Patents

Literature

63 results about "Carve out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carve out. 1. Literally, to remove the inner part of an object. A noun or pronoun can be used between "carve" and "out.". The first step in this recipe is to carve out your fruit and dispose of the seeds. They made canoes by carving out big logs. 2. To establish a niche or role for oneself.

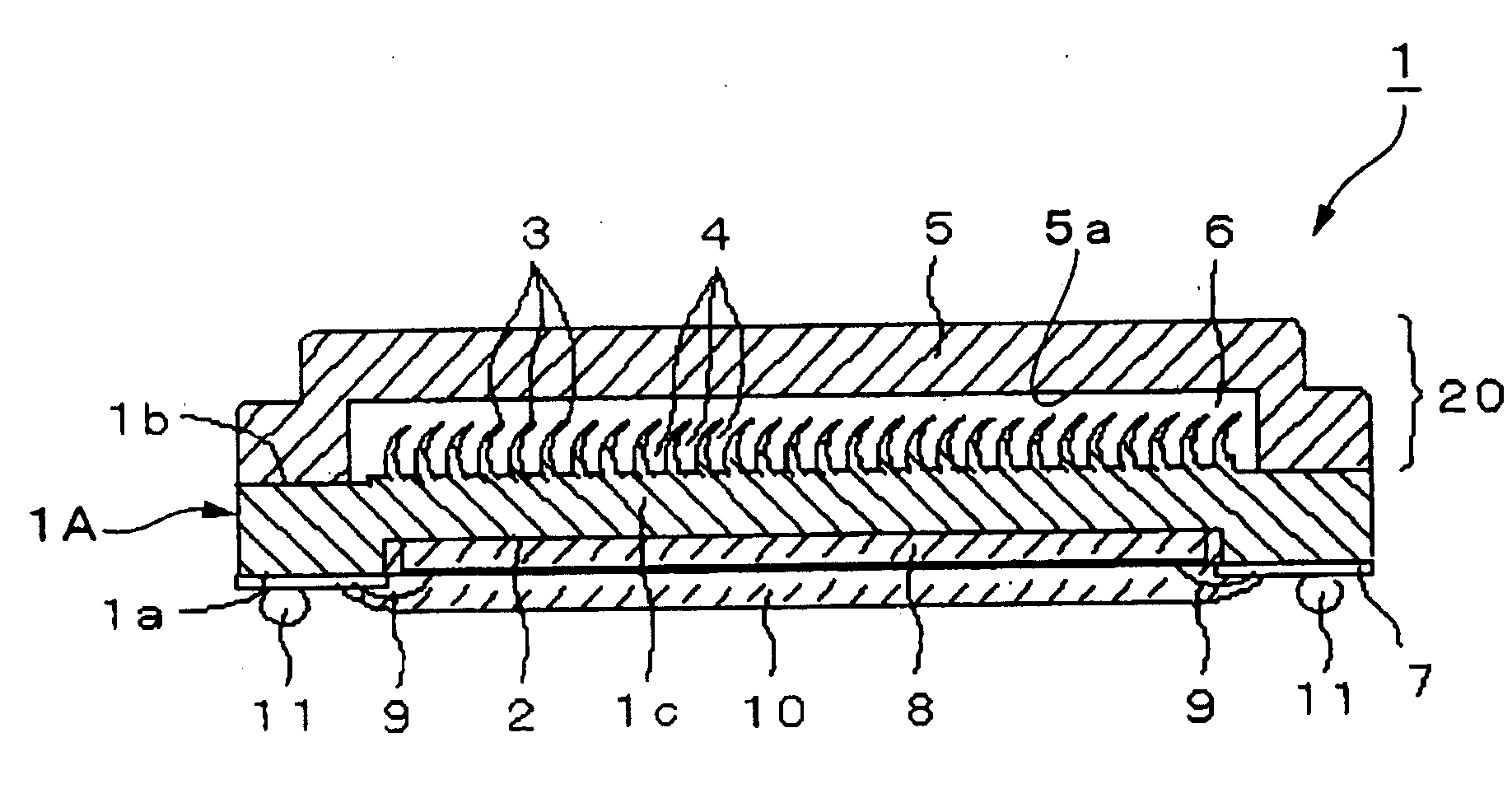

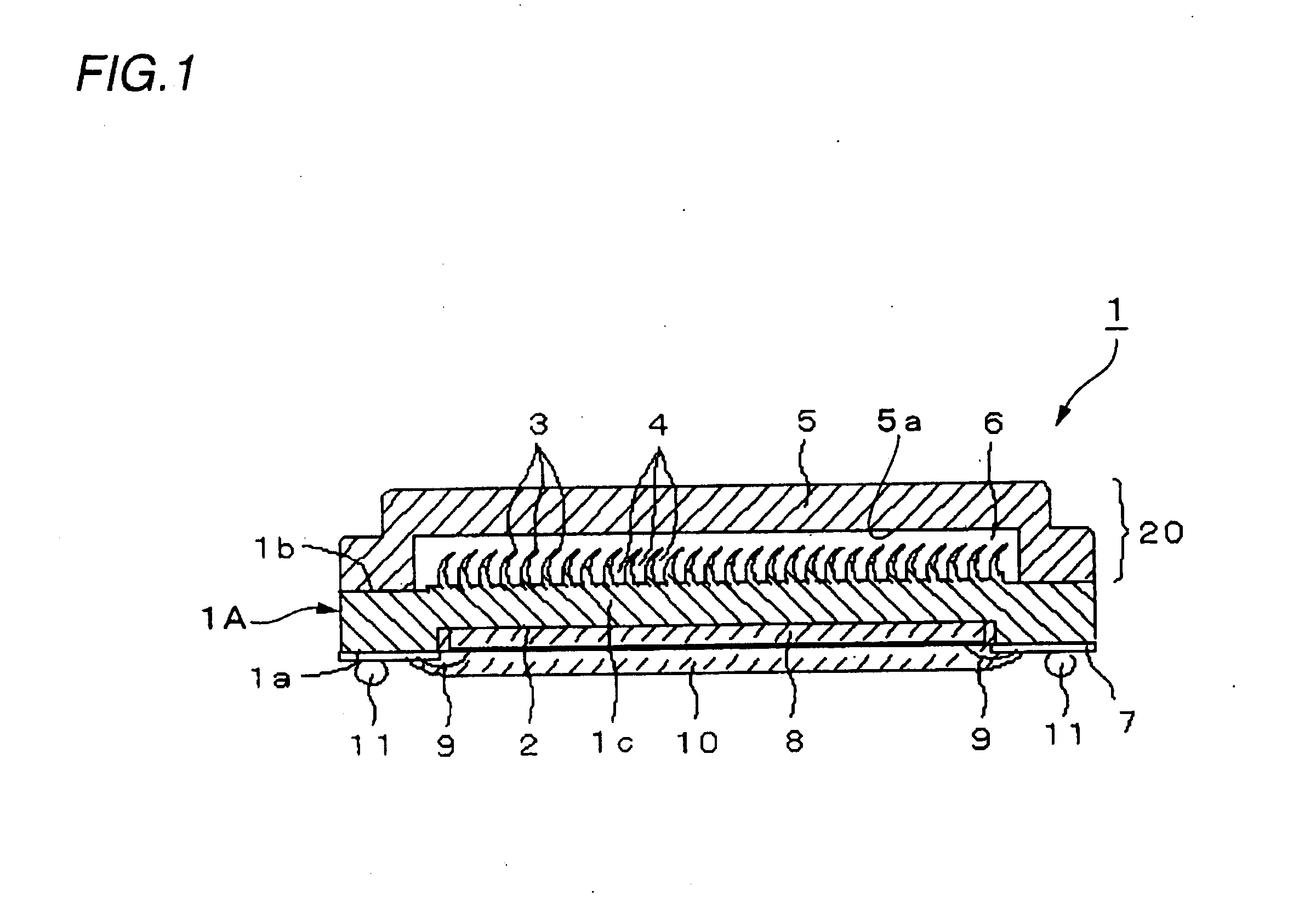

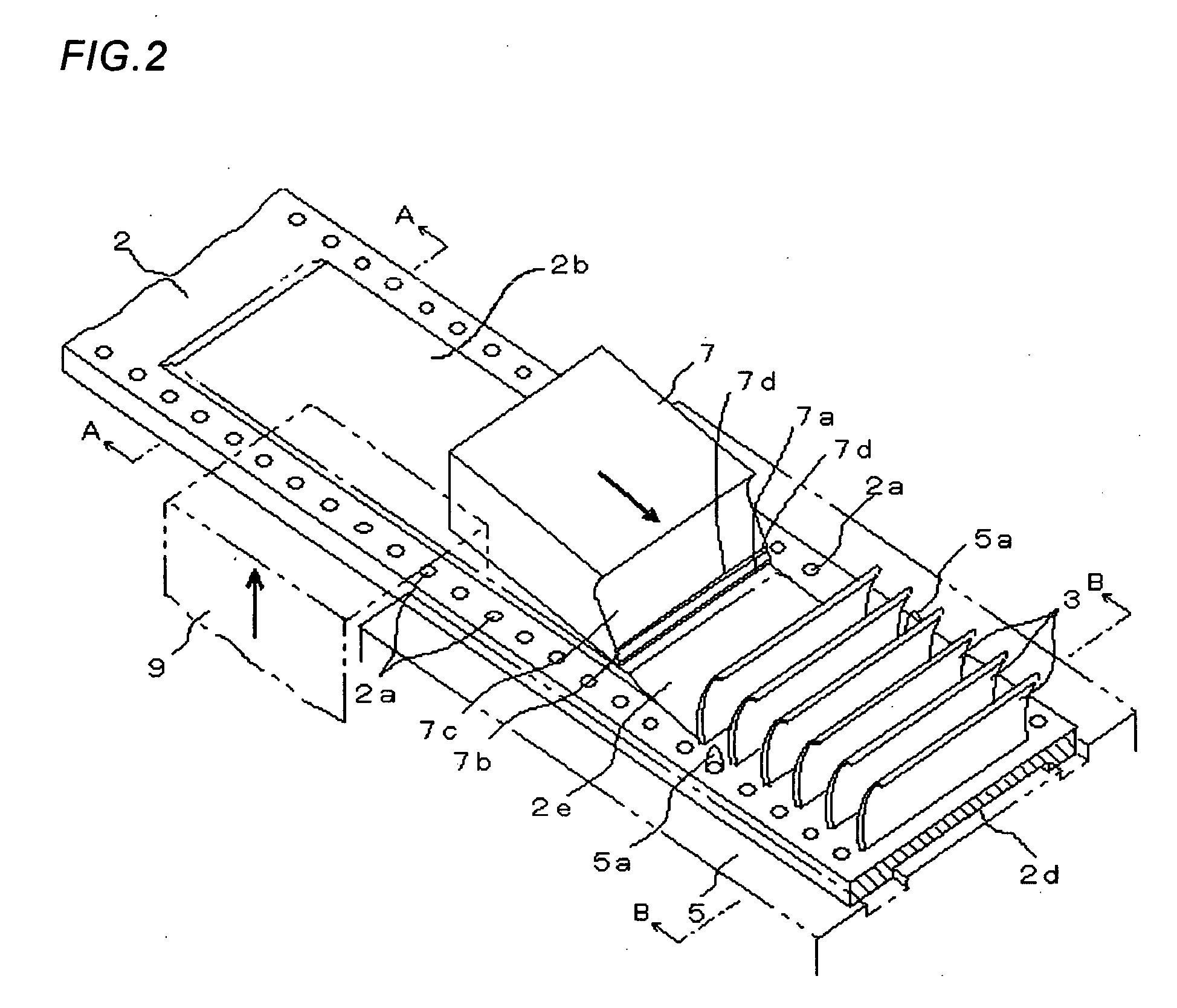

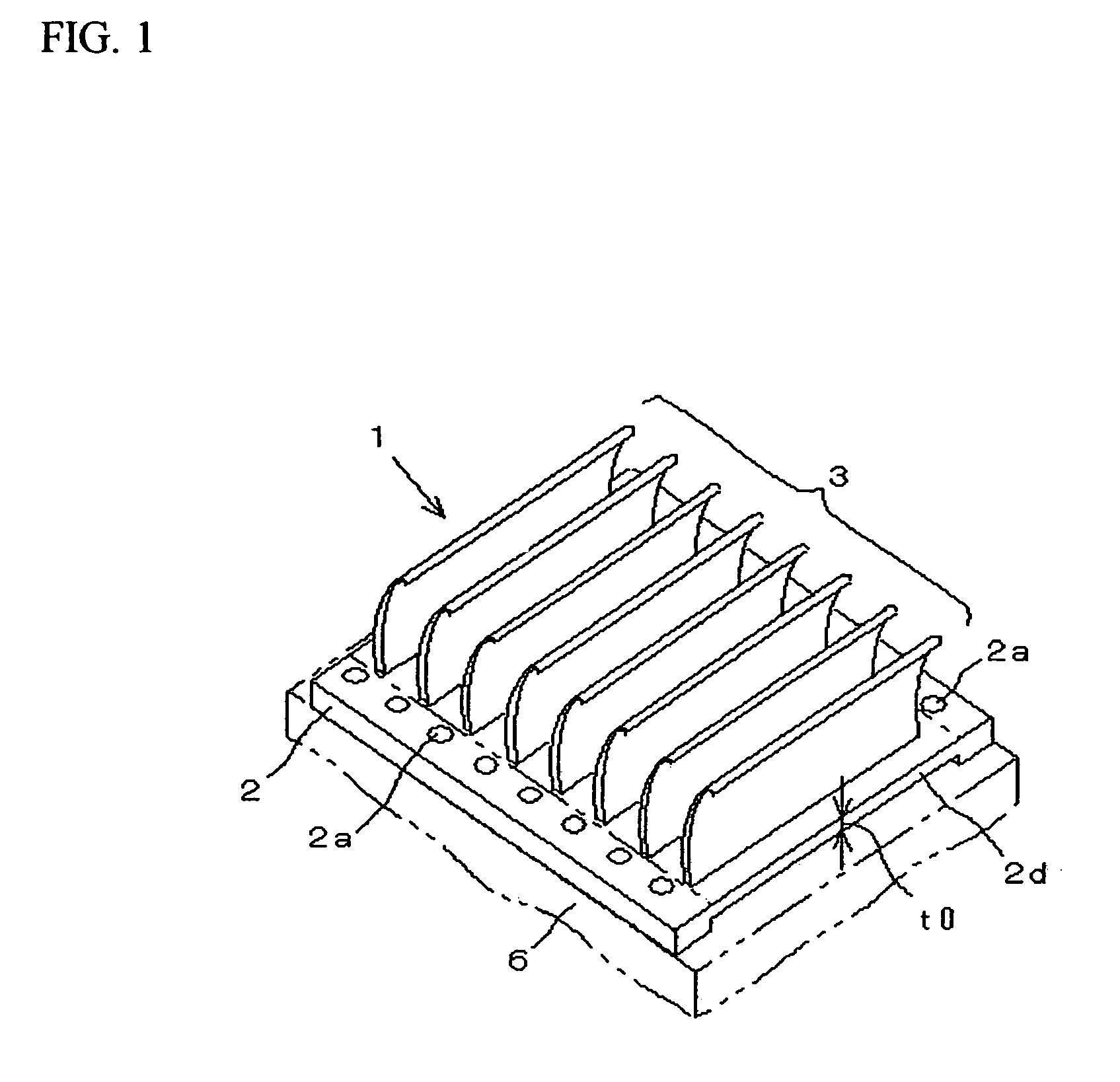

Component package having heat exchanger

InactiveUS20070163749A1Good cooling functionEfficient executionSemiconductor/solid-state device detailsSolid-state devicesWorking fluidCarve out

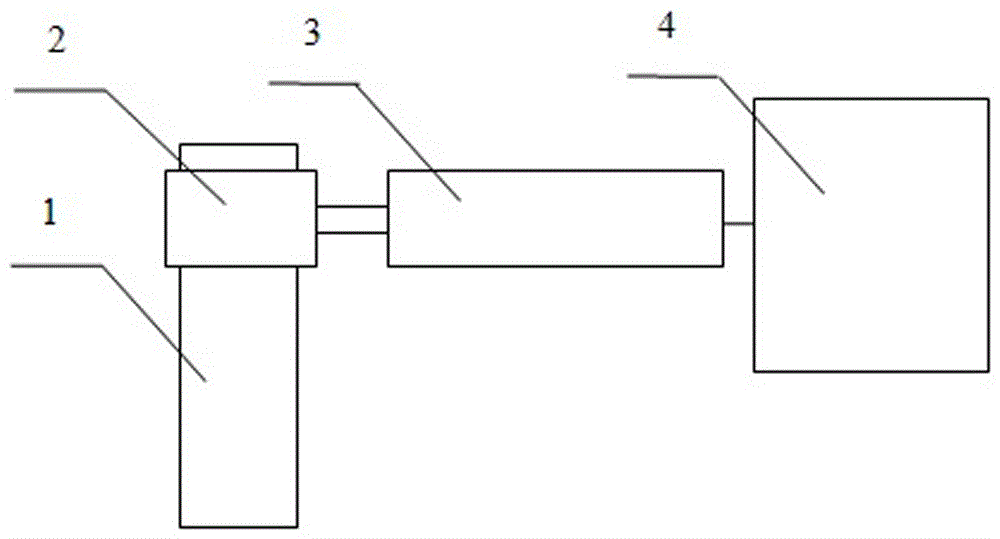

In an electrical component package (1) provided with a liquid-cooled heat exchanger (20), a main-body plate (1A) of the package and a crowning member (5) that are composed of metal plates are joined together, forming a hollow part (6) therebetween for use as a liquid-cooled heat exchanger in which a working fluid is sealed. A concavity (2) for use in mounting an electrical component (8) to be cooled is formed on the outer surface portion of the main-body plate (1A) of the package disposed opposite to the hollow part (6). An inner surface portion (5a) that faces into the hollow part (6) of the main-body plate (1A) of the package is carved out using a carving tool, whereby fins (3) are formed at a fine pitch on the inner surface portion. Minute channels (4) for moving the working fluid are formed between the fins. A flat electrical component package can [therefore] be provided with a liquid-cooled heat exchanger that has excellent heat-radiating functionality.

Owner:NAKAMURA IND MFG CO LTD

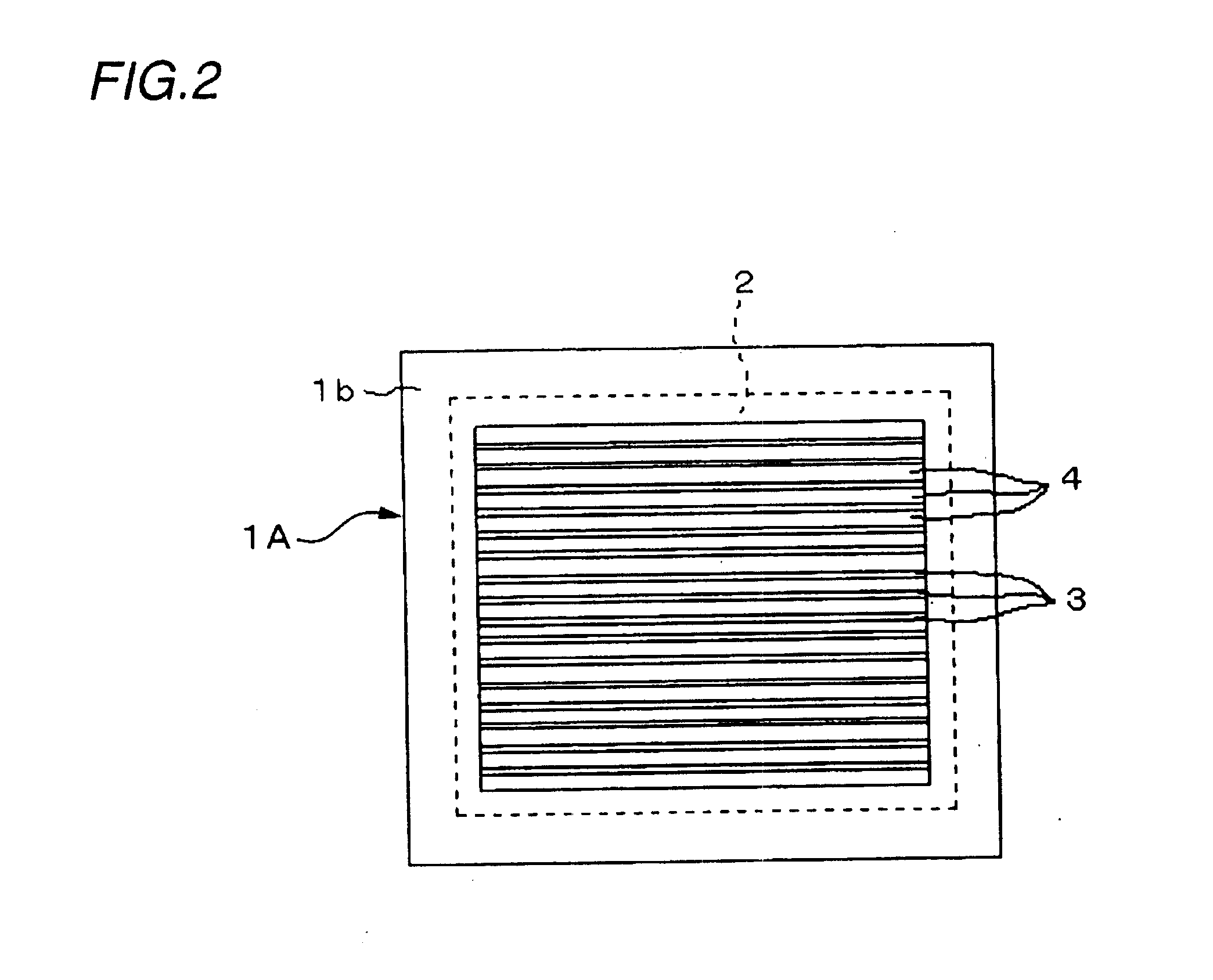

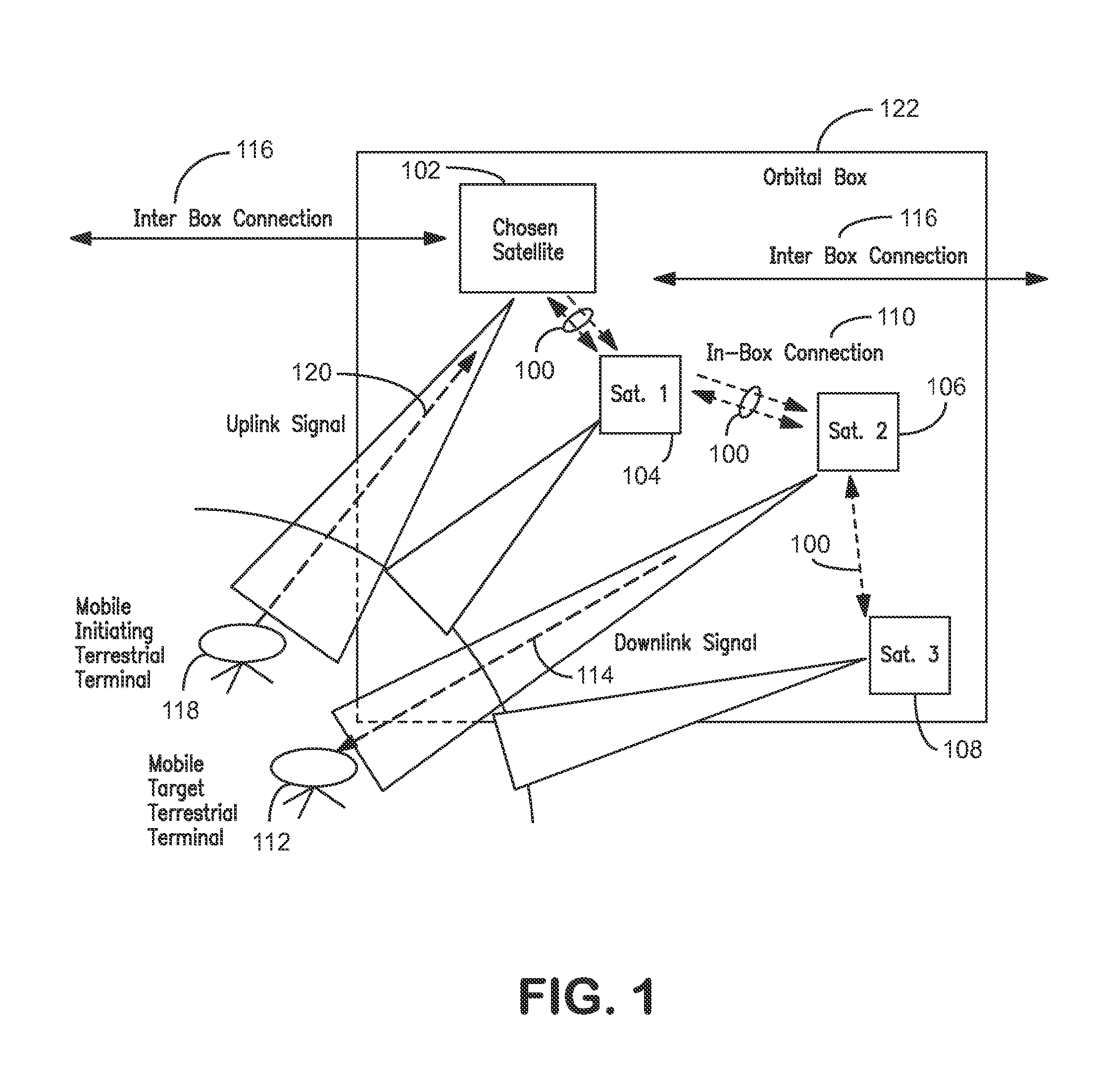

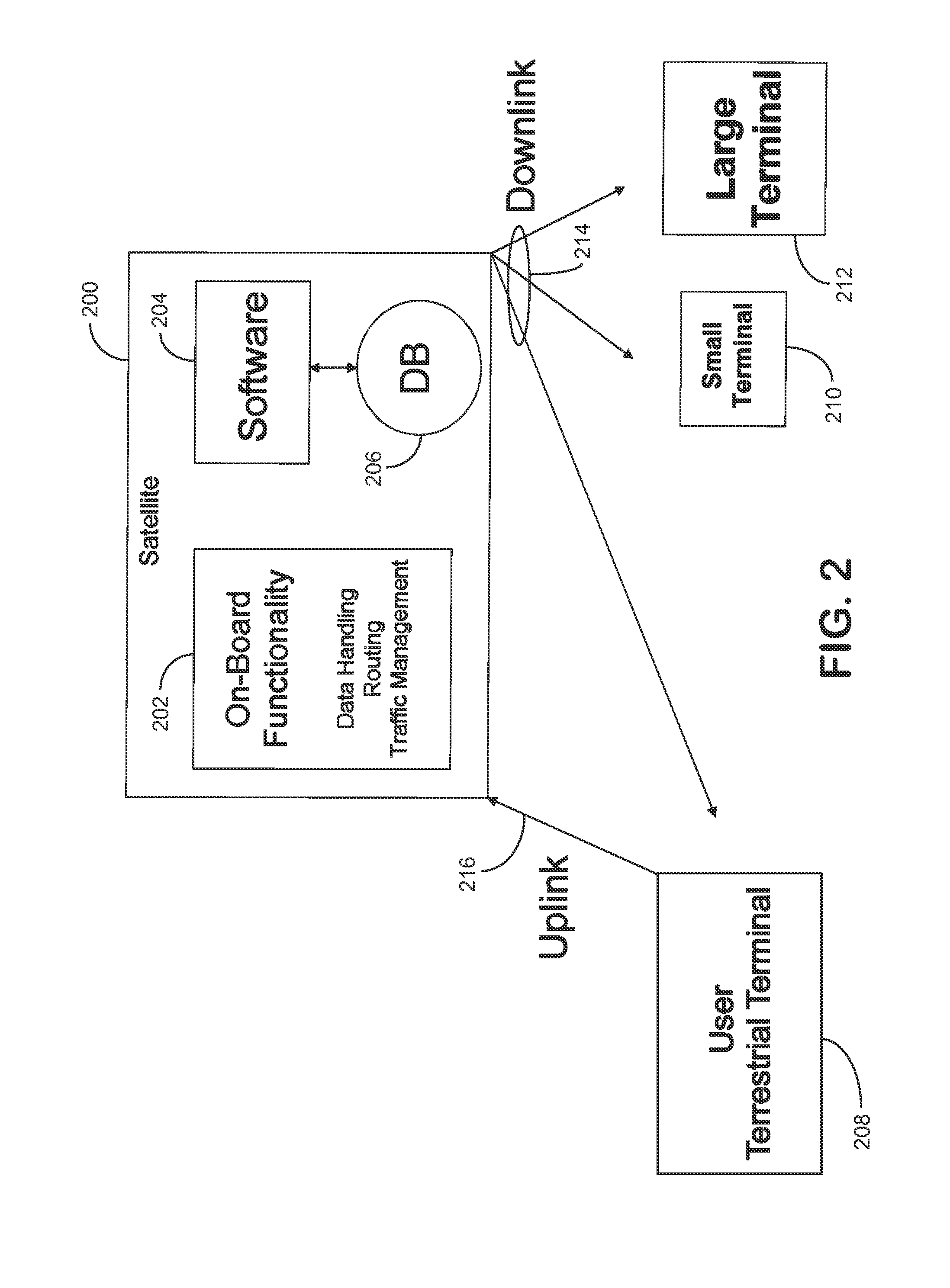

Systems and methods for establishing modular and flexible satellite communications networks

InactiveUS20080045146A1Small sizeLow costBroadcast transmission systemsRadio/inductive link selection arrangementsOn boardModularity

A system and method of building a satellite communications network provides a customer-driven, modular and flexible approach to providing satellite communications services. The satellite network provider carves out a solution for a customer problem from a design space constrained by satellite size, lifetime and payload given a set of specifications from a customer. The satellite network provider may continually gauge the needs of the users of the system in order to adapt the network to the current and future needs of the customer(s). Further, the use of small satellites utilizing on-board functionality provides modularity while maintaining economic feasibility.

