A kind of colored polymer gravel concrete and its preparation method

A polymer and concrete technology, applied in the field of concrete, can solve the problems of large surface color difference and poor overall application effect, and achieve the effects of excellent overall weather resistance, good compound synergy and modification effect, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

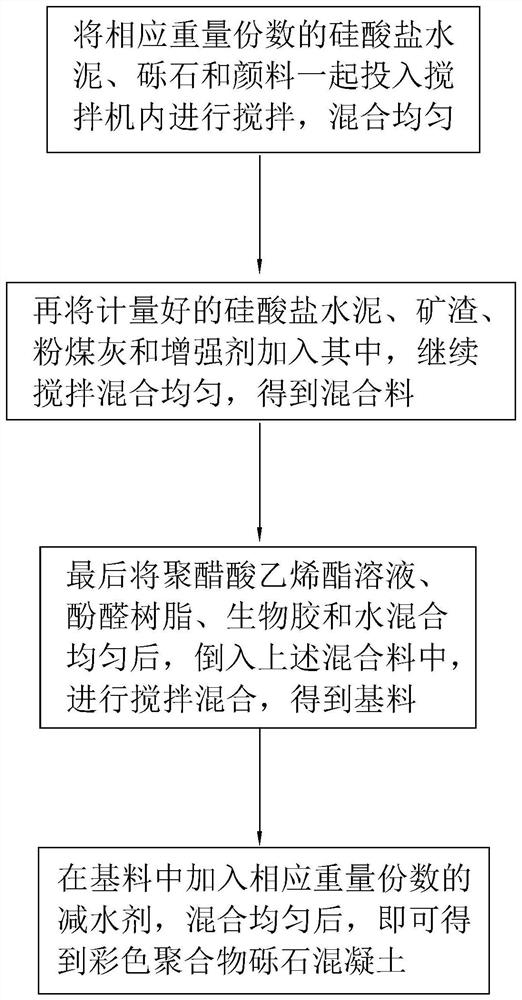

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A kind of colored polymer gravel concrete, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0047] Step 1, put Portland cement, gravel and iron blue in corresponding parts by weight together into a mixer for stirring, and mix evenly;

[0048] Step 2, adding the measured Portland cement, slag, fly ash and silicon carbide into it, and continuing to stir and mix evenly to obtain a mixture;

[0049] Step 3, finally mix the polyvinyl acetate solution, phenolic resin, guar gum and water evenly, pour into the above-mentioned mixture, stir and mix to obtain the base material;

[0050] Step 4, adding sodium lignosulfonate in corresponding parts by weight to the base material, and mixing evenly, to obtain colored polymer gravel concrete.

Embodiment 2-8

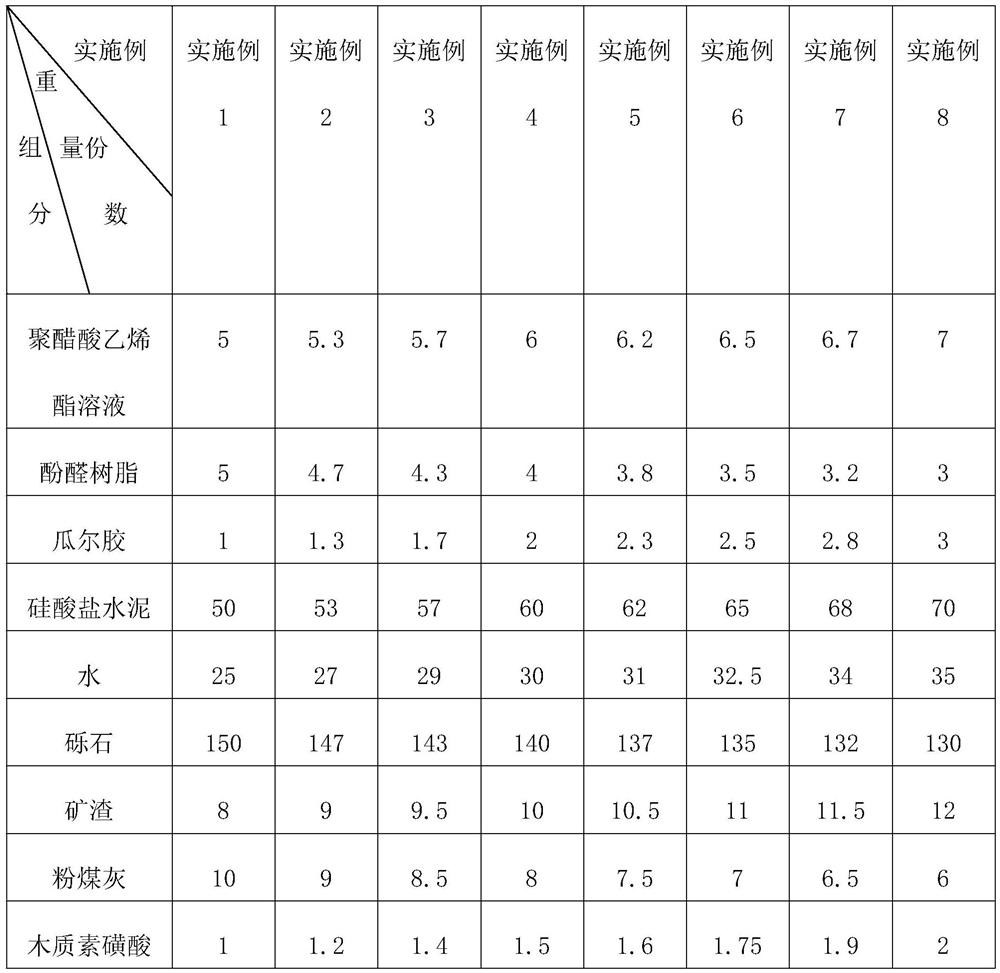

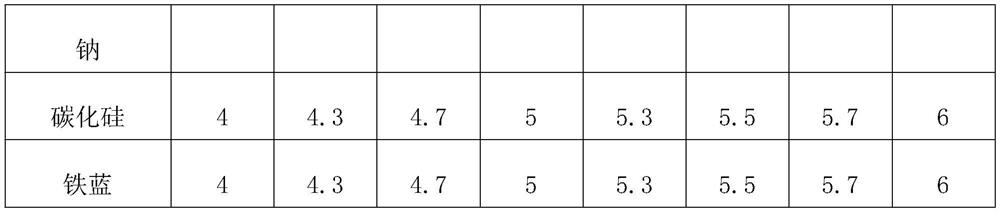

[0051] Embodiment 2-8: A colored polymer gravel concrete, the difference from Embodiment 1 is that each component and its corresponding weight parts are shown in Table 1.

[0052] Each component and parts by weight thereof in table 1 embodiment 1-8

[0053]

[0054]

Embodiment 9

[0055] Embodiment 9: a kind of colored polymer gravel concrete, the difference from embodiment 1 is that the guar gum in step 3 is replaced by carrageenan of equal quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com