Composite doctor blade chamber

A squeegee, combined technology, applied in the direction of bonding method, printing process, application, etc., can solve the problem of reducing printing quality, irritating workers, penetrating between the squeegee and the clamp rail, and the squeegee and the squeegee problems between cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

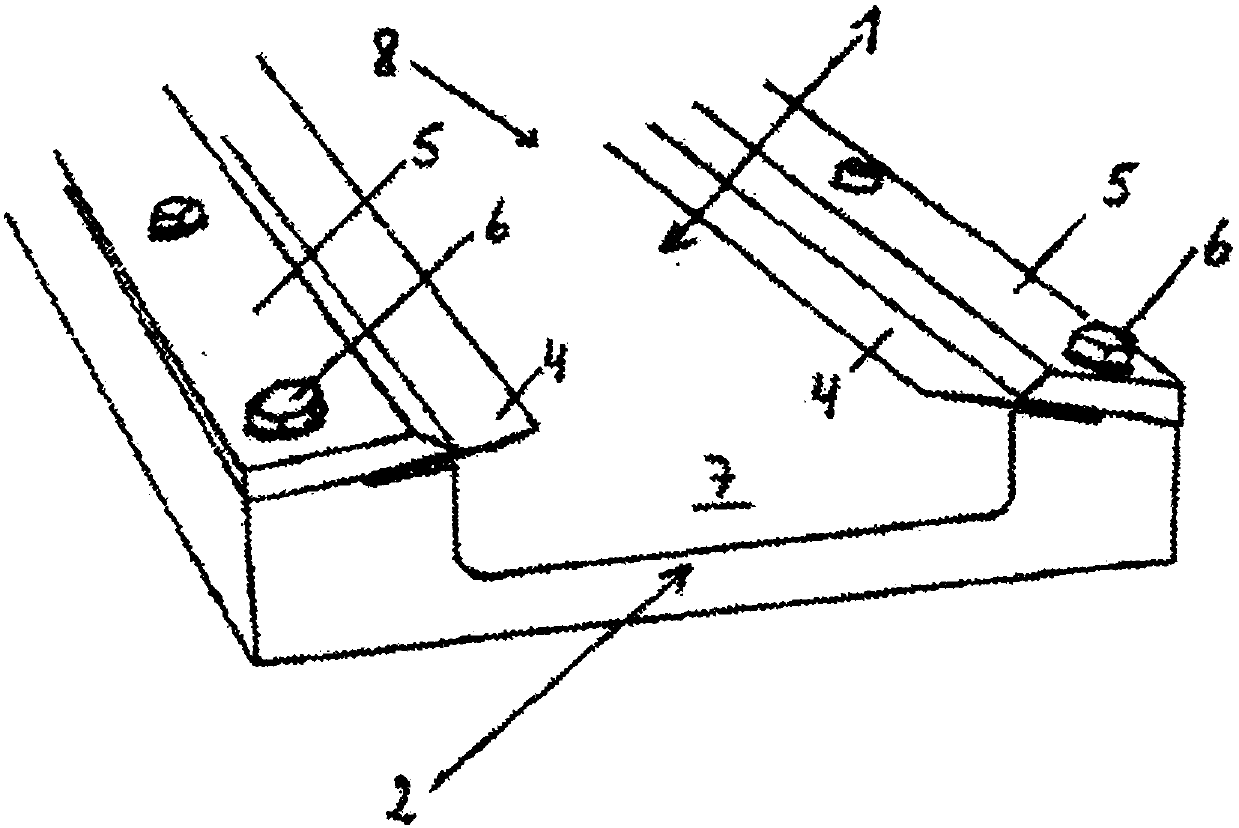

[0121] figure 1 is a perspective view of a part of a doctor blade chamber 1 according to the prior art. For illustration, the doctor blade chamber 1 is shown without an end cap, which normally seals the end 2 so that ink cannot flow out of the doctor blade chamber 1 . The doctor blade 4 sandwiched between the clamp rail 5 and the doctor blade chamber 1 is installed on the doctor blade chamber 1 . Screw the clamp rail 5 to the doctor blade chamber 1 with the bolt 6. The doctor blade chamber 1 together with the doctor blade 4 forms a wall of ink 7 . When the doctor blade cavity 1 is aligned with the ink transfer roller, the open channel 8 between the doctor blades 4 is closed.

