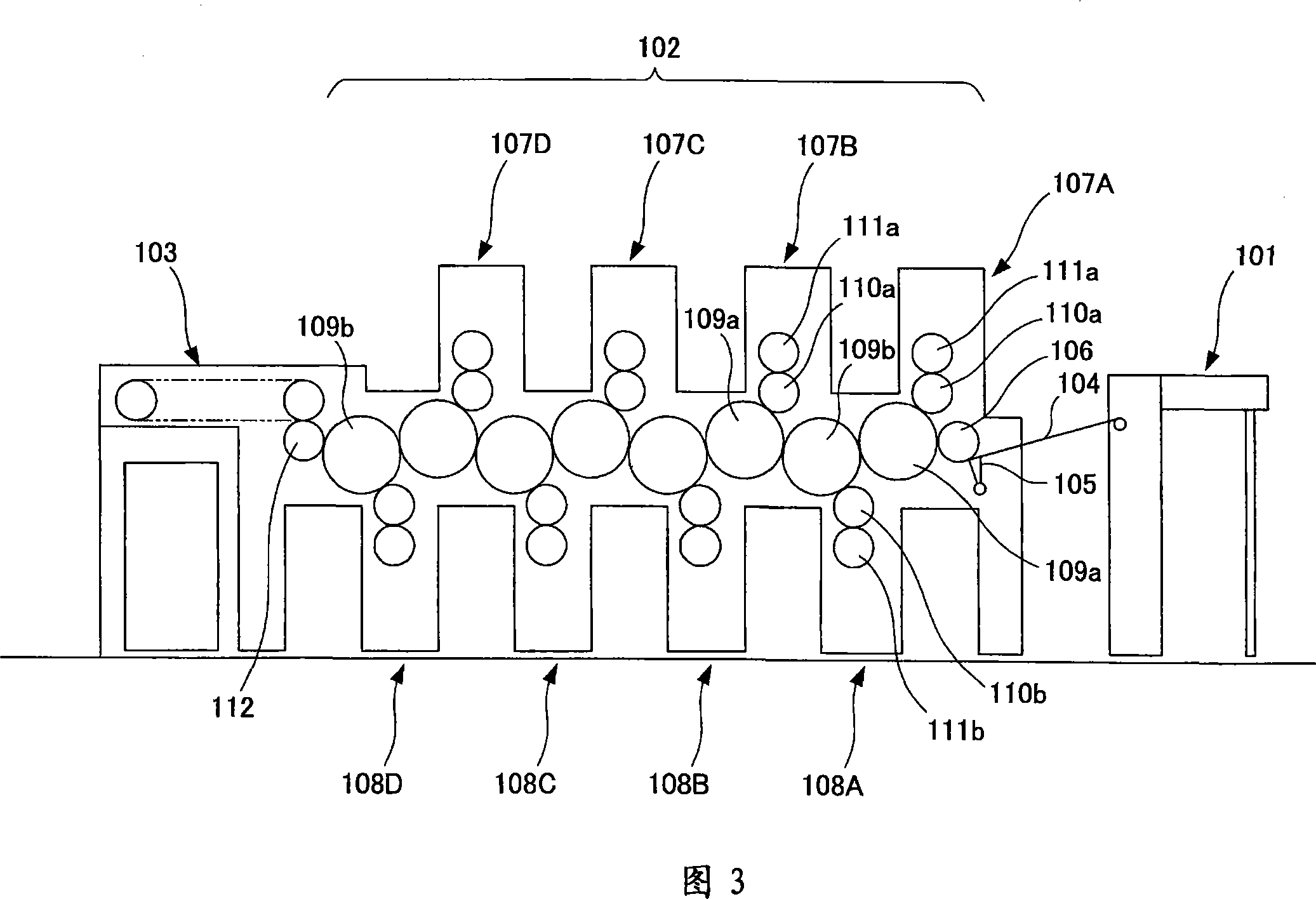

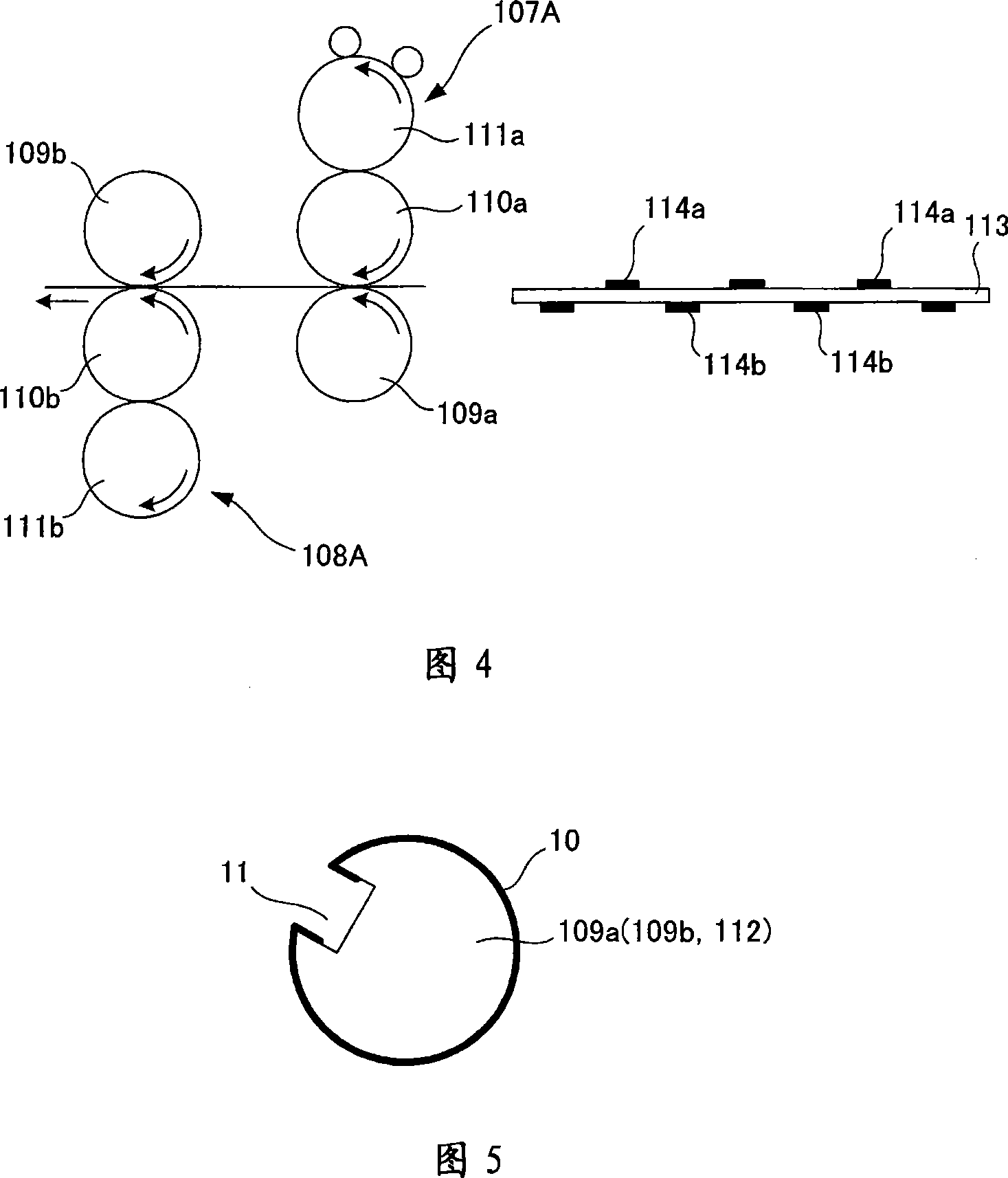

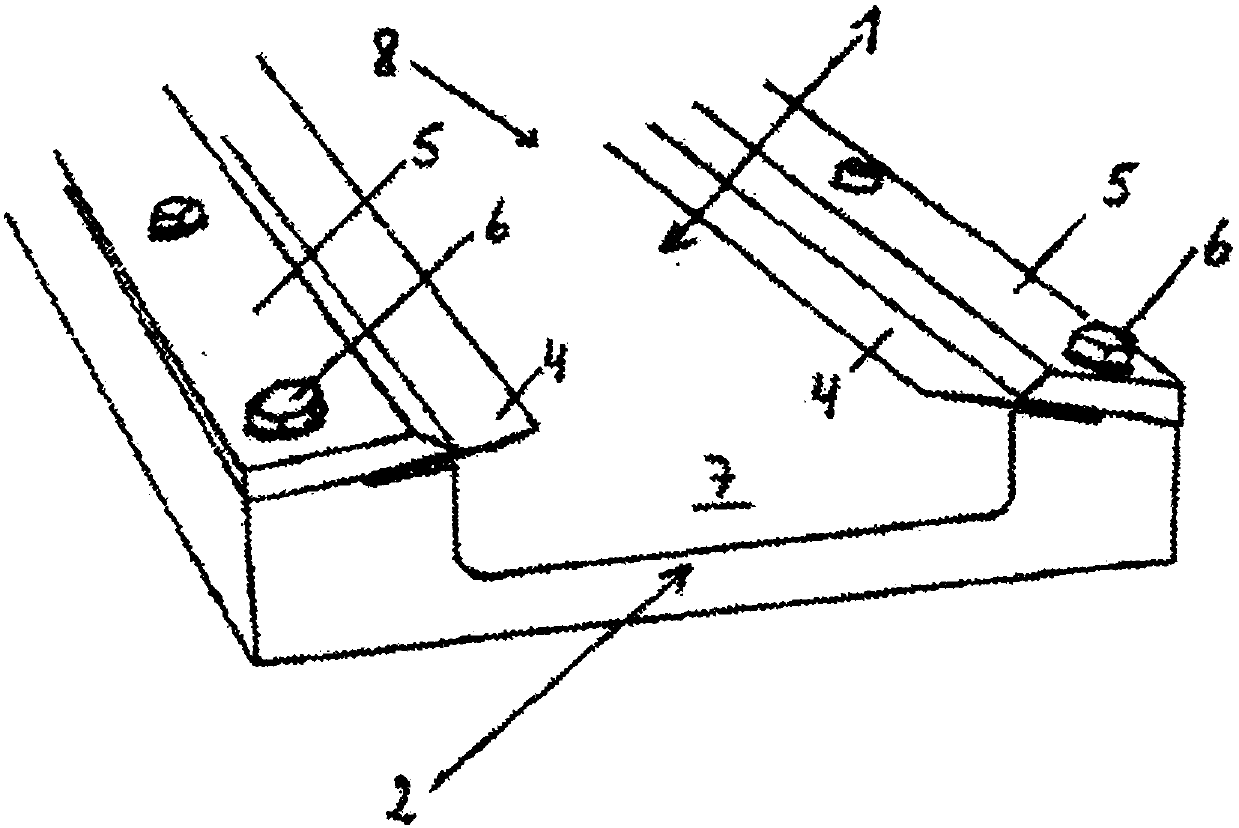

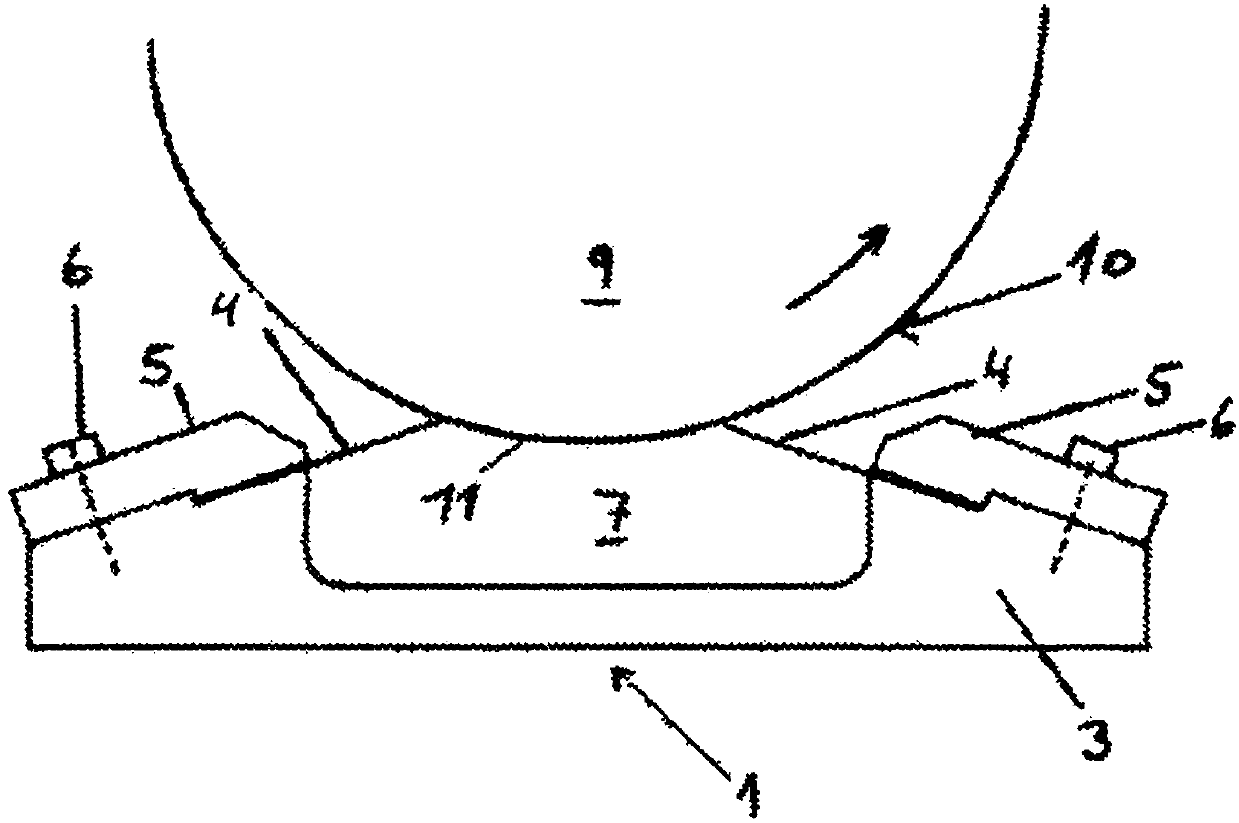

Jacket for impression cylinder or transport cylinder of printing press

InactiveCN101168332AResistance to adhesionAdhesion will notPrinting roller shellsPrinting press partsPrinting pressMechanical engineering

Disclosed is a jacket for any one of an impression cylinder (19a, 109b) and a transport cylinder (112) of a printing press, which jacket is wound around any one of the impression cylinder (19a,109b) and the transport cylinder (112) of a printing press so as to prevent ink from adhering to the cylinder, the jacket produced by plating the front side of a sheet-shaped base (1) having convex and concave portions (2) thereon with a metal having ink-repellent particles (3) dispersed therein, in a manner that the convex and concave portions (2) on the front side of the sheet-shaped base (1) are left.

