Patents

Literature

69results about How to "Highly reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

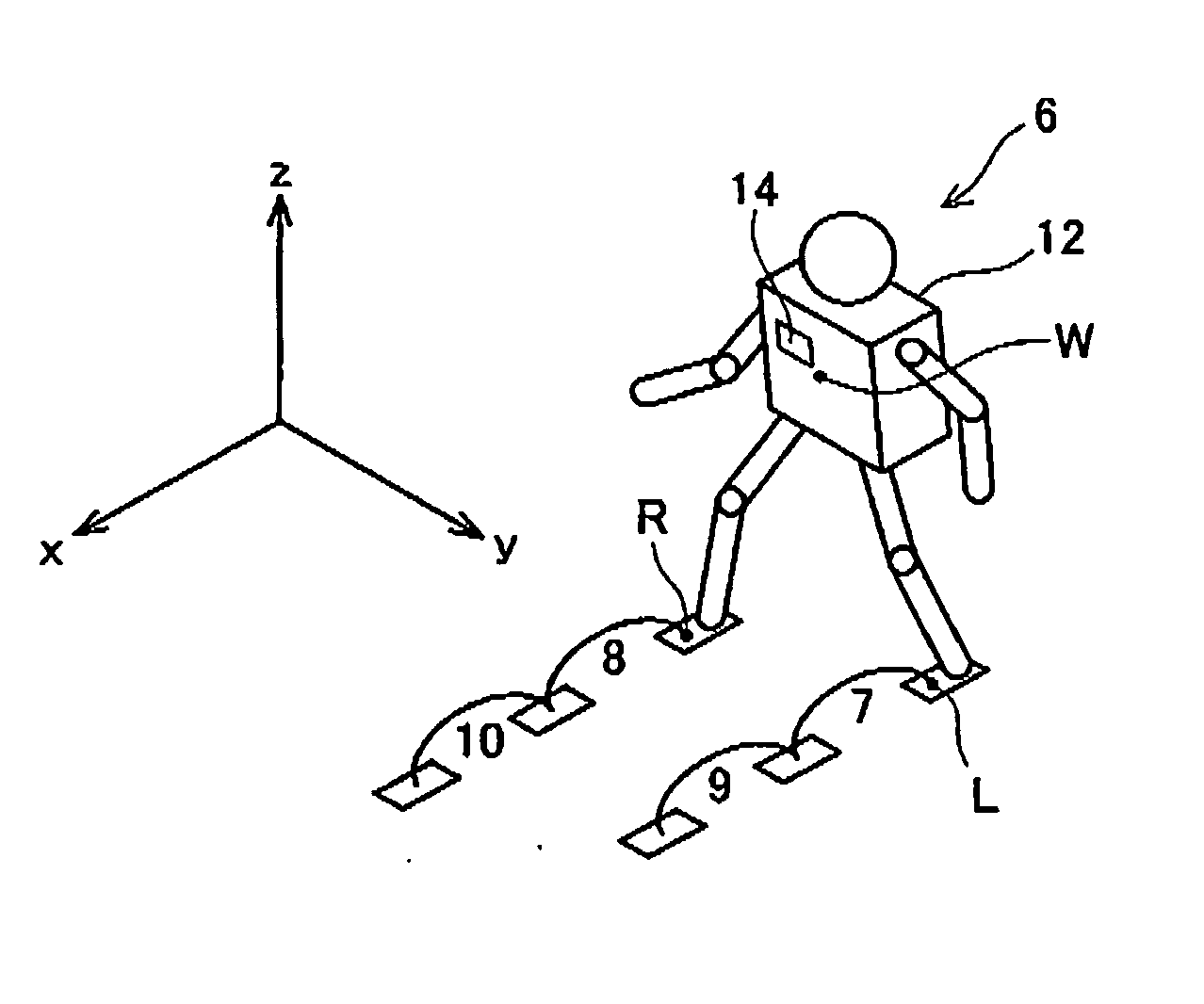

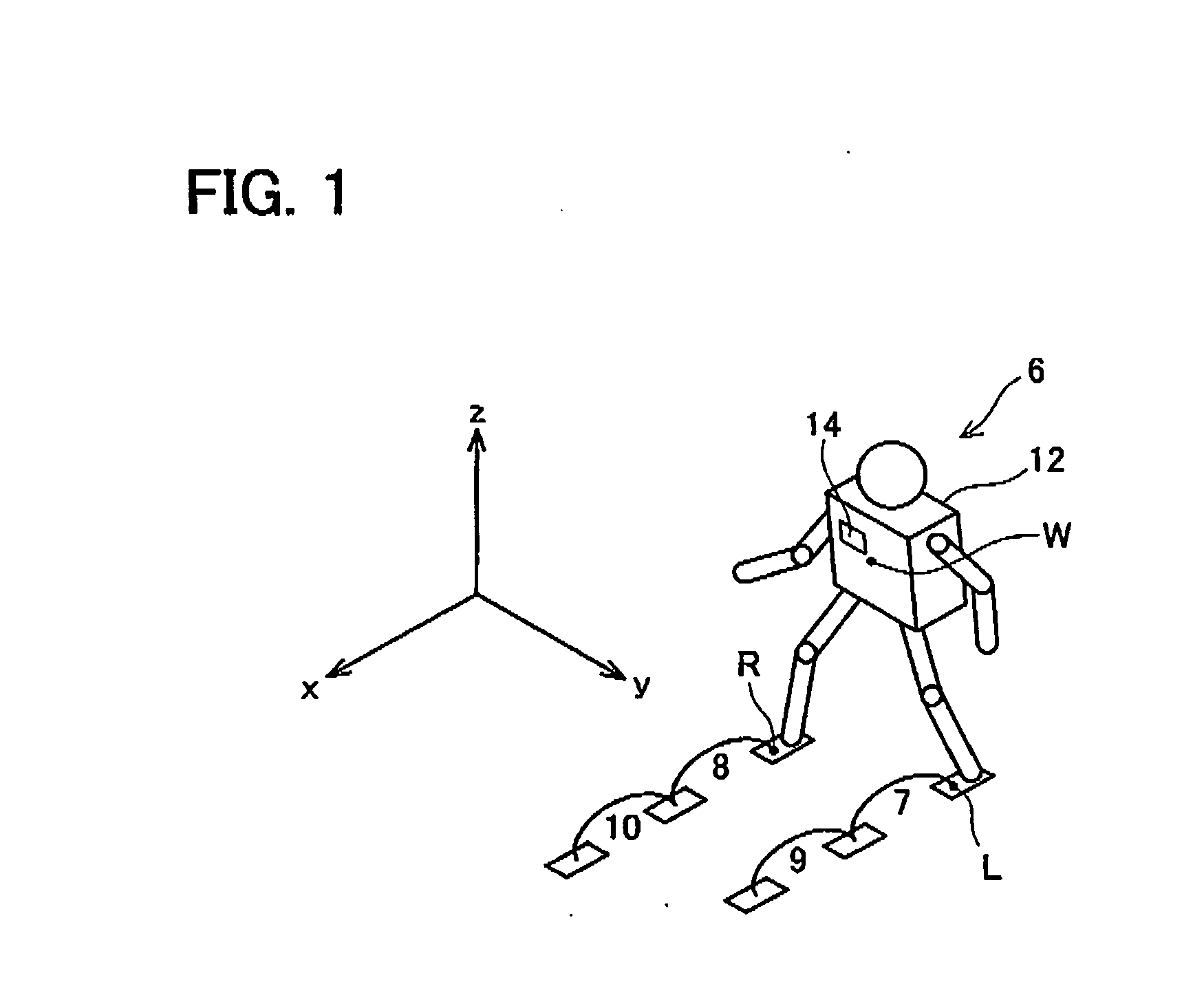

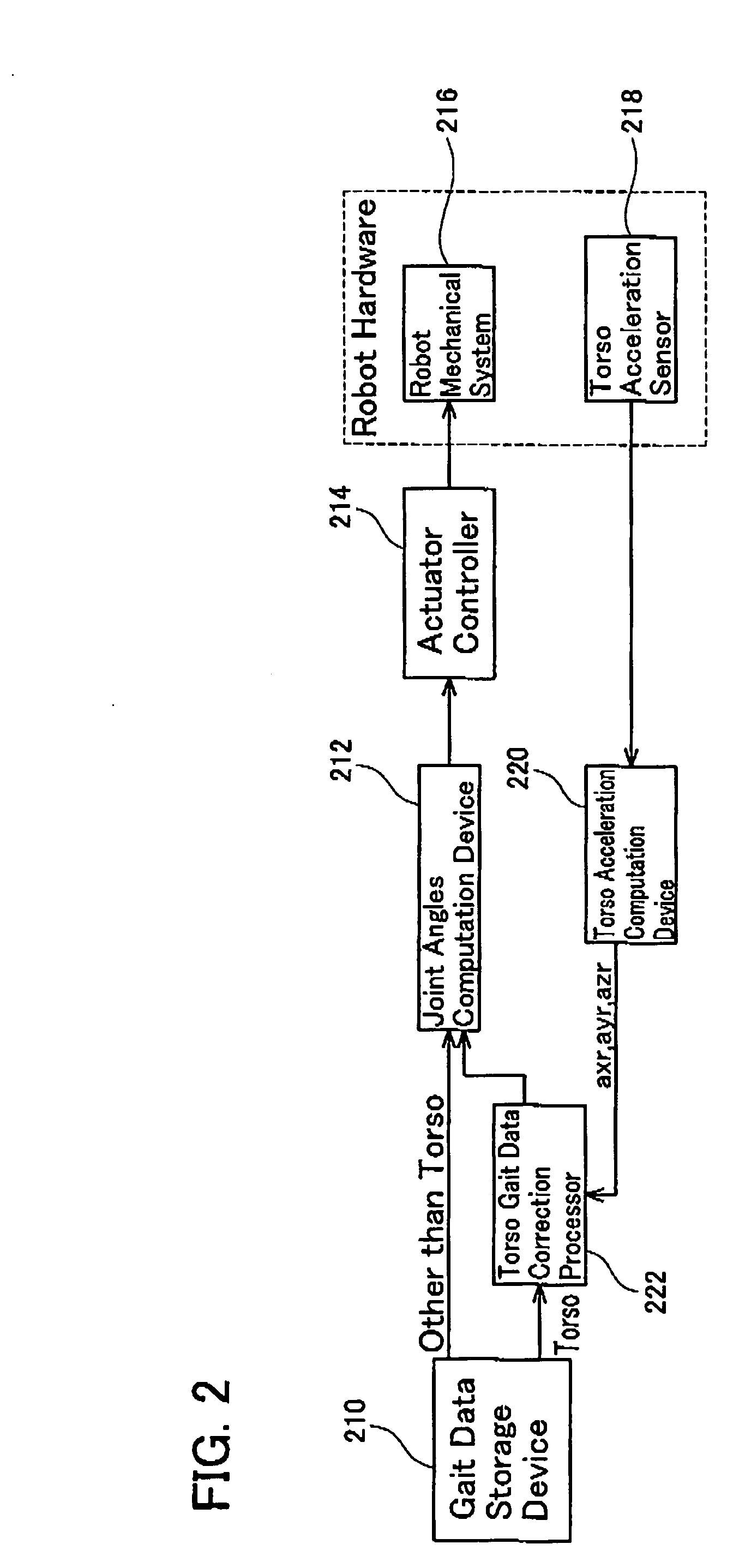

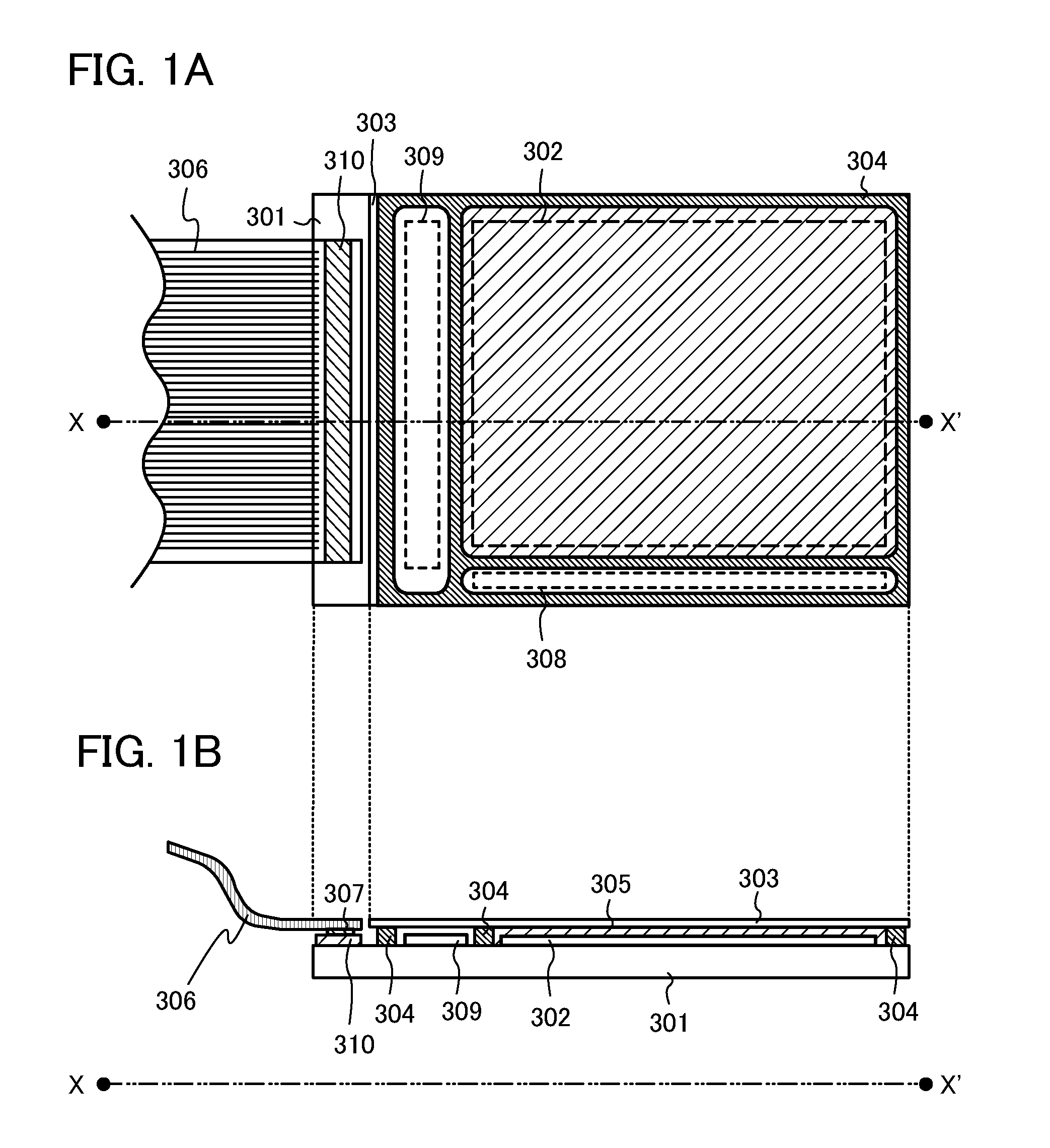

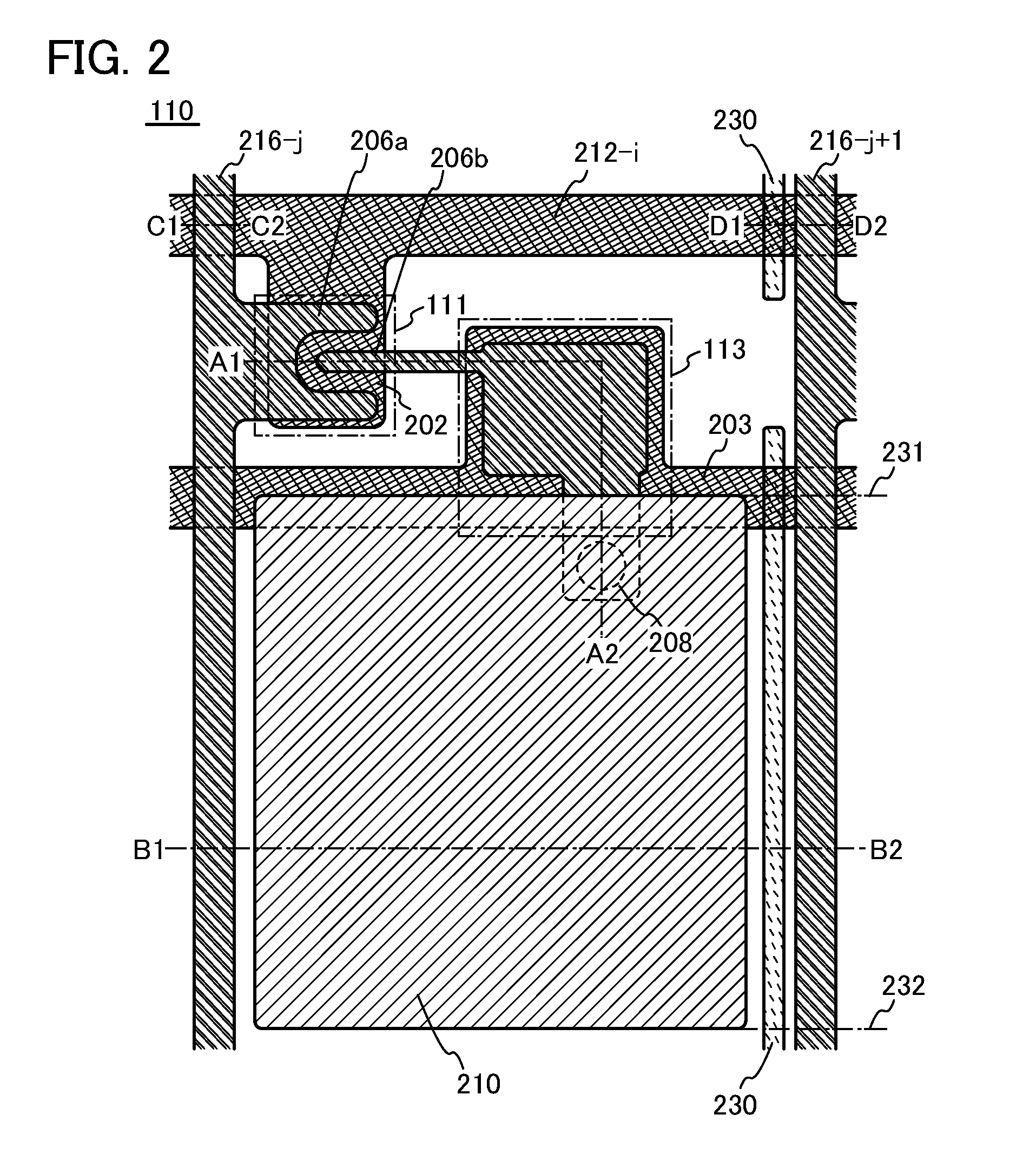

Legged Robot and Legged Robot Walking Control Method

InactiveUS20070241713A1Highly reliableImprove reliabilityProgramme-controlled manipulatorComputer controlEngineeringTorso

A legged robot and a legged robot walking control method are disclosed, which enable stable walking without force sensors on leg tips. A legged robot of the present invention comprises a torso, a leg link, which is swingably connected to the torso, storing means 210 for storing leg tip gait data describing a time-series change in a target leg tip motion, storing means 210 for storing torso gait data describing a time-series change in a target torso motion, which realizes a target ZMP following the change in the target leg tip motion, torso motion detection means 218, 220 for detecting an actual torso motion, deviation calculation means 312 for calculating a deviation of the actual torso motion from the target torso motion, correction quantity calculation means 308 for determining a correction quantity from the calculated deviation based on a prescribed transfer function, and correction means 306 for correcting the target torso gait data based on the determined correction quantity.

