Patents

Literature

218results about "Relief printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and methods for high speed variable printing

Systems and methods for high-speed variable printing are provided. Ink jet technology and lithographic systems may be combined in such a way to create a fully variable and high-quality print system. An aqueous solution is applied to a cylinder to produce a negative image. The aqueous solution may comprise a block copolymer capable of physical bonding with the cylinder. Ink is then applied to the cylinder, and a positive image is transferred in ink to a print medium. The systems and methods described herein may be used to create high-quality one-to-one marketing applications.

Owner:R R DONNELLEY & SONS CO

System and method for ink jet printing of water-based inks using aesthetically pleasing ink-receptive coatings

InactiveUS20060075916A1Promote absorptionDrop spreadCoatingsOther printing apparatusWater basedEngineering

A system and method for printing aqueous ink jet ink in selected areas of nonabsorbent and semi-nonabsorbent substrates includes applying an ink-receptive coating having an aesthetically pleasing appearance in the selected areas, for example with printing station having a printing and drying unit for applying the ink-receptive coating in the desired area or areas of the substrate and then drying the coating, and printing an aqueous ink jet ink in the coated area with a CIJ, TIJ, pr PIJ printer. Variable print may be printed with the ink jet ink in a high speed process.

Owner:ELECTRONICS FOR IMAGING

Systems and methods for high speed variable printing

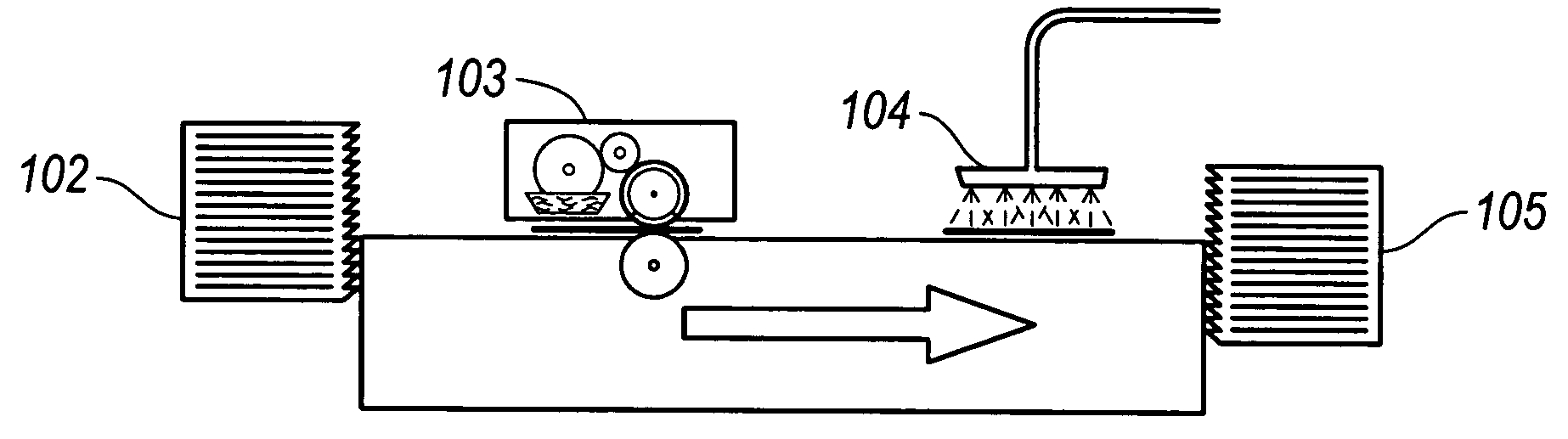

Systems and methods for high-speed variable printing are provided. Ink jet technology and lithographic systems may be combined in such a way to create a fully variable and high-quality print system. An aqueous solution is applied to a cylinder to produce a first negative image. A positive image in ink is transferred to a print medium. Residue ink and aqueous solution is then cleaned from the cylinder and aqueous solution is applied to the cylinder to produce a second negative image. The systems and methods described herein may be used to create high-quality one-to-one marketing applications.

Owner:R R DONNELLEY & SONS CO

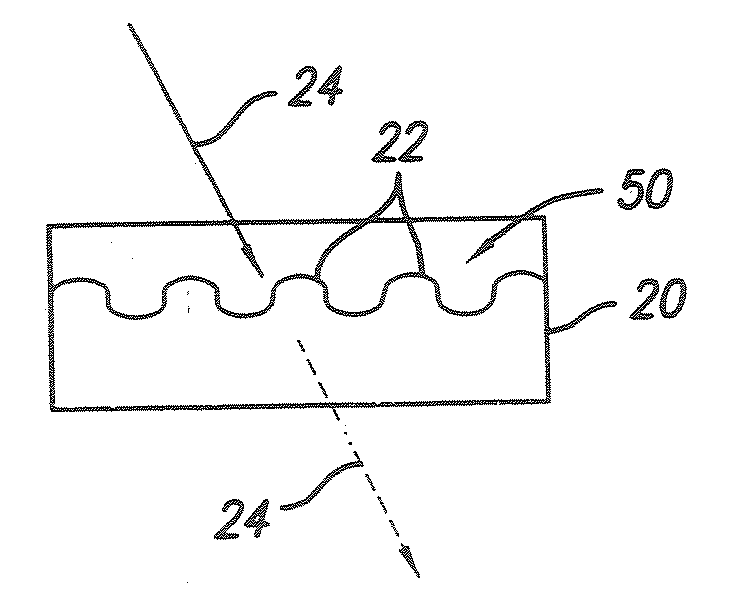

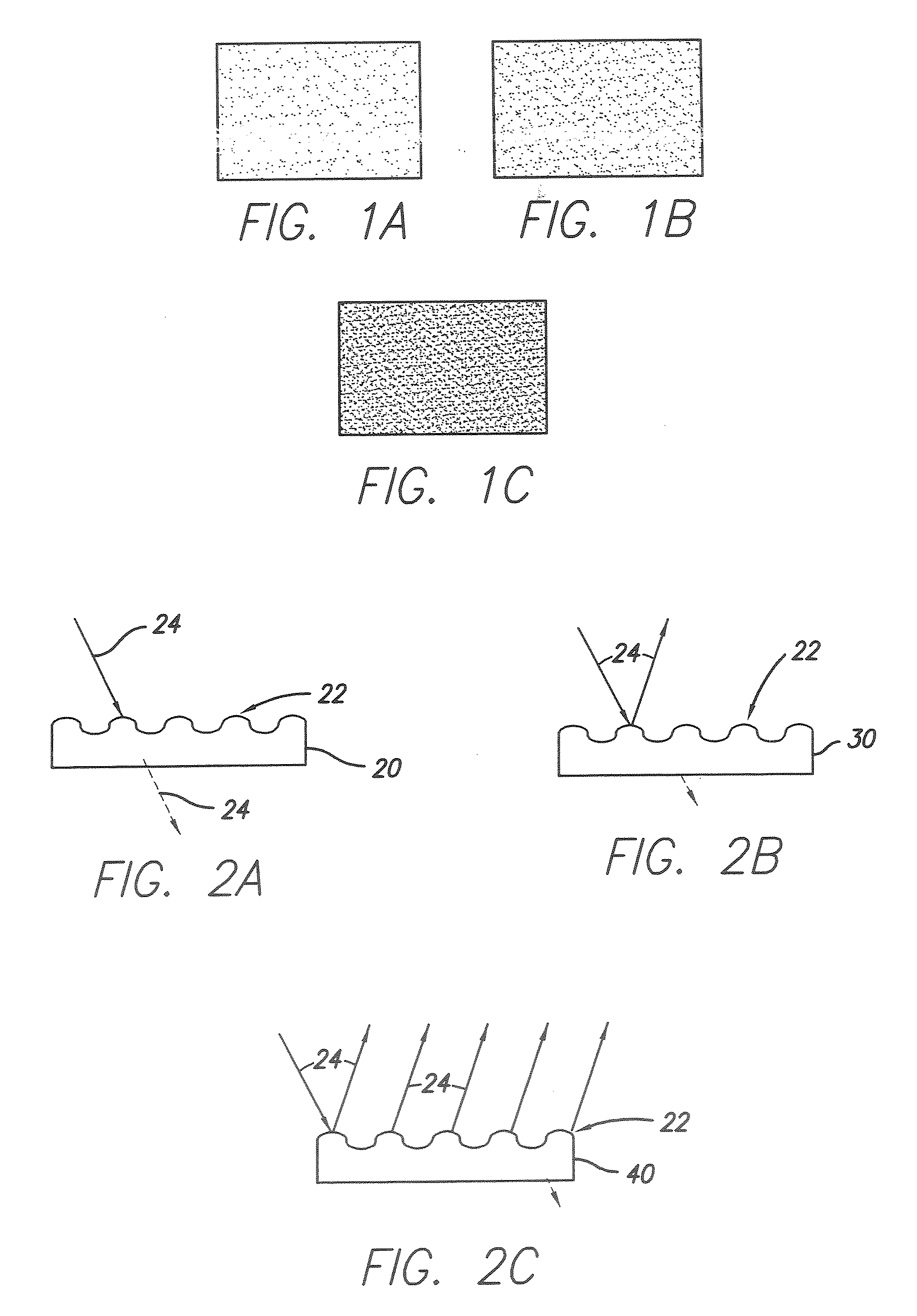

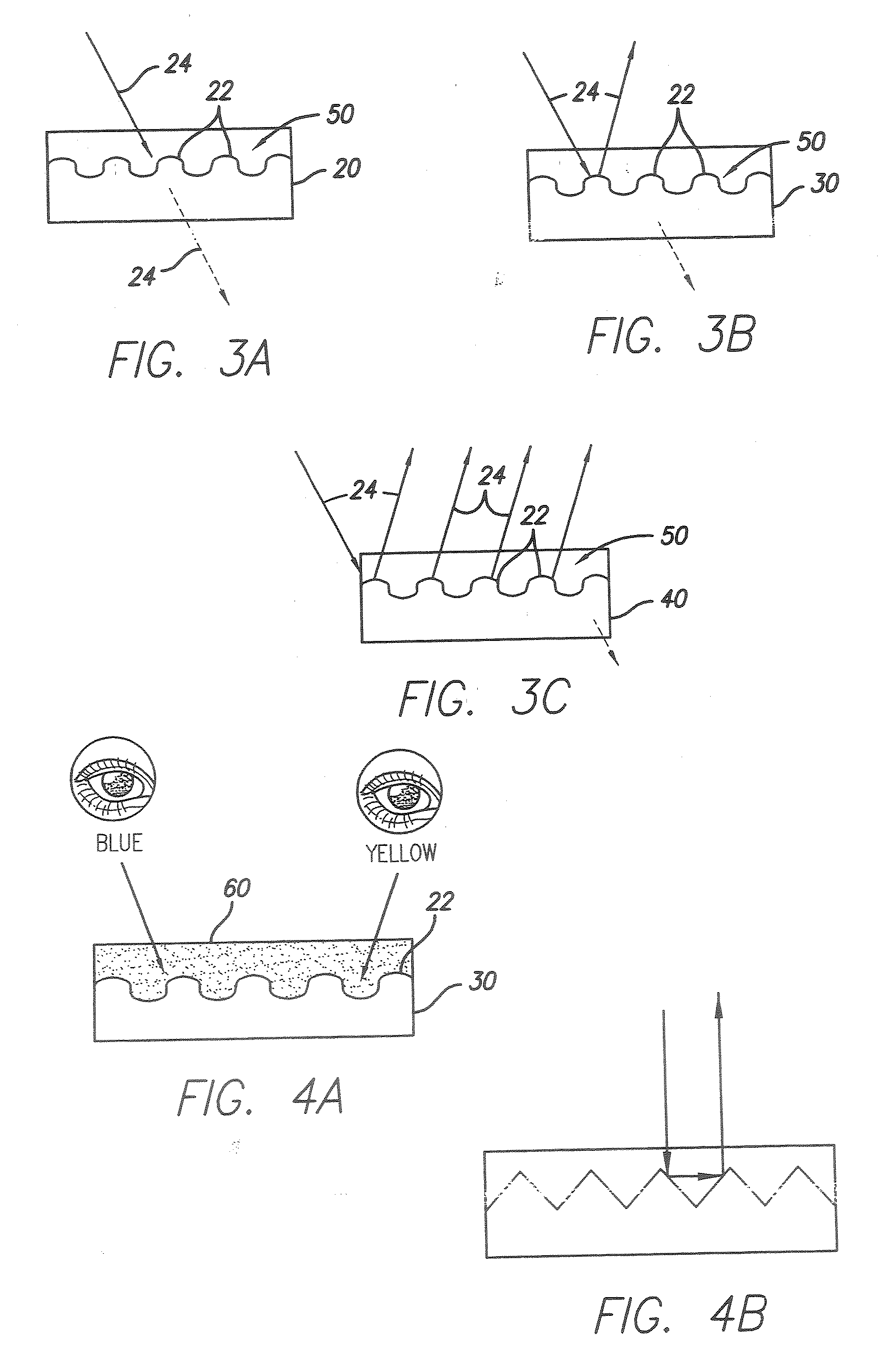

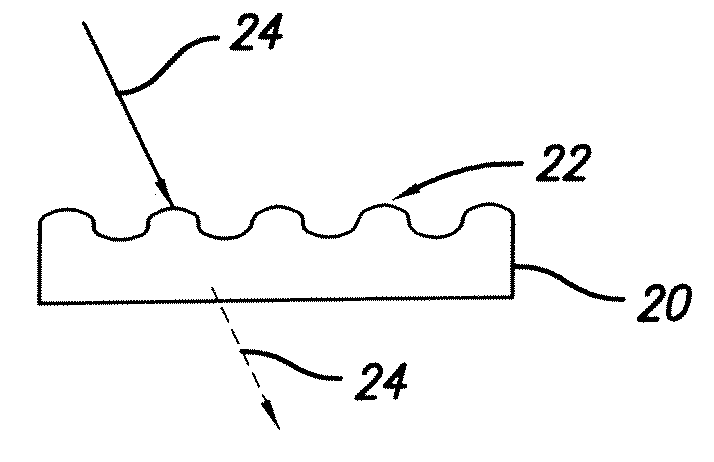

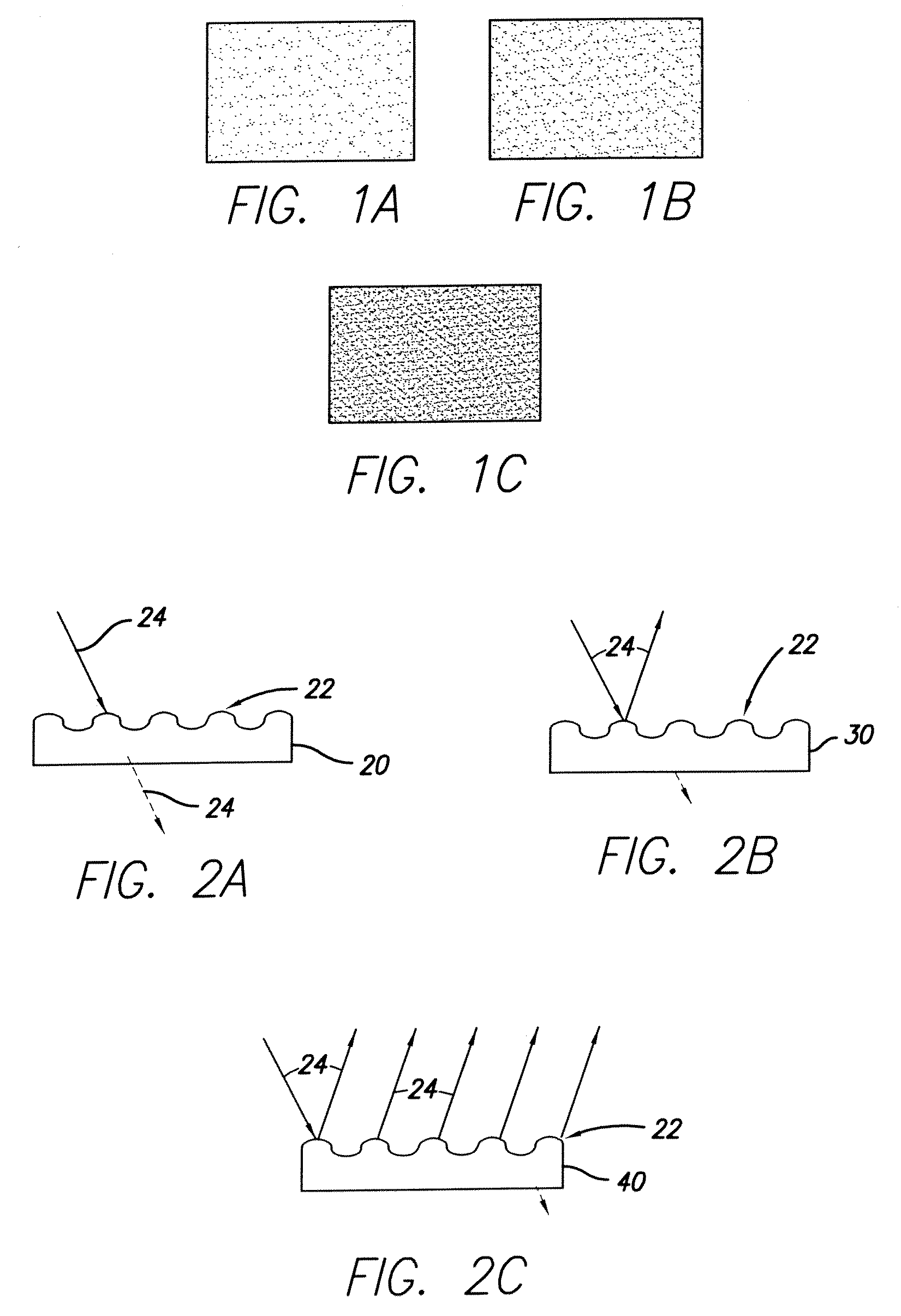

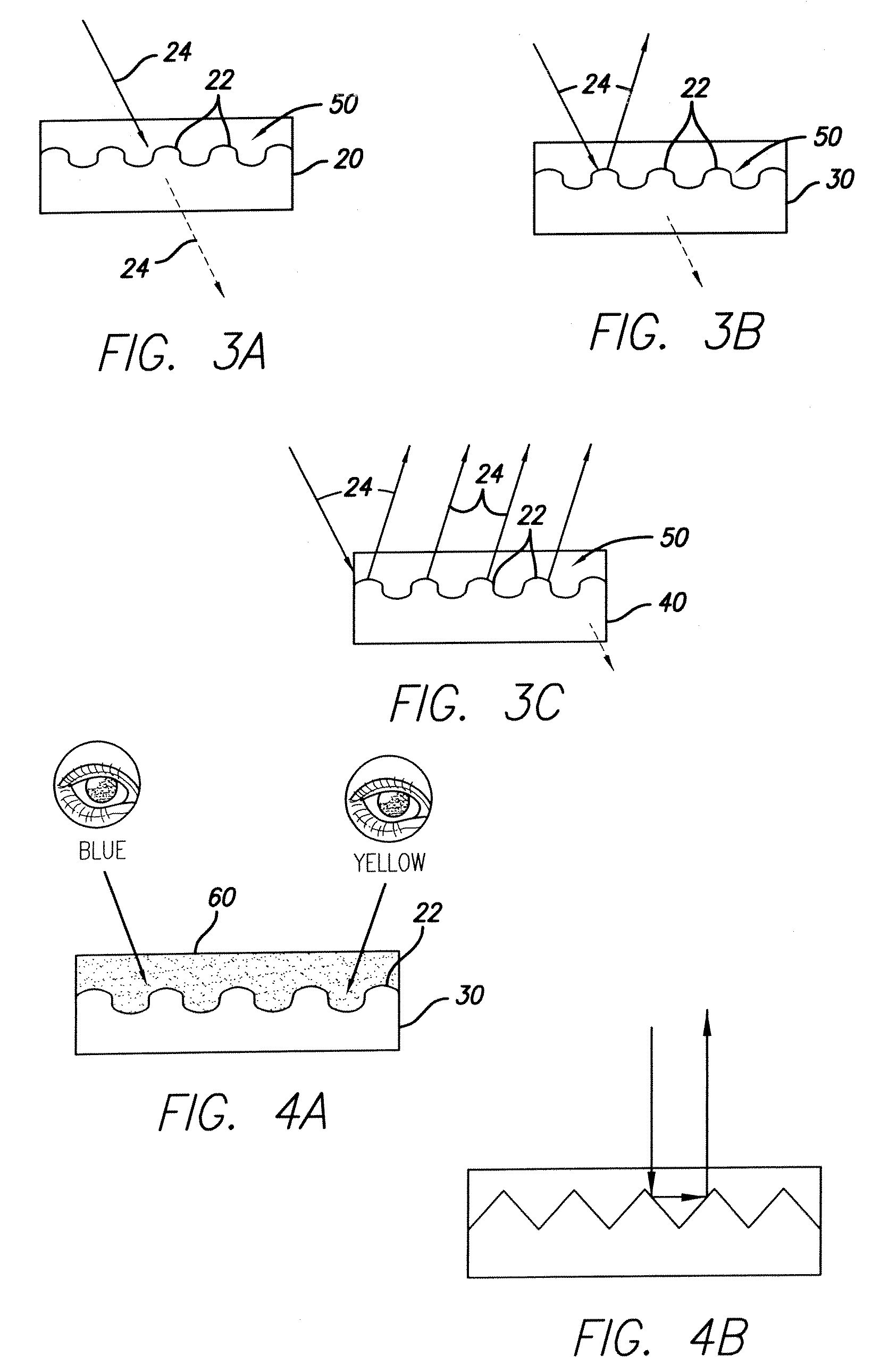

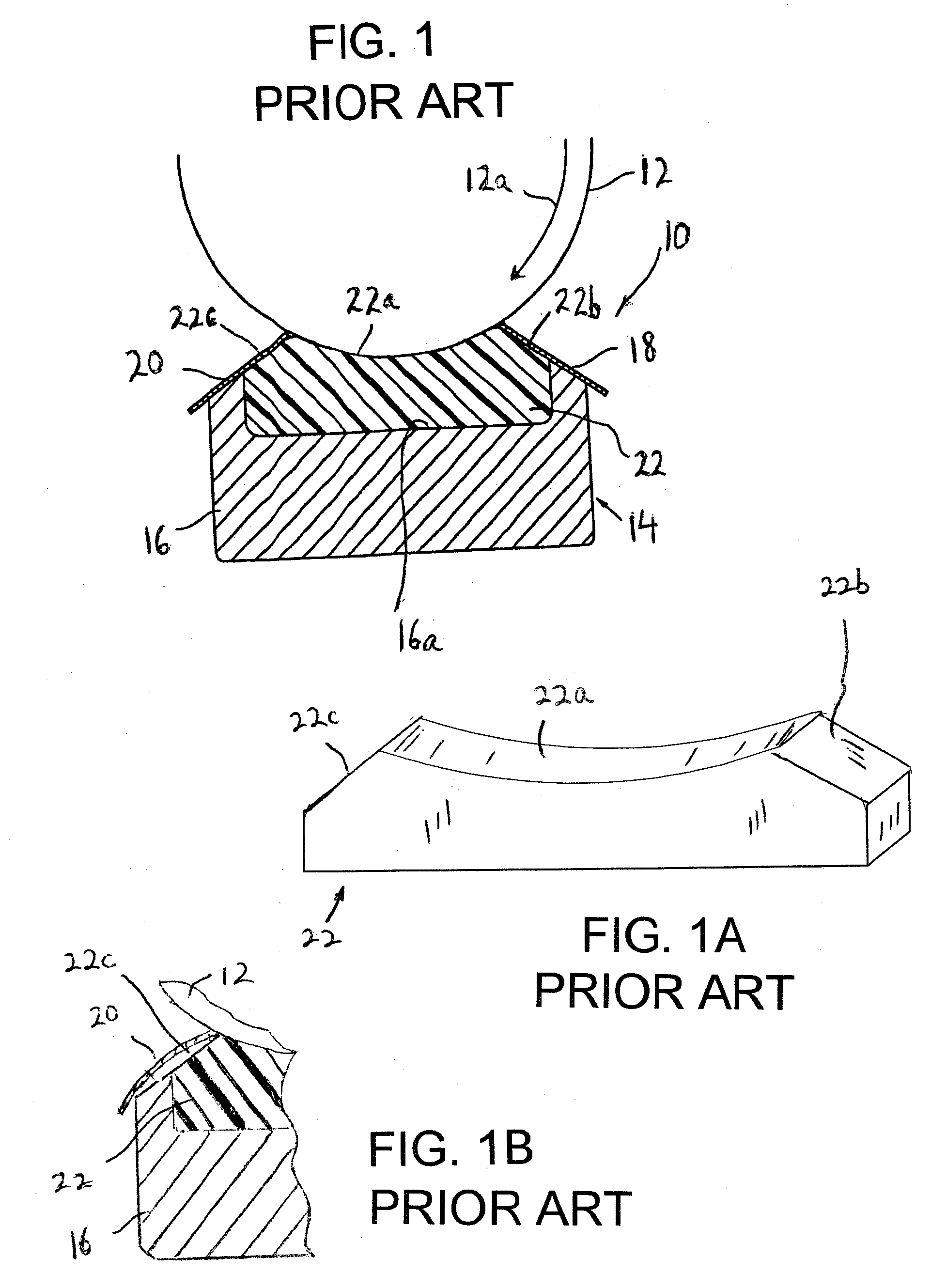

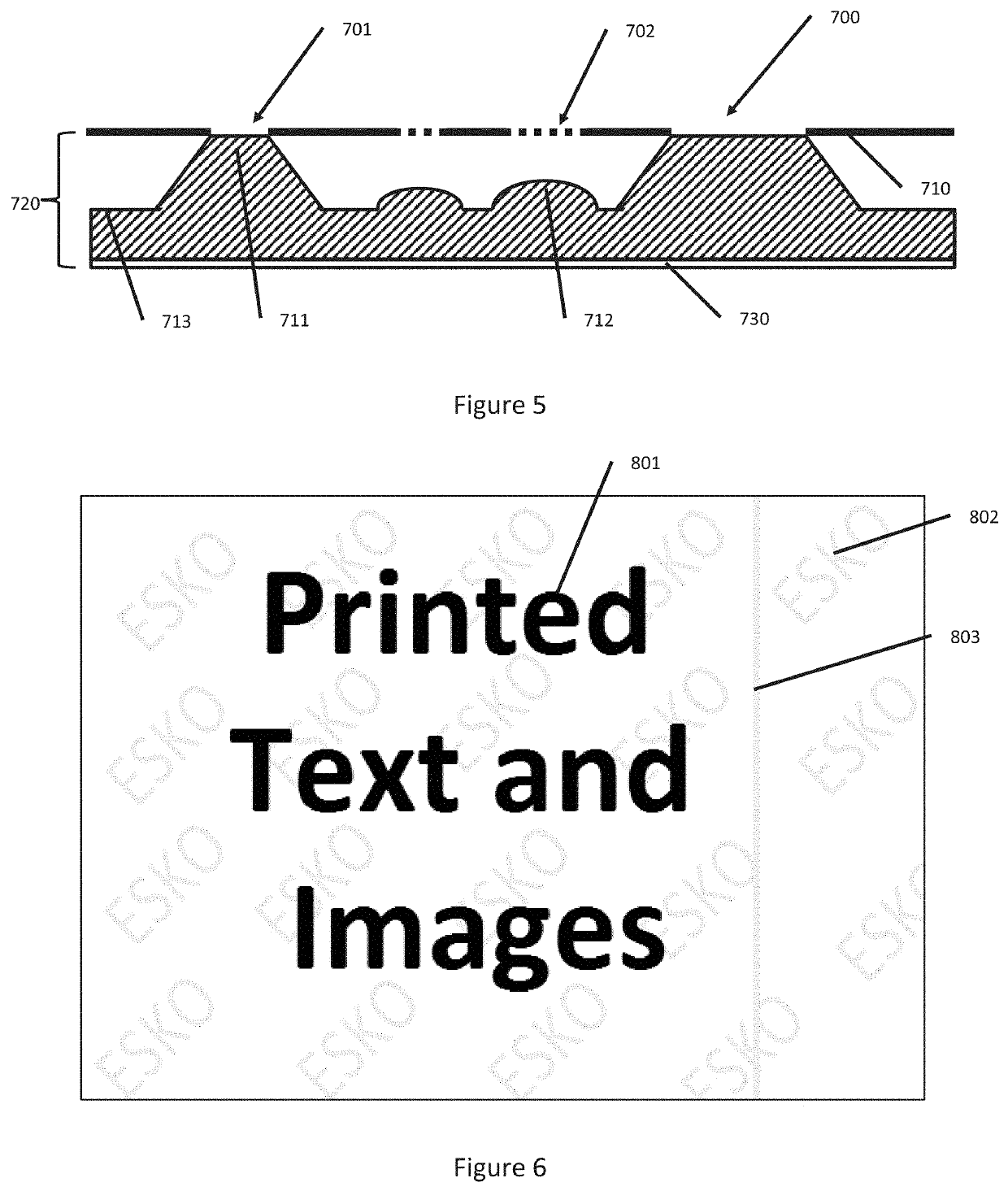

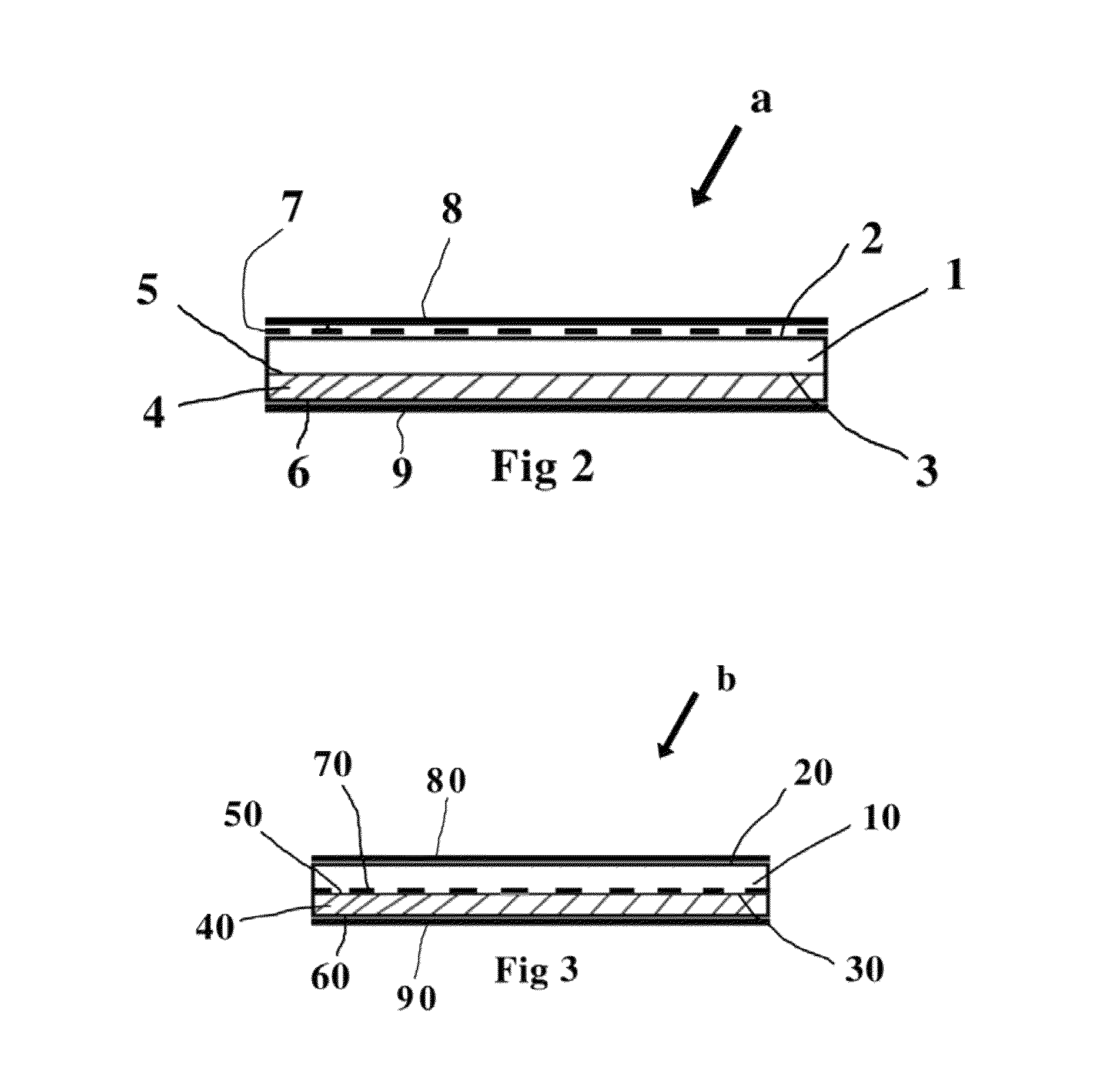

Substrates and articles having selective printed surface reliefs

The present invention provides articles comprising a substrate, a coating that is applied to the substrate, and surface reliefs that are cast or embossed onto the coating at substantially the same speeds and widths of conventional printing, and in substantially perfect register to conventional printing, wherein the coating is selected from the group consisting of HRISR coatings, LRISR coatings, water-based coatings, solvent-based coatings, UV / EB based coatings, sol-gel based coatings, conductive coatings, silver reduction based coatings and metallic coatings. A protective or printed layer may (or may not) be applied on top of the coating. Specifically, if the coating is an HRISR or LRISR coating, then it is unnecessary to apply a special high refractive layer because HRISR and LRISR coatings inherently contain the refractive index properties that are necessary to keep the surface reliefs viewable despite any printing on top of the coating. Otherwise, if the coating does not comprise an HRISR or LRISR coating, then a high refractive protective layer is applied on top of the coating, wherein the protective layer follows a topography of the surface reliefs such that a thickness of the protective coating is substantially uniform.

Owner:HOLOINKS

High and low refractive index and metallic surface relief coatings

InactiveUS20060275625A1Eliminate needNatural mineral layered productsRotary letterpress machinesRefractive indexThin membrane

The present invention provides articles comprising a substrate, a high (or low) refractive index and / or metallic surface relief coating that is applied to the substrate and surface relief structures that are applied to the coating at substantially the same speeds and widths of conventional printing systems, and in substantially perfect register to conventional printing systems, thereby obviating the need for already-embossed substrates including films and hot-stamping foils.

Owner:HOLOINKS

Anti-glare film, manufacturing method of anti-glare film, anti glaring anti-reflection film, polarizing plate, and display

The purpose of the present invention is to provide a high-definition image that does not decrease in sharpness due to miniaturization of the pixel size, and can prevent the reflection of external light and effectively prevent the decrease in contrast. An anti-glare film in which a desired fine uneven structure is stably formed and a method for producing the same, and an anti-glare antireflection film, a polarizing plate, and a display device using the anti-glare film are also provided. The method for producing the anti-glare film is characterized in that it uses a seamless resin printing plate with a diameter of 50 to 1000 mm and a rubber hardness in the range of 30 to 80 degrees, and forms an ink-adhered portion on the surface of the base material film by flexographic printing. The process of forming a concave-convex structure with ink non-adhered parts.