Owner:OVERHORIZON (CYPRUS) PLC

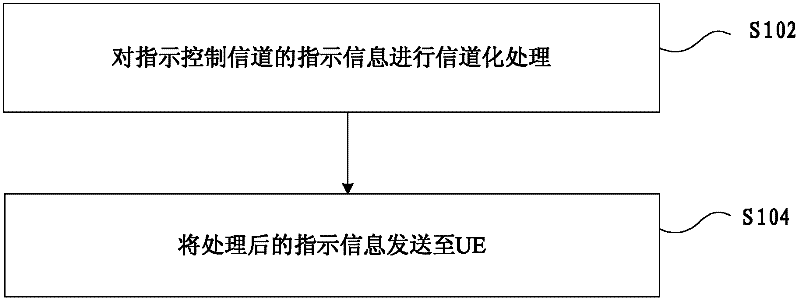

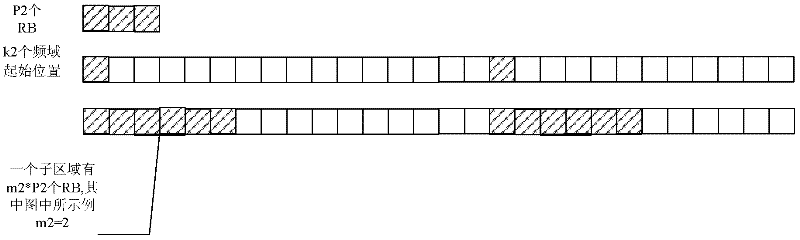

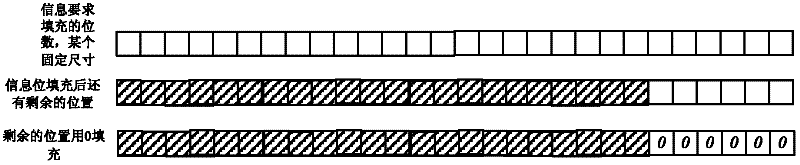

Method and device for indicating control channel

ActiveCN102263616ACorrect and convenient to receiveTransmission path divisionSignal allocationControl channelEngineering

Disclosed are a method and device for indicating a control channel. The method for indicating a control channel includes: channelization processing is performed on indication information indicating the control channel, wherein the control channel is a newly added control channel area or a control channel on a resource which is newly carved out of resources reserved for PDSCH and is for transmitting control information; and the processed indication information is sent to UE. By applying the present invention, the current problem that the UE cannot detect the newly added downlink control channel can be solved.

Owner:ZTE CORP

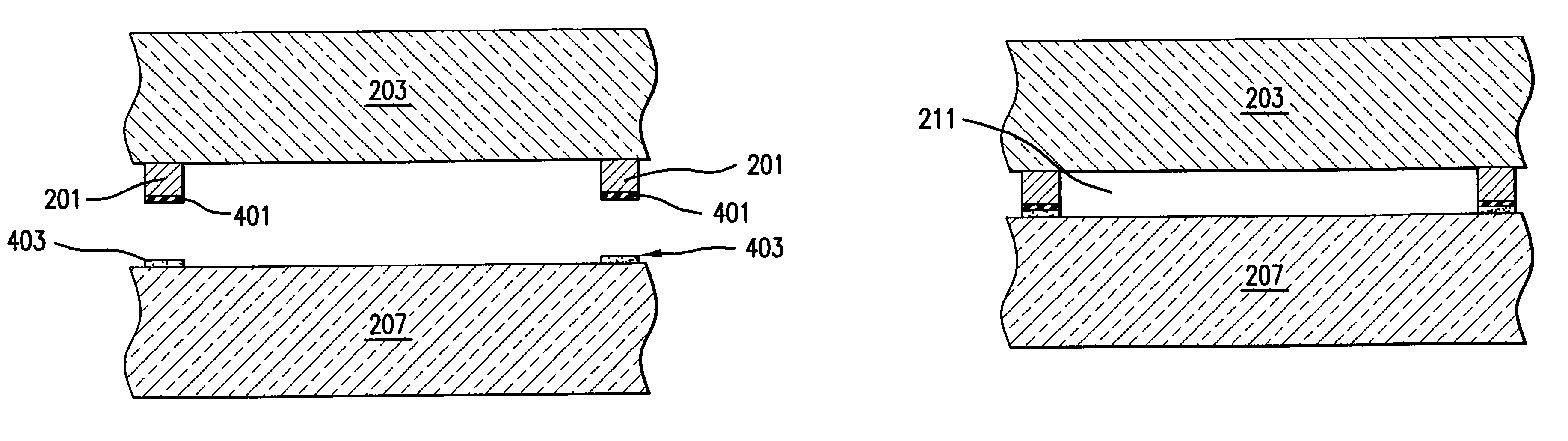

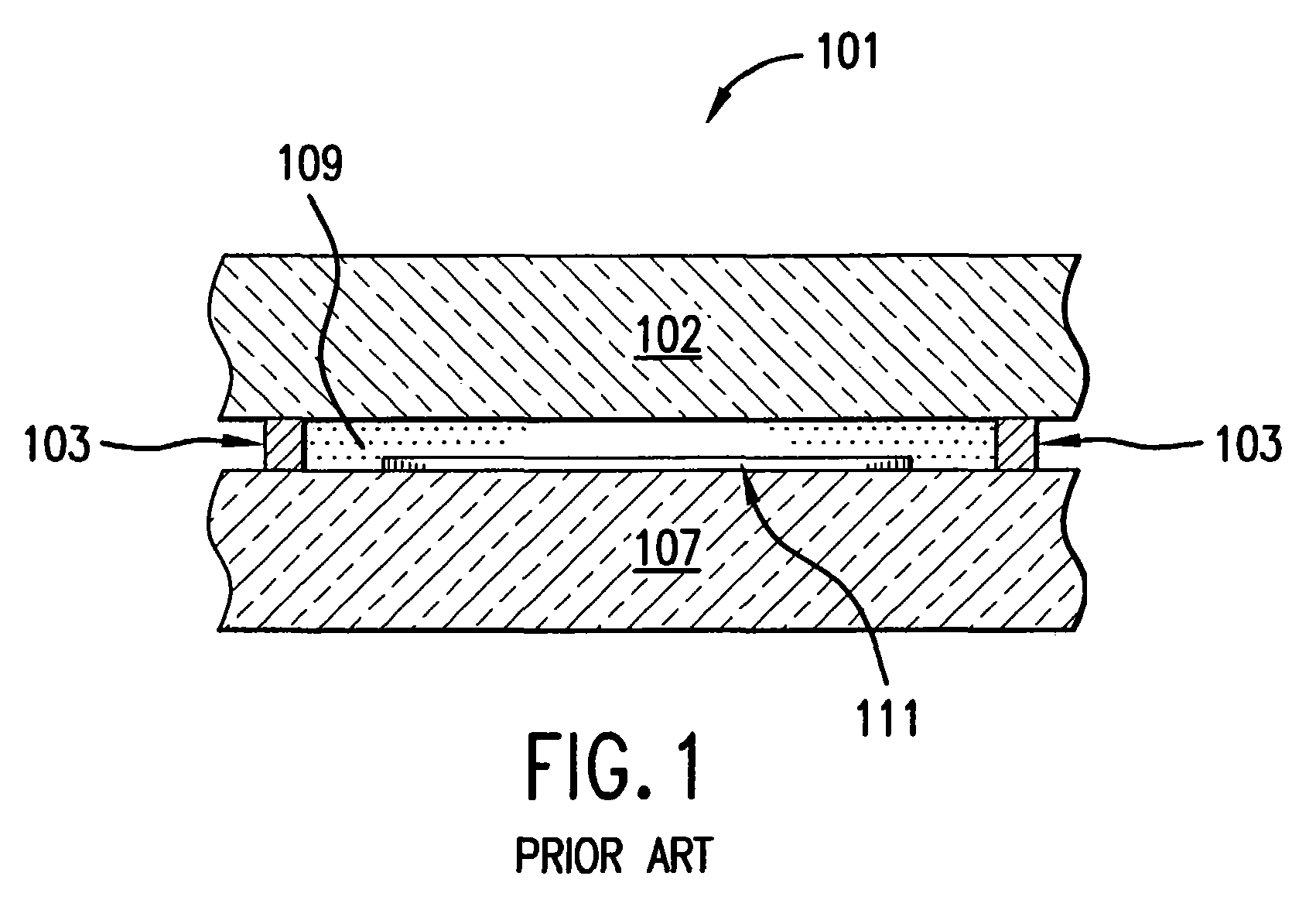

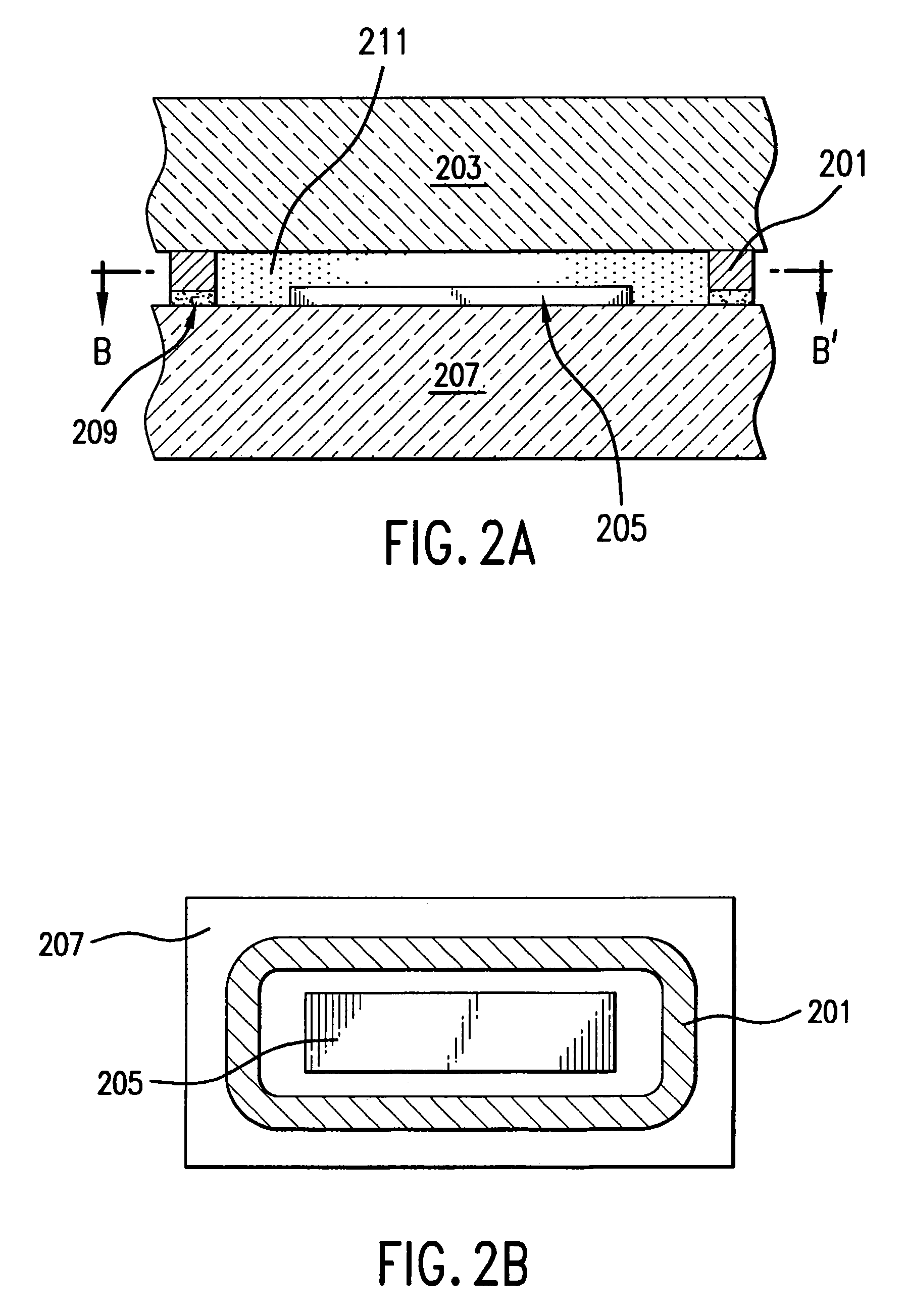

Wafer-level package with silicon gasket

InactiveUS6979597B2Less forceLess timeSemiconductor/solid-state device detailsSolid-state devicesHermetic sealEngineering

A gasket encloses a hermetically sealed environment between a cap wafer and a base wafer. The gasket is bonded to the base wafer using bonding material. The bonding material can be one or more of many substances that exhibit acceptable adhesion, sealing, and other properties that ensure a hermetically sealed environment. The gasket is carved out from the cap wafer material itself. The cap wafer is typically made of extremely strong and rigid material such as silicon. Since the gasket is made from the cap wafer, the gasket itself is also extremely strong and rigid.