Owner:KOMORI CORP

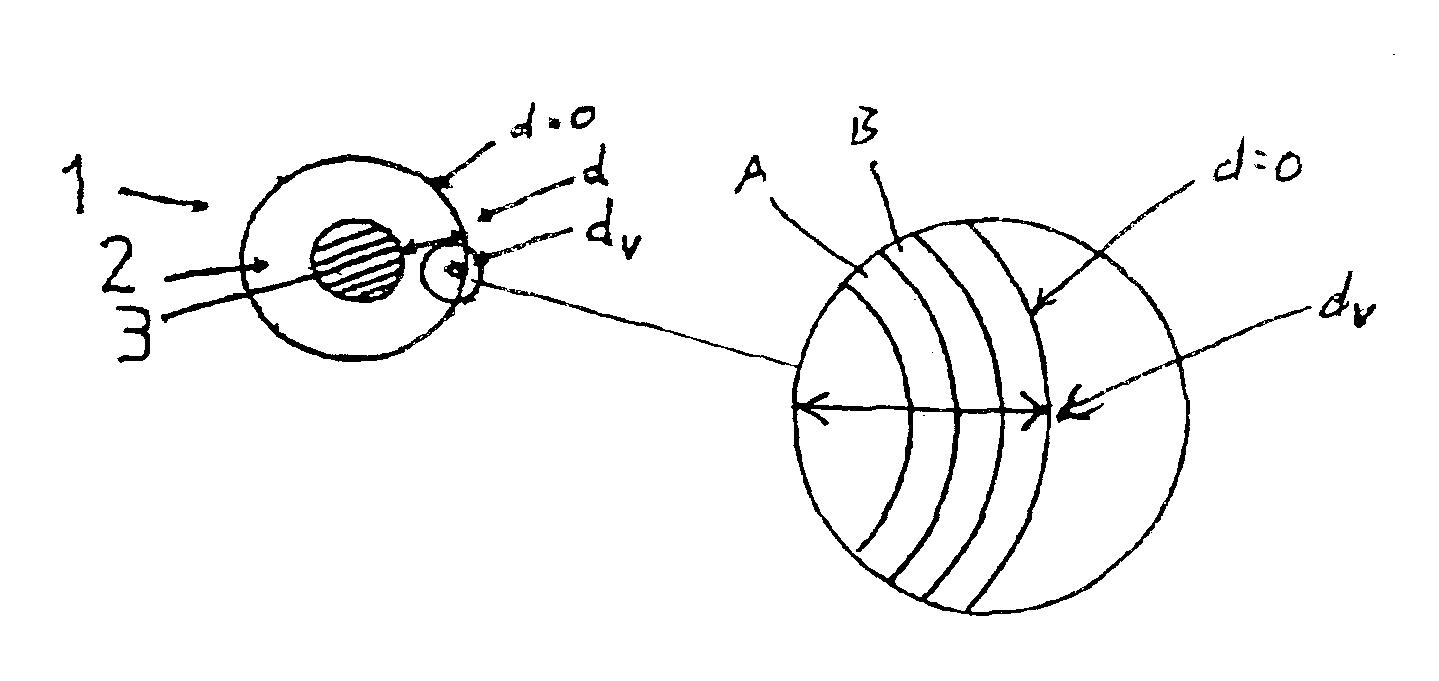

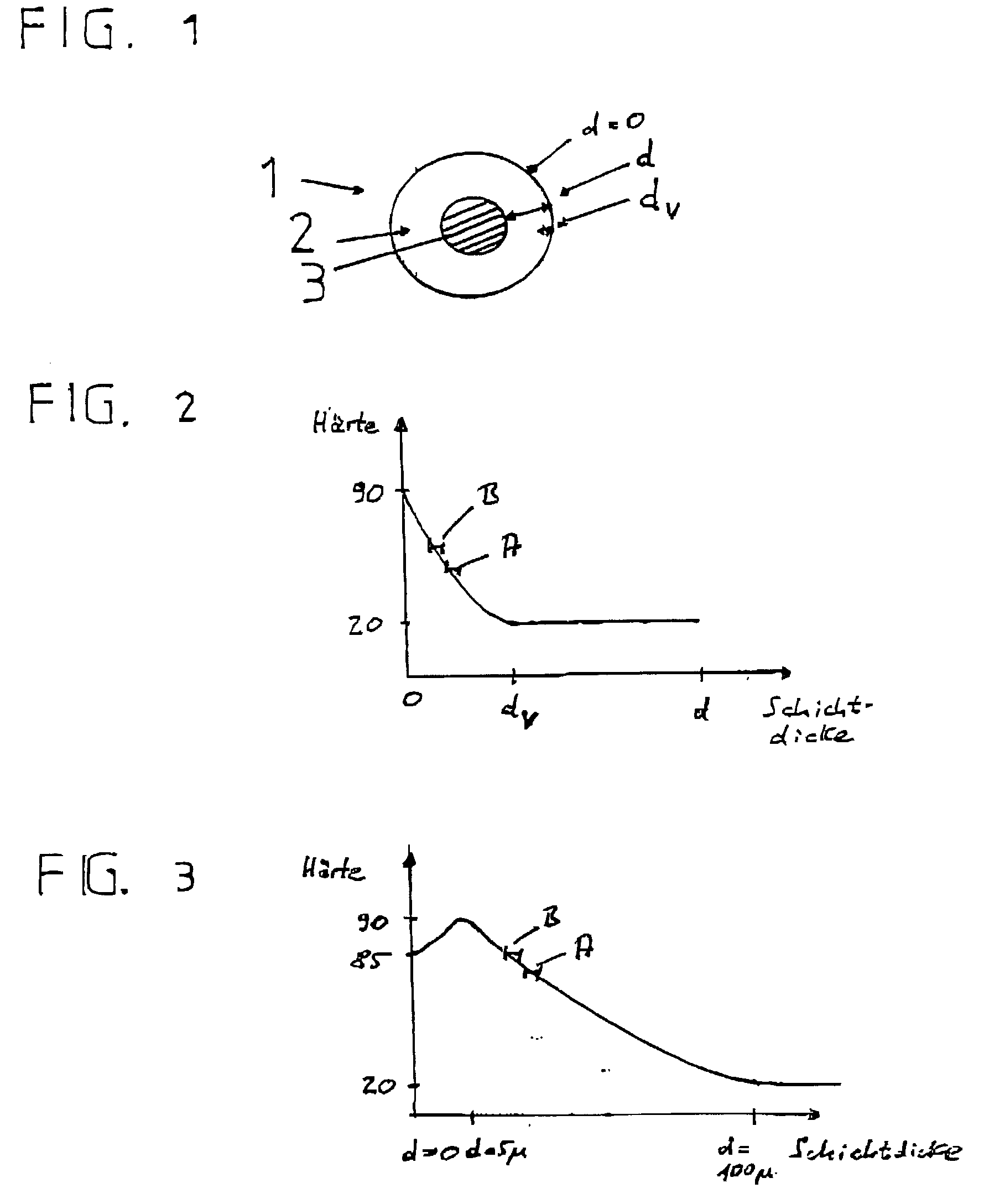

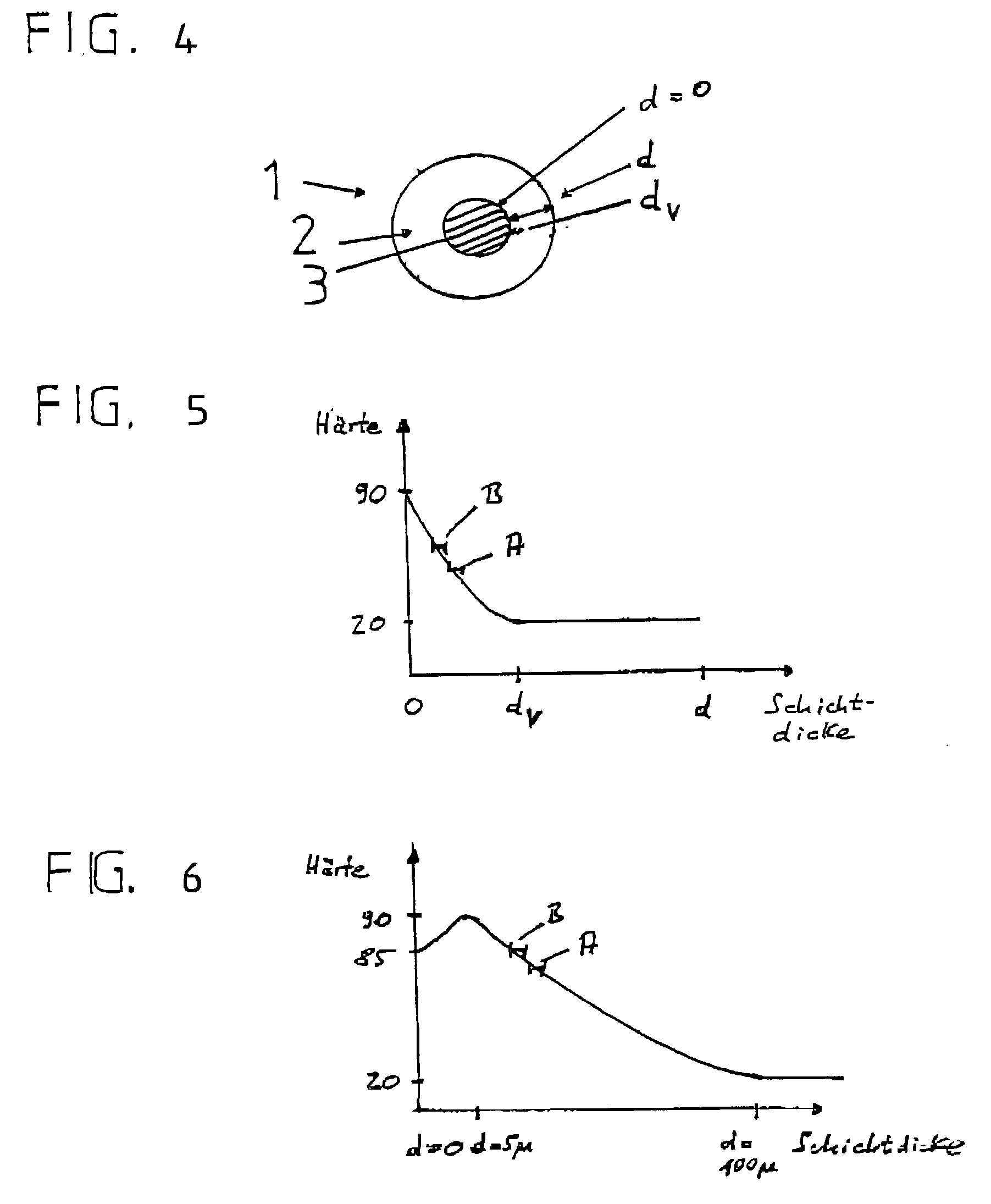

Roller for fluid film preparation or application

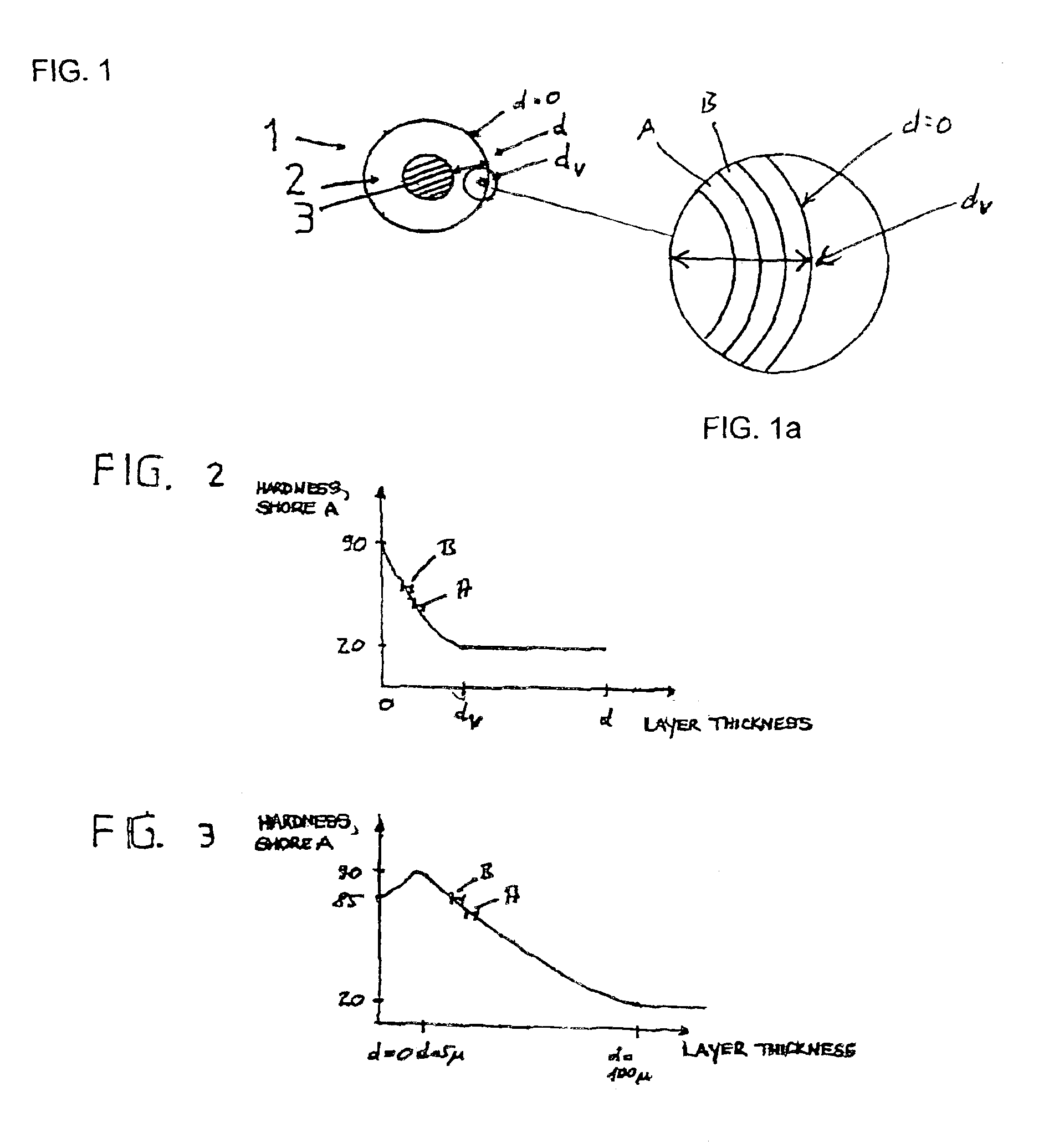

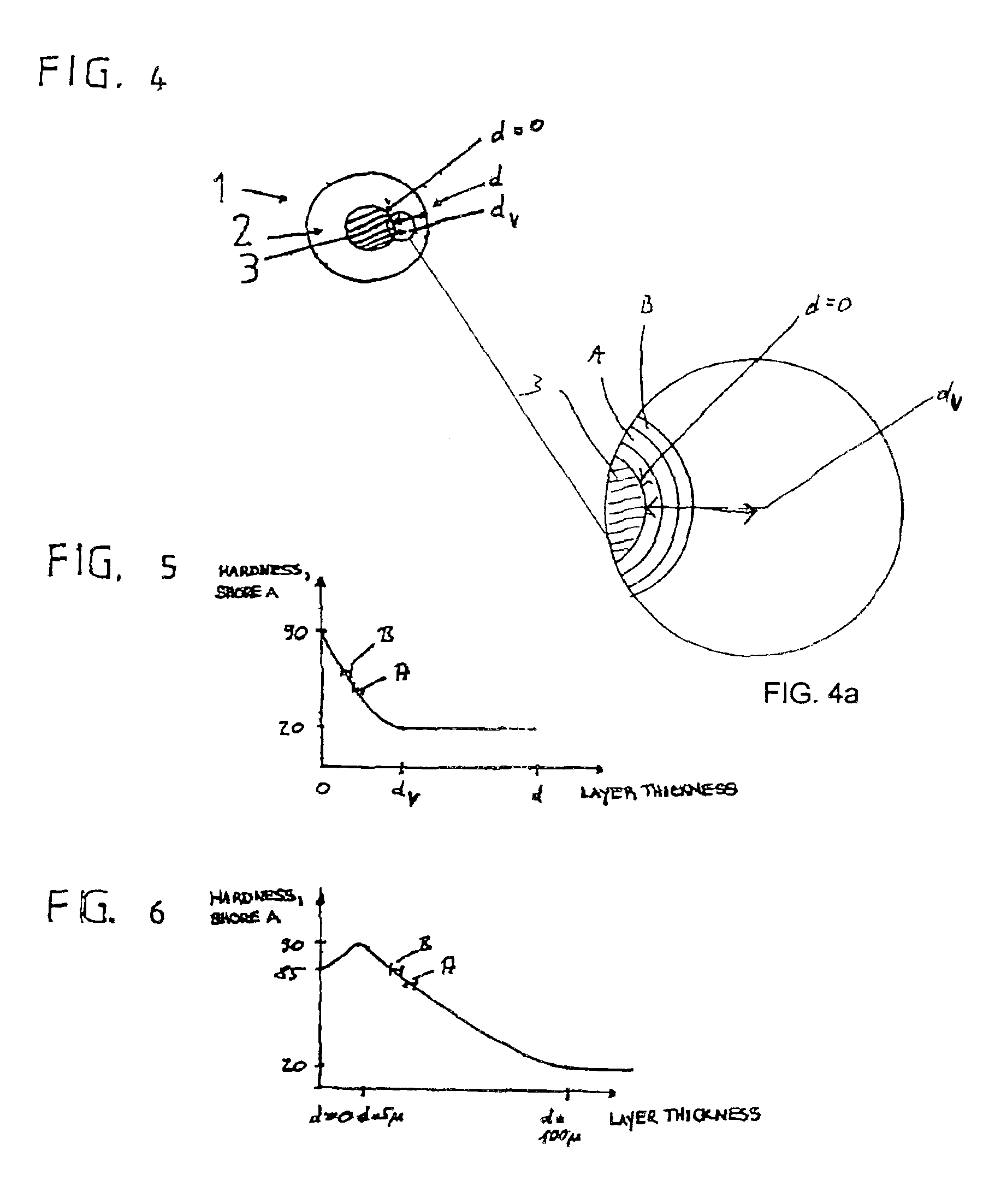

InactiveUS6935995B2Cost efficient to manufactureAvoid unevennessLiquid surface applicatorsShaft and bearingsHardnessLayer thickness

The invention relates to a roller for fluid film preparation, such as for offset printing, having an inside core, a first layer which surrounds the core and has a first hardness, and a second layer which surrounds first layer A and has a second hardness different from that of the first layer. The roller coating, including the first and second layers, is provided, at least in certain sections, with an essentially continuous hardness gradient through the layer thickness. The hardness gradient can be produced by incorporating a gradient of a hardness-modifying substance or agent, or a precursor thereof, e.g. an agent that increases the degree of cross-linking, by means of diffusion or migration of the substance or agent from at least one surface of the roller coating.

Owner:WESTLAND GUMMIWERKE GMBH & CO

Anilox roller and methods of manufacturing and recycling the same

InactiveUS20030134732A1Improve running stabilityReduce laborLiquid surface applicatorsShaft and bearingsEngineeringPrinting press

A method of manufacturing an anilox roller, in particular for a flexographic printing press, the anilox roller comprising a cylindrical core and a sleeve detachably held on the core and having at its surface an anilox layer with a grid pattern of pits, comprising the steps of mounting the sleeve on the core, and then forming the anilox layer on the sleeve

Owner:FISCHER & KRECKE

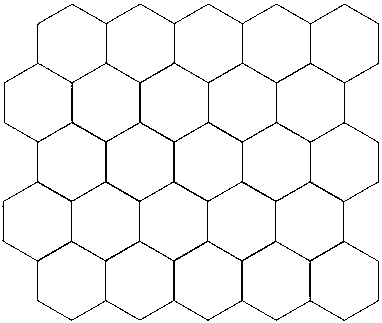

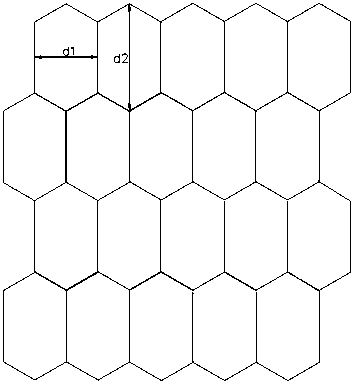

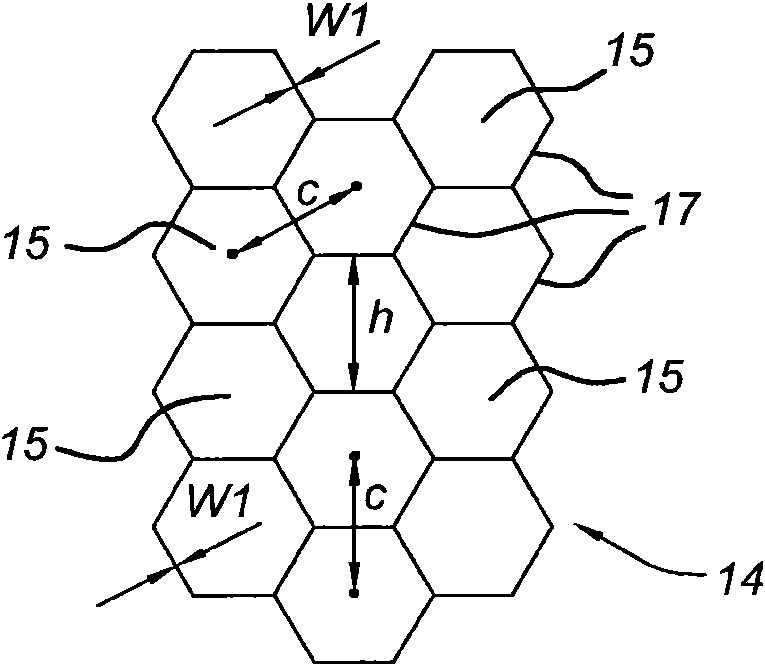

Improved type ceramic anilox roller and preparation method thereof

ActiveCN108528040ANot prone to chromatic aberrationStable amount of coatingPrinting roller shellsLaser beam welding apparatusSurface layerPrinting ink

The invention relates to the field of printing, in particular to an improved type ceramic anilox roller and a preparation method thereof. Anilox is arranged on a ceramic surface layer of the ceramic anilox roller and consists of a plurality of meshes which are the same and are arranged regularly, the cross section of each mesh is in the shape of a stretched hexagon, the stretched hexagon is a hexagon which is obtained by lengthening two opposite sides of a regular hexagon by the same length, and the stretched hexagon consists of two stretched sides and four non-stretched sides. When the improved type ceramic anilox roller is used, color difference is not easily caused, a coating quantity is stable, ink blockage is not easily caused, a printing ink covering effect can be improved, printingink transfer performance is good, the printing effect is good, and the meshes are easily cleaned. Compared with a traditional regularly hexagonal anilox roller, the improved type ceramic anilox rollerhas the advantages that the ink loading amount and transfer rate of the improved type ceramic anilox roller are remarkably higher than the ink loading amount and transfer rate of the traditional regularly hexagonal anilox roller under the condition of the same screen, the wear resistance is good, and the service life is long; and the preparation method is simple in process, an operation process is easily controlled, the quality of products is stable, and thus, the improved type ceramic anilox roller is suitable for industrial production.