Owner:KONICA MINOLTA OPTO

Method for correcting print repeat length variability in printed extensible materials and product

Owner:BERRY FILM PROD CO INC

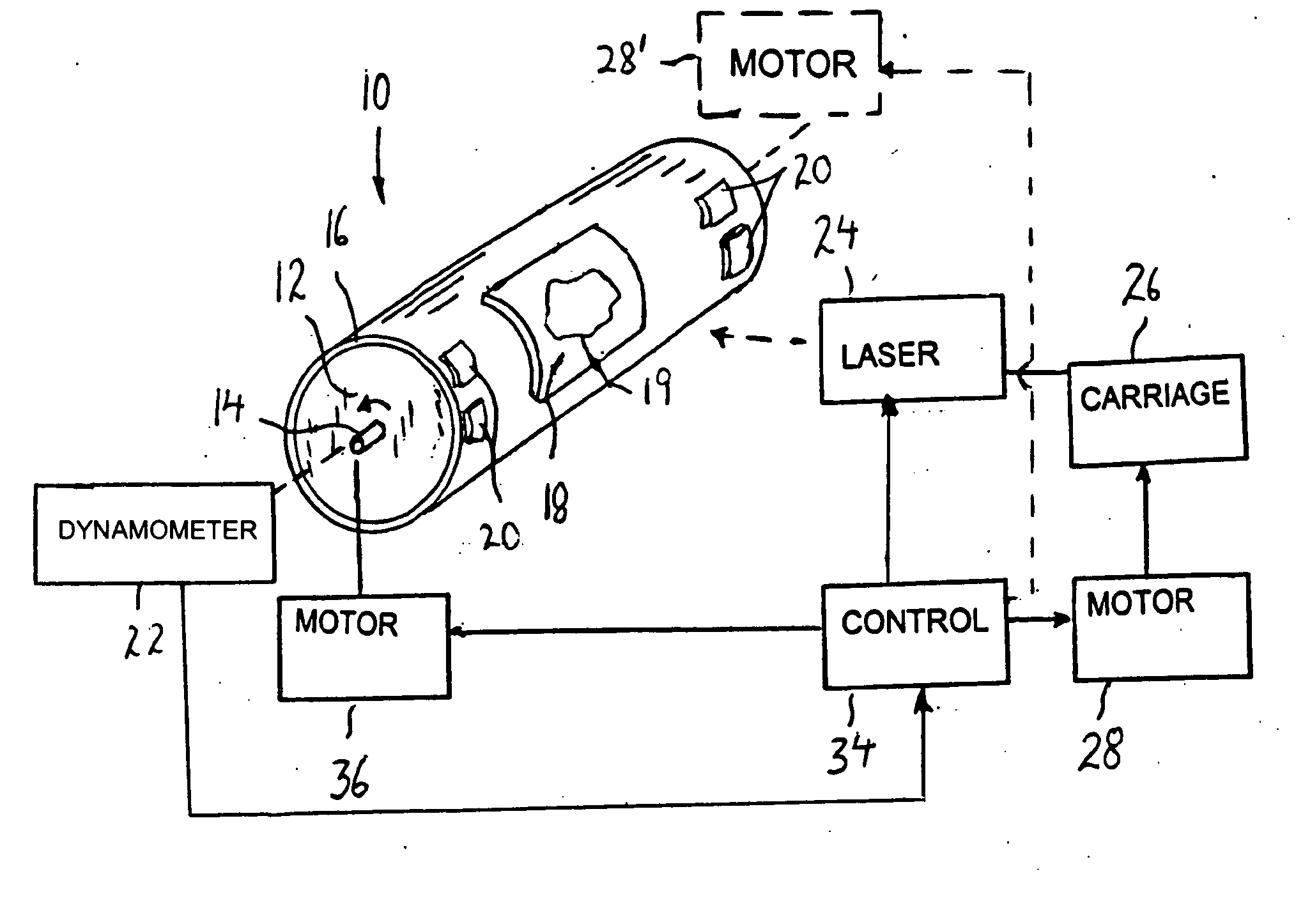

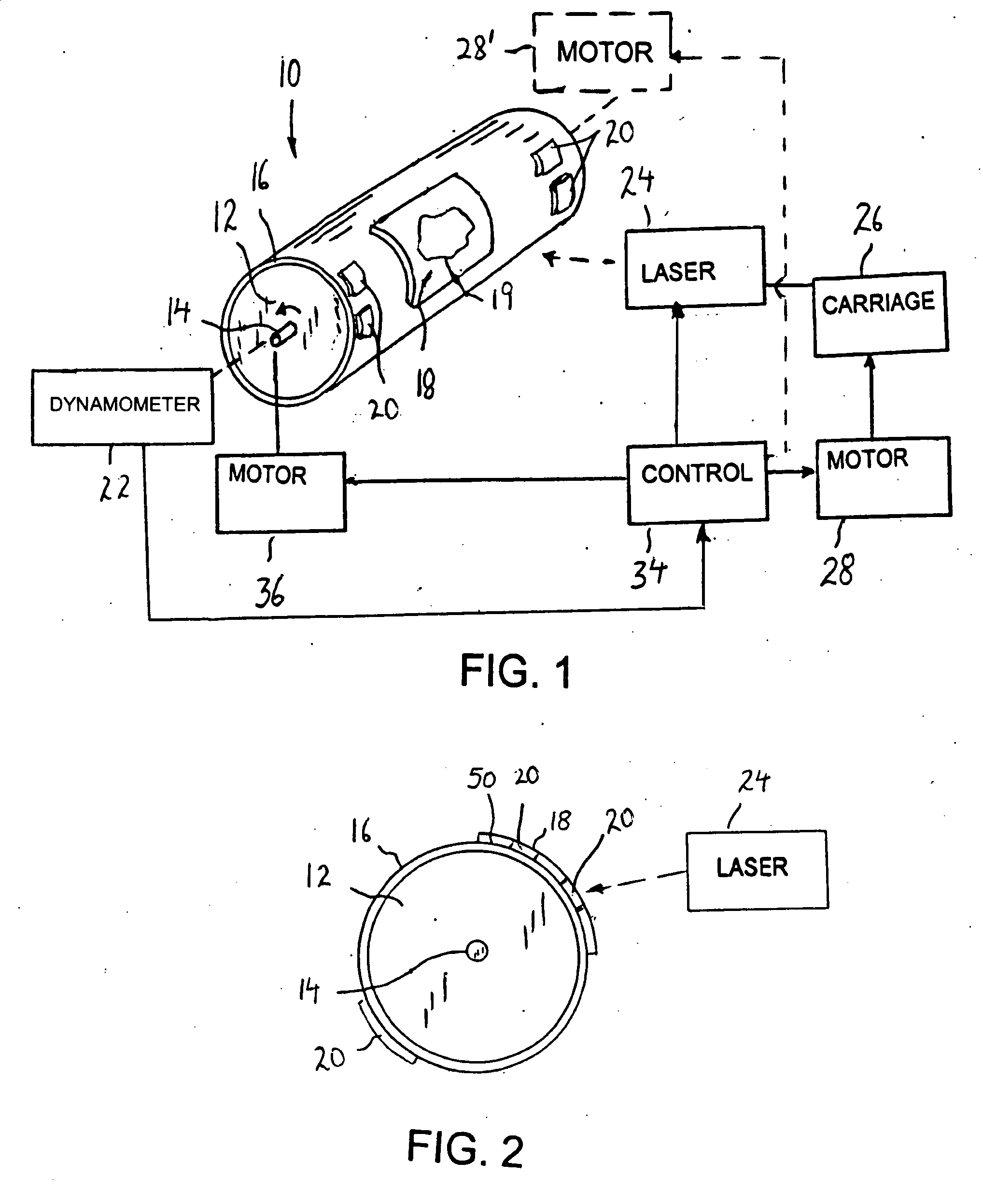

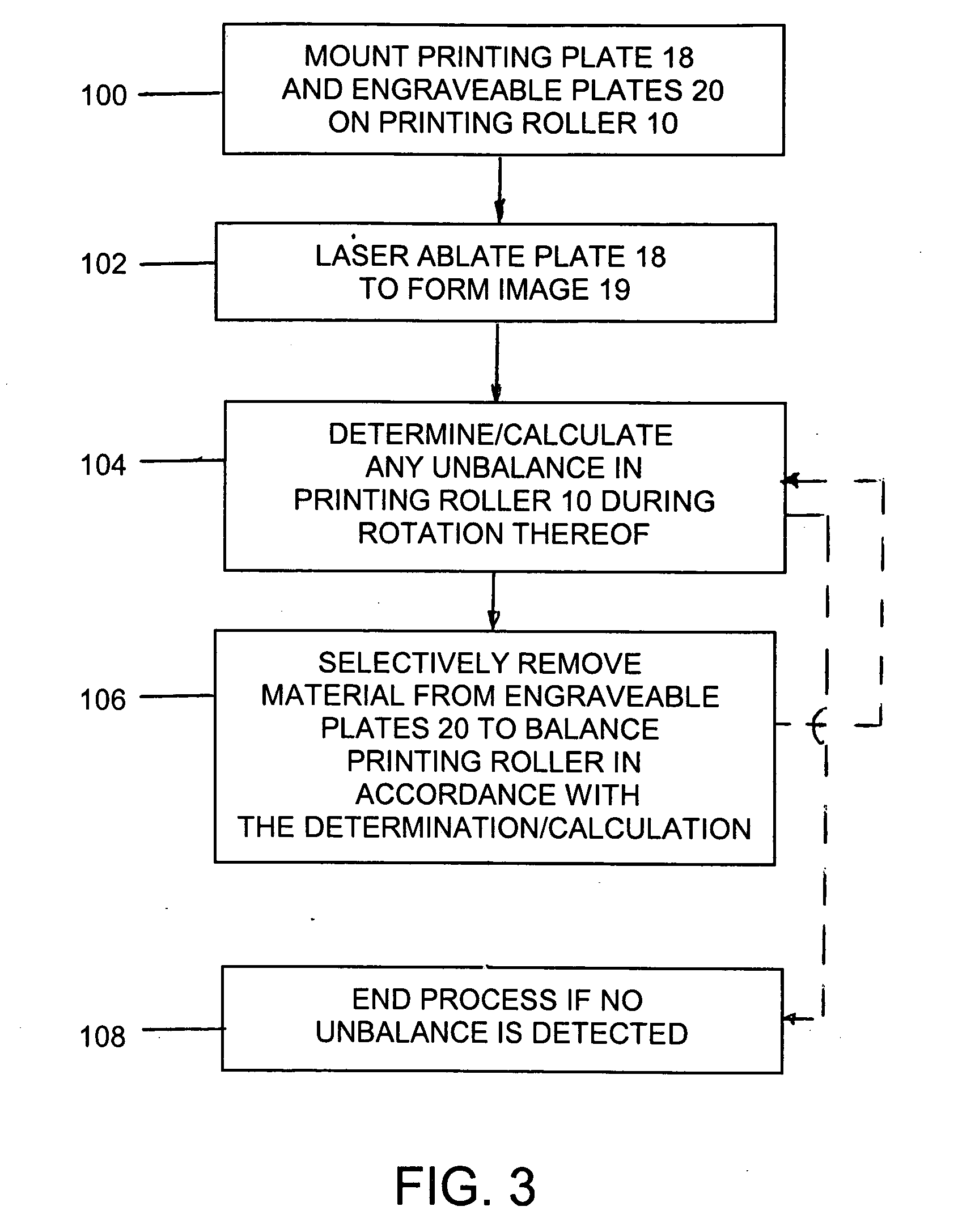

Apparatus and method for balancing a printing roller having an image producing area on its outer surface

InactiveUS20070095231A1Inexpensive and easy to useInexpensive and easy to and manufactureAddressographsLetterpress printingWeight adjustmentEngineering

Owner:VAN DENEND MARK E

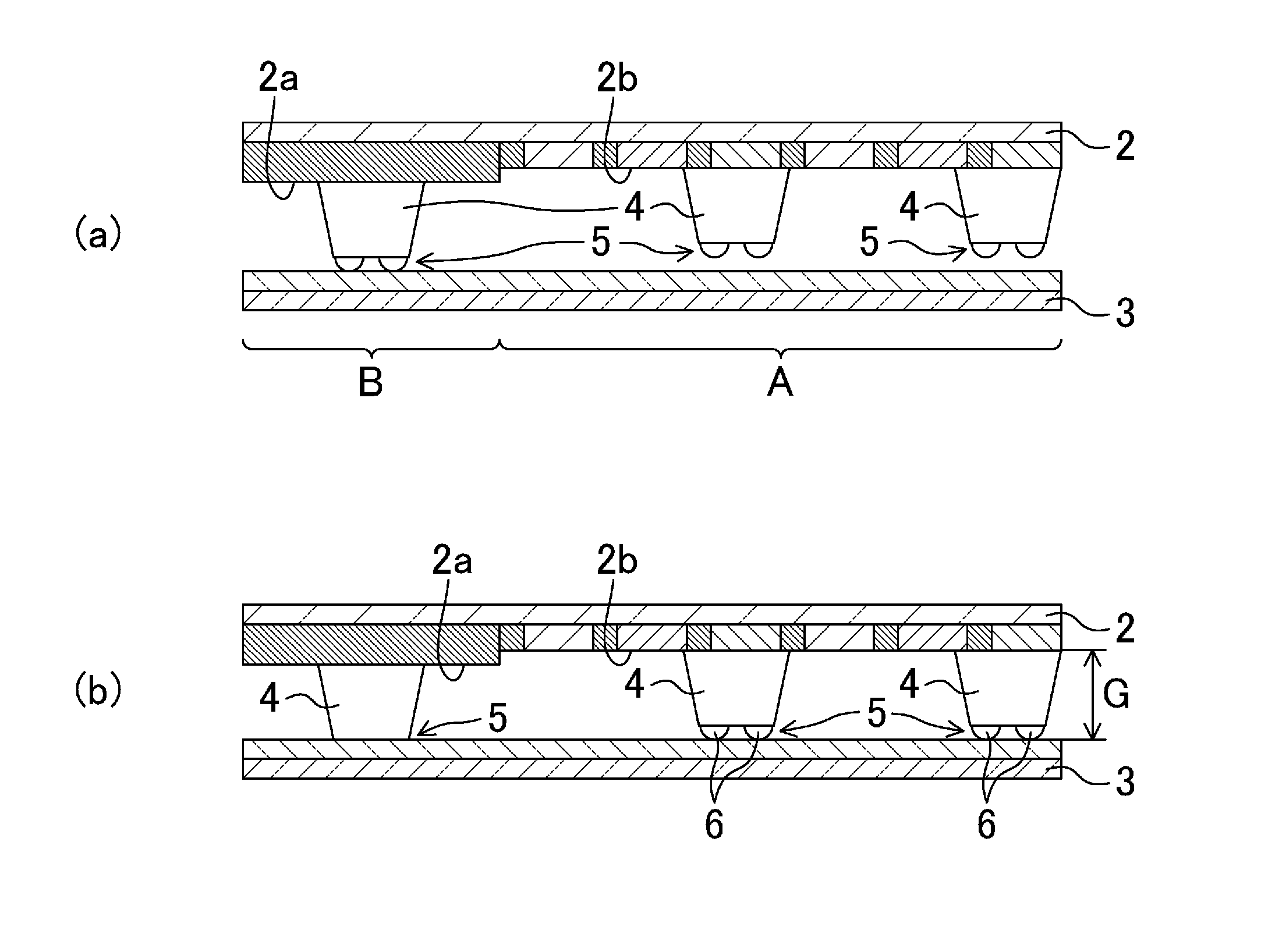

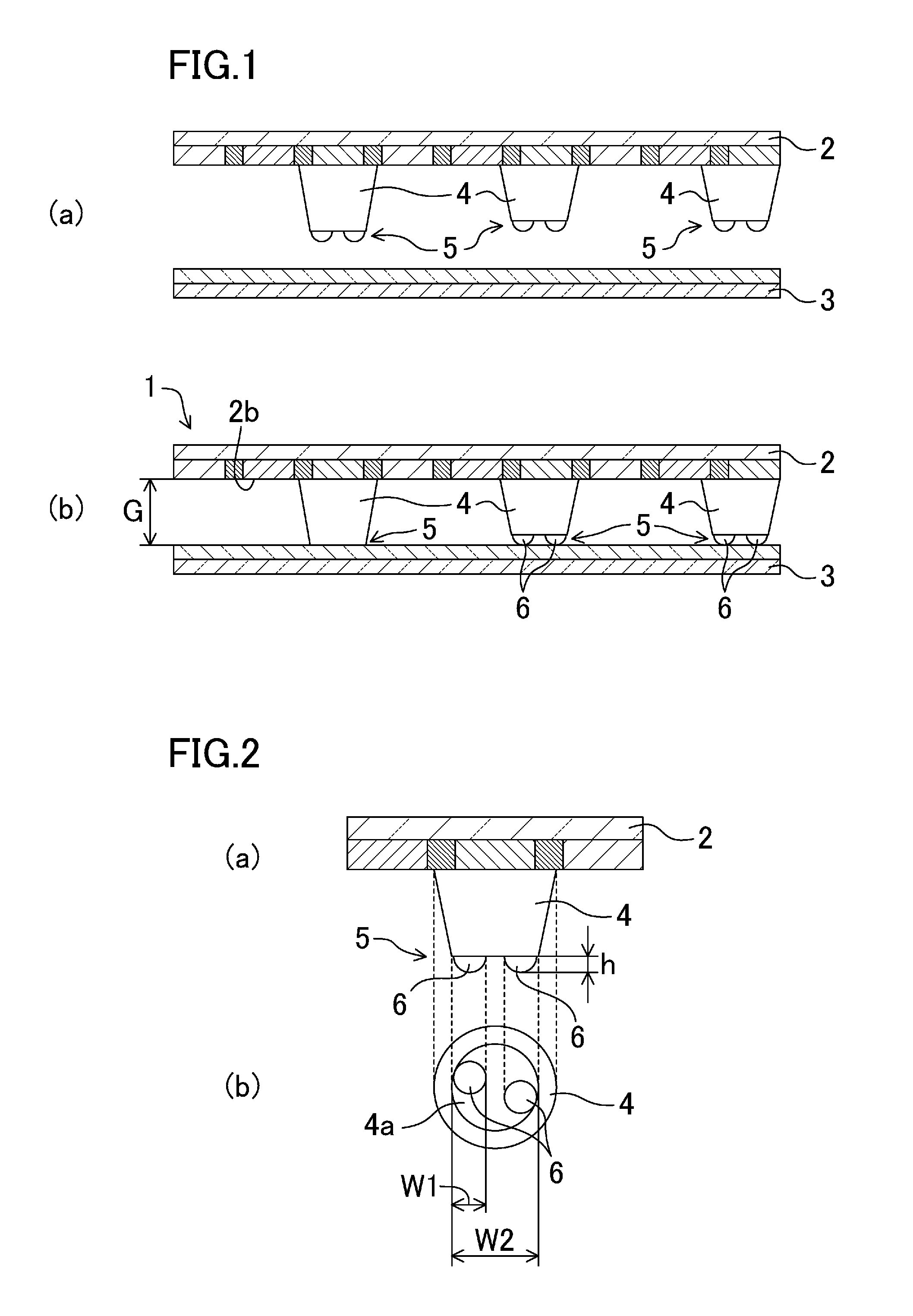

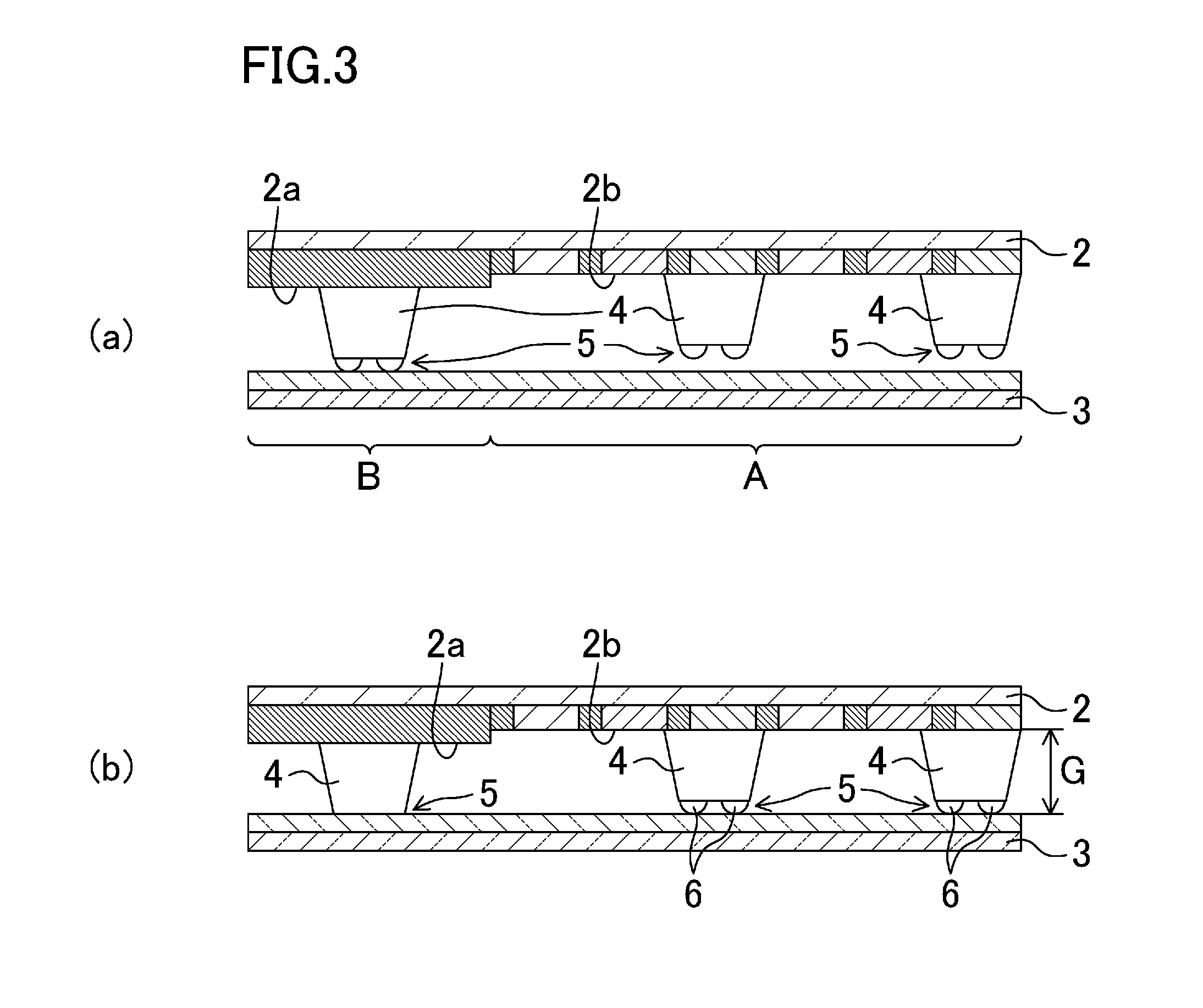

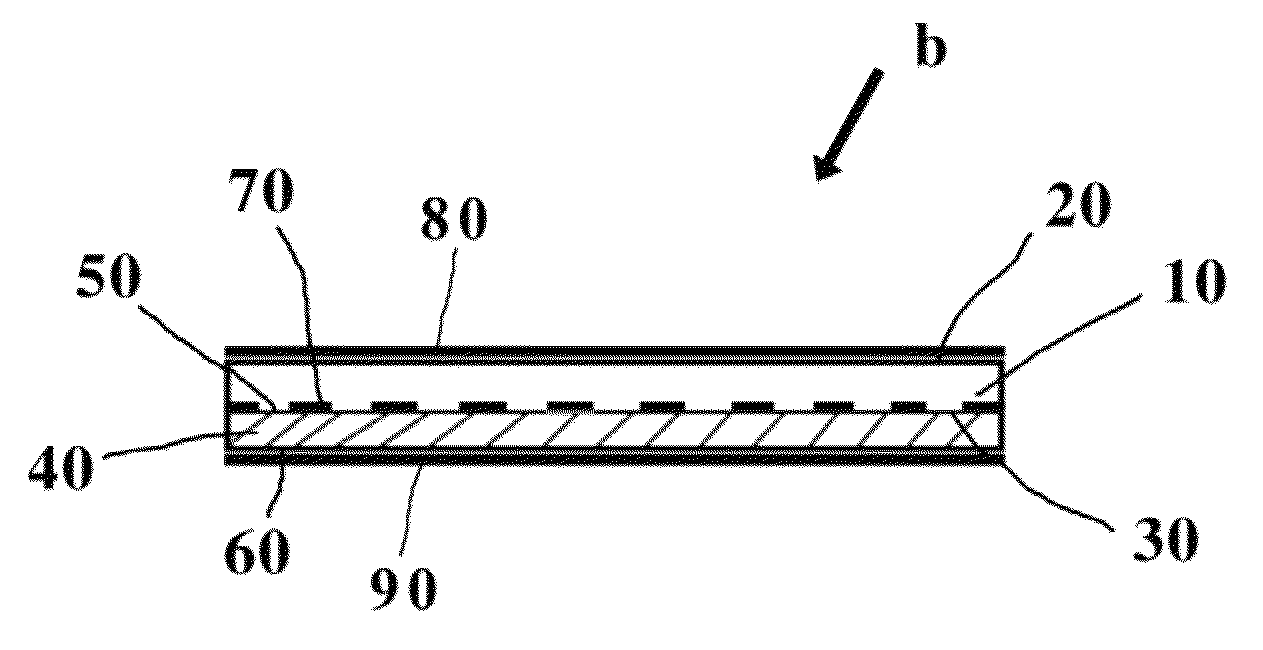

Liquid crystal display device and method for manufacturing the same

InactiveUS20120086901A1Constant gapSimple configurationNon-linear opticsRelief printingLiquid-crystal displayEngineering

A liquid crystal display device includes a plurality of columnar spacers configured to maintain a constant gap between substrates on a color filter substrate of the liquid crystal display device. At a tip end of each of the columnar spacers contacting an array substrate, a height adjusting portion which is easily deformed as compared to a portion of the columnar spacer other than the tip end portion when the pair of substrates are bonded together is provided.

Owner:SHARP KK

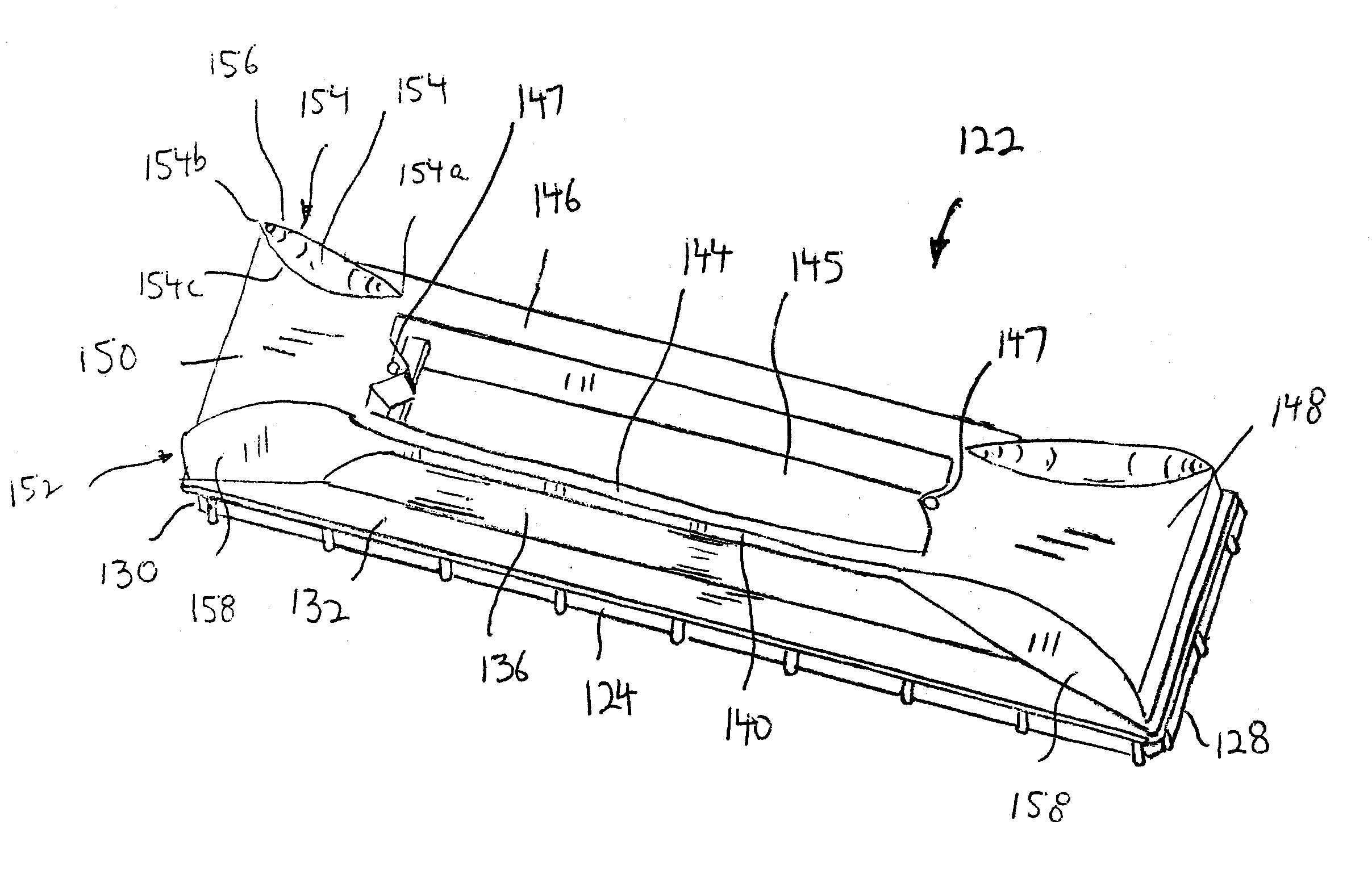

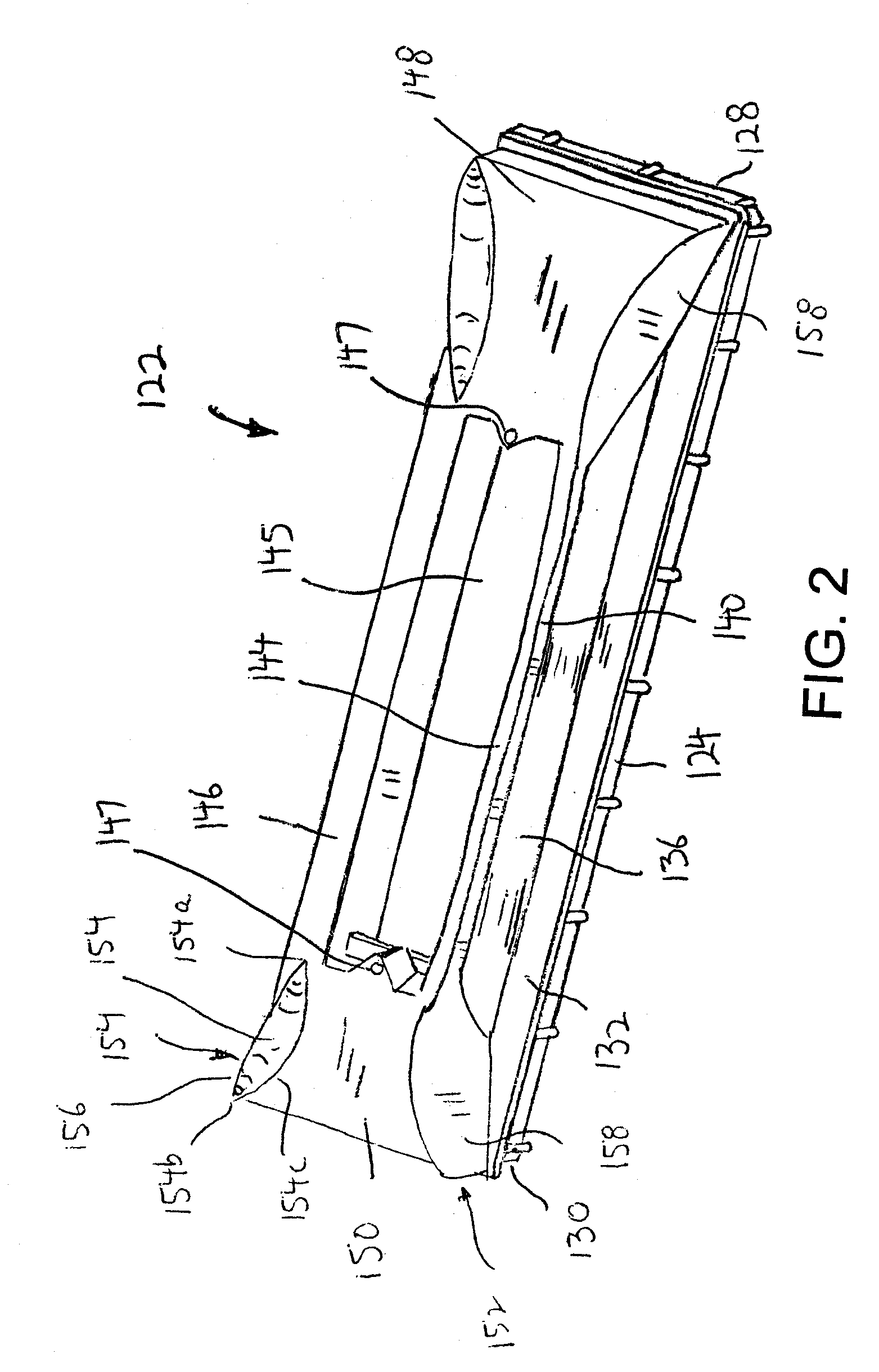

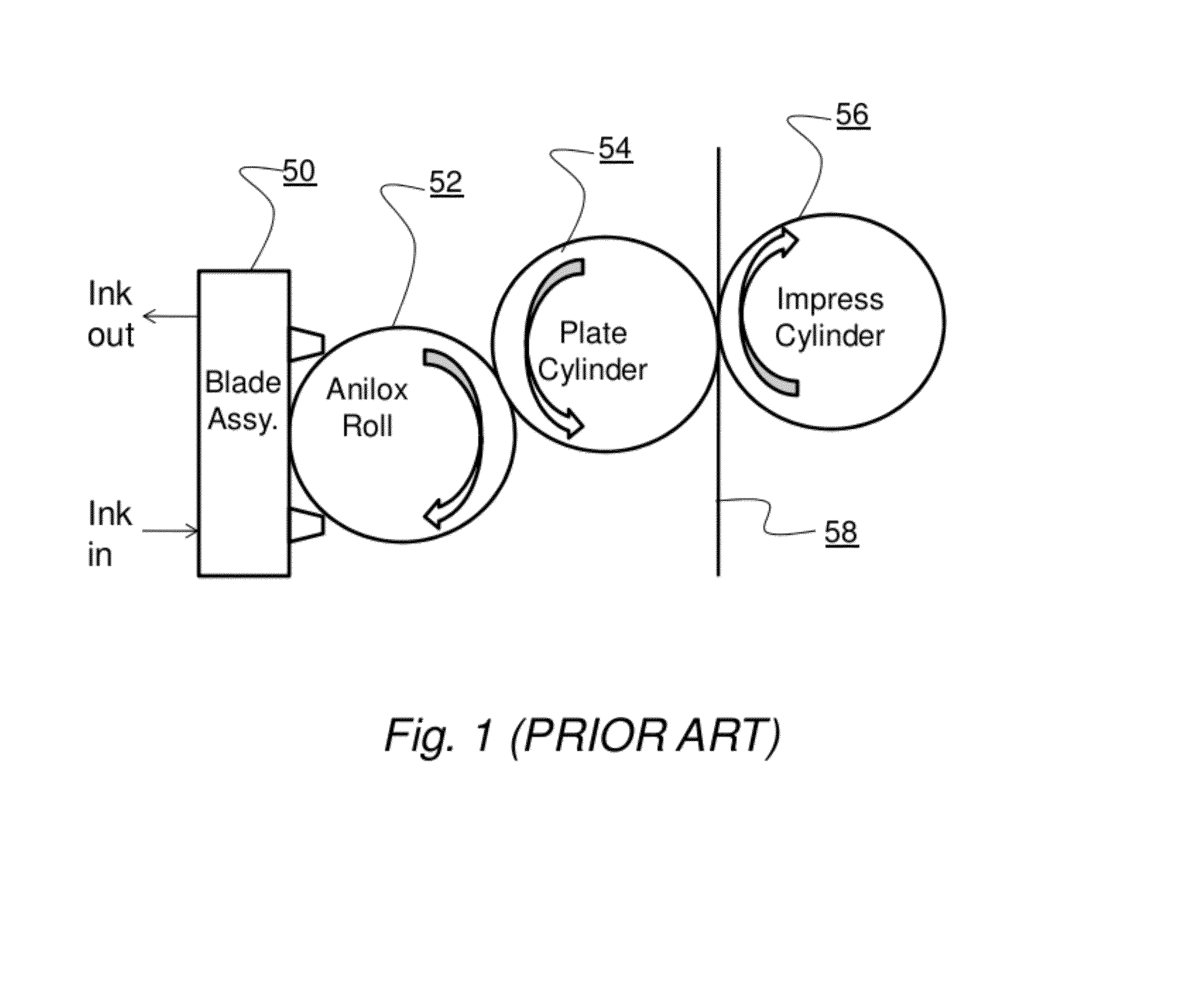

Seal for an Ink Chamber with Improved Blade/Seal Area

InactiveUS20090193990A1Easy to manufactureEasy to useRelief printingPrinting press partsEngineeringSupport surface

A seal adapted to seal an end of a fluid chamber which supplies fluid to a roll, includes at least one supporting wall and an upper concave surface on the at least one supporting wall and adapted to engage an outer surface of the roll. First and second, sloping, upper supporting surfaces are formed at opposite ends of the upper concave surface for receiving an end of a doctor / sealing blade thereon. Four flexible, resilient upstanding wings are provided along side edges of the first and second upper supporting surfaces for providing a sealing engagement with the doctor / sealing blades, even when the doctor / sealing blades bow outwardly away from the first and second upper supporting surfaces.