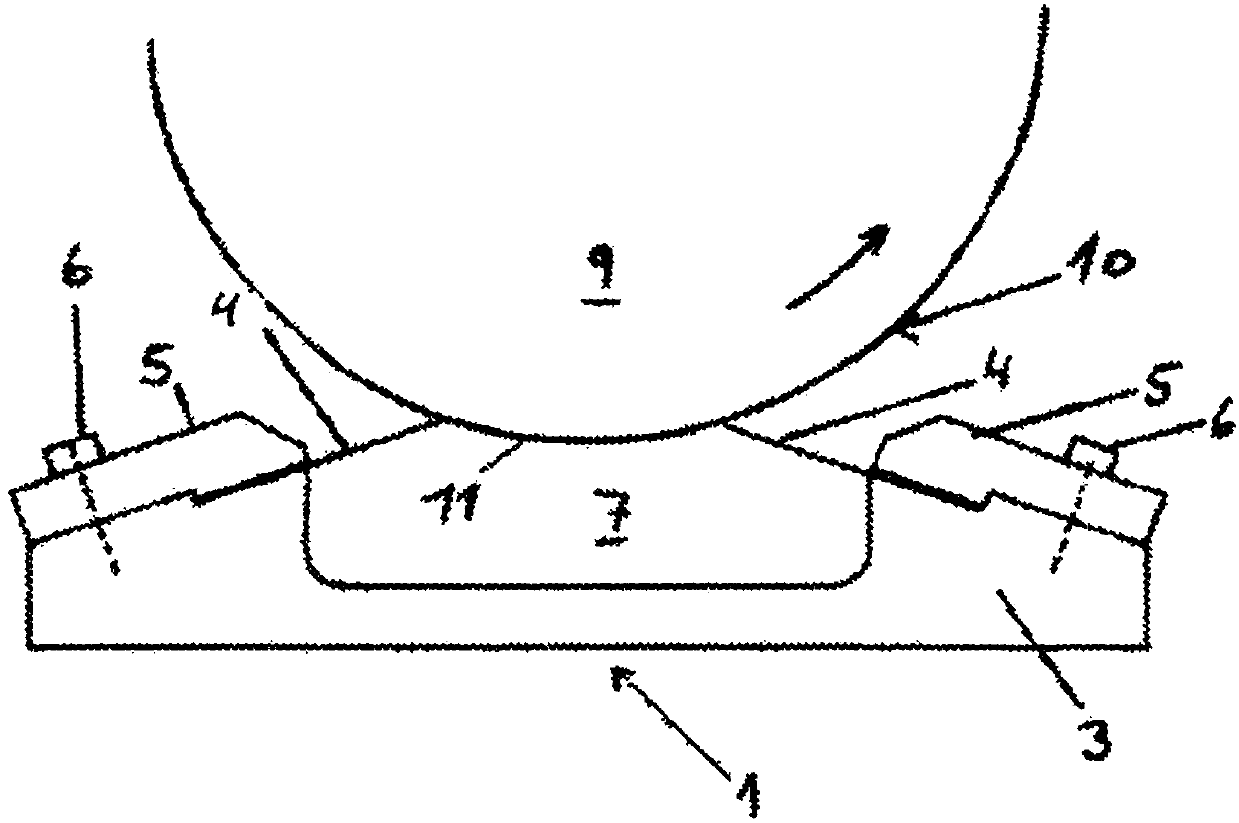

[0122] figure 2 A sectional view of a doctor blade chamber 1 and a transfer roller 9 according to the prior art is shown. When the two doctor blades 4 are in contact with the roller surface 10, the ink chamber 7 is substantially closed. When the ink transfer roller 9 rotates along its axis, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com