Improved type ceramic anilox roller and preparation method thereof

A ceramic mesh and improved technology, applied in the field of printing, can solve the problems of not meeting the production needs, the ink load cannot meet the requirements, and the printing effect is not good, achieving good ink transfer performance, good printing effect, and reducing pinholes. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] see image 3 with Figure 4 , in this embodiment, an improved ceramic anilox roller includes a metal roller body, the surface of the metal roller body is provided with a ceramic surface layer, and the ceramic surface layer is provided with an anilox pattern for loading ink, and the anilox pattern It consists of a plurality of identical and regularly arranged meshes. The cross-sectional shape of the mesh is a stretched hexagon, and the stretched hexagon is obtained by extending the two opposite sides of a regular hexagon to the same length. Hexagon, the stretched hexagon is composed of two stretched sides and four non-stretched sides, and the mesh wall of the mesh includes two stretched walls and four non-stretched walls.

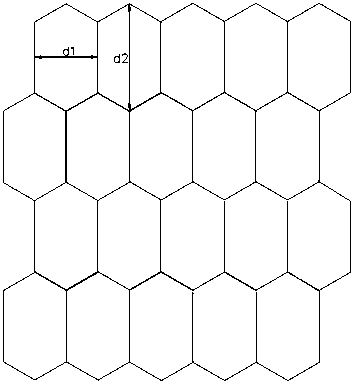

[0040] Further, the distance between the two stretched edges ( figure 2 marked with d1 in ), and the distance from the intersection point of two adjacent non-stretching edges to the intersection point of the other two adjacent non-stretching edges ...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is:

[0066] In this embodiment, the distance between the intersection of two adjacent non-stretching sides and the intersection of other two adjacent non-stretching sides is 175 μm. Further, the distance between the two stretched edges ( figure 2 marked with d1 in ), and the distance from the intersection point of two adjacent non-stretching edges to the intersection point of the other two adjacent non-stretching edges ( figure 2 Marked by d2) the ratio is 1:1.4.

[0067] The mesh is provided with two openings, and the two openings respectively pass through the two opposite stretching walls.

[0068] In this embodiment, a method for preparing an improved ceramic anilox roll includes the following steps:

[0069] (1) Get the ceramic anilox roller initial product that surface spraying is coated with ceramic surface layer, adopt laser engraving method to carve out mesh in ceramic surface layer; Wherein, describe...

Embodiment 3

[0082] In this embodiment, the distance between the intersection of two adjacent non-stretching sides and the intersection of other two adjacent non-stretching sides is 205 μm. Further, the distance between the two stretched edges ( figure 2 marked with d1 in ), and the distance from the intersection point of two adjacent non-stretching edges to the intersection point of the other two adjacent non-stretching edges ( figure 2 Marked by d2) the ratio is 1:1.6.

[0083] In this embodiment, a method for preparing an improved ceramic anilox roll includes the following steps:

[0084] (1) Get the ceramic anilox roller initial product that surface spraying is coated with ceramic surface layer, adopt laser engraving method to carve out mesh in ceramic surface layer; Wherein, described laser engraving step comprises:

[0085] A1. Preset the laser engraving speed, pulse frequency, pulse height and duty cycle, change the mesh wall length of the mesh; optimize the engraving program, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com