Owner:TOYOTA JIDOSHA KK

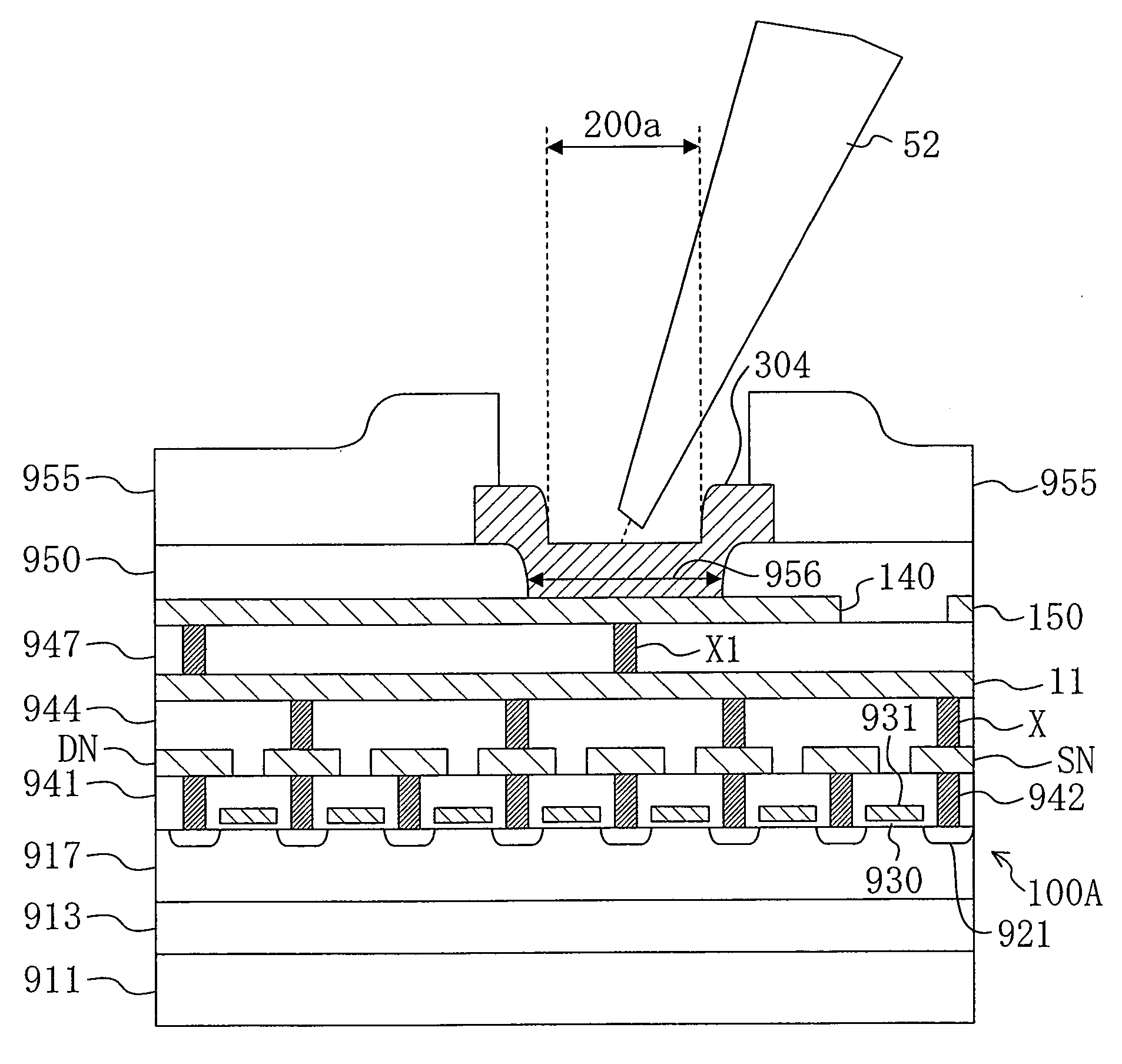

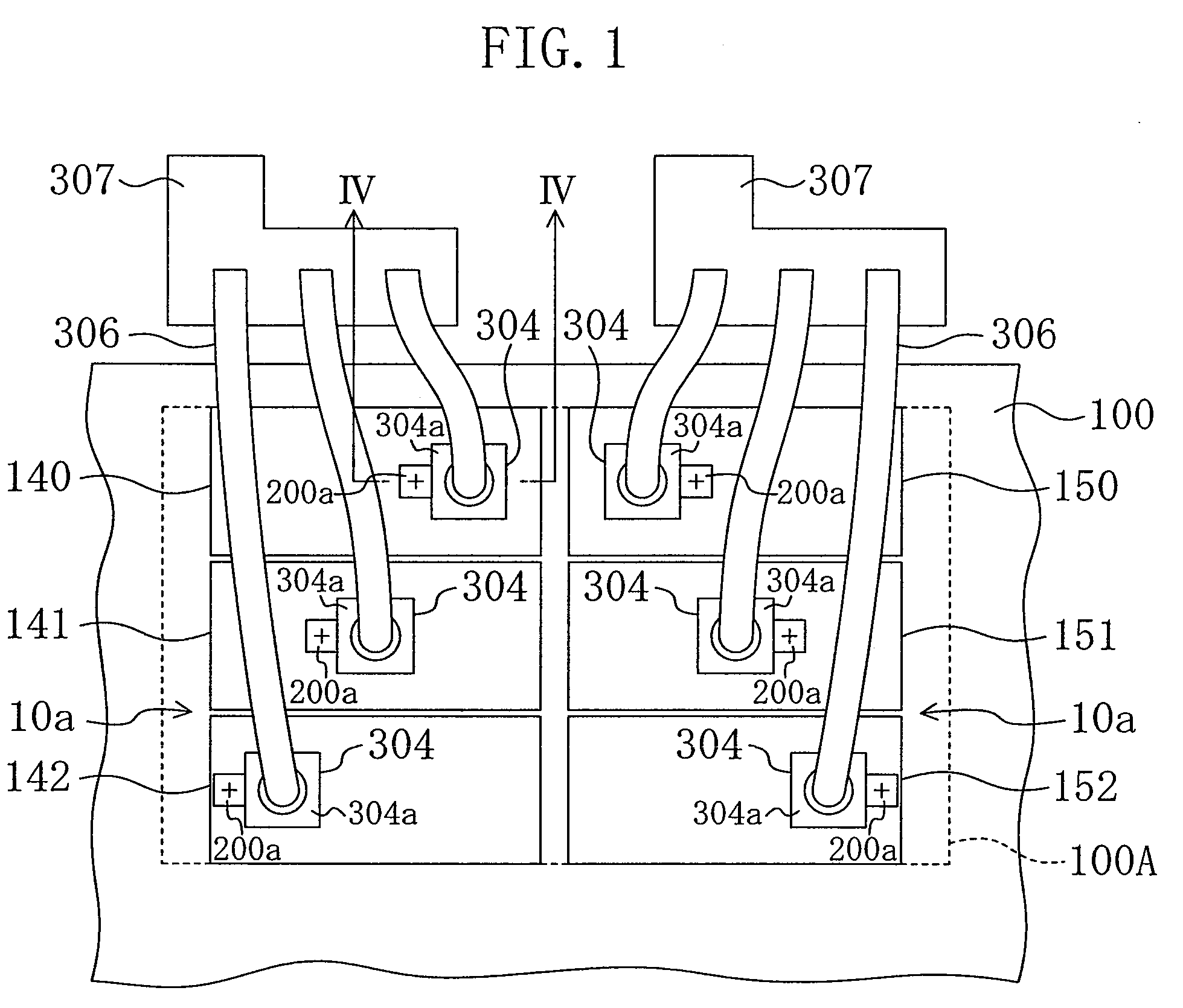

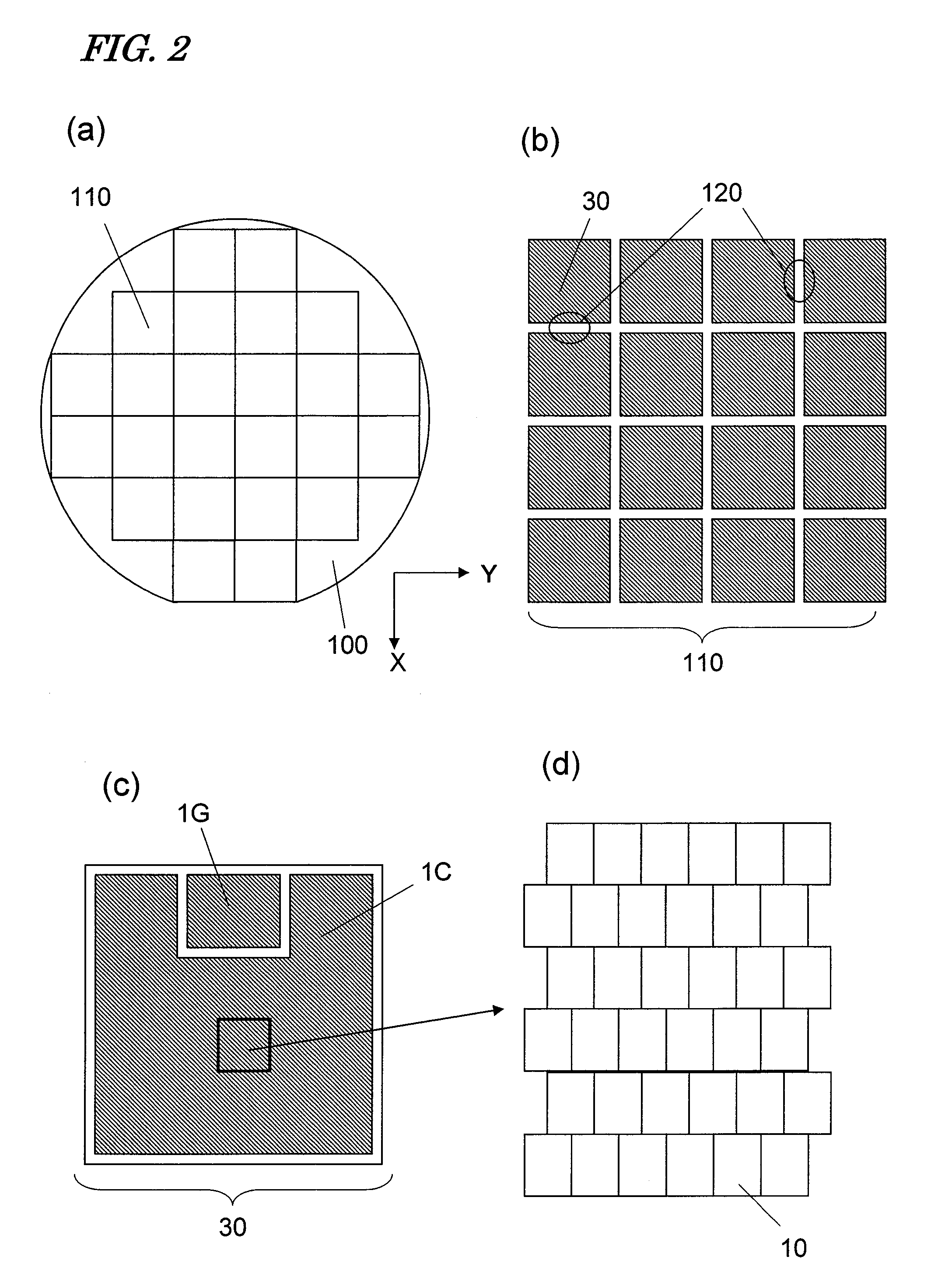

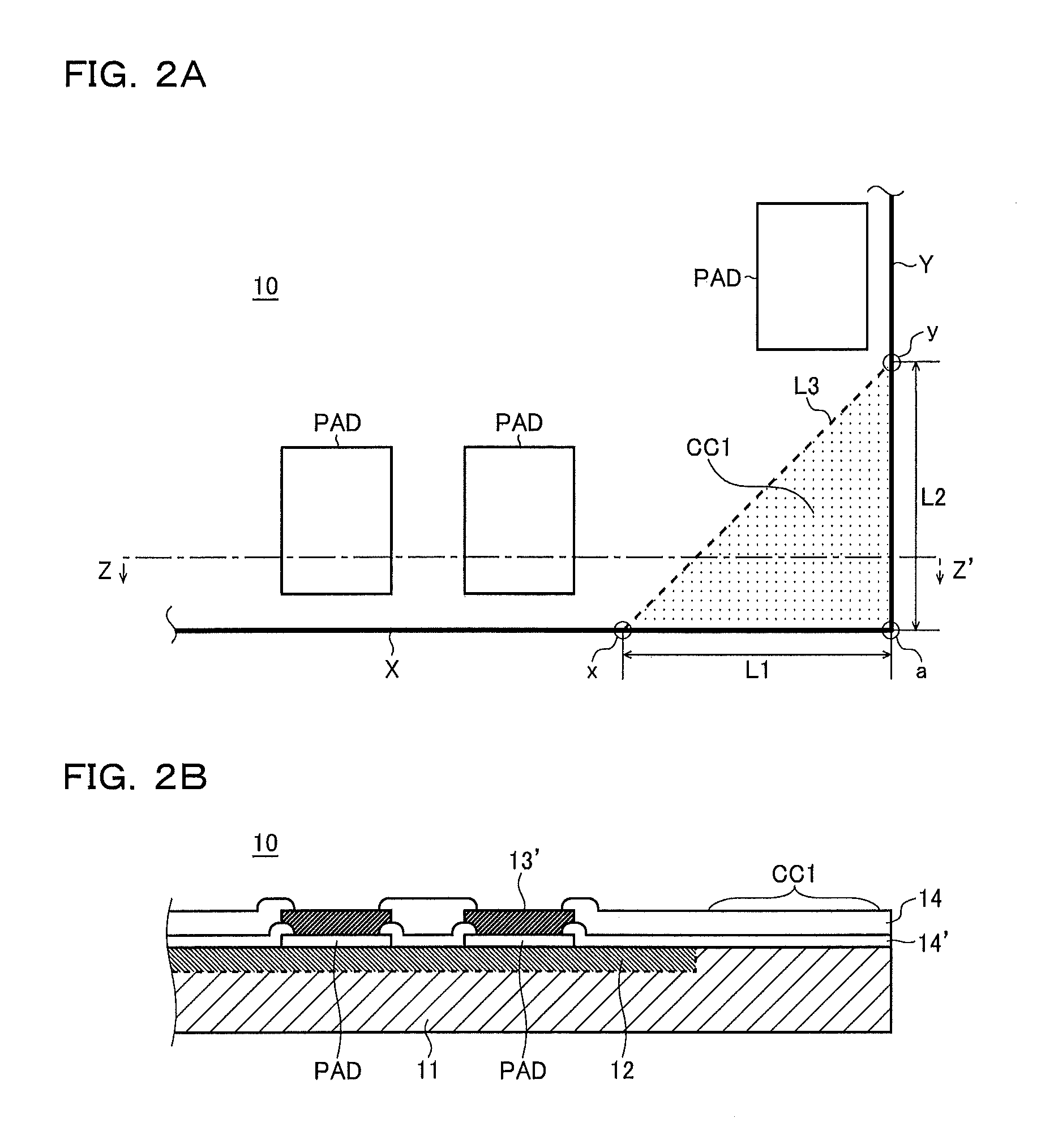

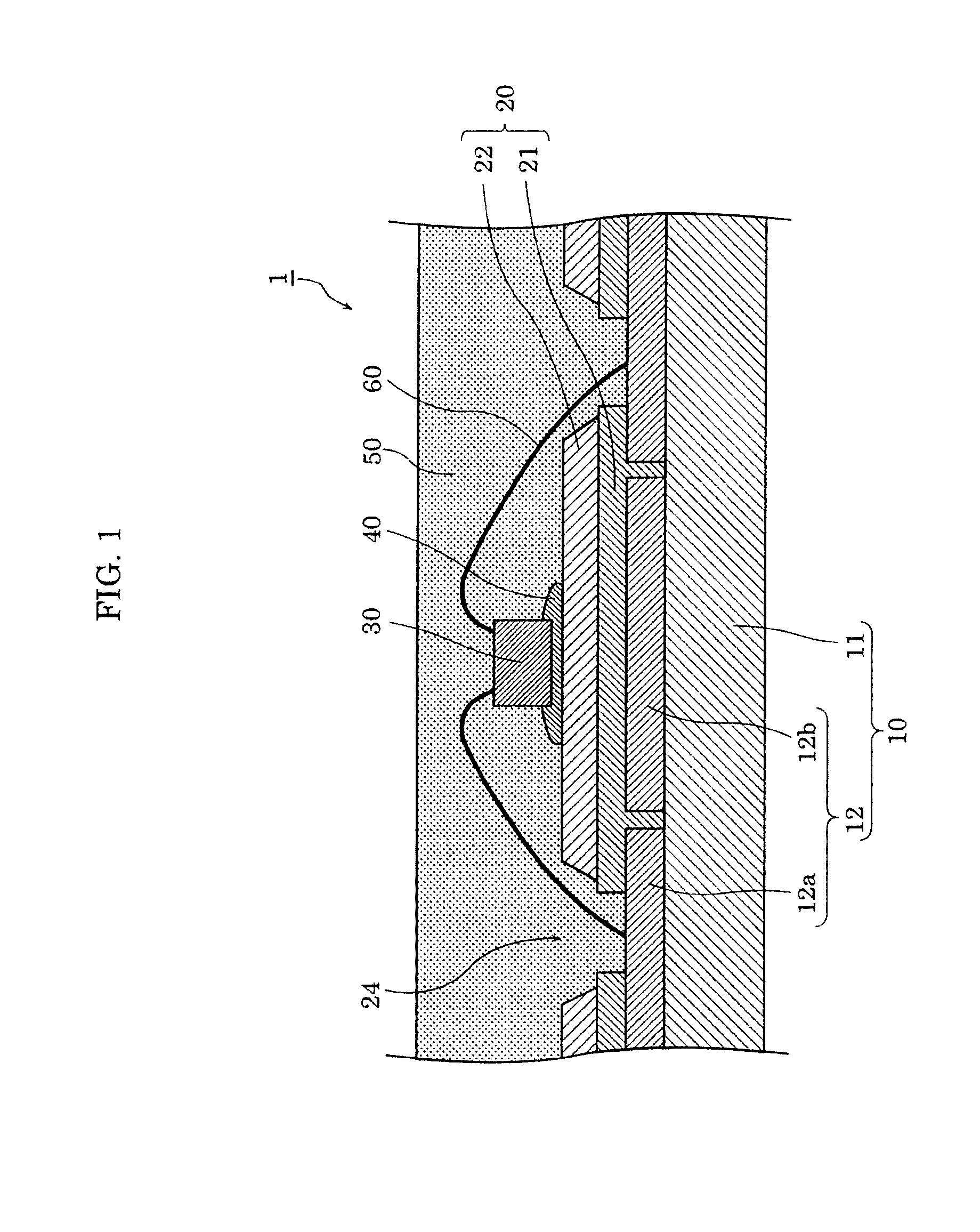

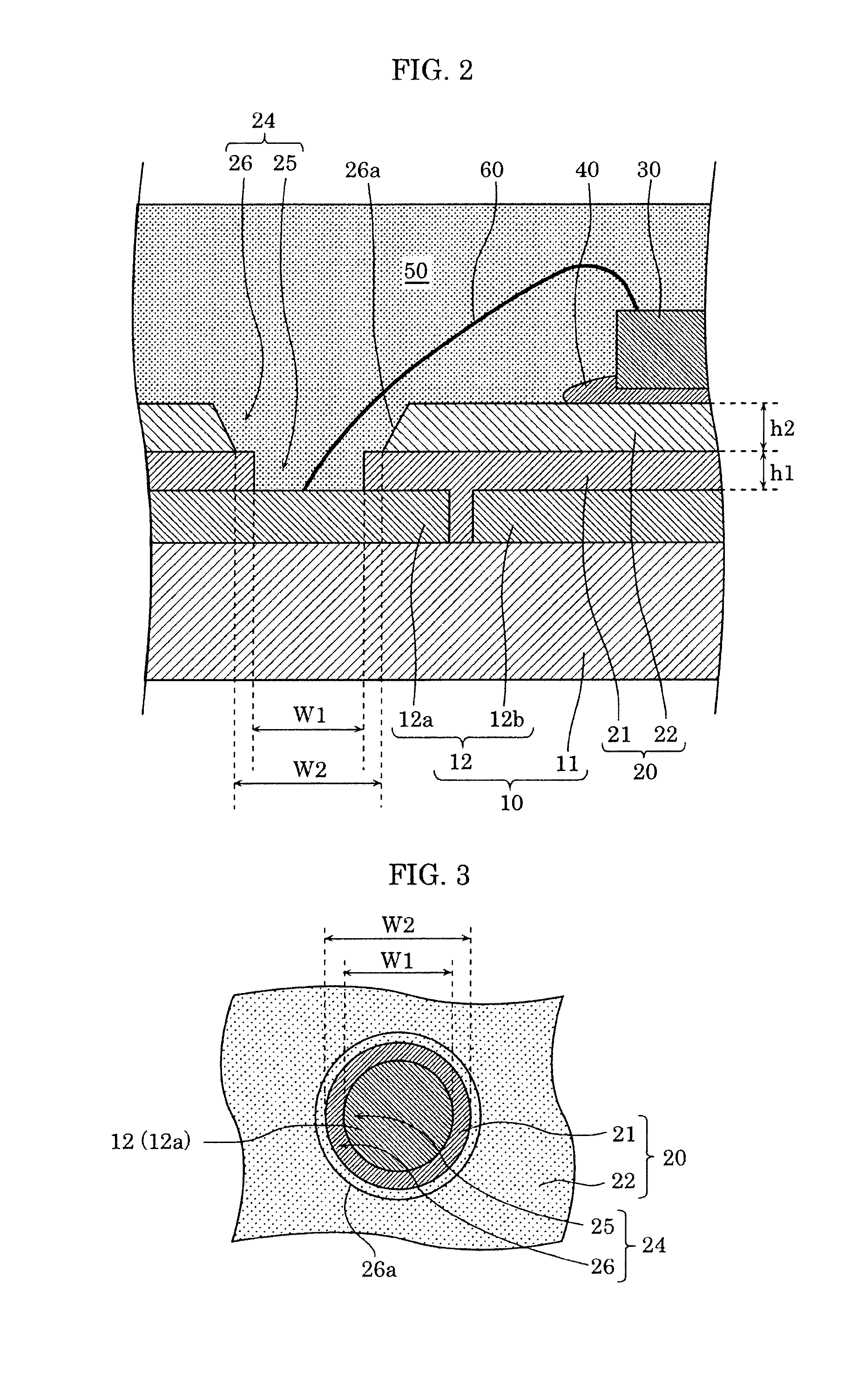

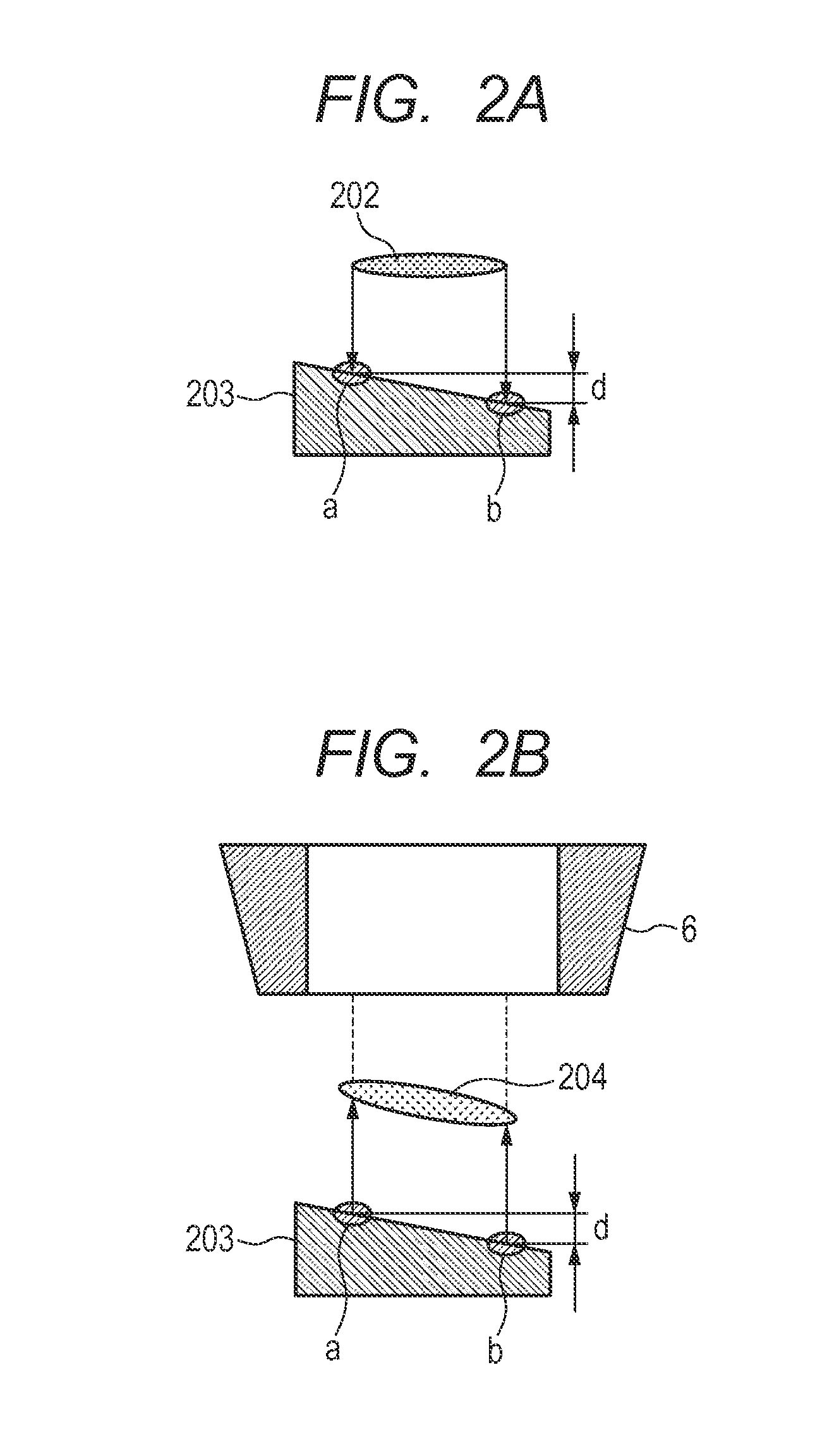

Semiconductor integrated circuit device and fabrication method for the same

InactiveUS20080203577A1Highly reliableSaving in IC chip areaSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsContact padIntegrated circuit

The semiconductor integrated circuit device includes: an active element, an interlayer insulting film, first and second metal patterns made of a first metal layer formed right above the active element, first and second buses made of a second metal layer formed right above the first metal layer, and contact pads provided on the first and second buses. The contact pad has a probe testing region and a bonding region.