Owner:AVAGO TECH INT SALES PTE LTD

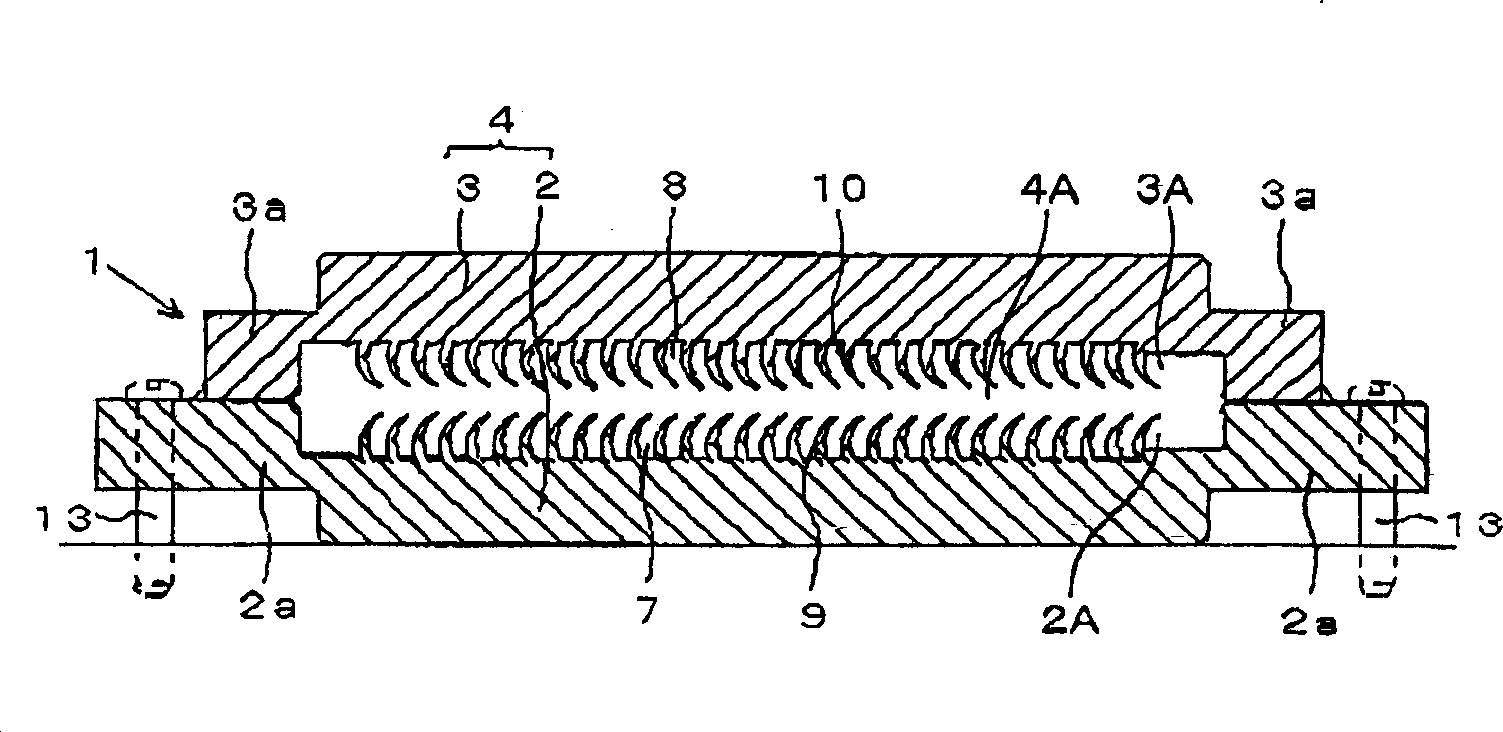

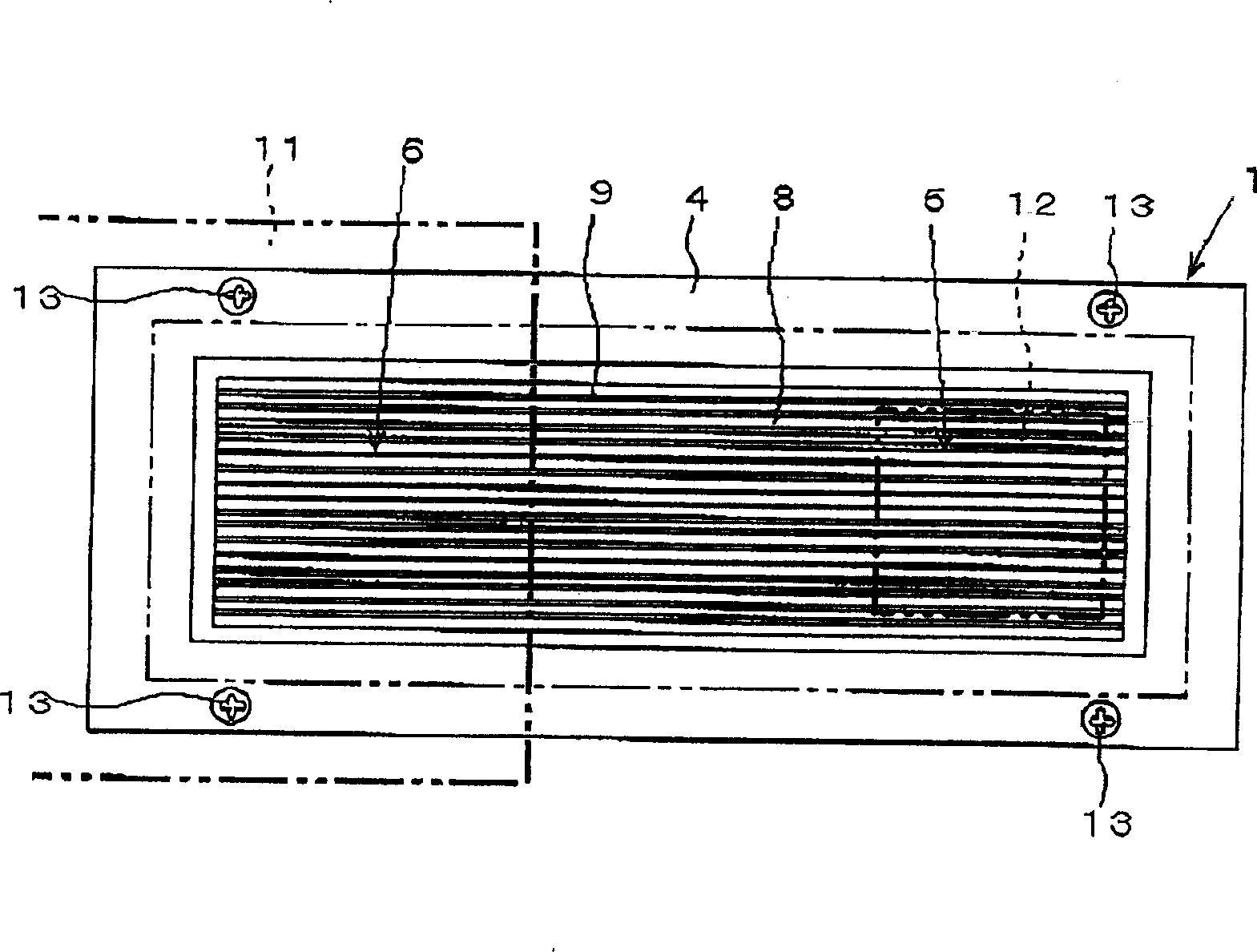

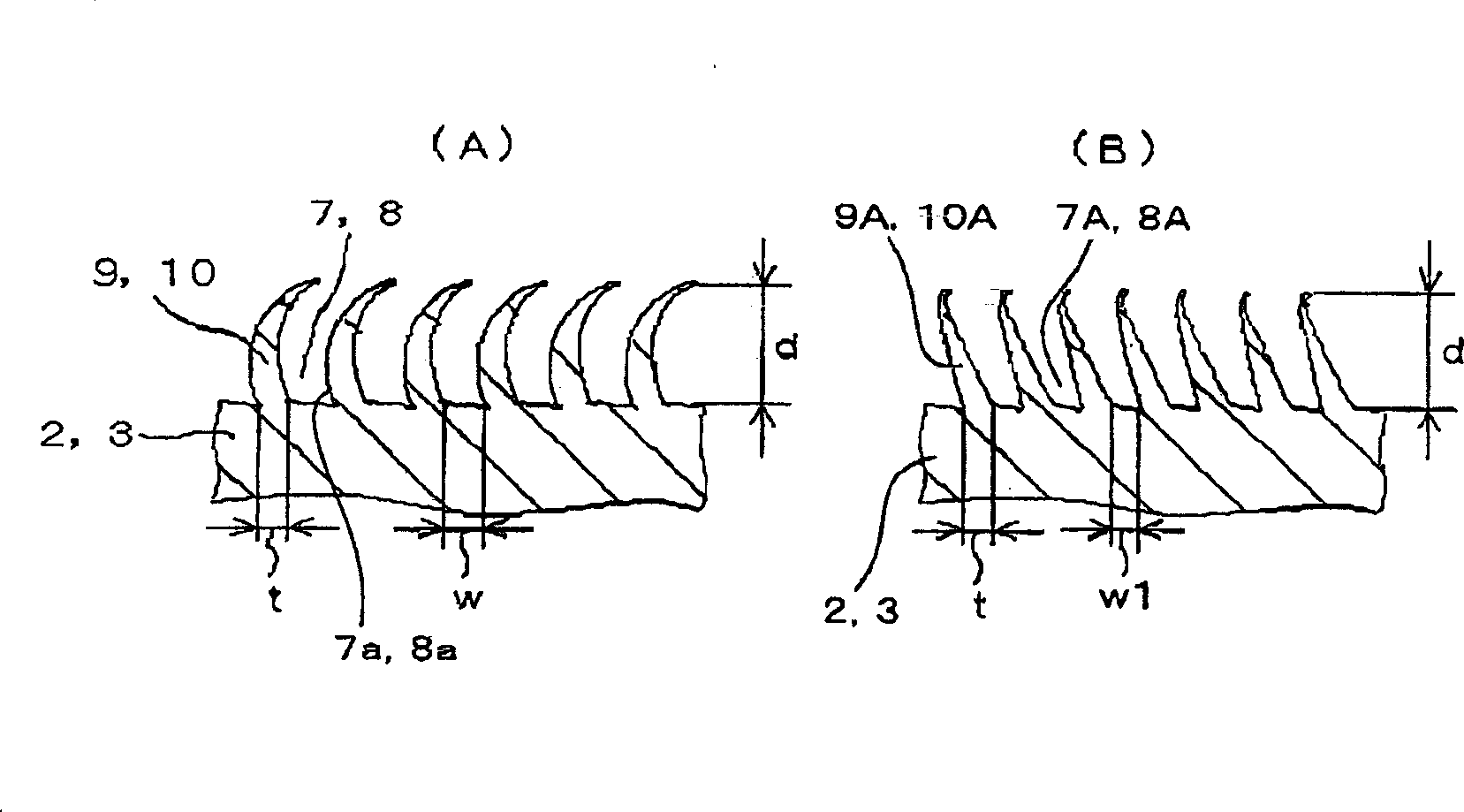

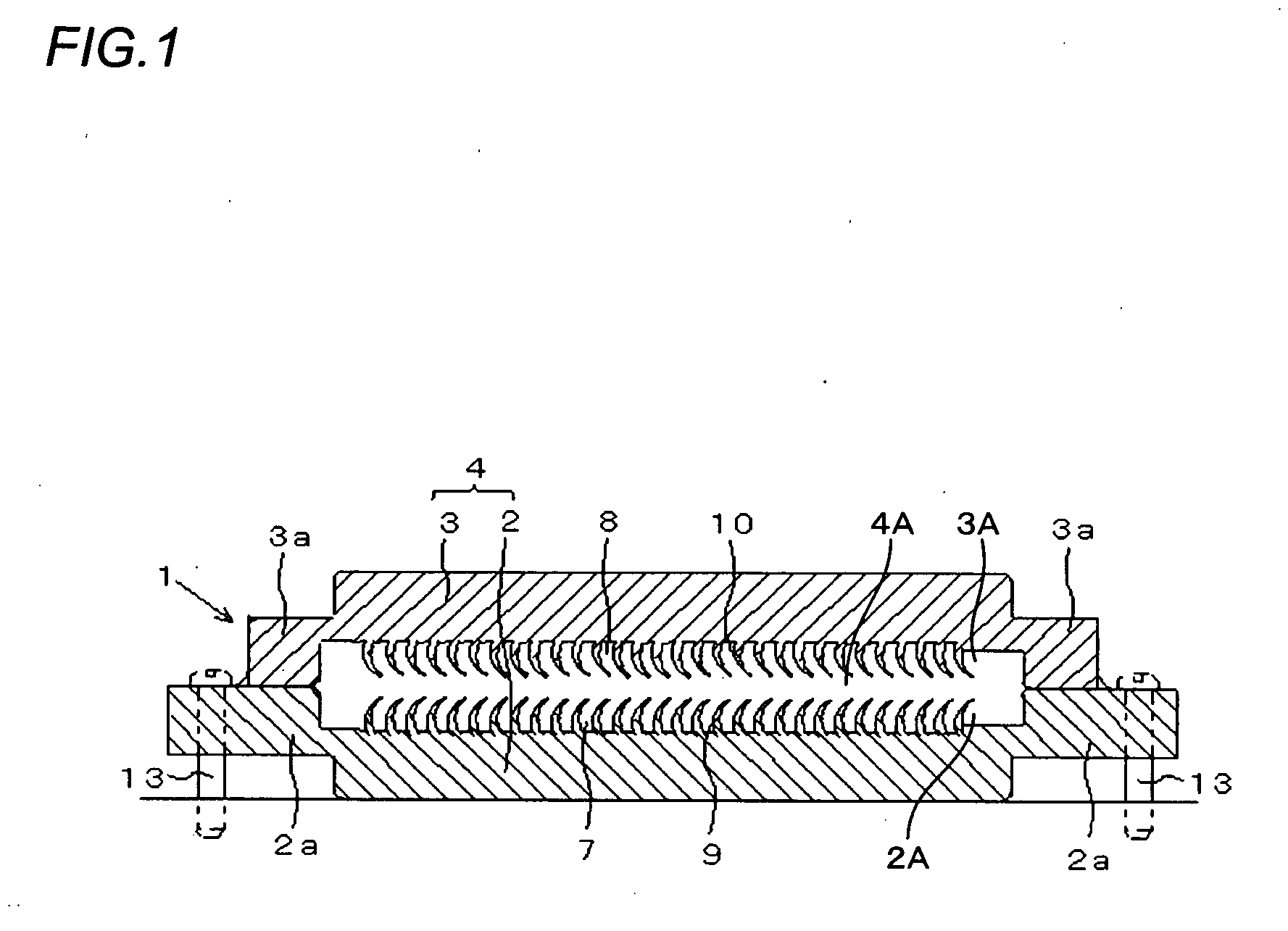

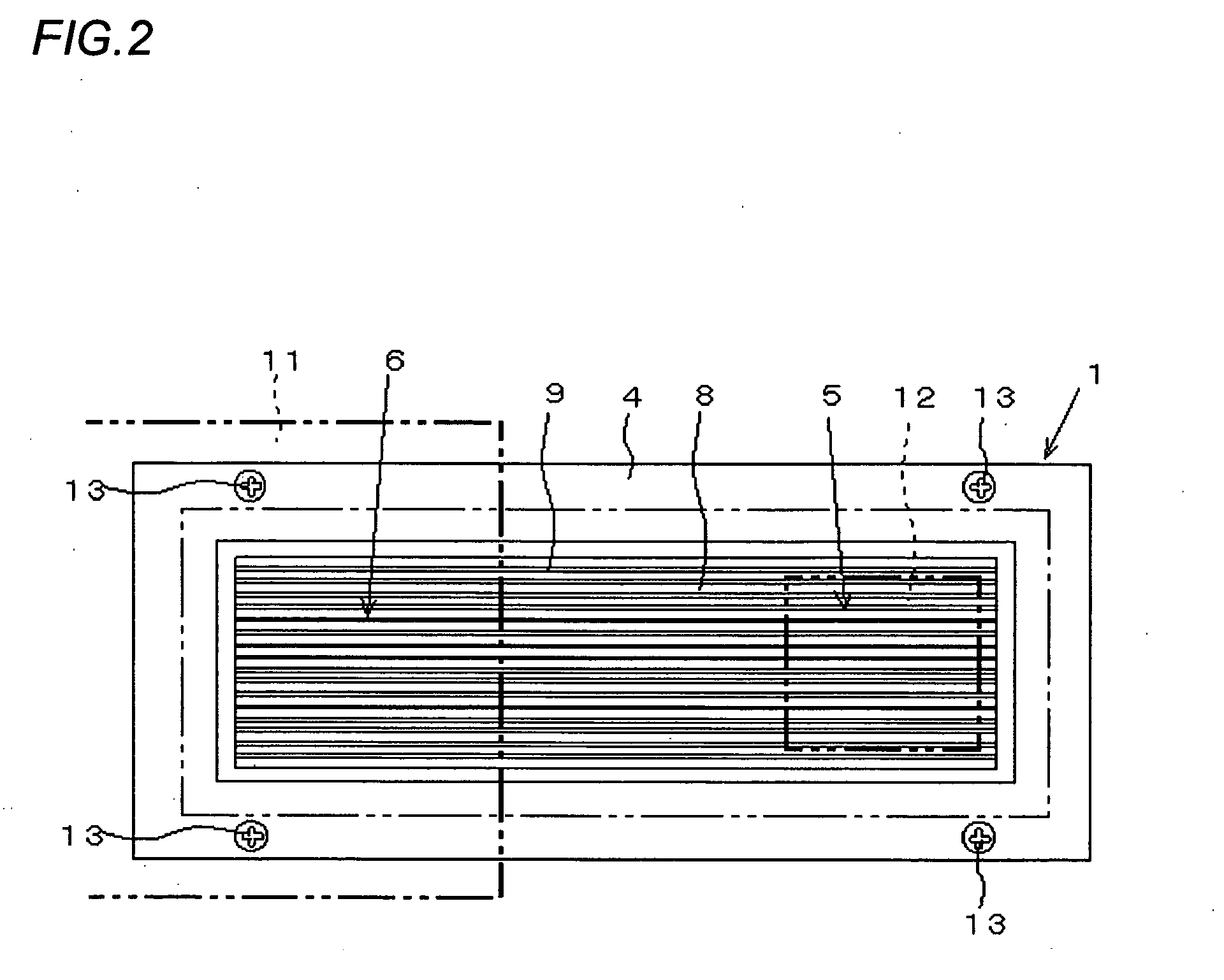

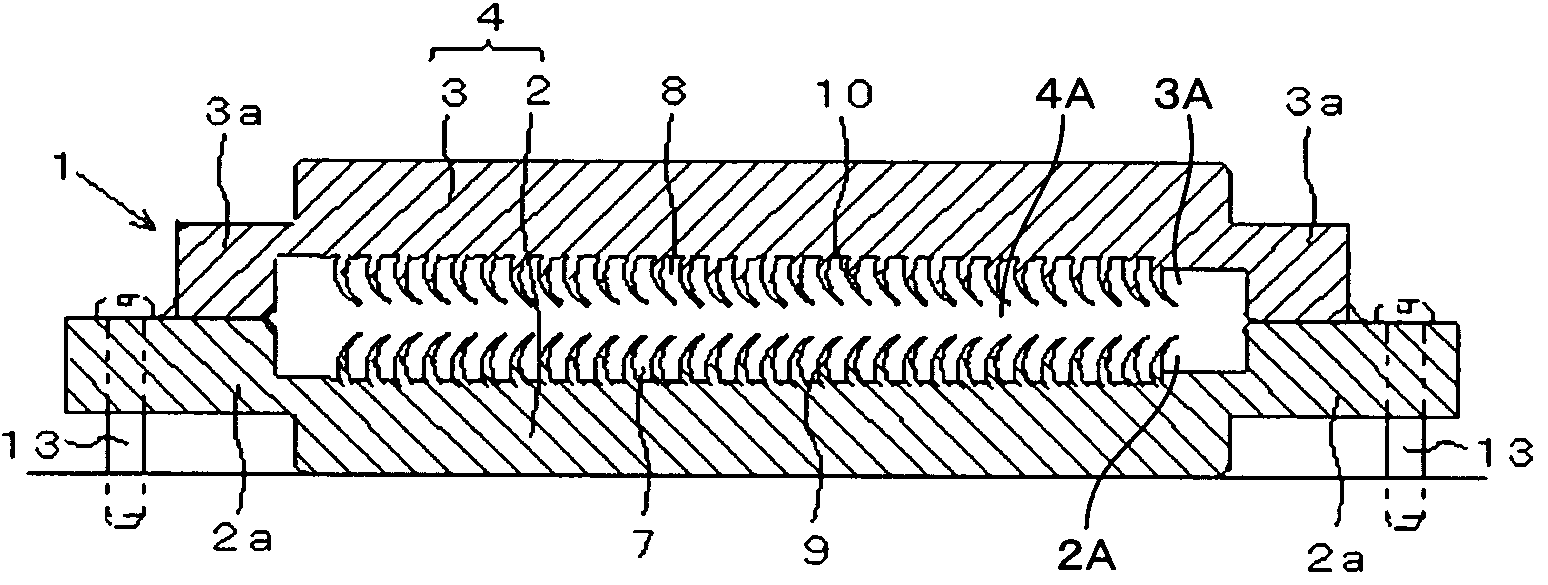

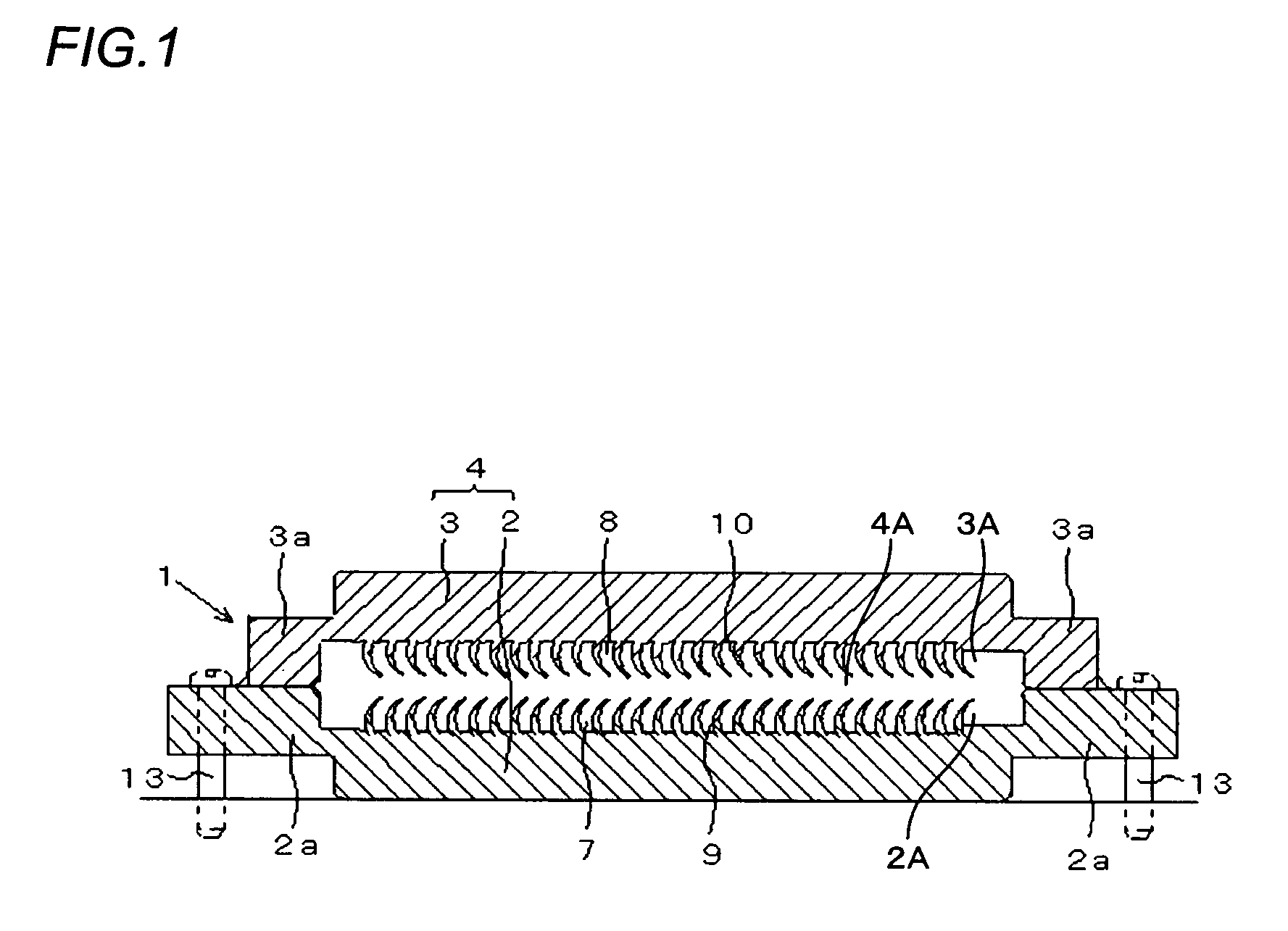

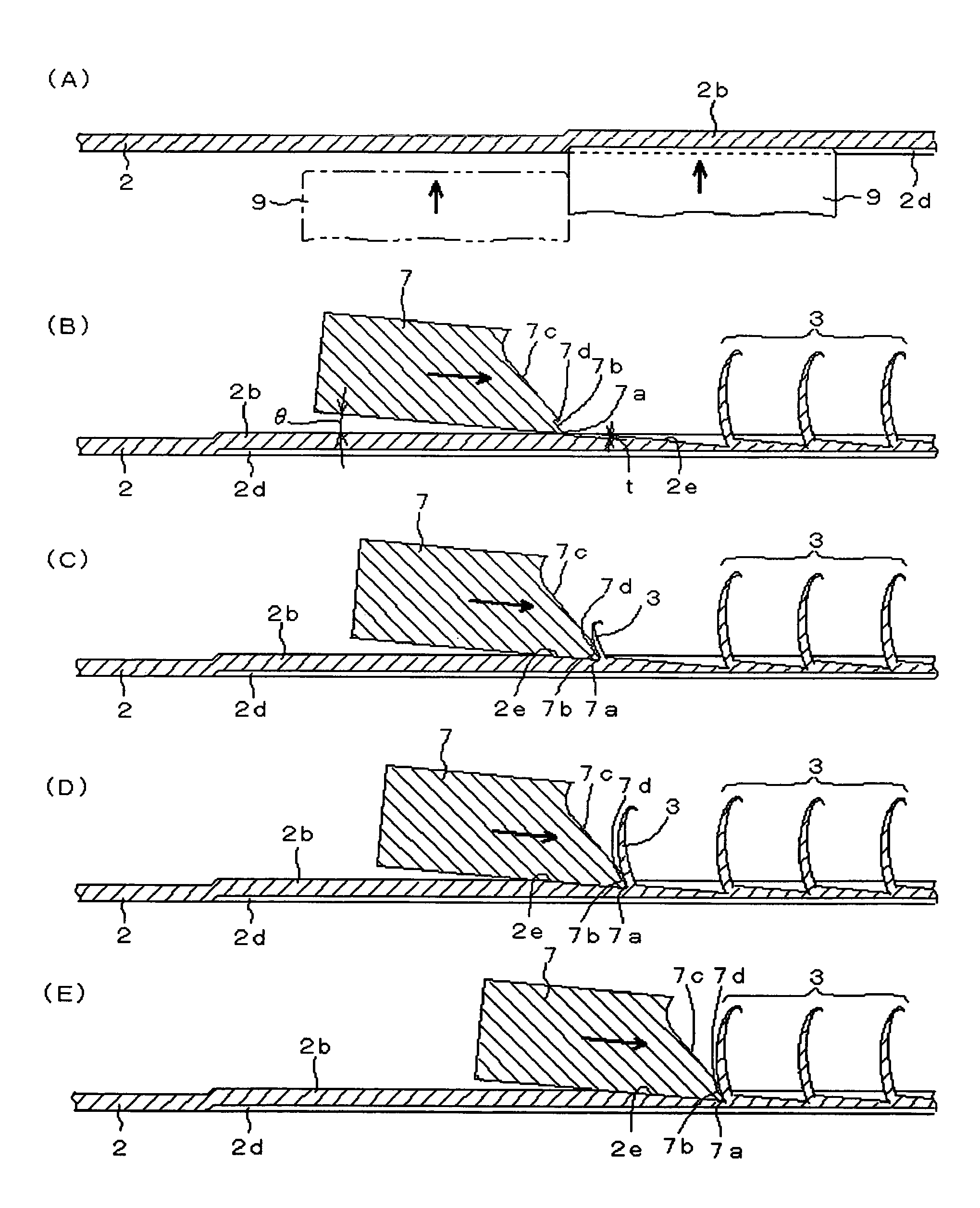

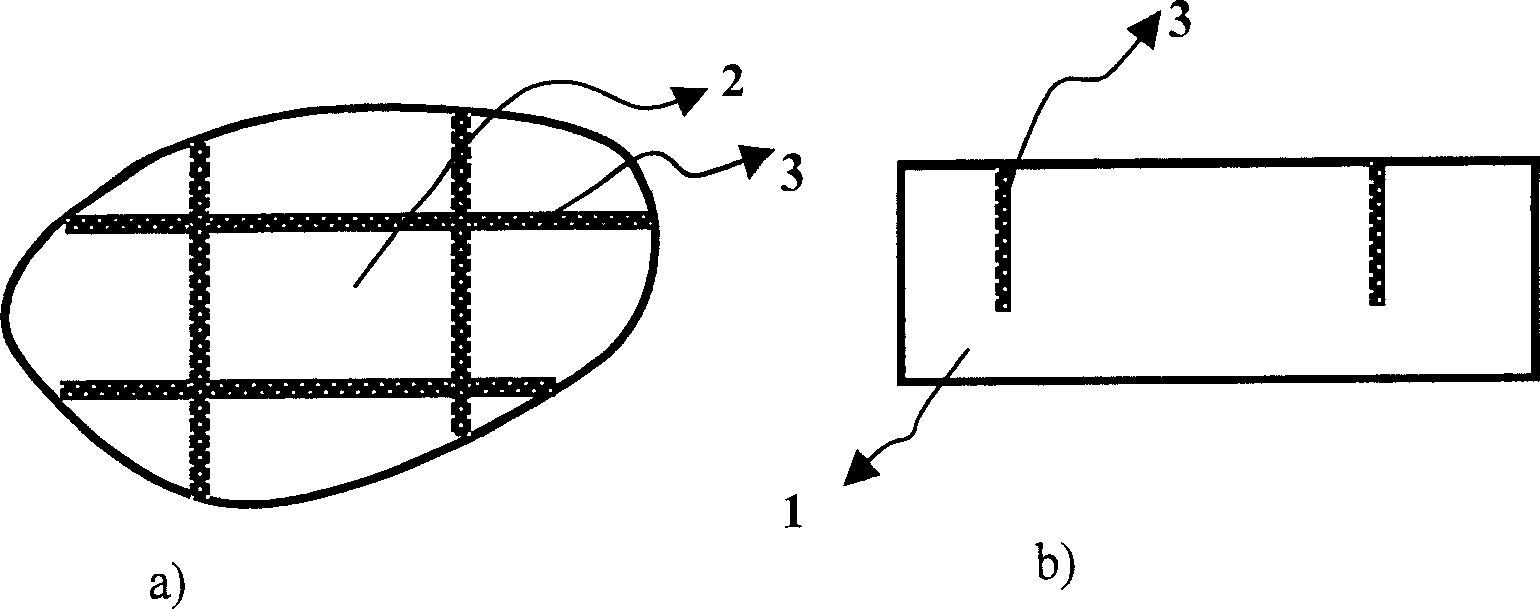

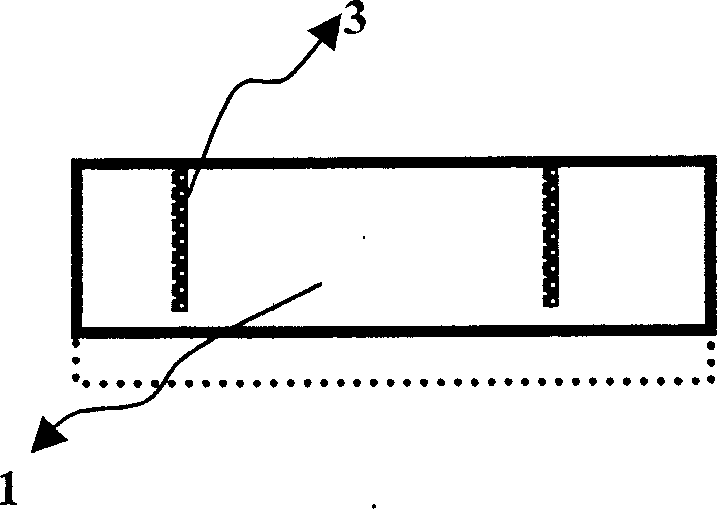

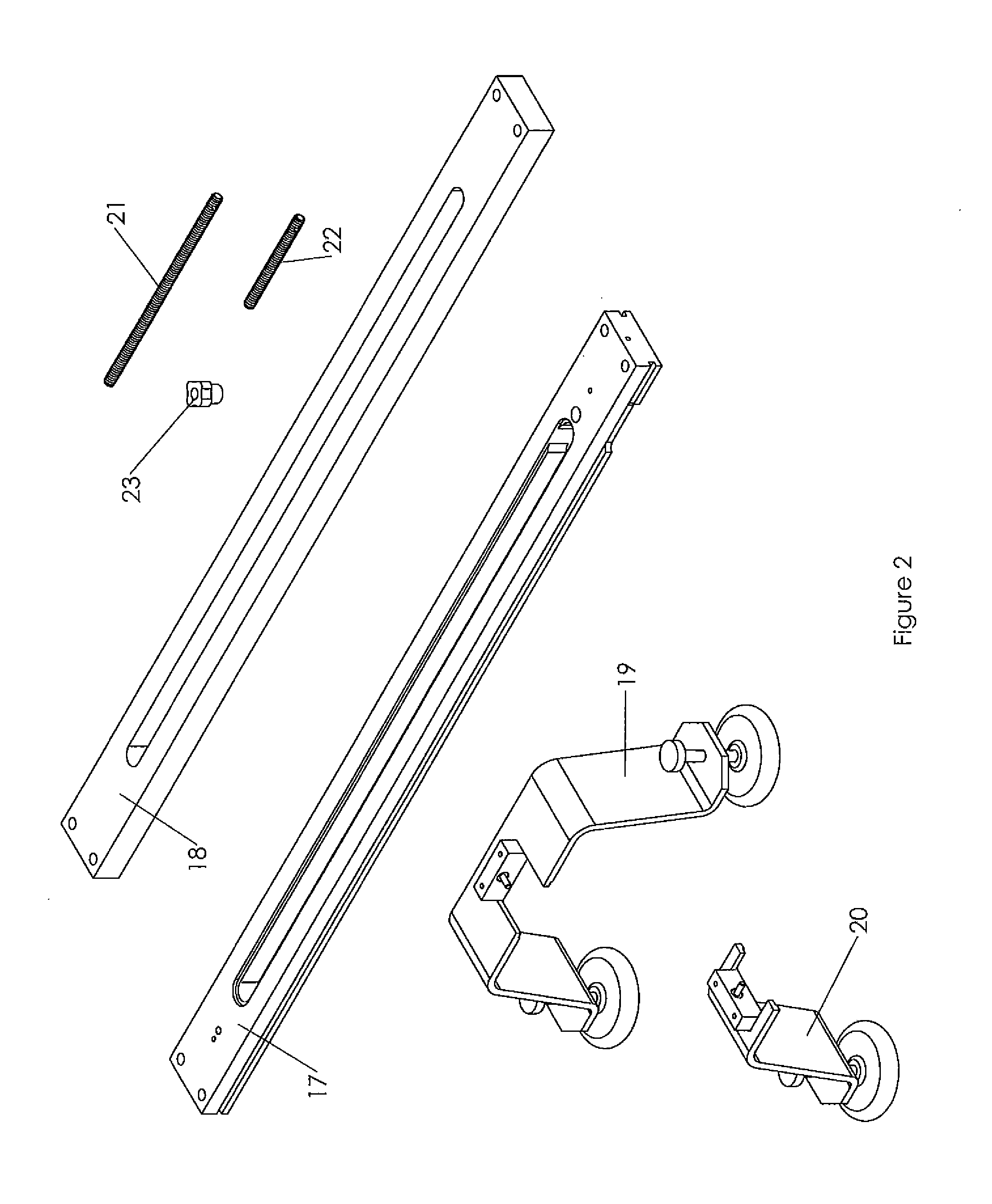

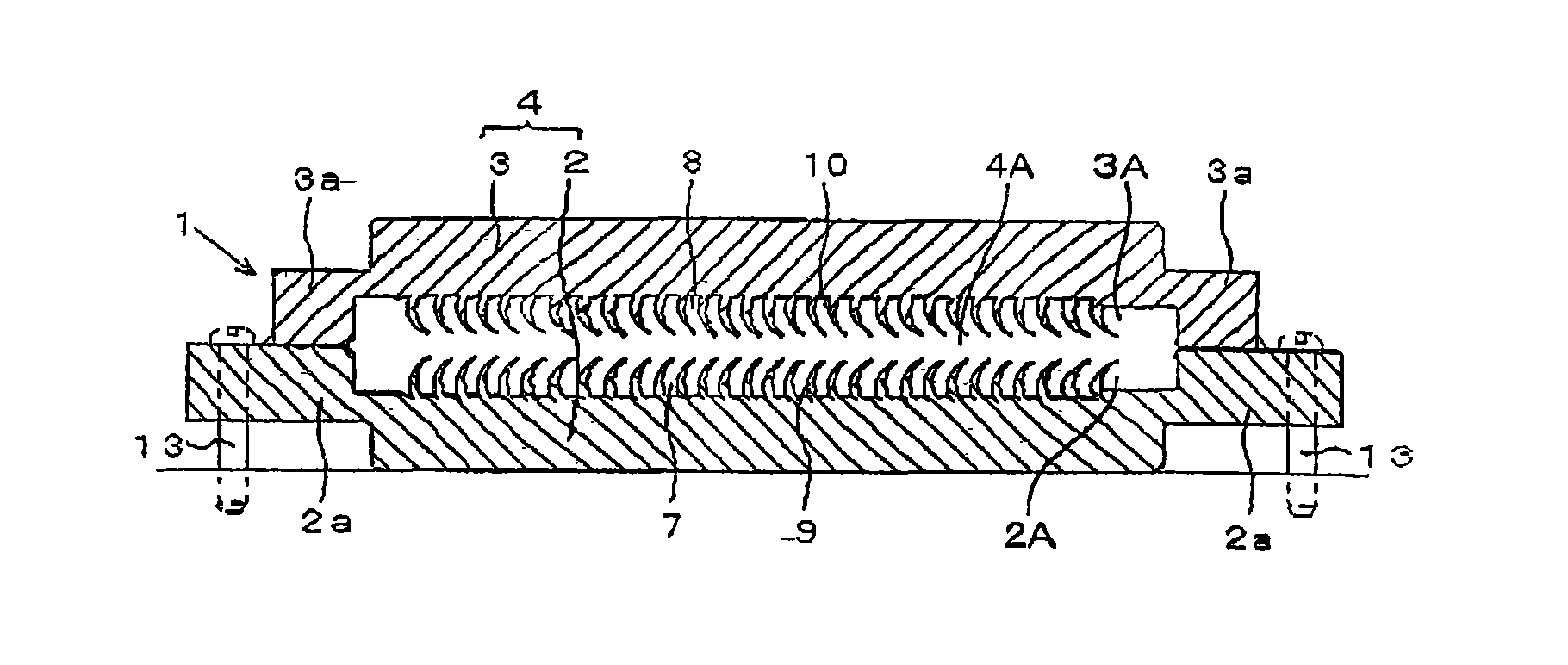

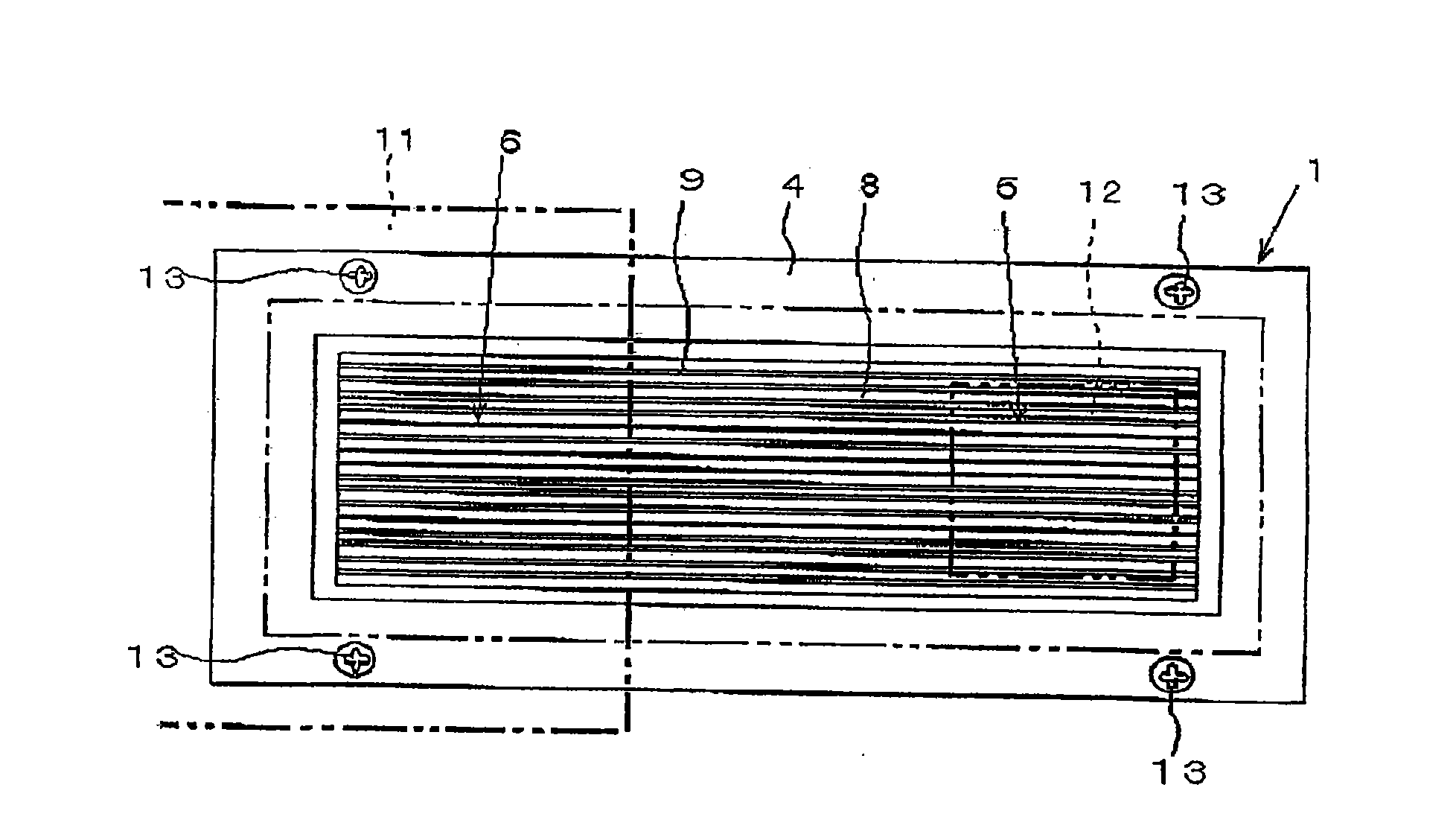

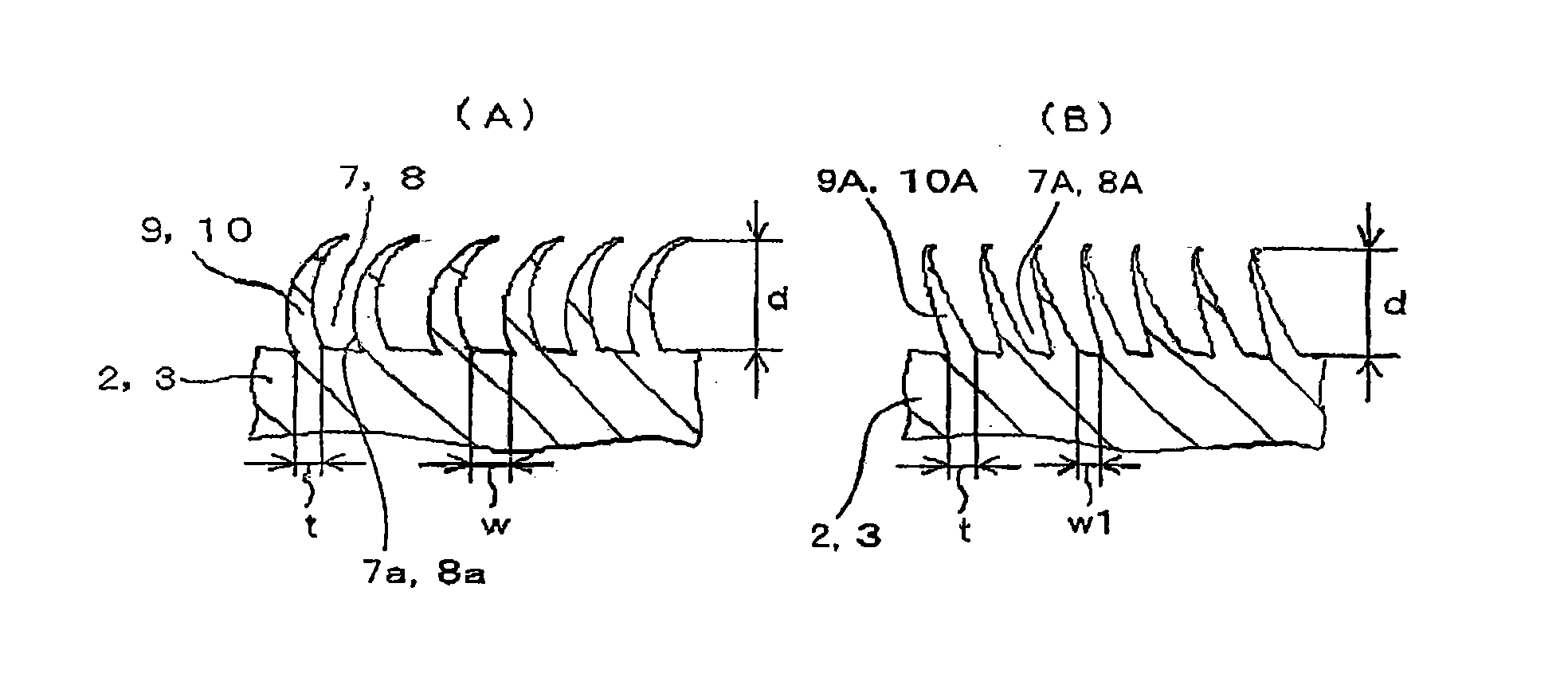

Plate type heat exchanger and method of manufacturing the same

InactiveCN1892164AImprove cooling efficiencySuppression of variation in transfer capabilitySolid-state devicesMetal-working apparatusHeat sinkCarve out

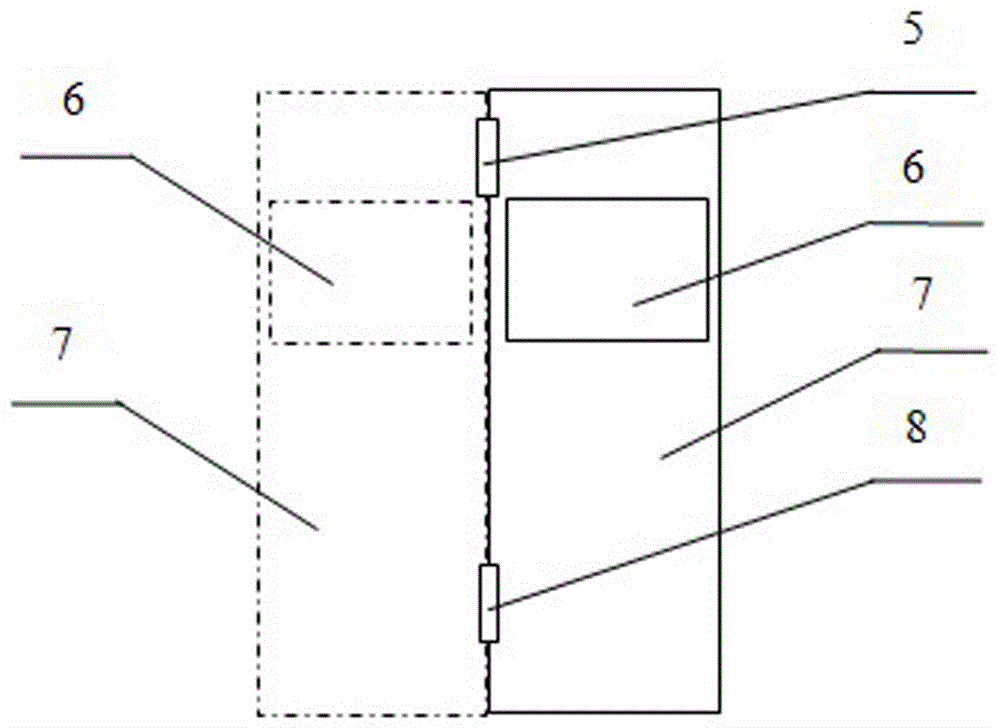

A method for manufacturing a plate-type heat exchanger in which a heat medium is sealed in a hollow part of an airtight structure formed in the interior of a plate-like container, and the heat medium is moved by capillary force from a condensing part to an evaporating part in the hollow part along heat-medium-guiding grooves formed in the container's inside surface portions that face the hollow part; wherein a plastic workable metal plate of specific thermal conductivity is prepared; a carving tool is used to repeatedly carve out a surface portion of the metal plate at specific intervals along the surface portion, forming a plurality of plate-like fins; and a plurality of grooves formed between these fins is used as heat-medium-guiding grooves. A plate-type heat exchanger is obtained which comprises extremely small heat-medium-guiding grooves that have the necessary capillary force to move the heat medium from the condensing part to the evaporating part without affecting the set alignment or other such characteristics.