Owner:VAN DENEND MARK E

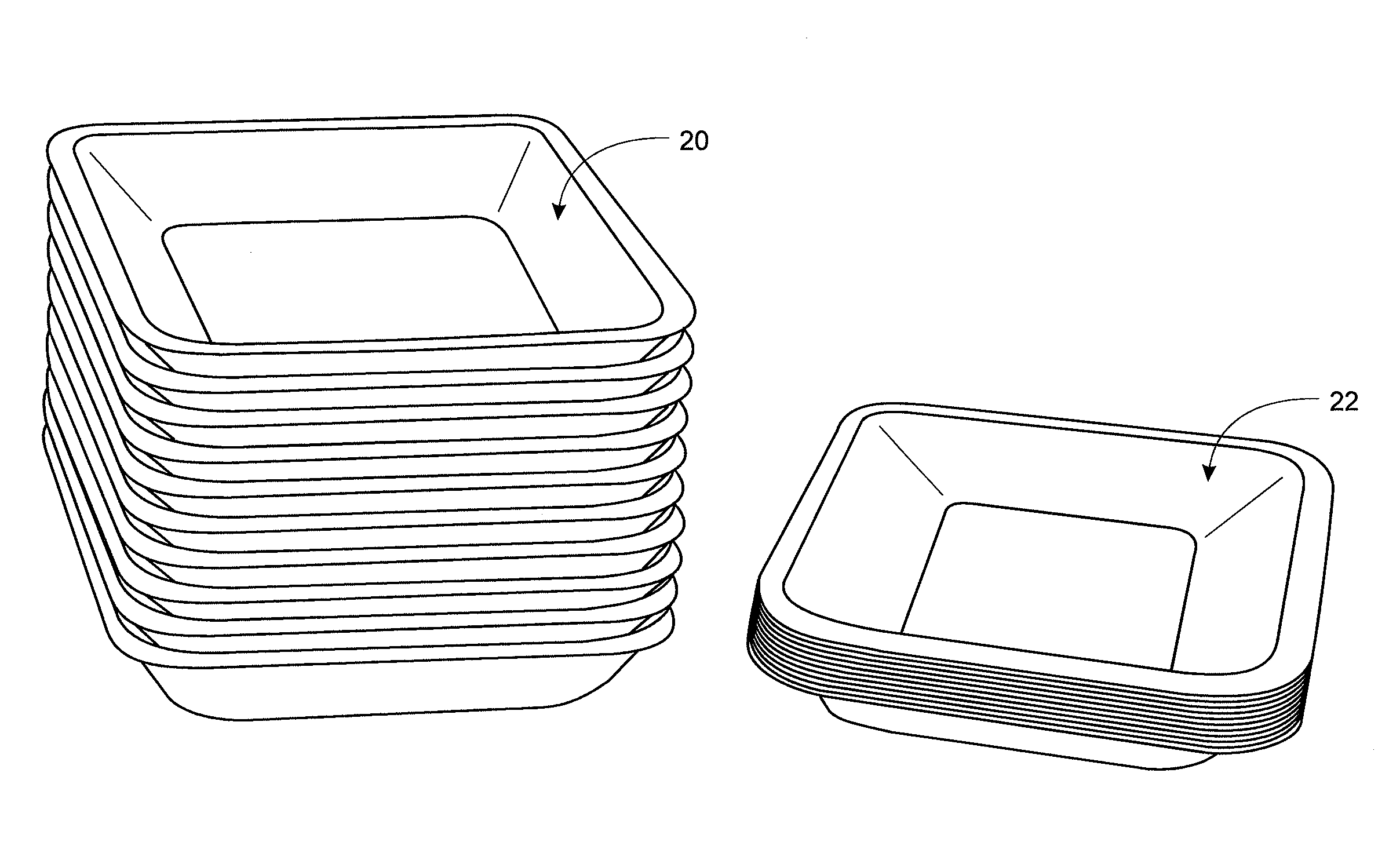

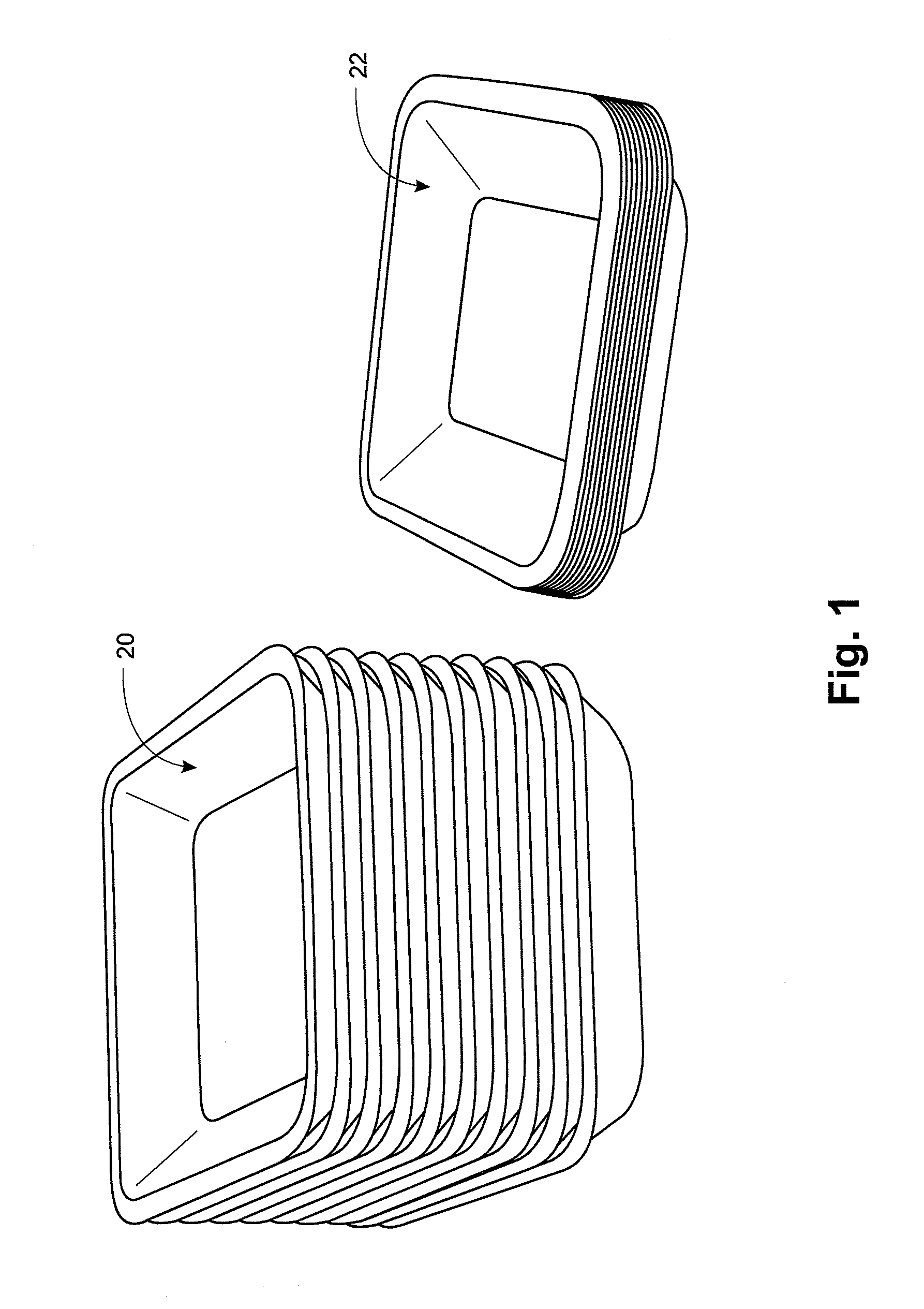

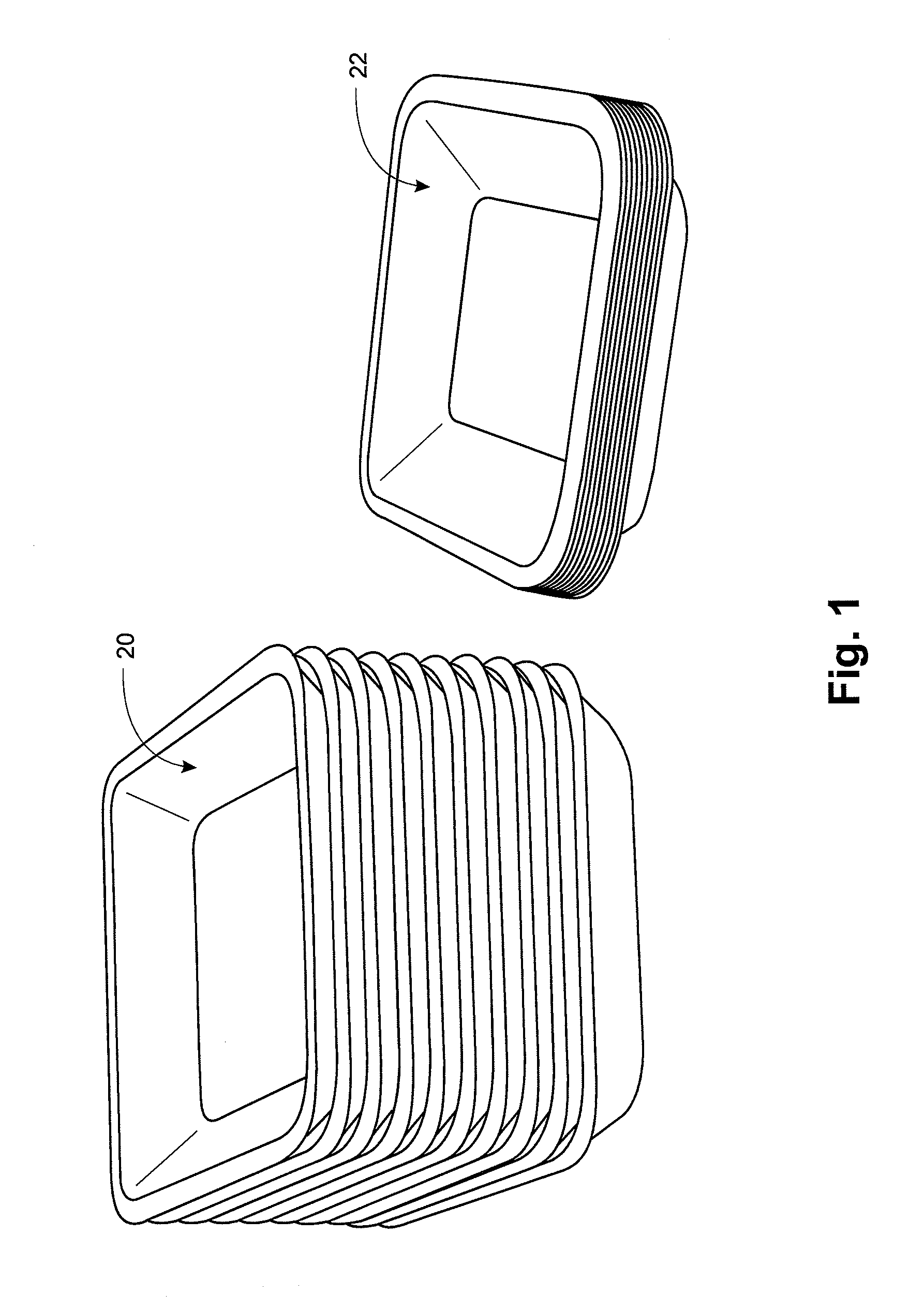

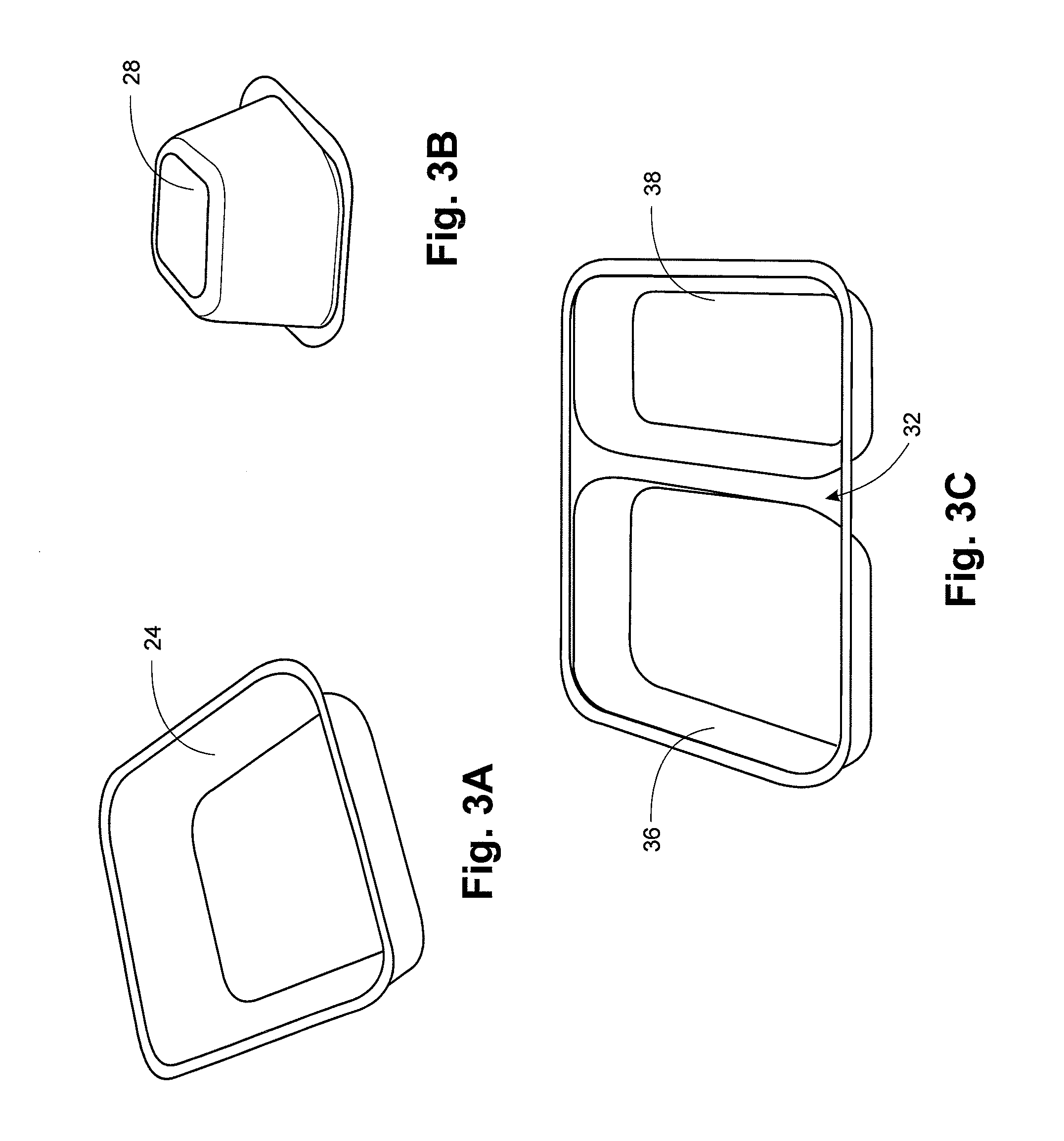

Disposable food tray

ActiveUS20120292226A1Prevent liquid leakageReduce food costPackage recyclingWrappersWood fibrePaperboard

A repulpable and recyclable case ready food tray is disclosed for carrying various food items, such as meat, poultry and produce that is typically used for retail display. The food tray is formed from paperboard made from natural wood fiber that is coated to provide a waterproof food cavity for preventing leakage of liquid from the food item and a moisture proof exterior support surface which allows excess liquid to be released from the food tray during the manufacturing process while providing a moisture proof surface to prevent wicking of liquid into the food tray if the tray is placed on a wet surface.

Owner:GRAPHIC PACKAGING HLDG CO

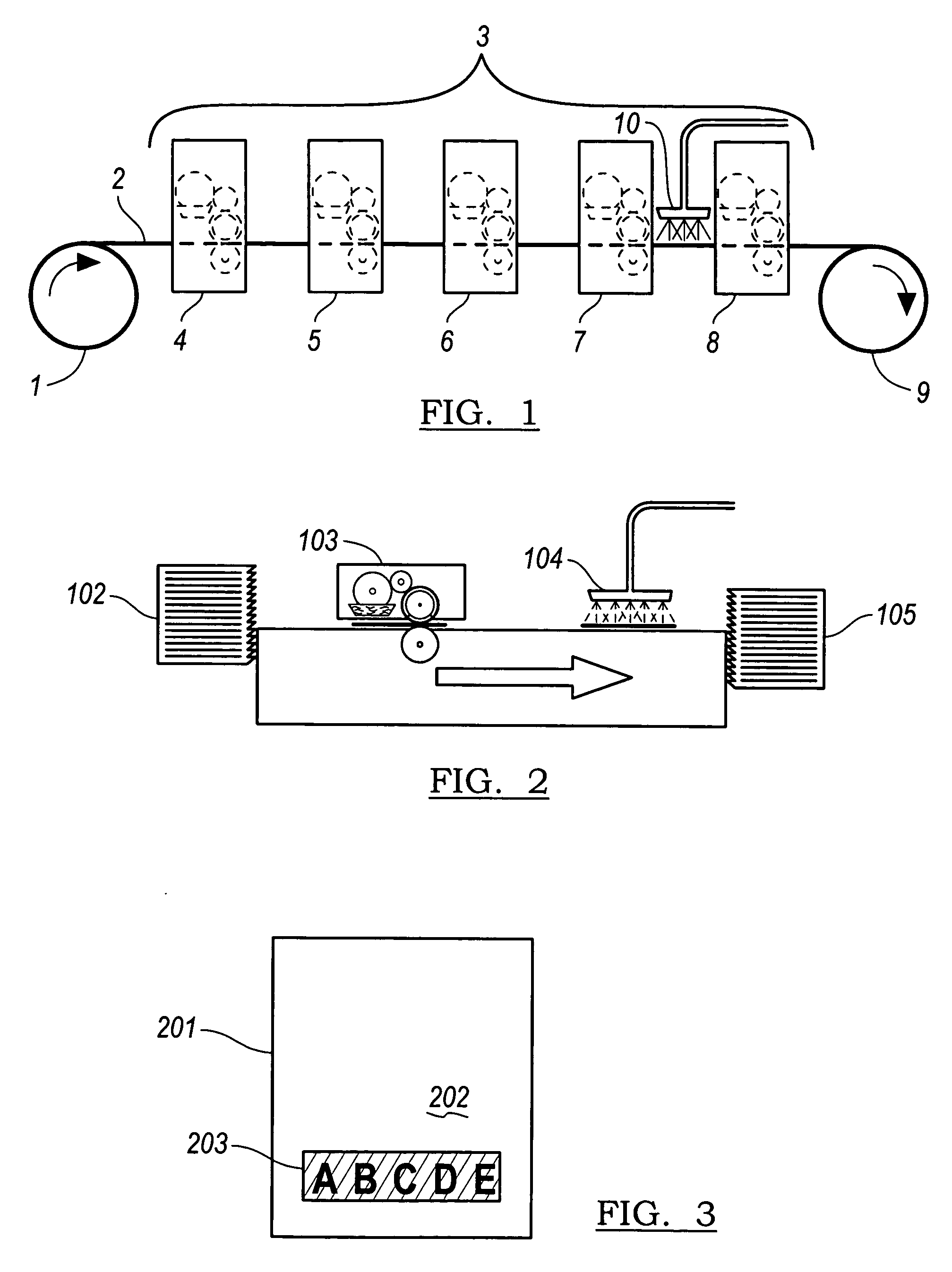

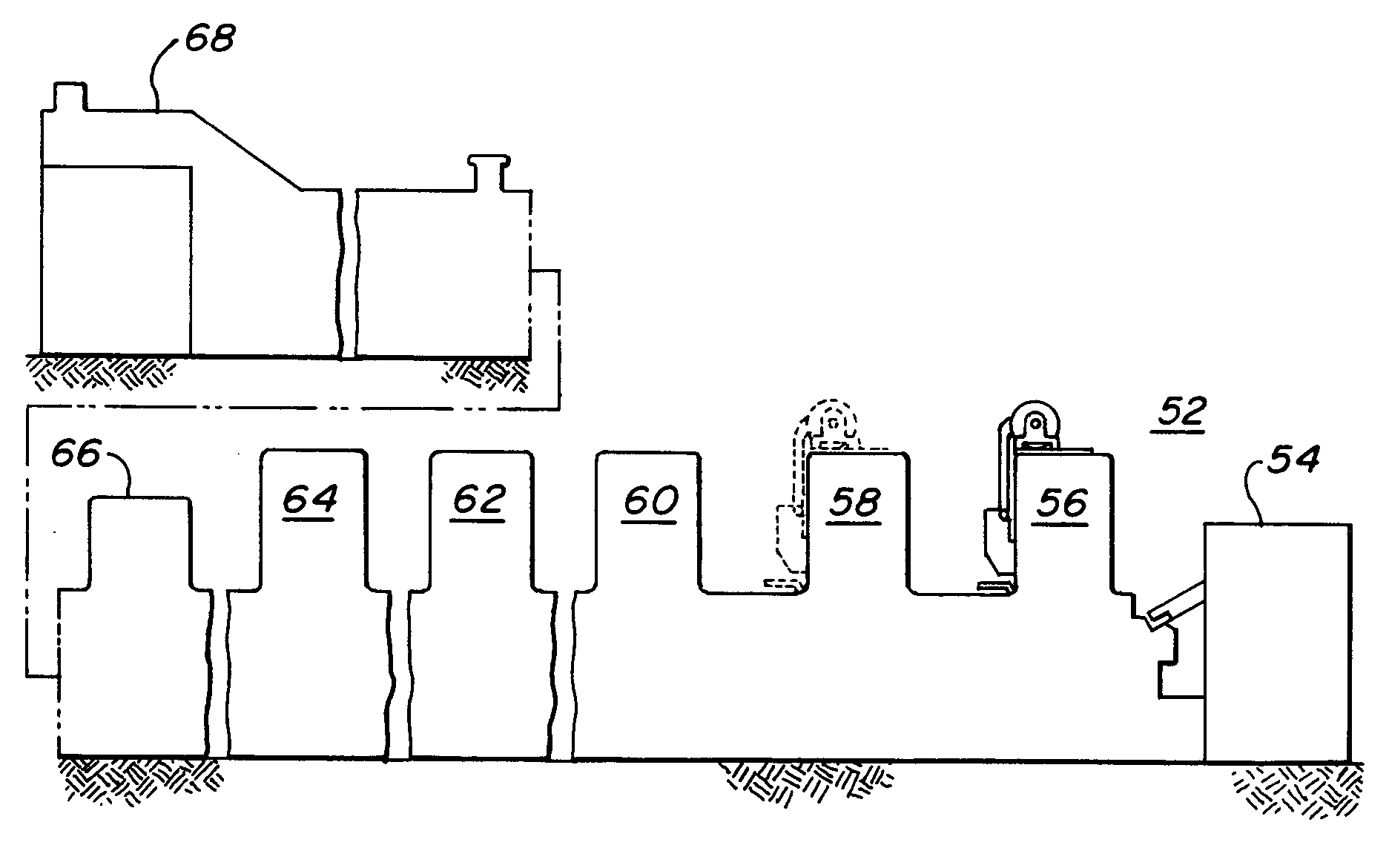

Flexographic printing on containers

InactiveUS20050081725A1Automate the processImprove throughputRotary pressesOther printing apparatusEngineeringPrinting press

A flexographic press of conventional design is used to print on a container, with the container to be printed upon replacing the web and the impression roll of the conventional press. In order to maintain the registration between the print stations, the container is placed into a carrier and stays registered to the carrier until all colors are printed. The carrier is moved between the different print stations and is registered to each print station independently. All print stations are set up to print in exactly the same place relative to the carrier, thus registration is achieved.

Owner:KODAK CANADA ULC

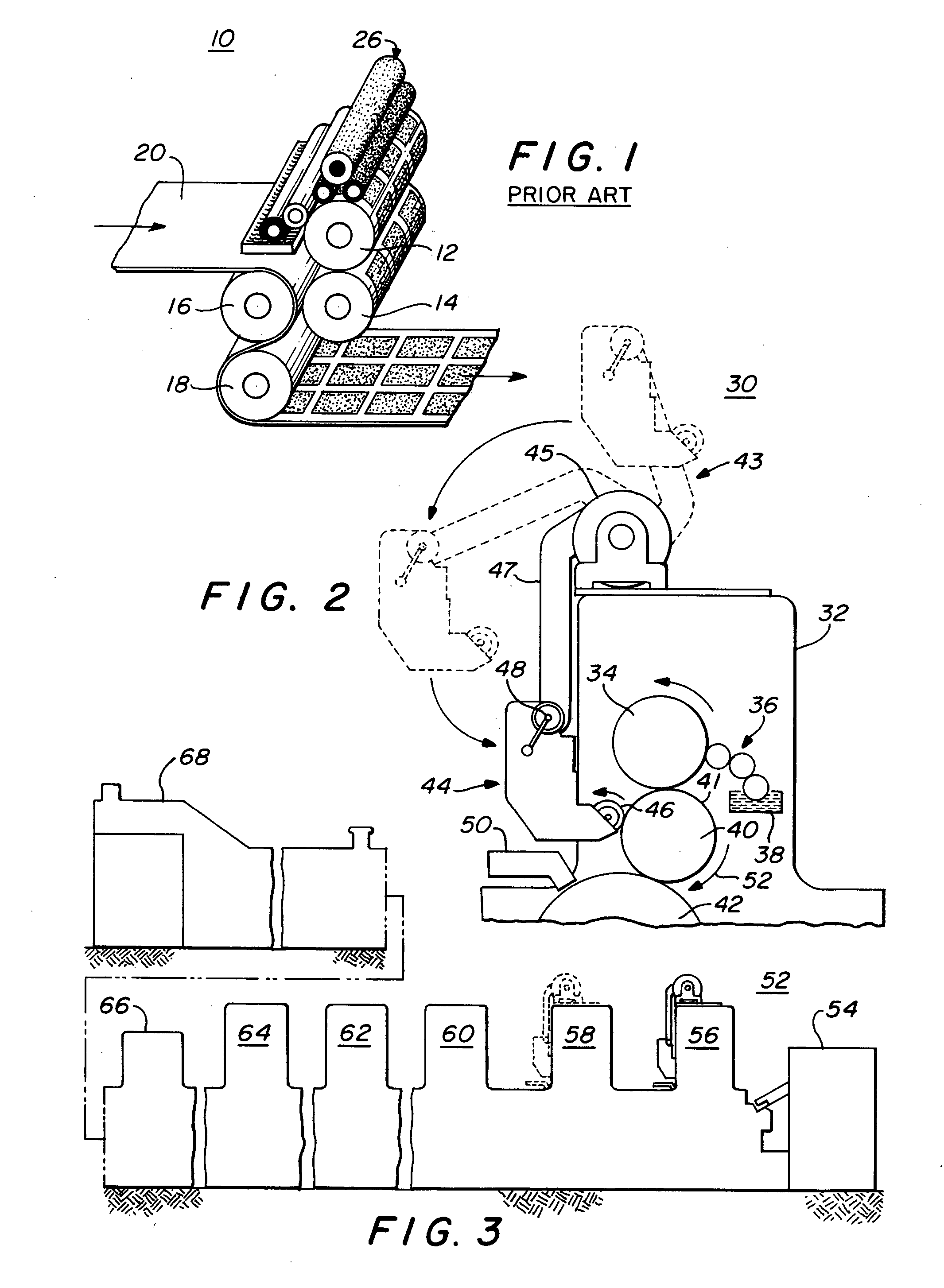

Combined lithographic/flexographic printing apparatus and process

A combined lithographic / flexographic printing process having a plurality of successive printing stations for printing color images on a substrate in a continuous in-line process. One of the stations prints a first color image using the flexographic process and at least one of the successive printing stations prints a second color image over the first color image using an offset lithographic process in the continuous in-line process.

Owner:WILLIAMSON PRINTING CORP

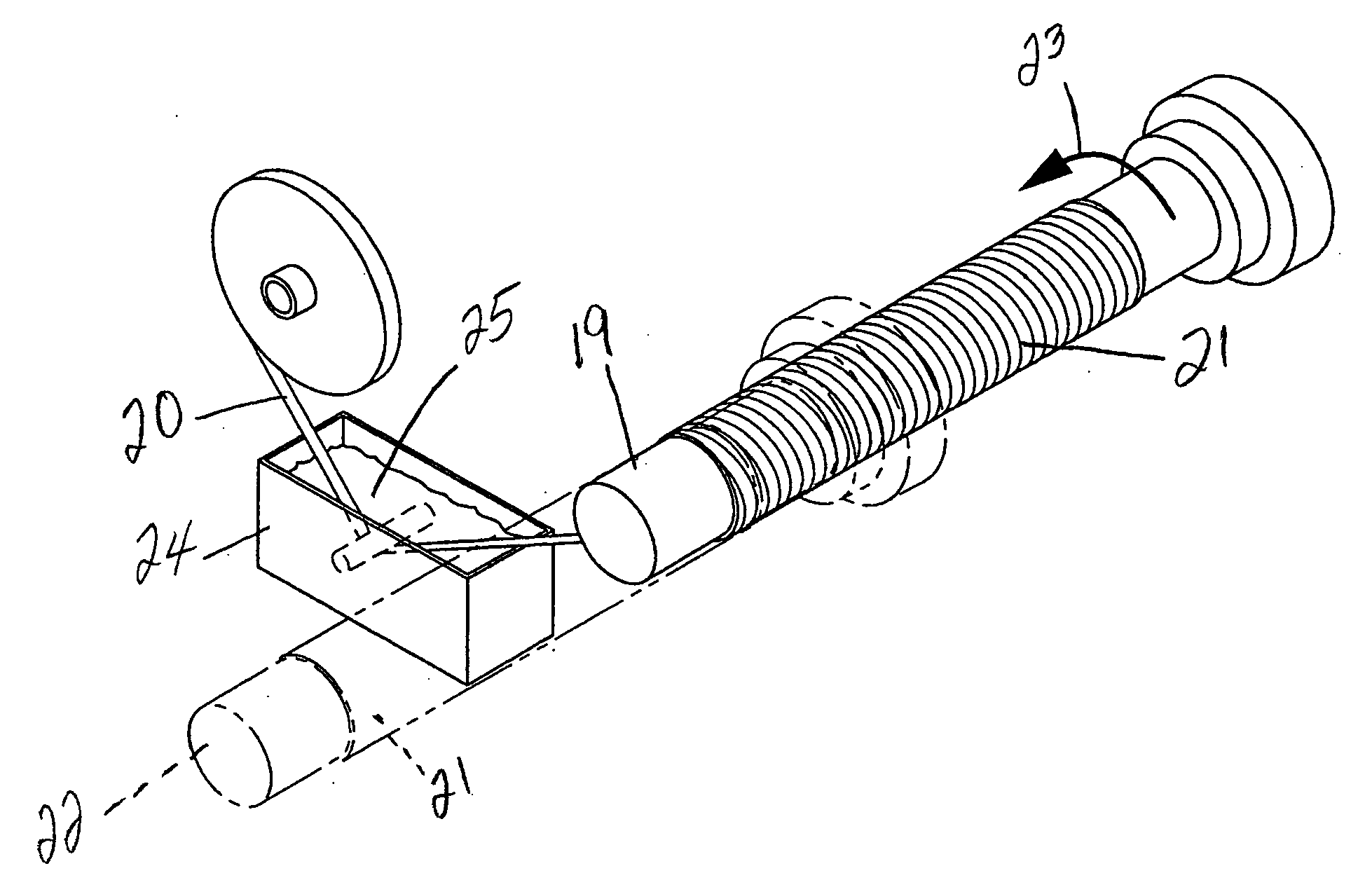

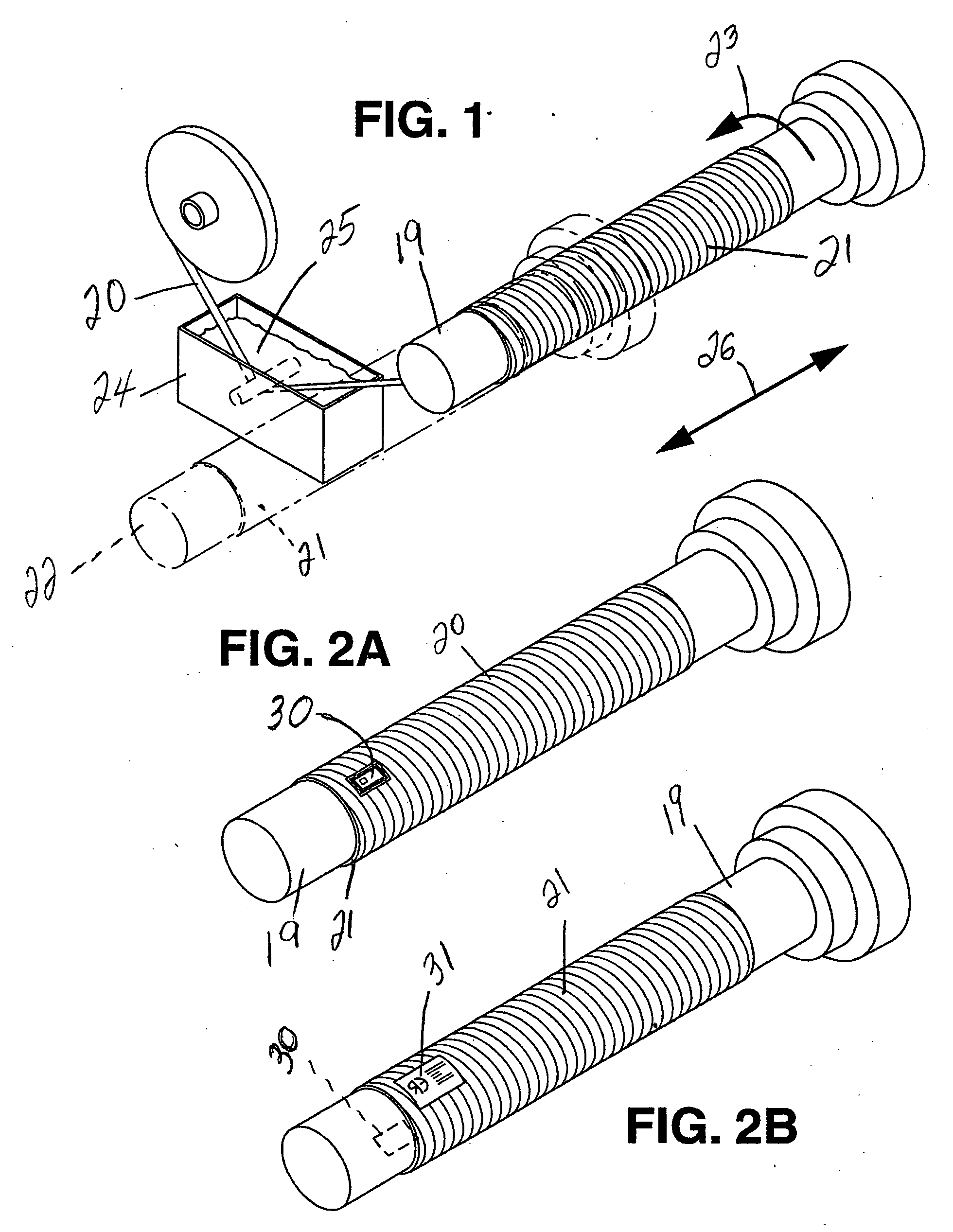

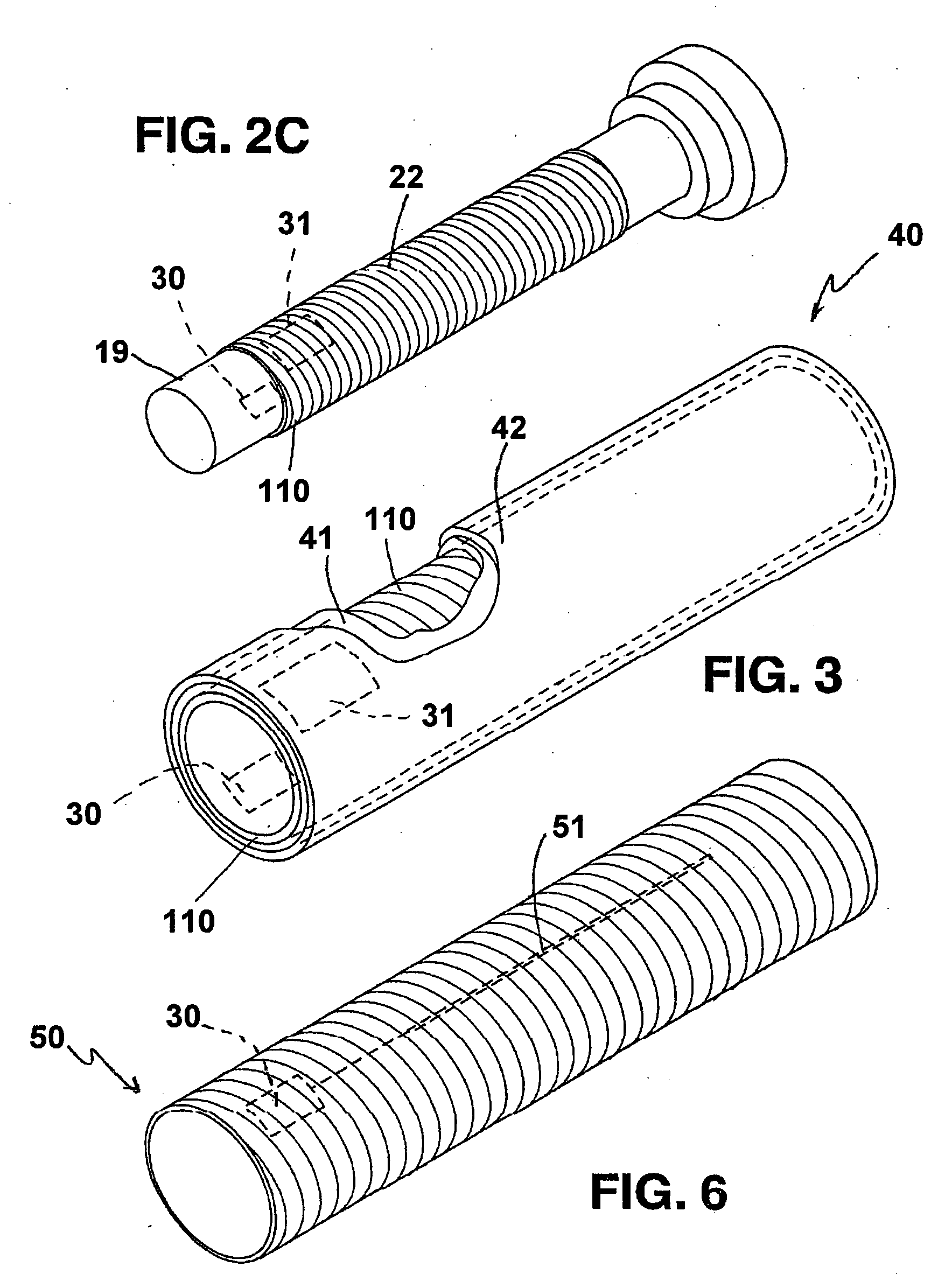

Printing member provided with identification means defined by or connectable to updateable means for recording data relative to the member and useful for its utilization

ActiveUS20050194087A1Easy to readAddressographsPaper/cardboard wound articlesIdentification deviceMetal cylinder

A printing member such as a printing cylinder includes an at least partly metal cylinder, or a sleeve to be mounted on a mandrel rotating about its axis. The printing member comprises a body having a thickness. With the printing member there is associated an activatable signaling device that is connectable to a recording device that is arranged to store data related to at least one characteristic of the printing member or to the use of the printing member. The activatable signaling device can include a transponder such as an RFID.