Owner:COLLABO INNOVATIONS INC

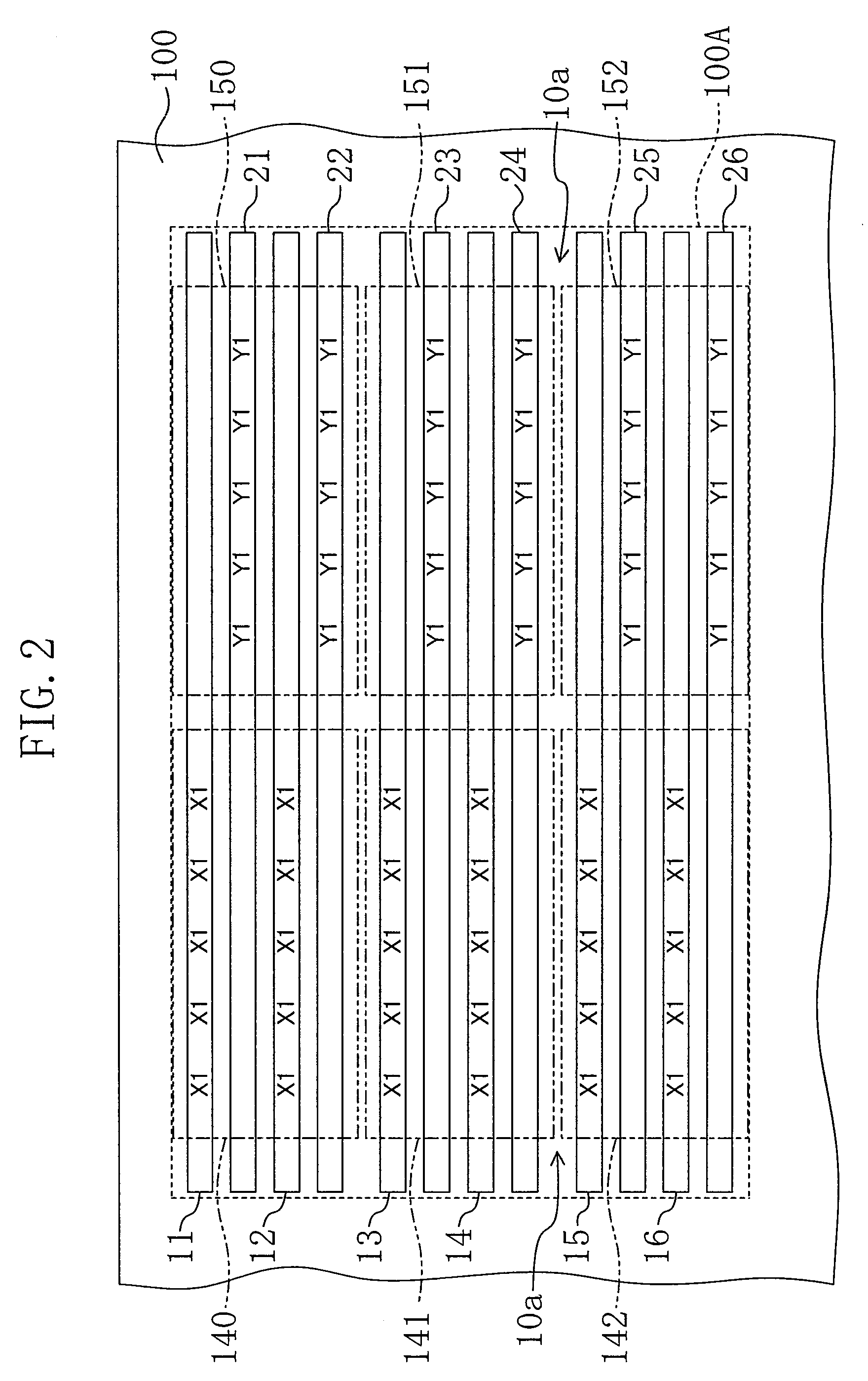

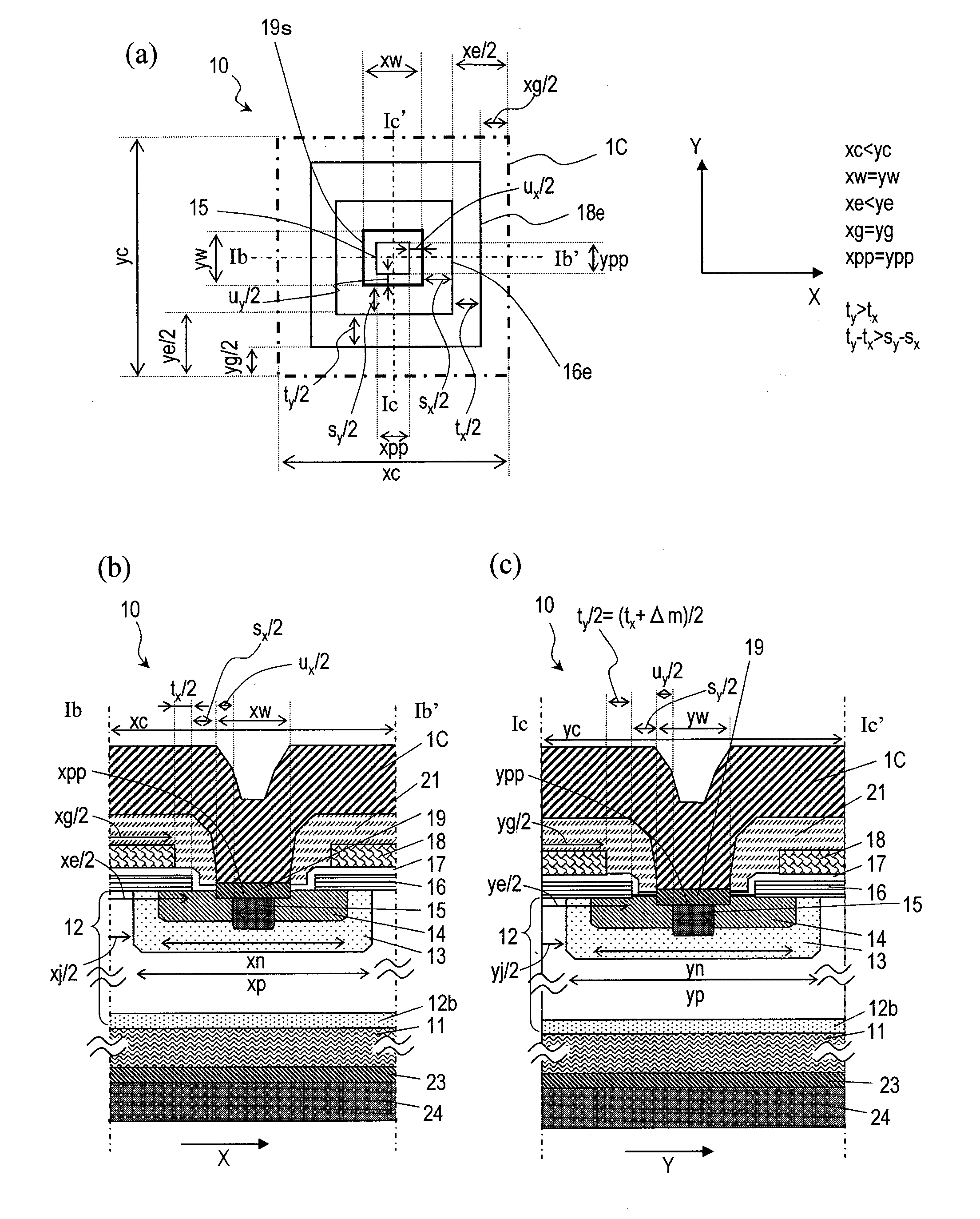

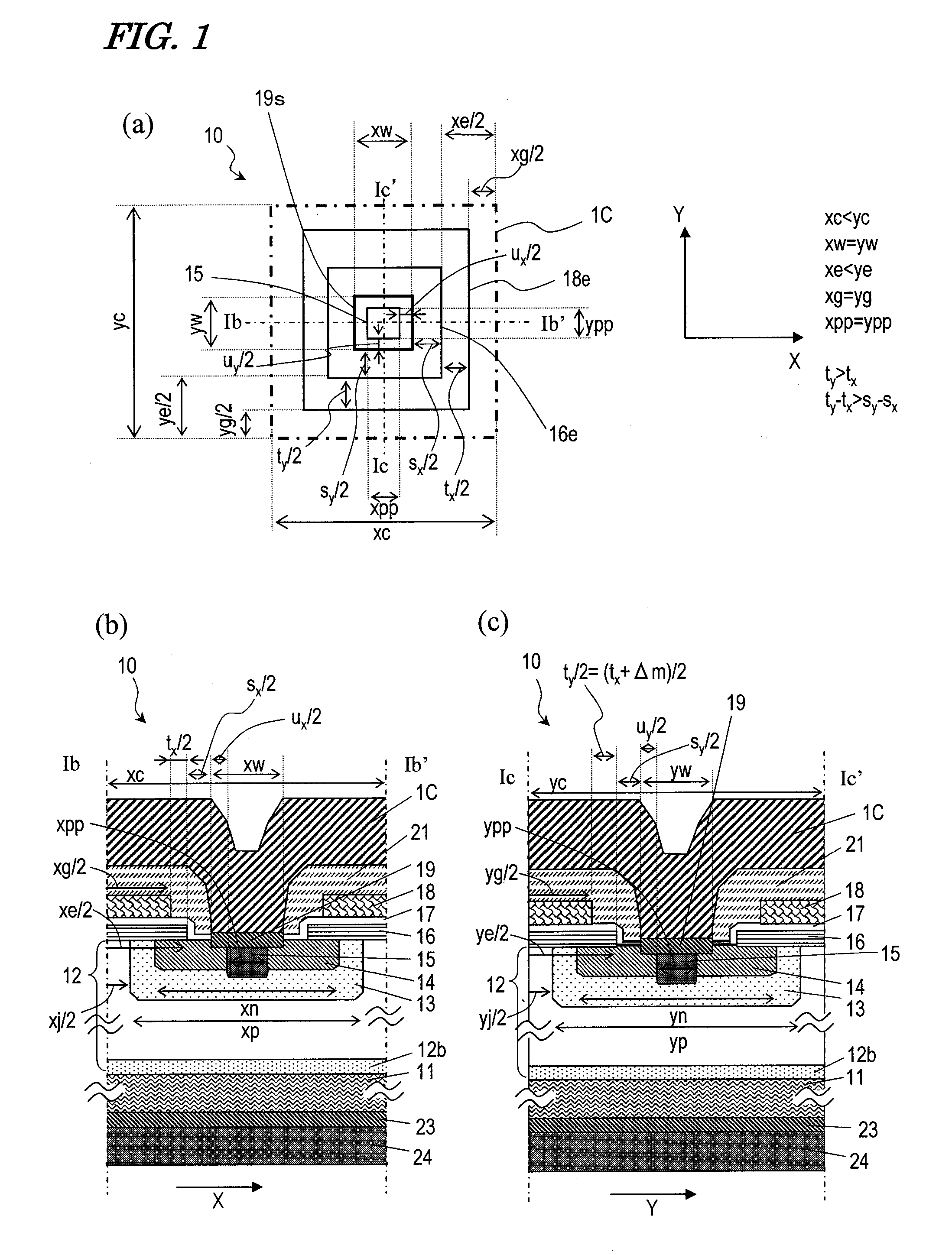

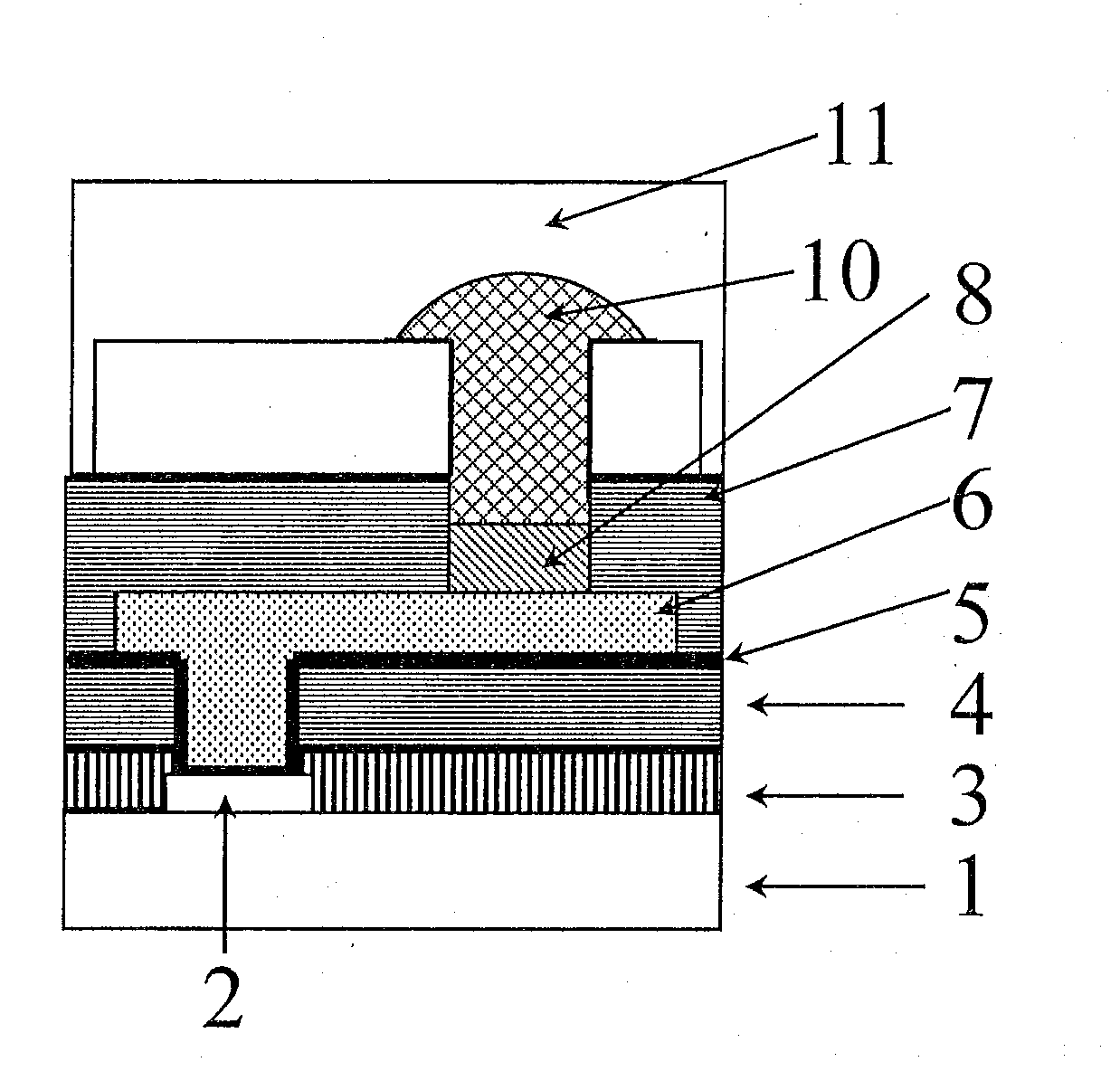

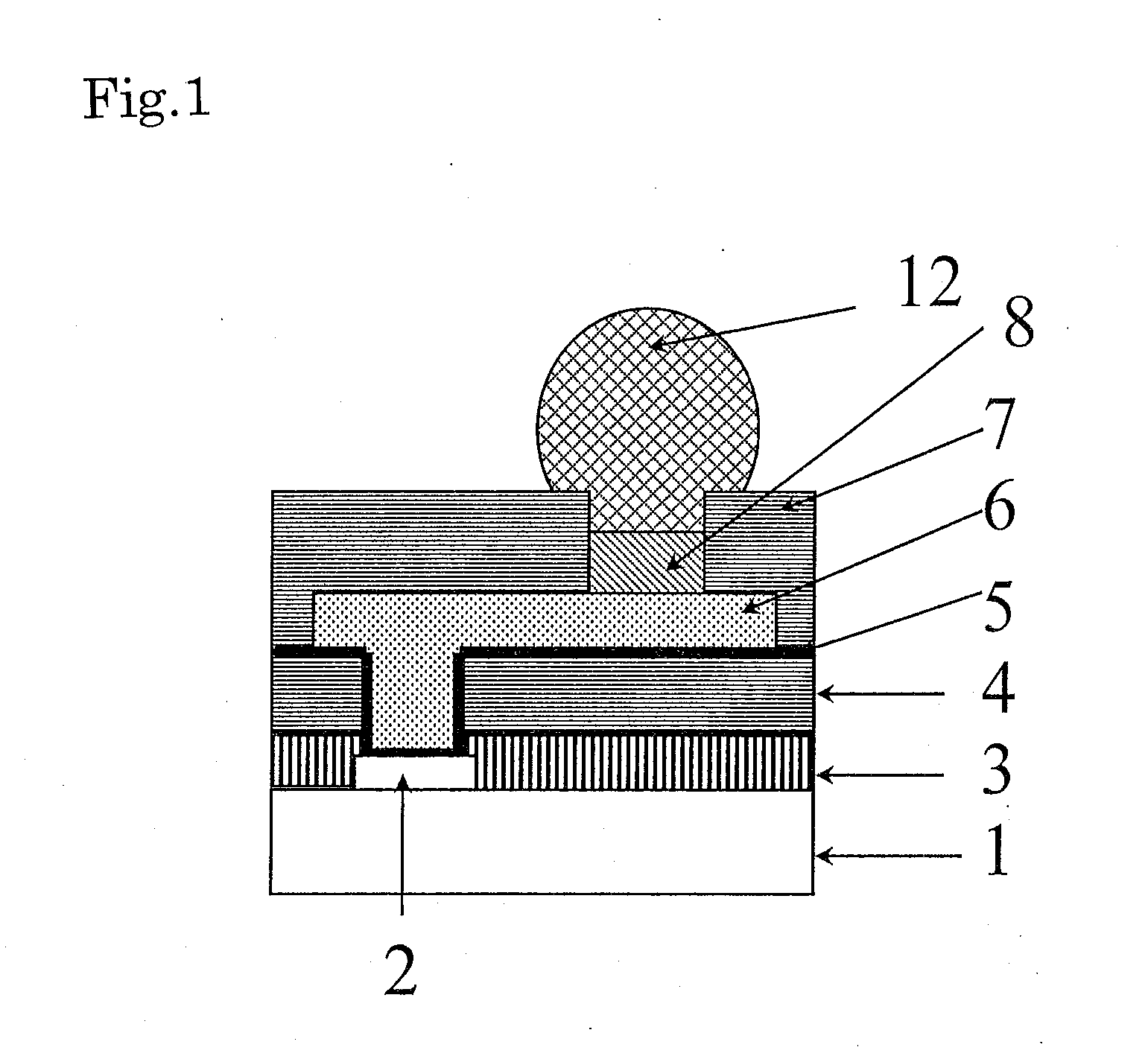

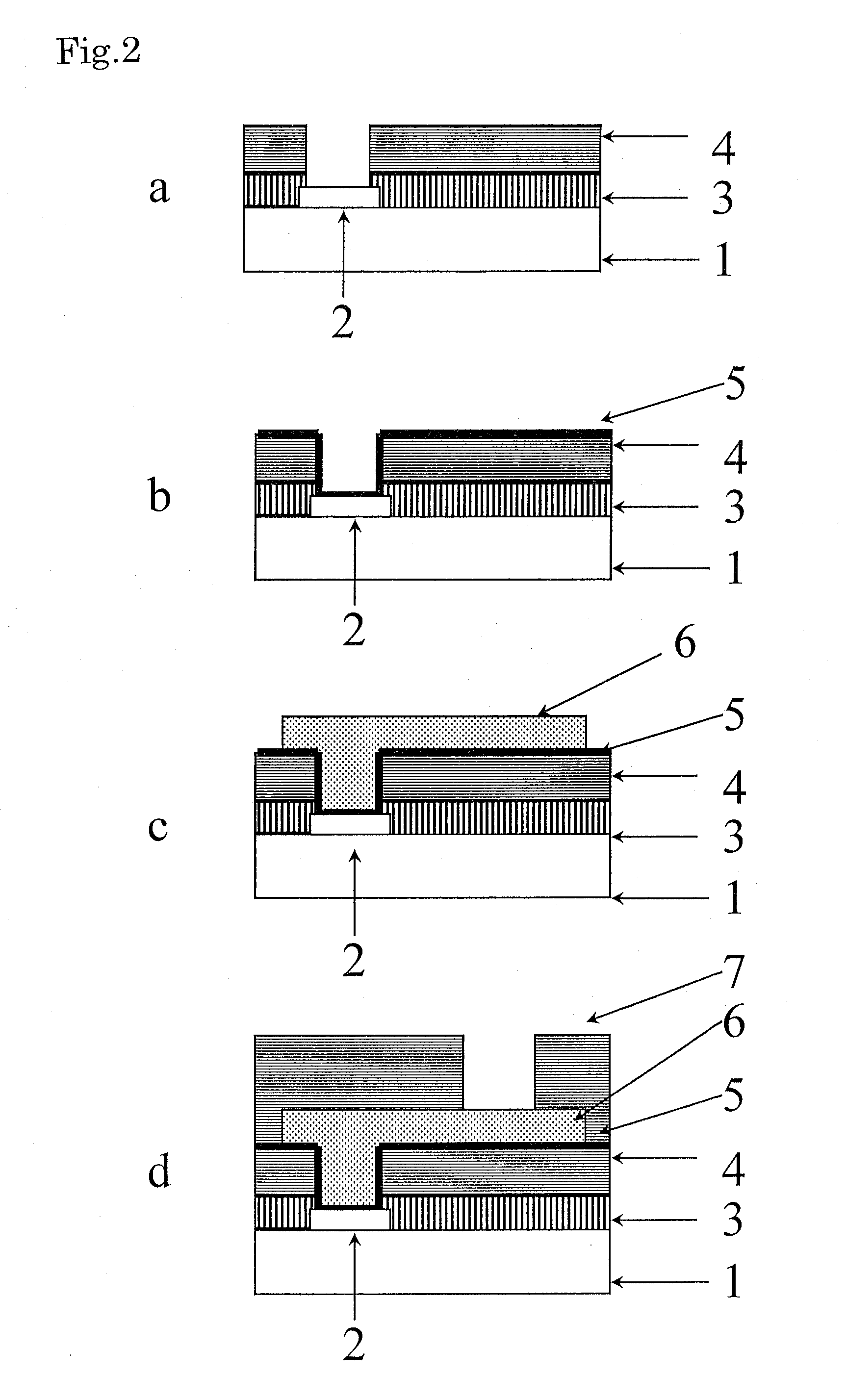

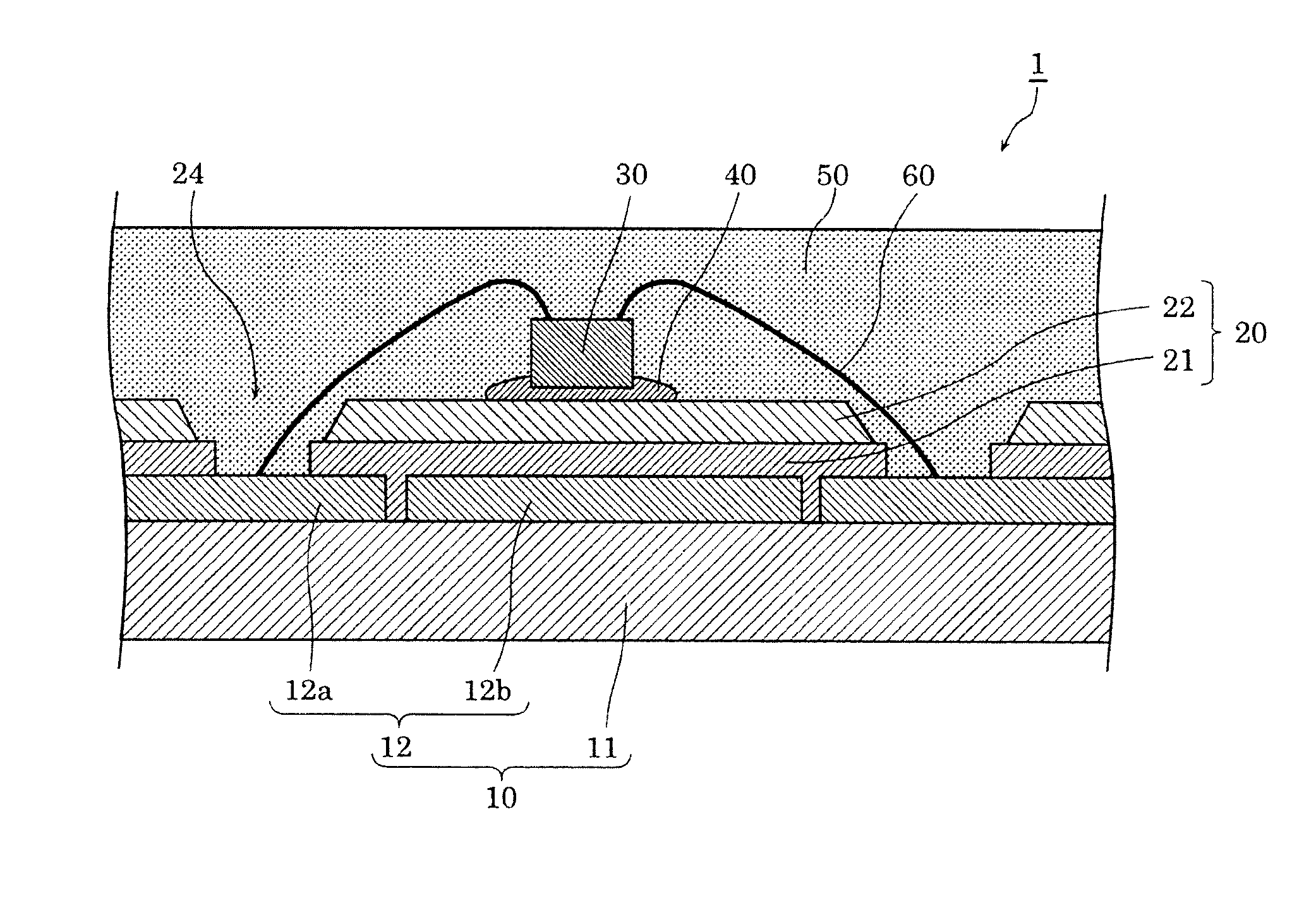

Semiconductor device

ActiveUS20100193800A1Highly reliableReducing recognizabilitySemiconductor/solid-state device detailsSolid-state devicesPhysicsElectrical conductor

A semiconductor device is fabricated on an off-cut semiconductor substrate 11. Each unit cell 10 thereof includes: a first semiconductor layer 12 on the surface of the substrate 11; a second semiconductor layer 16 stacked on the first semiconductor layer 12 to have an opening 16e that exposes first and second conductive regions 15 and 14 at least partially; a first conductor 19 located inside the opening 16e of the second semiconductor layer 16 and having a conductive surface 19s that contacts with the first and second conductive regions 15 and 14; and a second conductor 17 arranged on the second semiconductor layer 16 and having an opening 18e corresponding to the opening 16s of the second semiconductor layer 16. In a plane that is defined parallel to the surface of the substrate 11, the absolute value of a difference between the respective lengths of the second semiconductor layer 16 and the second conductor 18 as measured in the off-cut direction is greater than the absolute value of their difference as measured perpendicularly to the off-cut direction.