Owner:NAKAMURA IND MFG CO LTD

Manufacturing technique of stereoscopic underglaze multicolor ceramic

The invention relates to a manufacturing technique of stereoscopic underglaze multicolor ceramic, which comprises the following steps: carrying out ball milling on a selected ceramic raw material, screening, slurrying, carrying out injection forming on a mold to obtain a required shape, preparing a blank, and carrying out bisque firing to obtain a biscuit; carving out a stereoscopic multilayer plain color picture on the biscuit with a carving tool; dipping a drawing tool into underglaze multicolor pigments, and drawing and decorating on the stereoscopic picture of the biscuit to obtain a colored biscuit; carrying out color depth gradation treatment on the picture of the colored biscuit by using a special brush; and covering a glaze layer on the surface of the colored biscuit subjected to color treatment; and firing the glaze-covered colored biscuit in a kiln again to obtain the finished product. The technique adopts the two modes of biscuit carving and mold carving. The ceramic article prepared by the technique has the advantages of strong stereoscopic effect, abundant colors, high color layering effect and glossy and bright glaze.

Owner:HUNAN NEW CENTURY CERAMICS

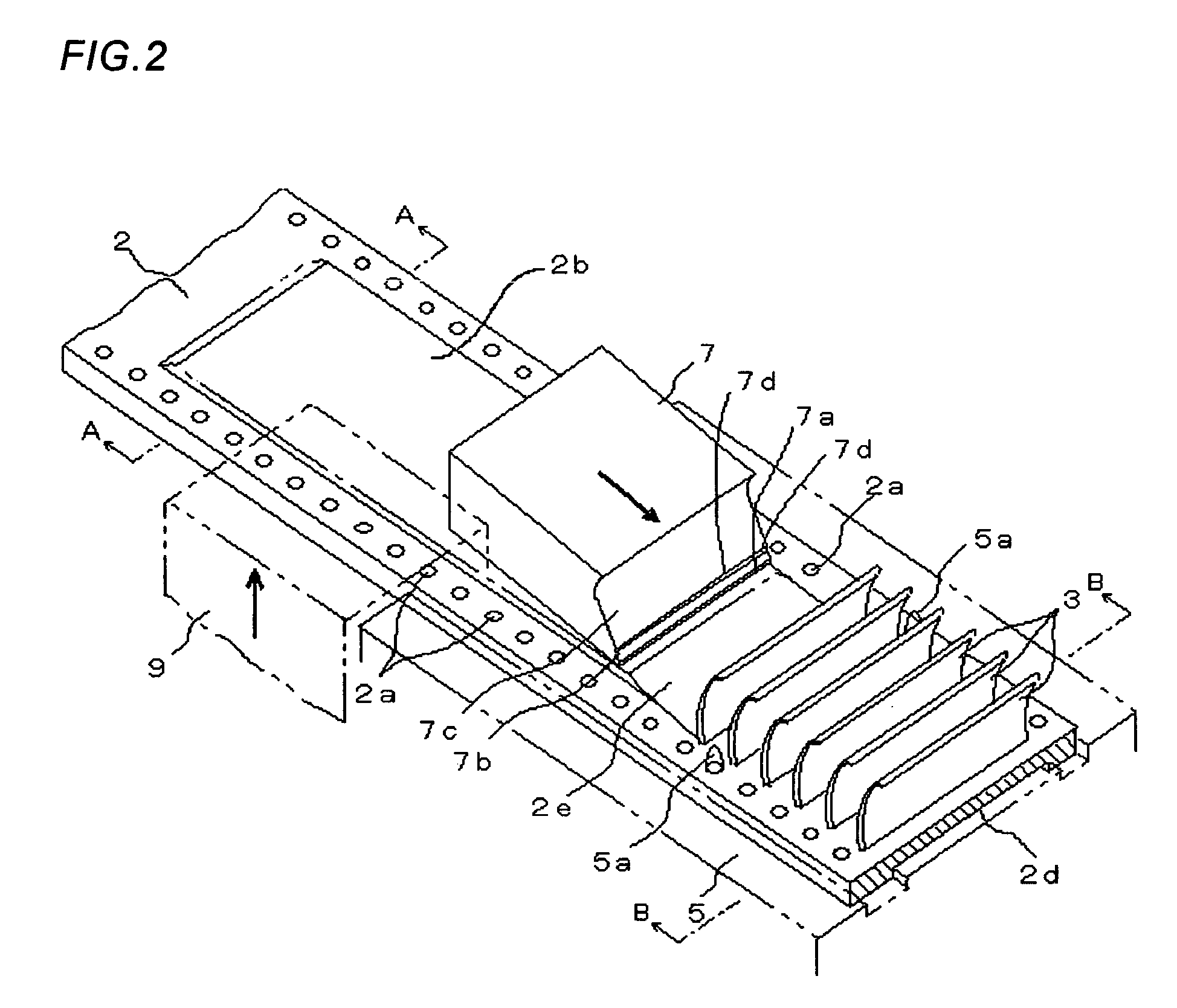

Plate type heat exchanger and method of manufacturing the same

ActiveUS20070012431A1Small widthEasy to buildAir heatersCorrosion preventionPlate heat exchangerEngineering

A method for manufacturing a plate-type heat exchanger in which a heat medium is sealed in a hollow part of an airtight structure formed in the interior of a plate-like container, and the heat medium is moved by capillary force from a condensing part to an evaporating part in the hollow part along heat-medium-guiding grooves formed in the container's inside surface portions that face the hollow part; wherein a plastic workable metal plate of specific thermal conductivity is prepared; a carving tool is used to repeatedly carve out a surface portion of the metal plate at specific intervals along the surface portion, forming a plurality of plate-like fins; and a plurality of grooves formed between these fins is used as heat-medium-guiding grooves. A plate-type heat exchanger is obtained which comprises extremely small heat-medium-guiding grooves that have the necessary capillary force to move the heat medium from the condensing part to the evaporating part without affecting the set alignment or other such characteristics.

Owner:NAKAMURA IND MFG CO LTD

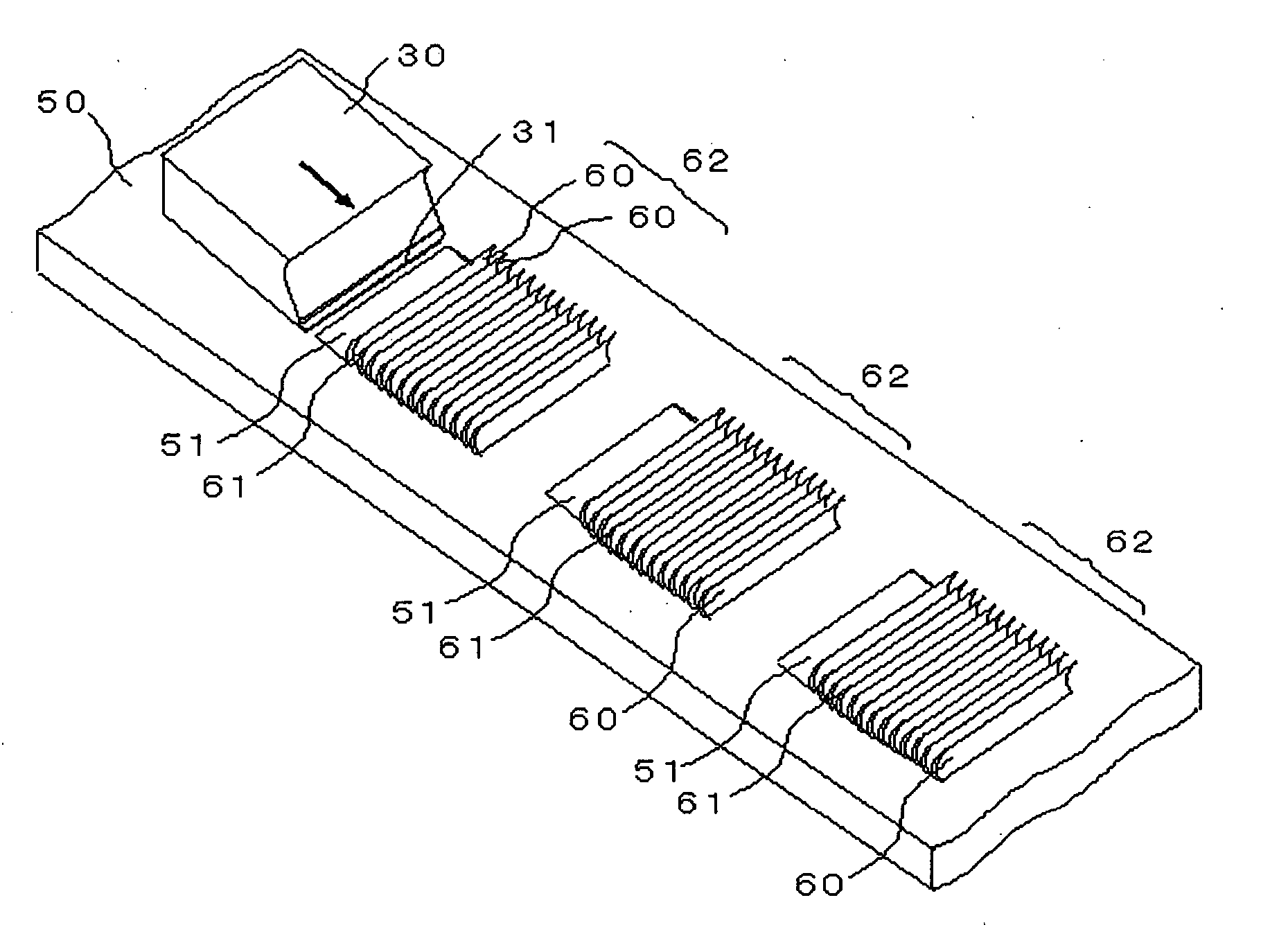

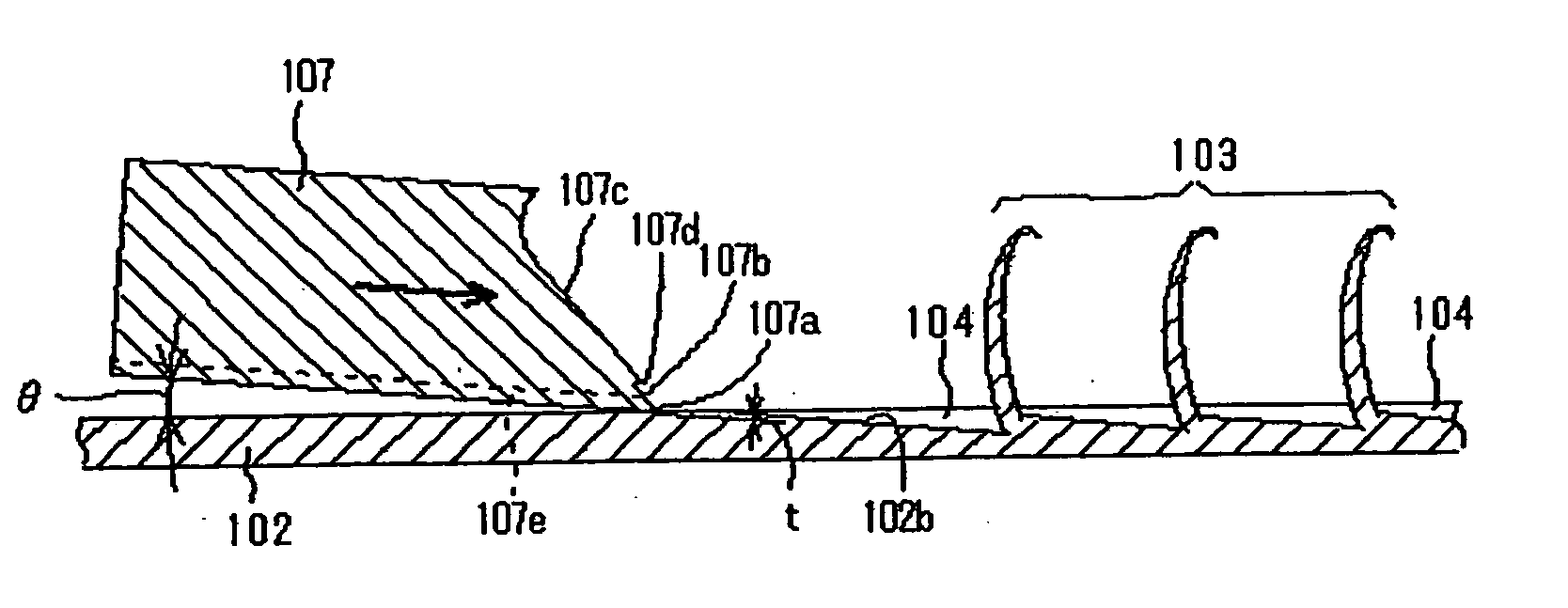

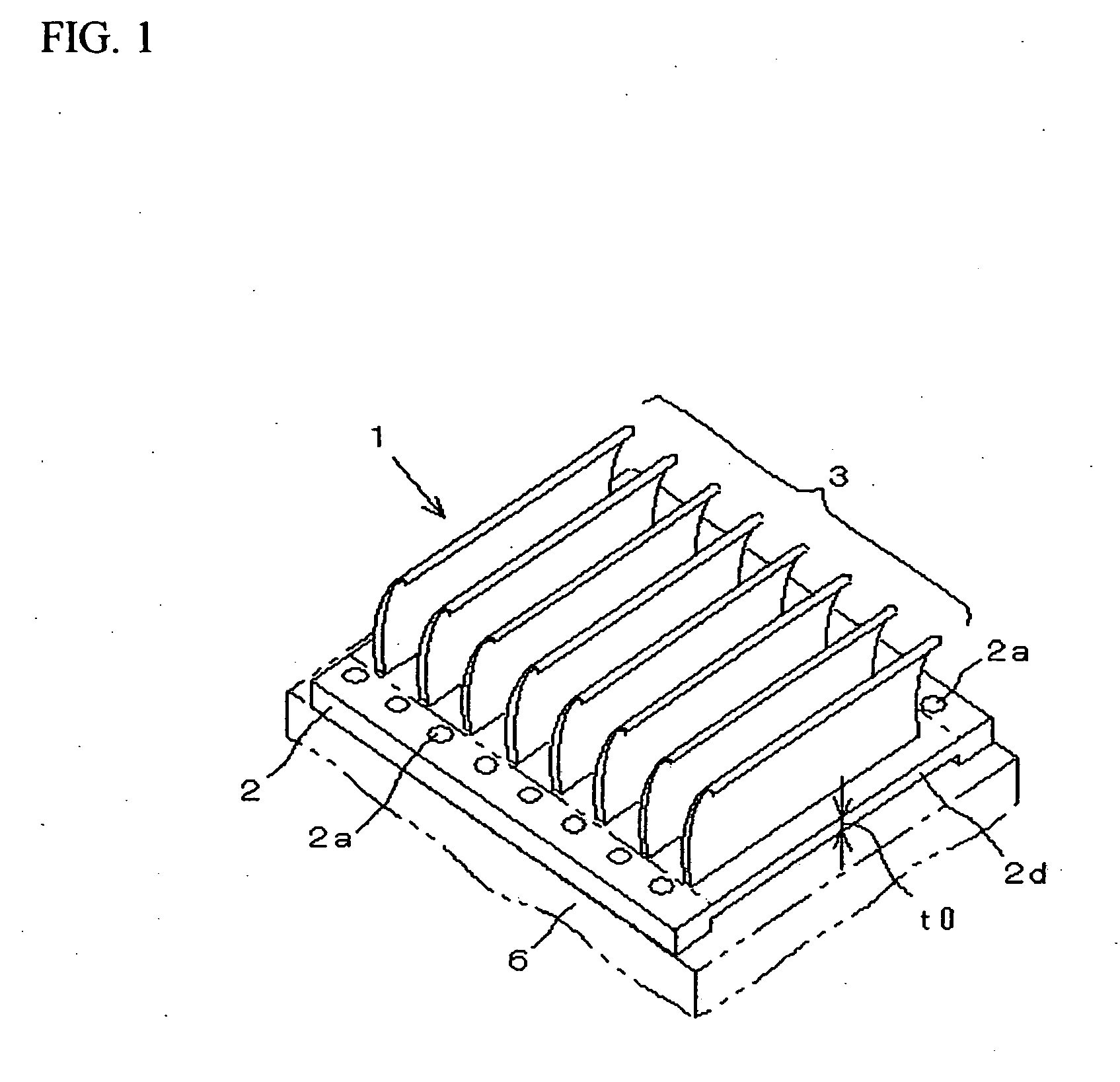

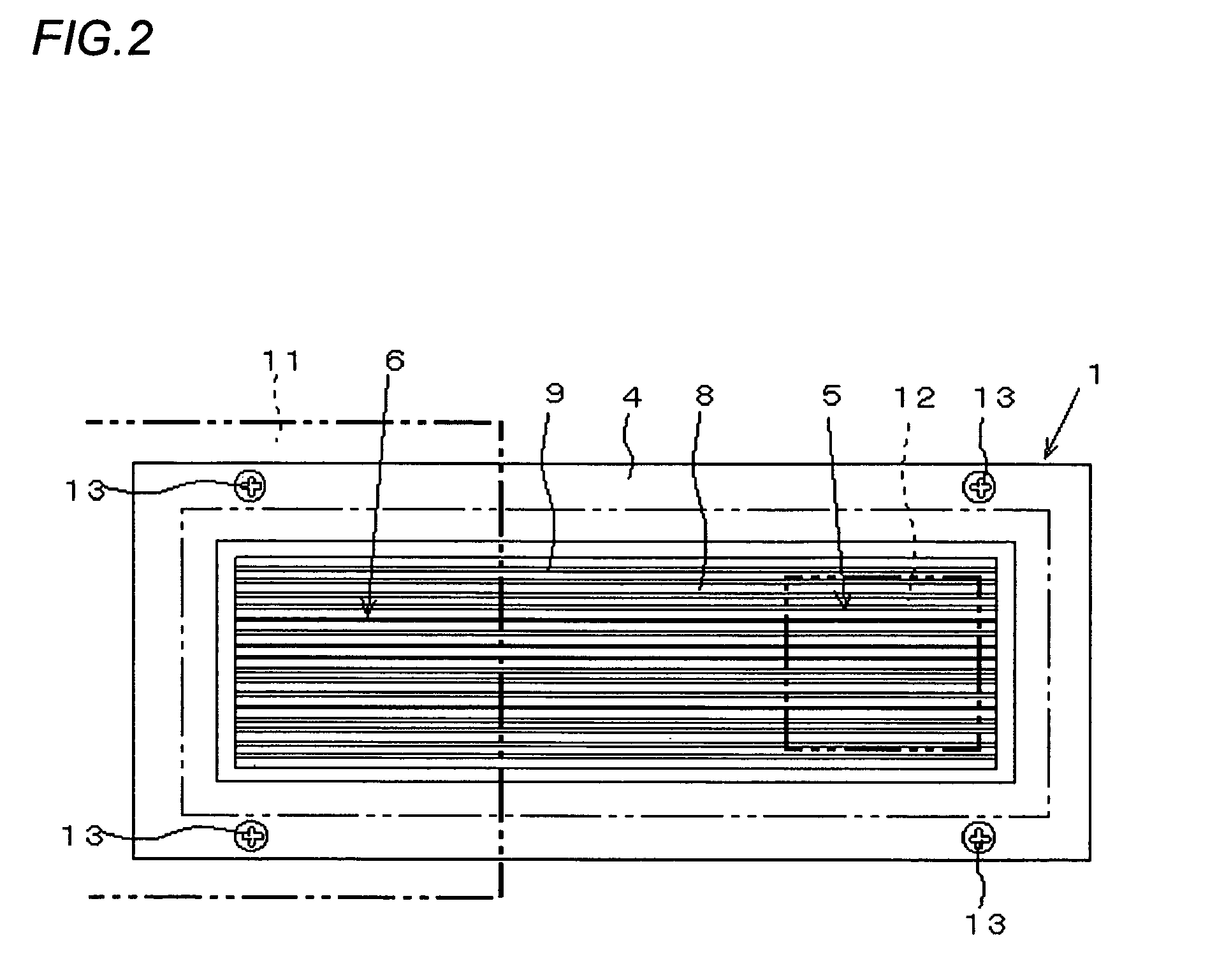

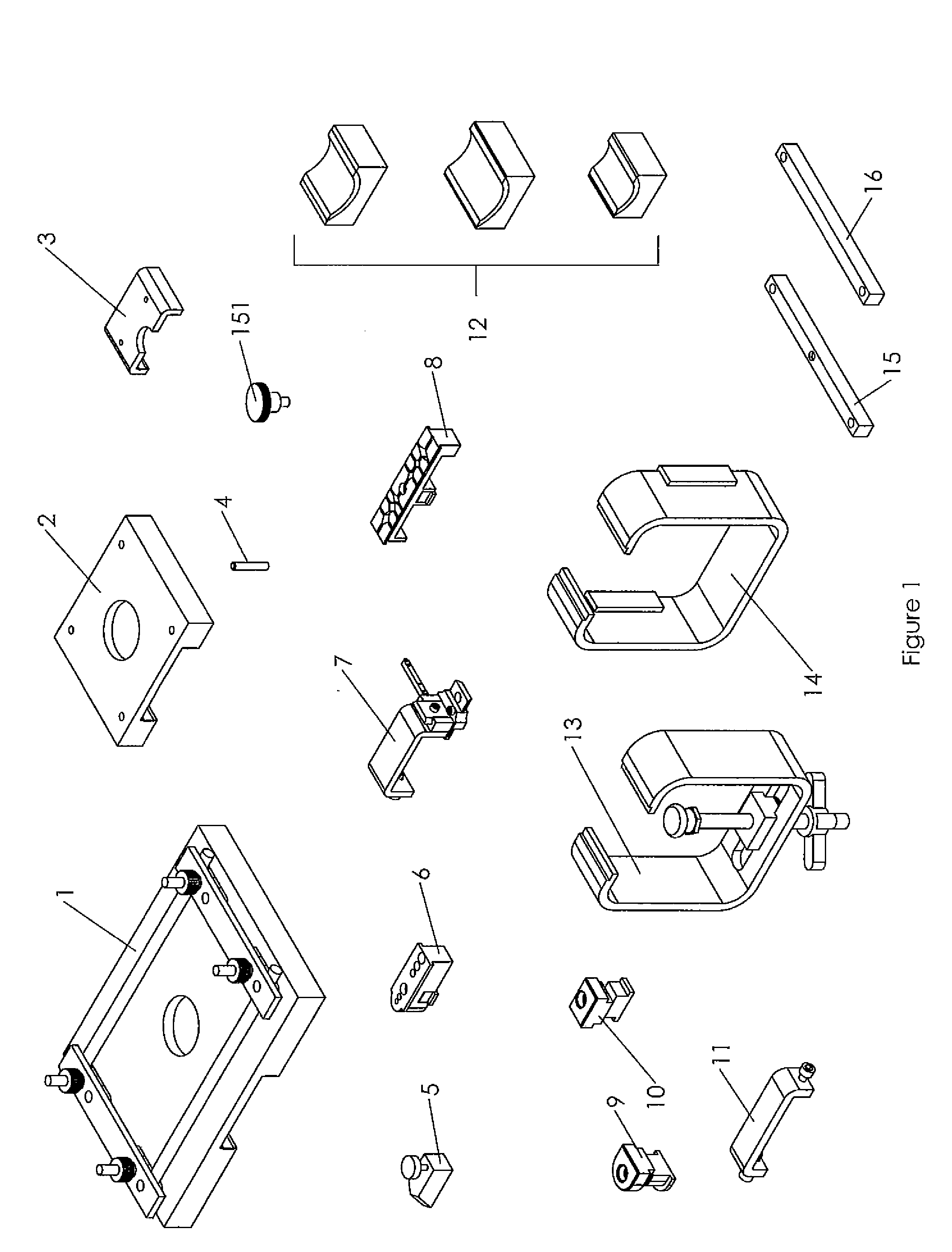

Radiator and method of manufacturing the same

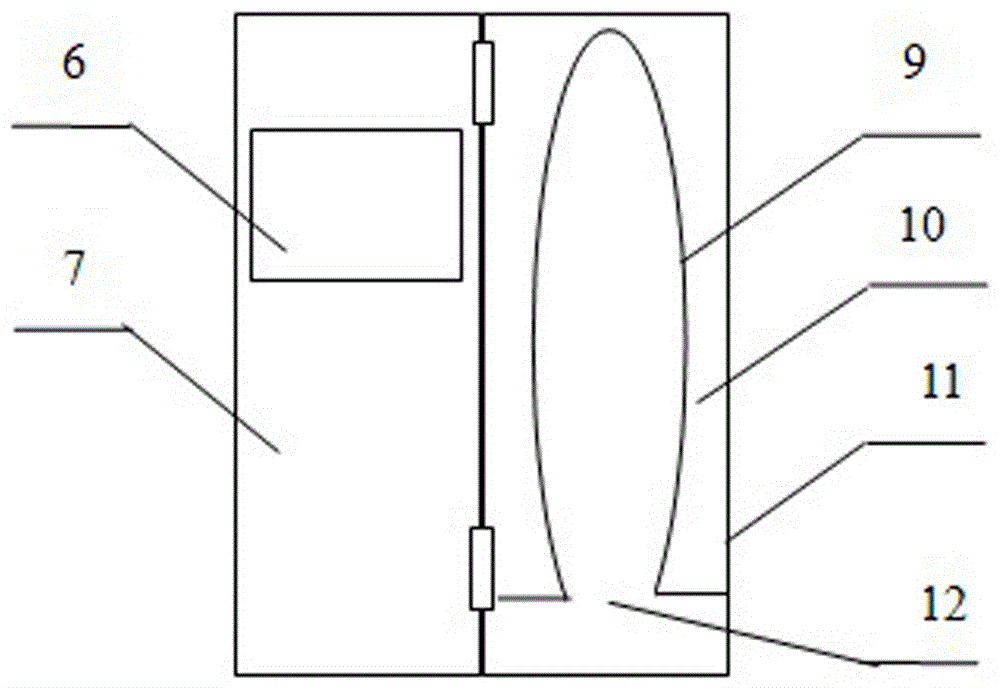

ActiveUS20050193559A1Reduce thicknessIncrease friction forceSemiconductor/solid-state device detailsSolid-state devicesEngineeringCarve out

In a method of manufacturing a radiator, the blade of a carving tool is applied at a specific angle to the surface of a metal plate with a high coefficient of thermal conductivity, the carving tool is advanced while the angle is maintained, and the surface of the metal plate is carved out to form plate-shaped heat-radiating fins vertically upward. A radiator is manufactured in which a plurality of heat-radiating fins are integrally formed vertically upward at a specific pitch from a single metal plate by repeating a step in which the carving tool is retracted at a specific pitch, the metal plate is carved out, and a heat-radiating fin is formed. A radiator that has high radiation efficiency and is highly safe during handling can be manufactured at low cost.