Owner:ROSSINI SPA

Apparatus to print on water-soluble film

InactiveUS20150290926A1Quality improvementConvenient registrationDecorative surface effectsDuplicating/marking methodsSheet filmWater soluble

Owner:THE PROCTER & GAMBLE COMPANY

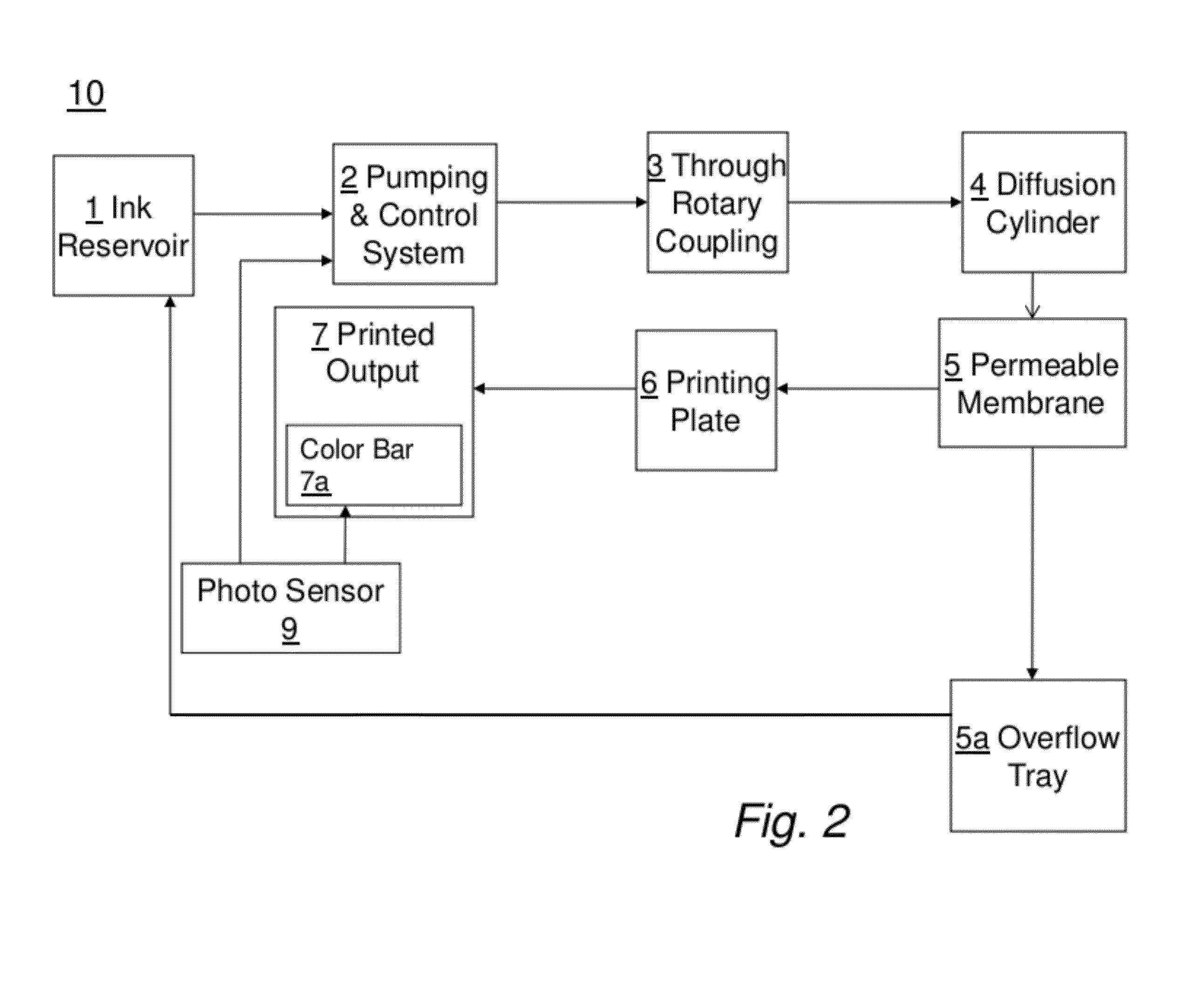

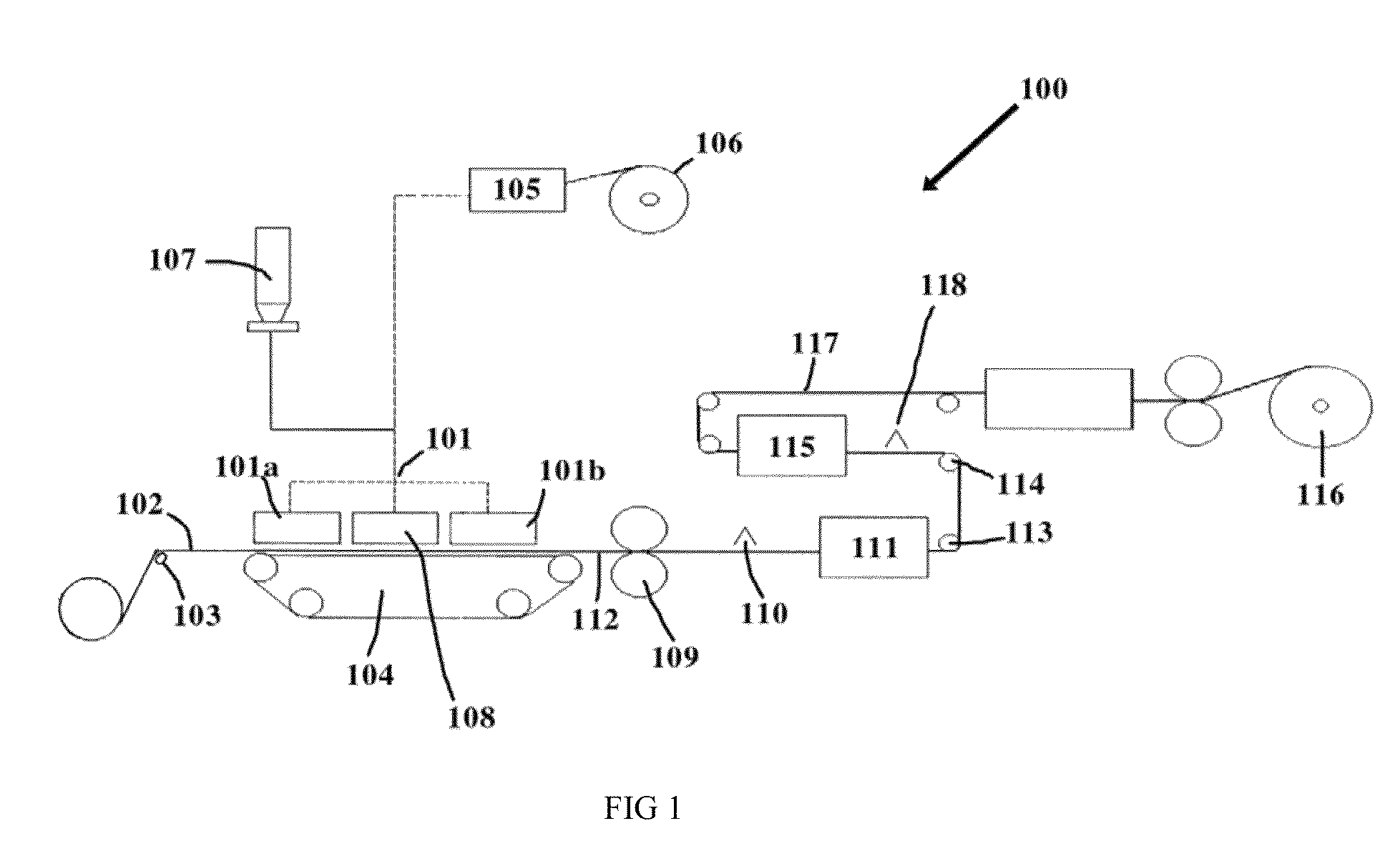

Variable Ink Metering and Delivery System for Flexographic Printing

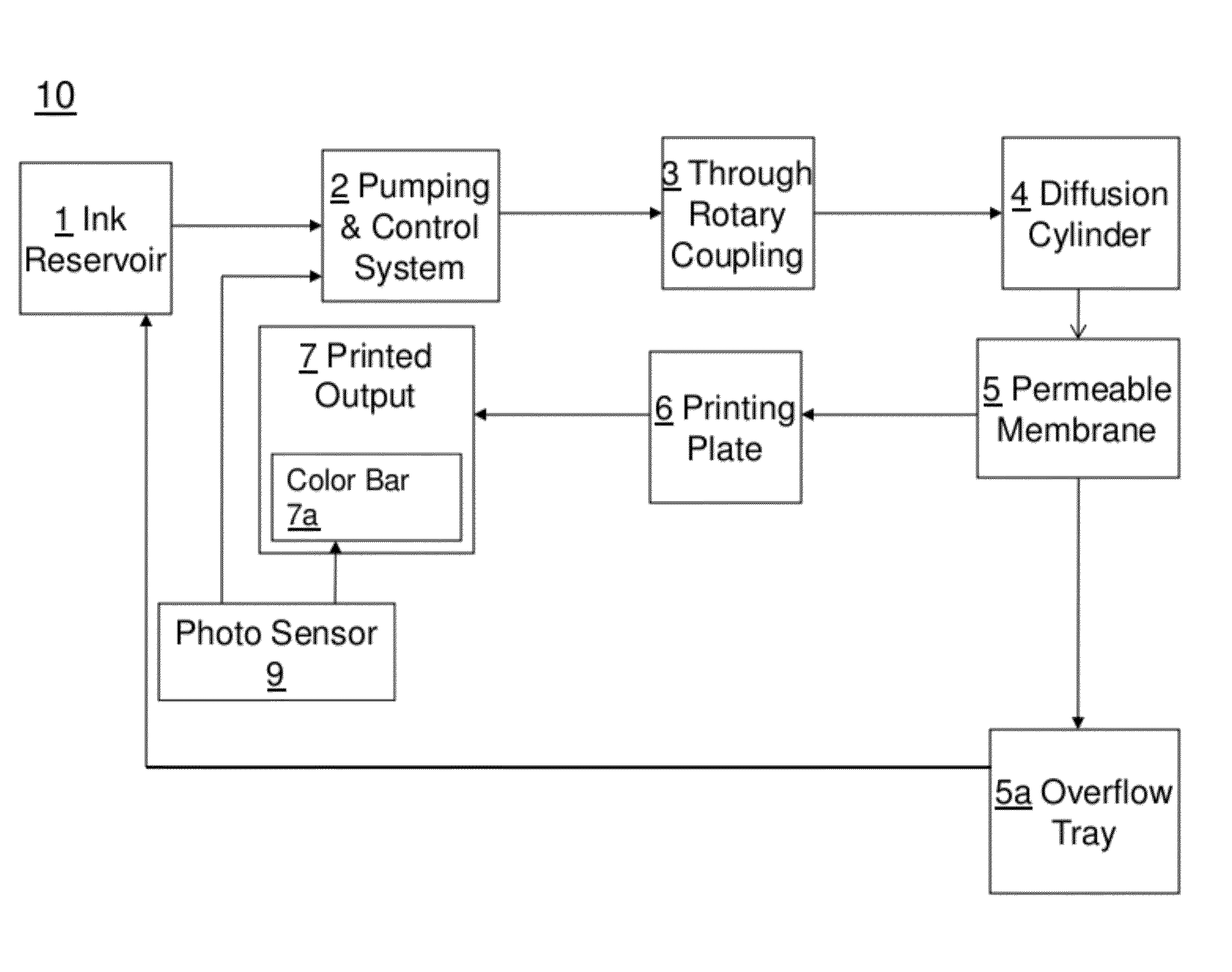

Flexographic printing using a processor to apply a control value to an ink pumping and control system responsive to the control value, where the control value sets an operating mode of the ink pumping and control system, where the ink pumping and control system includes a stepper motor coupled to a peristaltic pump. Ink is pumped through the rotary coupling into a rotating diffusion cylinder and metered through a plurality of passages so as to contact a permeable membrane covering the diffusion cylinder. A dual blade assembly cleans the permeable membrane and ink passing through the permeable membrane is metered onto a printing plate or printing sleeve.

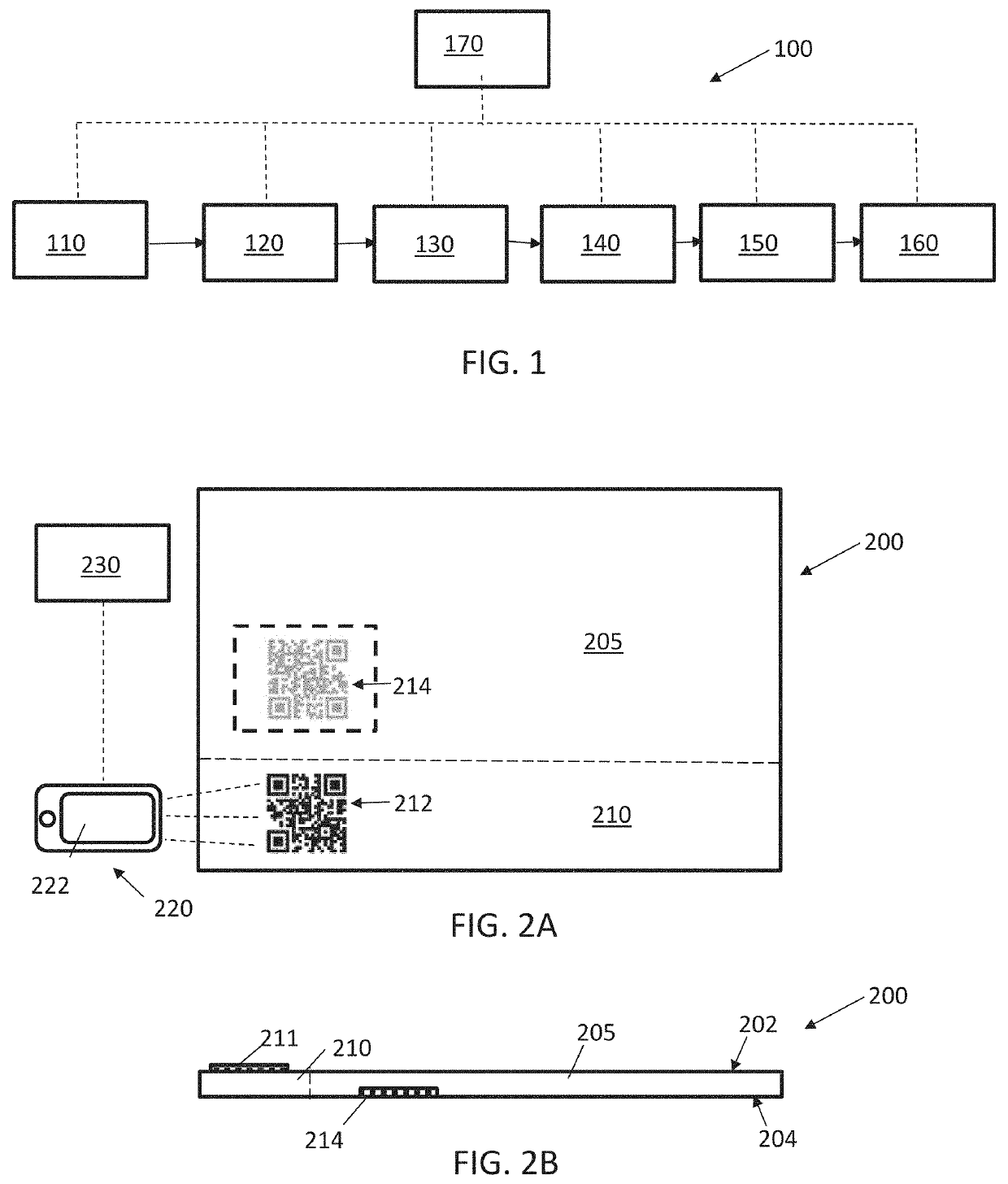

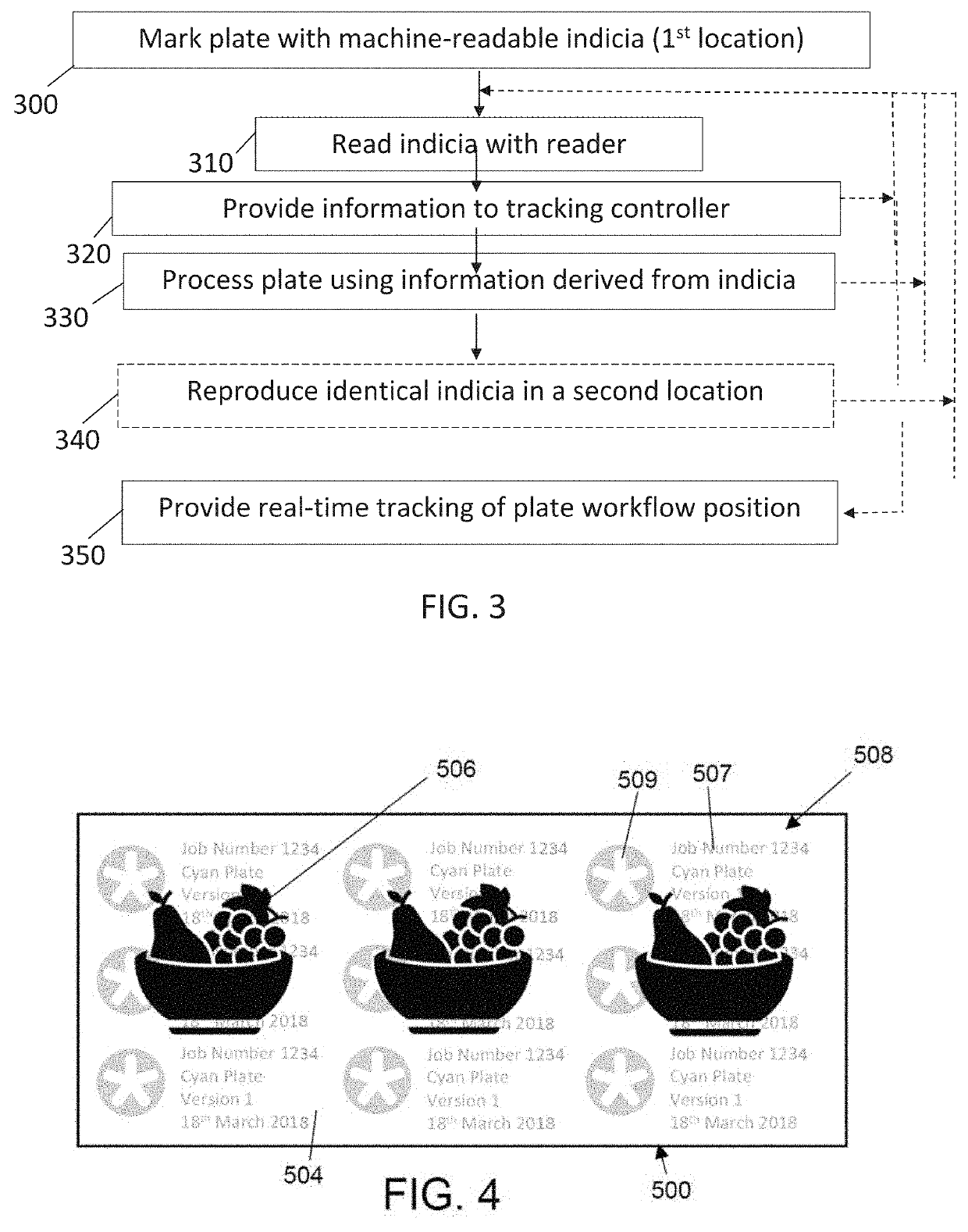

System and process for persistent marking of flexo plates and plates marked therewith

Systems and processes for making a flexo plate, and plates made thereby. Non-printing indicia defined by areas of presence and absence of polymer in the plate floor created using microdots imaged during a LAMS layer imaging step are readable downstream of the washing or other non-cured-polymer-removal step but not to print in the printing step. The non-printing indicia may define a repeating pattern of alphanumeric characters, non-text graphics, or a combination thereof. A difference in growth of plate structures corresponding to different types of microdots may be used for characterizing processing conditions.

Owner:ESKO GRAPHICS IMAGING

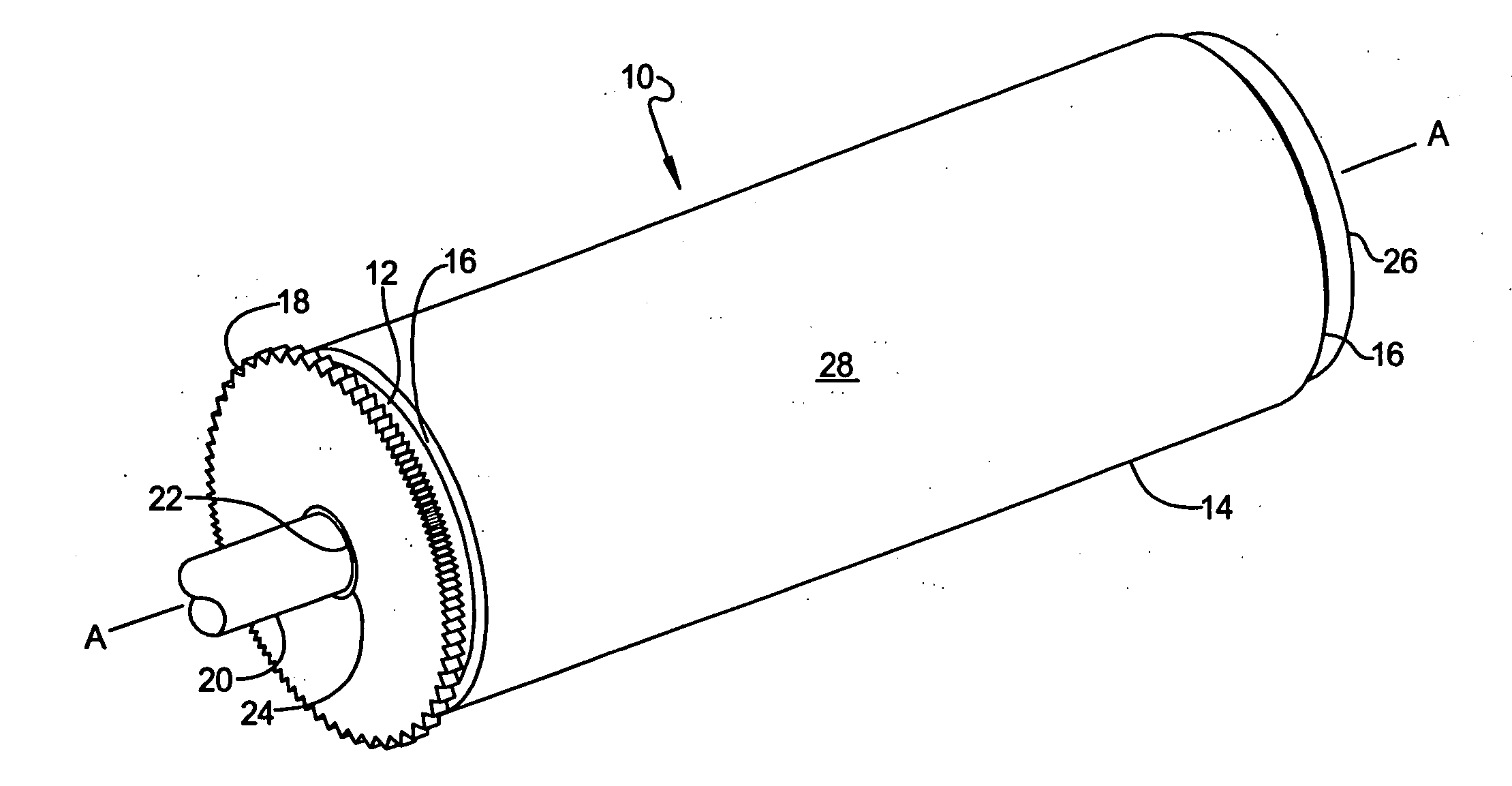

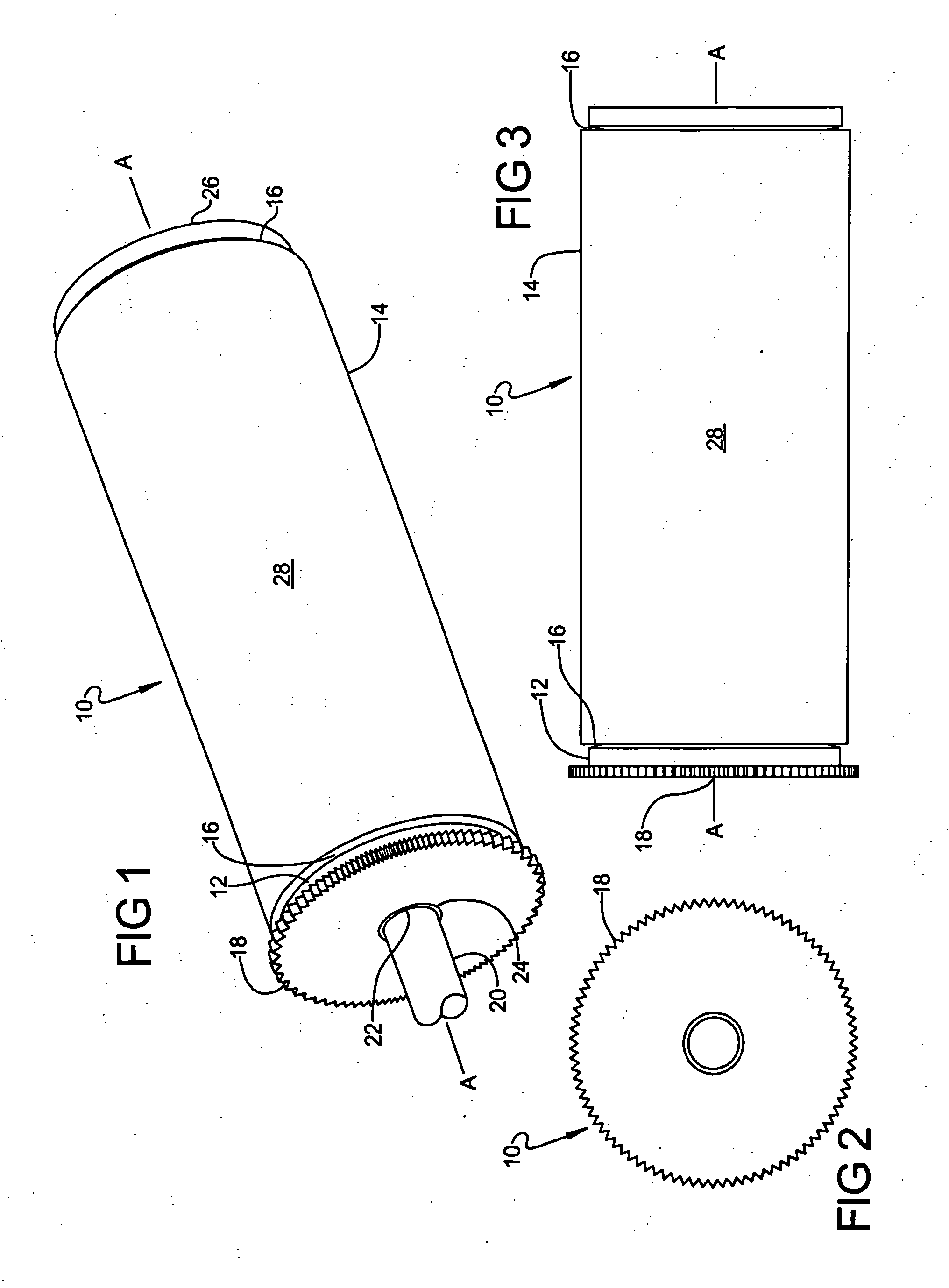

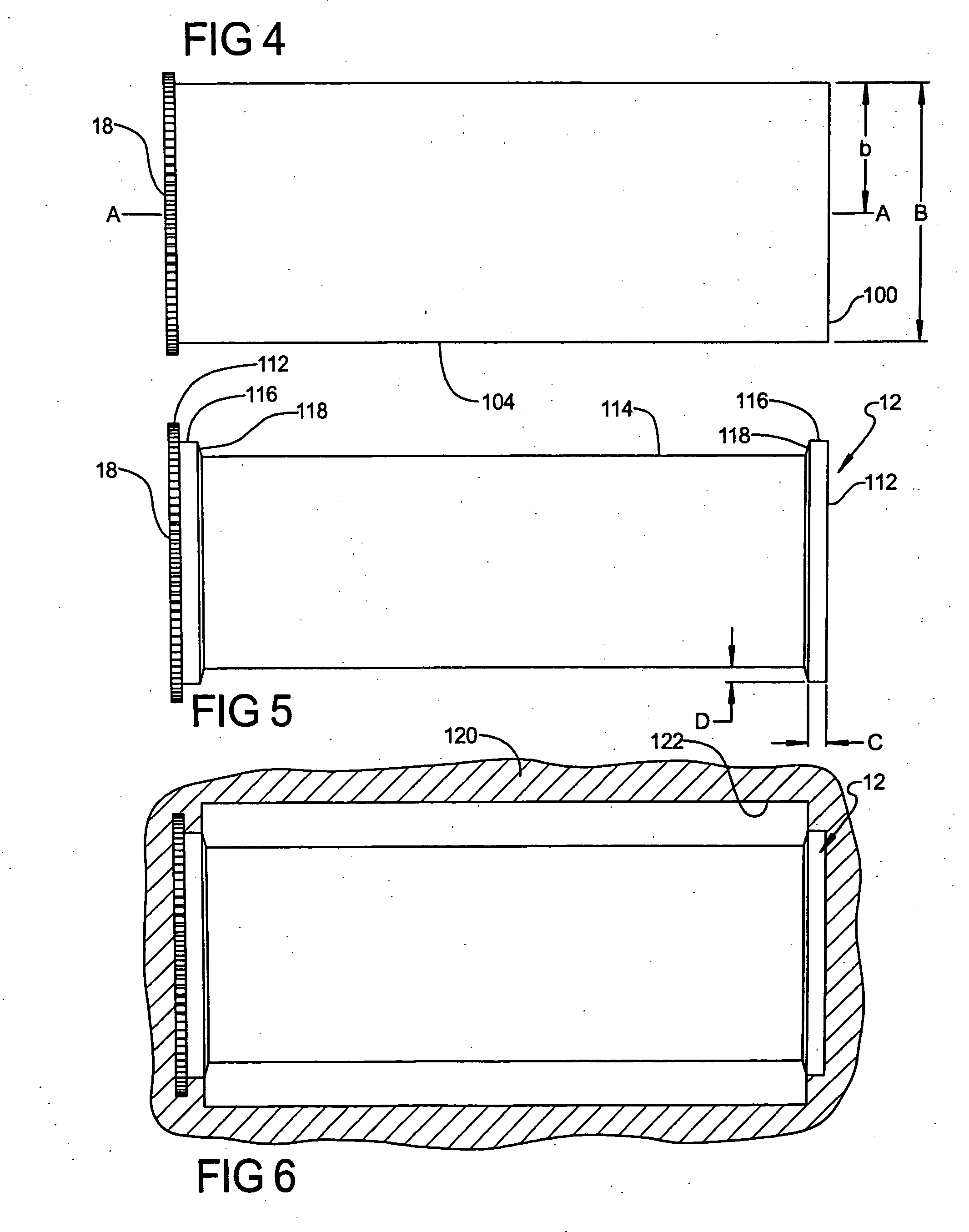

Apparatus and method of enhancing printing press cylinders

InactiveUS20060021530A1Consume energyAvoid print qualityRotary letterpress machinesRelief printingEngineeringPrinting press

A printing press cylinder and a method of manufacturing the same. The printing press cylinder includes a rigid base member having a reduced radius section and a polymer layer formed about the rigid base member generally within the reduced radius section. The polymer layer is operable to absorb forces and dissipate energy that degrades print quality. A gear portion is operably coupled to the rigid base member for rotation therewith. The printing press cylinder is manufactured by turning a rigid base member to produce a reduced radius section and subsequently molding a polymer layer generally within the reduced radius section of the rigid base member. The polymer layer is cured and then turned to reduce the circumference thereof and produce a smooth surface.