Owner:DONGGUAN SHANGYUN LASER PLATE MAKING CO LTD

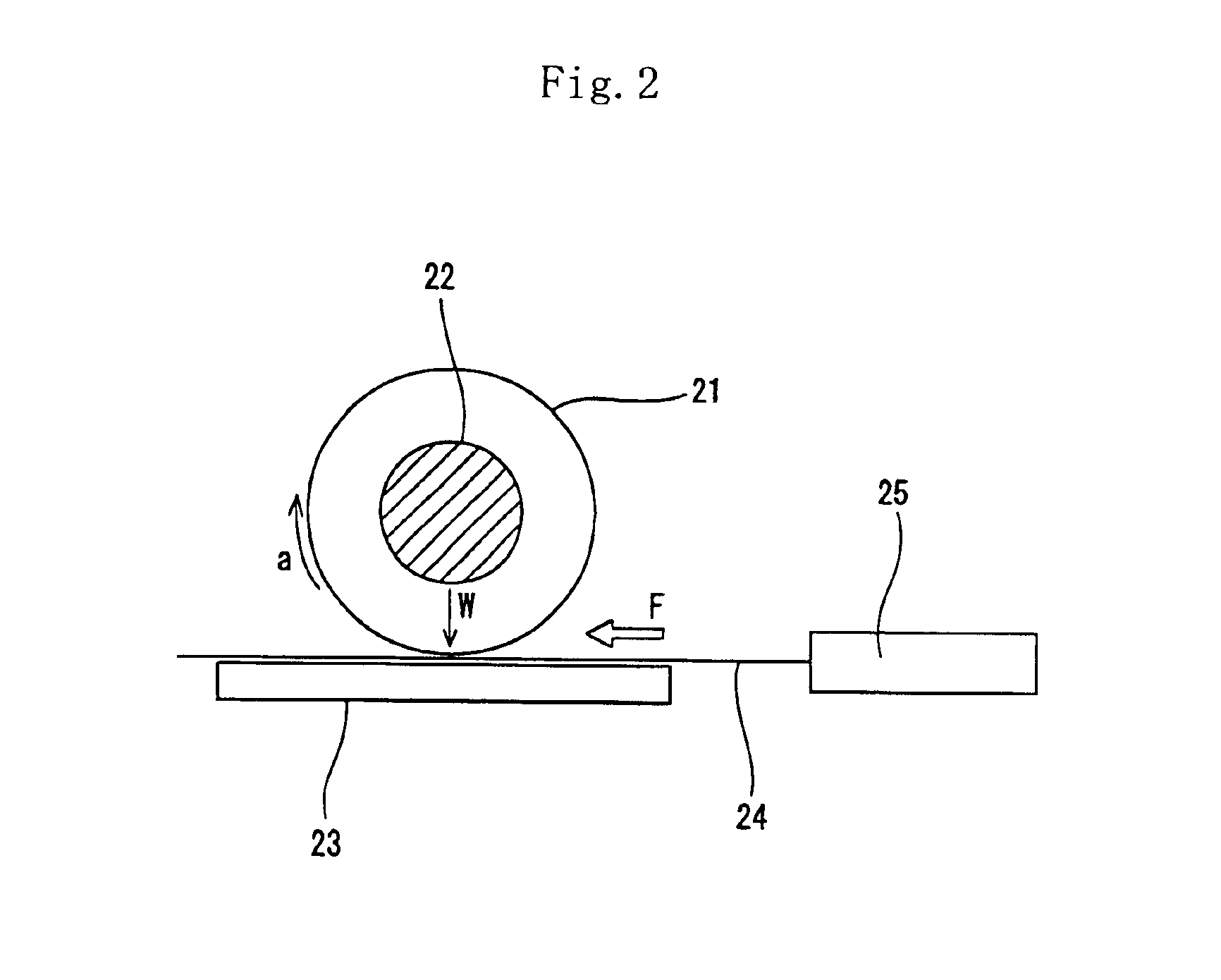

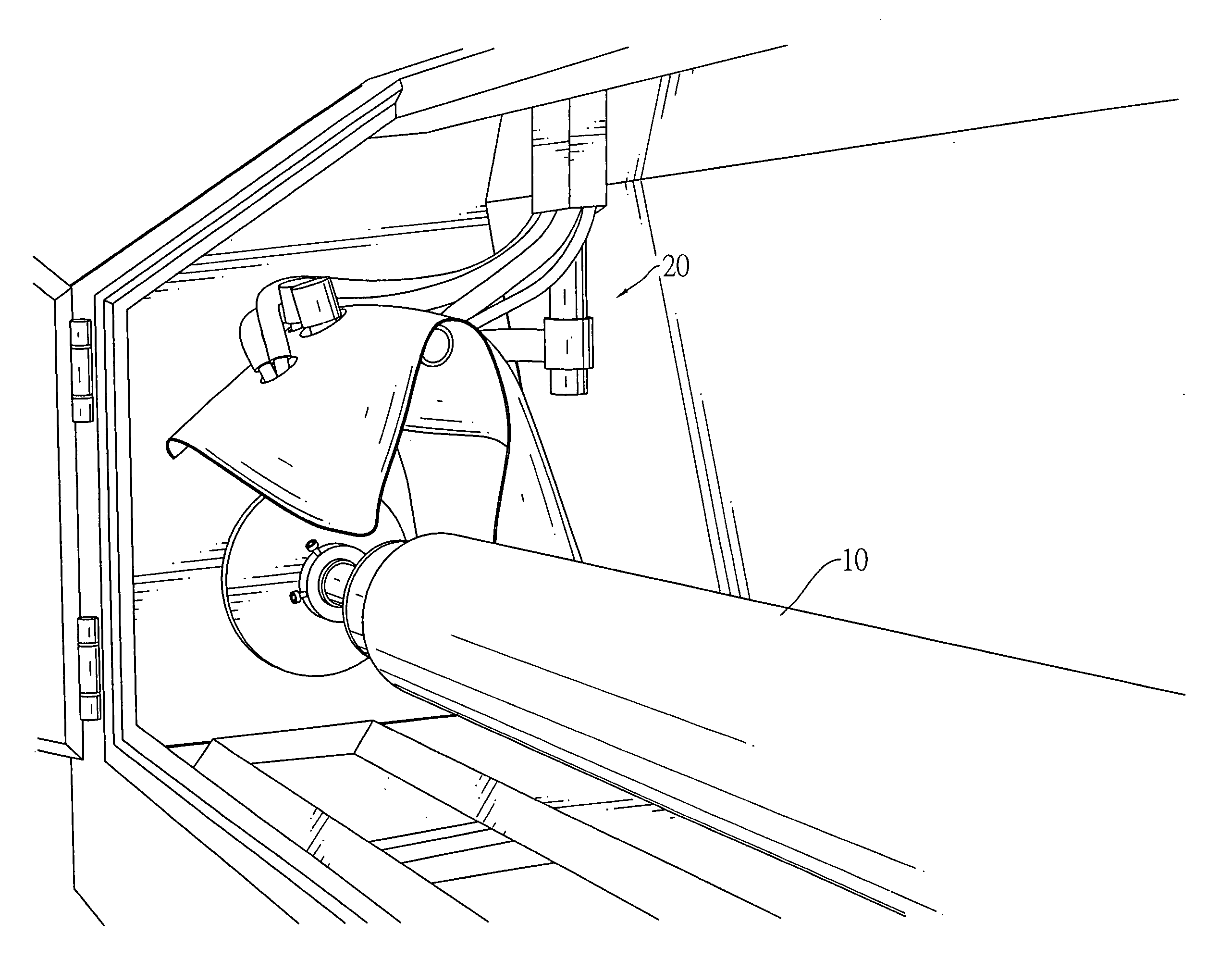

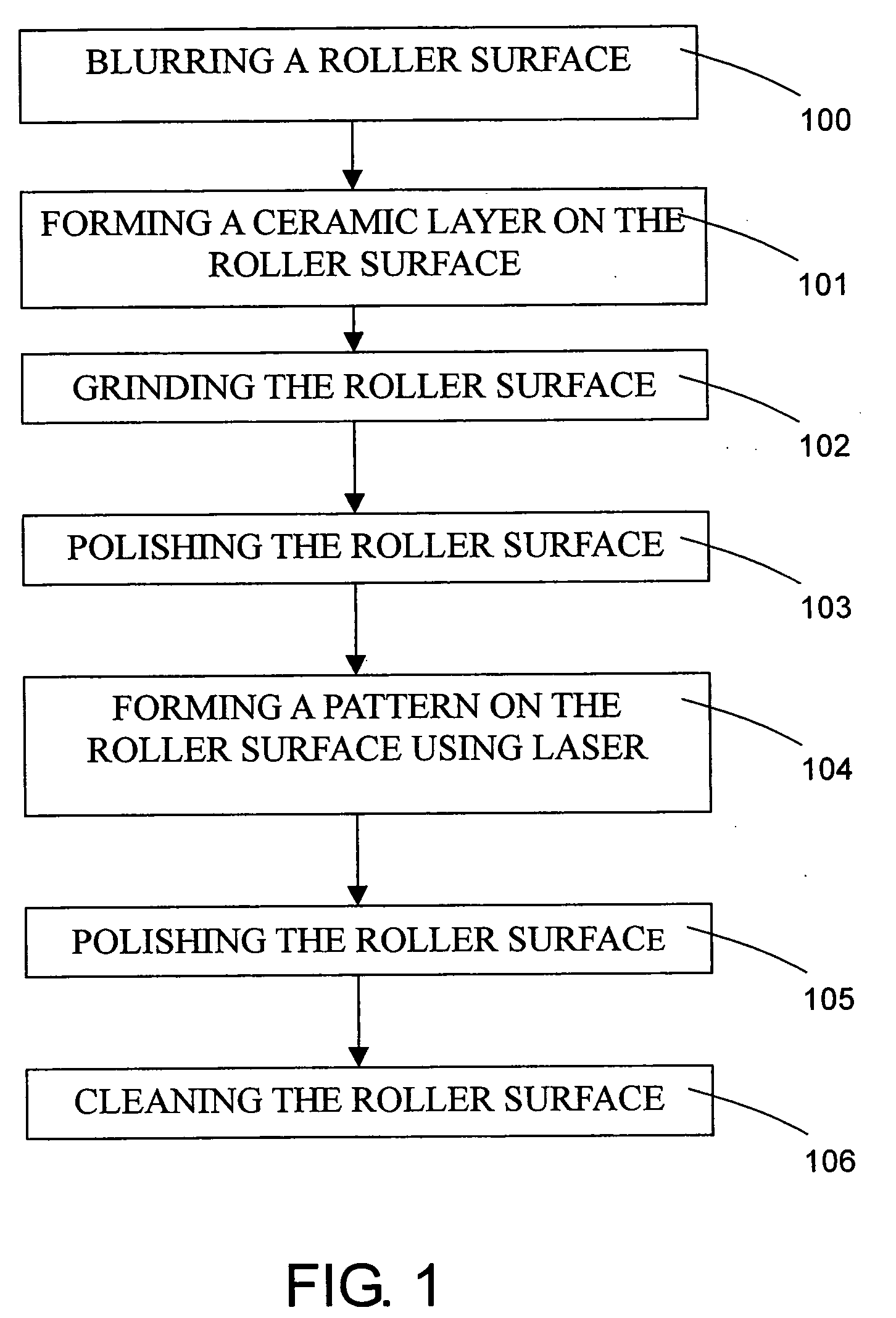

Method of making rollers with a fine pattern

InactiveUS20100015354A1Increase roller lifetimeHigh-precision patternMolten spray coatingRadiation applicationsLaserErosion

A method of making rollers with a fine pattern has the acts of casting a ceramic layer onto a roller surface, grinding and polishing the roller surface, forming a pattern on the roller surface with laser, and cleaning the roller surface. Therefore, the roller thus made has a pattern with higher precision than the conventional method of mold casting. Since the roller surface has a ceramic layer that has better resistance to erosion than steel, the roller has a longer lifetime.

Owner:LEE TAI CHEUNG

Method for printing substrate using anilox roll, ilox roll for printing method and printing apparatus

ActiveCN101925462AWith desired color intensityEvenly distributedPrinting roller shellsLaser beam welding apparatusEngineeringLinear distribution

The invention relates to an anilox roll for a printing apparatus. The anilox roll comprises a cylinder having a surface. The surface comprises a fluid distribution structure for receiving, distributing and transferring a fluid such as an ink. The fluid distribution structure comprises a channel formed in the surface having channel walls. This channel is arranged for distributing the fluid over the fluid distribution structure. The channel comprises channel parts, wherein the courses of connected channel parts are at an angle with respect to each other for preventing a linear distribution of the fluids to be received in a course direction of the channel, allowing a meandering distribution of the fluid to be received in the channel. Side walls of the channel are arranged for allowing a meandering flow of the fluid throughout the fluid distribution surface.

Owner:APEX EUROPE BV

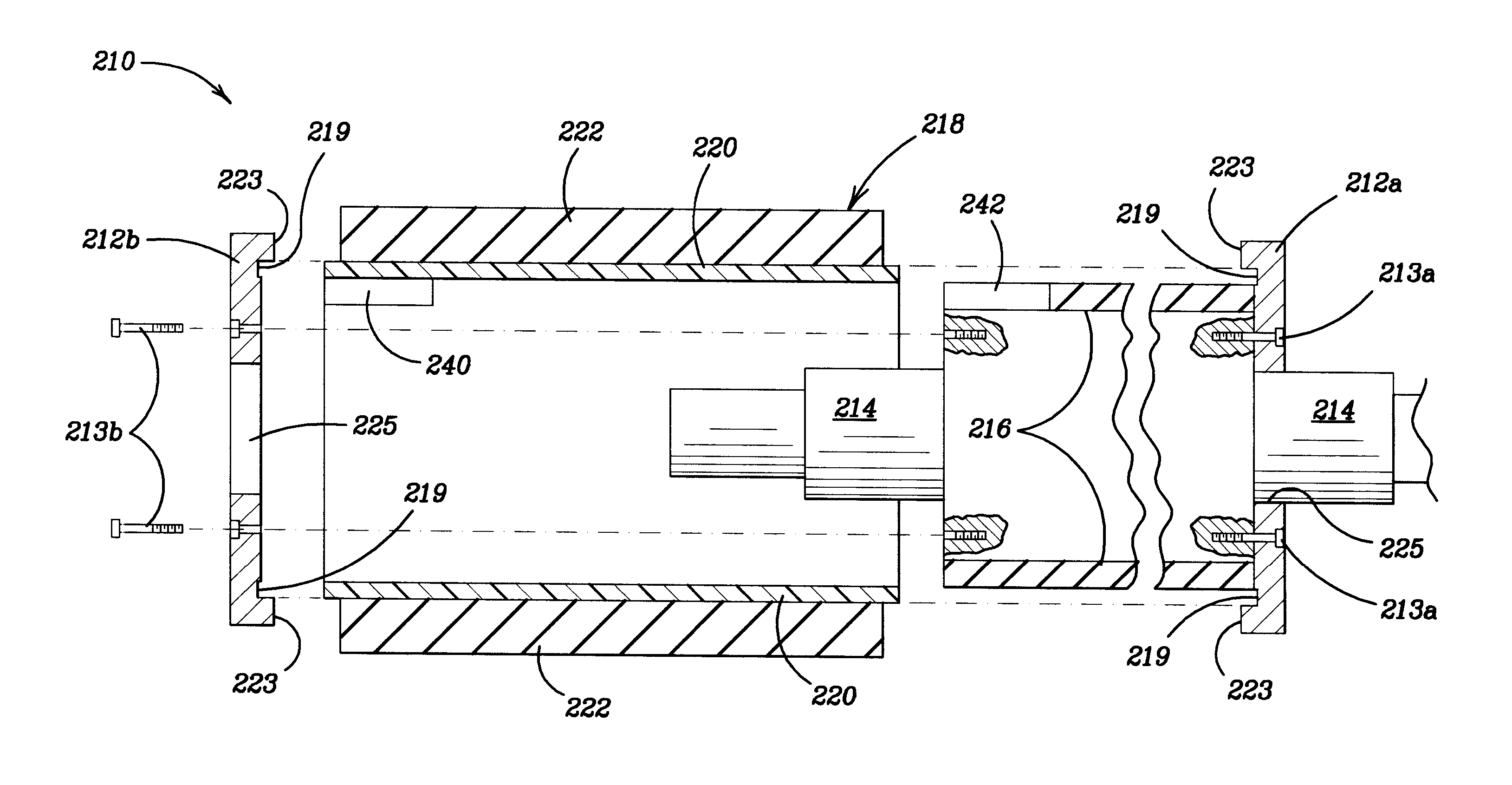

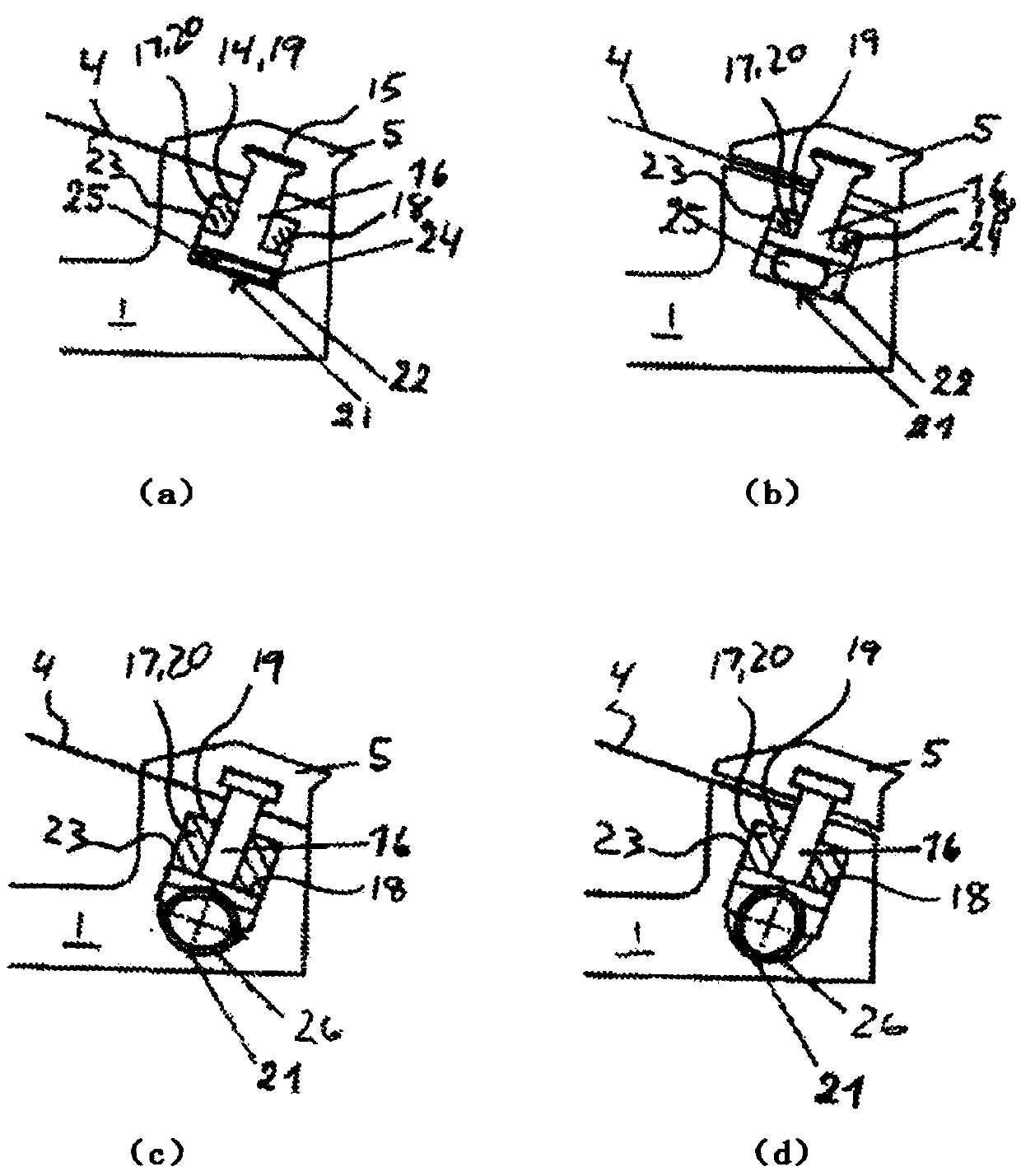

Quick Release Roller Sleeve Mounting Hub

ActiveUS20140113784A1The relative position is appropriateMaintain speedShaft and bearingsPortable power-driven toolsFlange

A quick release roller sleeve and mounting hub assembly is described for use with high speed roller machines. The assembly includes an outer flange plate that can be detached from the assembly in order for the roller sleeve to be dismounted and a new roller sleeve mounted as the existing roller sleeve becomes worn and needs to be replaced. The quick release permits the mounting hub and other parts of the assembly to remain in their aligned configuration and positions while only exchanging the roller sleeve portion of the assembly.

Owner:FRC HLDG

Method for producing anilox rolls

ActiveCN102307730AIncrease energy densityPrinting roller shellsForme preparationPulse energyEngineering

The invention relates to anilox rolls for anilox color decks, engraved by a short-pulse laser, wherein the cross-sectional shape of the engraved cells or hachures is machined out by a plurality of pulses of the repeatedly operating laser. The pulse energy and mean power of the laser are selected or set so that at least 0.5 cm3 of material / hour is ablated. The surface of the roll is subsequently smoothed or cleaned by a mechanical finishing step.