Owner:NAKAMURA IND MFG CO LTD

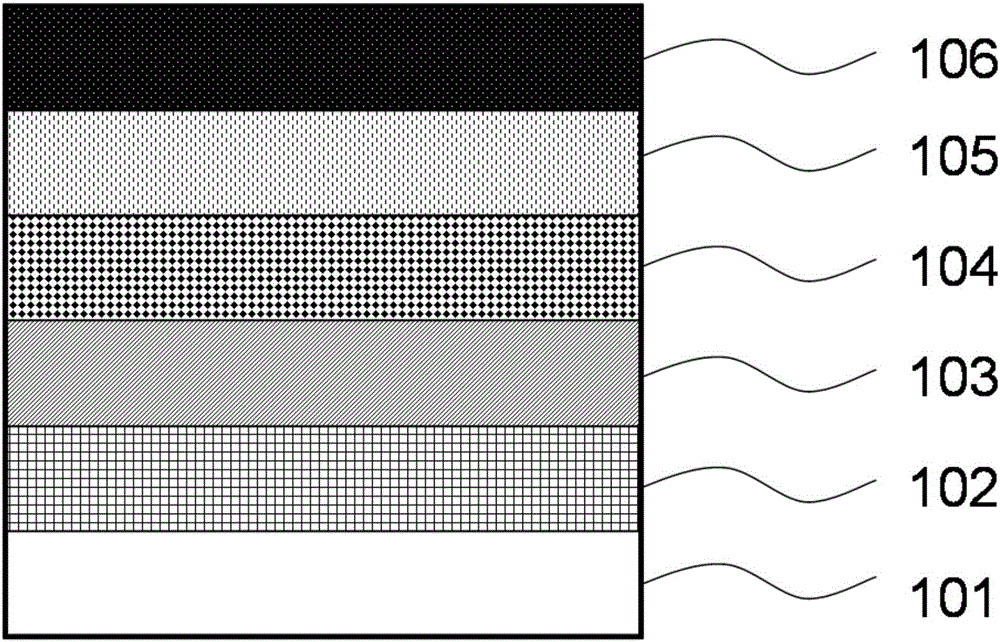

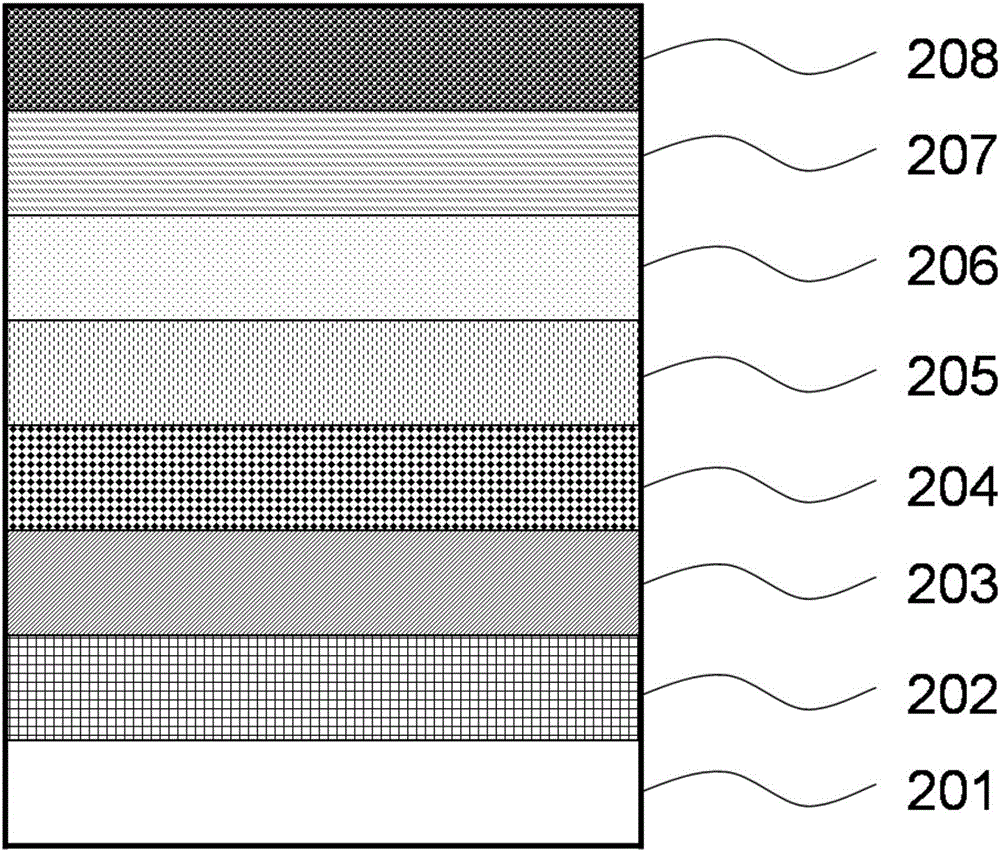

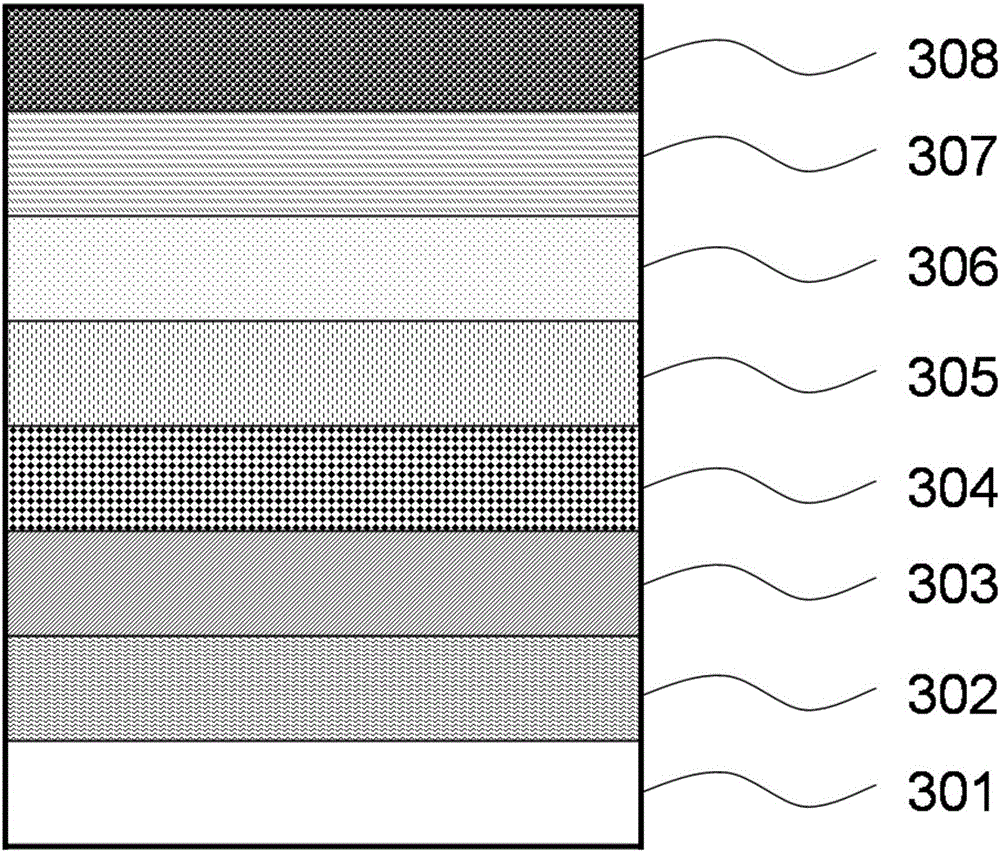

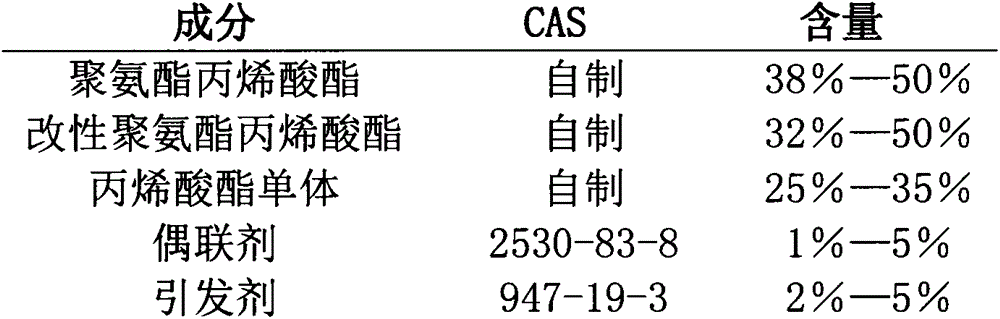

Flexible perovskite solar cell

InactiveCN106058057AHigh light transmittanceReduce square resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellMolecular materials

The invention provides a flexible perovskite solar cell, and the structure of the solar cell sequentially comprises a flexible substrate, a photoelectrode, a first carrier transmission layer, a perovskite light absorption layer, a second carrier transmission layer and a back electrode from the bottom to the top, wherein the photoelectrode is made of multilayer graphene or a conductive polymeric material. The solar cell is high in flexibility, is light and thin, is low in cost, and is high in efficiency. Diversified products can be developed through employing the flexibility of the solar cell, and the solar cell will be wide in application range. Meanwhile, the solar cell carves out a way for the utilization of the large-batch big-area roll-to-roll technology, and provides a new idea for the final industrialization of perovskite.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Inlaying process of Nixing pottery

The invention discloses an inlaying process of Nixing pottery. The inlaying process comprises the following steps: (1) preparing a preform body; (2) preparing a color clay material; (3) preparing mixed slurry: mixing the color clay material and the preform body to obtain a mixture, and charging water in the mixture to obtain the mixed slurry; (4) forming a green body; (5) engraving and inlaying, namely drawing a picture on the green body, wrapping an opening and a part, which is not engraved currently, of the green body with a plastic film, carving out grooves on two side edges along ink marks for the engraving part, smearing a layer of mixed slurry into the grooves, inlaying the color clay material into the grooves, leveling the color clay material, slightly drying the color clay material until the color clay material is concaved, smearing the mixed slurry into the grooves again, then inlaying the color clay material, leveling the color clay material, repeating for 3 to 6 times until the grooves are completely leveled by the color clay material; then tearing off partial plastic film, engraving and inlaying further in the above method until all engraving and inlaying work is completed; and (6) burning the green body. By adopting the inlaying process of Nixing pottery, the mutual absorption of the color clay material and the green body can be realized, the color clay material and the green body are unlikely to drop and crack in the burning process, and the burning success rate is high.

Owner:广西钦州大民坭兴陶有限公司

Plate type heat exchanger and method of manufacturing the same

ActiveUS7770633B2Small widthEasy to buildAir heatersCorrosion preventionPlate heat exchangerCarve out

A method for manufacturing a plate-type heat exchanger in which a heat medium is sealed in a hollow part of an airtight structure formed in the interior of a plate-like container, and the heat medium is moved by capillary force from a condensing part to an evaporating part in the hollow part along heat-medium-guiding grooves formed in the container's inside surface portions that face the hollow part; wherein a plastic workable metal plate of specific thermal conductivity is prepared; a carving tool is used to repeatedly carve out a surface portion of the metal plate at specific intervals along the surface portion, forming a plurality of plate-like fins; and a plurality of grooves formed between these fins is used as heat-medium-guiding grooves. A plate-type heat exchanger is obtained which comprises extremely small heat-medium-guiding grooves that have the necessary capillary force to move the heat medium from the condensing part to the evaporating part without affecting the set alignment or other such characteristics.

Owner:NAKAMURA SEISAKUSHO KK

Radiator and method of manufacturing the same

ActiveUS7320177B2High heat radiation efficiencyReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringCarve out

In a method of manufacturing a radiator, the blade of a carving tool is applied at a specific angle to the surface of a metal plate with a high coefficient of thermal conductivity, the carving tool is advanced while the angle is maintained, and the surface of the metal plate is carved out to form plate-shaped heat-radiating fins vertically upward. A radiator is manufactured in which a plurality of heat-radiating fins are integrally formed vertically upward at a specific pitch from a single metal plate by repeating a step in which the carving tool is retracted at a specific pitch, the metal plate is carved out, and a heat-radiating fin is formed. A radiator that has high radiation efficiency and is highly safe during handling can be manufactured at low cost.

Owner:NAKAMURA IND MFG CO LTD

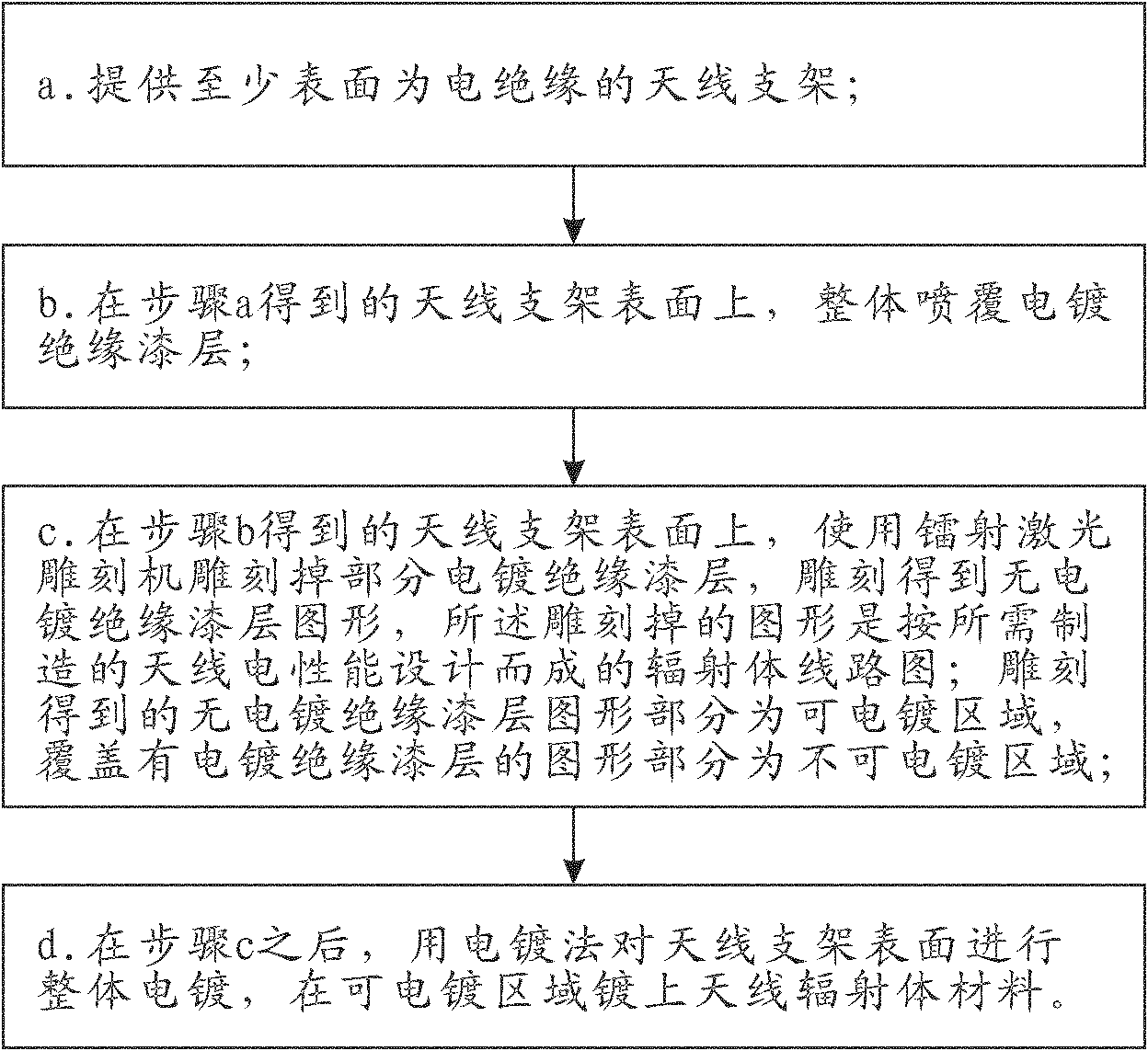

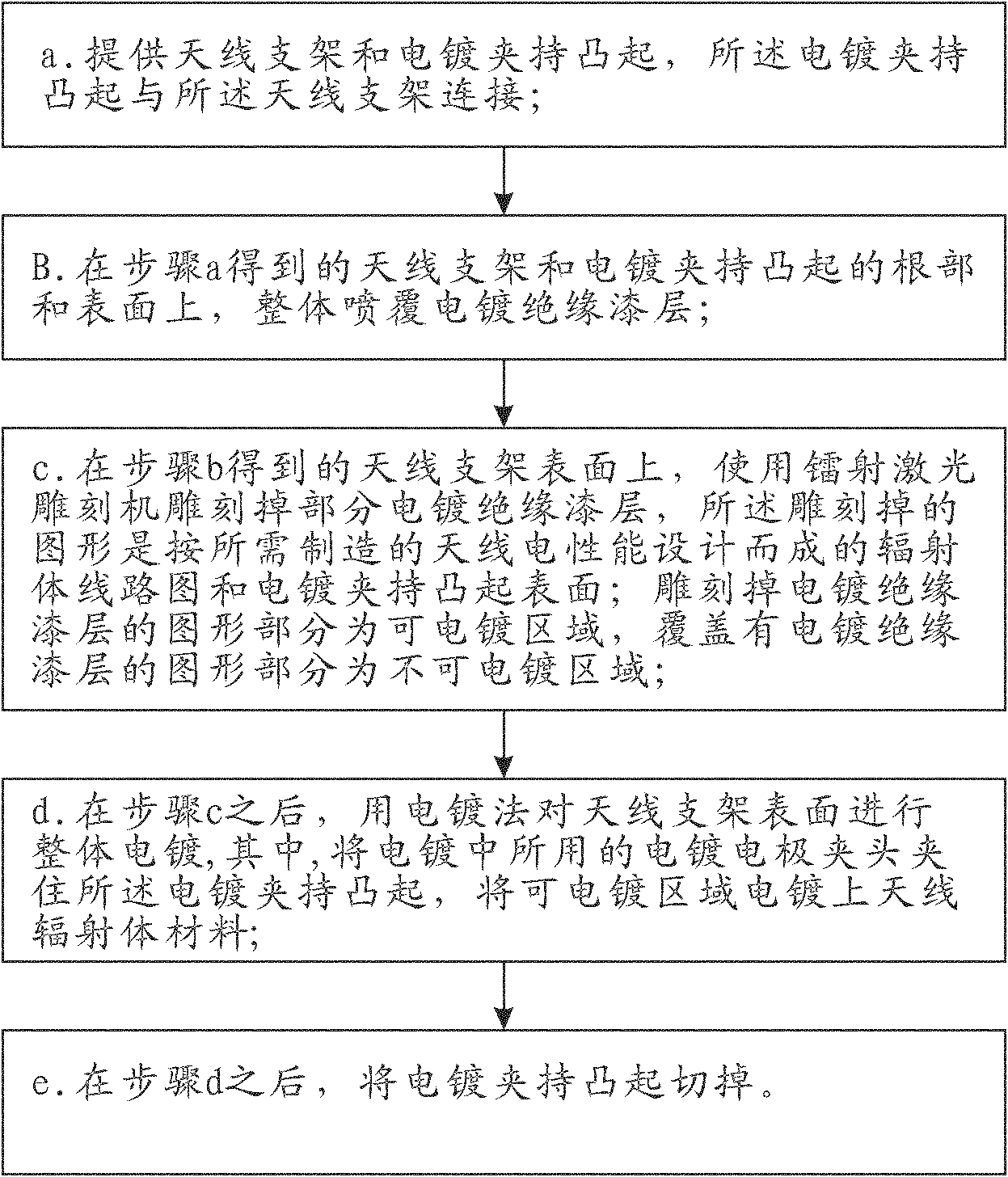

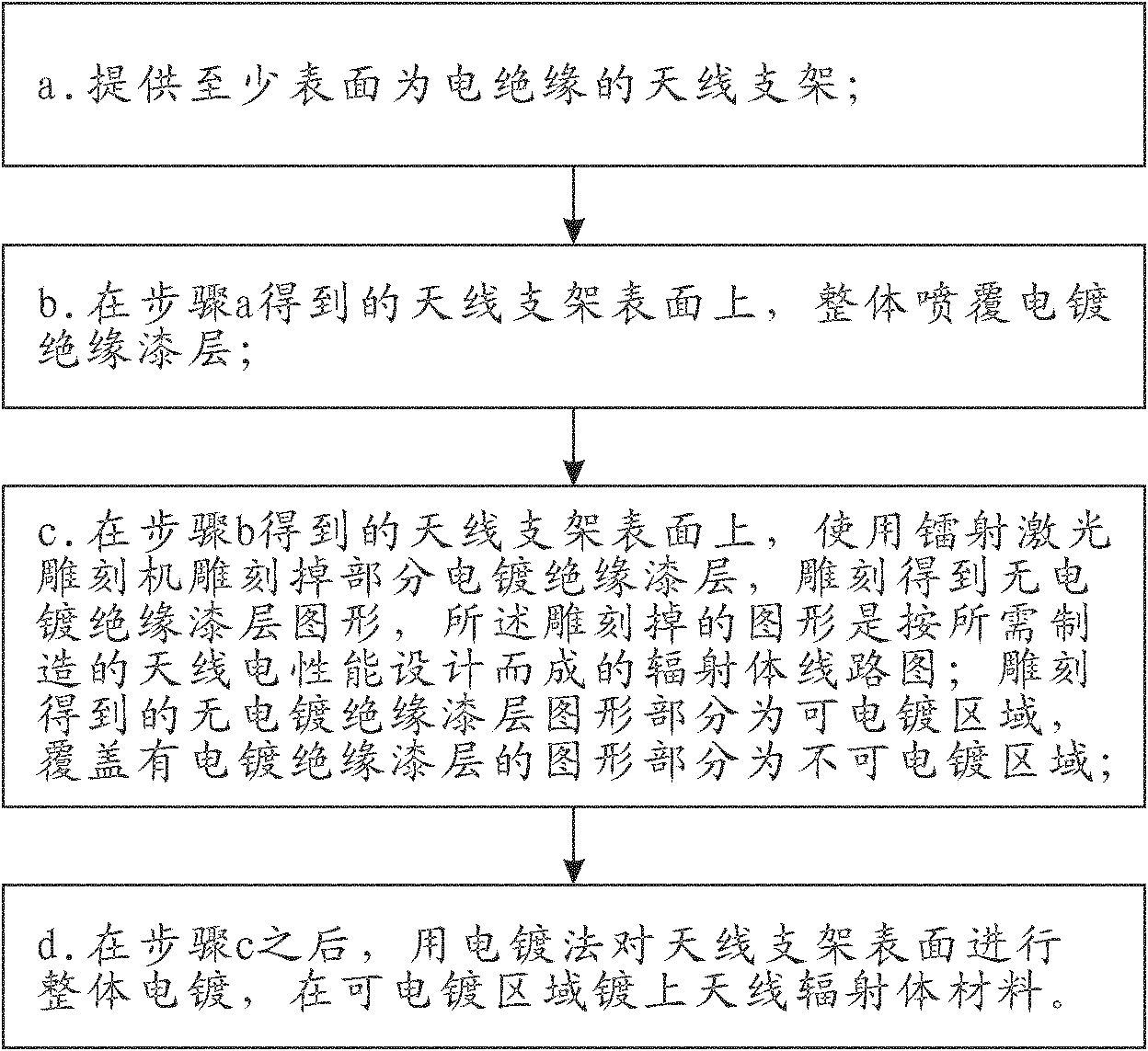

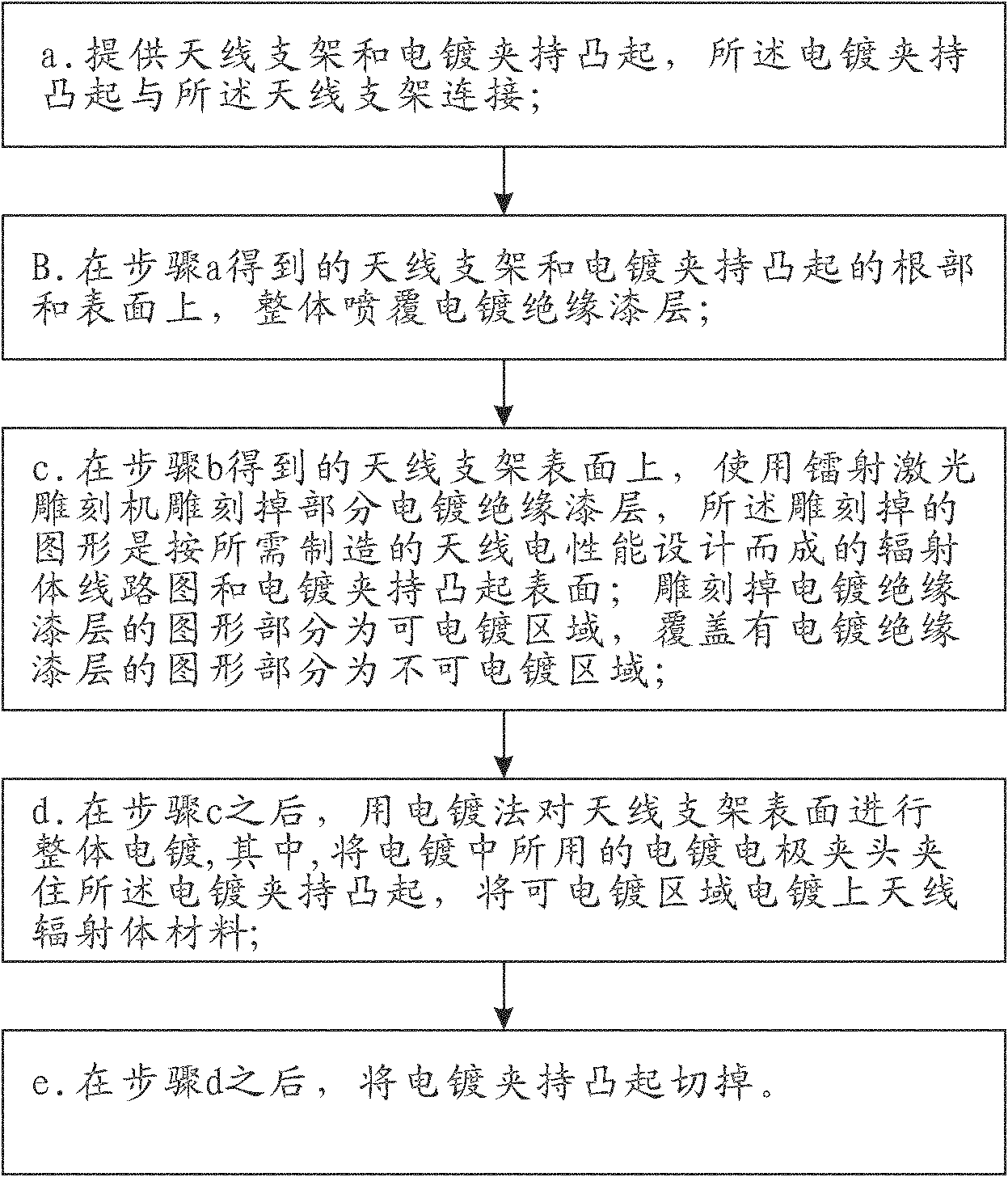

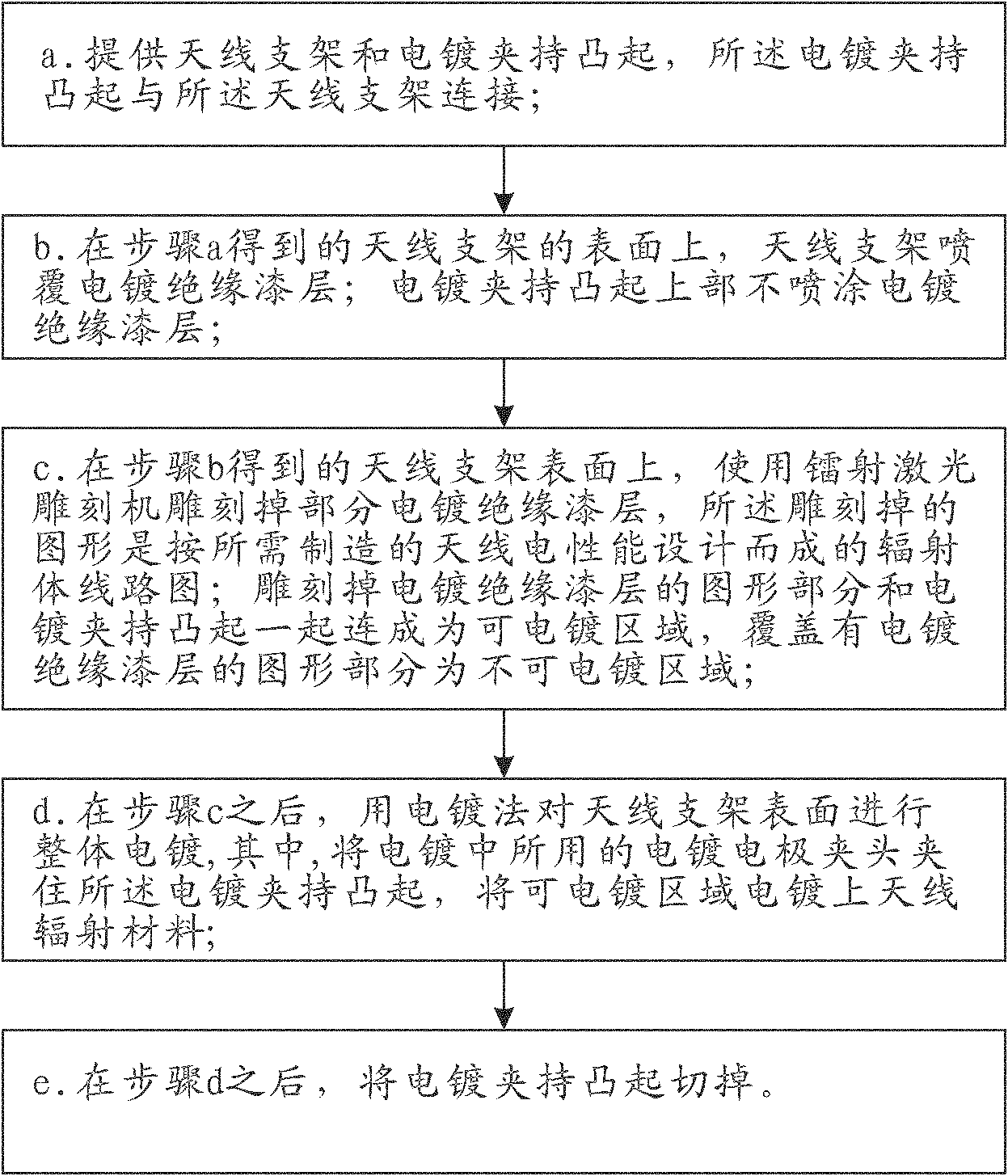

Antenna manufacturing method

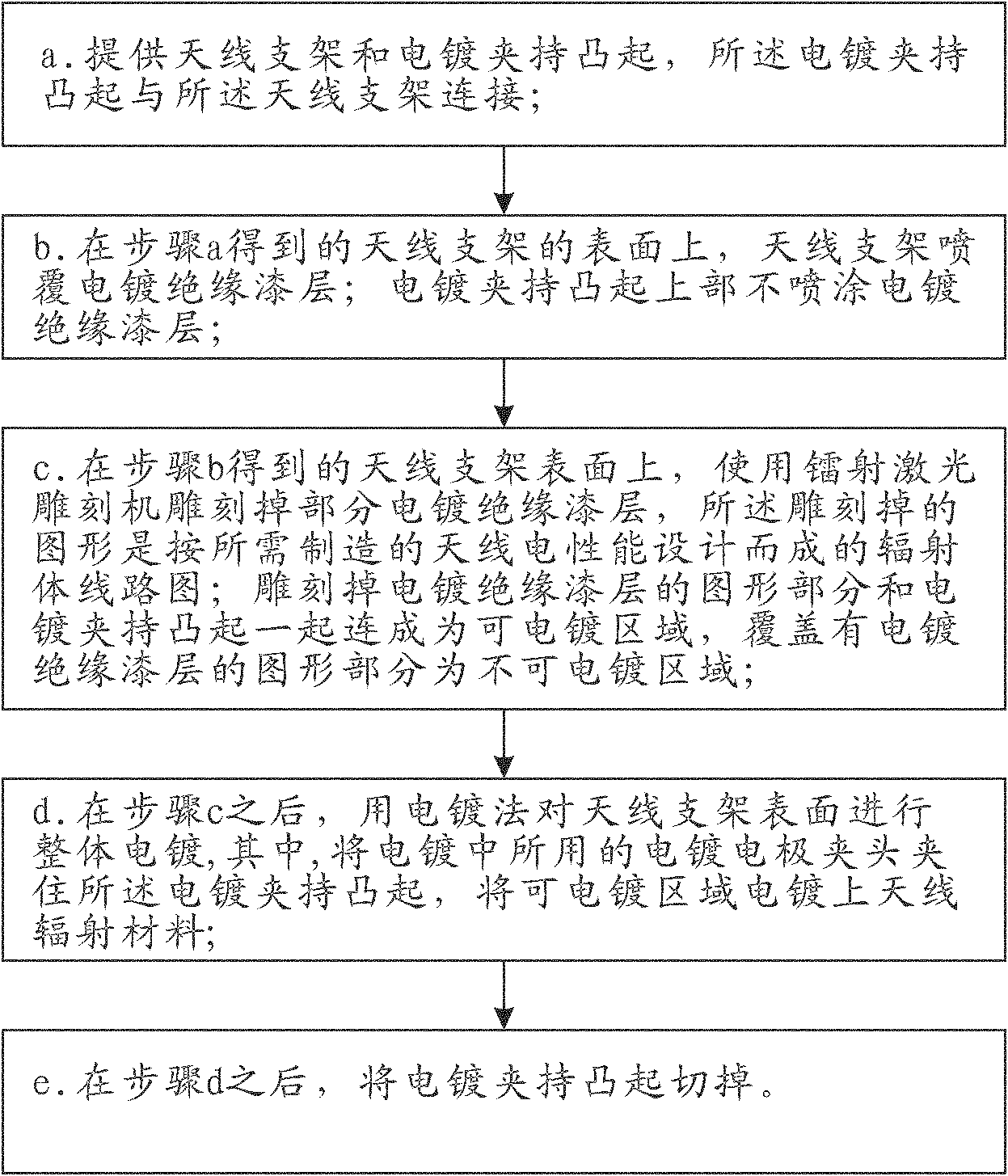

InactiveCN102142605AImprove bindingImprove consistencyRadiating elements structural formsElectricityLacquer

The invention discloses an antenna manufacturing method, which comprises the following steps of: a, providing an antenna bracket of which at least the surface is electrically isolated; b, spraying an electroplating insulated paint layer on the whole electrically-isolated surface of the antenna bracket obtained in the step a; c, using a laser engraving machine to carve out part of the electroplating insulated paint layer on the surface of the antenna bracket obtained in the step b, and carving to obtain a pattern without an electroplating insulated paint layer; the carved pattern is a radiation body circuit diagram designed according to the electrical property of the antenna needing to be manufactured; part of the carved pattern without the electroplating insulated paint layer is an area capable of being electroplated, and the area covered with the electroplating insulated paint layer is an area which can not be electroplated; and d, after the step c, electroplating the whole surface of the antenna bracket with an electroplating method, and plating an antenna radiation body material on the area capable of being electroplated. The antenna manufacturing method has simple manufacturing process and does not need assembly, the bonding force of a radiation body and a bracket body is good, the consistency of the antenna property is good, the molding speed is high, and the production efficiency is high.