Owner:NU TECH COATINGS

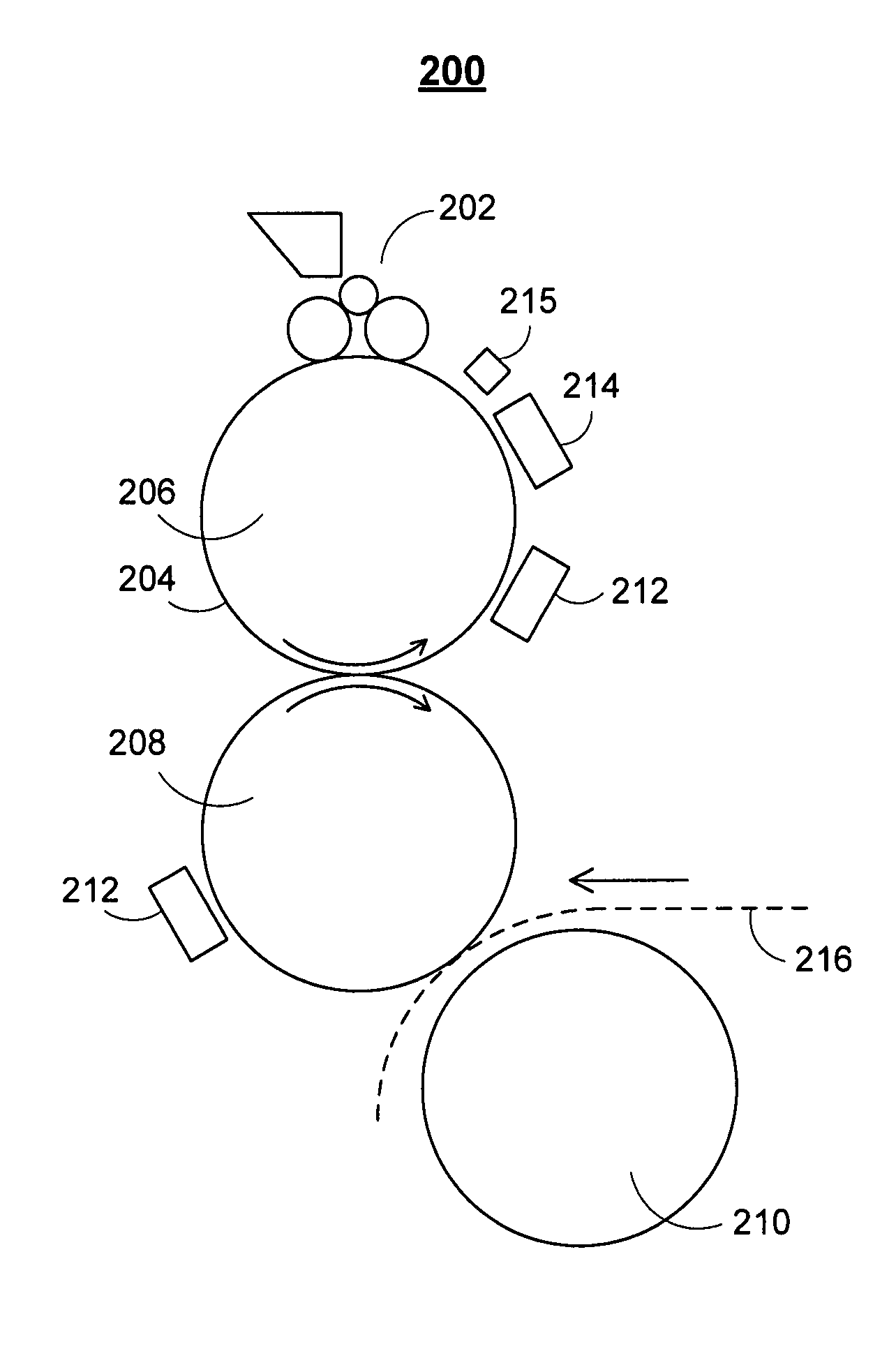

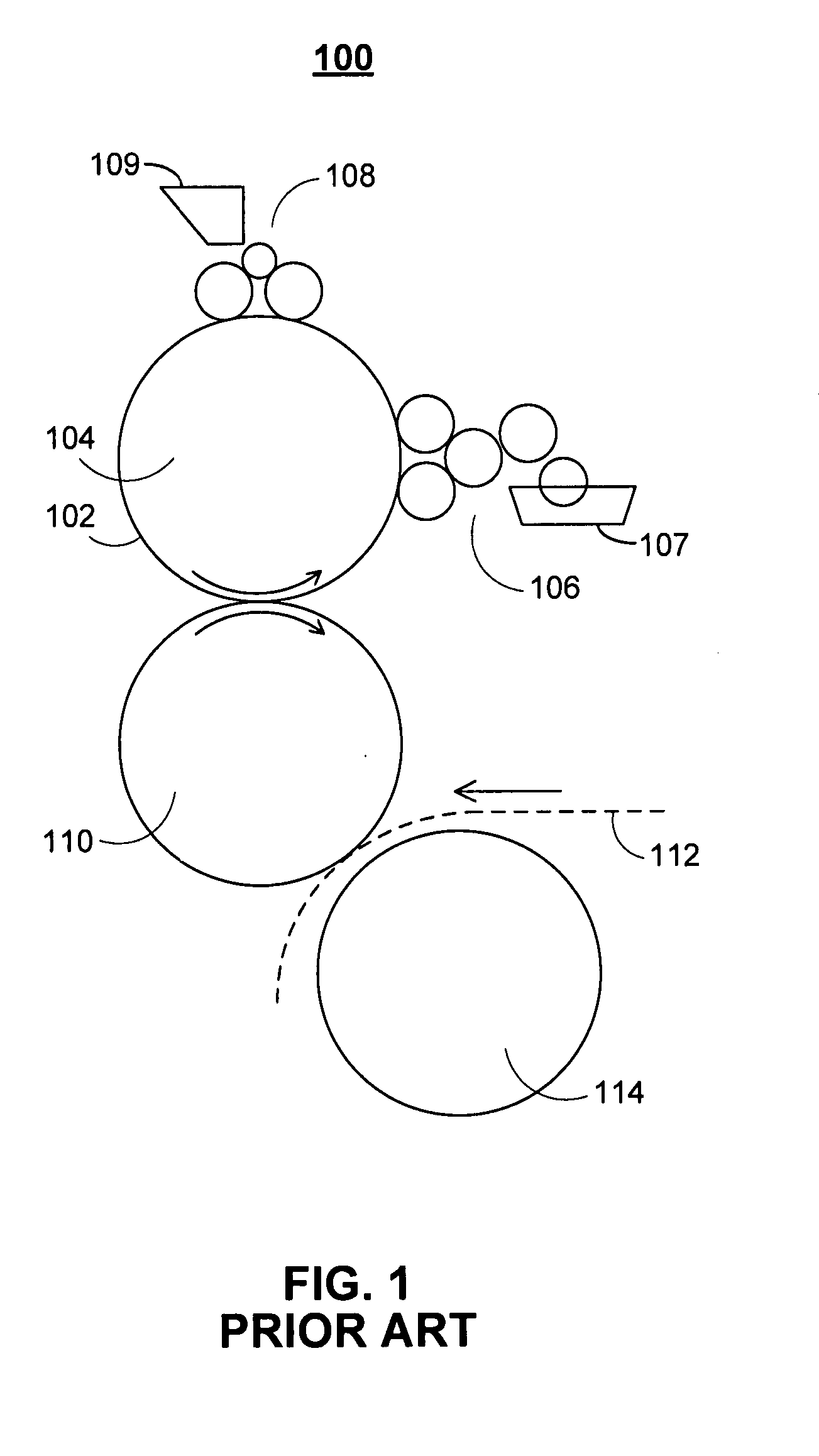

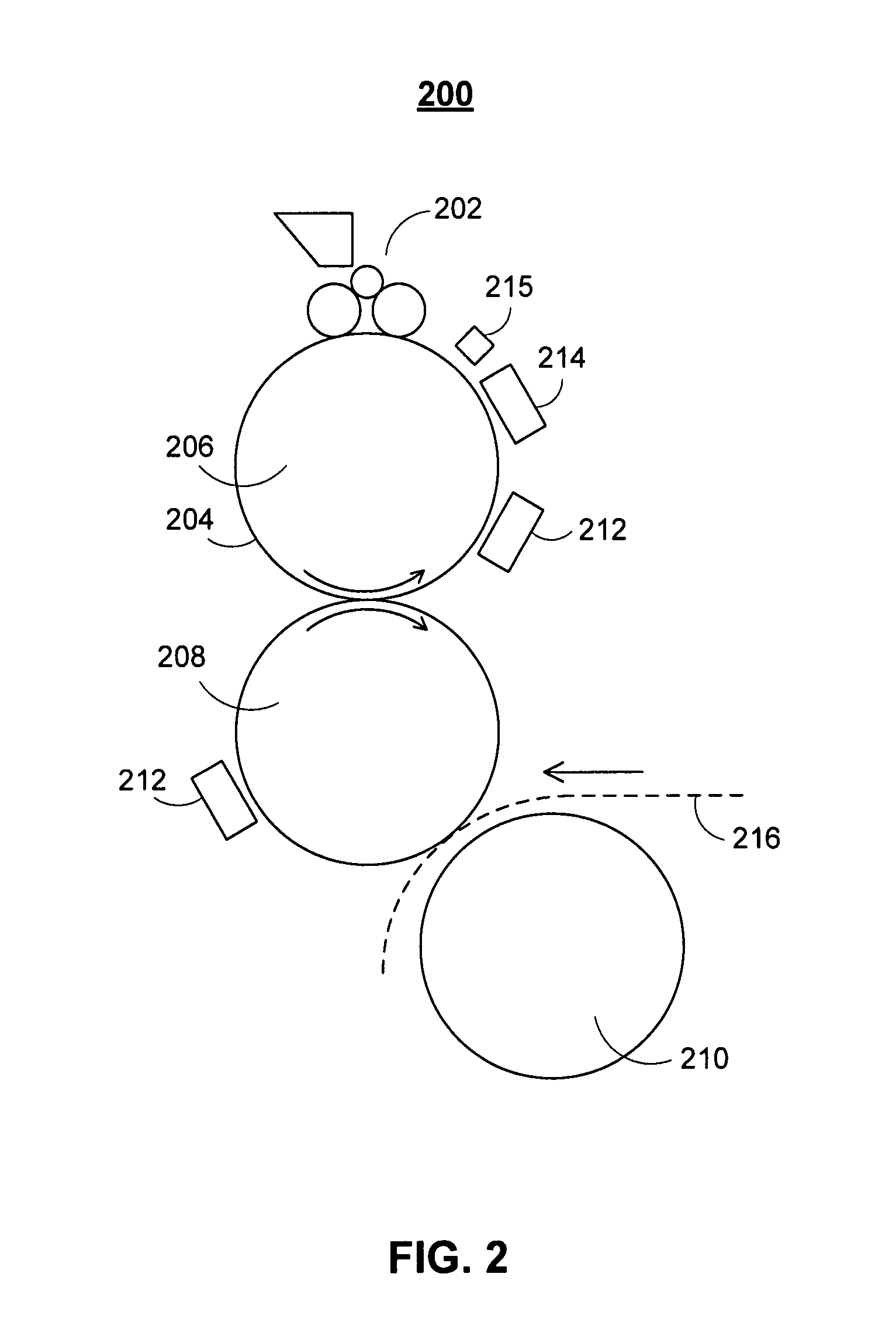

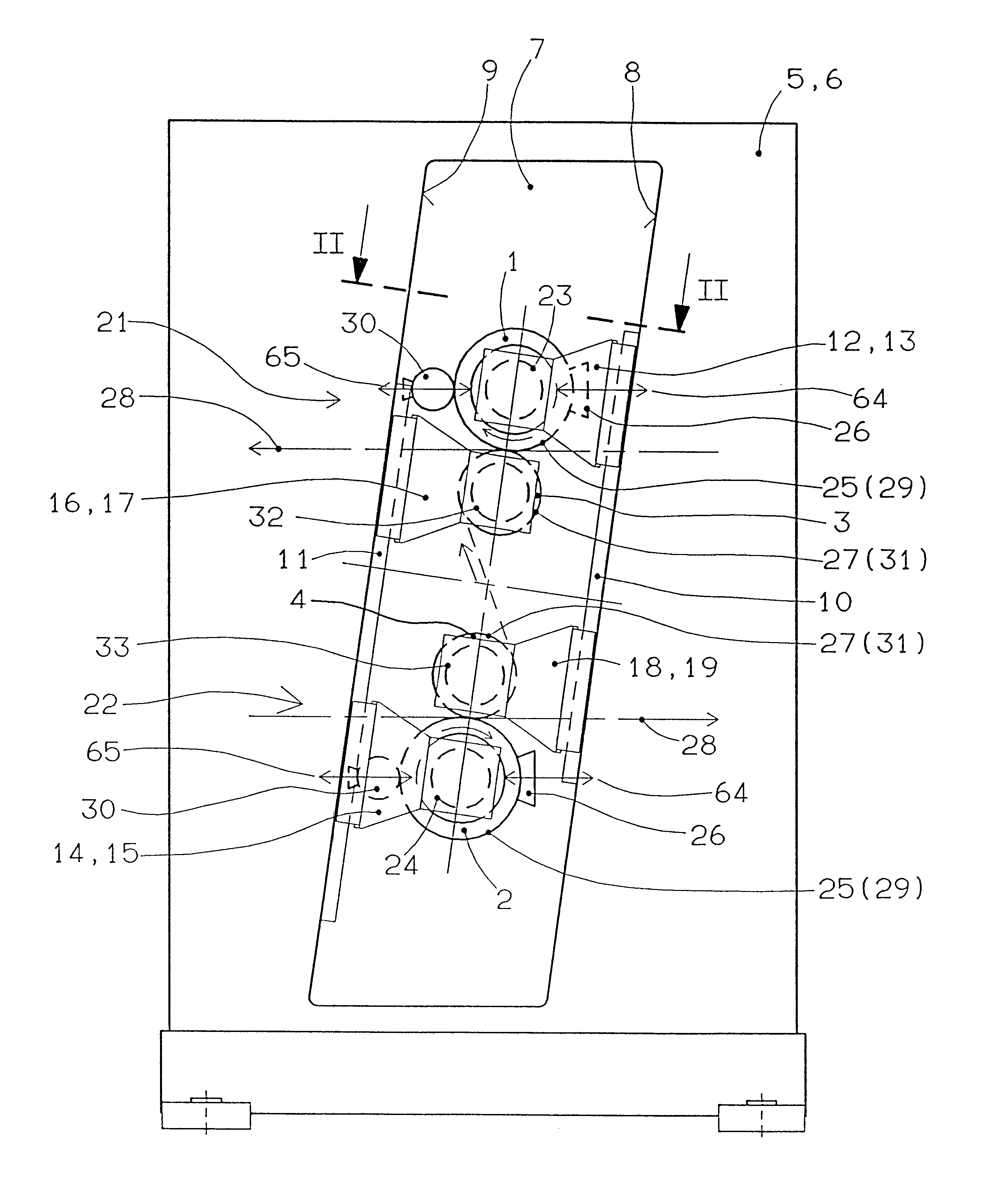

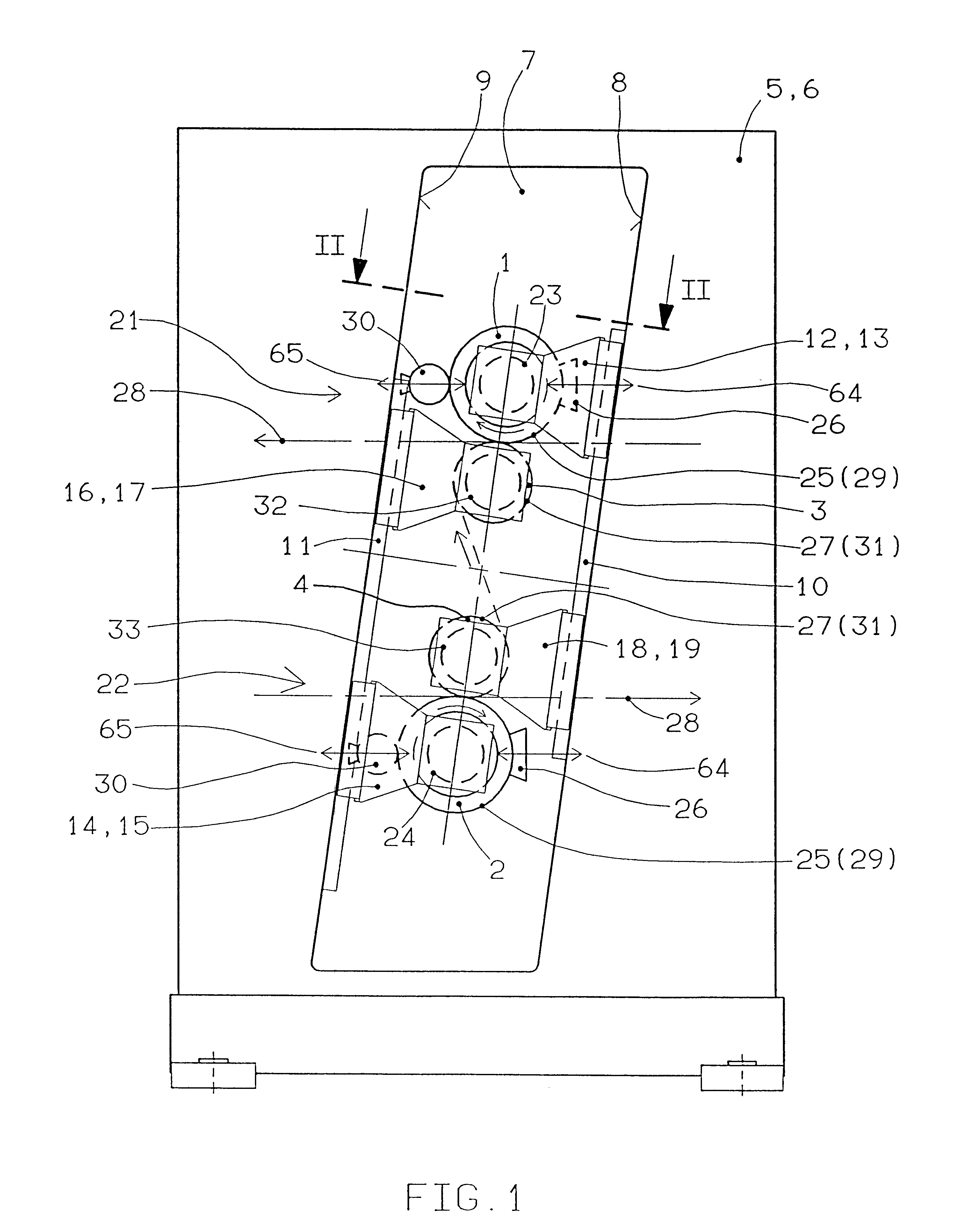

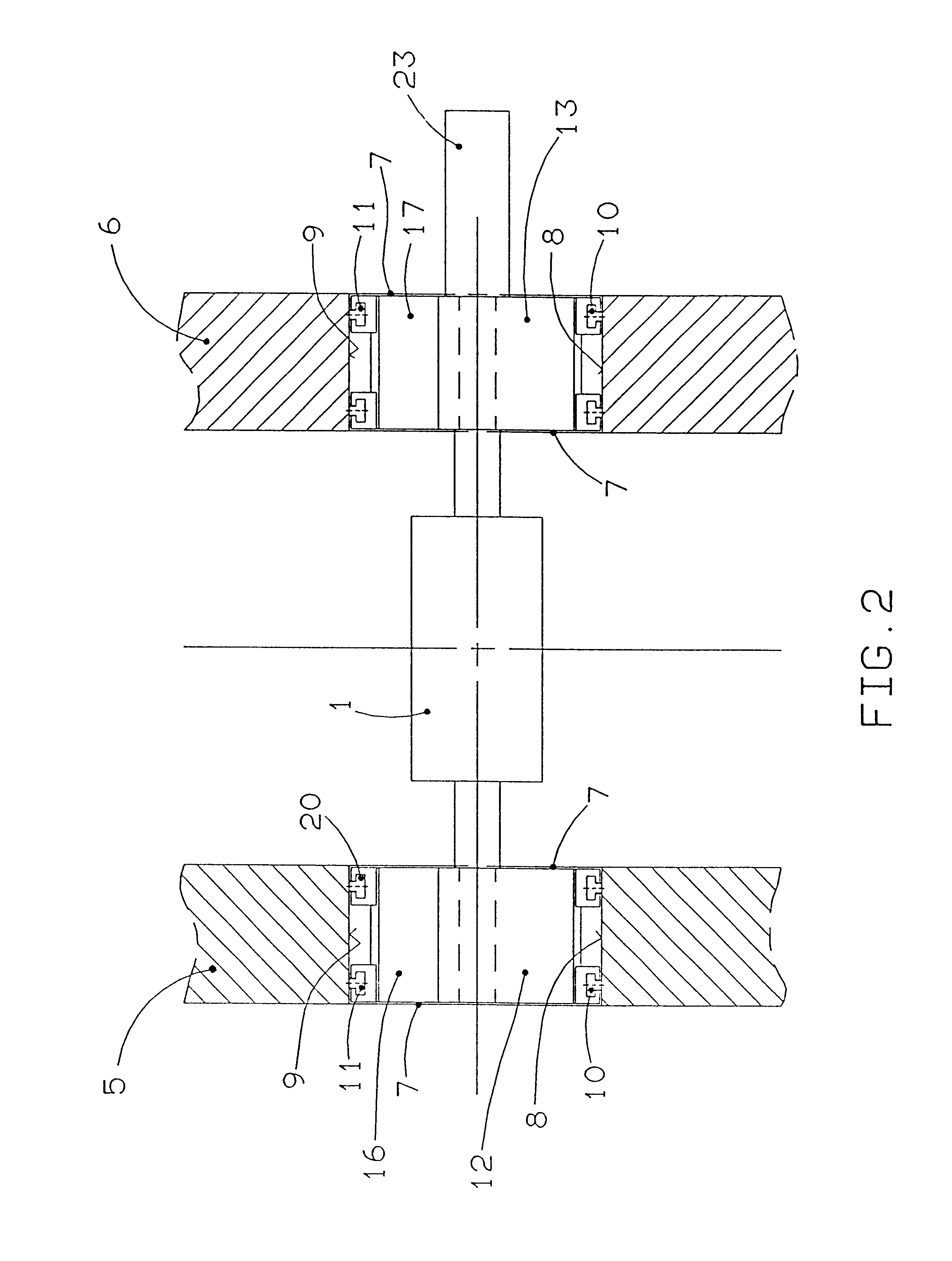

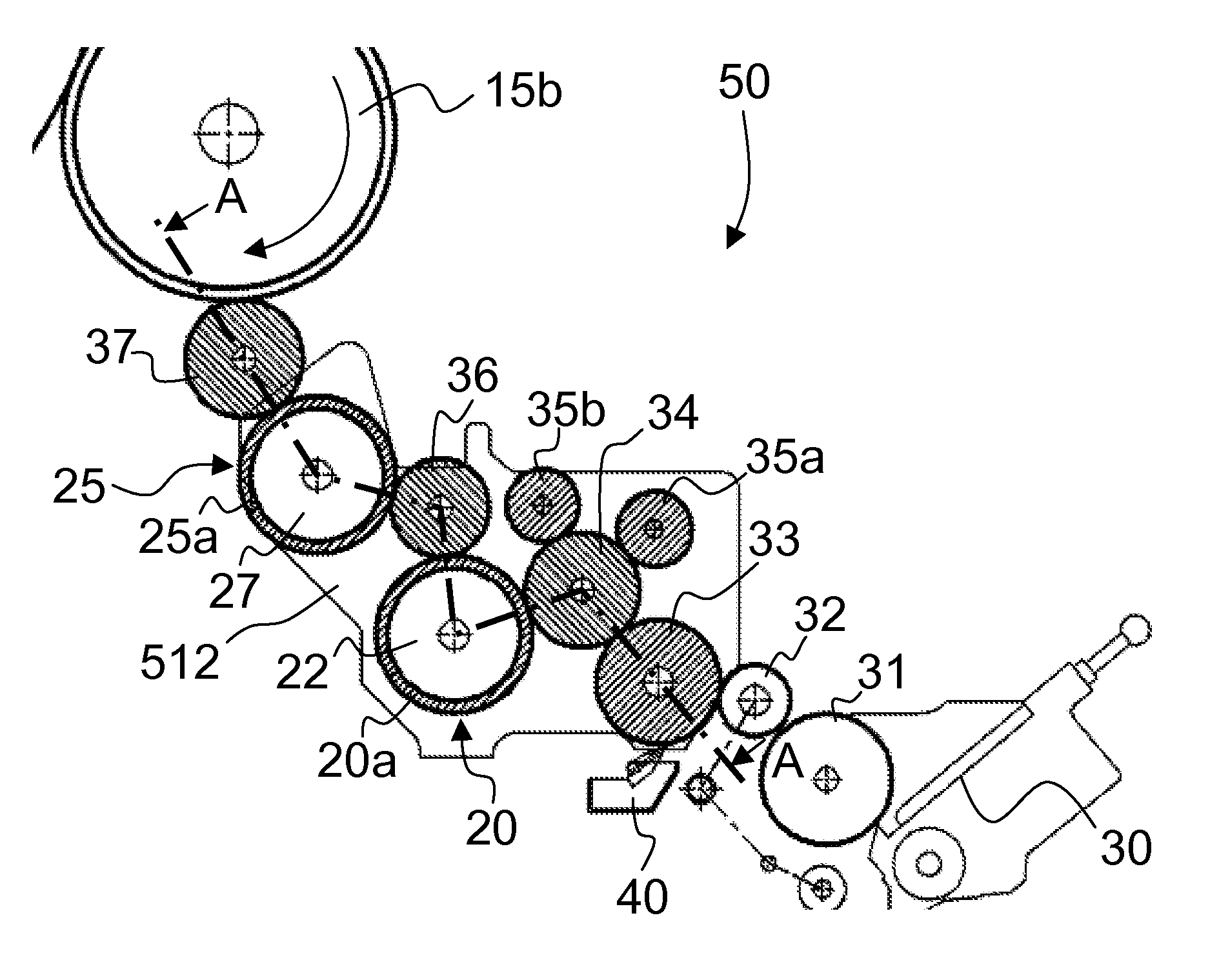

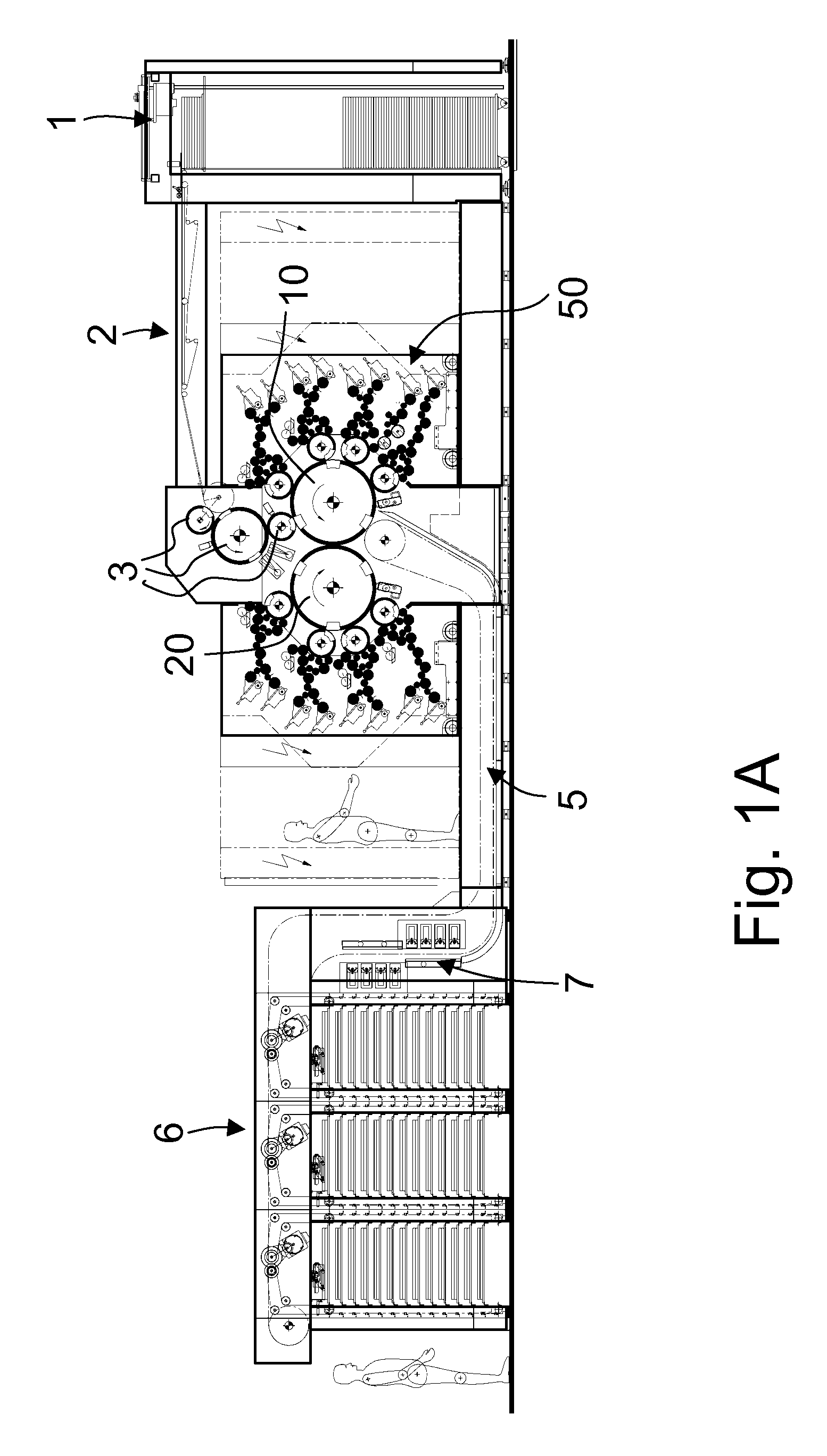

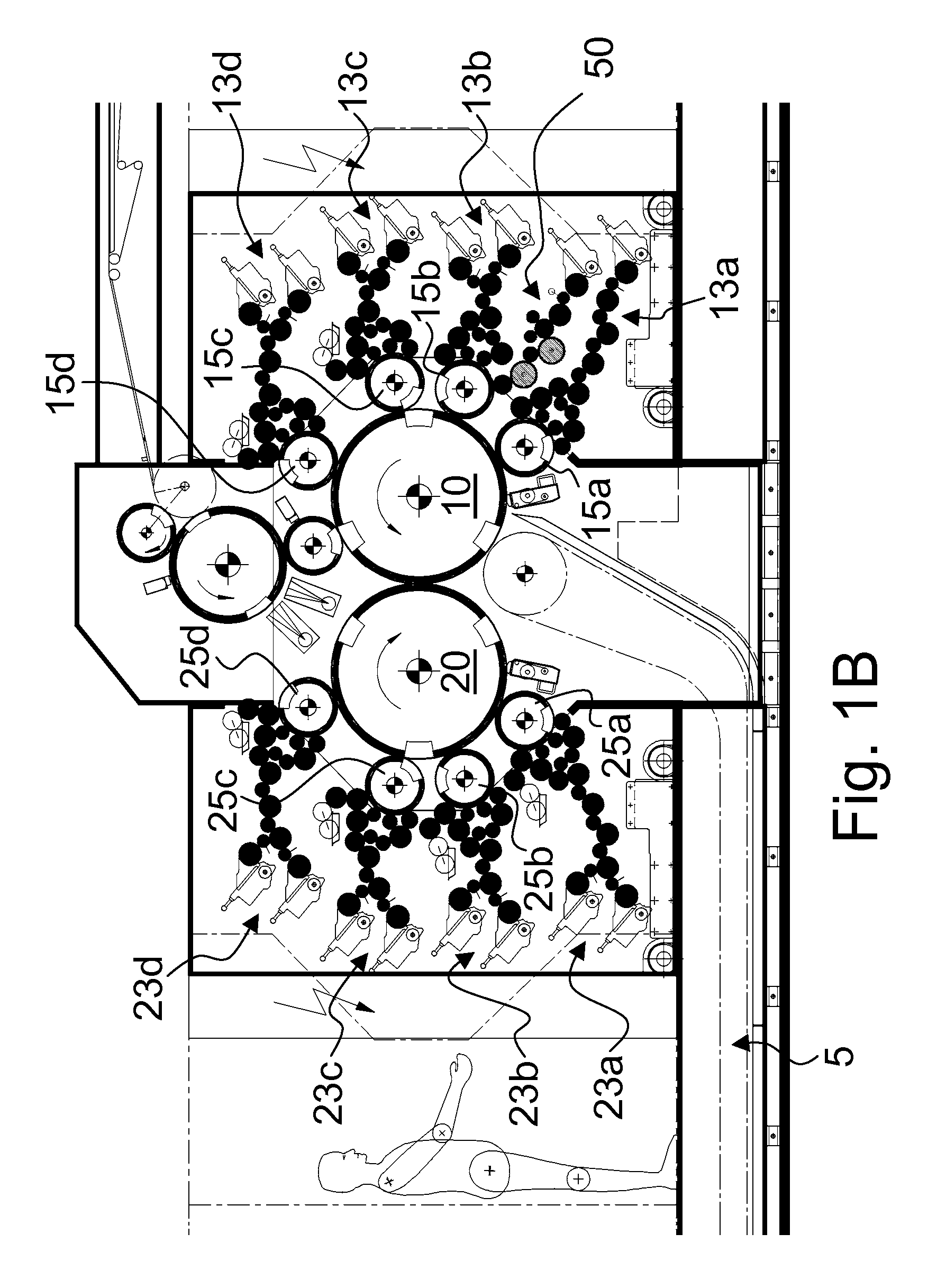

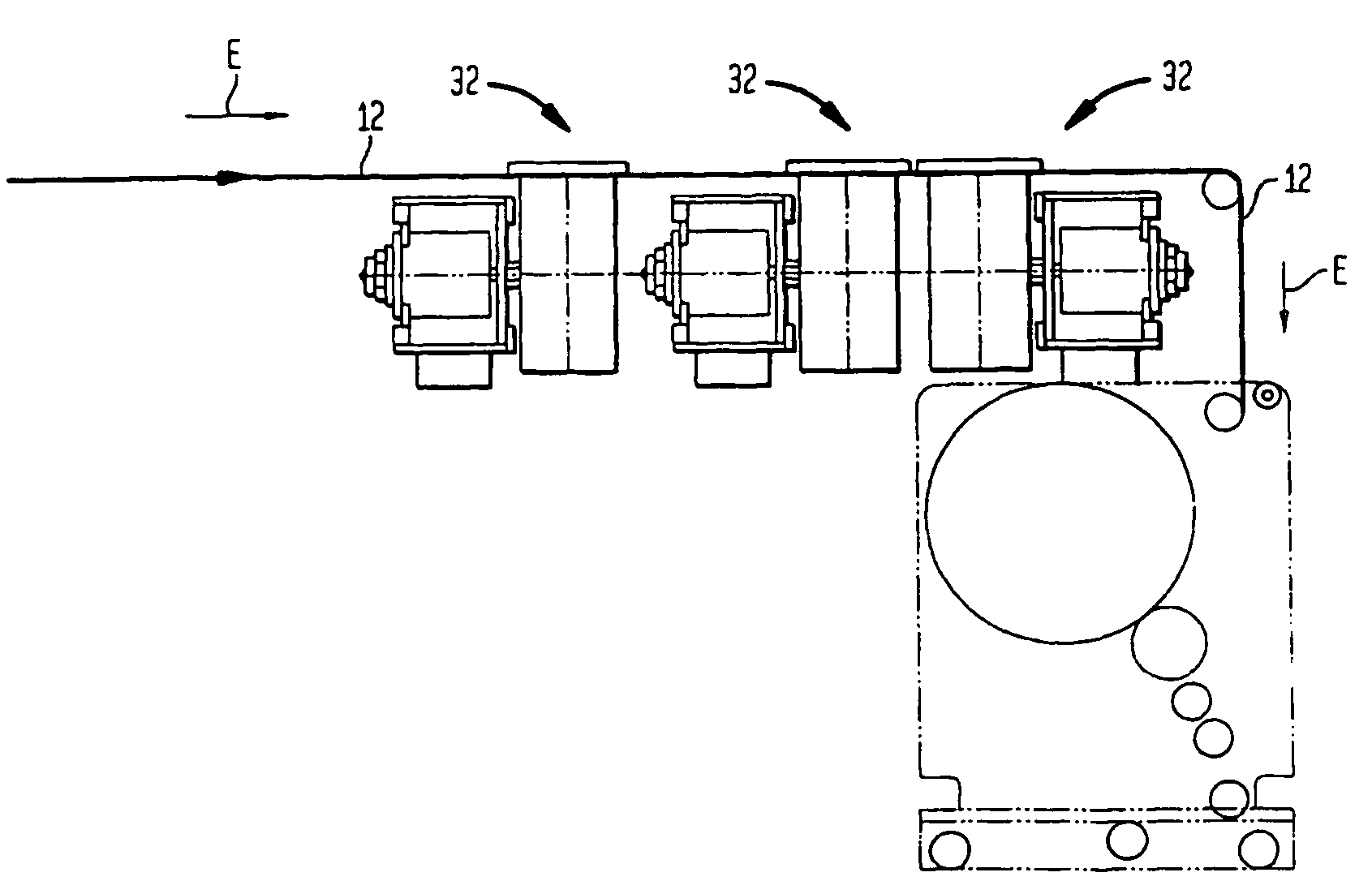

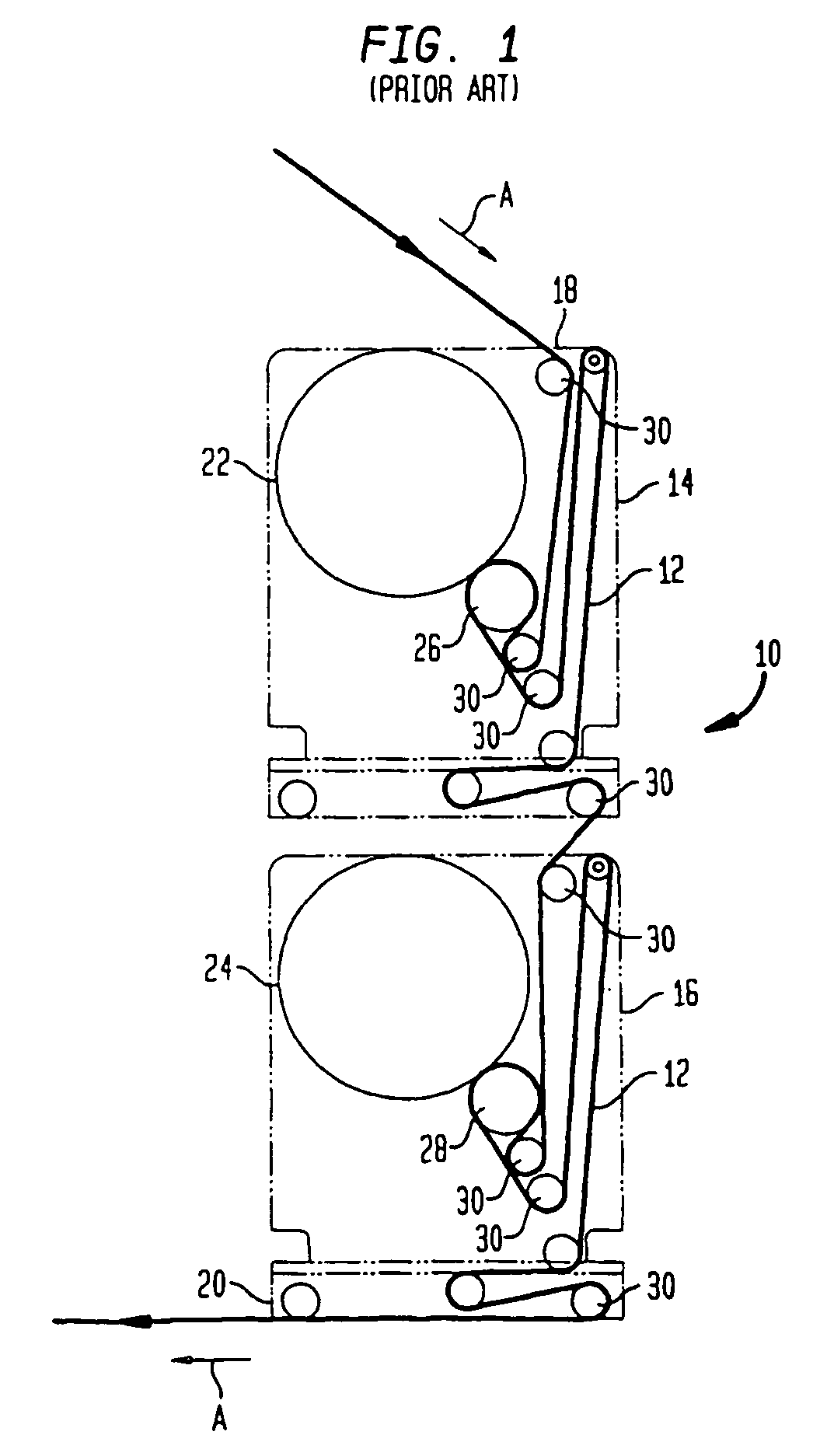

Method and Apparatus for Forming an Ink Pattern Exhibiting a Two-Dimensional Ink Gradient

InactiveUS20100089261A1Increase distanceIncrease the oscillation amplitudeRotary intaglio printing pressOther printing apparatusEngineeringPrinting press

