Brushless direct current motor control method based on magnetic linkage tracking

A brushed DC motor and control method technology, applied in the direction of torque ripple control, etc., can solve the problems of complexity, limitation, and influence on the utilization rate of DC bus voltage, etc., and achieve the effect of natural transition and small calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

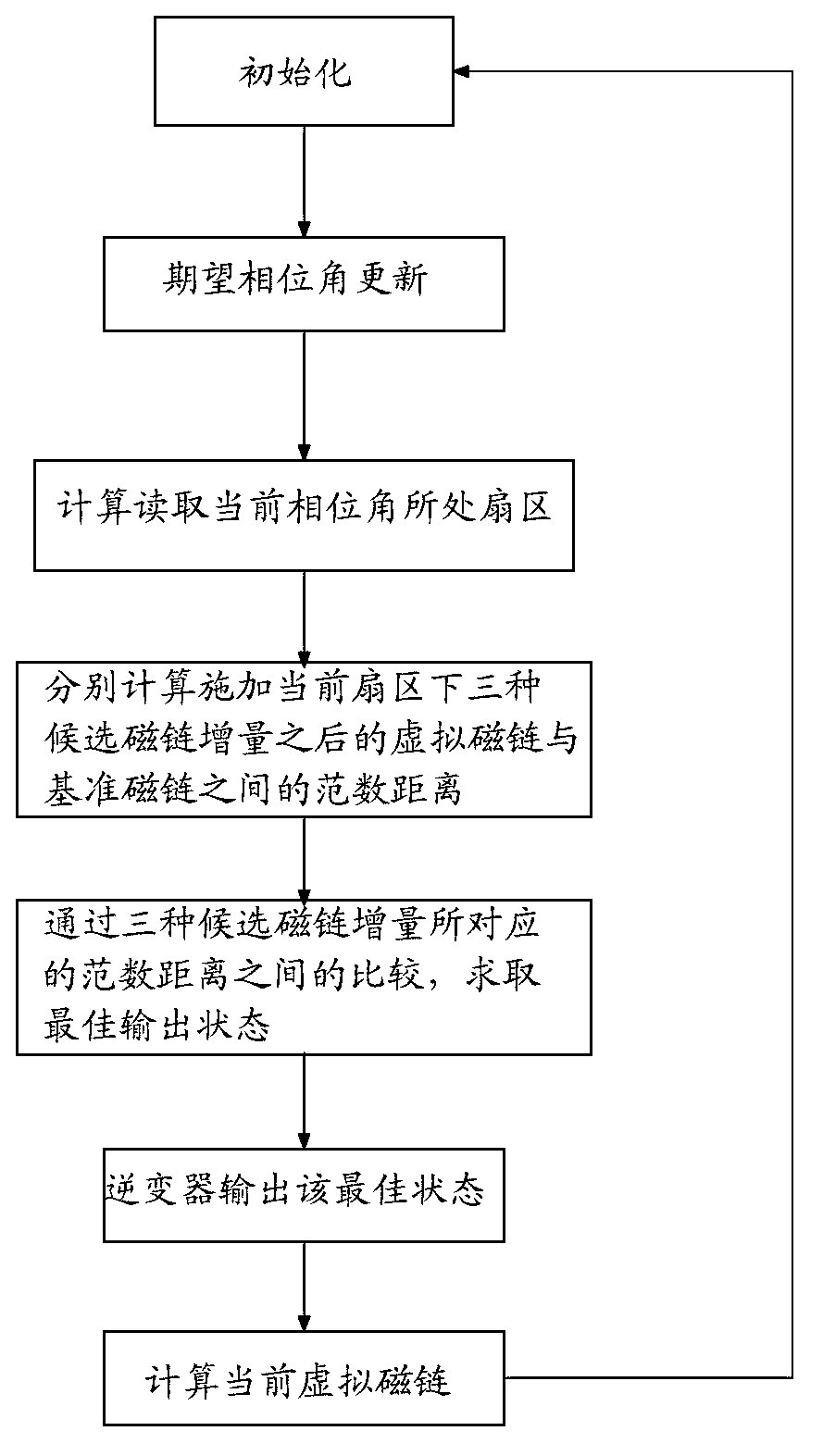

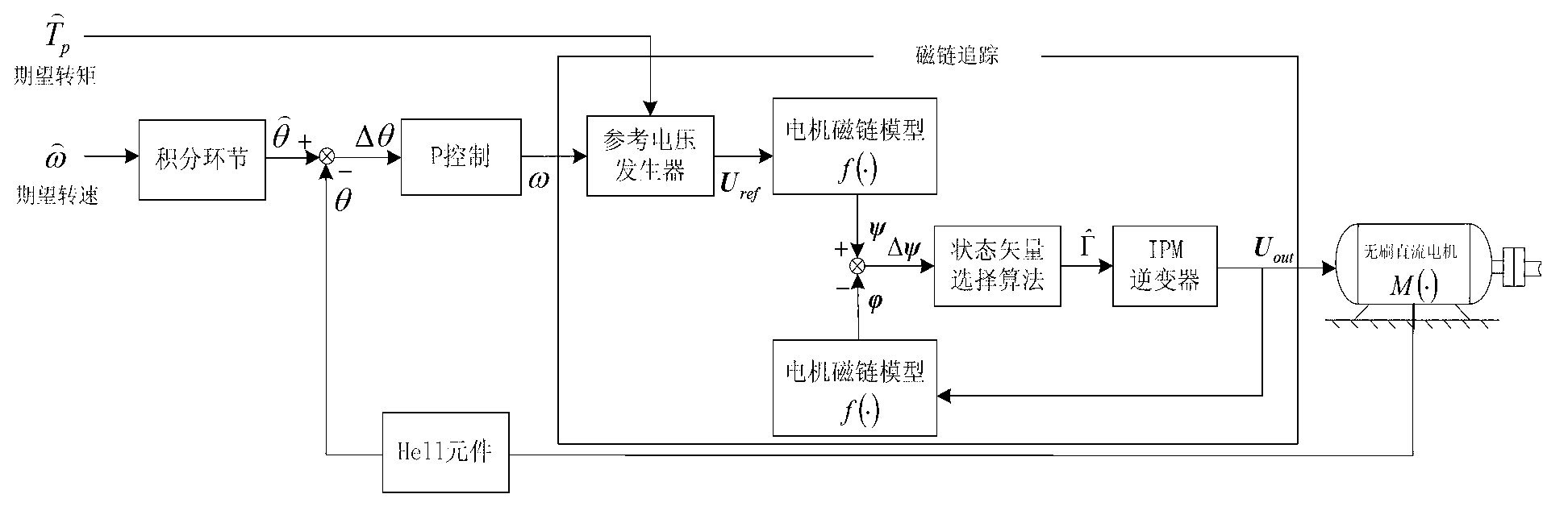

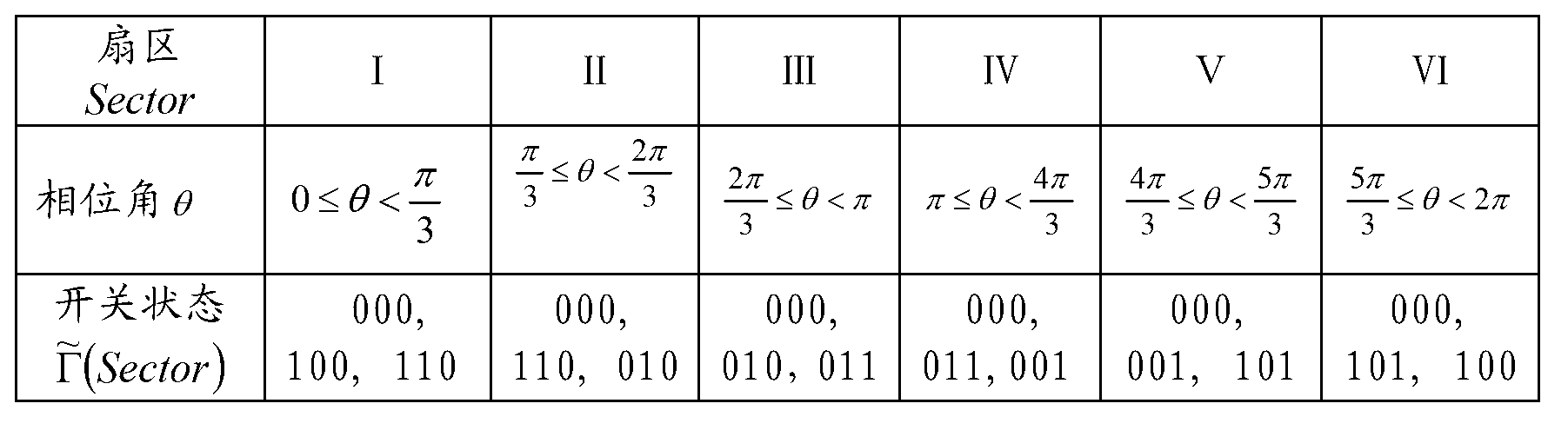

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific embodiments.

[0029] Compared with the brushed DC motor, the biggest difference between the brushless DC motor and the brushed DC motor is that the mechanical commutation is replaced by the electronic commutation. The armature, while the brushless DC motor converts the DC current into a quasi-square wave current through an electronic commutator and sends it to the armature.

[0030] However, since the harmonic component contained in the six-beat wave will generate the sixth harmonic torque, under the condition of large torque, this ripple may be filtered out by the rotor inertia. However, under the condition of small torque, it will cause the rotor speed to fluctuate, seriously affecting the stability of the speed, and will also have a certain impact on the positioning accuracy and repeatability of the position servo system.

[0031] Exploring the process of motor speed regulation, it will be found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com