Owner:海德堡印刷机械知识产权股份两合公司

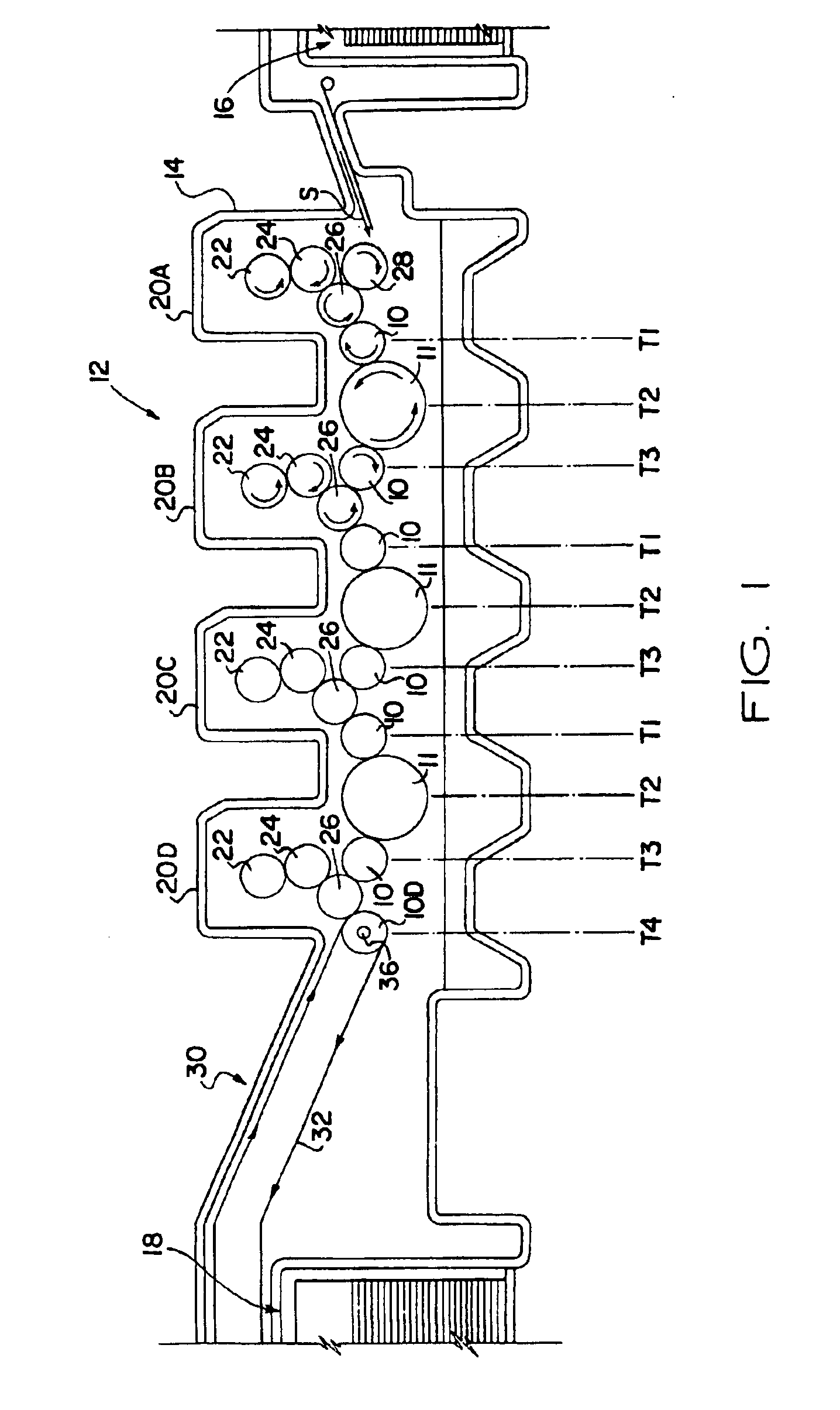

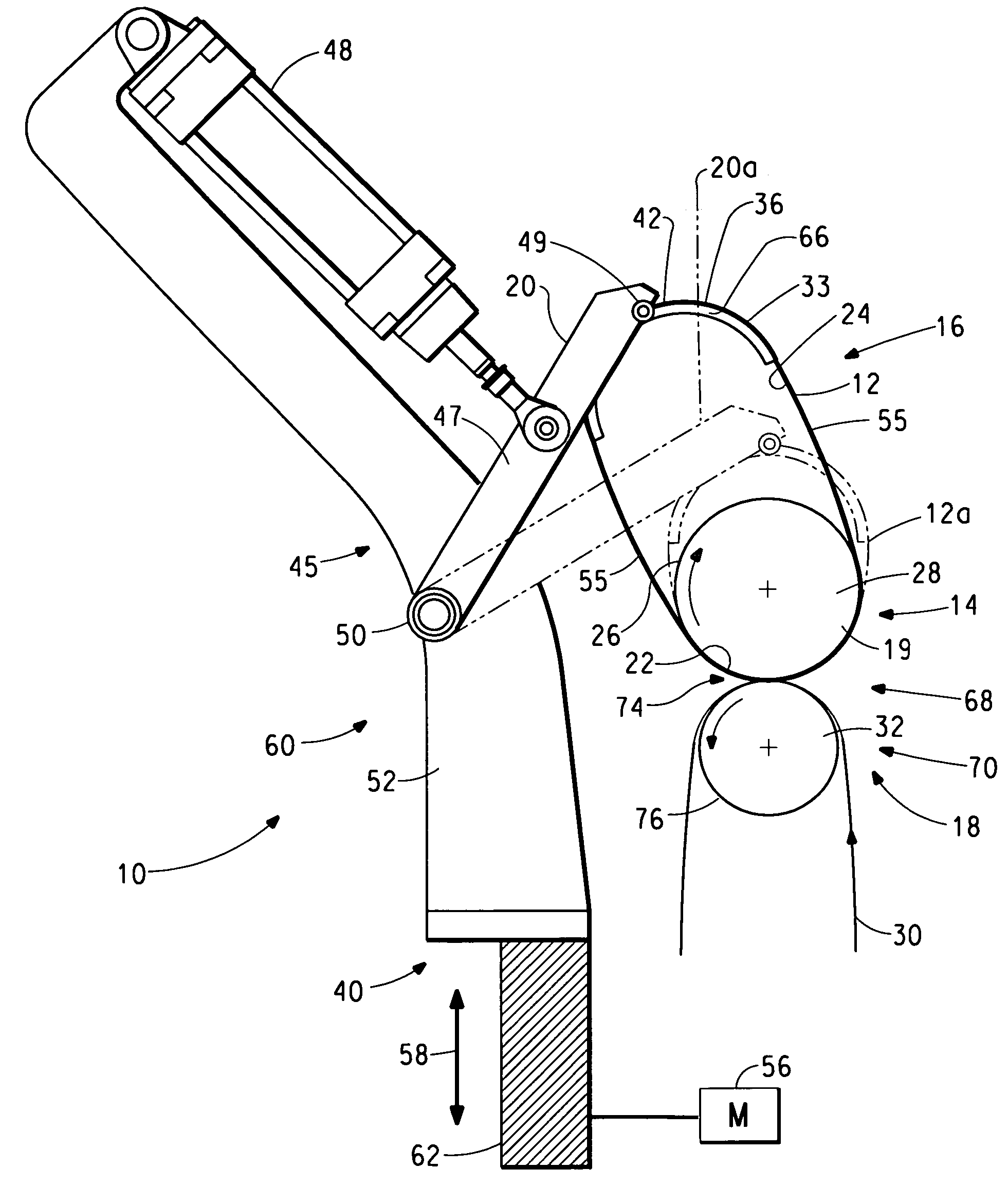

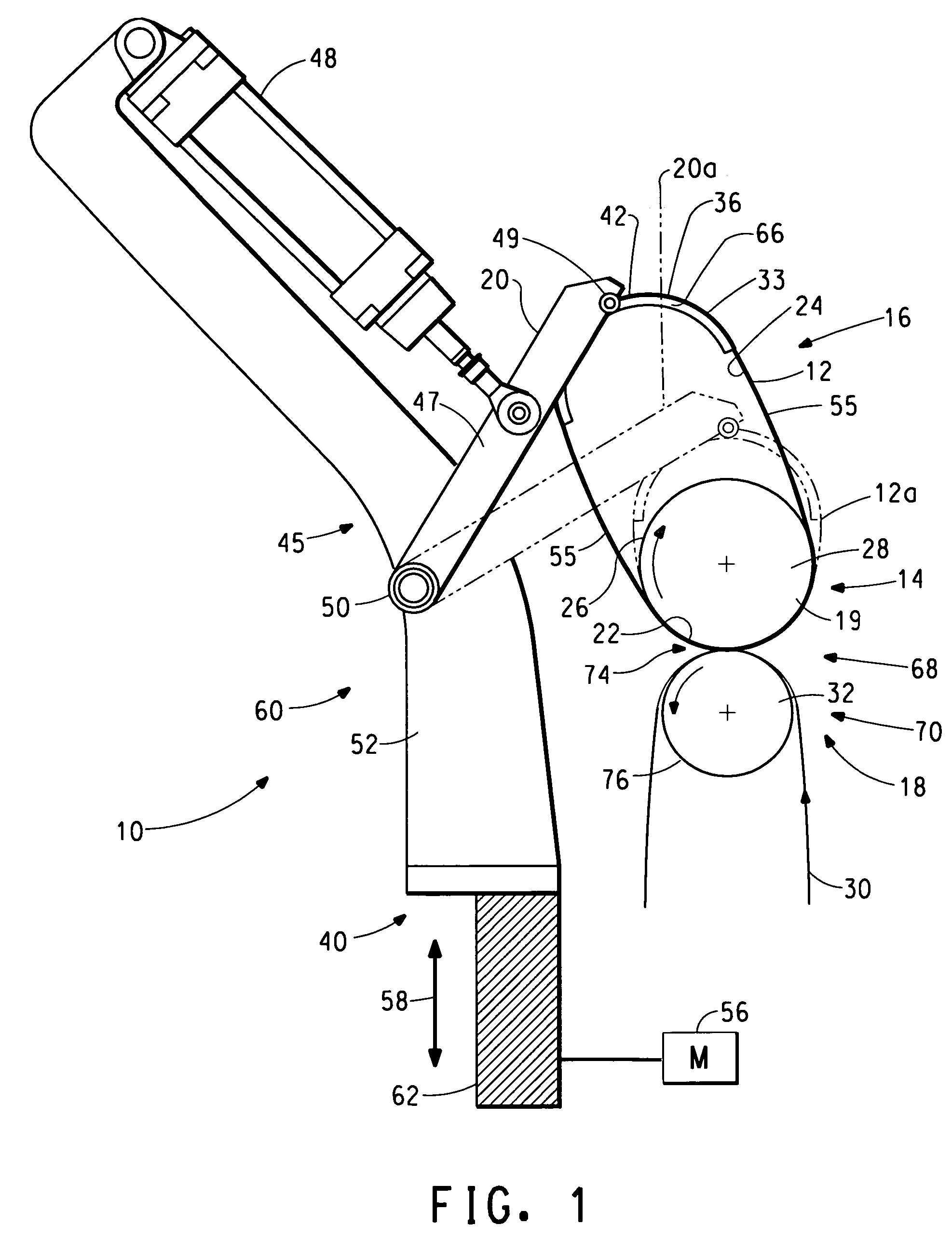

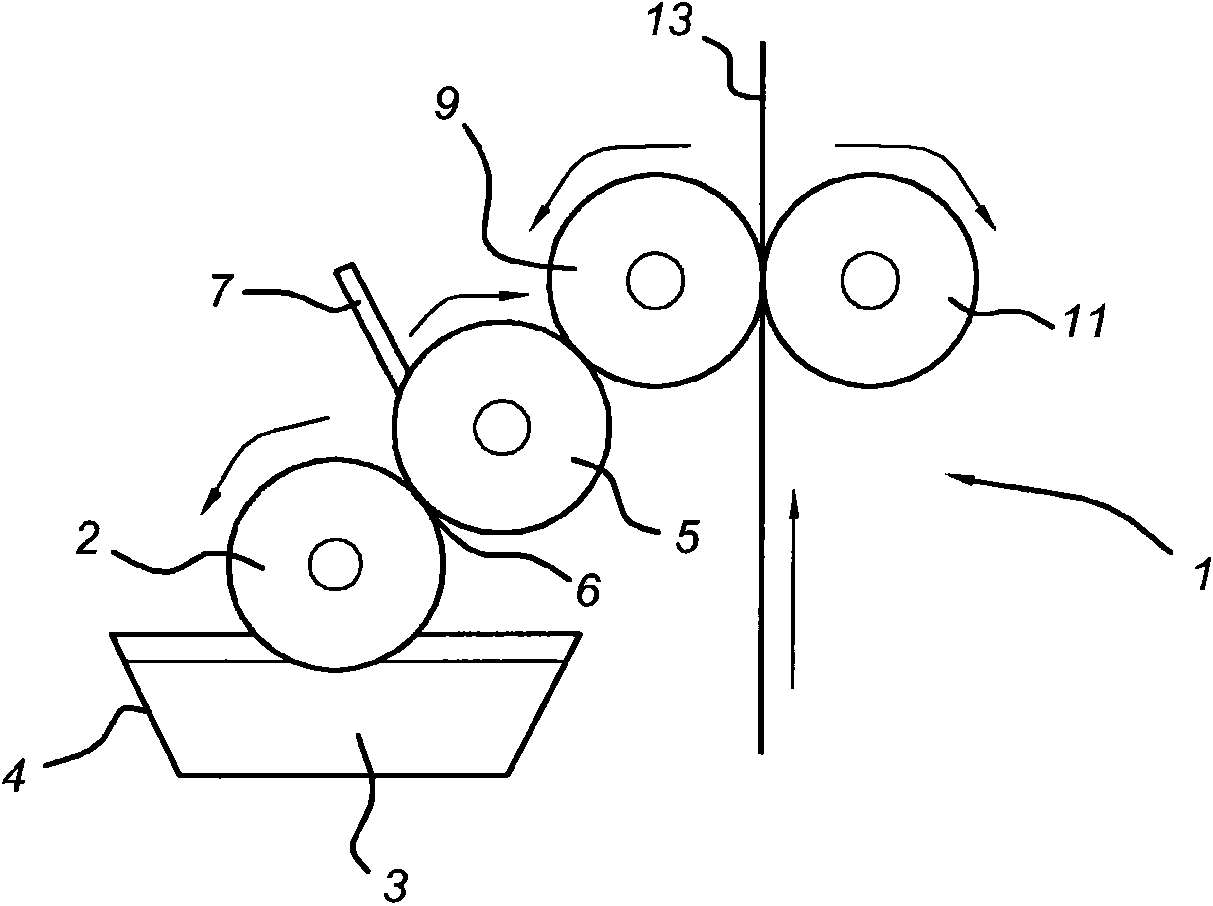

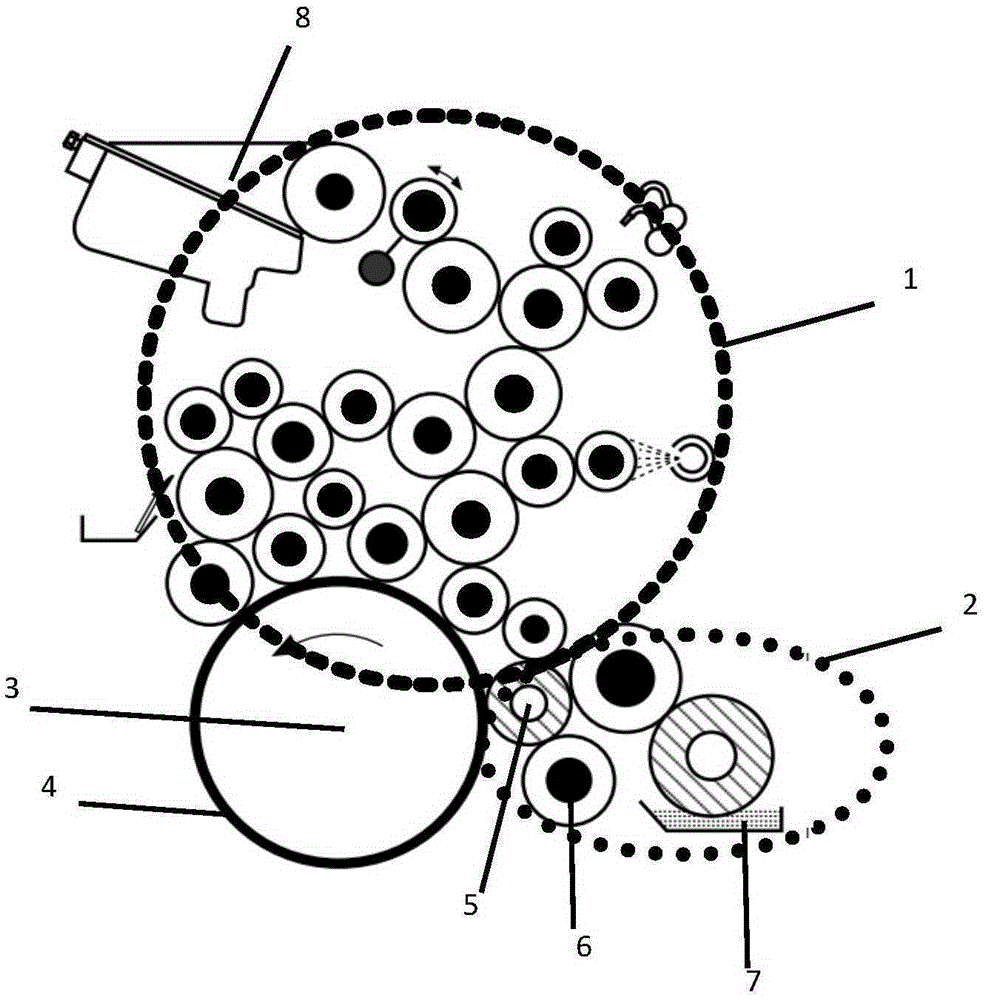

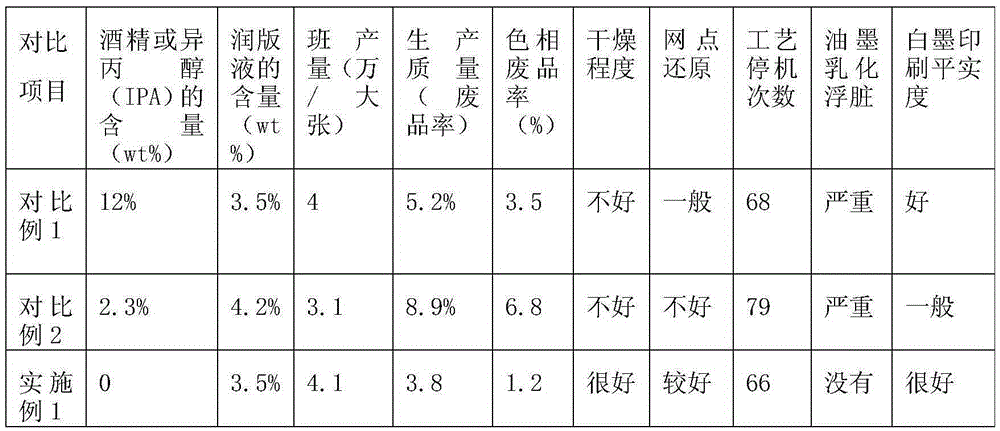

Zero alcohol type lithographic printing system

ActiveCN106585071AImprove the environmentGood for healthInking apparatusPrinting roller shellsWater sourceEther

The invention relates to a zero alcohol type lithographic printing system. The zero alcohol type lithographic printing system comprises the following parts of a plate cylinder (3), a printing ink applying system (1) and a plate wetting water applying system (2), wherein the cylindrical outer surface of the plate cylinder (3) is provided with a printing plate (4); the printing ink applying system (1) comprises a printing ink source (8) and a plurality of printing ink rollers, and is used for applying printing ink onto the printing plate; the plate wetting water applying system (2) comprises a plate wetting water source (7) and a plurality of plate wetting water rollers, and is used for applying plate wetting water onto the printing plate; the plurality of plate wetting water rollers include a dampening vibrator (6); and the structure of the dampening vibrator (6) as follows includes a metal roller and a ceramic layer covering the outer surface of the metal roller; the outer surface of the ceramic layer is provided with a net pattern; and the content of alcohol type substances or ether type substances in plate wetting water is zero.