Owner:SHENZHEN SUNWAY COMM

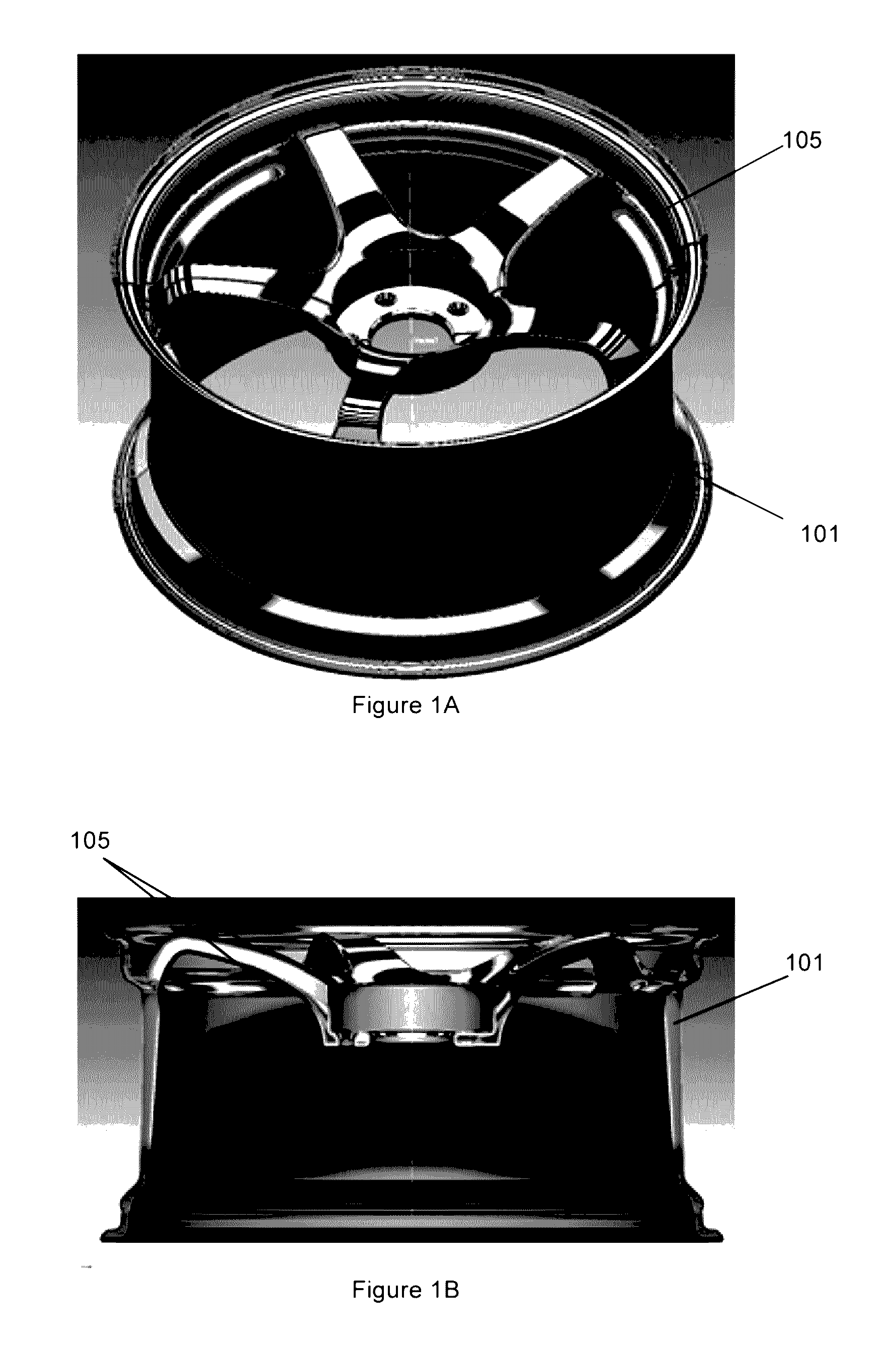

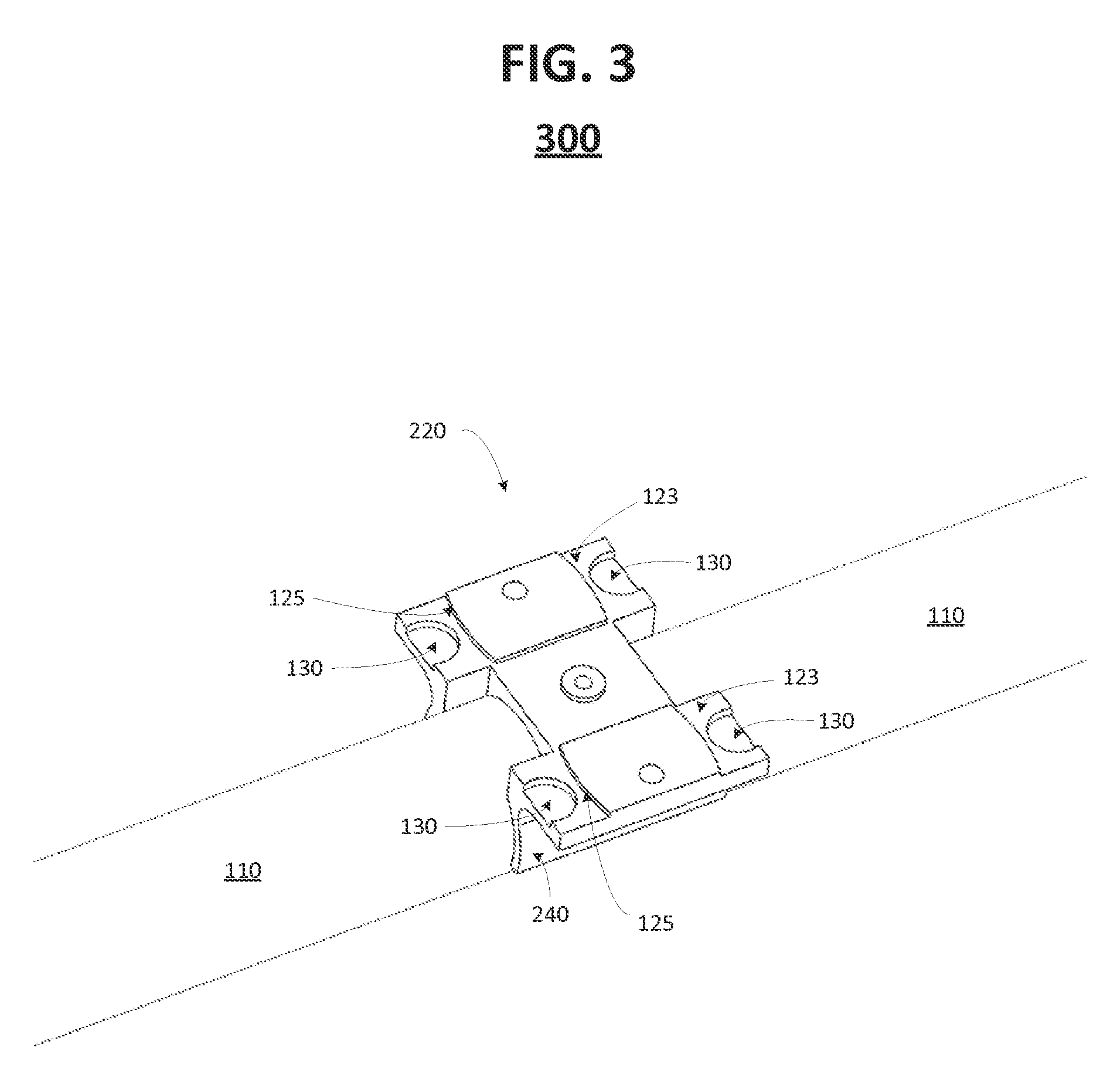

Molded wheel device

A method of manufacturing a wheel device including bonding a hub portion with lug holes and center bore hole, a spokes portion, and a barrel portion to generally form a mandrel or an inner frame of the wheel device. The inner frame is a scaled down size of the wheel device, in which a composite skin is wrapped around the inner frame to form an uncured wheel device. The uncured wheel device is encased inside a mold apparatus to cure. A cured wheel device of this method provides a wheel device with barrel, spokes, hub, lug holes and center bore hole molded into said wheel device without the use of a machine to carve out the spokes, hub, log holes or center bore hole.

Owner:QUIROZ JOSHUA

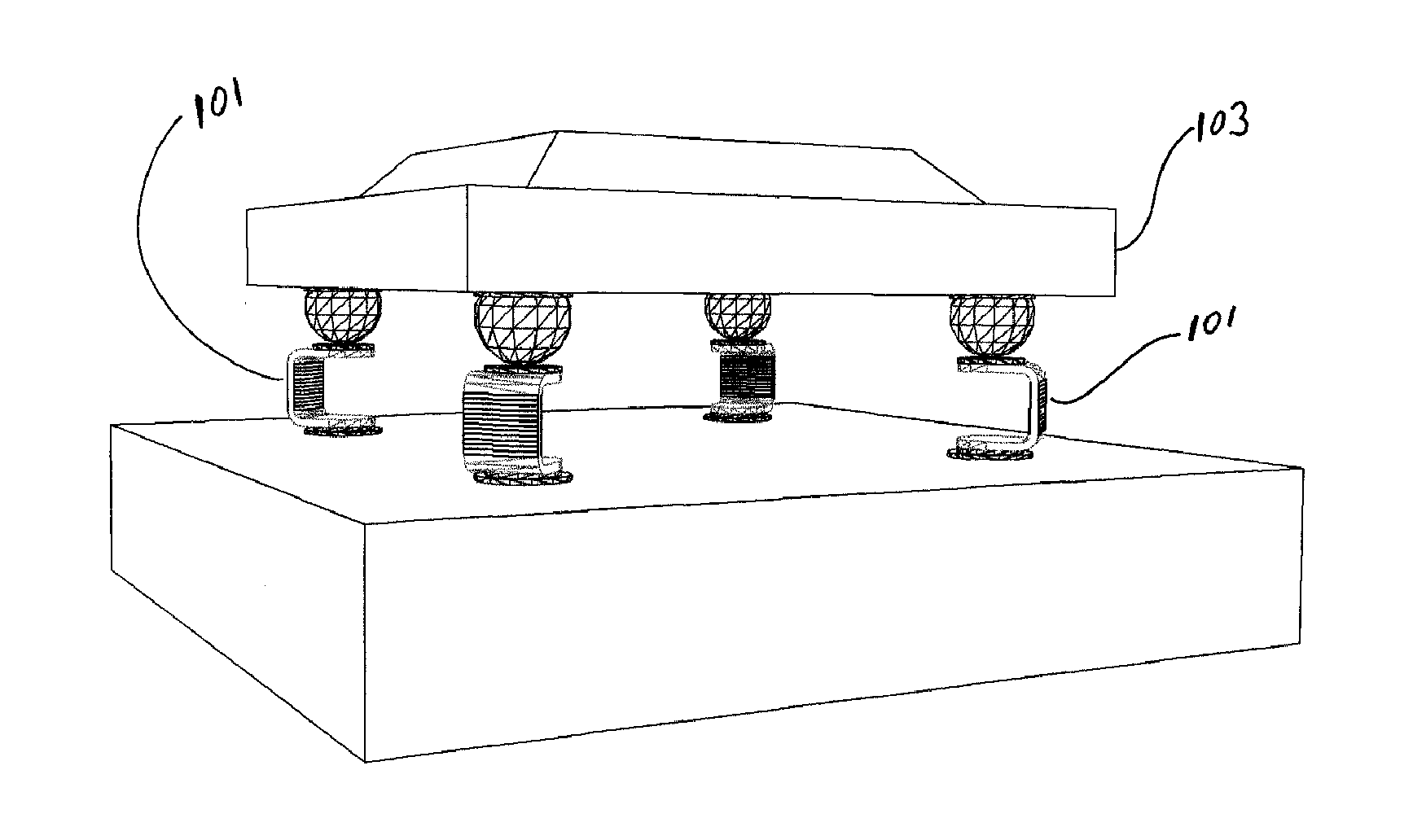

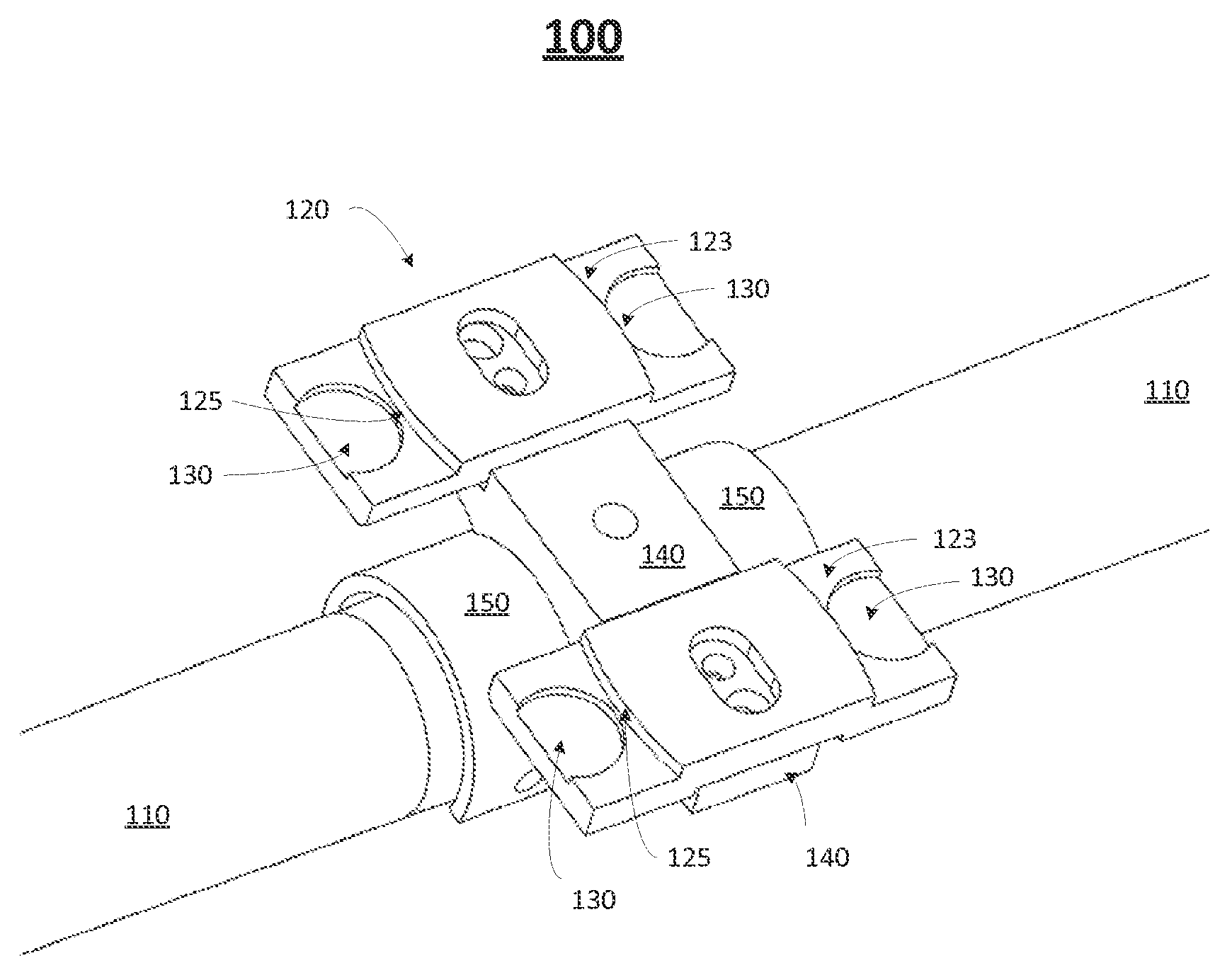

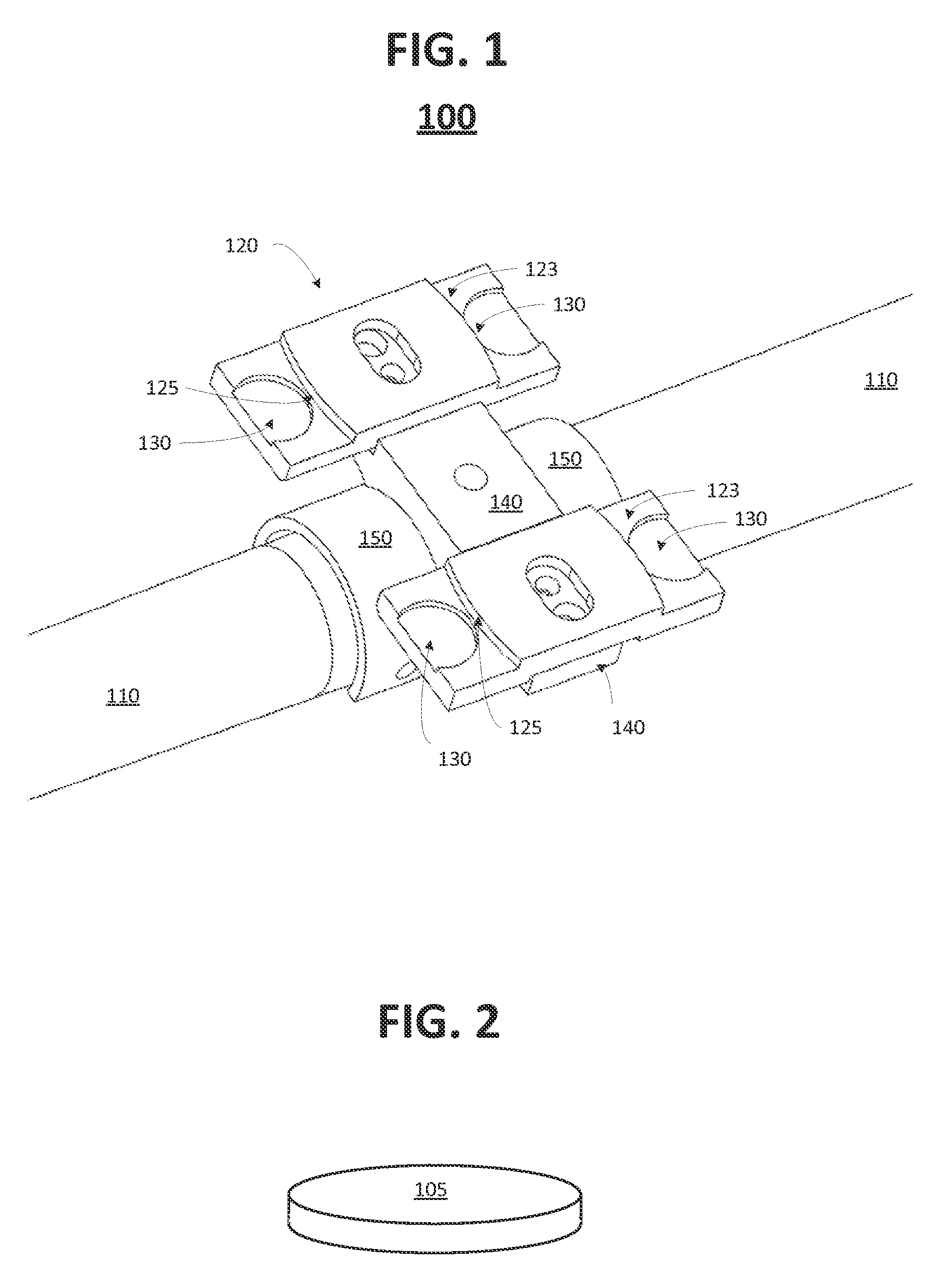

Wafer handling apparatus

Disclosed is a wafer support and alignment apparatus. The wafer support and alignment apparatus includes a wafer support component adapted to seat, align and support a wafer. The wafer support component includes at least one flat portion to support the wafer, at least one alignment lip portion protruding upward from the at least one flat portion, and at least one recessed pocket carved out of a portion of the at least one base portion. The at least one recessed pocket is adapted to receive at least one pad.

