Method and equipment for making magic coloured polished bricks

A technology of polished tiles and magic colors, applied in the direction of ceramic extrusion dies, etc., can solve the problems of low production efficiency, complicated process, and rigid transition, and achieve the effect of high production efficiency, rich colors, and chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

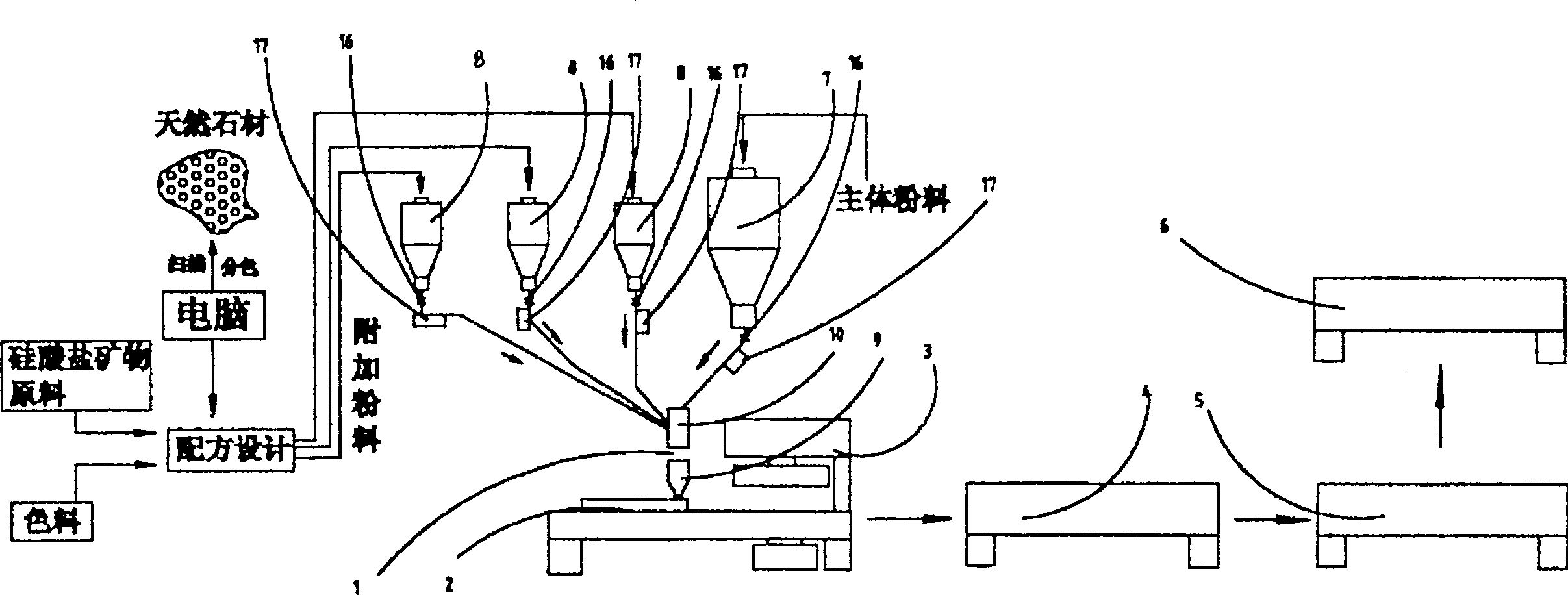

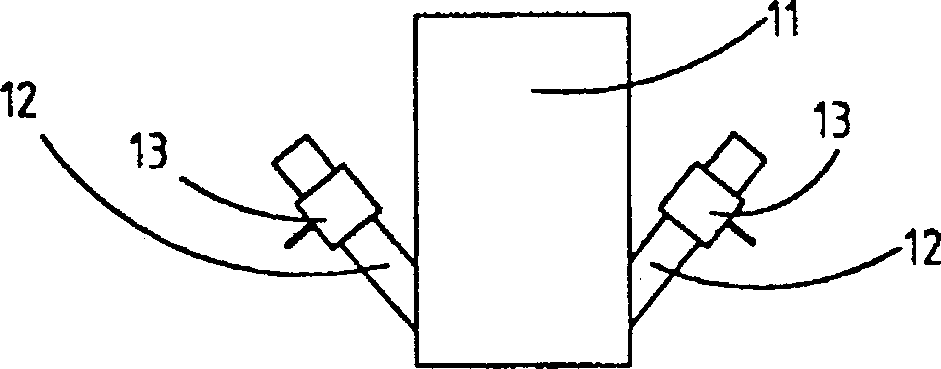

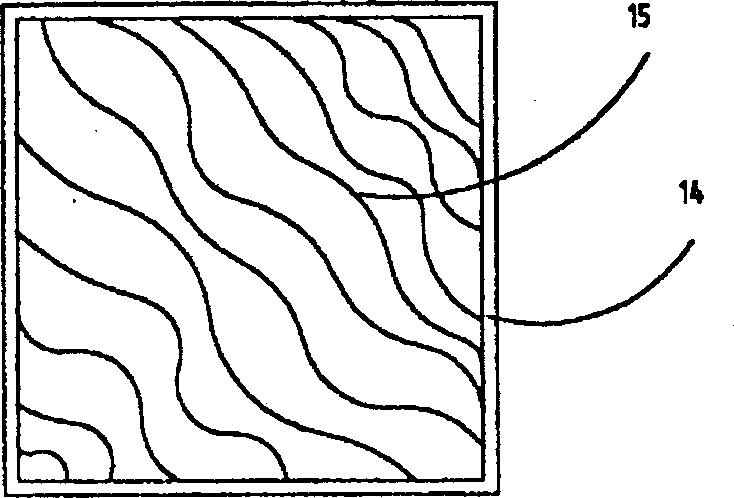

[0017] Such as figure 1 Shown, the method for manufacturing magic color polished brick of the present invention is realized in this way, comprises polished brick bad body forming process, drying process, firing process, polishing forming process, wherein polished brick body forming process mainly consists of mixing batching process, following It is composed of material process, cloth process and pressing process. The special feature is that in the batching process, the natural marble or marble is first scanned and color-separated by computer. Based on this, the raw materials and color materials are selected, and then the formula design is carried out. Use brick salt mineral raw materials and corresponding colorants to configure a variety of additional powders with different colors after firing, and then place them in corresponding silos; the feeding process is to put the additional powders in each silo The material is put into the trough above the pushing device according to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com