Owner:YUNNAN JOY PRINTING TECH CO LTD

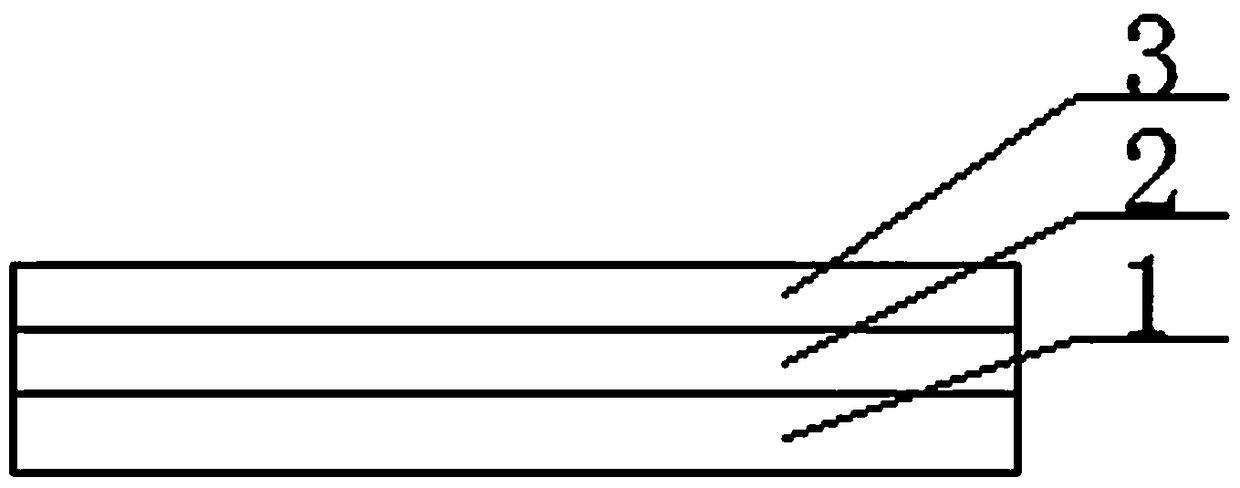

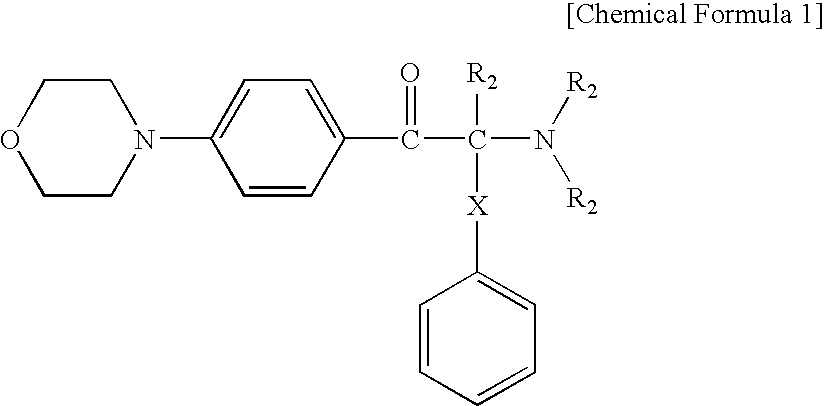

On-press developing treatment-free thermal-sensitive plate with nano-micron-structure protective layer

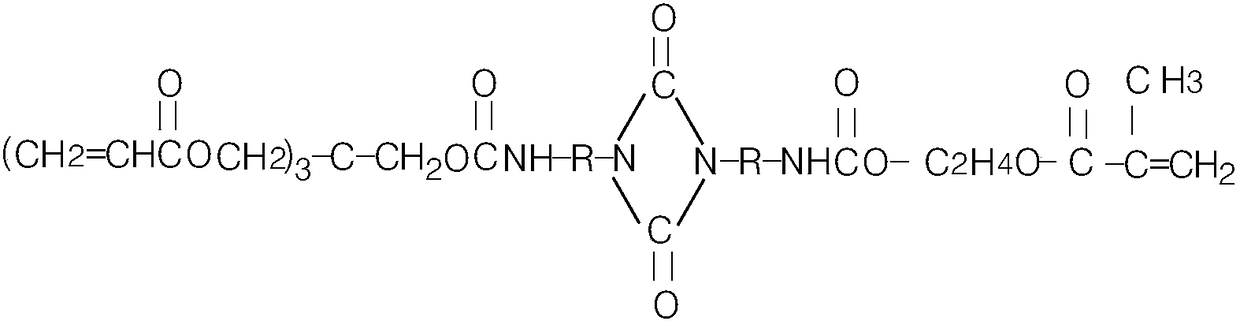

ActiveCN108297565AImprove the running forceImprove wear resistancePlate printingPrinting roller shellsElectrolysisPrepolymer

The invention relates to an on-press developing treatment-free thermal-sensitive plate with a nano-micron-structure protective layer. The on-press developing treatment-free thermal-sensitive plate comprises an aluminum plate base support, a coating layer containing a negative image light-sensitive composition and the protective layer with a nano-micron structure, all of which are distributed frombottom to top. The aluminum plate base support is subjected to electrolytic roughening, anodic oxidation and hole sealing treatment, wherein the average roughness of center lines ranges from 0.4 micron to 0.6 micron; the negative image light-sensitive composition mainly contains discrete nano-micron particles, diurethone prepolymer, multi-functional-group monomers, a thermal polymerization initiator and an infrared absorbent; and the diameter of the discrete nano-micron particles in the protective layer with the nano-micron structure ranges from 50 nm to 150 nm. The protective layer which is hydrophilic but insoluble in water and has the nano-micron structure is adopted, the problems that a fountain solution is contaminated by the protective layer, and the normal-temperature permeability of a formed film is poor are solved, the plate on-press developing capacity is improved, the number of plate passing paper is greatly reduced, plates can be directly subjected to on-press printing, high durability is achieved, and environment-friendly printing is achieved.