Owner:VARIAN SEMICON EQUIP ASSOC INC

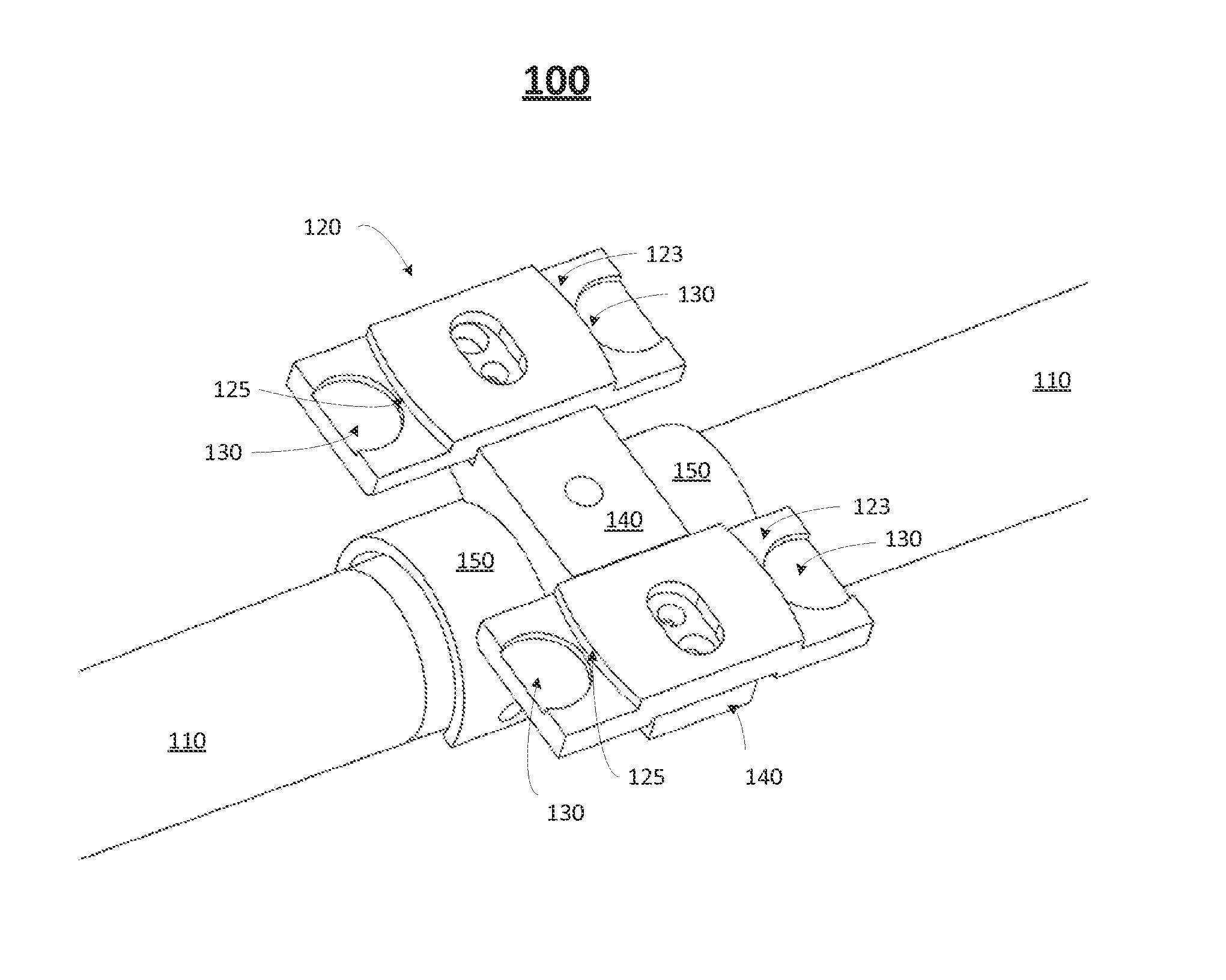

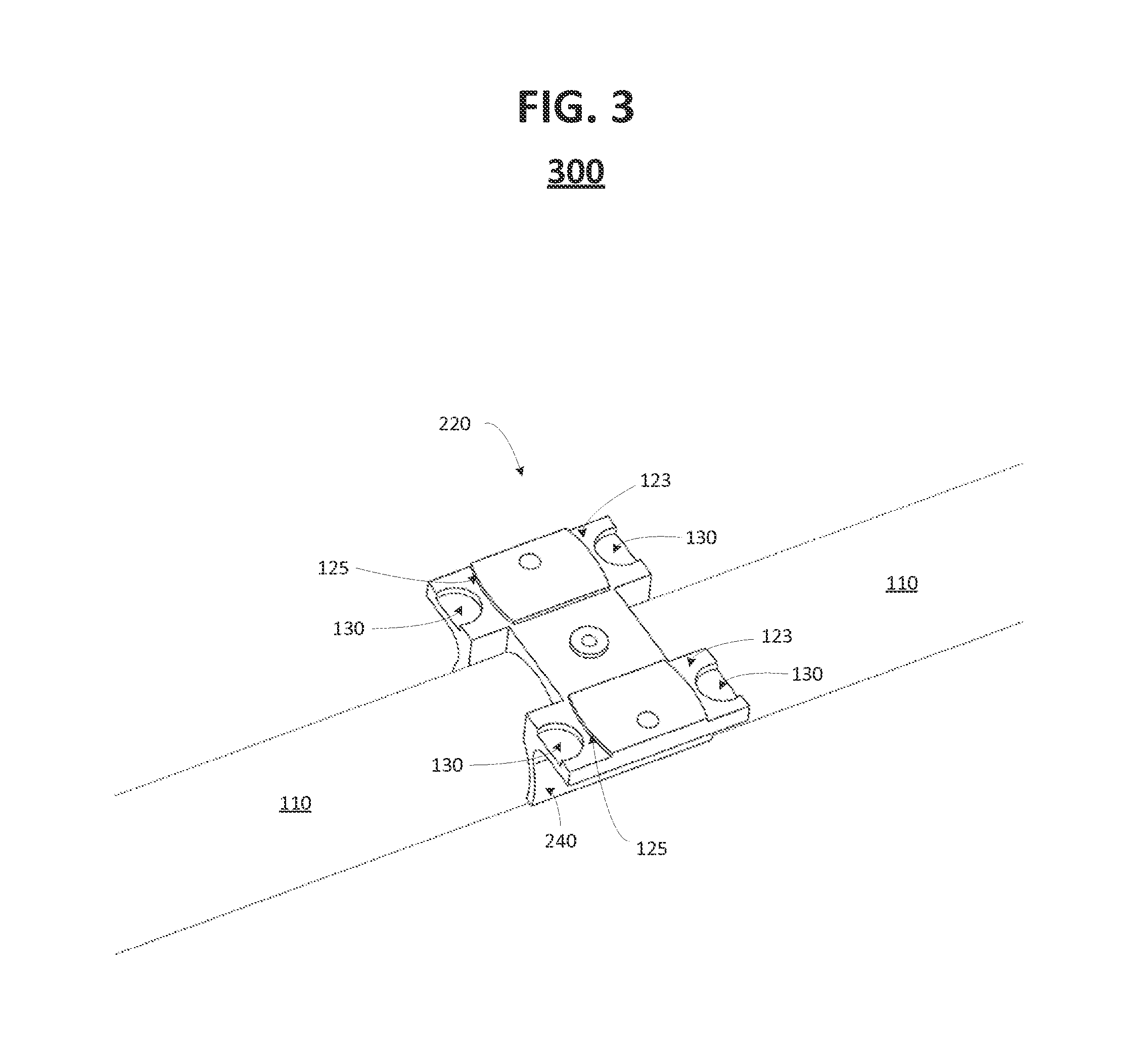

TFCC (TM) & SWCC (TM) thermal flex contact carriers

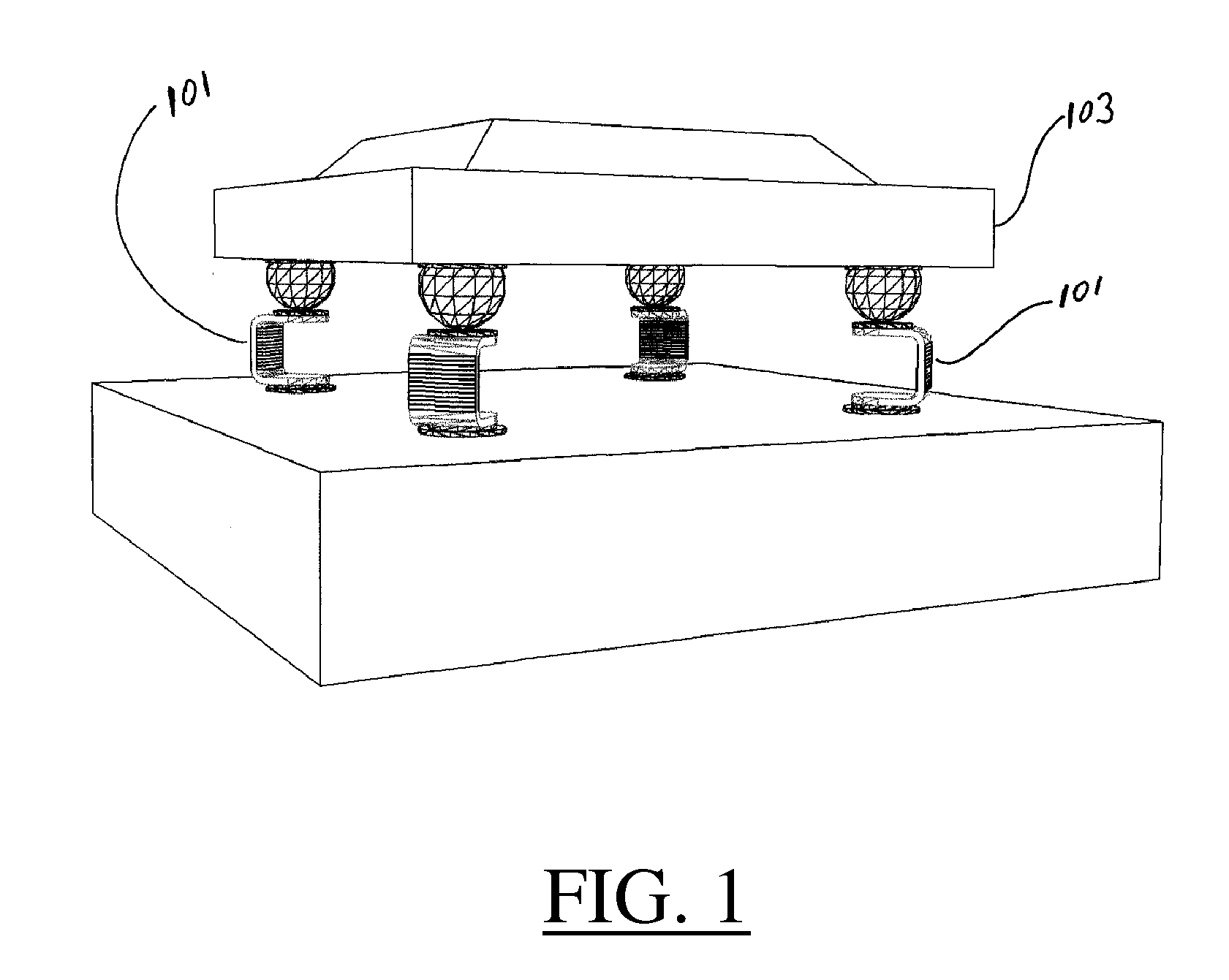

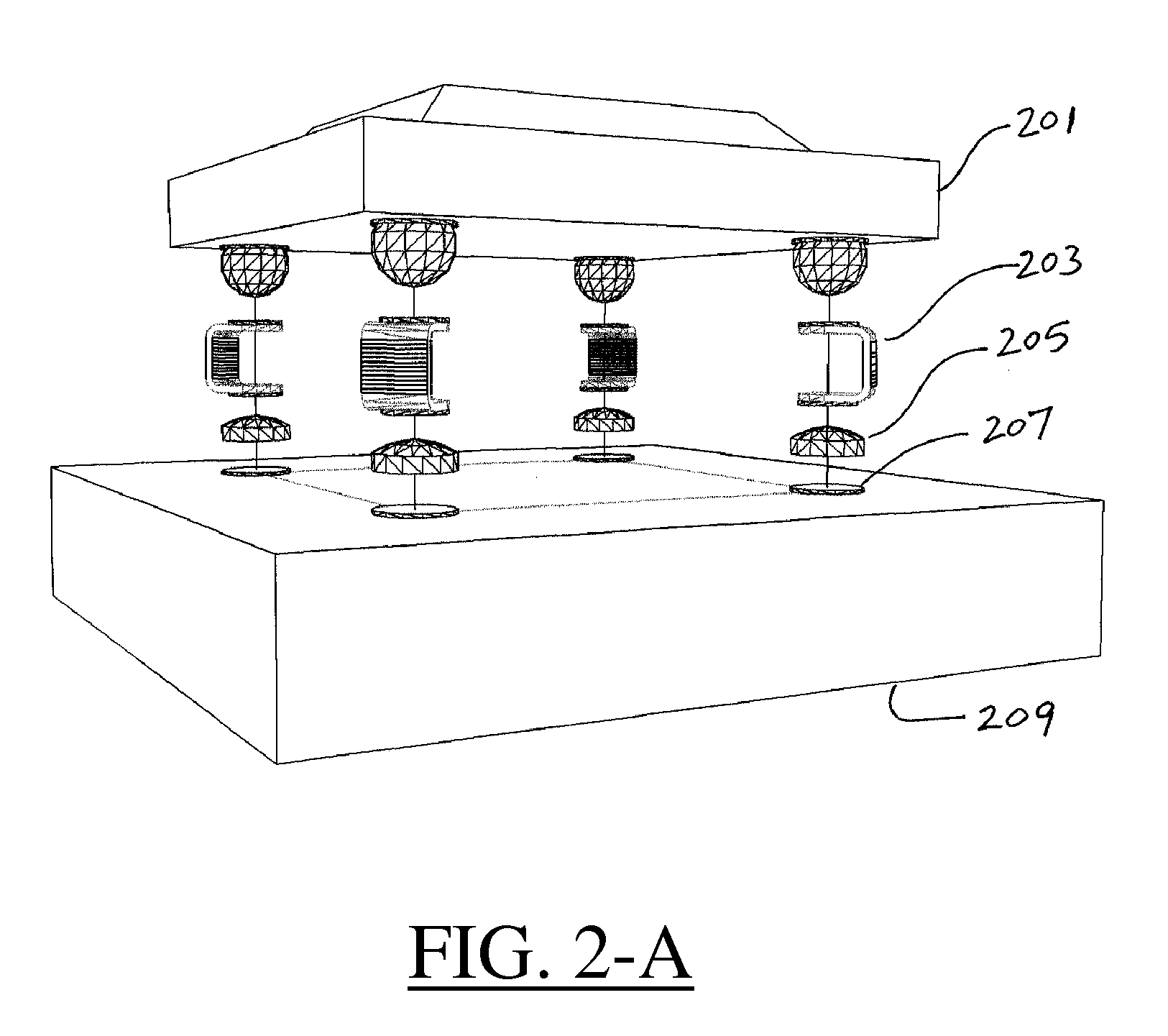

InactiveUS20090032915A1Better withstandMore reliableFinal product manufactureSemiconductor/solid-state device detailsSolder maskInterconnection

Two groups of interconnection devices and methods are described. Both provide columns between electronic packages and boards or between chips and substrates or the like. In the first group, called Thermal Flex Contact Carrier (TFCC), the column elements are carved out of a flat laminated structure and then formed to suit. In the second group, the carrier, which carries the connecting elements, is made out of a soluble or removable material, which acts at the same time, as a solder mask, to prevent the solder from wicking along the stem of the elements.

Owner:CHERIAN GABE

Surface polishing method for protective side edge of group II-VI semiconductor material

ActiveCN1883881AAvoid the disadvantage of poor grinding and polishing effectPolishing machinesSemiconductor/solid-state device manufacturingSemiconductor materialsEngineering

Disclosed is a polishing method for protection of group II-VI semiconductor materials side edge by carving out but not penetrating demanded forming wafer area on the original wafer and polishing same. That is, peripheral small wafer is used as teat wafer to be polished, thus, the peripheral small wafer can prevent the extrusion between the middle forming wafer edge and abrasive materials and the chip, gapping, and defect can be prevented caused by extrusion, as a result, the protection of side edge can be realized.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Fluid delivery system and mounting panel therefor

InactiveUS20050241707A1Increase flexibilityLow costServomotor componentsEnergy industryCarve outDelivery system

A novel fluid delivery system includes a mounting panel, where the mounting panel includes channels that define the flow of fluid between any flow-control components mounted on the mounting panel. The mounting panel comprises a top plate and a bottom plate, and the channels are carved out of the underside of the top plate and are enclosed by the bottom plate. In a complex fluid delivery system having many fluid channels, the mounting panel may include one or more interior panels with additional channels carved out of the interior plates to accommodate all routing paths. The channels run in two or more directions to connect two or more gas / channel sticks together.

Owner:SMC CORP

Non-segmented composite barrel for gas operated firearms

A method of making a continuous fiber barrel wrap sheath onto a steel riffled barrel liner of a gas-operated firearm is described. A wrap made up of composite fiber is wrapped onto a steel riffled barrel liner in a continuous fashion, with no interruption within the steel liner for the purpose of delivering high pressure gas through the steel liner. After joining the composite wrap to the steel barrel liner, either by mechanical or chemical procedure, a slot is formed by carving out a top and / or a bottom of the composite. A gas key insert is then placed in the made slots and retained by mechanical or chemical procedure. Finally, a gas port is drilled through the key insert.

Owner:NEWMAN CORY J

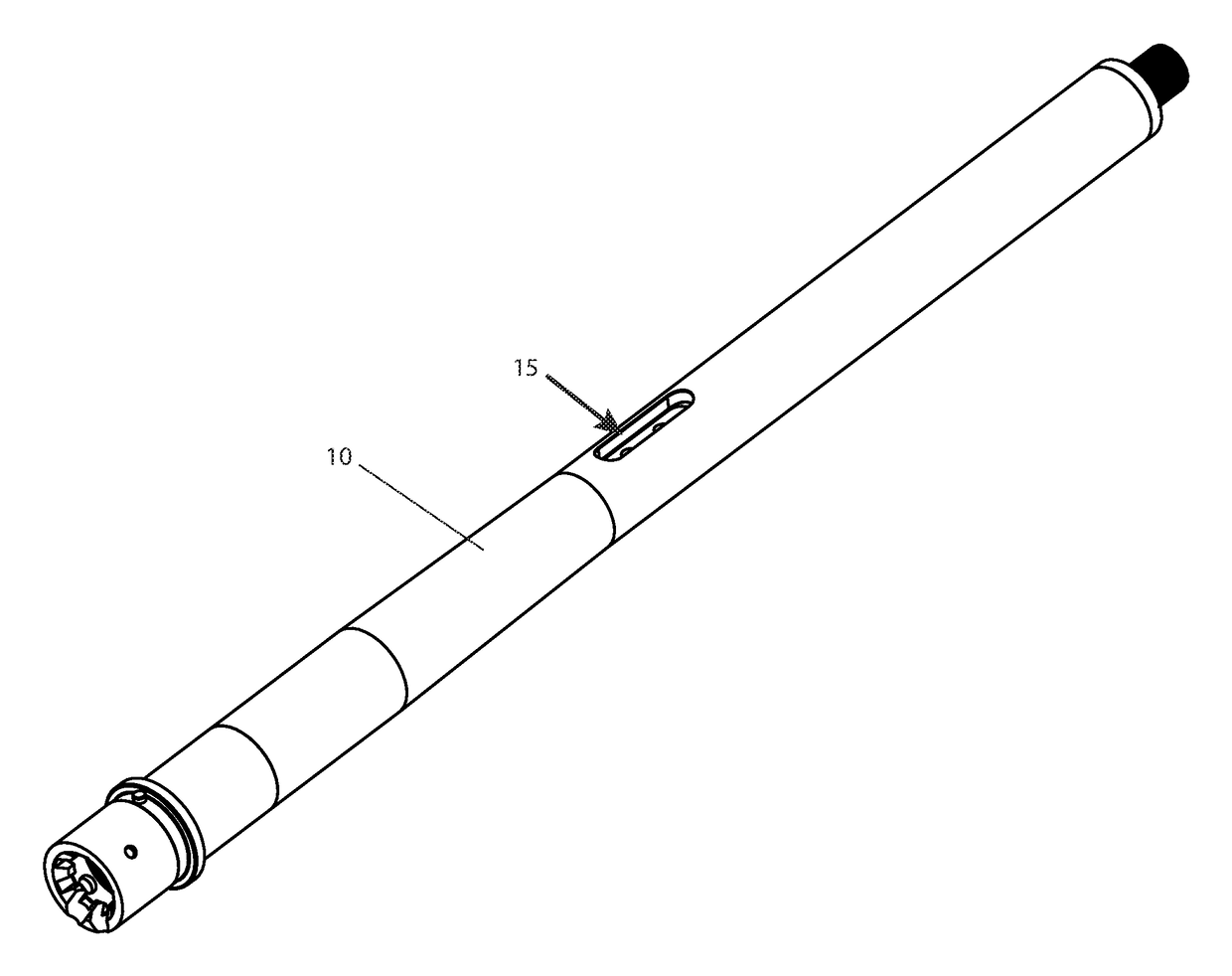

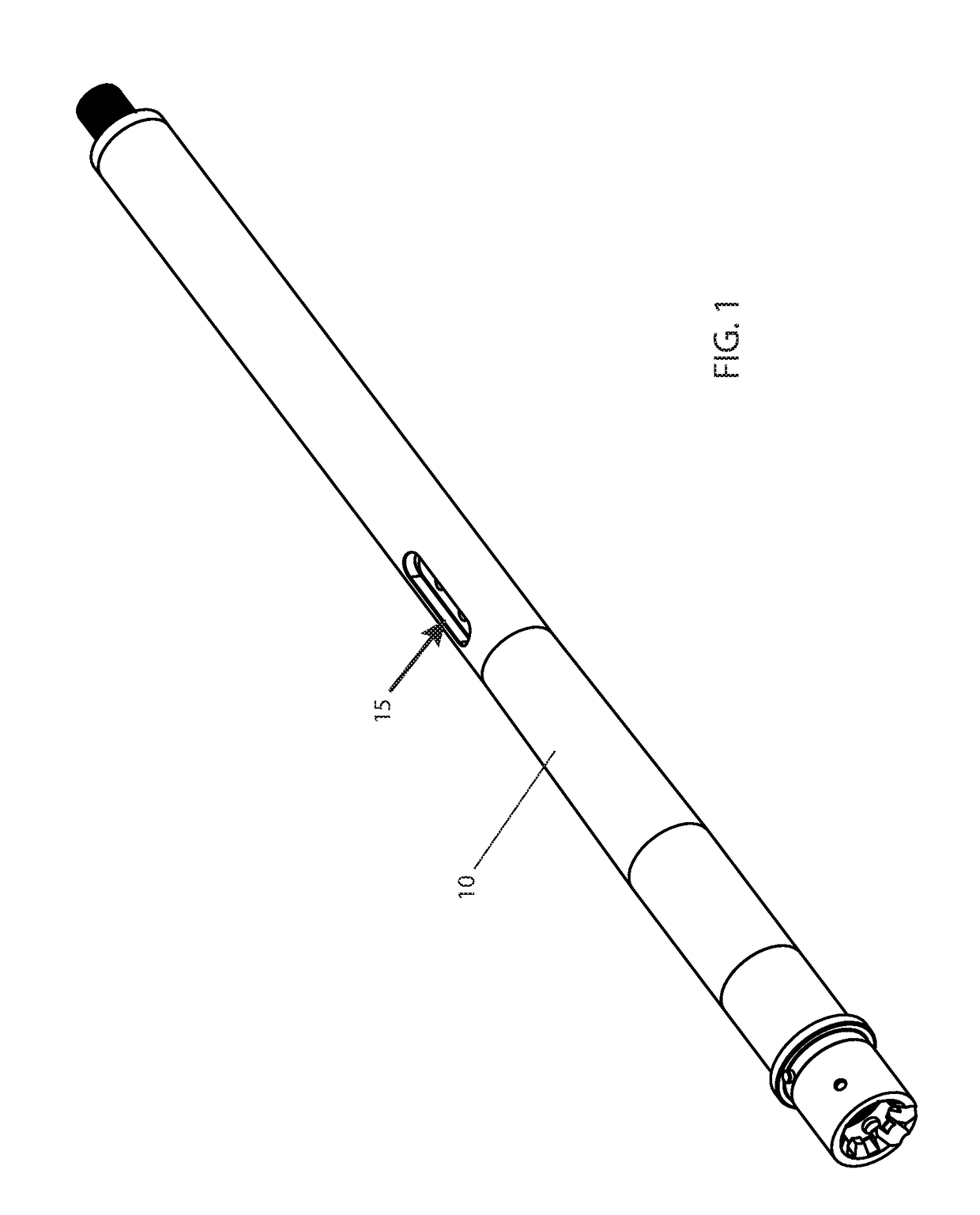

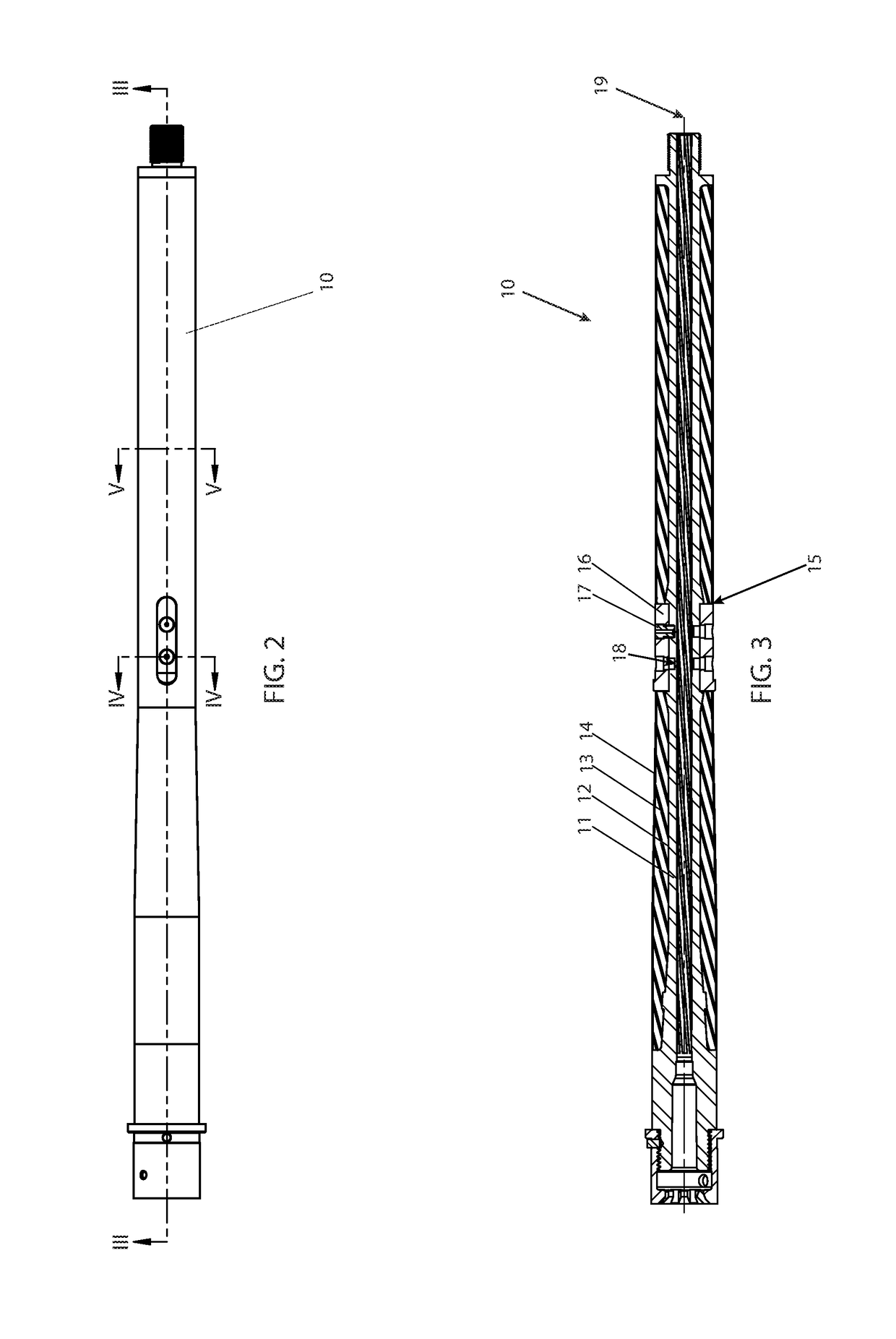

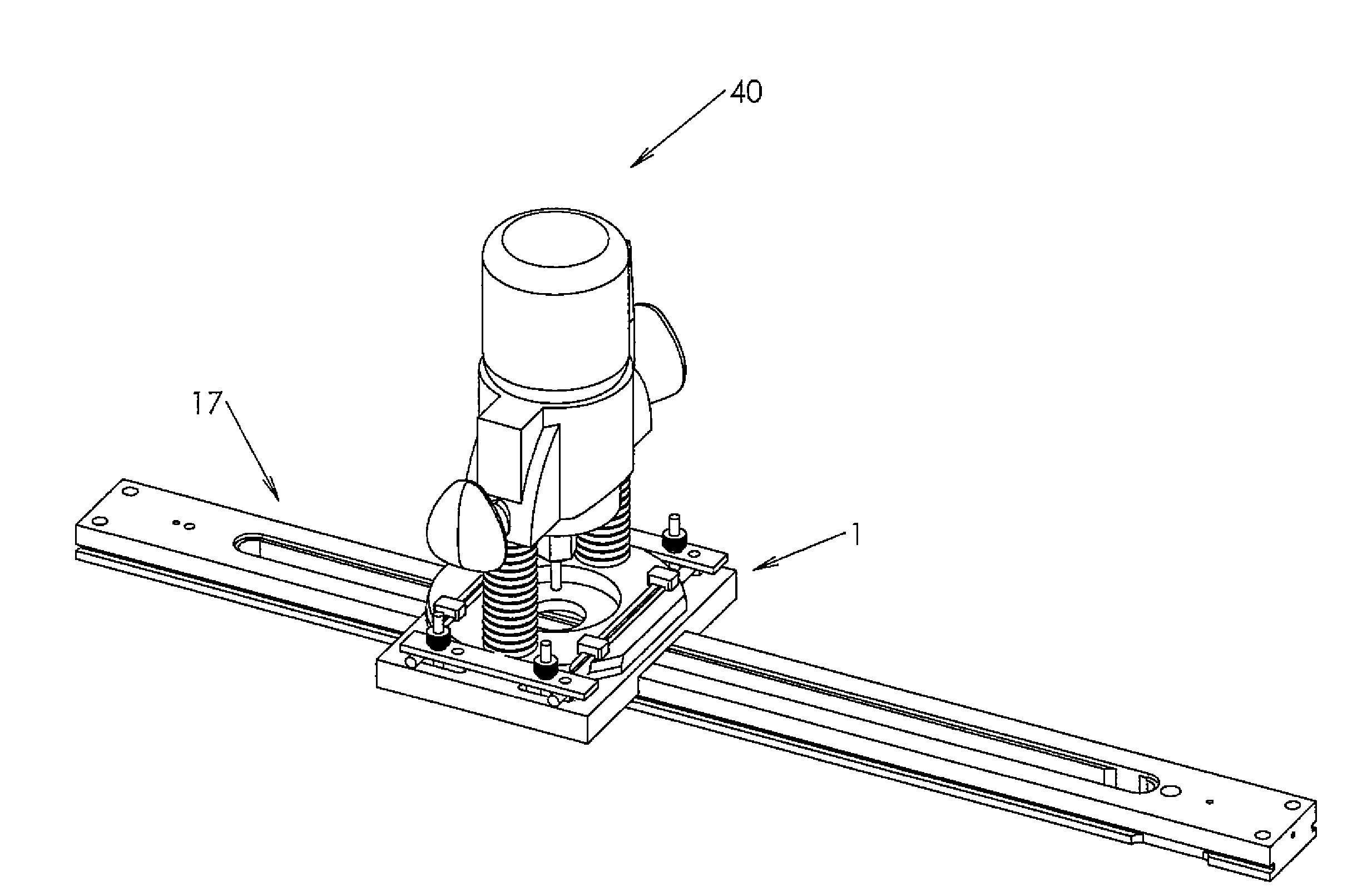

Apparatus for facilitating work on stringed instruments

A tool for luthiers comprising a main slide bar; router or rotary tool attachment piece; and two slotted clamps; wherein the main slide bar comprises a first channel that runs longitudinally from the first to the second end of the main slide bar and that comprises a lip that extends around the perimeter of the channel and that is carved out at the front end of the main slide bar to allow various parts to be inserted into the channel; wherein each side surface of the main slide bar comprises a second channel that runs longitudinally from the first to the second end of the main slide bar; wherein each end of the slotted clamps fits into the second channel via a recess in the side surface; and wherein the router or rotary tool attachment piece comprises a third channel that fits over the main slide bar.

Owner:HINTHER DARYL

Wafer handling apparatus

Owner:VARIAN SEMICON EQUIP ASSOC INC

Antenna manufacturing method

InactiveCN102142605BImprove bindingImprove consistencyRadiating elements structural formsElectricityLacquer

The invention discloses an antenna manufacturing method, which comprises the following steps of: a, providing an antenna bracket of which at least the surface is electrically isolated; b, spraying an electroplating insulated paint layer on the whole electrically-isolated surface of the antenna bracket obtained in the step a; c, using a laser engraving machine to carve out part of the electroplating insulated paint layer on the surface of the antenna bracket obtained in the step b, and carving to obtain a pattern without an electroplating insulated paint layer; the carved pattern is a radiation body circuit diagram designed according to the electrical property of the antenna needing to be manufactured; part of the carved pattern without the electroplating insulated paint layer is an area capable of being electroplated, and the area covered with the electroplating insulated paint layer is an area which can not be electroplated; and d, after the step c, electroplating the whole surface of the antenna bracket with an electroplating method, and plating an antenna radiation body material on the area capable of being electroplated. The antenna manufacturing method has simple manufacturing process and does not need assembly, the bonding force of a radiation body and a bracket body is good, the consistency of the antenna property is good, the molding speed is high, and the production efficiency is high.

Owner:SHENZHEN SUNWAY COMM

Method for making noble metal paper part

InactiveCN106696433AHigh collection valueImprove practicalityLayered product treatmentLaminationPunch pressAdhesive

The invention relates to a method for making a noble metal paper part. The method comprises the following steps: a noble metal preliminary processing step used for making a noble metal blank material into slices with patterns; and a bonding step for attaching the noble metal slices to a paper part as a substrate by an adhesive. The noble metal preliminary processing step comprises the following steps: rolling the noble metal blank material into the slices with the thickness of 5 microns to 0.5 mm; using a cutting punching machine to cut and punch the rolled slices into a preset shape; and carving out the set patterns on the cut and punched slices. Compared with the prior art, the beneficial effect are that: the paper part as the substrate is attached with the noble metal slices, the process is simple and easy to implement, the cost is not high, the combining application range of the paper part and the noble metal is improved, and collection value and practicability of the paper part are improved.

Owner:SHENZHEN JINBAOYING CULTURE

Device for marking on fish body

InactiveCN106165662AReduced activityEasy letteringClimate change adaptationPisciculture and aquariaBody shapeLaser engraving

The invention relates to a device for marking on a fish body. The device is composed of two independent parts of a laser engraving machine and a fish containing box; the fish containing box can move to the position near a laser head of the laser engraving machine, and laser engraving can be conducted on the fish body; the fish containing box is internally provided with a fish fixing tank which is similar to the fish body shape and is used for fixing the fish body. The laser head emits a laser beam to conduct ablation on the fish in the fish containing box, figures or characters or bar codes are carved out, and the purpose of marking on the fish body is achieved. The device for marking on the fish body has the advantages that the marking speed is high, marks are not accessories hanging outside and are not prone to falling off, durability is achieved, crucially, the marks are prevented from being replaced secretly, and identification on sales and dining tables is guaranteed.

Owner:桂林聚龙潭生态渔业有限公司

Color enamel product and preparation method thereof

InactiveCN103144488AThere will be no glaze jumping phenomenonSpecial ornamental structuresWaxEngineering

The invention provides a color enamel product. The color enamel product comprises a crystal article, blank bodies and color enamel, wherein the blank bodies are connected through at least one threaded fastening piece in a locking mode, the color enamel with the same color as crystal is filled in a connection position of the blank bodies and the crystal, and the color enamel blank bodies of the color enamel product are tightly attached to the crystal. The invention further provides a preparation method of the color enamel product. The preparation method of the color enamel product comprises the steps of drawing a plane design drawing, carving out a clay model, casting a wax impression, casting metal, baking color and assembling, wherein in the step of metal casting, the connection position of the blank bodies is provided with at least one hole, the blank bodies are connected through the metal fastening pieces in a locking mode, and in the step of color baking, the color enamel with the same color as crystal is filled in the connection position of the blank bodies, and the blank bodies of the prepared color enamel product are tightly attached to the crystal.

Owner:岳钢

Process method for making three-dimensional paper-cut work

InactiveCN106335315AEnhance layered stereo effectNon-fibrous pulp additionOutline designsAdipic acidPre treatment

The invention discloses a process method for making a three-dimensional paper-cut work. The method comprises the steps that moisture-proof paint is prepared, wherein the moisture-proof paint is prepared from, by weight, 1-8 parts of rice wine, 1-12 parts of ethyl acetate, 1-12 parts of bentonite, 5-30 parts of hexamethylene diisocyanate, 3-10 parts of polyurethane and 1-12 parts of adipic acid; the two sides of Chinese art paper are uniformly coated with the moisture-proof paint, drying is conducted, and moisture-proof Chinese art paper is made; a target graph is selected, Photoshop computer software is utilized for pretreating the size and color of the target graph, a supergraph is formed and divided into multiple subgraphs, the multiple subgraphs are drawn to the moisture-proof Chinese art paper respectively and carved out from the moisture-proof Chinese art paper, and a group of paper-cut sheets are formed; a base board is prepared, and the peripheral edges of the base board are continuously surrounded by frame strips; the group of paper-cut sheets stick to the substrate to form a three-dimensional structure, and the three-dimensional paper-cut work is made and is an artistic work showing a three-dimensional effect. According to the process method for making the three-dimensional paper-cut work, the made paper-cut is resistant to moisture and corrugations, and the laminating three-dimensional effect of multiple layers of paper-cut sheets made of Chinese art paper is further improved.