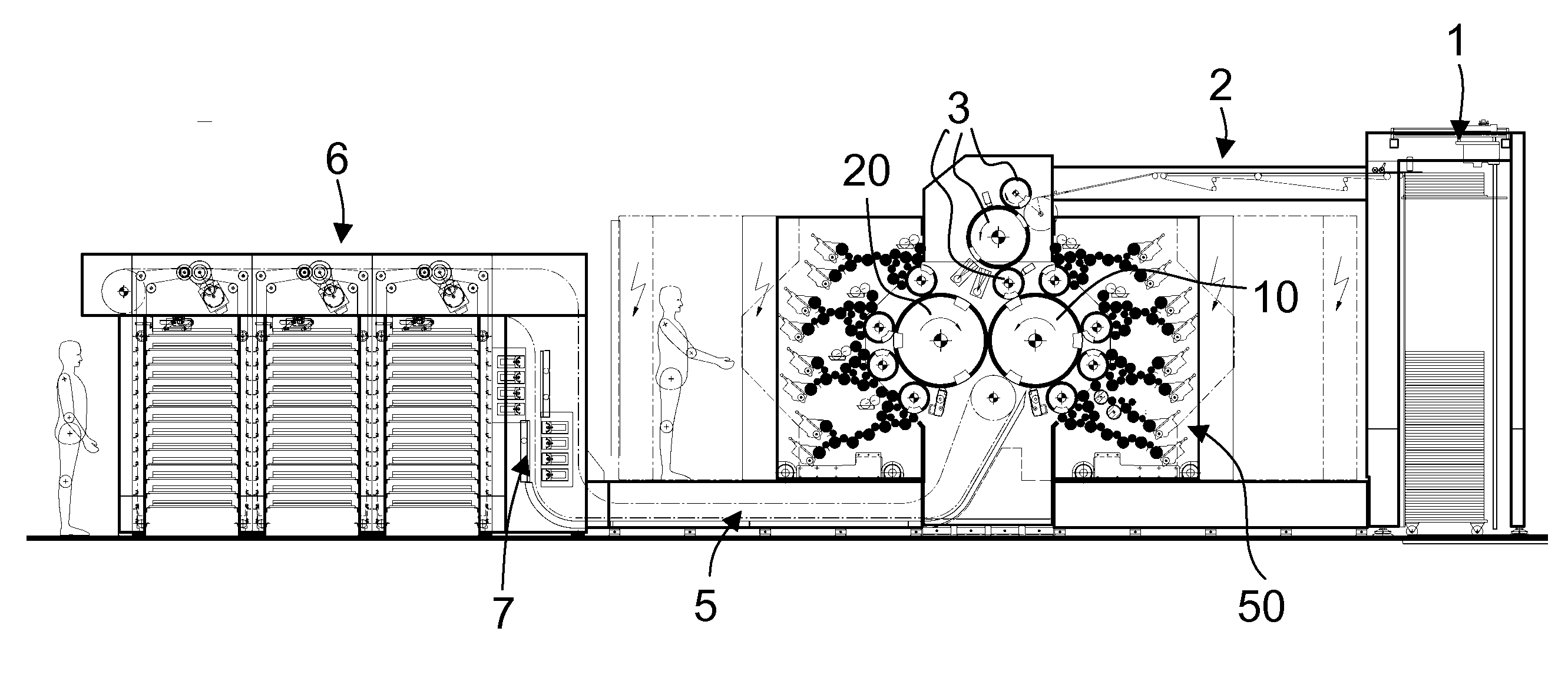

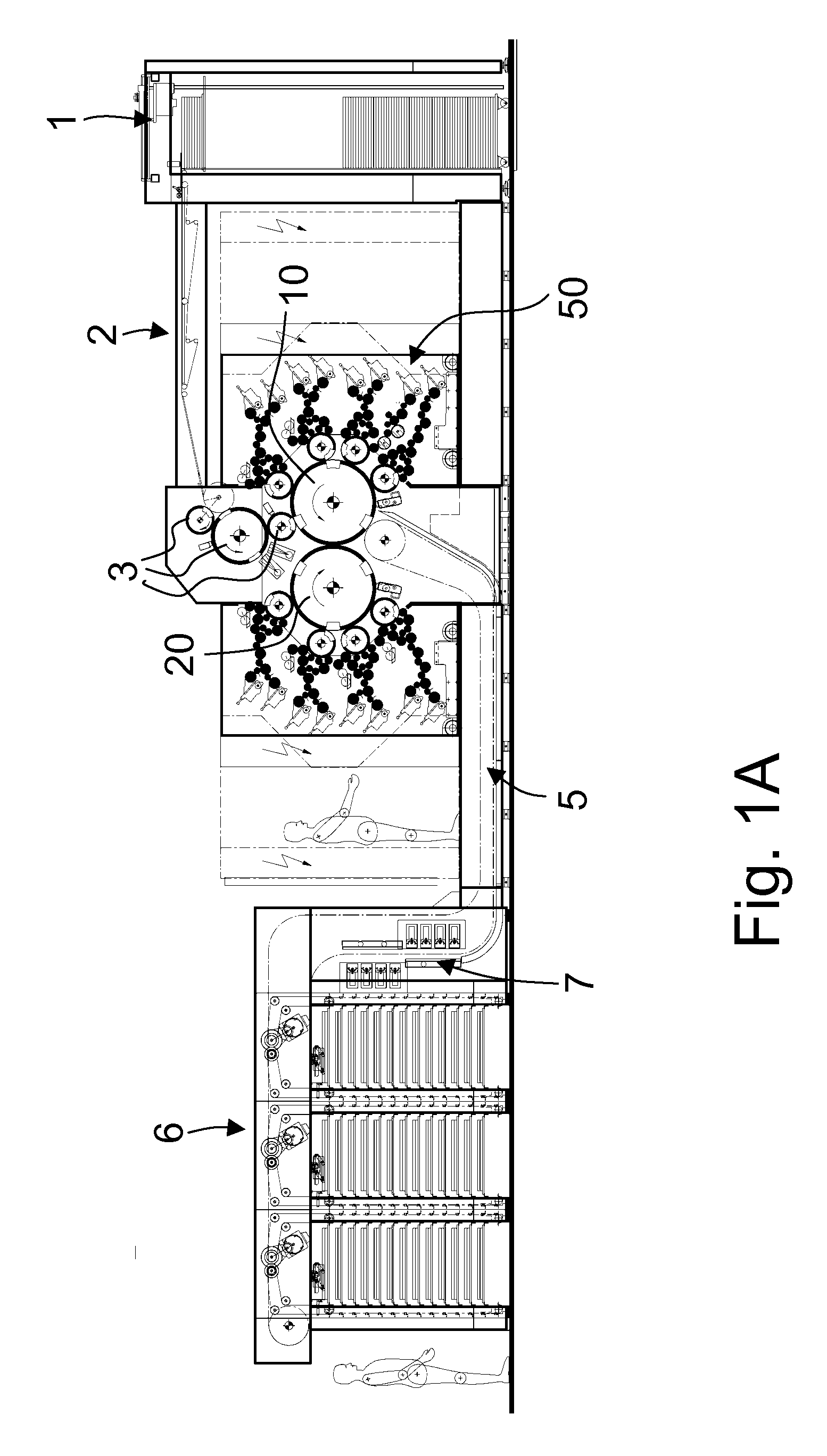

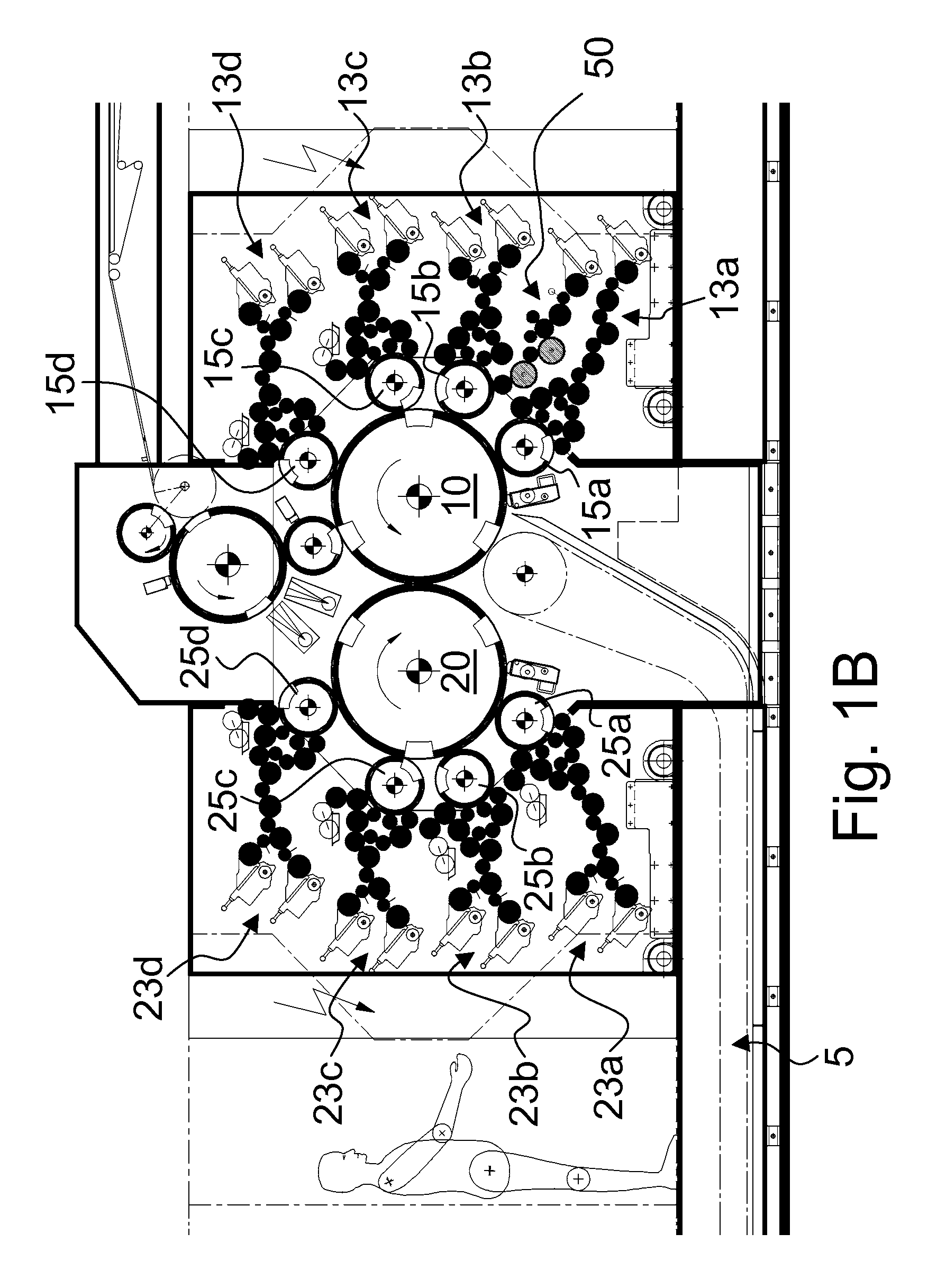

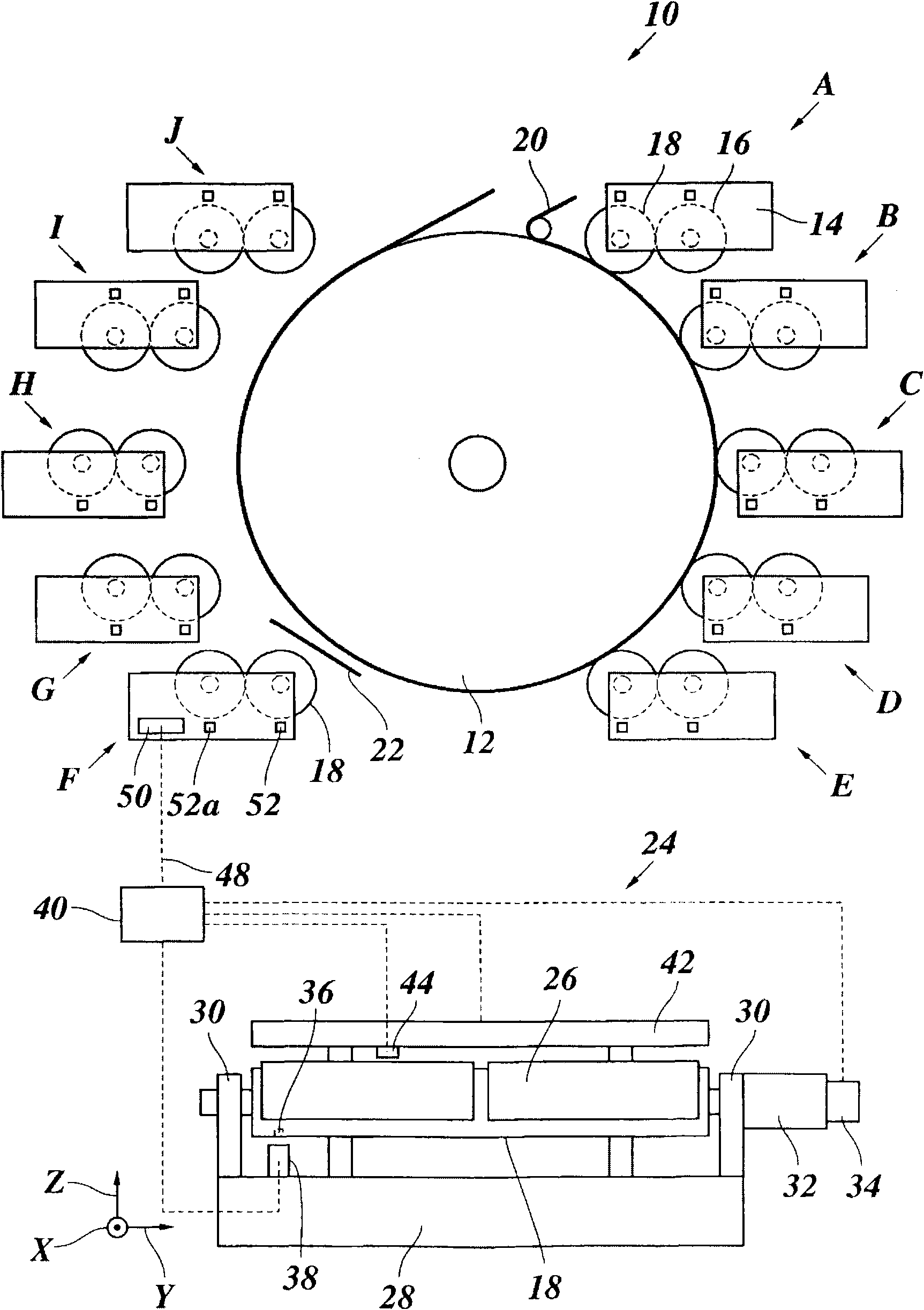

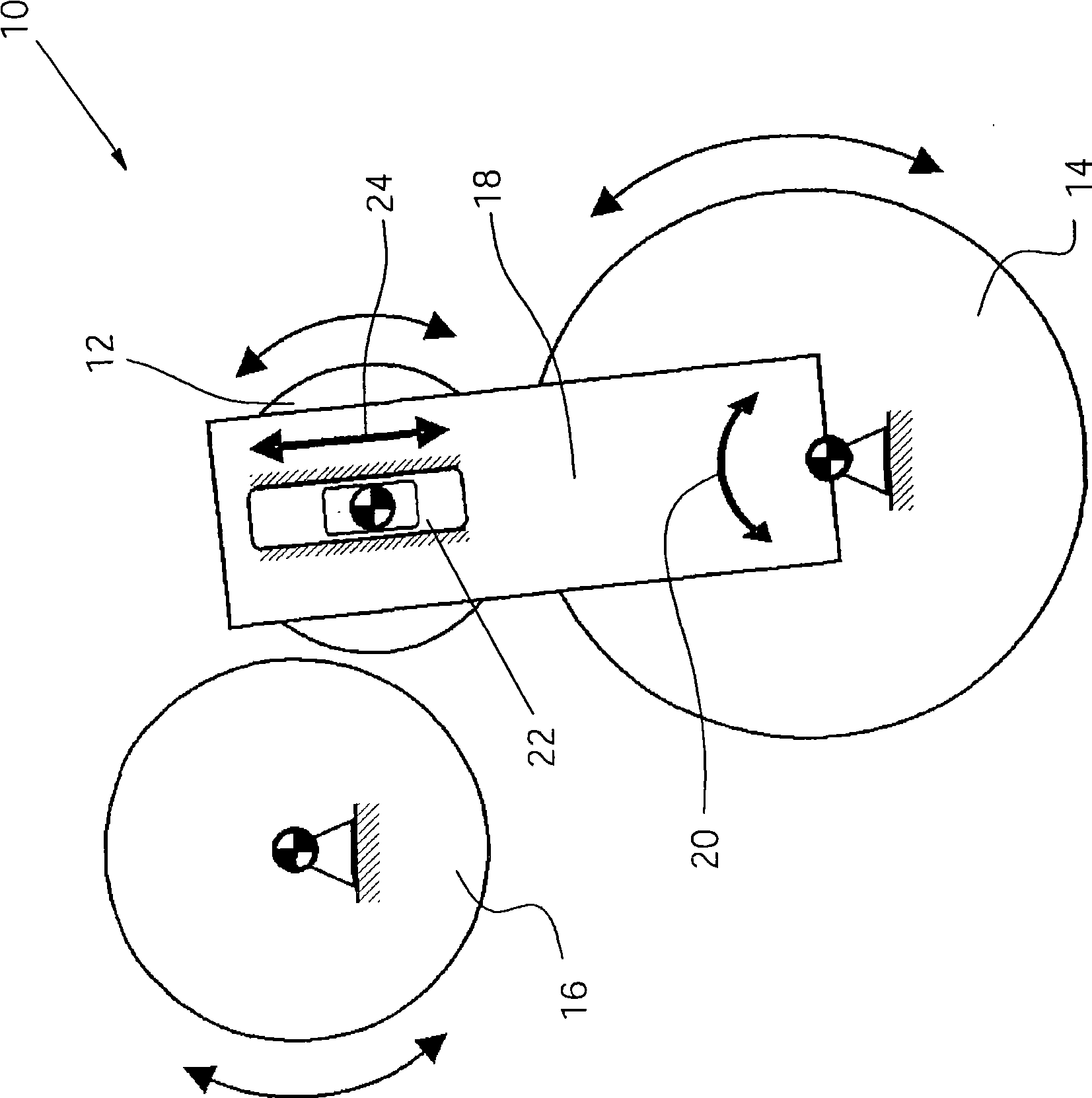

There is described a method and an inking apparatus (50) for forming an ink pattern (80) on the surface of a form cylinder (15b) of a printing press, which ink pattern (80) exhibits, at least in part, a two-dimensional ink gradient extending in an axial direction and a circumferential direction on the surface of the form cylinder (15b). At least first and second chablon cylinders (20, 25) are placed one after the other along an inking path of the ink train (20, 25, 30, 31, 32, 33, 34, 35a, 35b, 36, 37) inking the form cylinder (15b) for distributing ink in the axial and circumferential directions and means (200, 201, 210, 211, 212, 250, 251, 260, 261, 262) are provided for subjecting the first and second chablon cylinders (20, 25) to cyclical oscillation movements in the axial direction and the circumferential direction.

Owner:KBA NOTASYS SA

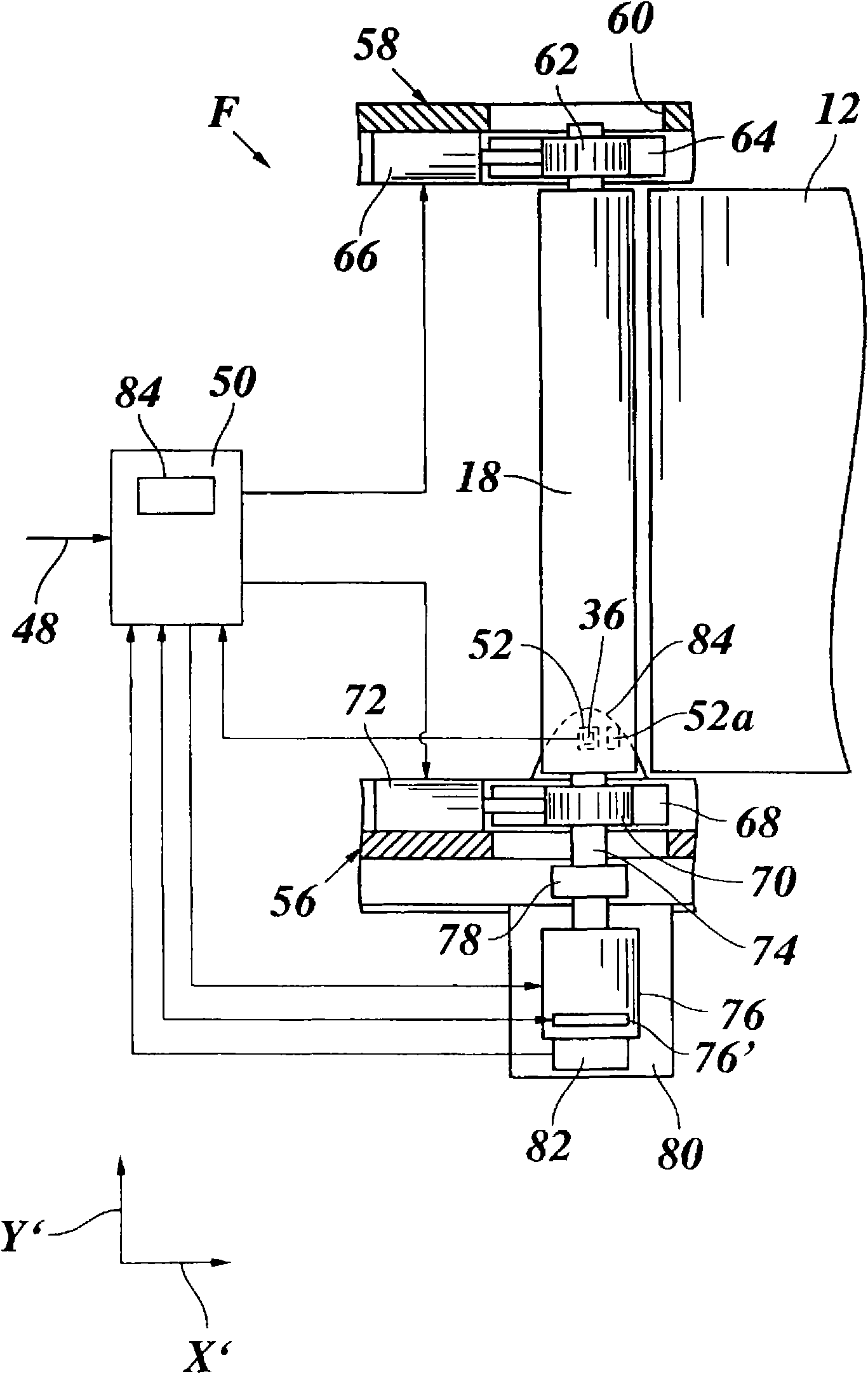

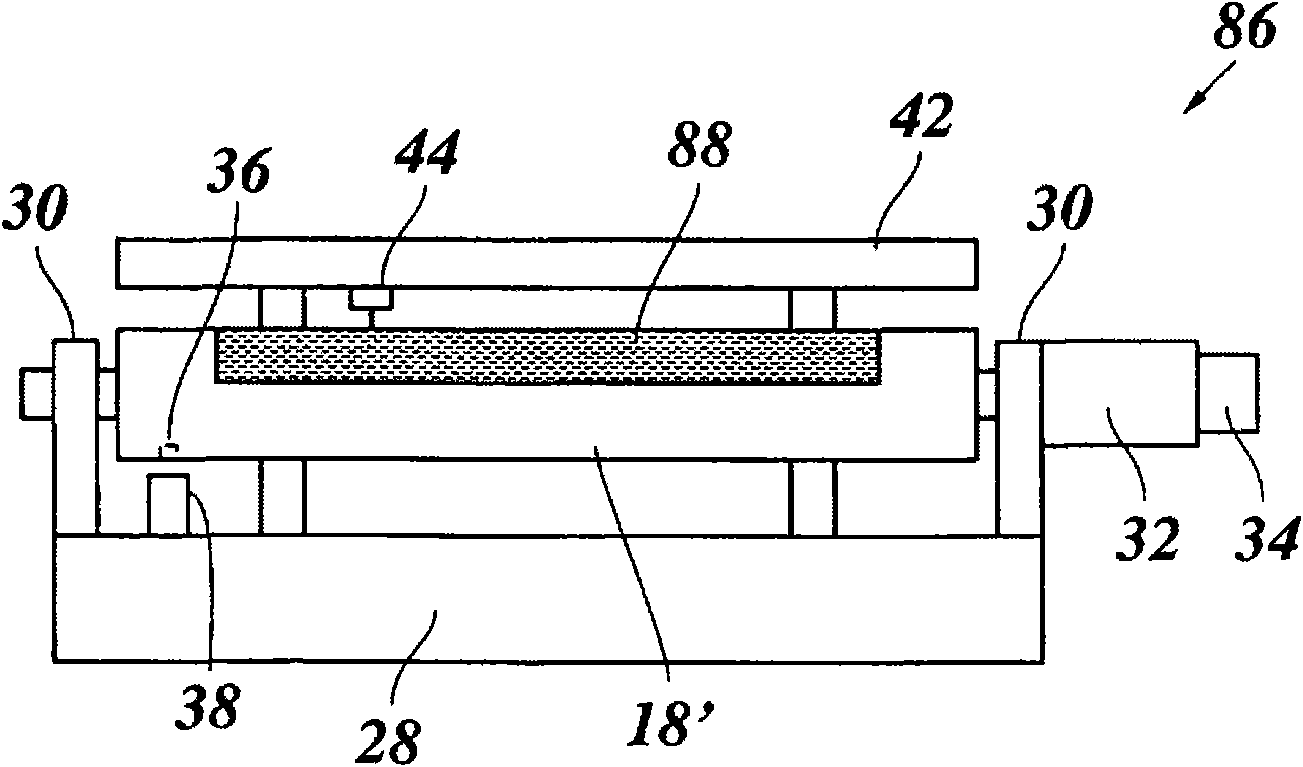

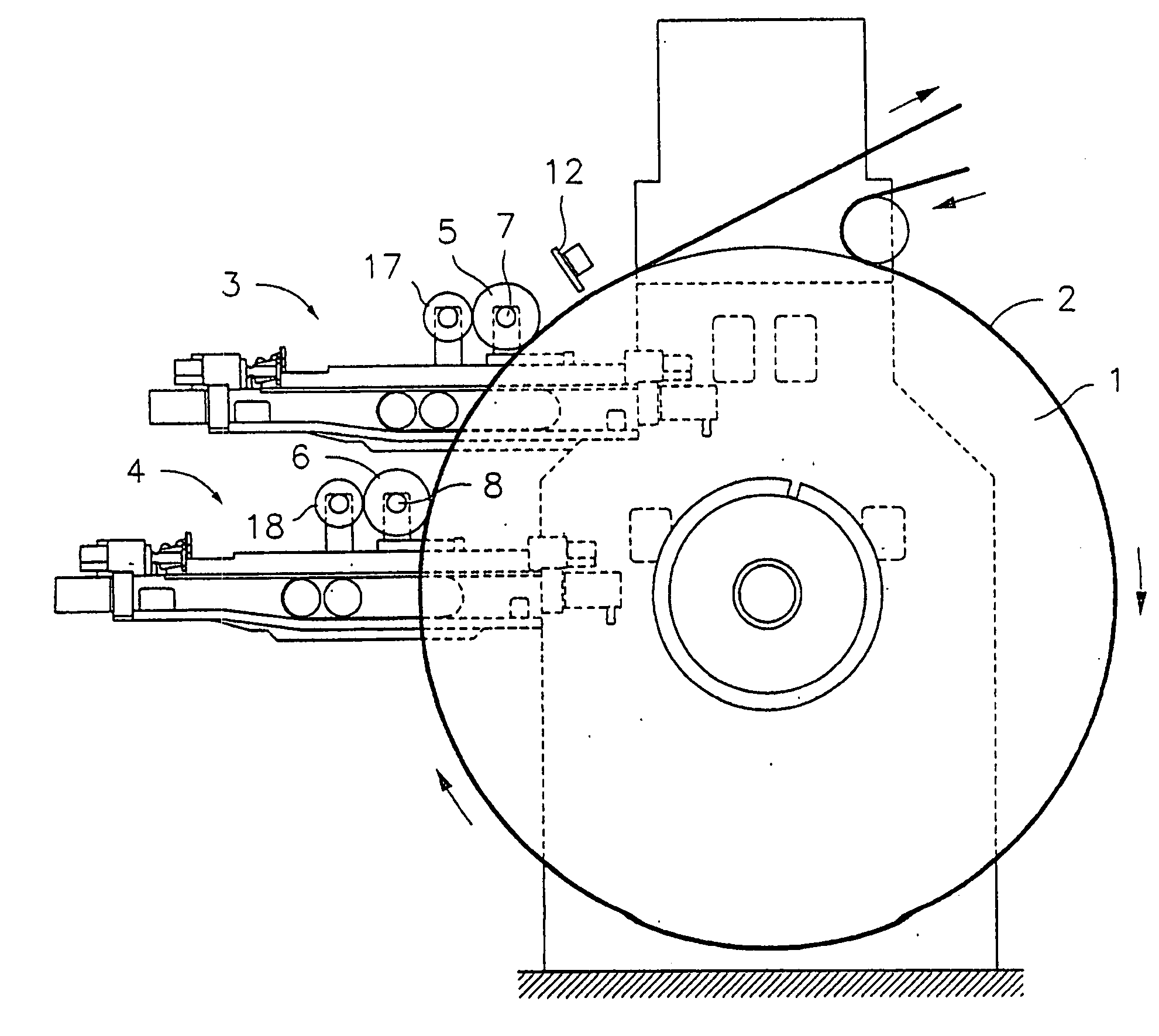

Rotary printing press and method for adjusting a cylinder thereof

ActiveCN101594995AQuality improvementNo lossCylinder pressesRotary intaglio printing pressEngineeringPrinting press

The invention relates to a rotary printing press comprising a number of colour decks (A-J), at least one of which comprises a cylinder (16, 18), and an adjusting system for adjusting the position of the cylinder (16, 18) in relation to at least one other component (12) of said printing press. Said rotary printing press is characterised in that the at least one colour deck (F) comprises a control unit (50) that is configured to capture and process data relating to the cylinder, said data describing the topography of the surface of said specific cylinder and / or a spatial relationship between a printing pattern and a reference mark (36) embodied on the cylinder. The control unit (50) is configured such that the adjusting system can be controlled according to said adjusting data in order to optimally adjust the position of the cylinder for printing, producing little or no waste at all.

Owner:BOBST BIELEFELD

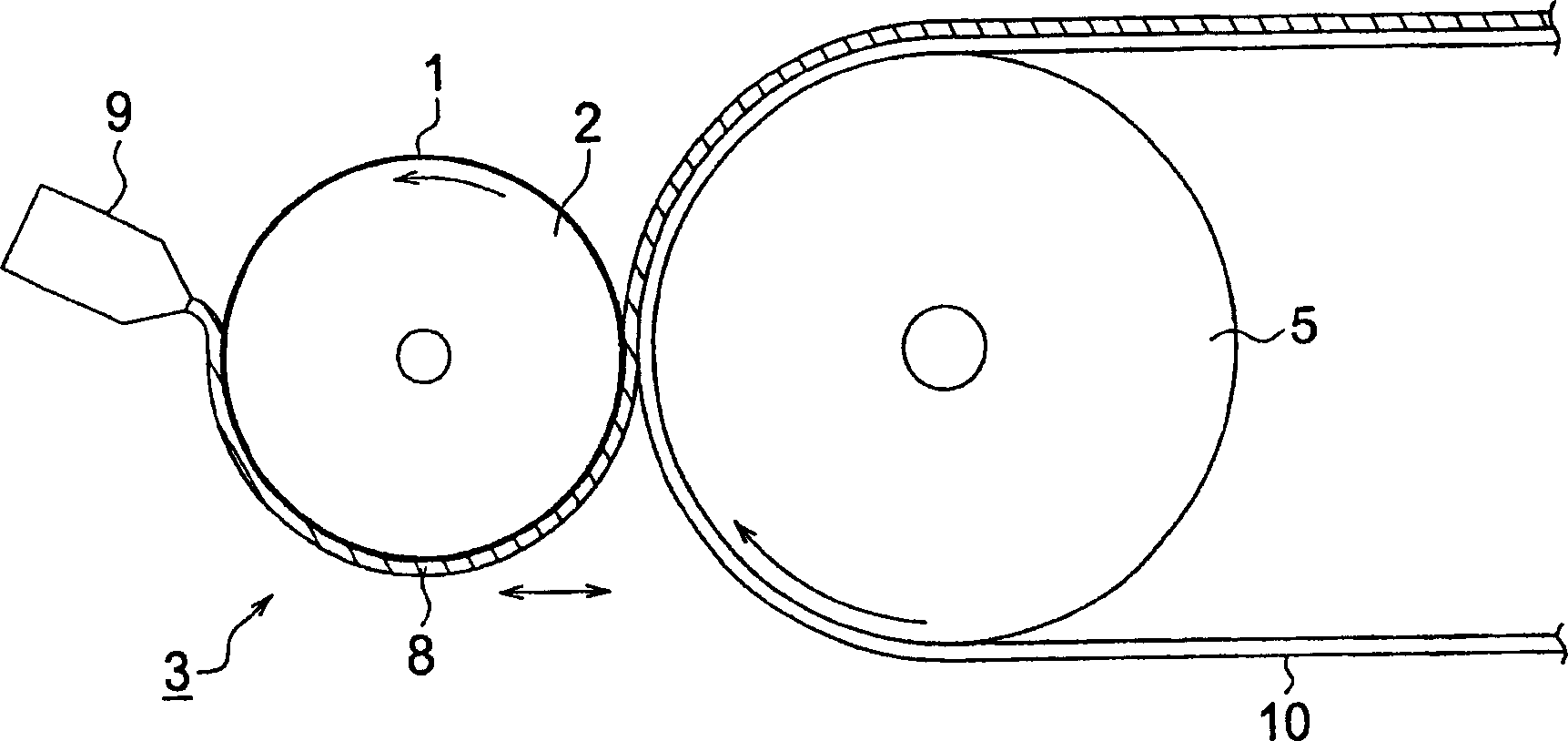

Web-fed rotary printing machine

In order to provide a rotary printing machine for direct printing, in which the printing-assembly cylinders are guided in a stable manner by means of a cost-effective device, the forme cylinder and the impression cylinder of a printing assembly are mounted, adjustably in terms of their mutual spacing, in side walls. At least one of the two cylinders is mounted on both sides in slides movable on straight guide elements which are arranged in each case on at least one of two opposite panels of an aperture in the side walls.

Owner:MANROLANAD AG

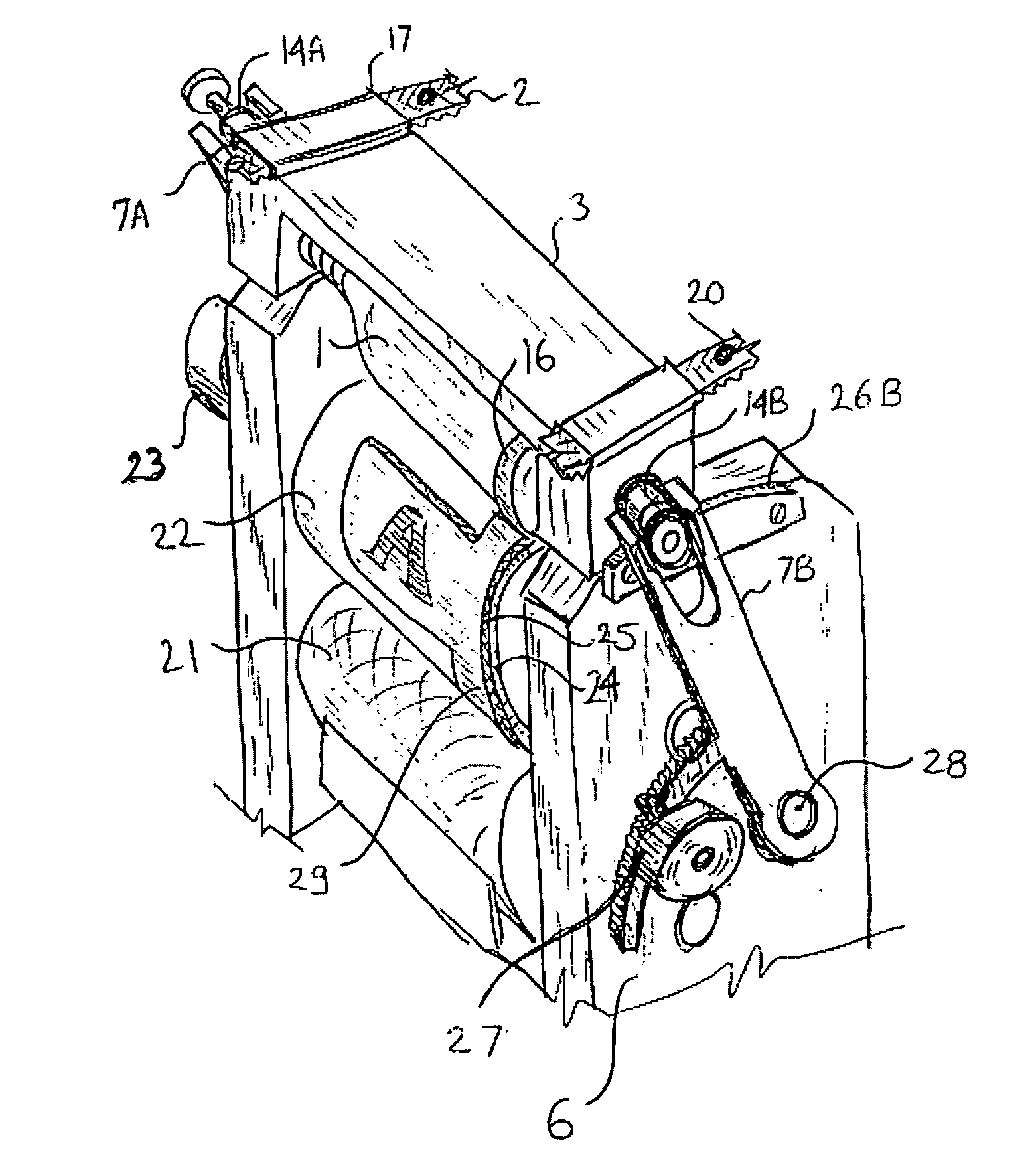

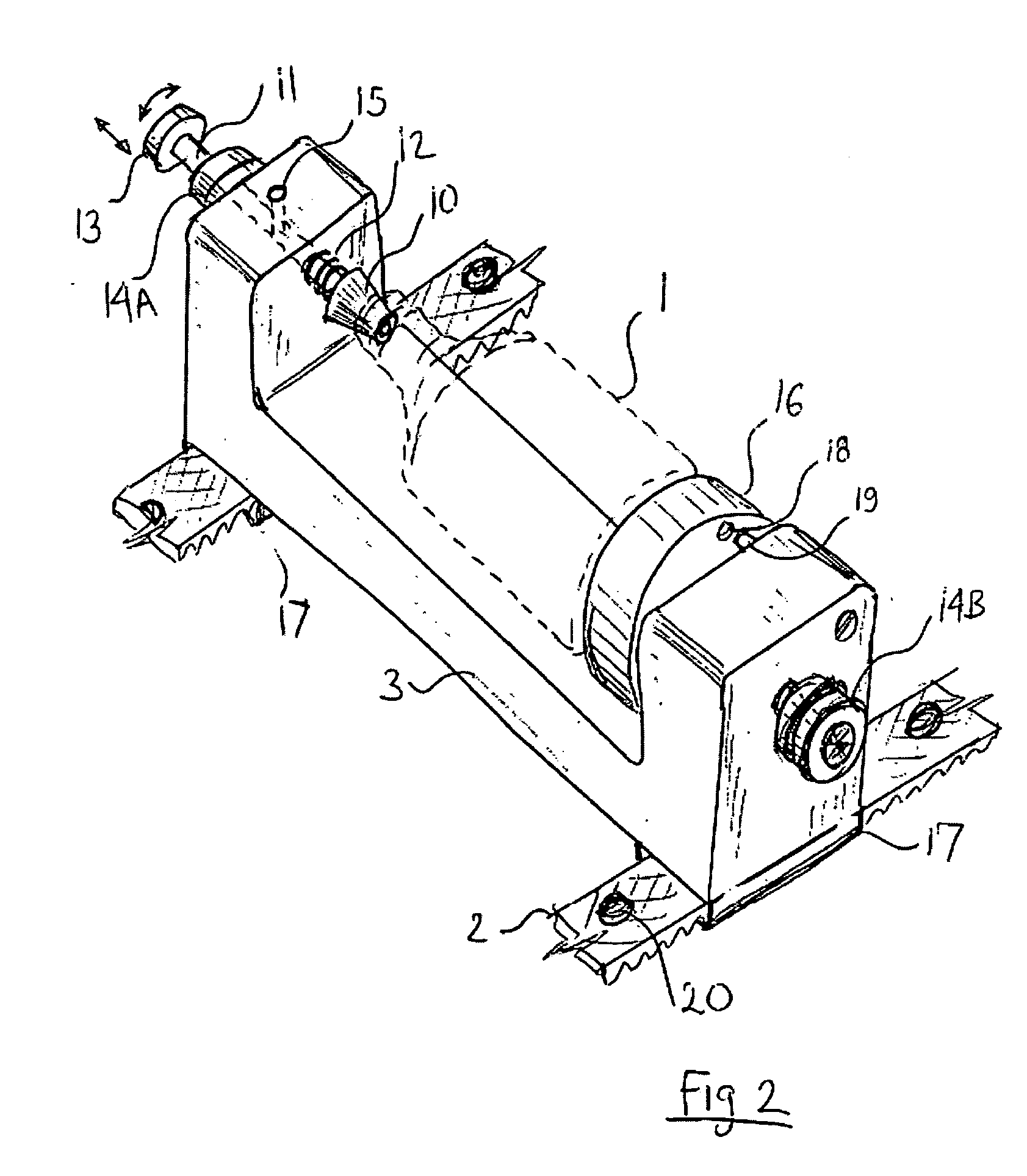

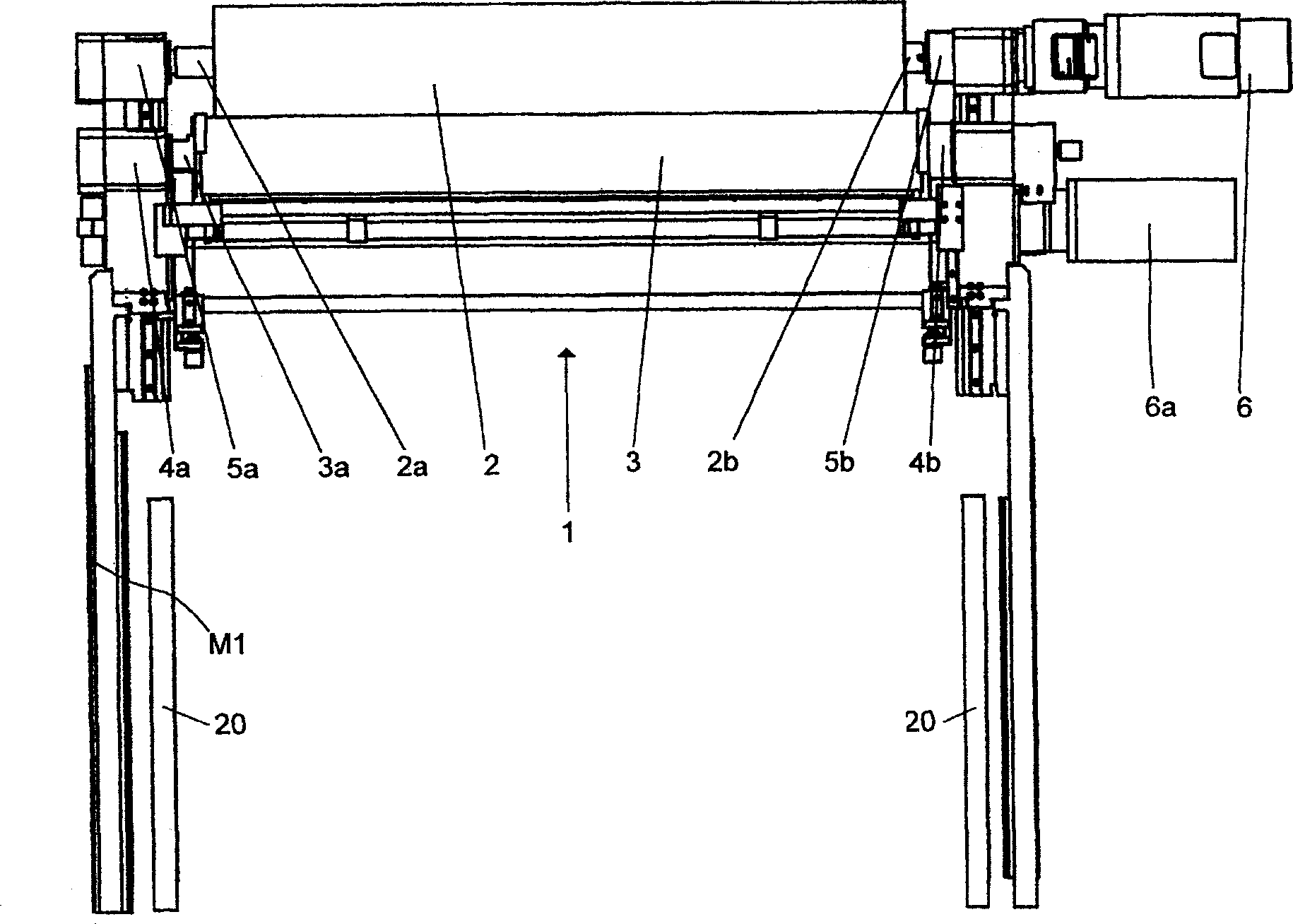

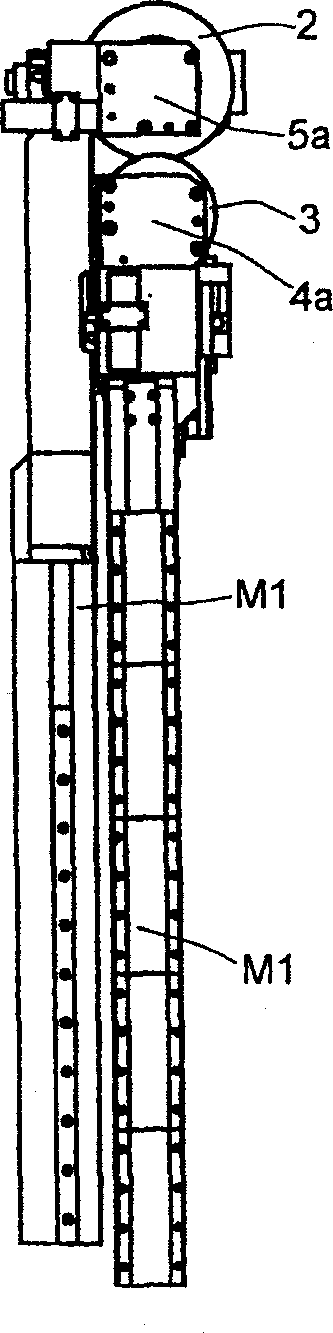

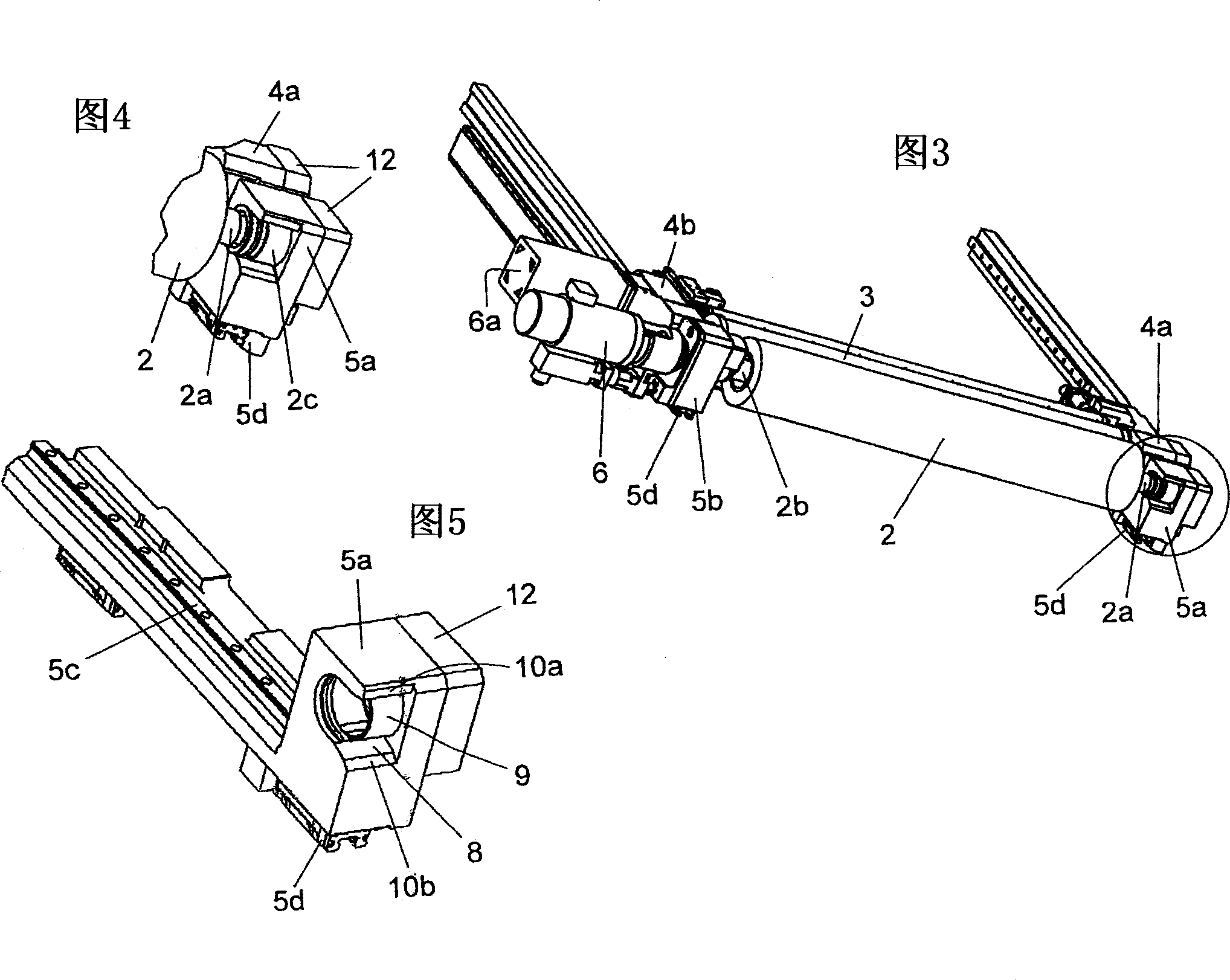

Supporting and releasably holding device for a printing cylinder hub

InactiveCN1746025AHighly reliableSolution to short lifeRotary letterpress machinesRelief printingMechanical engineering