Owner:LUCKY HUAGUANG GRAPHICS +1

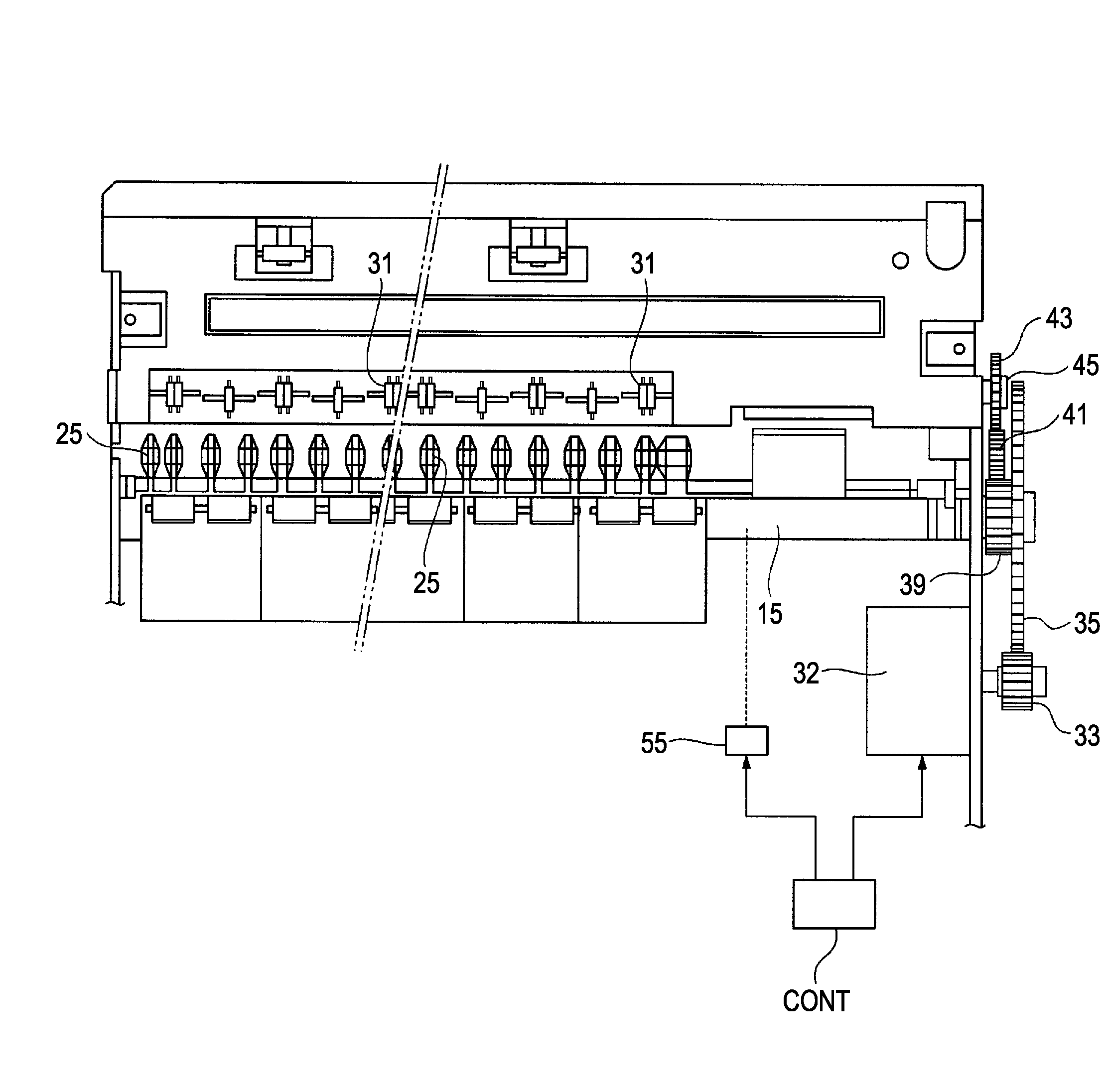

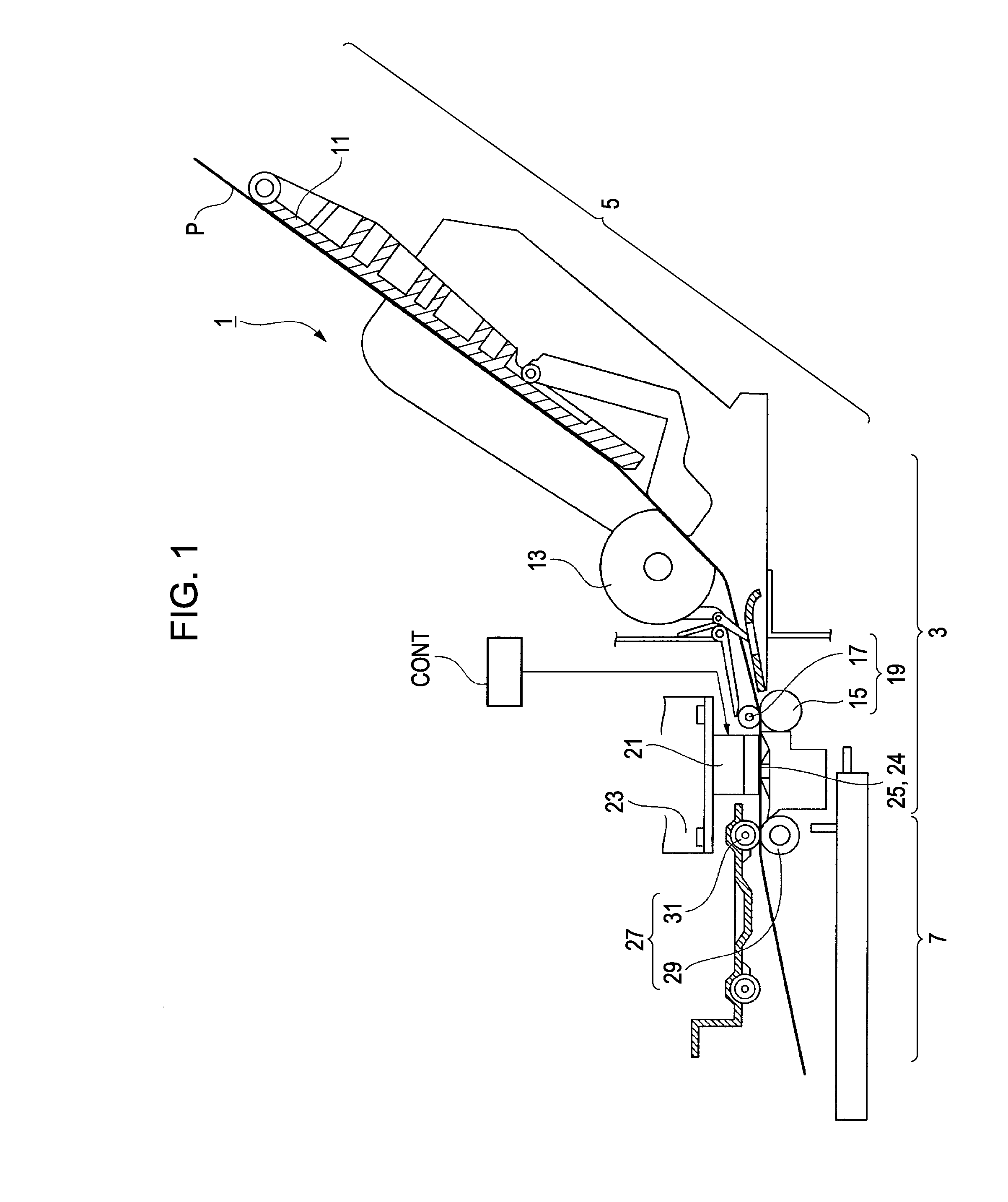

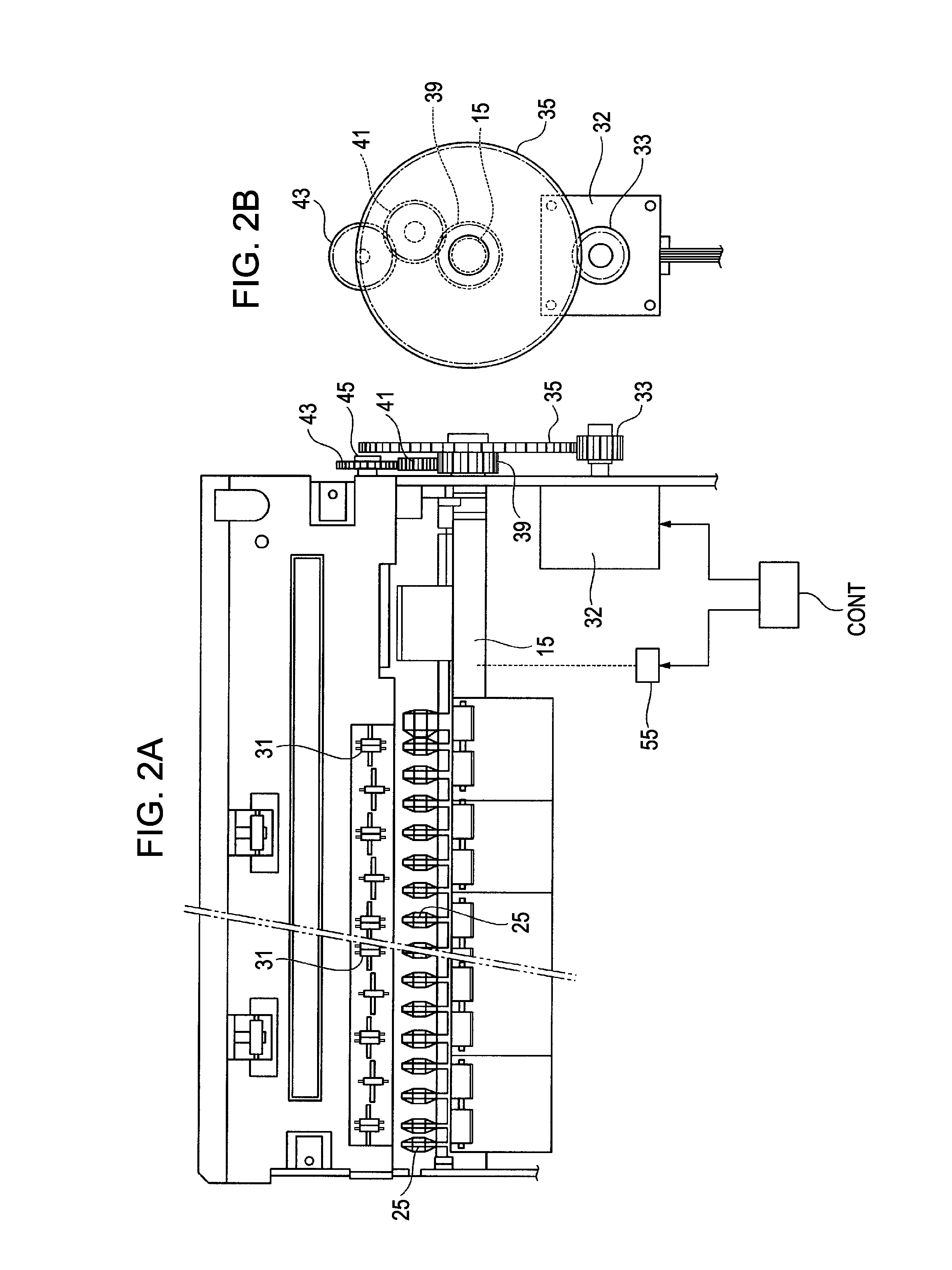

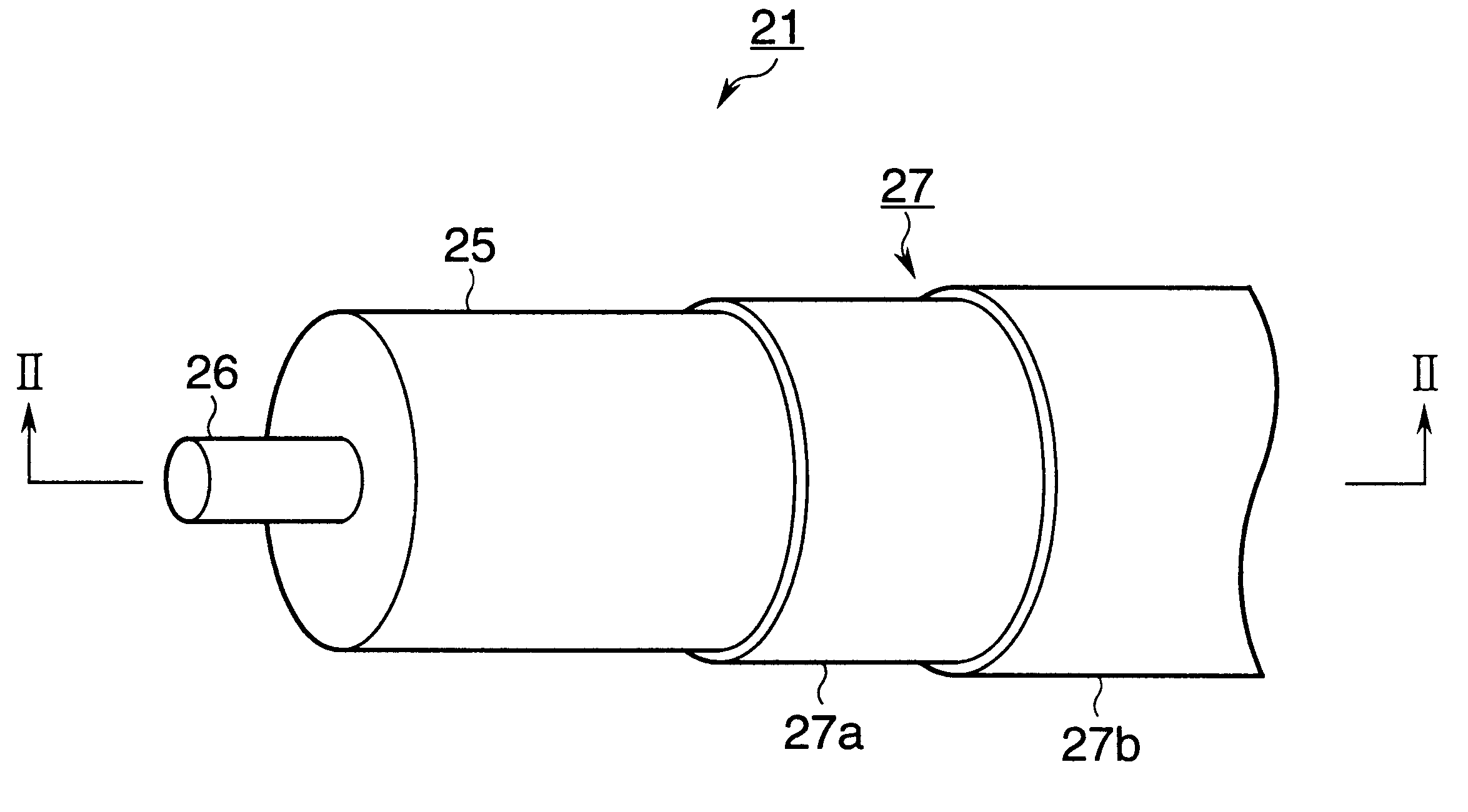

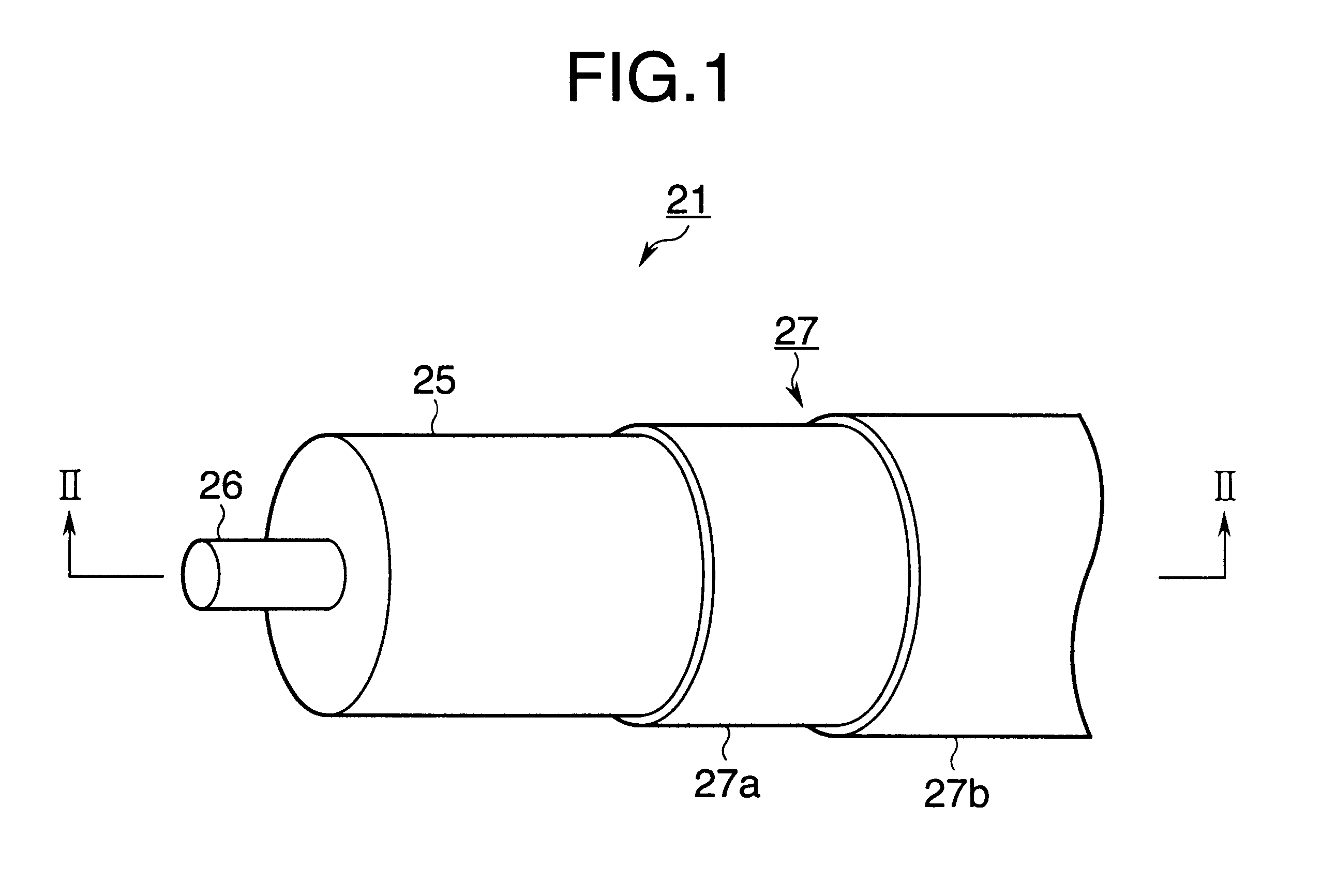

Transport roller, transport unit, and printing apparatus

ActiveUS20100209168A1Low costReduce weightShaft and bearingsPrinting roller shellsInorganic particleEngineering

A transport roller includes: a roller body of which a pair of end surfaces face each other by a press work so as to be in a cylindrical shape; and a high friction layer which contains inorganic particles and is provided on a surface of the roller body. Here, the roller body is provided with a joining portion which is formed by separating the pair of end surfaces. In addition, an average particle diameter of the inorganic particle is larger than a distance between the pair of the end surfaces of the roller body on an outer peripheral surface side thereof.