Owner:ANHUI SANLIAN UNIV

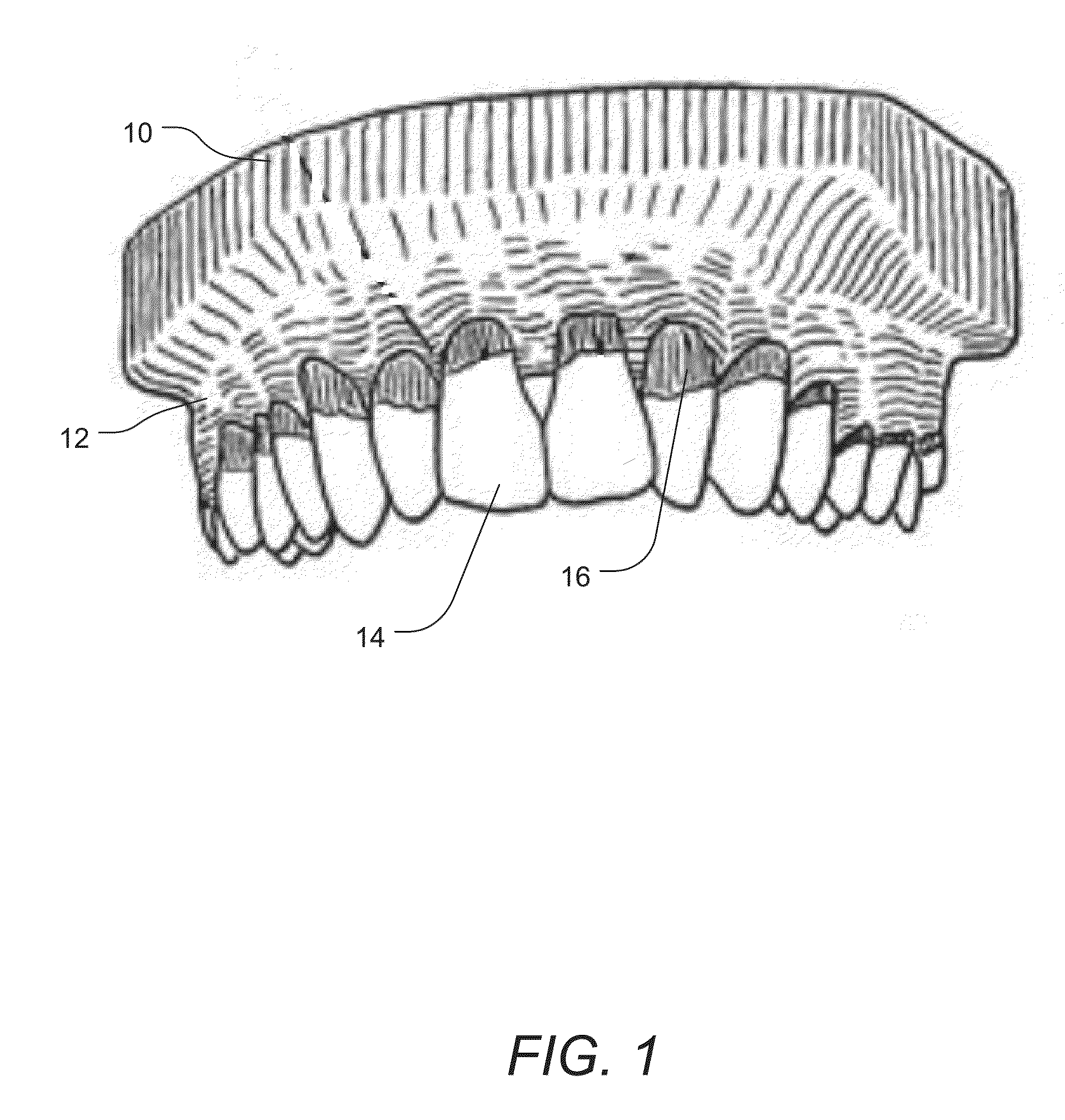

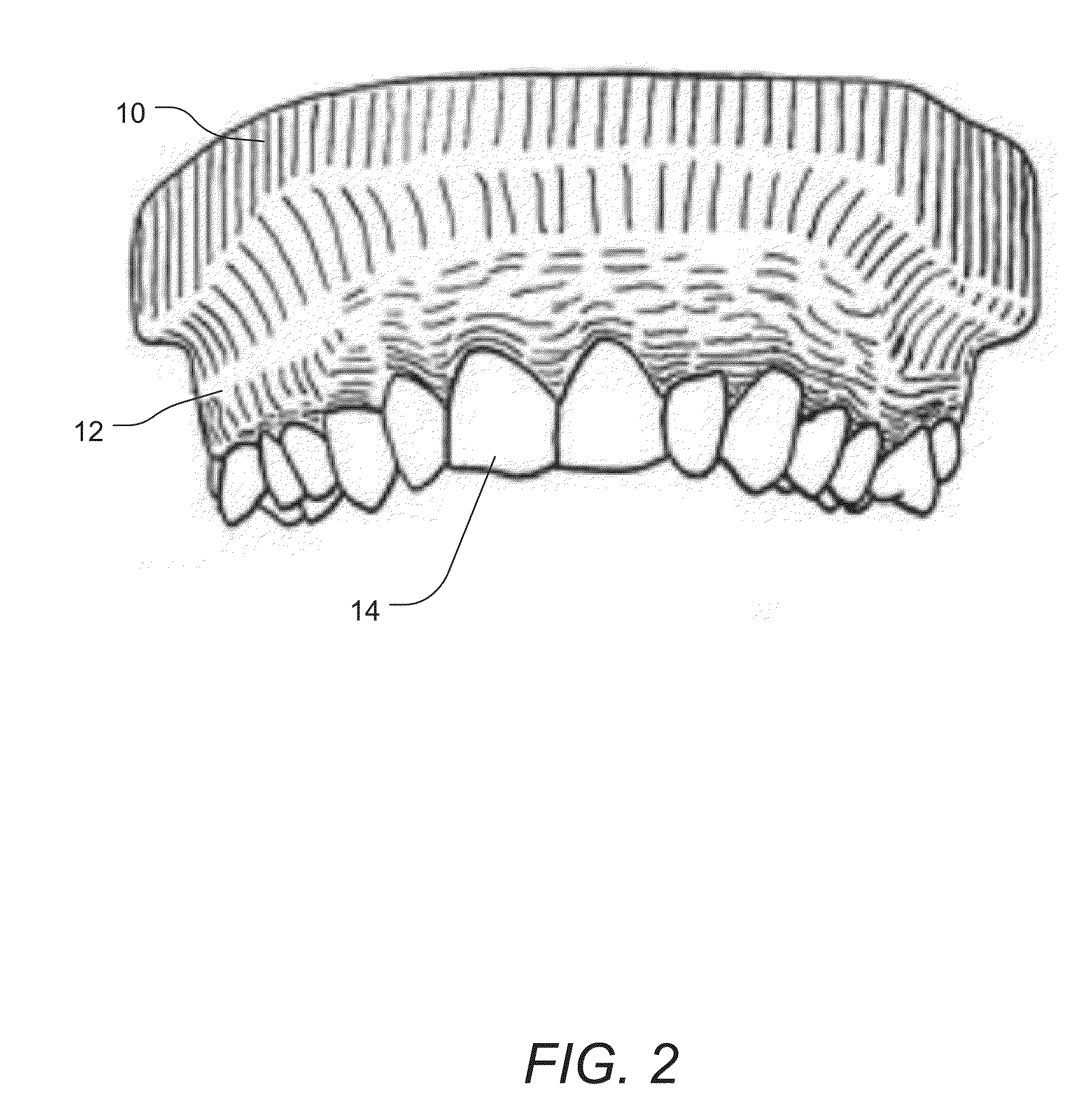

Non-surgical systems and methods for treating receding gums

A non-surgical treatment for receding gums utilizes the fact that tissue responds to continuous controlled mechanical forces with growth. The treatment system includes an impression of the upper and / or lower teeth, including the surrounding existing gums, so that a vacuum can be established within the impression around teeth and gums. Before use, selected portions of the impression are carved out a desired amount to create a location for the expansion and regrowth of the gums. Additionally, one or more channels may be included in the impression for delivery of the vacuum to all areas encompassed by the impression. The treatment system also includes a vacuum source operatively attached to the impression so as to be able to deliver a vacuum to the impression once the impression is place in the patient's mouth over the teeth and gums.

Owner:ALEXANDER ERIC JAY

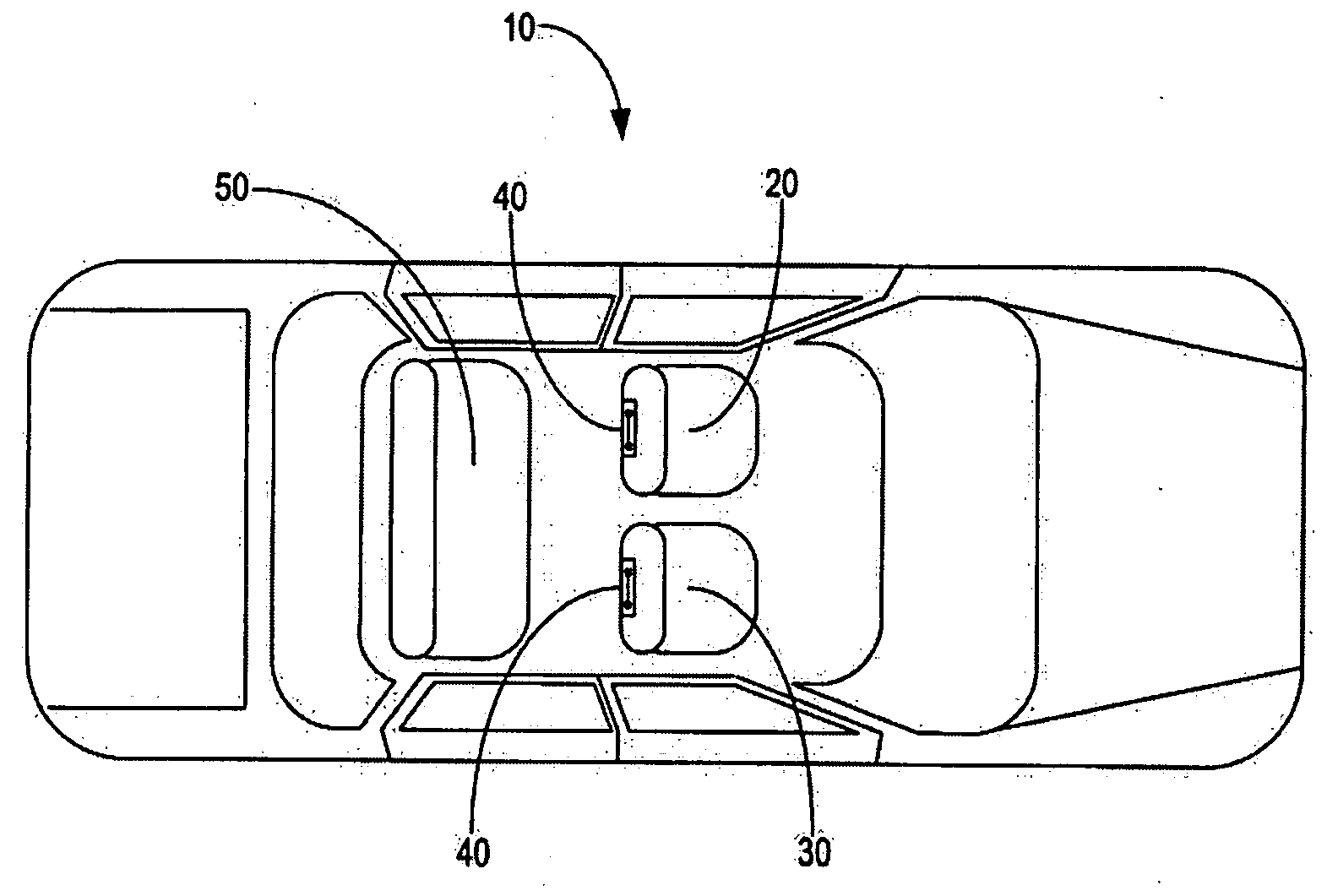

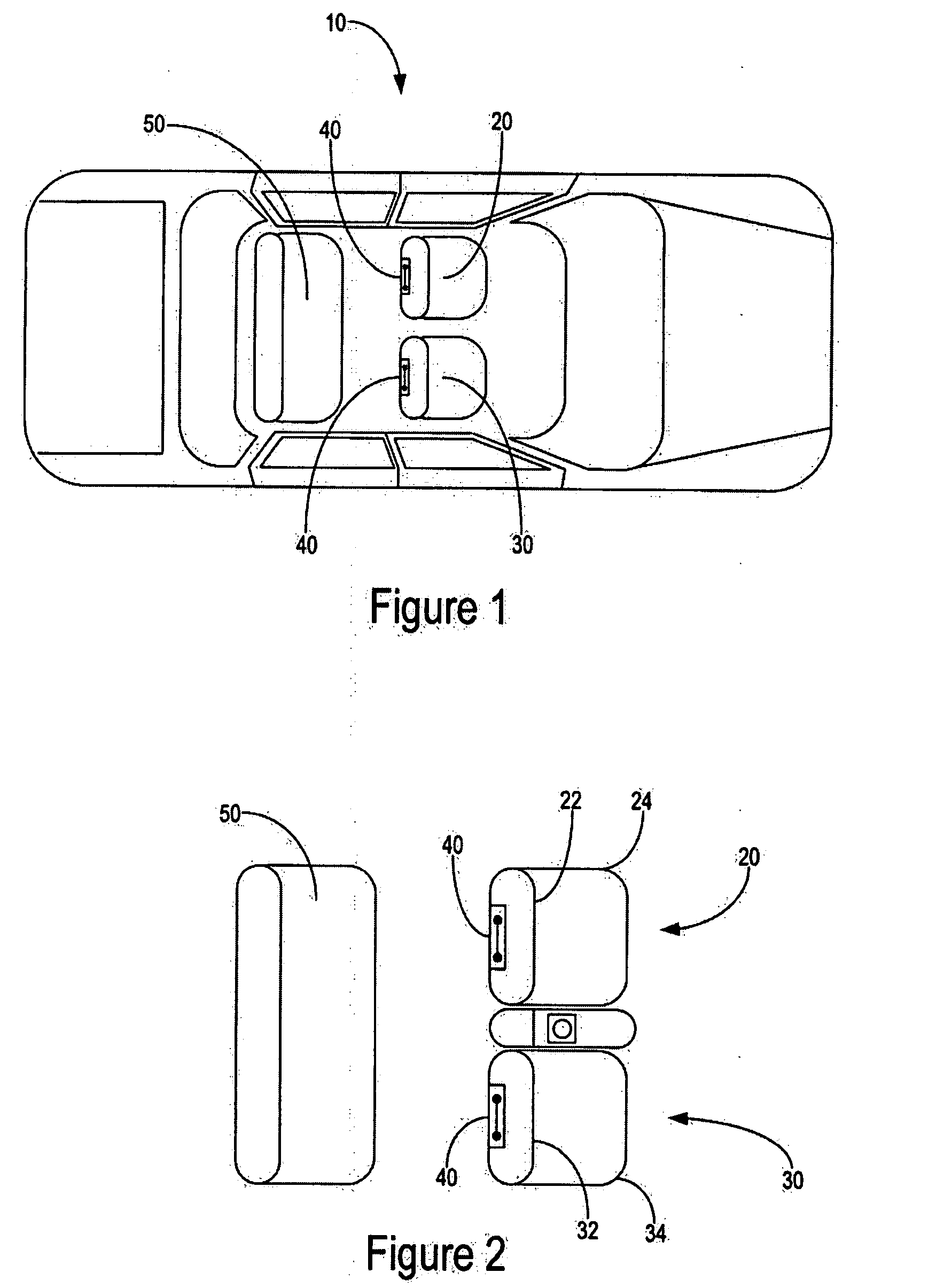

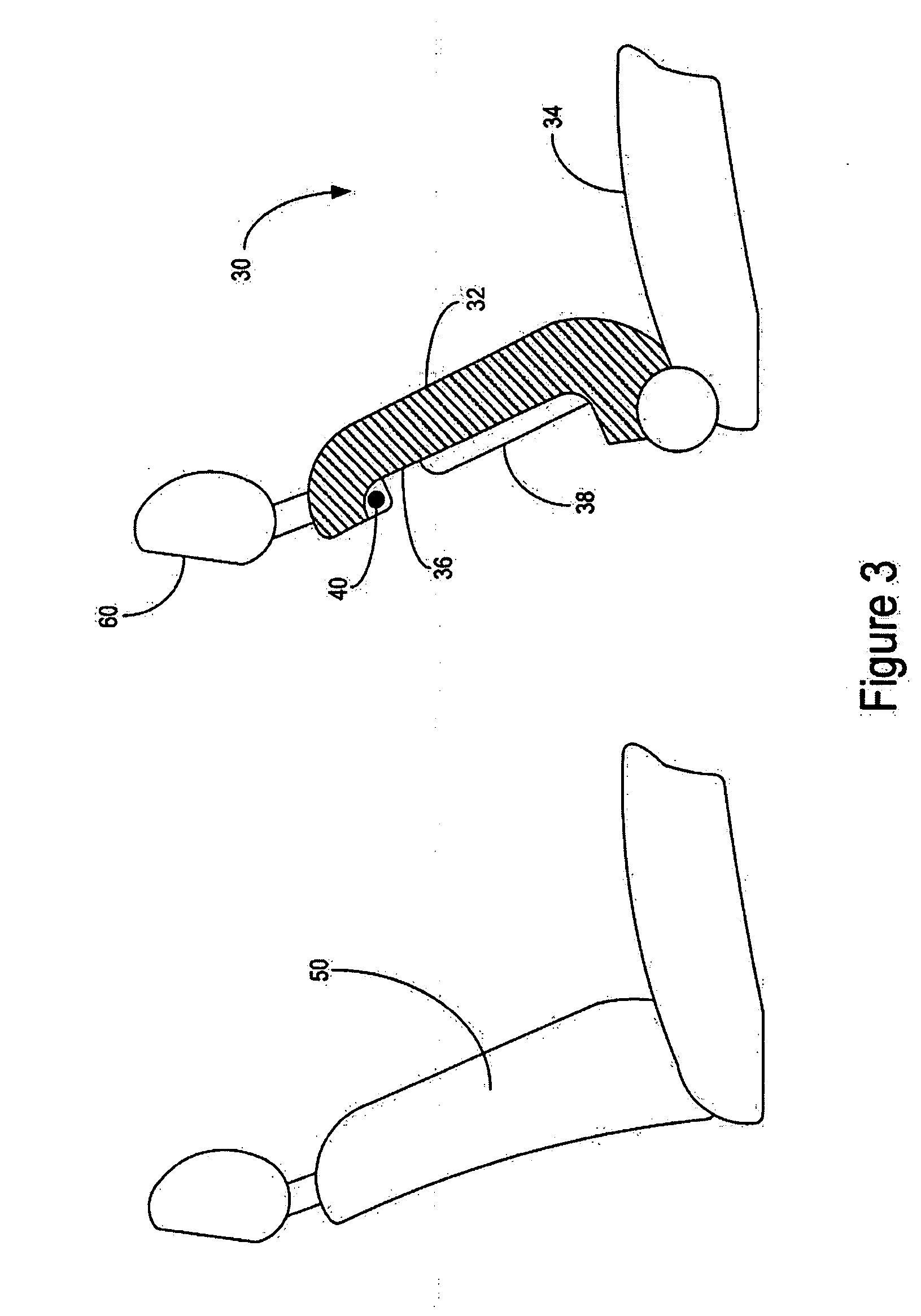

Automobile seat light for rear compartment lighting

InactiveUS20080219016A1Passenger/driving compartment lightingsOptical signallingCar seatEffect light

The present invention provides a light located in a carved out portion of the front seat back in an automobile. In an exemplary embodiment, the light includes a light-emitting diode (LED) lamp attached to the top ledge that the carved out portion creates. This LED lamp is small in nature, and therefore hidden from the view of passengers and out of the way as to not interfere with the front seat back. Additional exemplary embodiments can include incandescent lamps, fluorescent lamps, and the like. Advantageously, the light in the carved out portion can be utilized as a courtesy lamp, a reading lamp, a map pocket lamp, and the like. Additionally, the present invention is designed to allow illumination while the automobile is operating without interference with the driver or neighboring automobiles by positioning the light such that the light angles downward while on.

Owner:CHRYSLER GROUP LLC

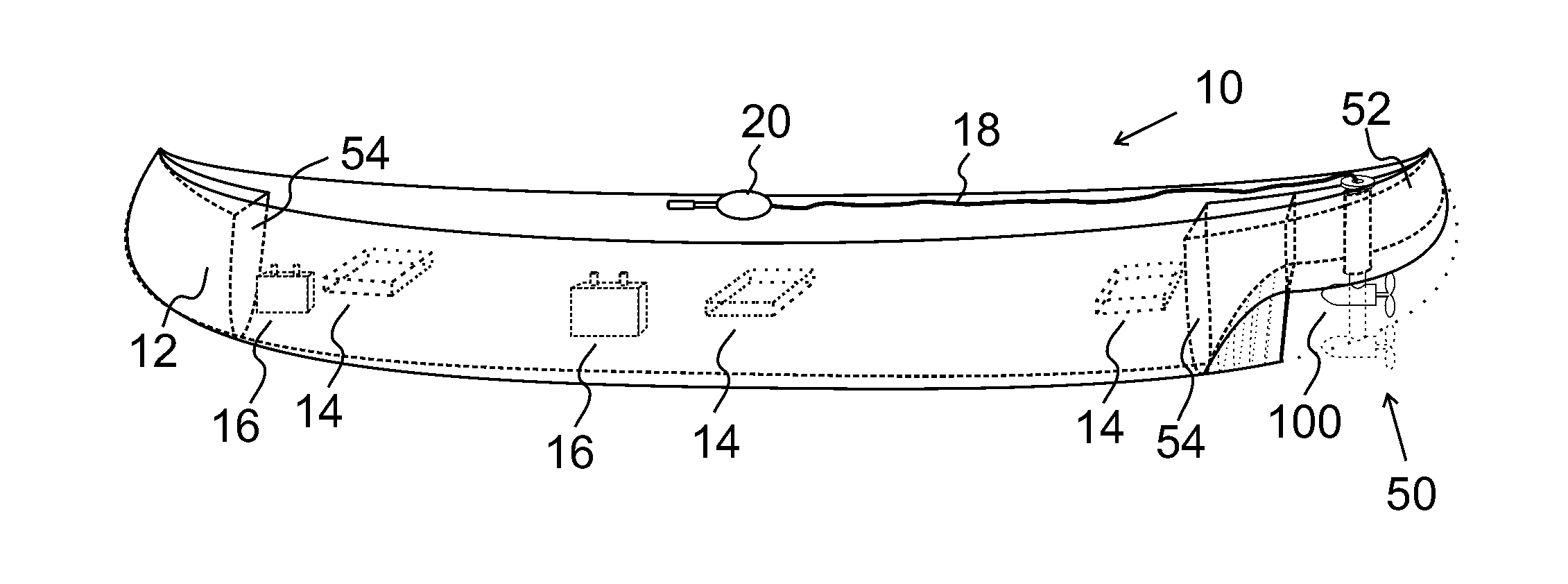

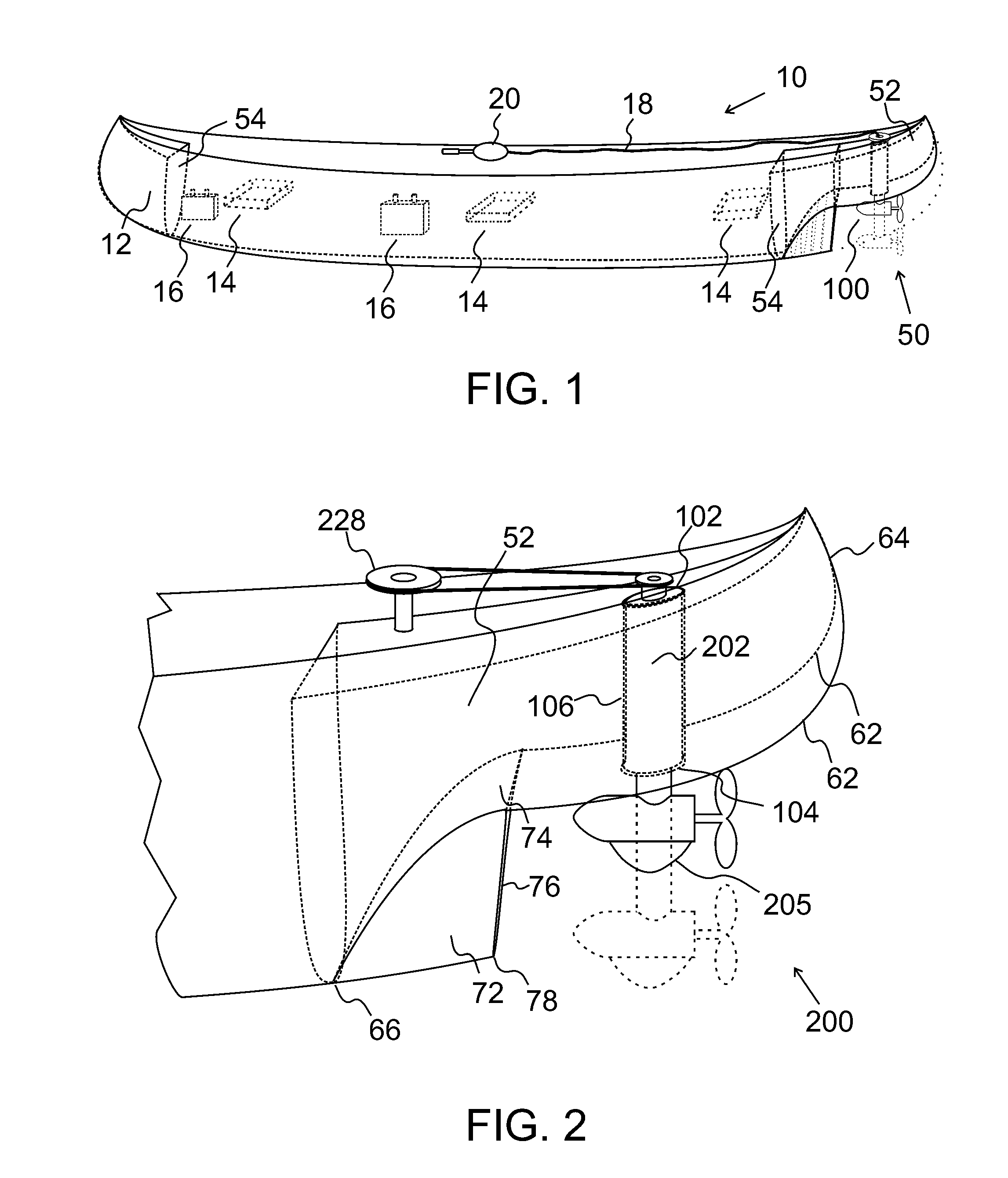

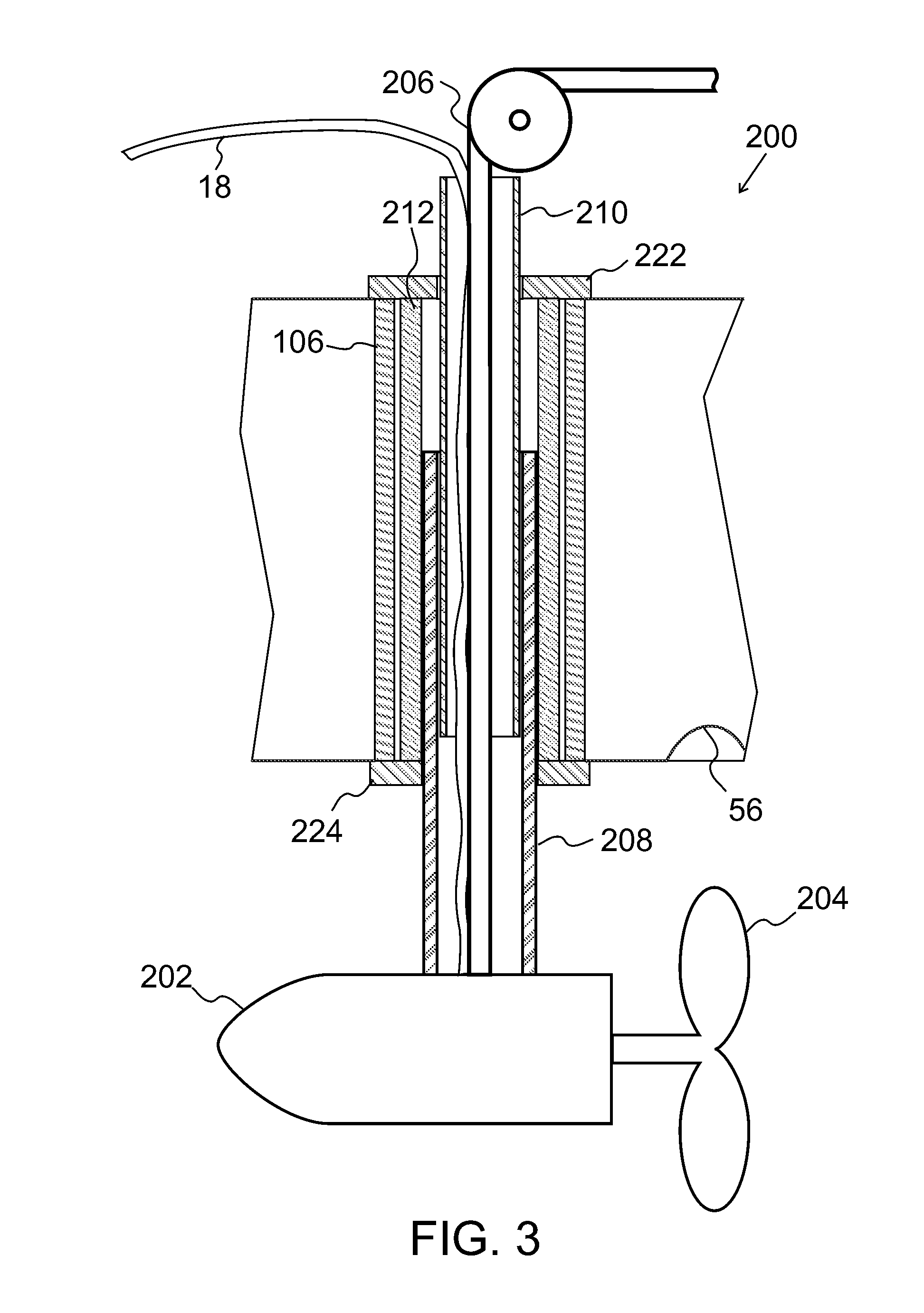

Shallow-draft watercraft propulsion and steering apparatus

InactiveUS20140162507A1Eliminate the problemPropulsion power plantsCanoes/kayaksPower cableWatercraft

A watercraft includes a stern flotation compartment. The hull is carved out underneath the gunwales to admit a vertical cylindrical sleeve extending through the flotation compartment from top to bottom, and sealed top and bottom. A studded vertical mounting tube carrying an electric motor fits within a slotted cylindrical steering tube; the latter is carried on rotatable bearings affixed to the vertical cylindrical sleeve. A steering assembly is affixed to the slotted cylindrical steering tube and a guide tube fits closely within the vertical mounting tube. An electrical power cable is connected to the electric motor and a retraction assembly is affixed to the electric motor.

Owner:CASE ROBERT

Plate type heat exchanger and method of manufacturing the same

InactiveCN101592453AEasy to manufactureLow costSemiconductor/solid-state device detailsMetal-working apparatusEngineeringHeat sink

A method for manufacturing a plate-type heat exchanger in which a heat medium is sealed in a hollow part of an airtight structure formed in the interior of a plate-like container, and the heat medium is moved by capillary force from a condensing part to an evaporating part in the hollow part along heat-medium-guiding grooves formed in the container's inside surface portions that face the hollow part; wherein a plastic workable metal plate of specific thermal conductivity is prepared; a carving tool is used to repeatedly carve out a surface portion of the metal plate at specific intervals along the surface portion, forming a plurality of plate-like fins; and a plurality of grooves formed between these fins is used as heat-medium-guiding grooves. A plate-type heat exchanger is obtained which comprises extremely small heat-medium-guiding grooves that have the necessary capillary force to move the heat medium from the condensing part to the evaporating part without affecting the set alignment or other such characteristics.

Owner:NAKAMURA SEISAKUSHO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com