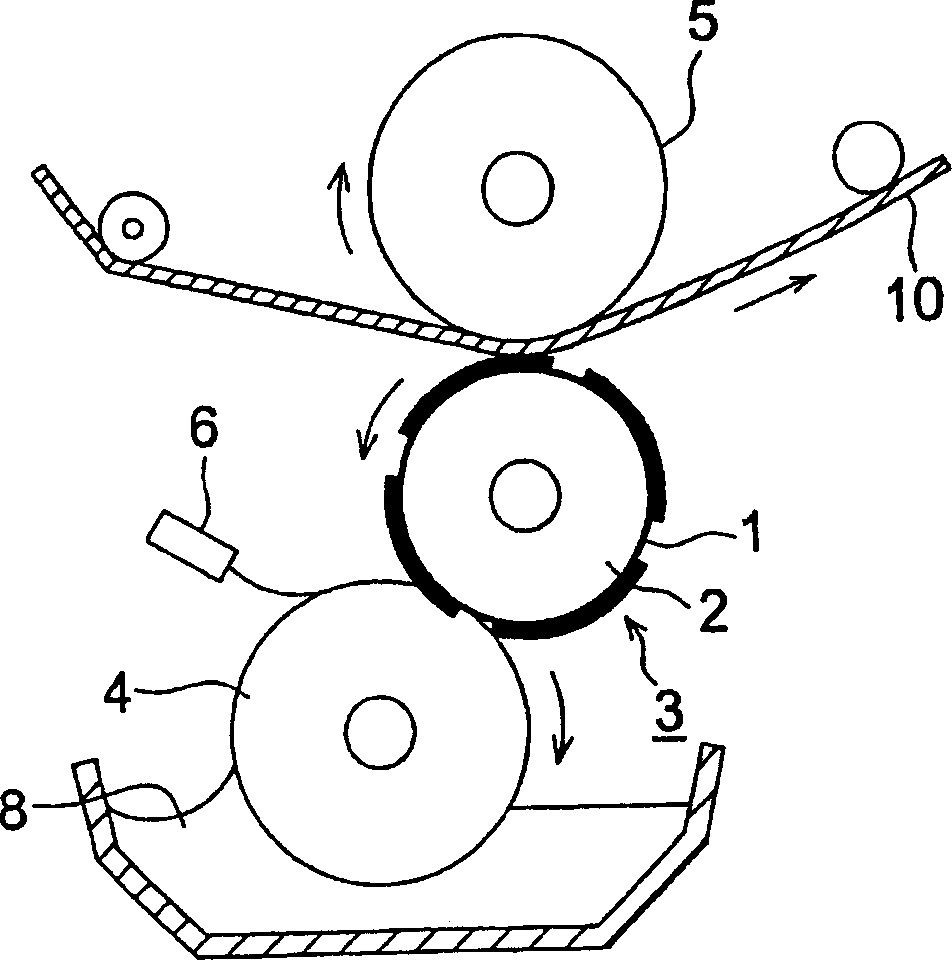

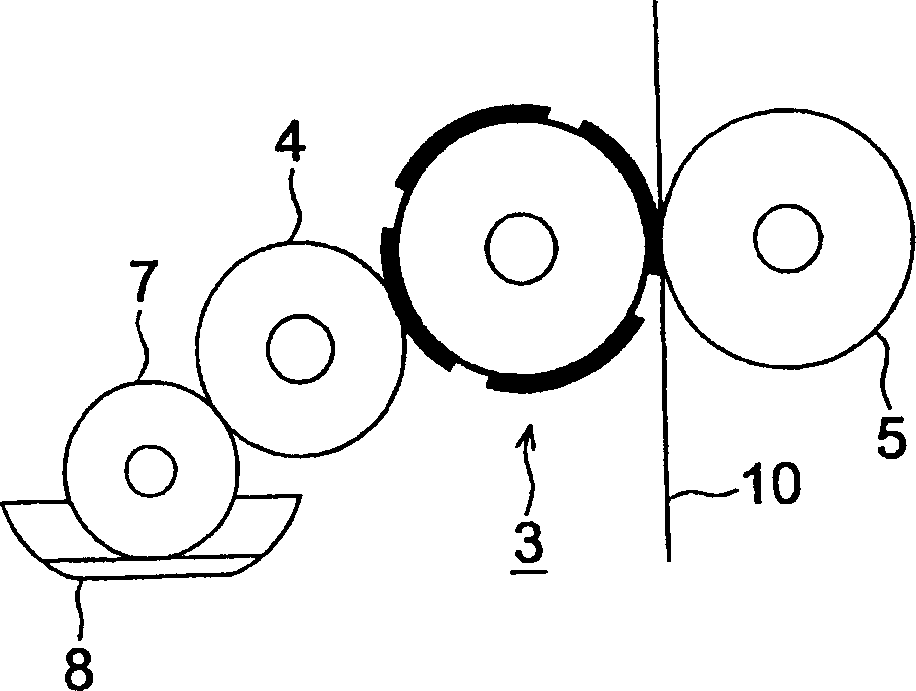

A printing machine colour assembly having a main or clich-carrying cylinder (2) and an interlocking or screened cylinder (3), each carried at its hubs (2a, 2b; 3a, 3b) by first (4a; 5a - operator side) and second (4b; 5b - motor side) slidable supports positioned on different sides of the printing machine and parallel displaceable independently from one another. The first support (5a) of at least the main cylinder (2) is detachable from the respective hub (2a) to cantileverwise position the main cylinder (2) on the second support (5b) thereby carrying out sleeve replacement on the main cylinder (2). At least one auxiliary supporting means (17) at the second support (5b) of at least the main cylinder (2) is designed to engage with, and assist in supporting, it when cantileverwise positioned for replacing a sleeve.

Owner:马里亚·格拉齐亚·瓦伦蒂尼

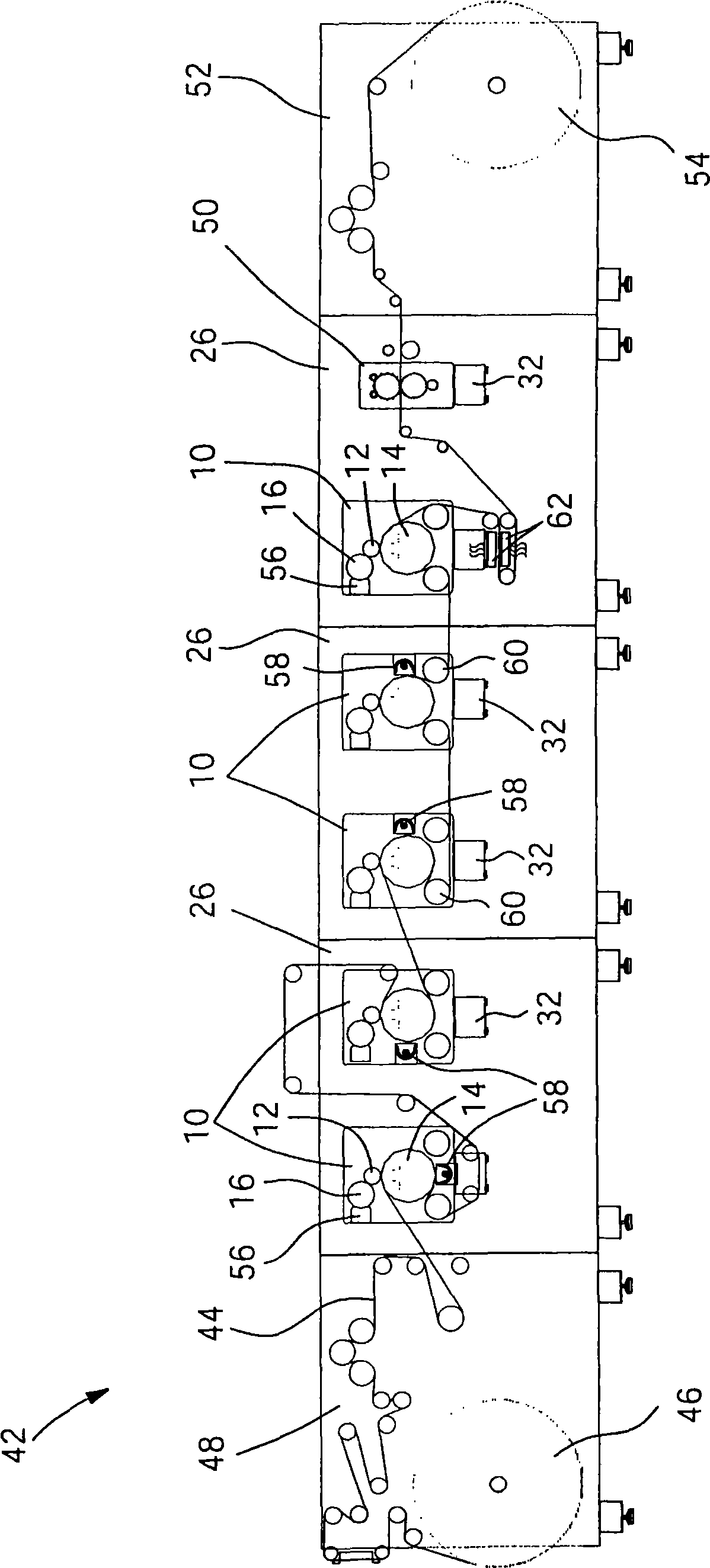

Printing unit and press with format change

InactiveCN101531088AAdjustable contactRotary pressesOther printing apparatusPrinting pressMechanical engineering

The invention relates to a printing unit (10) of compact construction and includes an impression cylinder (14) and a printing form cylinder (12) to be pivoted around the impression cylinder (14) about a pivot axis running parallel to an axis of rotation of the impression cylinder (14). A spacing between the axes of rotation of the printing form cylinder (12) and of the impression cylinder (14) can be varied and the printing form cylinder (14) and the impression cylinder (14) can be set against each other, to form a press nip in which a substrate (44) can be printed. A first drive (38) for producing a rotational movement of the printing form cylinder (12) is connected to the printing form cylinder (12) through a drive train (64). At least one component of the drive train (64) has a torque axis running through the impression cylinder (14). A printing press (42) according to the invention comprises at least one printing unit (10).

Owner:GALLUS DRUCKMASCHINEN GMBH

Color printed laminated structure, absorbent article comprising the same and process for manufacturing the same

InactiveUS9050220B2Wood working apparatusBaby linensEngineeringElectrical and Electronics engineering

Owner:THE PROCTER & GAMBLE COMPANY

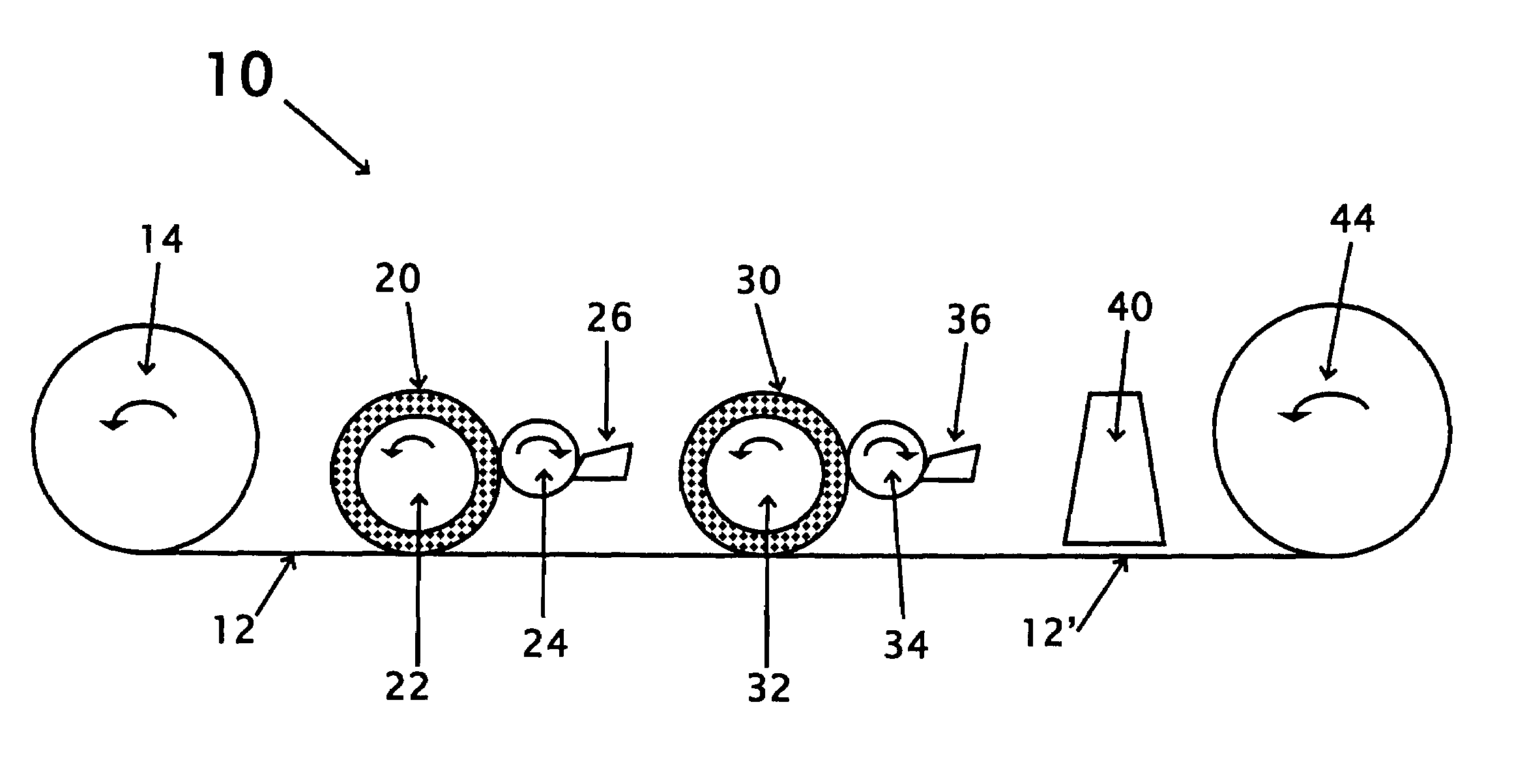

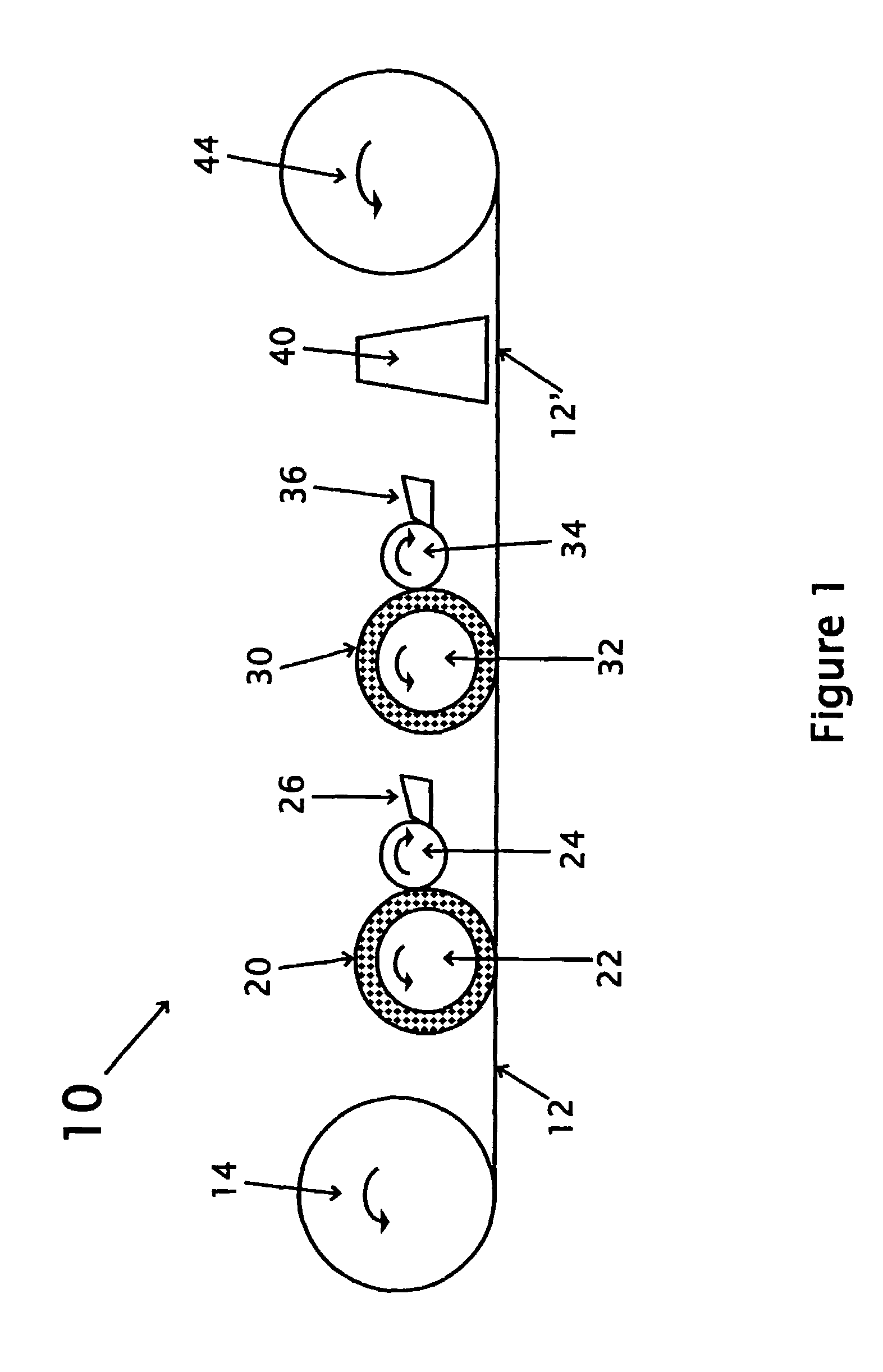

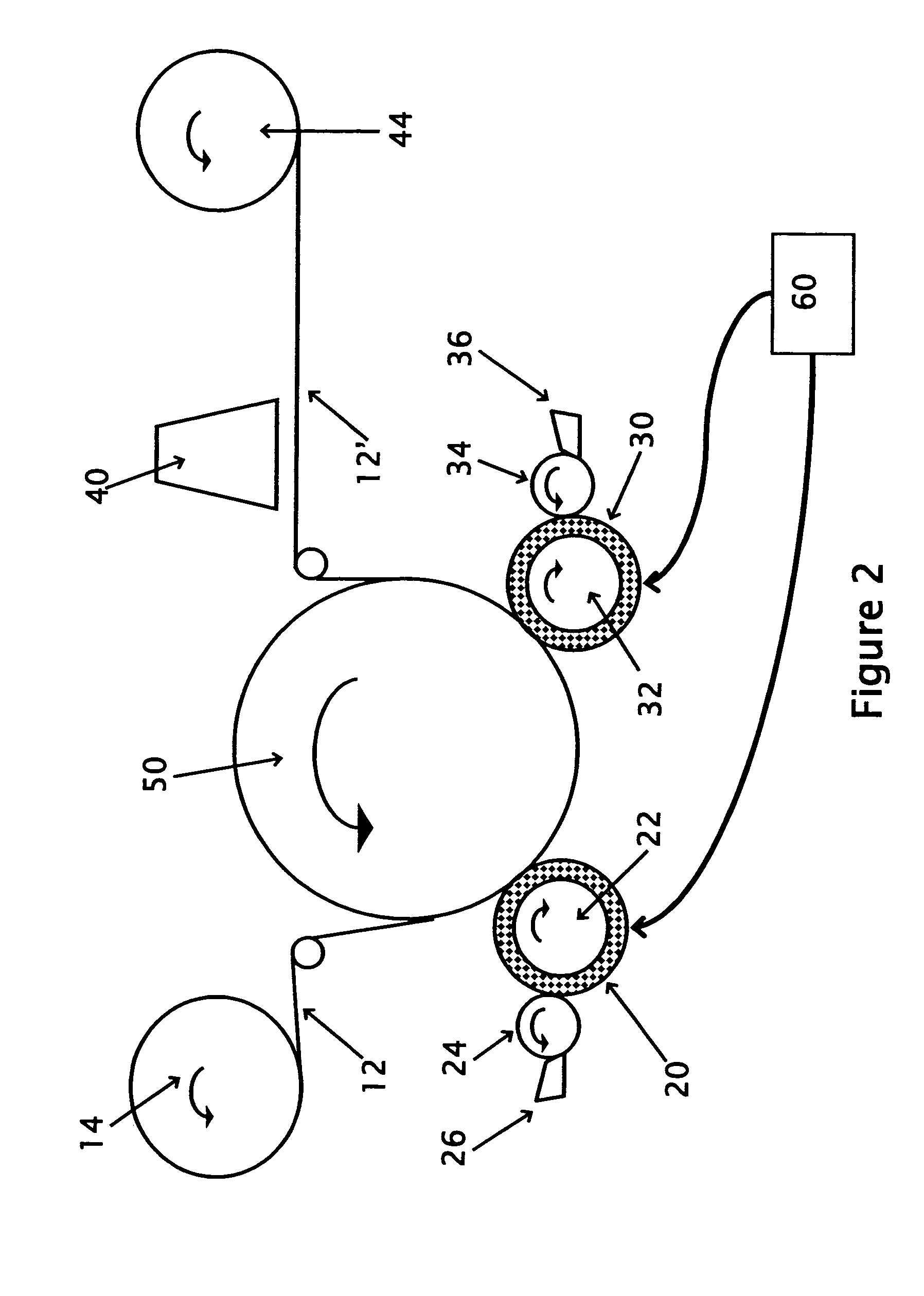

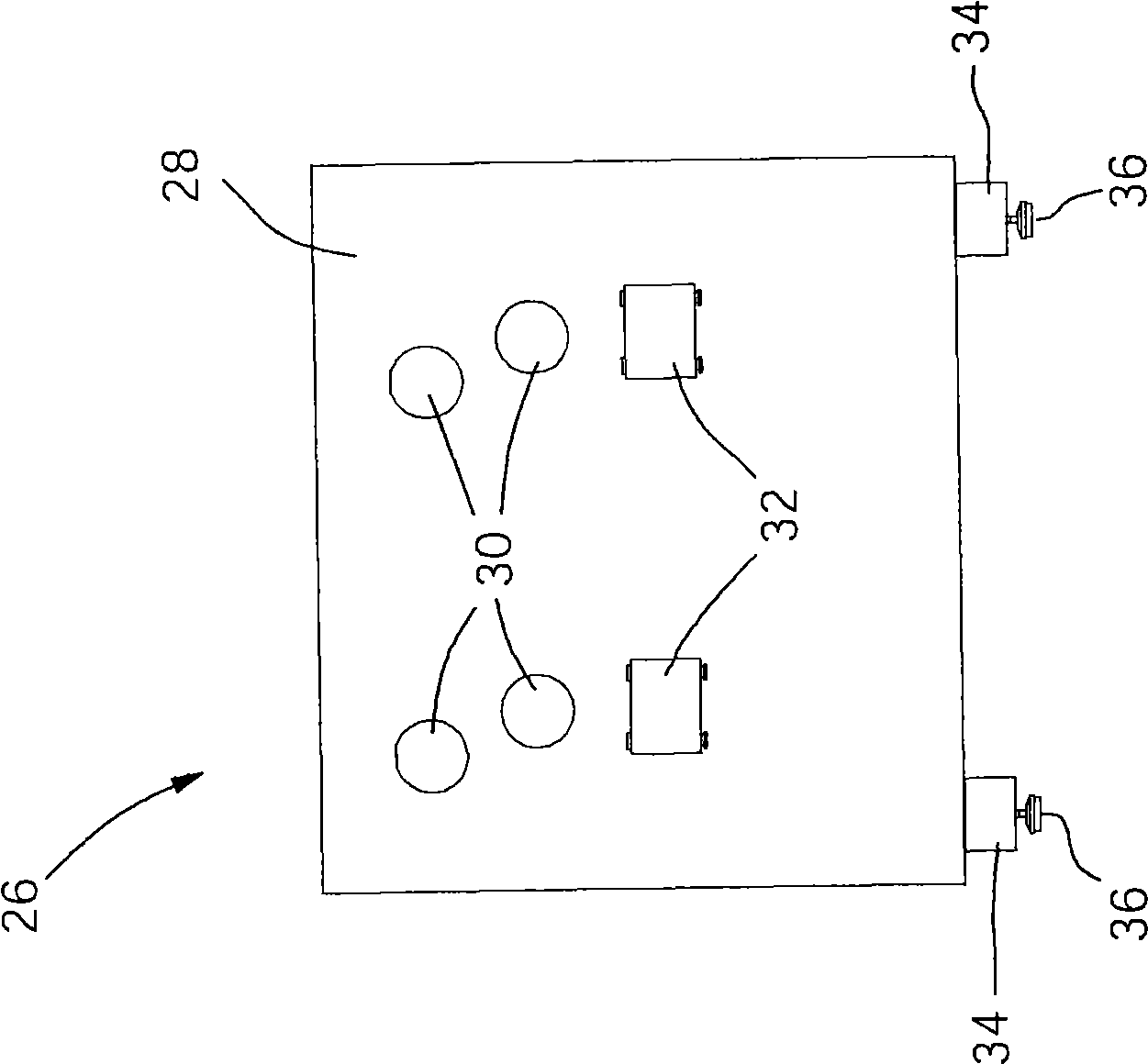

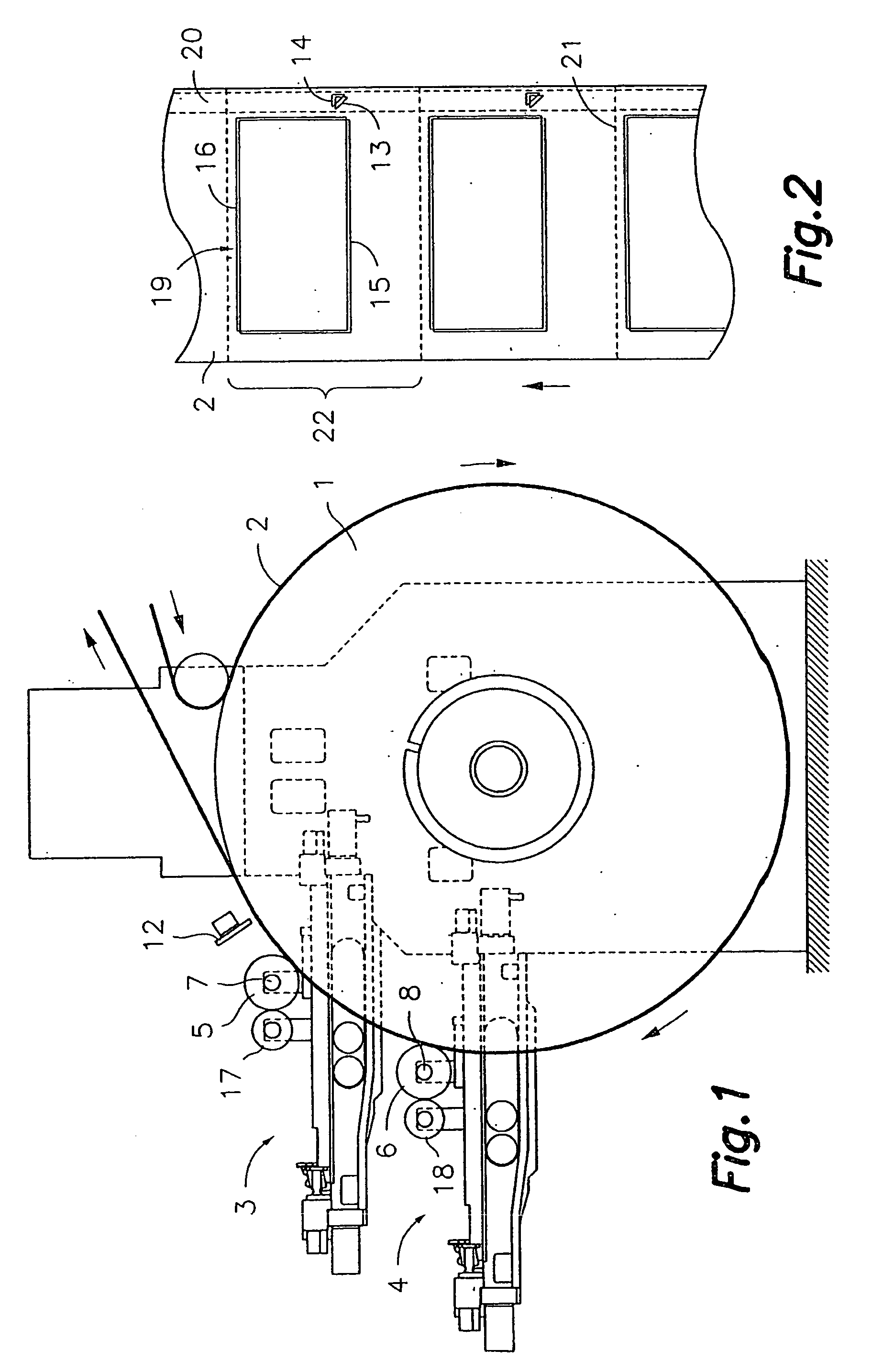

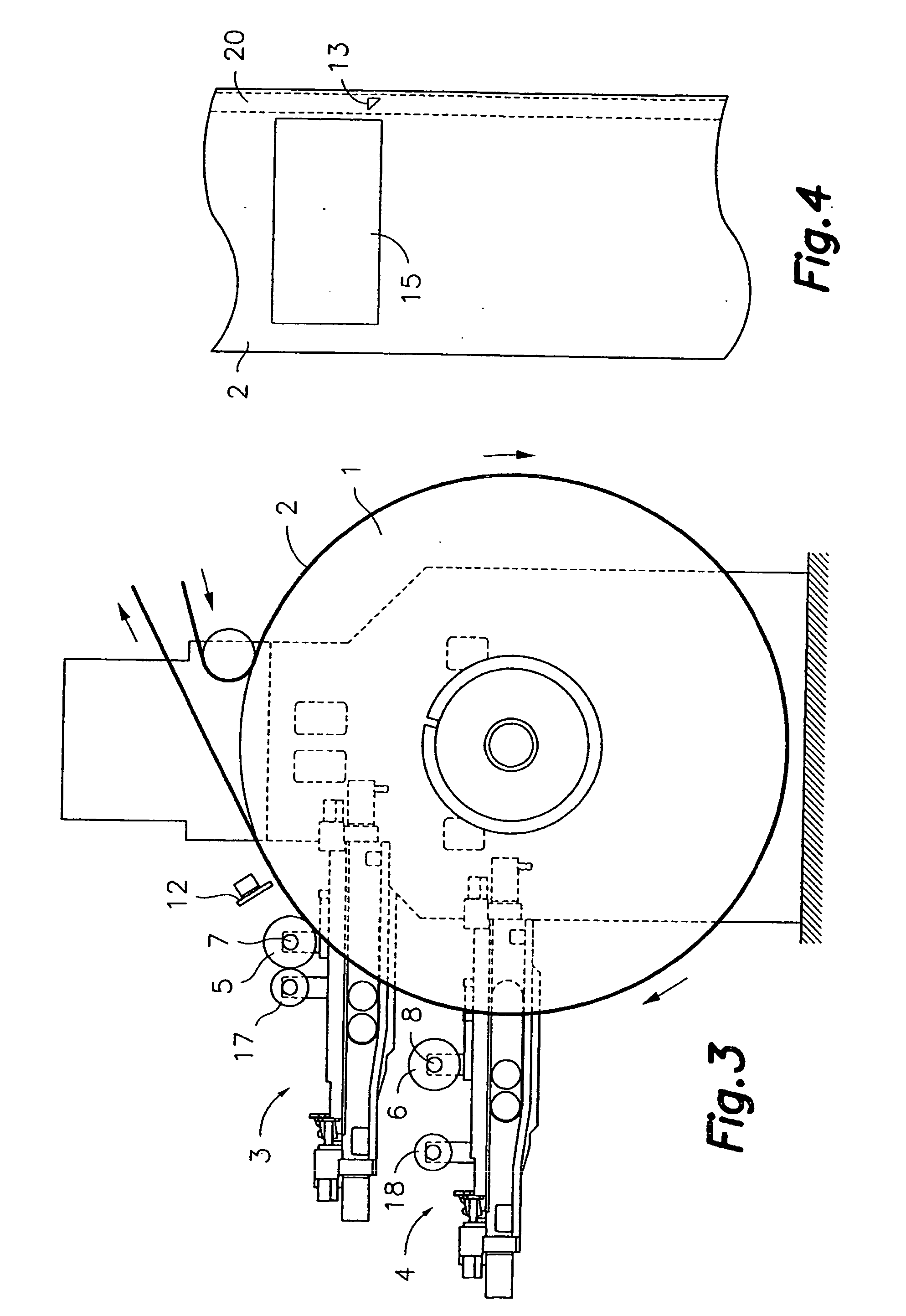

Method of registering different colours in flexography, and flexographic printer comprising a device for implementing said method

InactiveUS20060219109A1Less timeNo loss of precisionRotary pressesOther printing apparatusPrinting pressElectrical and Electronics engineering