Owner:SEIKO EPSON CORP

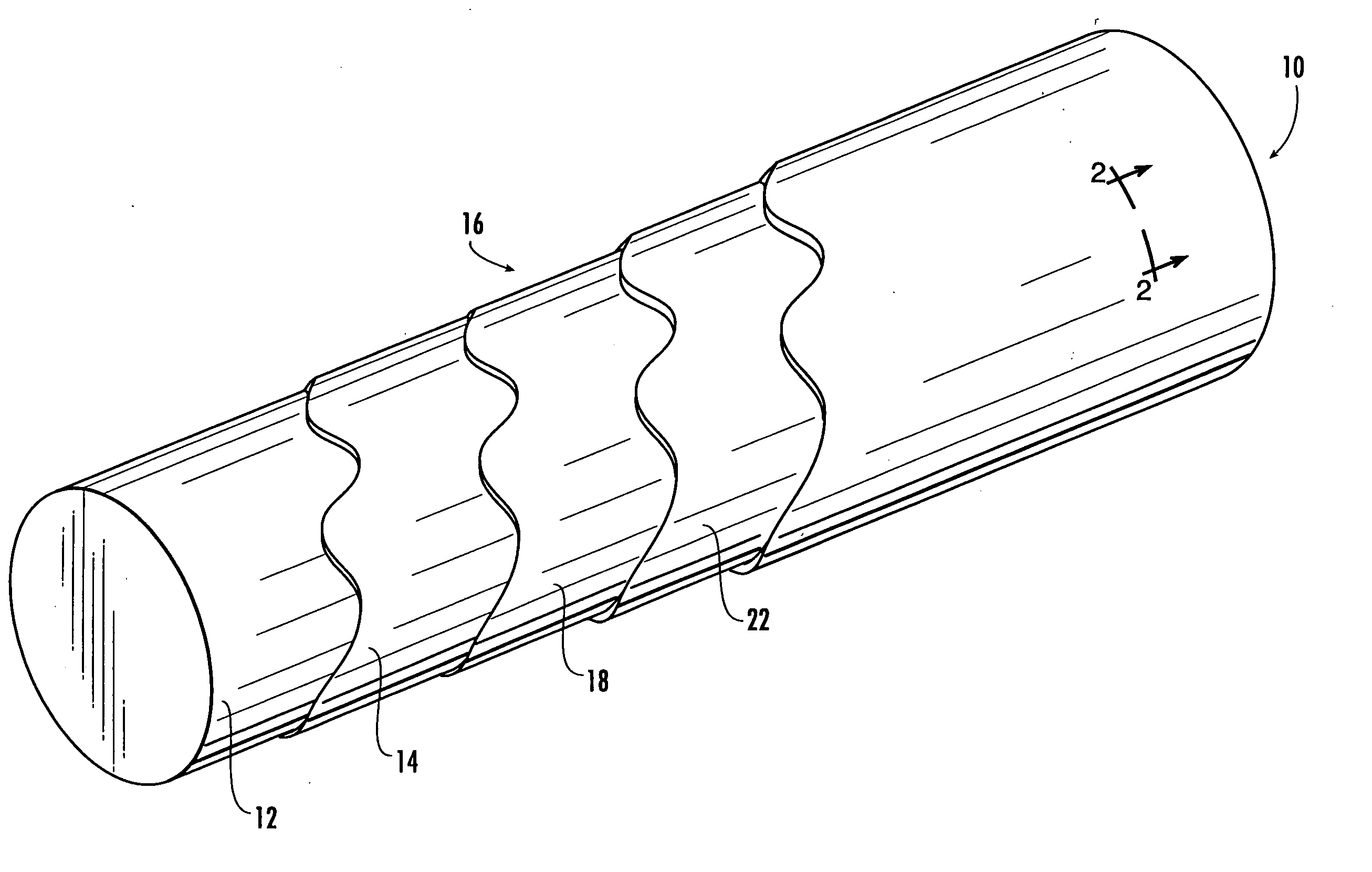

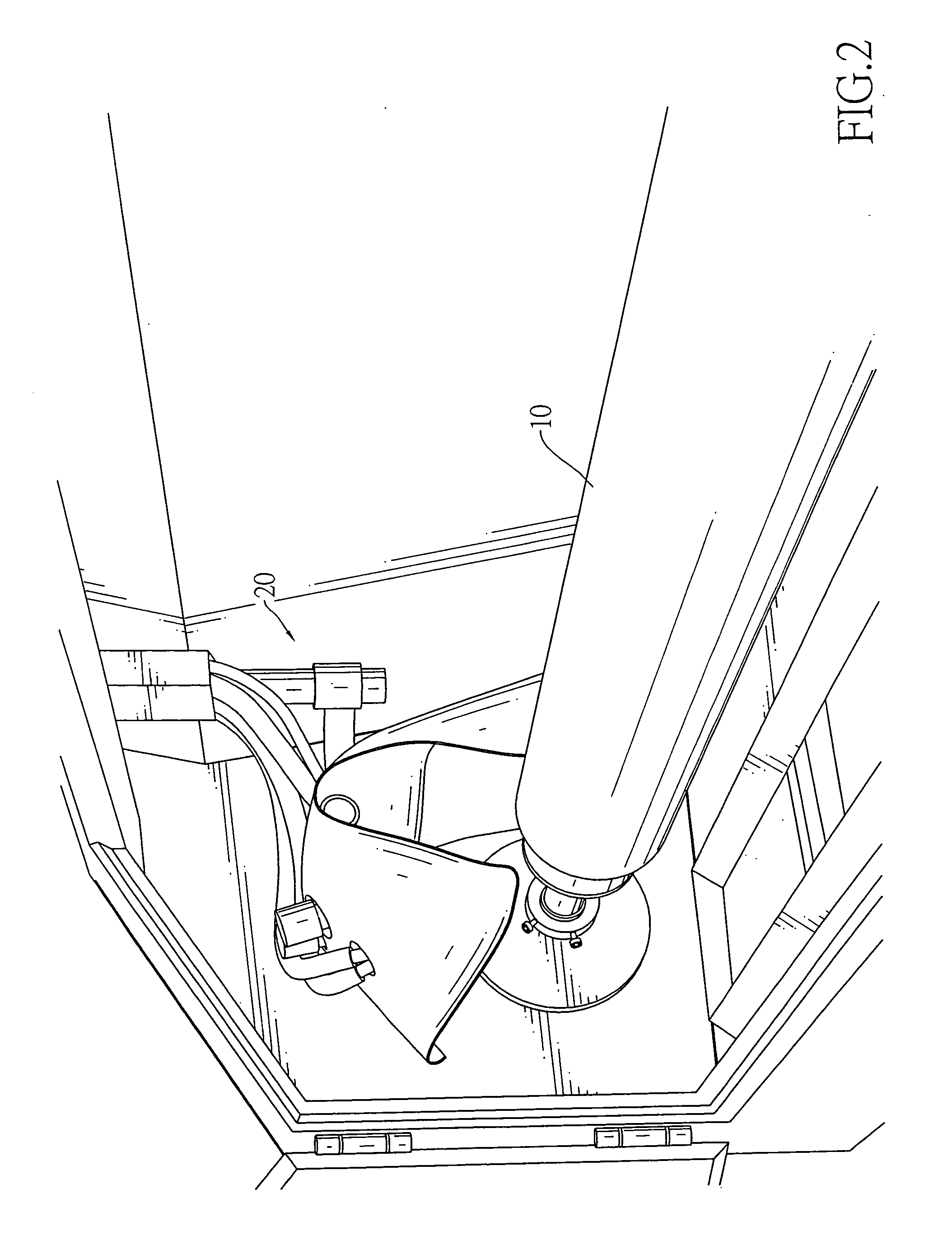

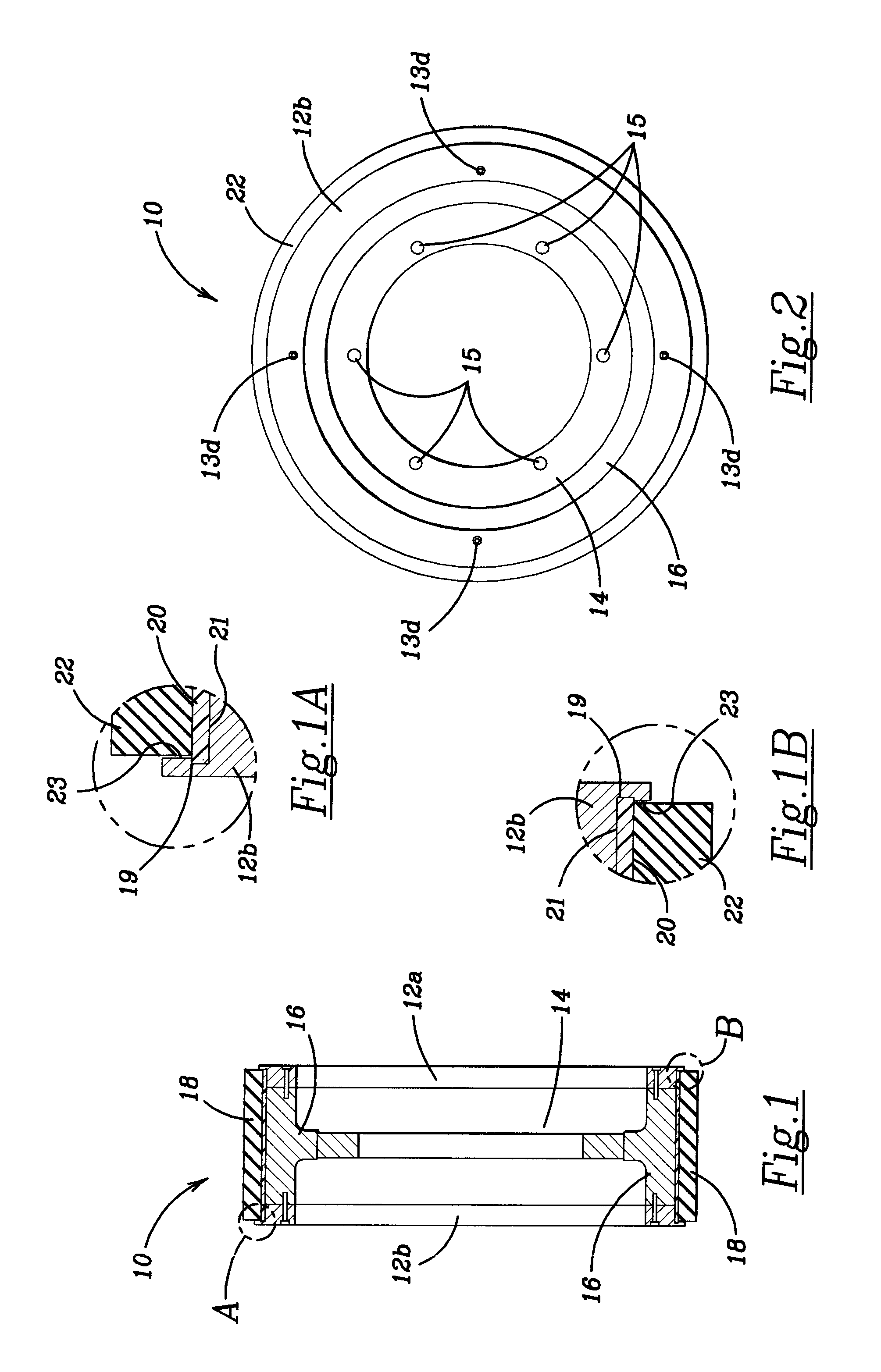

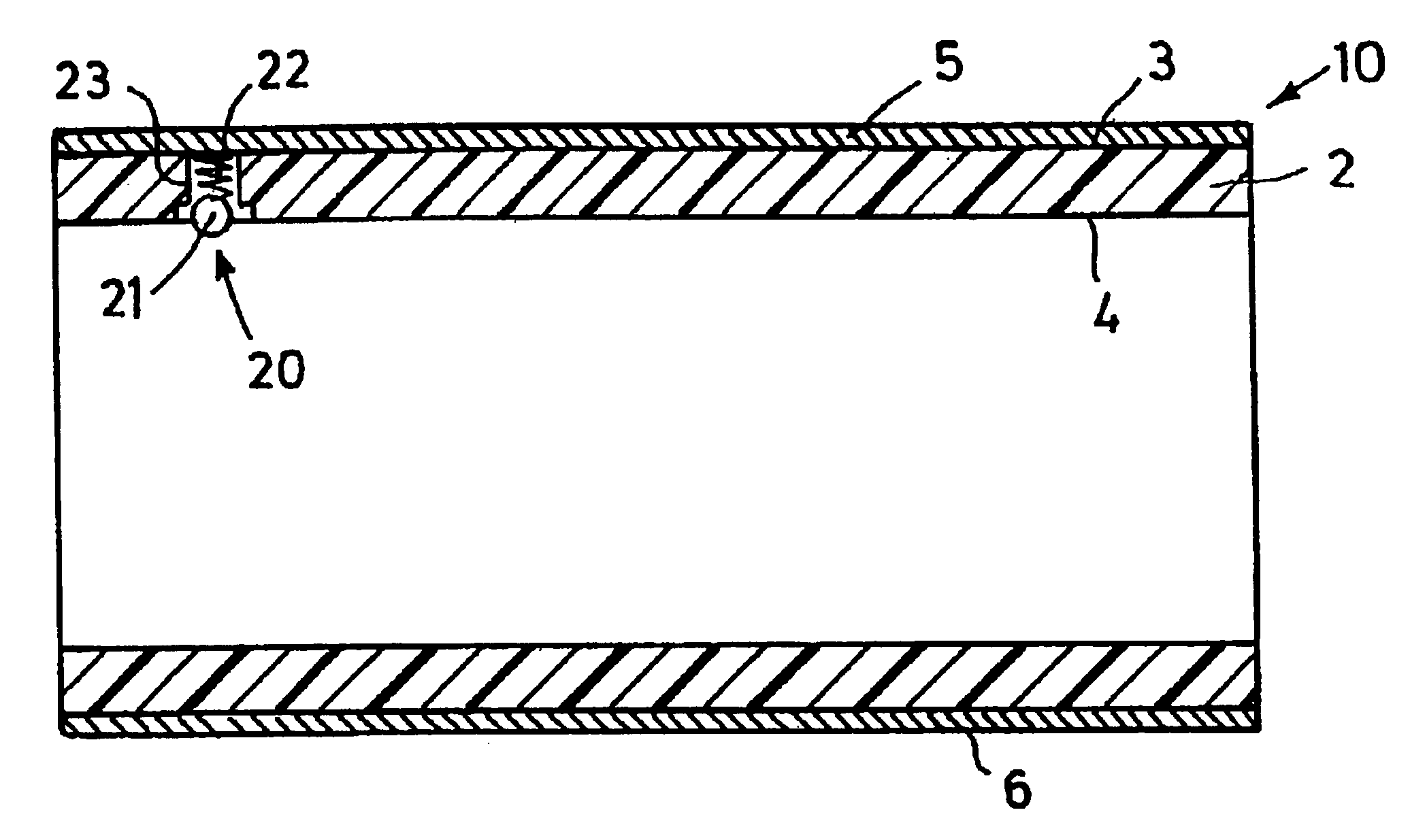

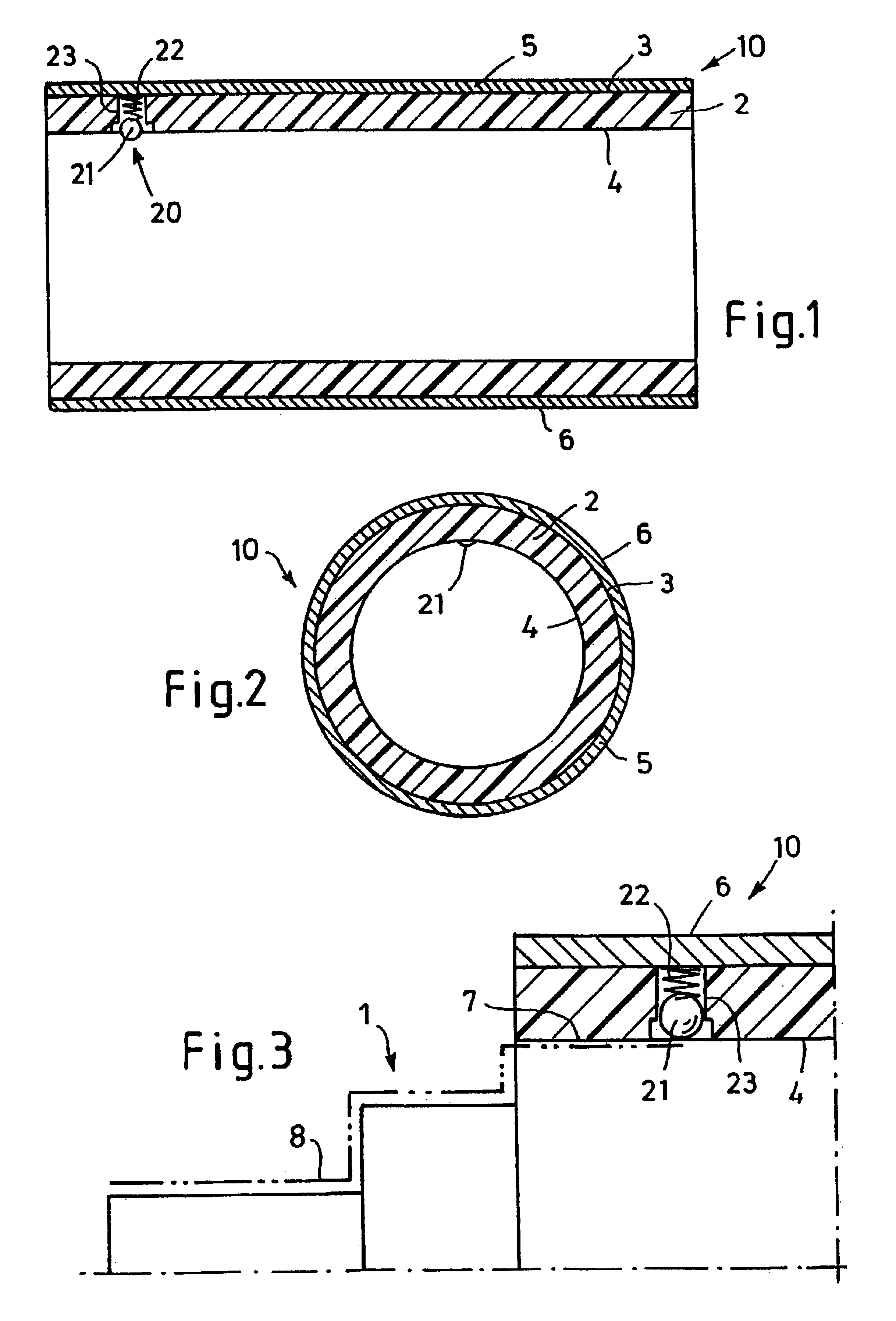

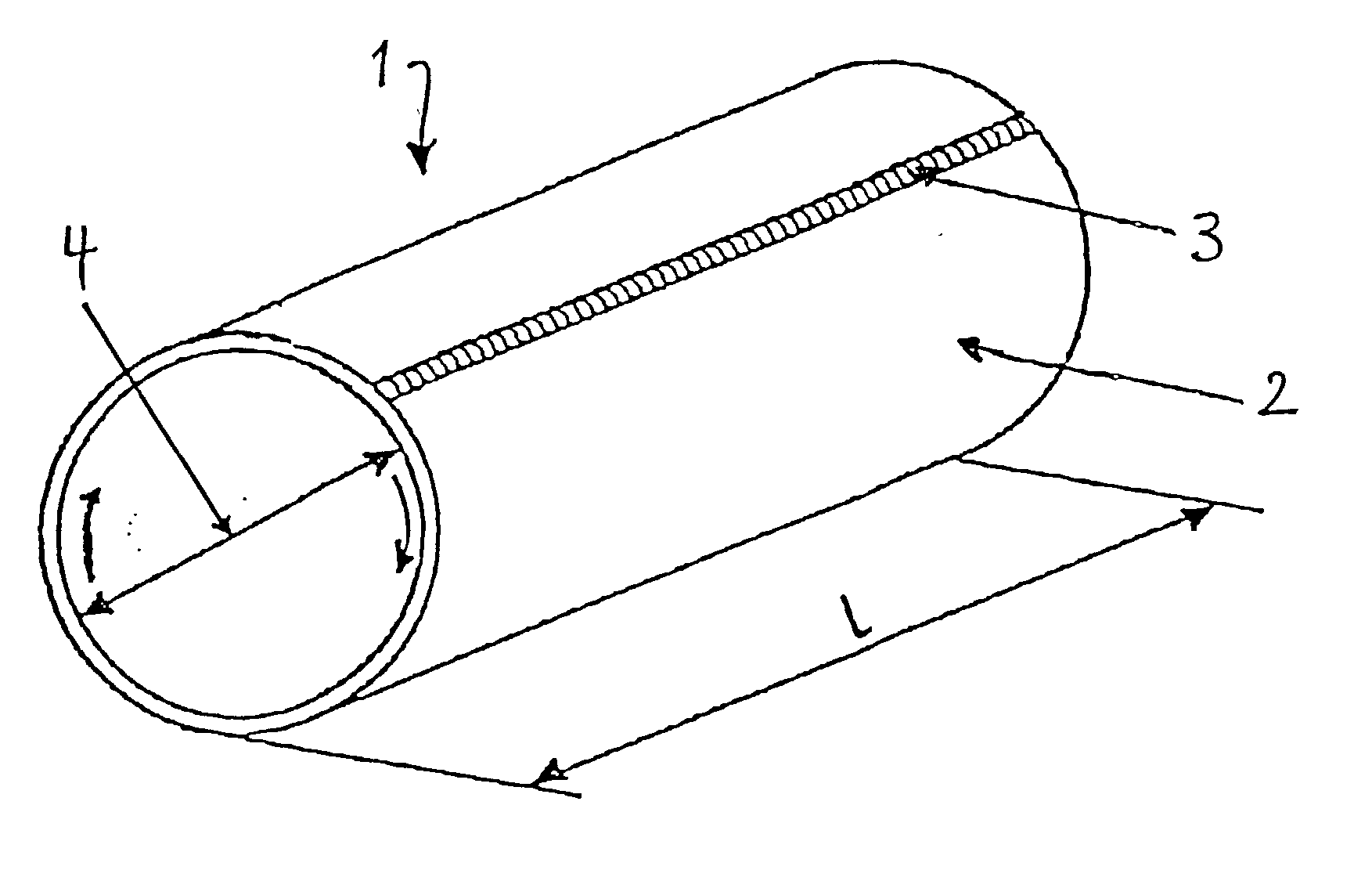

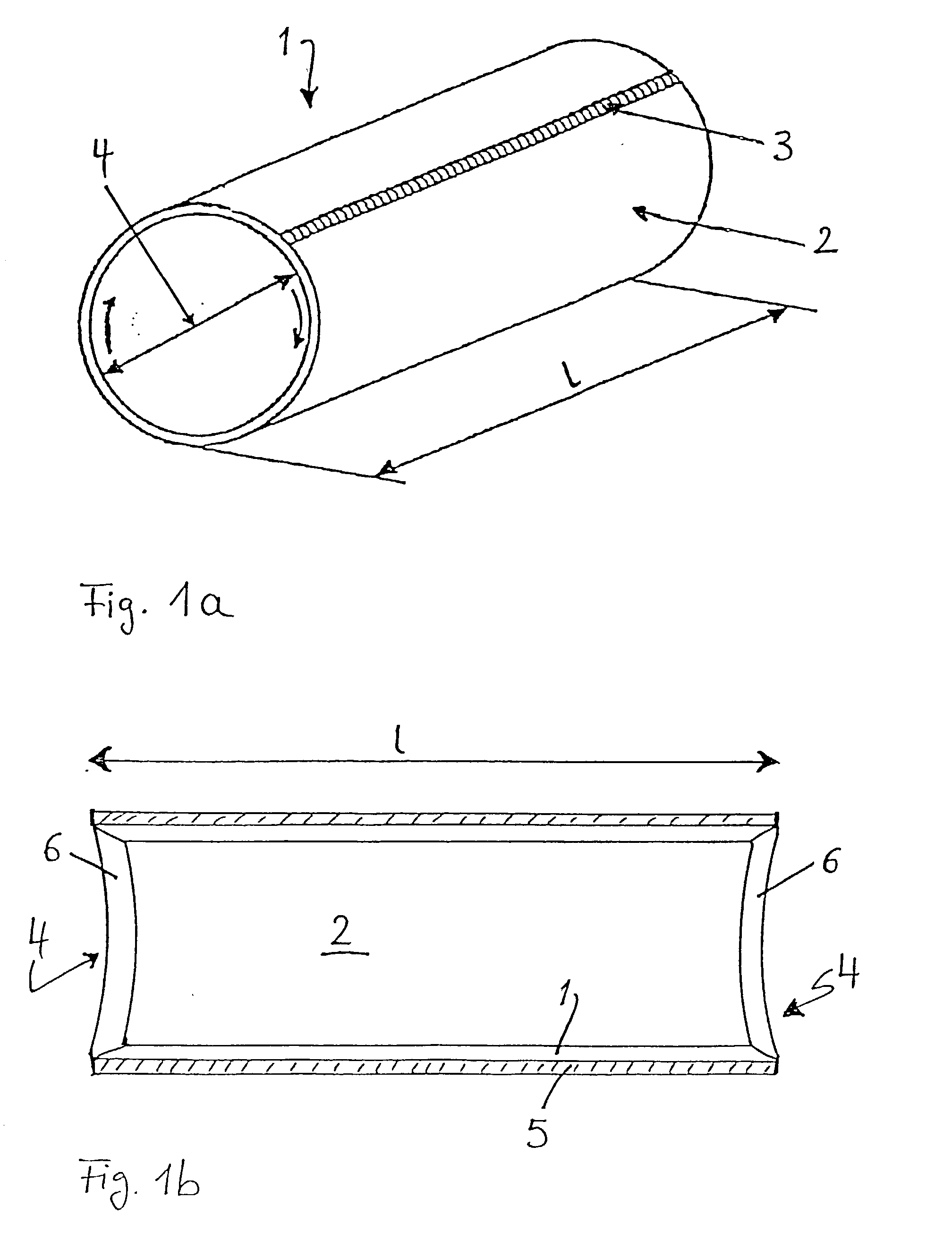

Sleeve for flexographic printing

InactiveUS6745692B2Hinder compressibilityEasy to assembleTransfer printingAddressographsPolymer scienceEngineering

A sleeve (10) for flexographic printing includes a sleeve body (2) made of an at least partially non-electroconductive material, which within its inside (4) is mountable on an electroconductive king roll on the outer wall of the roll, of a printing press, the king roll being designed as an air cylinder, and exhibiting at least one contact zone with the king roll. The sleeve exhibits an electroconductive surface (6), which is connected to the contact zone via at least one electroconductive element (20) provided in the sleeve body (2) for diverting electrostatic charges into the outer wall of the roll of the king roll. The sleeve is therefore given an electroconductive structure, through which the unavoidable electrostatic charges in printing presses with a plurality of printing couples are diverted via the king roll before it reaches a scale that would suffice for a discharge, ignition, or deflagration of the solvents used in the printing.

Owner:POLYWEST KUNST SAUERSSIG & PARTNER

Transfer roller

InactiveUS6293895B1Improve sealingImprove stabilityShaft and bearingsPortable power-driven toolsElectrical resistance and conductanceUpper floor

A transfer roller is used in an electrophotographic printer. The transfer roller rotates in contact with a rotating photoconductive drum with a print medium travelling therebetween. The transfer roller has a metal shaft around which a rubber roller is formed. The rubber roller is sponge-like and electrically semiconductive. The rubber roller is covered with a resin tube which has a lower layer formed on the rubber roller and an upper layer formed on the lower layer. One of the upper and lower layers has a higher sealing effect than the other of the upper and lower layers, and the other of the upper and lower layers has a higher stability of electrical resistance than the one of the upper and lower layer.

Owner:OKI DATA CORP

Wear-resisting, ink-repellent coating process for printing-press components

A wear-resistant, ink-repellent coating, for printing-press components, and in particular, web-fed printing presses. In order to provide a seal for this low-wear coating which results in a permanent ink-repellent surface quality and which additionally has a high resistance to standard cleaning agents used in printing technology, the printing-press component which is to be protected is first provided with oxide ceramic or hard metal layer. This layer may be applied by thermal spraying. In addition, the component is treated with a polyorganosiloxane sealant, particularly polyhydridomethylsiloxane, including the necessary heat-curing at moderate temperatures of from 100° C. to 170° C. so as to prevent ink deposition. The sealing may also take place after the wear-resistant layer has undergone a grinding and polishing treatment.

Owner:MANROLANAD AG

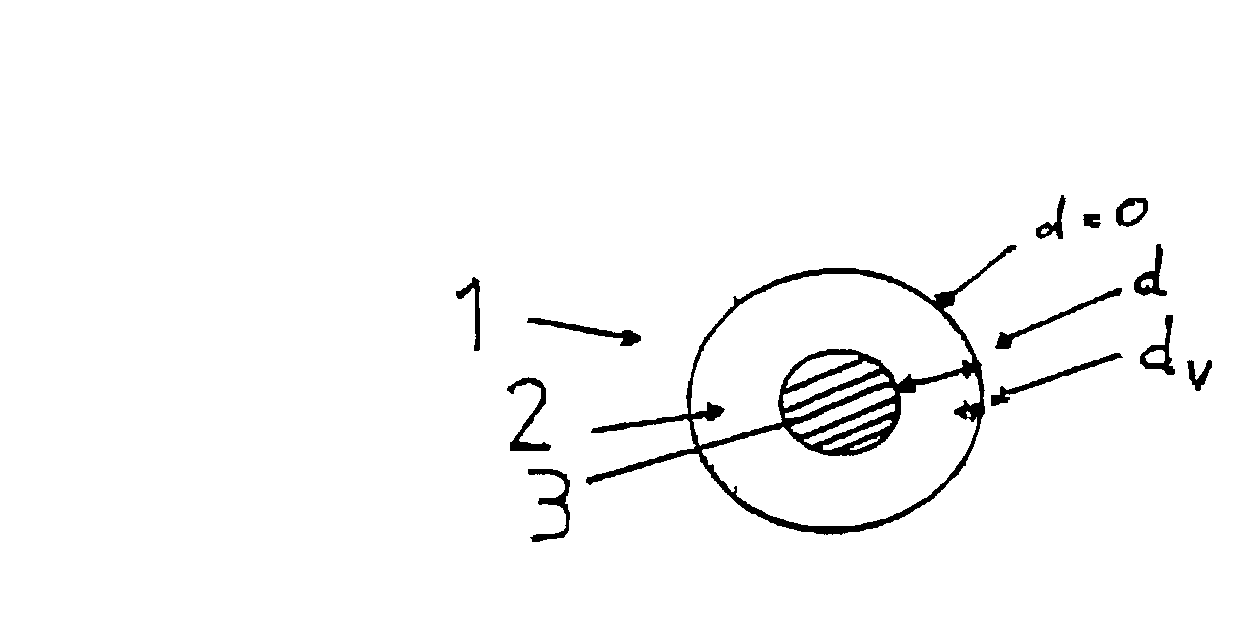

Roller for fluid film preparation or application

InactiveUS20030078147A1Ribbing can be avoidedEfficient qualityLiquid surface applicatorsShaft and bearingsCost effectivenessEngineering

The invention relates to a roller for fluid film preparation, having an inside core (3), a first layer A, which surrounds the core and has a first hardness, and a second layer B, which surrounds first layer A and has a second hardness different from that of the first layer, where the two surround the core with a layer thickness d. In order to design a roller for fluid film preparation, particularly for offset printing, with which inhomogeneities in the printing medium or printed product, particularly ribbing on the printed product, can be at least largely avoided, and which is cost-efficient to manufacture, it is proposed that the roller coating be provided, at least in certain sections, with an essentially continuous hardness gradient through the layer thickness (dV). In order to produce the hardness gradient, a gradient of a hardness-modifying substance or agent, or a precursor thereof, e.g. an agent that increases the degree of cross-linking, can be incorporated into the coating material by means of diffusion or migration of the substance or agent from at least one surface of the roller coating.