Owner:PANASONIC CORP

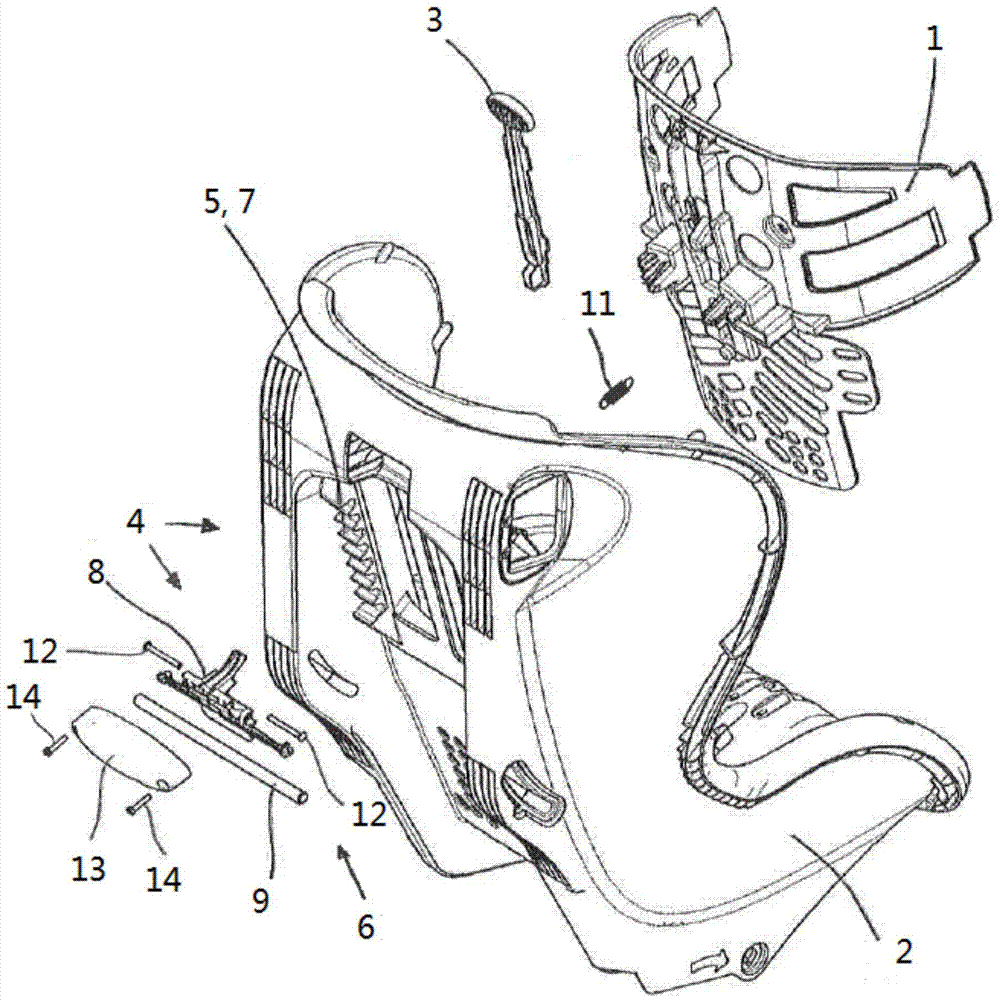

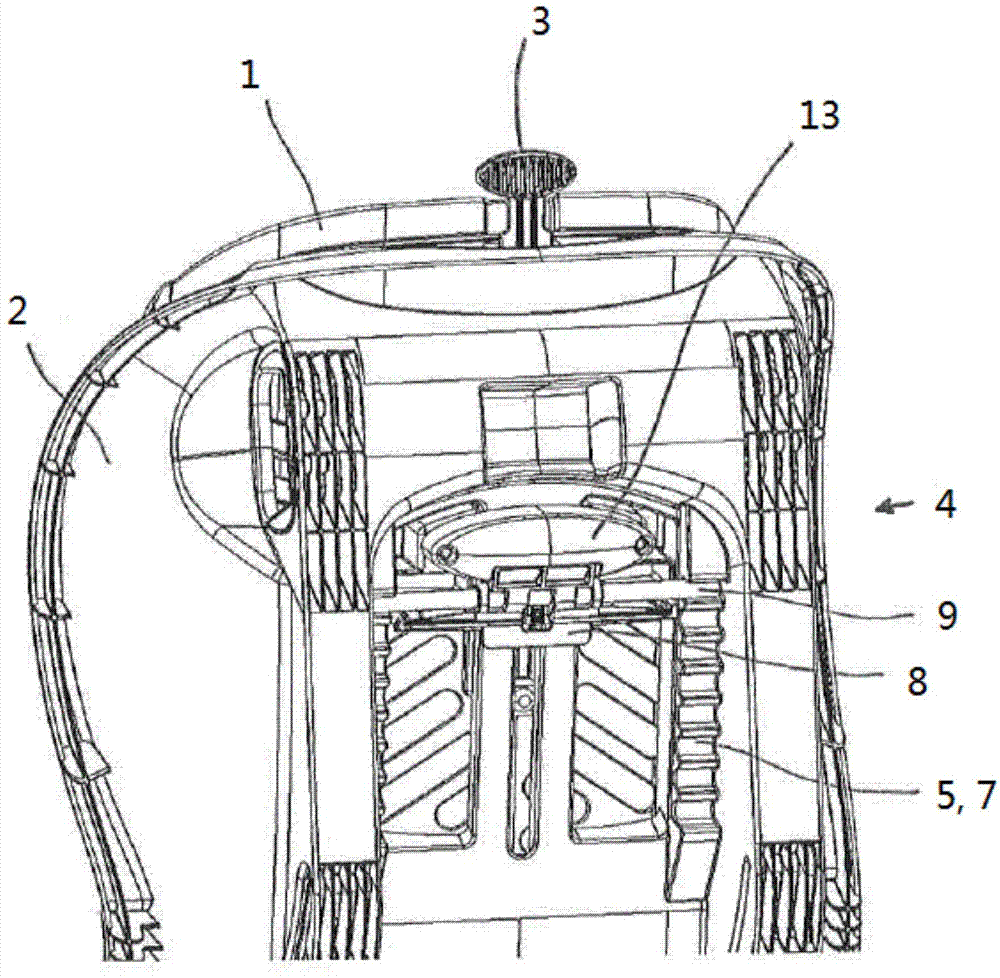

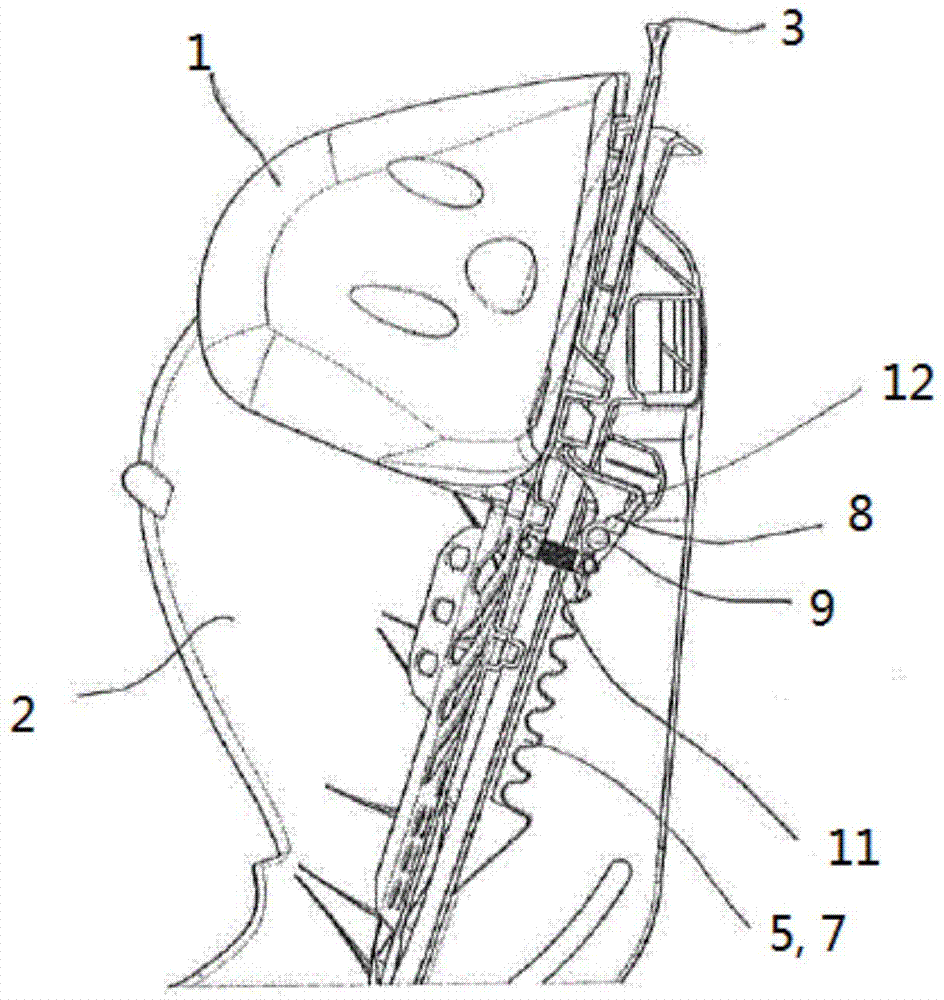