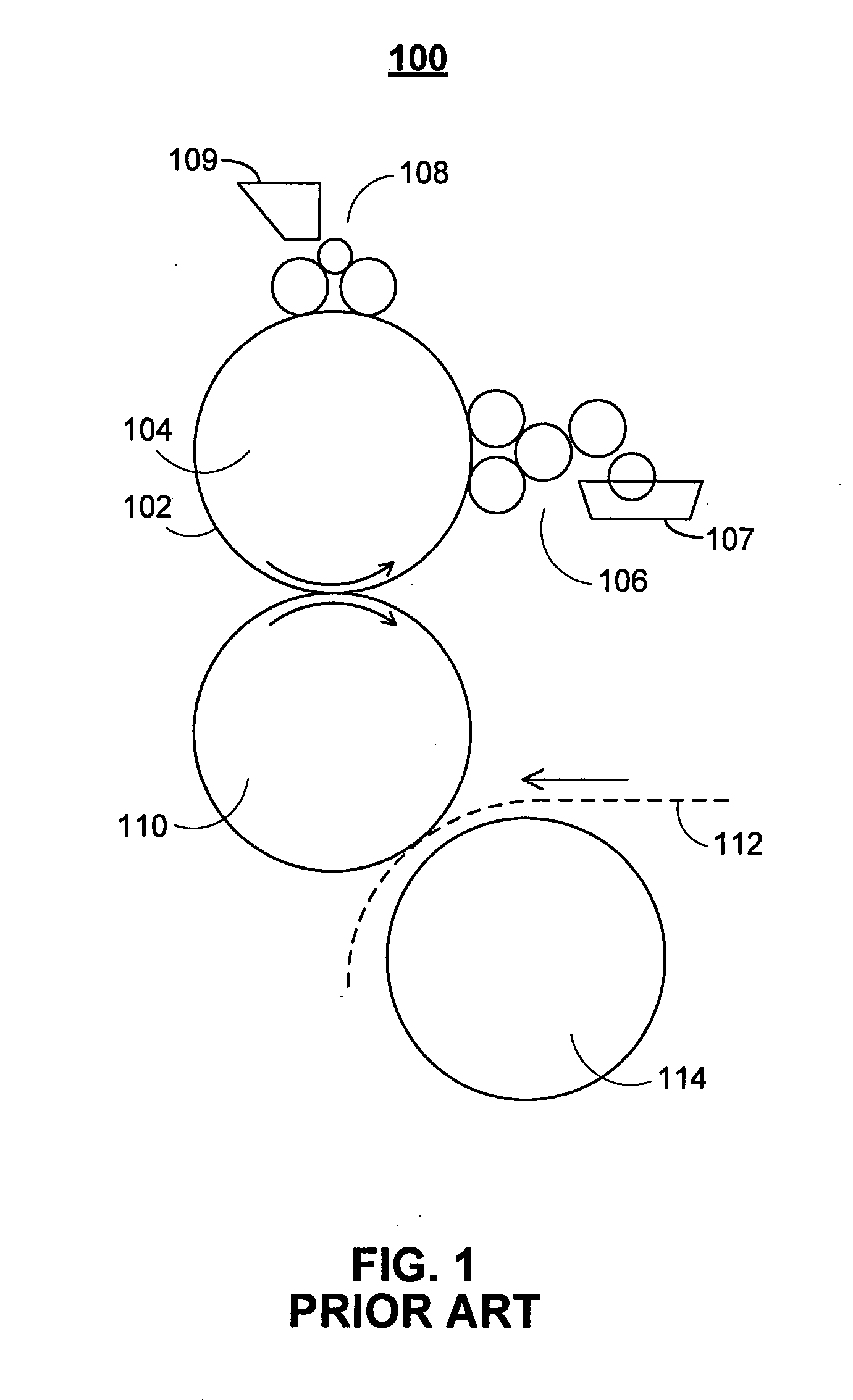

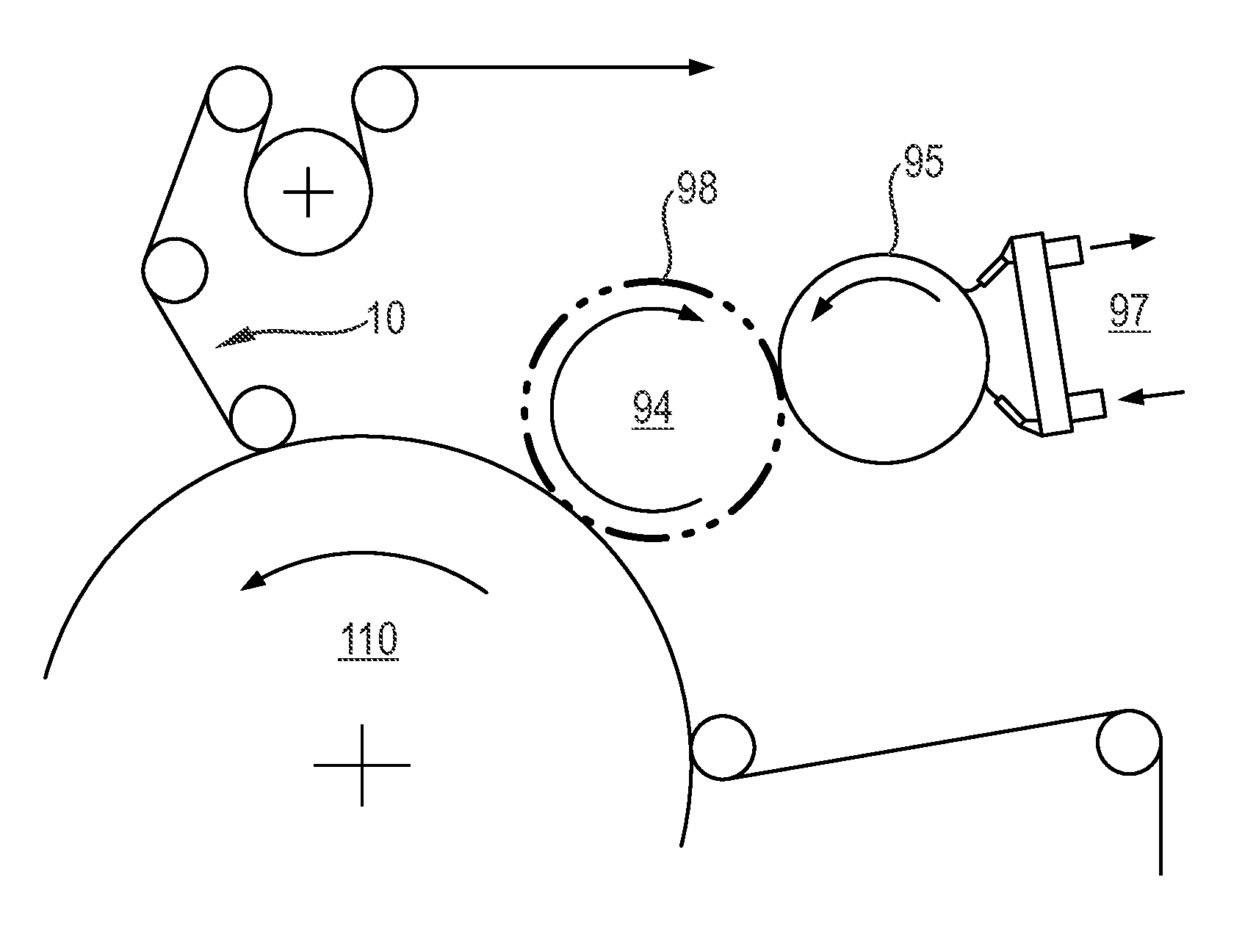

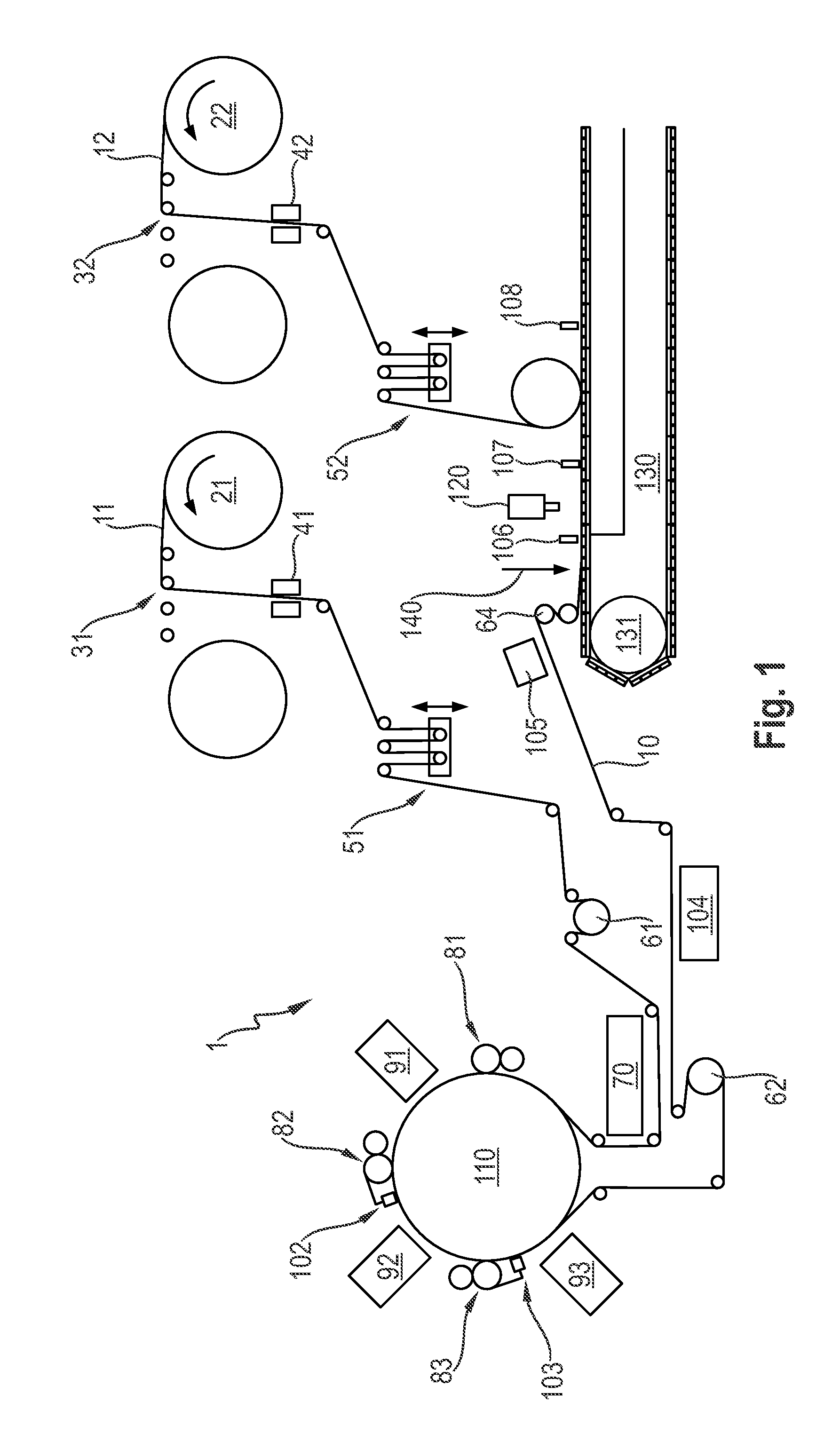

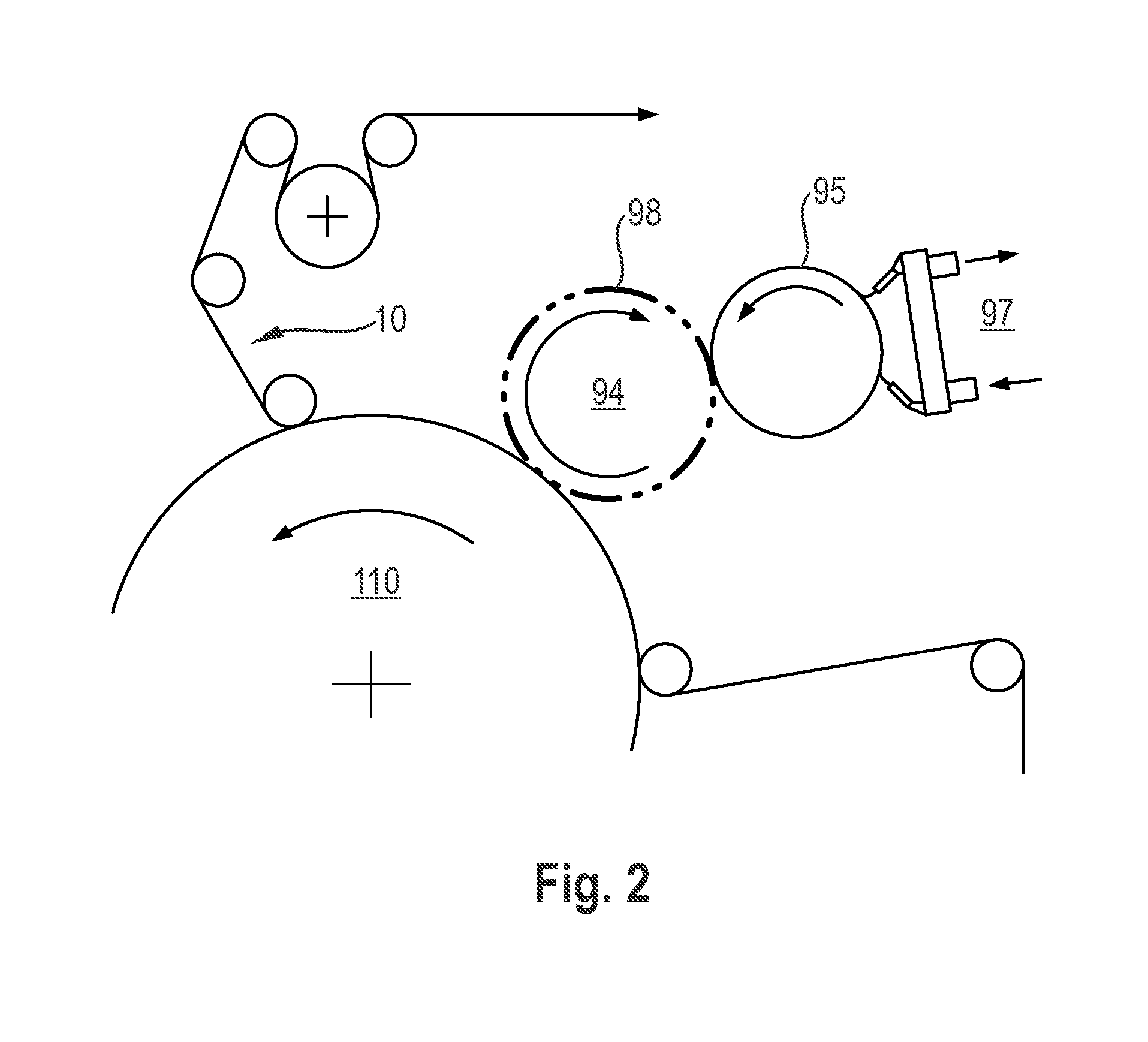

A method of registering various colours in flexography, and a flexographic printer comprising a device for implementing the method are provided. The printer comprises at least one supporting drum with at least first and second printing rollers and an optical sensor, downstream from the rollers. The method comprises consecutively printing first and second marks with the first and second rollers, using the sensor to generate first and second position signals that are representative of the positions of the first and second marks within a printing length and to generate adjustment signals by comparison of the second position signal with the first position signal, taken as reference, or the first and second position signals with a pre-established position signal. The positions of rollers are adjusted based on the adjustment signals.

Owner:COMEXI GRP IND

Disposable food tray

A repulpable and recyclable case ready food tray is disclosed for carrying various food items, such as meat, poultry and produce that is typically used for retail display. The food tray is formed from paperboard made from natural wood fiber that is coated to provide a waterproof food cavity for preventing leakage of liquid from the food item and a moisture proof exterior support surface which allows excess liquid to be released from the food tray during the manufacturing process while providing a moisture proof surface to prevent wicking of liquid into the food tray if the tray is placed on a wet surface.

Owner:GRAPHIC PACKAGING HLDG CO

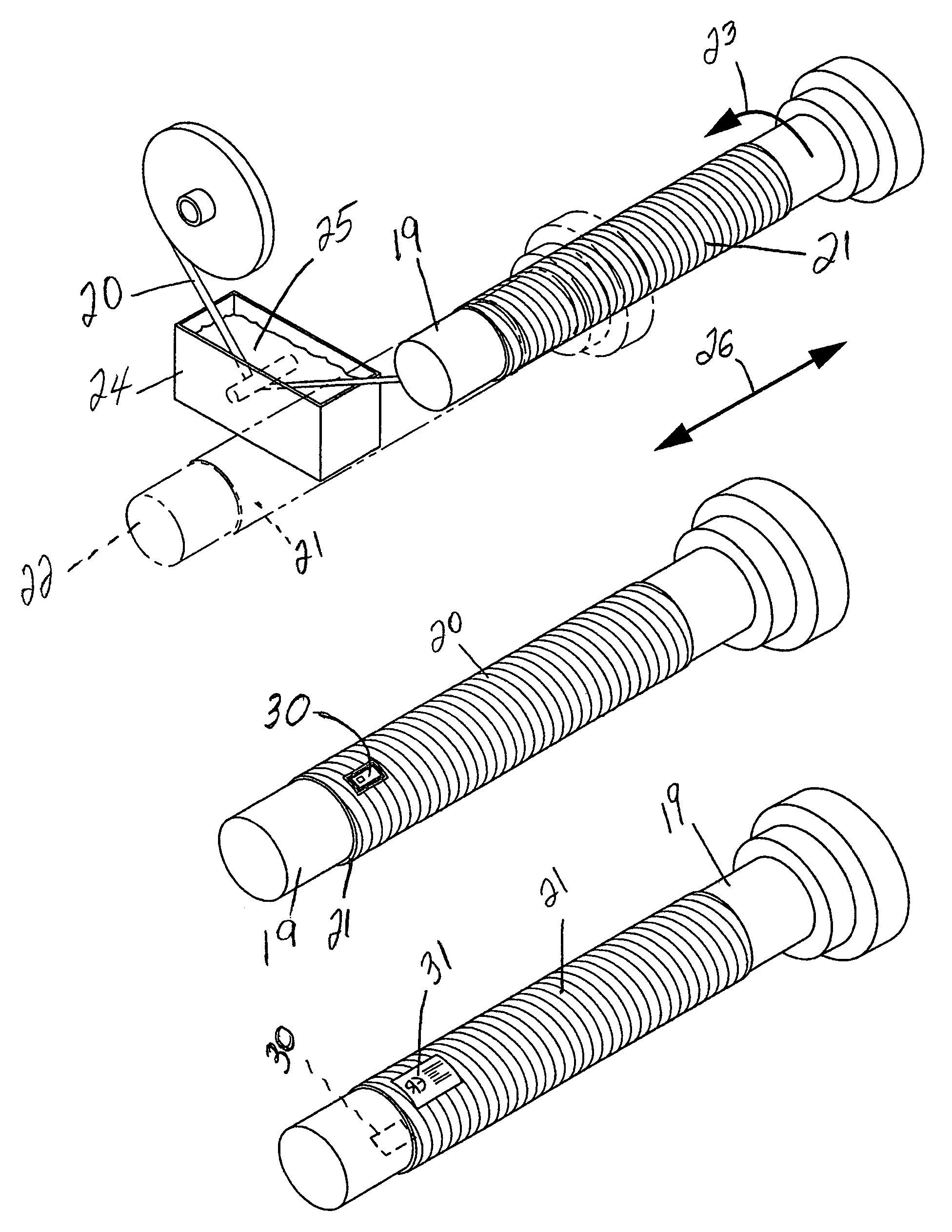

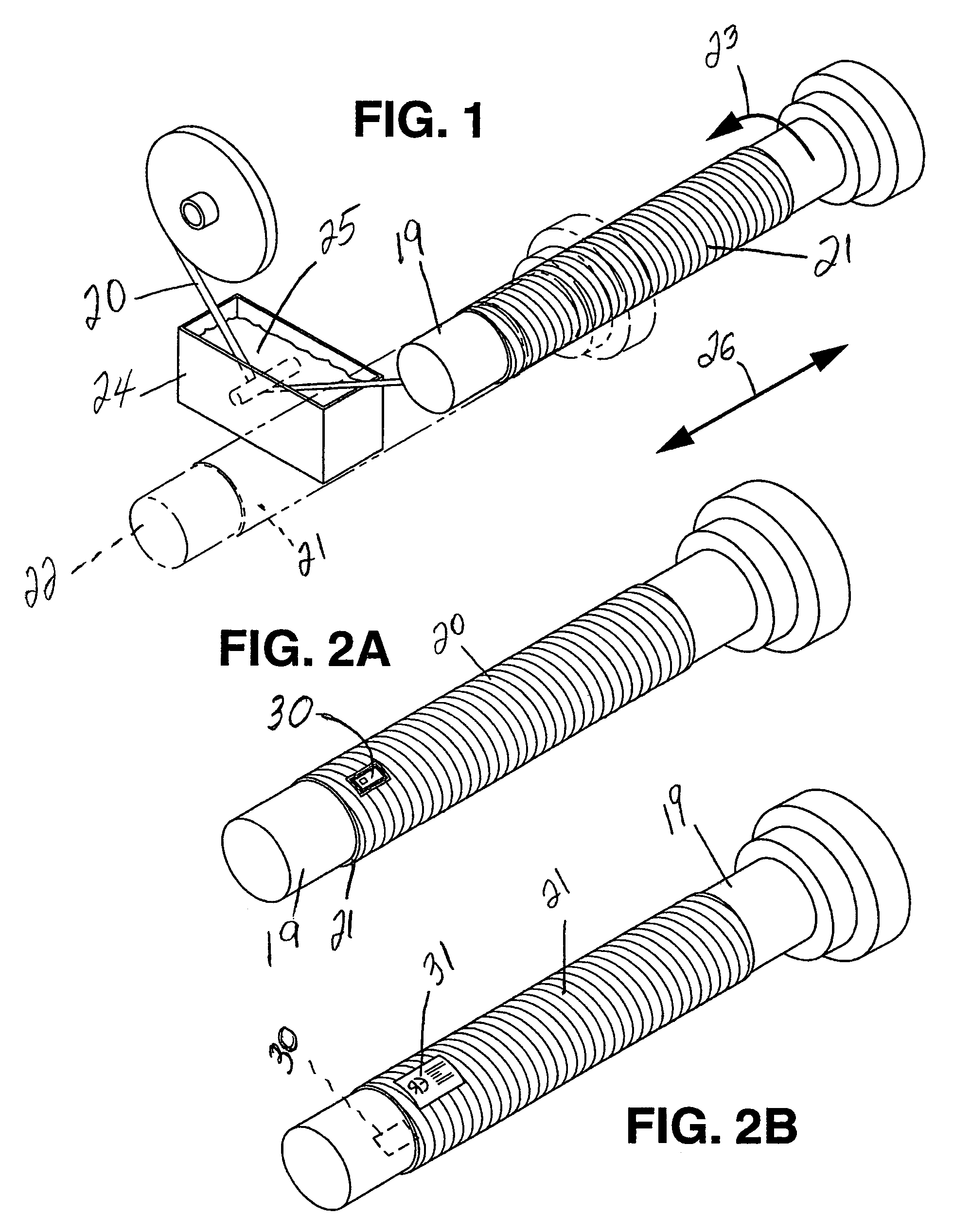

Method and apparatus for forming an ink pattern exhibiting a two-dimensional ink gradient

InactiveUS8499690B2Increase distanceIncrease the oscillation amplitudeRotary intaglio printing pressOther printing apparatusEngineeringPrinting press

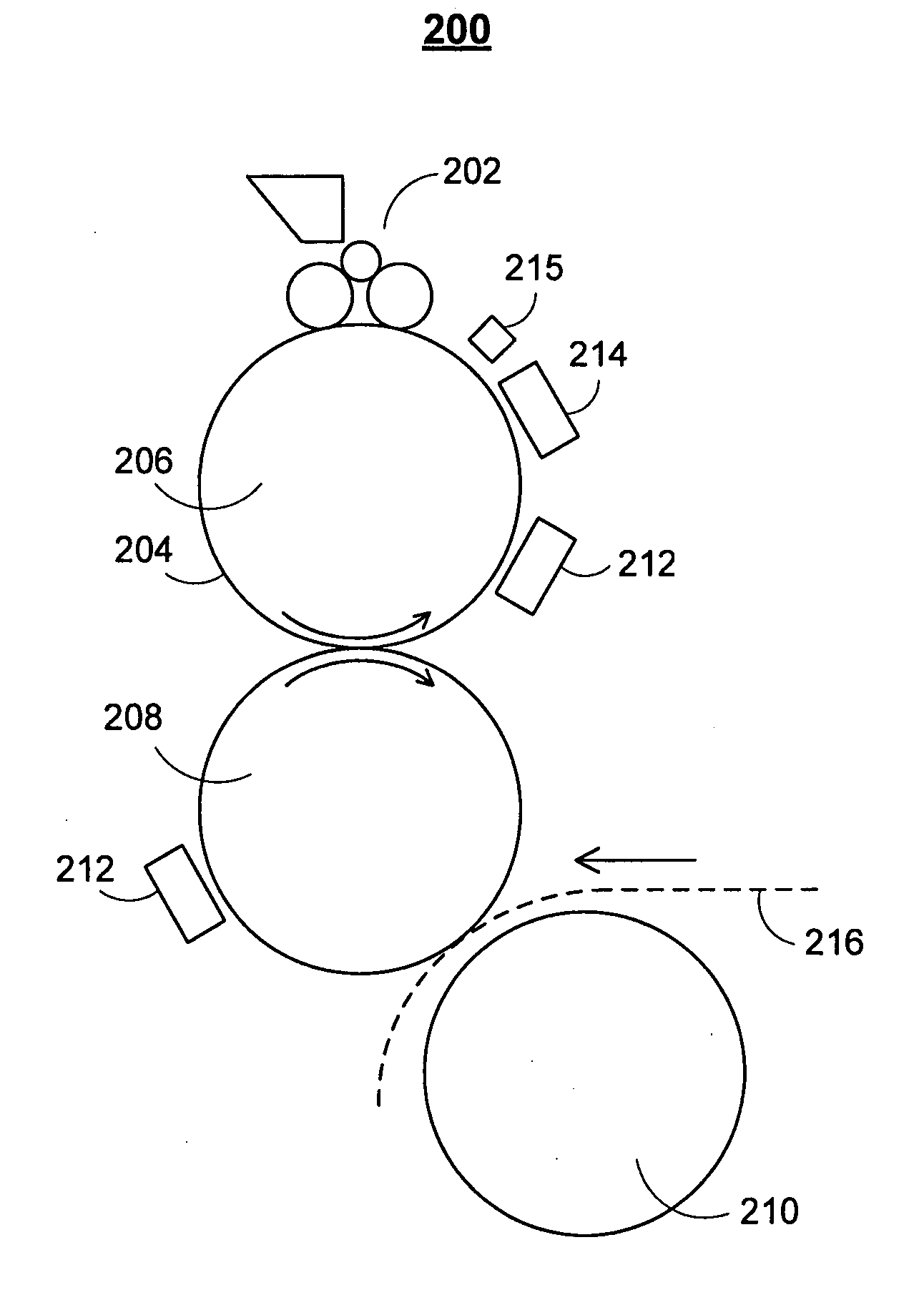

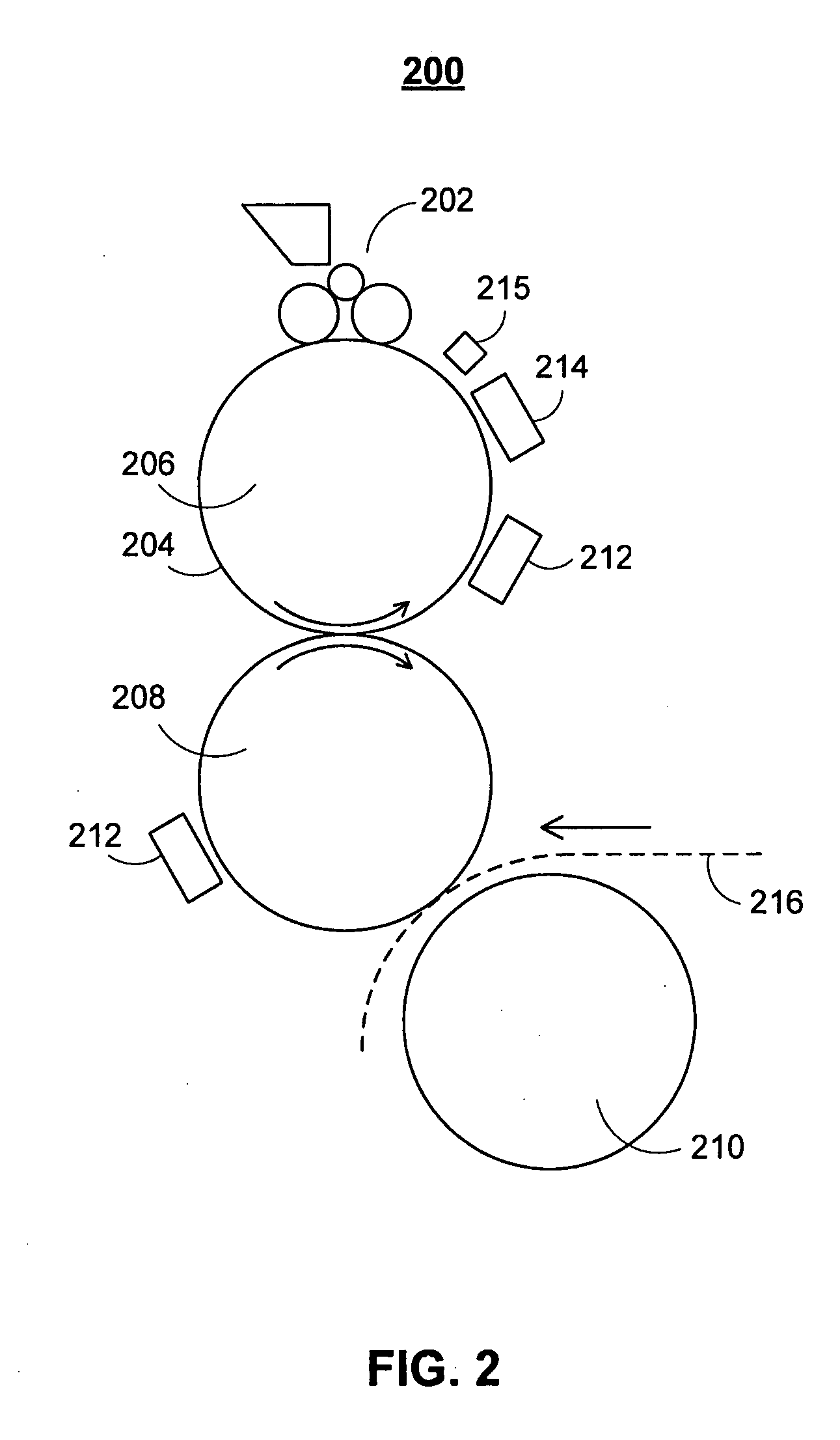

There is described a method and an inking apparatus (50) for forming an ink pattern (80) on the surface of a form cylinder (15b) of a printing press, which ink pattern (80) exhibits, at least in part, a two-dimensional ink gradient extending in an axial direction and a circumferential direction on the surface of the form cylinder (15b). At least first and second chablon cylinders (20, 25) are placed one after the other along an inking path of the ink train (20, 25, 30, 31, 32, 33, 34, 35a, 35b, 36, 37) inking the form cylinder (15b) for distributing ink in the axial and circumferential directions and means (200, 201, 210, 211, 212, 250, 251, 260, 261, 262) are provided for subjecting the first and second chablon cylinders (20, 25) to cyclical oscillation movements in the axial direction and the circumferential direction.

Owner:KBA NOTASYS SA

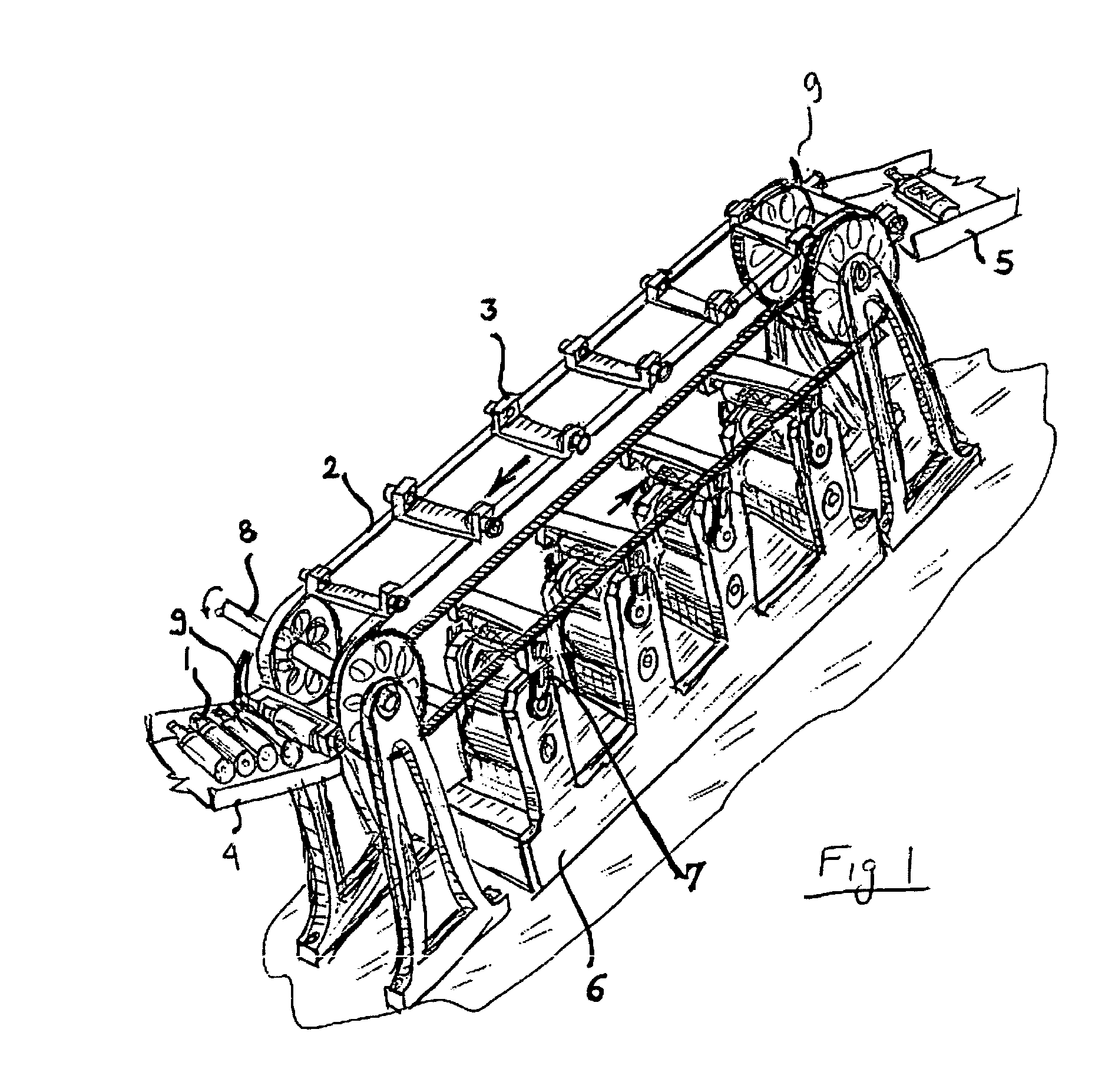

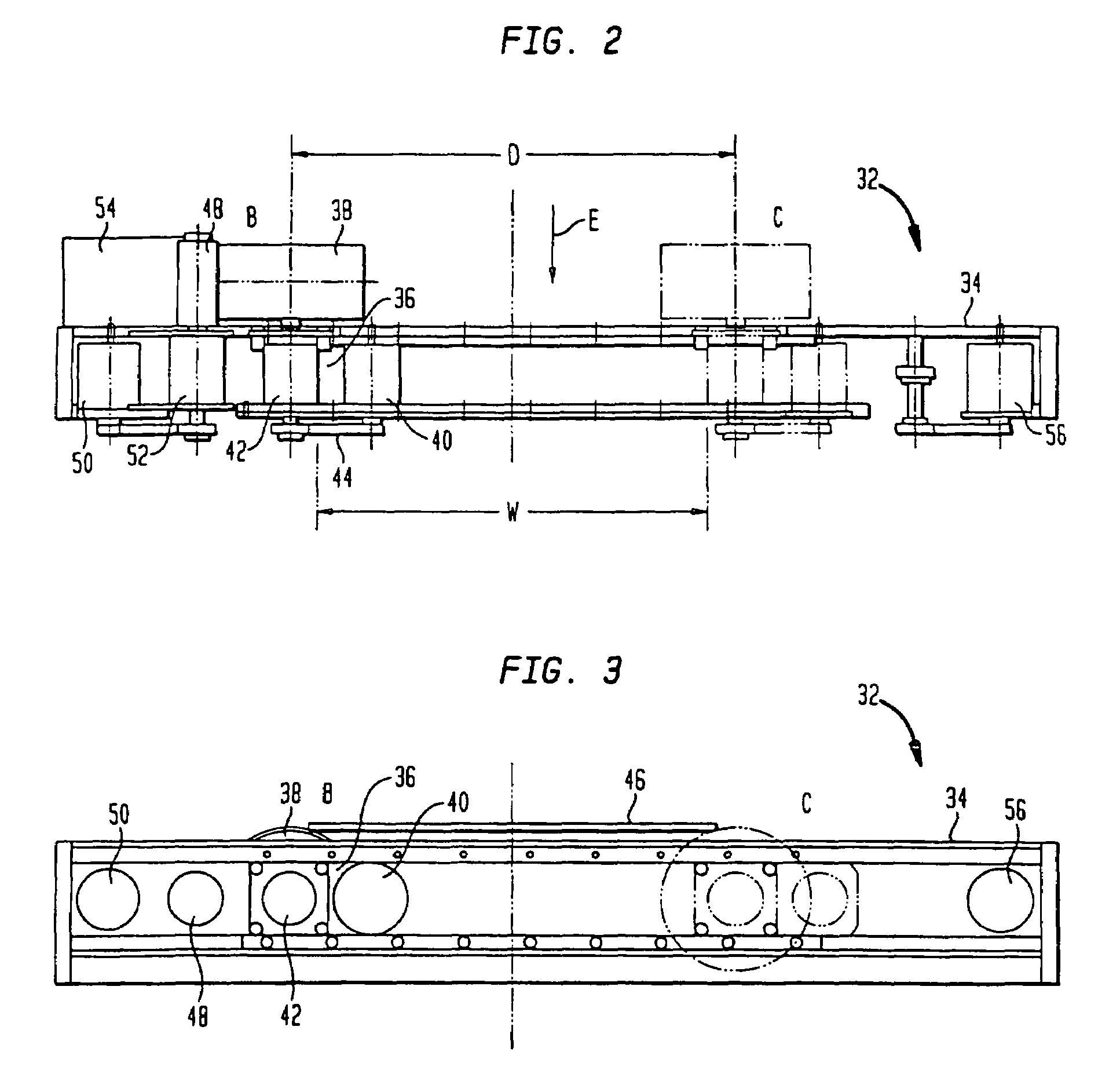

Flexographic rotary platen printing press

InactiveUS7100507B1Accurately carry-outPrecise positioningCylinder pressesRotary letterpress machinesColor printingEngineering

A flexographic rotary platen printing press for printing indicia on a web of flexible material moving along a longitudinal axis. The flexographic rotary platen printing press includes a print drum assembly that is affixed to a trolley that is moveable in a linear direction across the web generally transverse to the direction of the web movement. When the web is stopped, the print drum is caused to roll across the web that is sandwiched between the print drum and a flat, planar platen to print indicia onto the web in a line contact. A linear drive system causes the movement of the print drum assembly. The speed of the transverse movement is electronically coordinated to the speed of the rotation of the print drum as it moves across the web to carry out the printing operation. A multi-color printing process is created by serially positioning two or more flexographic presses without the use of a large number of idler rollers or changes of direction in the path of the web as it moves from one flexographic printing press to a subsequent flexographic printing press.

Owner:GREYDON

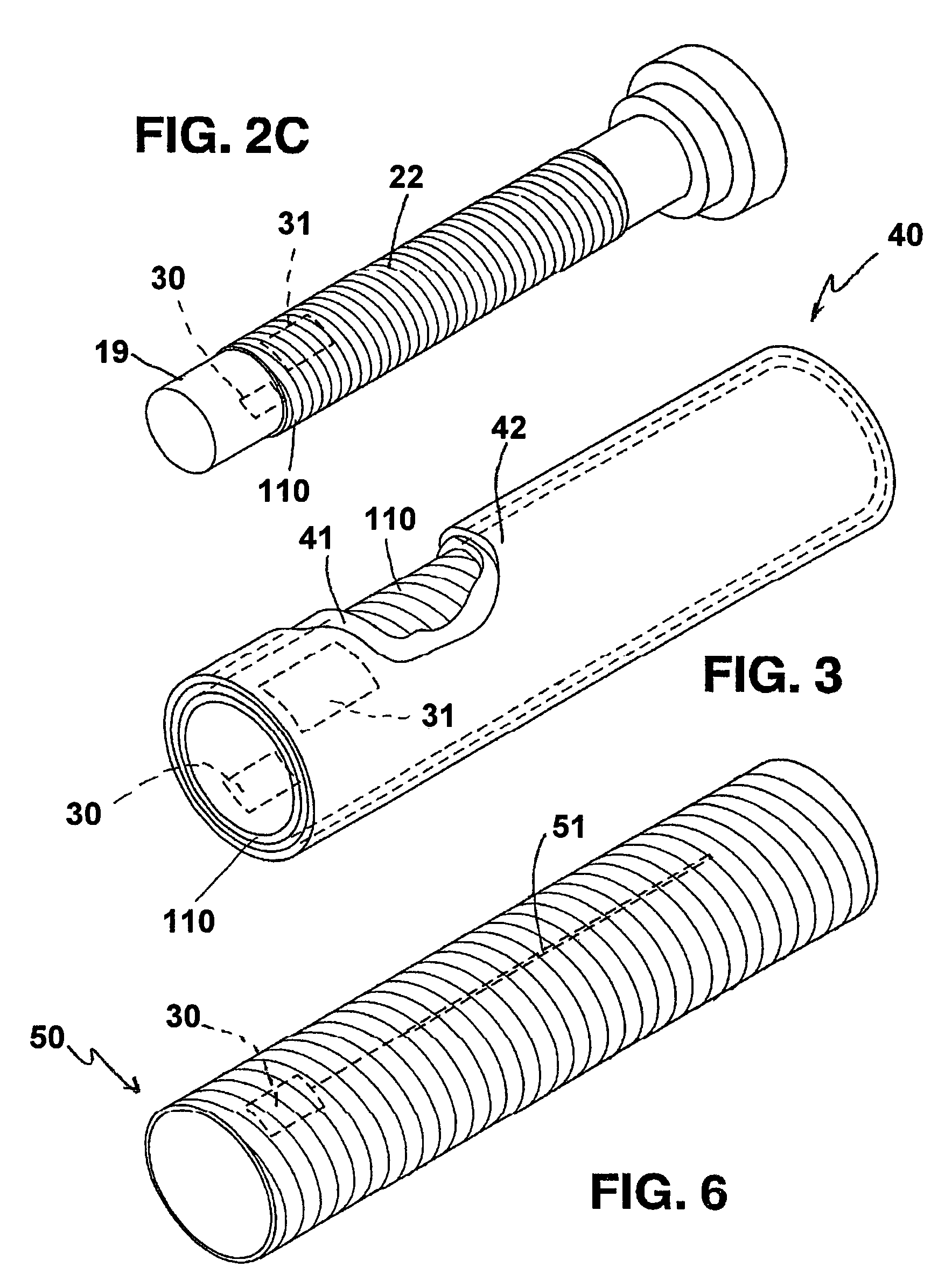

Flexo Cushion

InactiveUS20090211480A1Reduces smutting during printingConvenient registrationPrinting platesStereotype printingEngineeringCushion

A method of improving performance of a relief image printing plate on a printing cylinder which includes mounting a compressible cushion element on a surface of the printing cylinder. The surface of the cushion element that is contactable with the relief image printing plate is a low friction surface that allows a relief image printing plate to slide freely across its surface and settle into position on the printing cylinder. The use of a cushion element having a low friction surface reduces smut and improves registration of the printing plate on the printing cylinder.

Owner:NAPP SYSTEMS (USA) INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com