Owner:WESTLAND GUMMIWERKE GMBH & CO

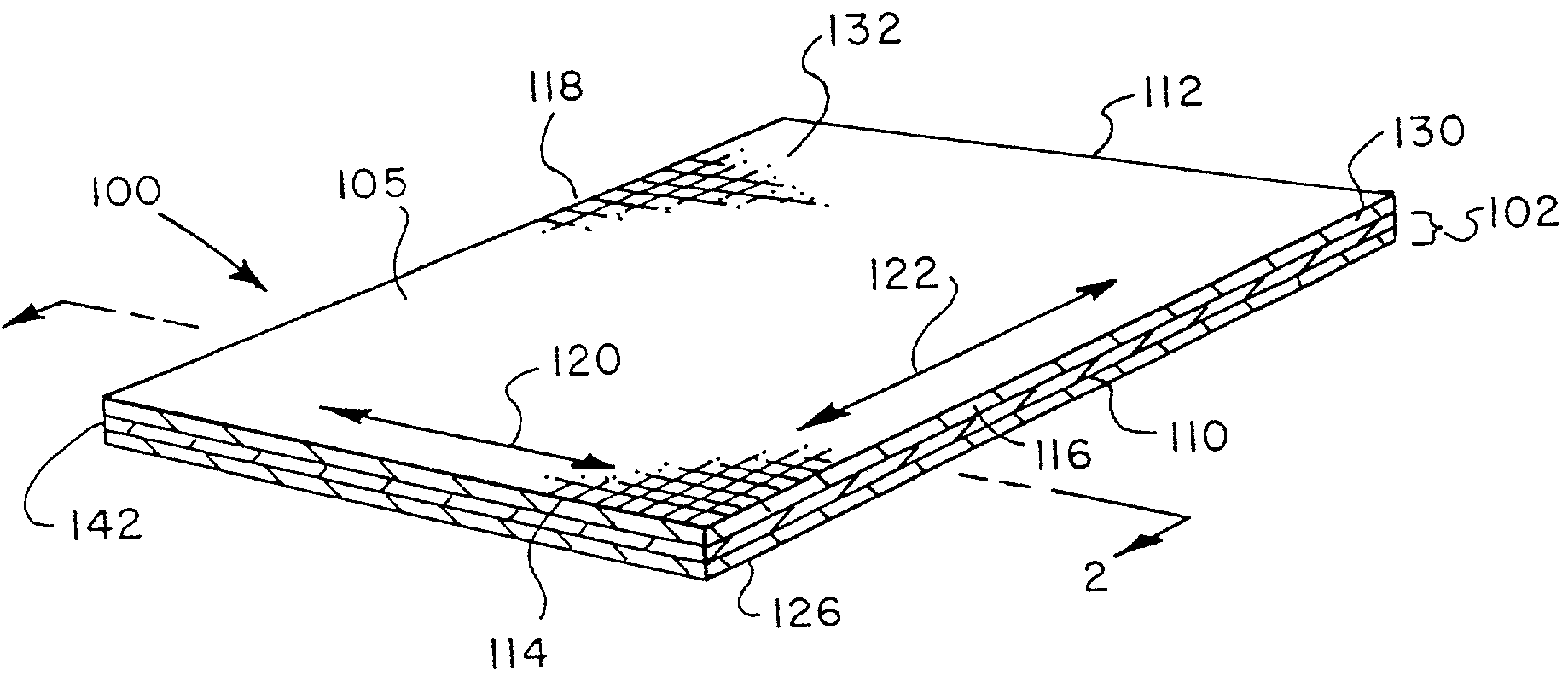

Sleeve-like printing or transfer form and device for chamfering the longitudinal ends of a sleeve-like printing or transfer form

A support sleeve made of a metallic material, preferably of nickel, is provided at at least one longitudinal end with a chamfer running all around in the inner circumference. This prevents damage to a film-like coating or thin intermediate sleeve, which surrounds the cylinder core to which the sleeve is fitted. A device for chamfering and deburring the longitudinal ends of the sleeve include a supporting body having a cylindrical journal with a diameter only slightly smaller than the internal diameter of the sleeve to be machined, in order to accommodate a longitudinal end of the sleeve and to guide the cut. A cutting holder is machined on the supporting body by means of which holder a cutter can be brought up to the inner circumference of the longitudinal end of the sleeve to be machined, and the supporting body can be rotated relative to the sleeve to be machined and pushed onto the journal.

Owner:MANROLANAD AG

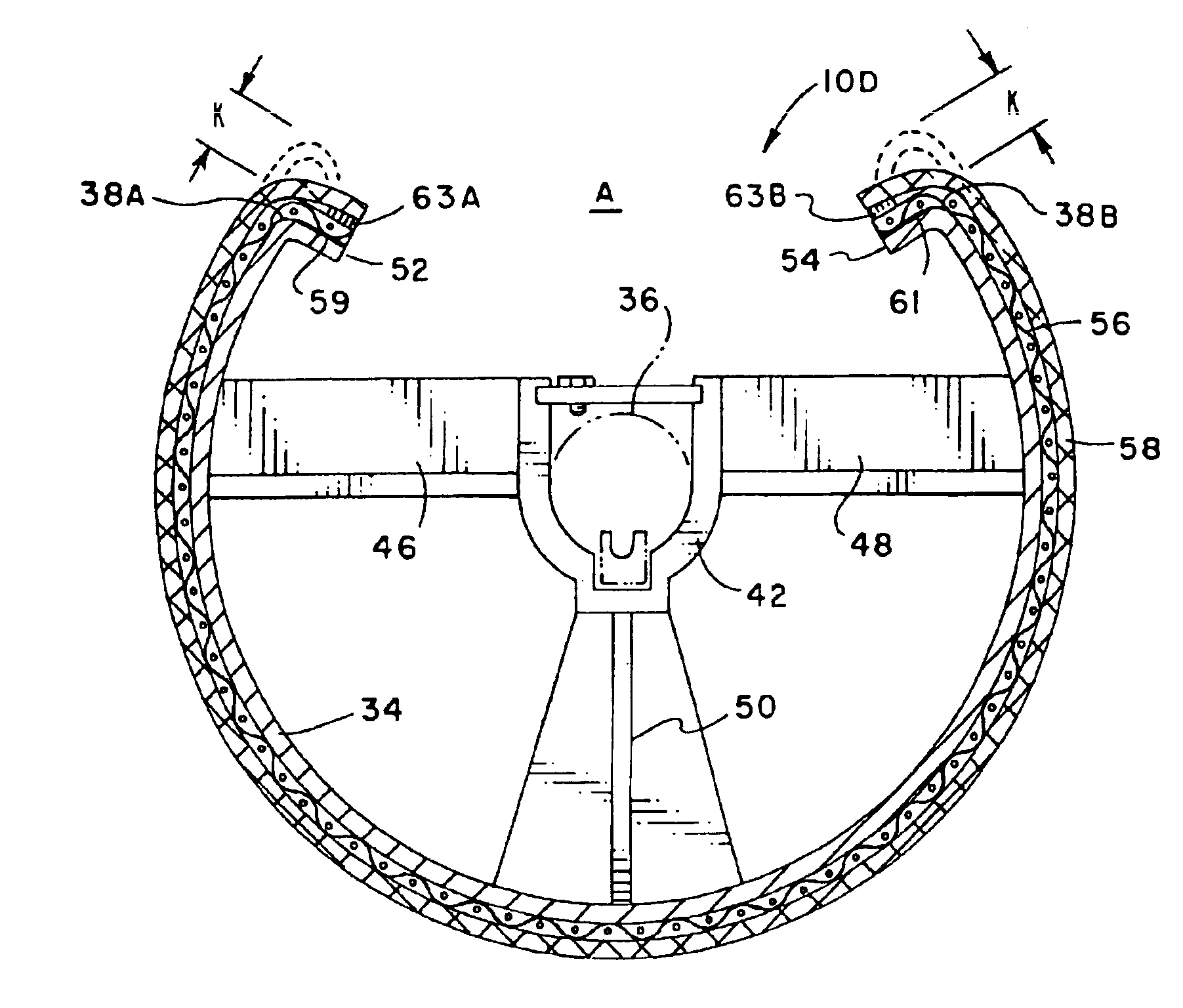

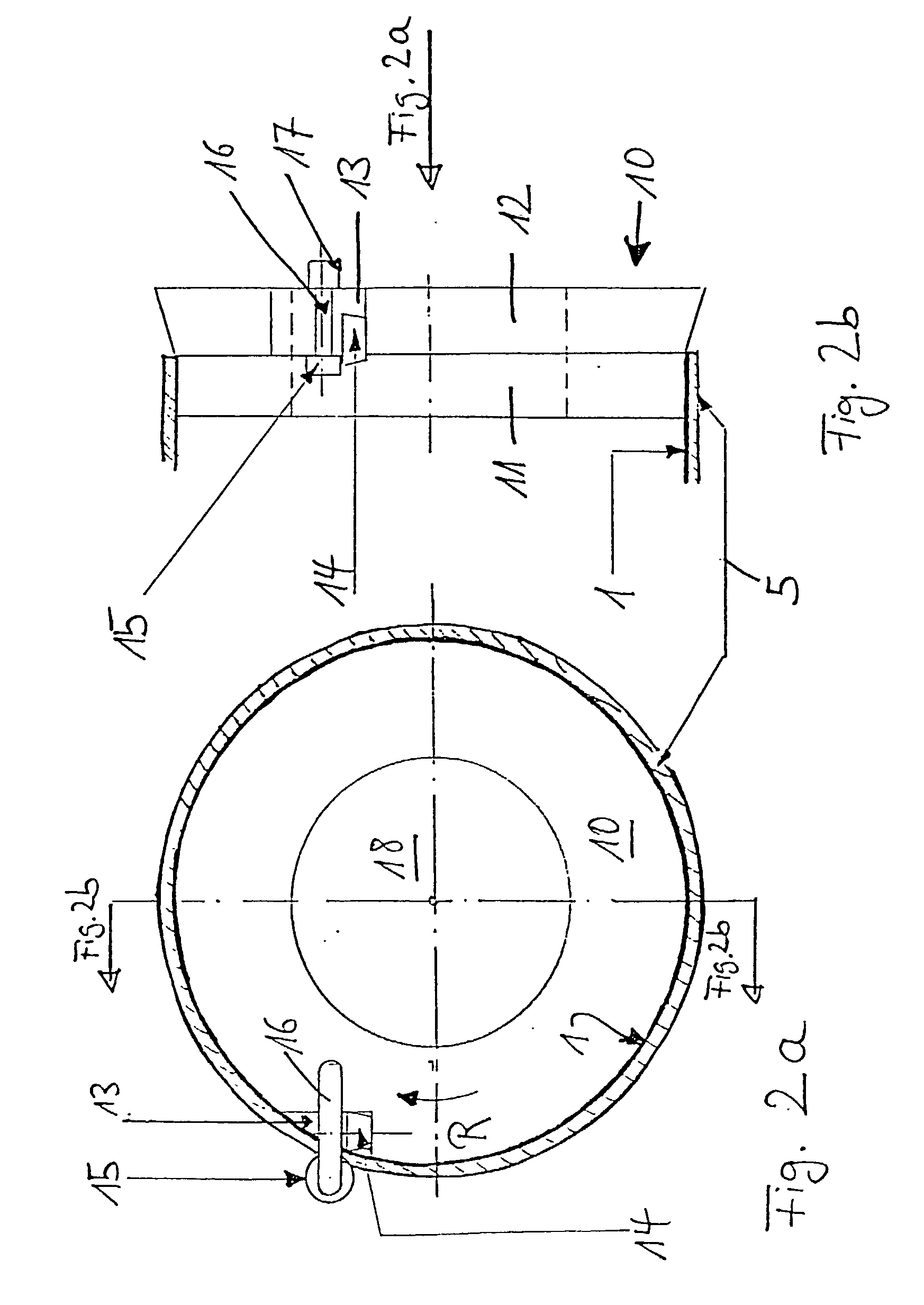

Inexpensive, wash-free integrated cover for printing press transfer cylinders

The invention is a simple, inexpensive, wash-free integrated cover for a printing transfer cylinder (preferably, but not necessarily, in a Komori press), comprising a flexible jacket covering permanently attached to a cylinder base cover. The invention provides advantages over T-Y paper and non-tack film in that dampening solution, washing, and cleaning causes failure in both over time, whereas dampening solution is beneficial to the present invention as such is retained in the flexible jacket cover and helps to prevent ink buildup and marking. The flexible jacket covering is moveable relative to the cylinder base cover, thereby further reducing ink buildup and marking. The integrated cover is disposable, which reduces periodic maintenance and cleaning of the transfer cylinder coverings and provides for fresh, clean substrate support surfaces upon each new installation. The flexible jacket covering and cylinder base cover are integrated into a single, convenient unit, thereby speeding and simplifying installation.

Owner:PRINTING RES

Composite doctor blade chamber

InactiveCN107614266AFaster and easier replacementAdhesive processesRotary intaglio printing pressWorking environmentEngineering

A composite doctor blade chamber (1) for a doctor blade chamber system for rotary printing units, the doctor blade chamber (1) including a front side with an open channel (8), wherein the doctor bladechamber is made of two composite profiles, an open profile (30) with a front side and a back side and a closed profile (33) with a front side and a back side, wherein the front side (31) of the openprofile is joined with the back side of the closed profile (35), whereby is achieved low weight and high strength, high corrosion resistance, a cleaning-friendly surface, less waste of ink, nice appearance and an improved working environment. In addition it is an object of the invention to provide a doctor blade chamber system with the above mentioned advantages where replacement of doctor bladescan be performed faster, more easily and without use of tools.

Owner:TRESU

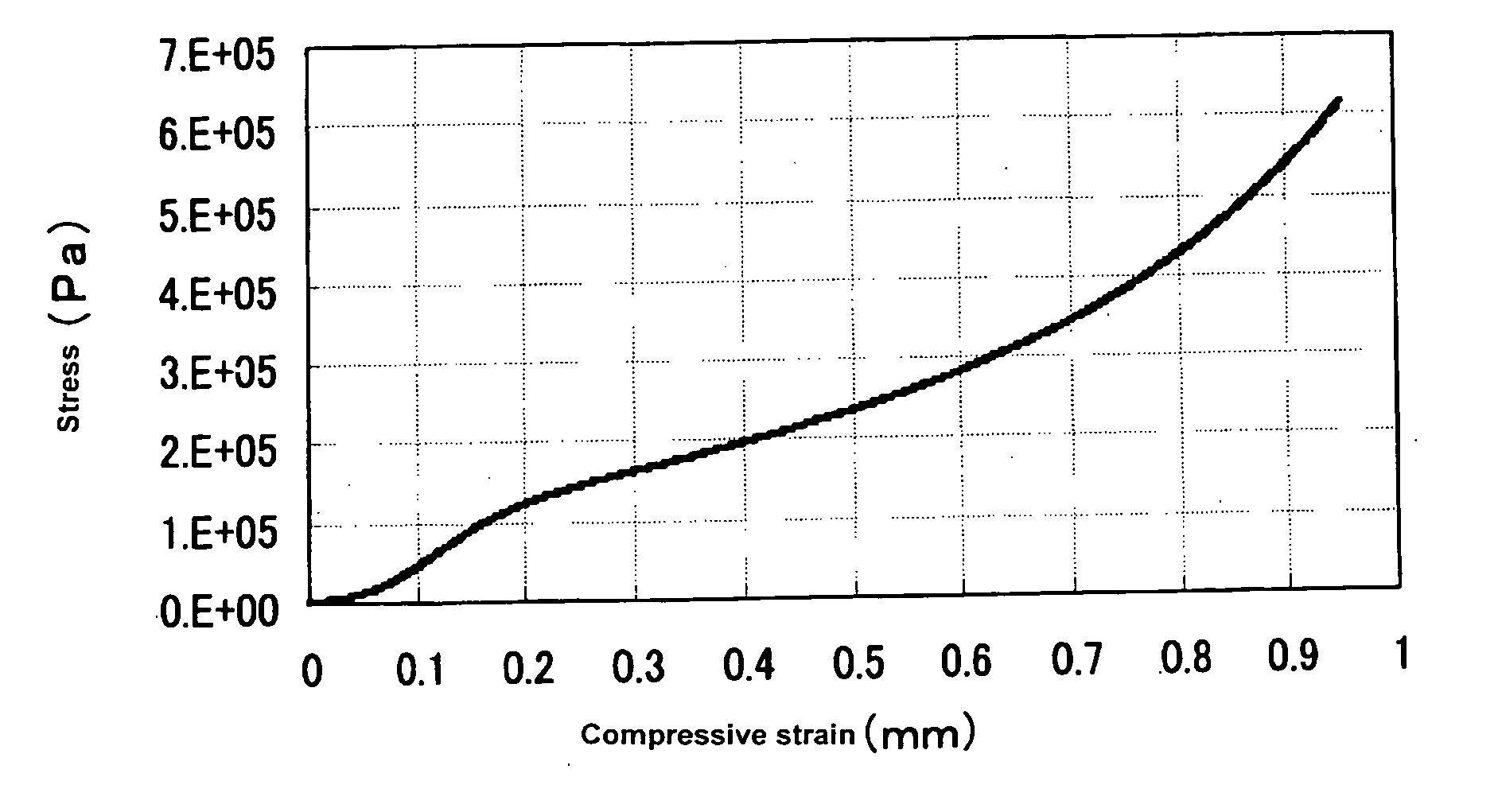

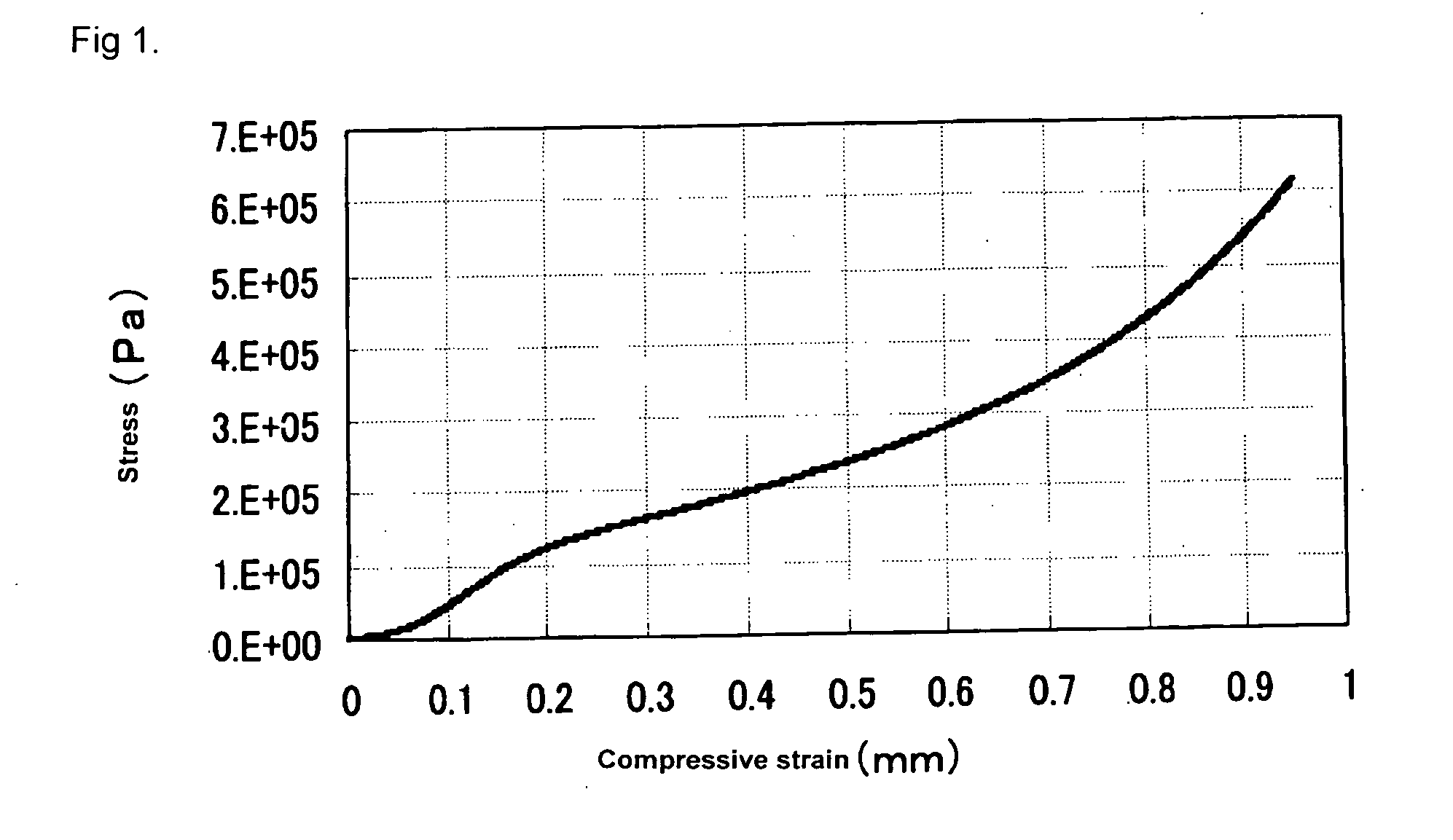

Cushioning Material for Printing

InactiveUS20090238984A1Good dot reproductionExcellent in solvent resistance characteristicDecorative surface effectsRecord information storageCushioningEngineering

A cushion for printing or a cushioning layer for printing plate manufactured using a cushioning material for printing having a storage elastic modulus (E′) of 1.0×108 Pa or greater at 20° C. and 1000 Hz enables high-speed printing while keeping a printing quality.

Owner:ASAHI KASEI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com