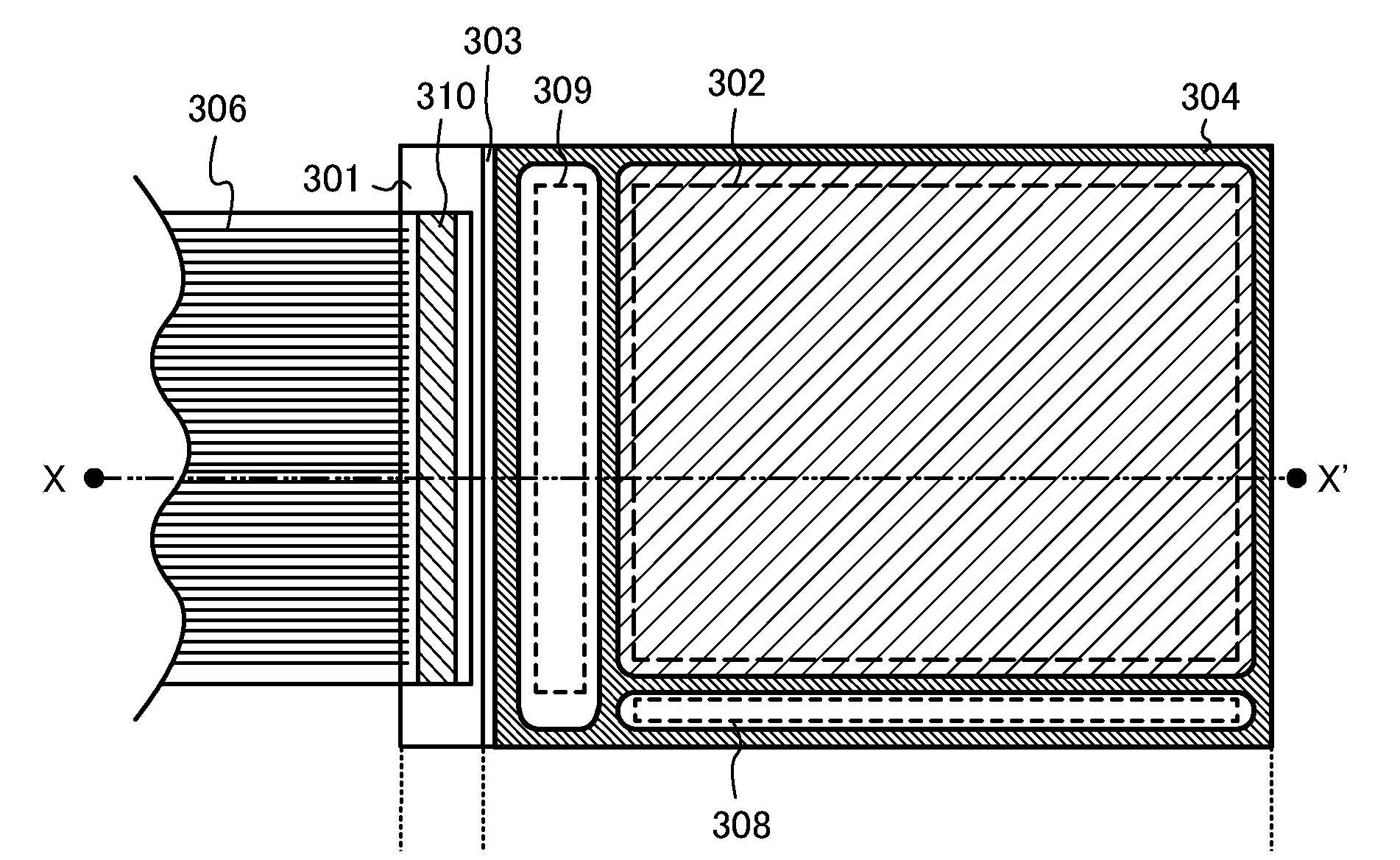

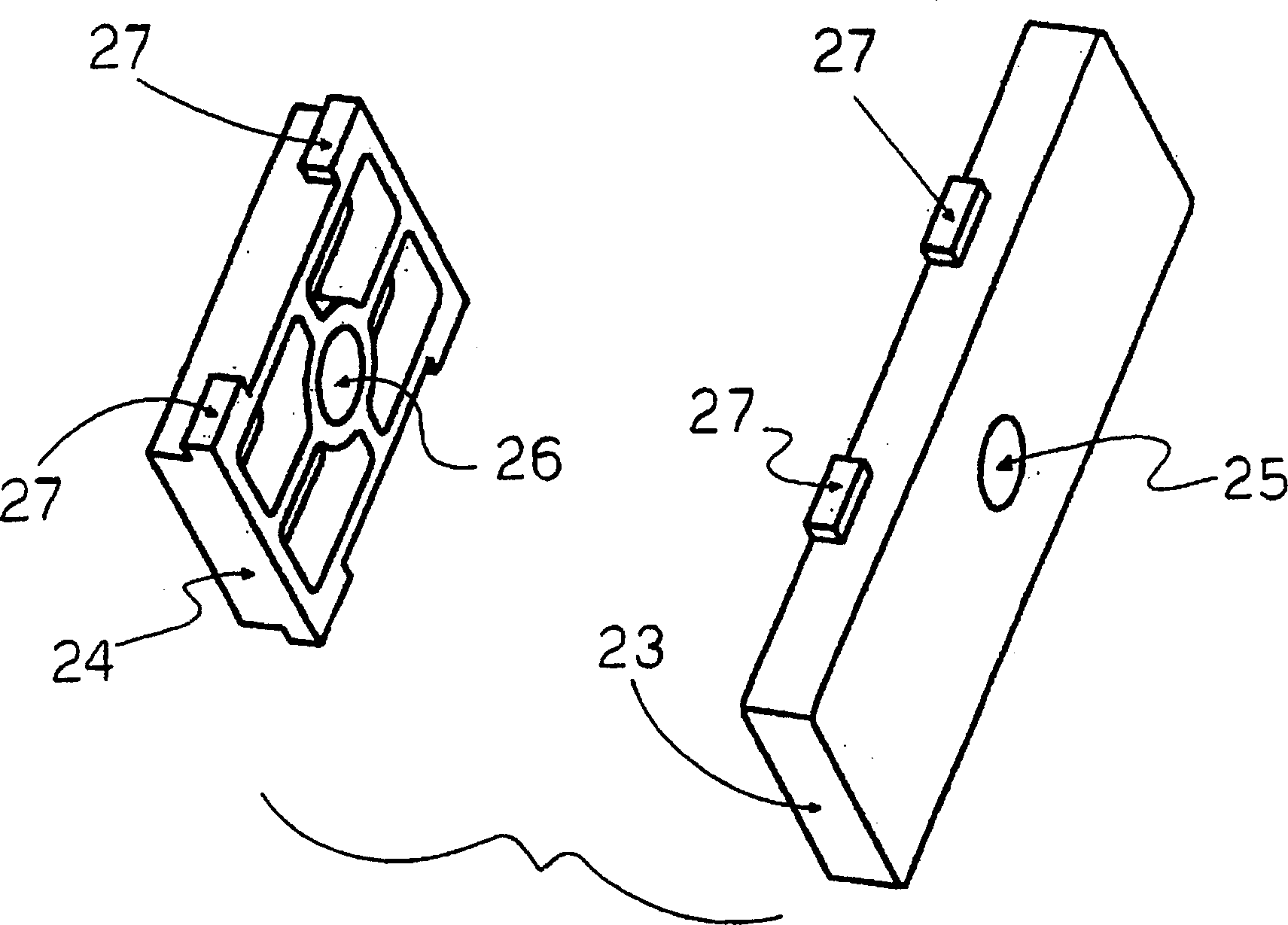

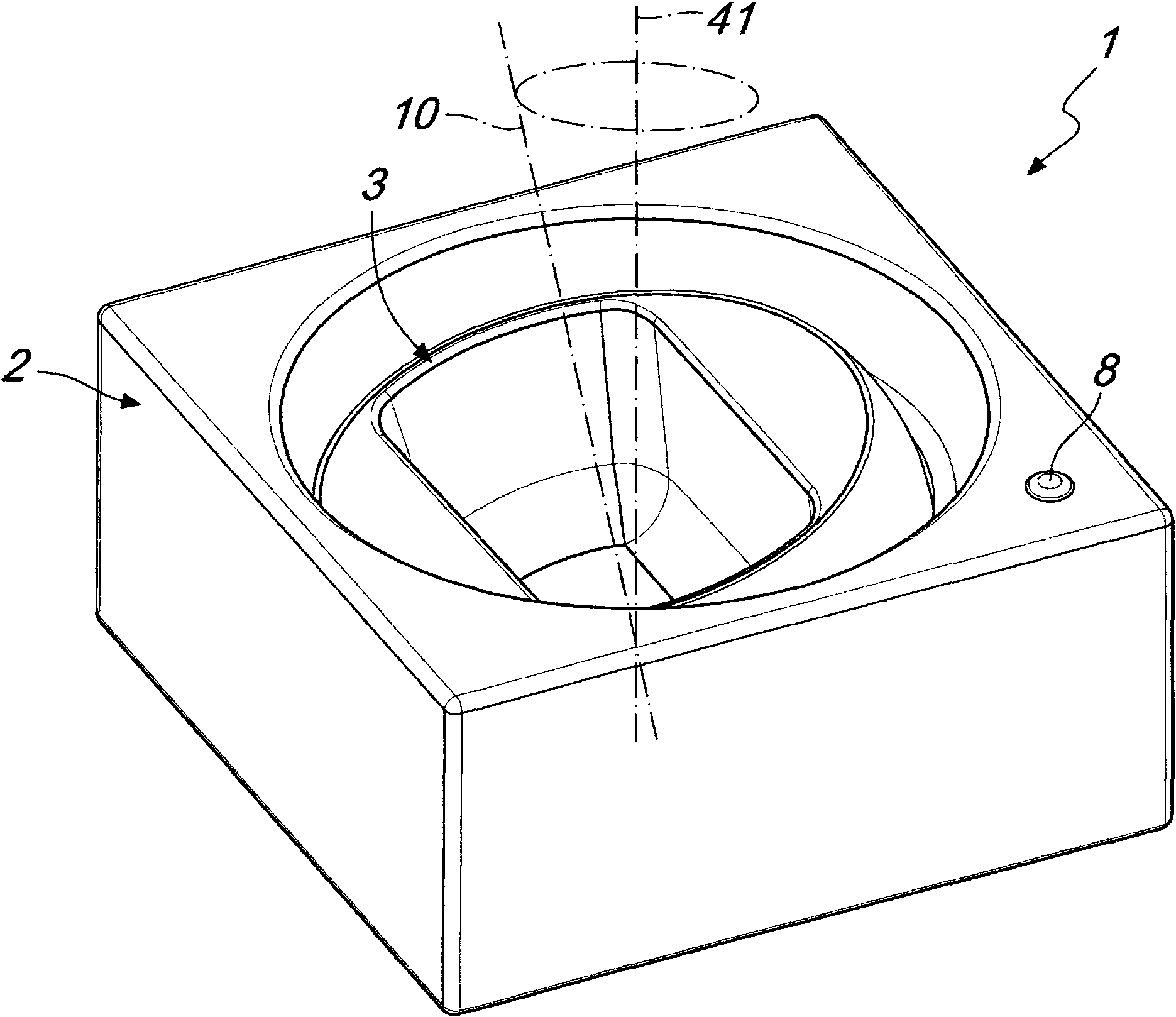

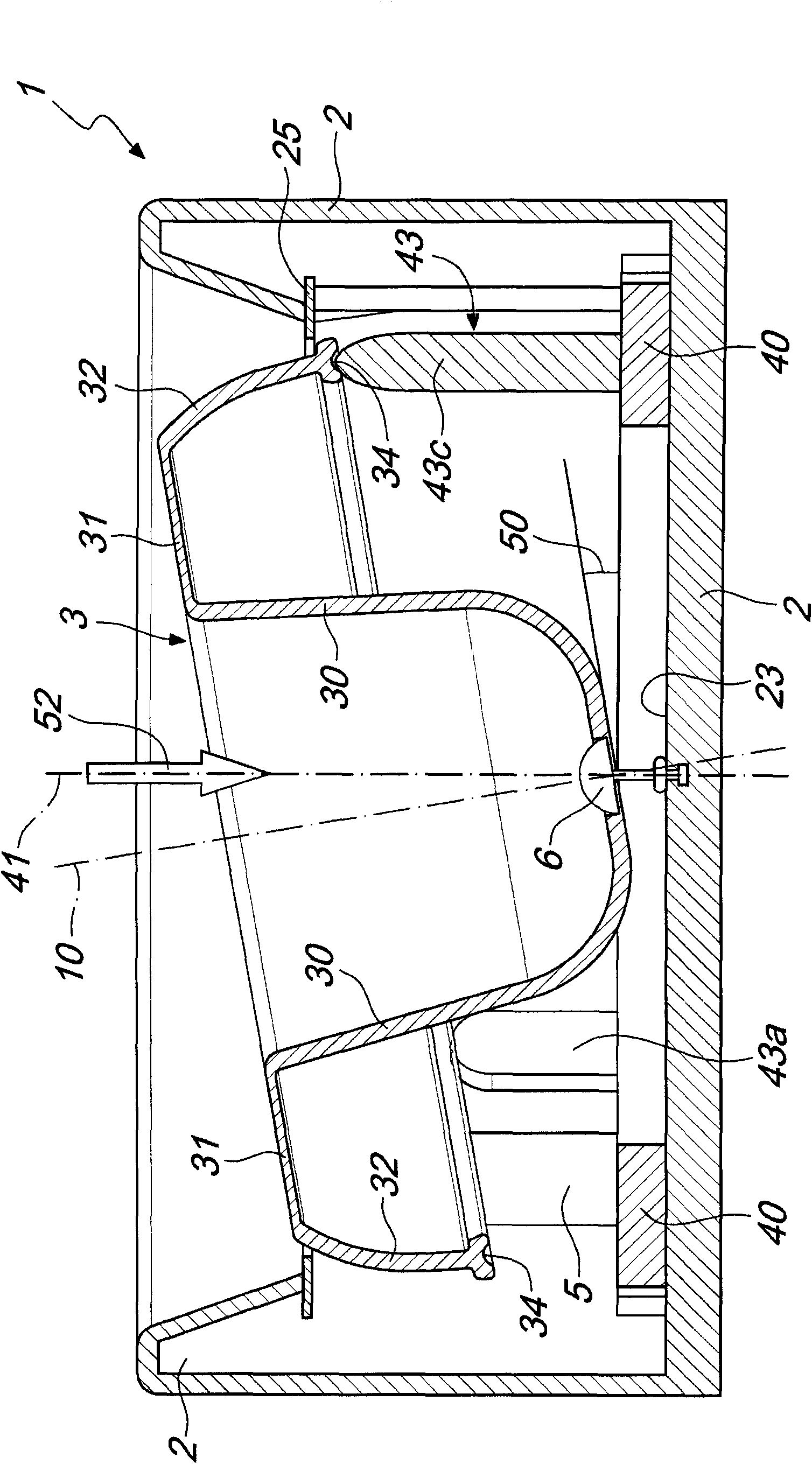

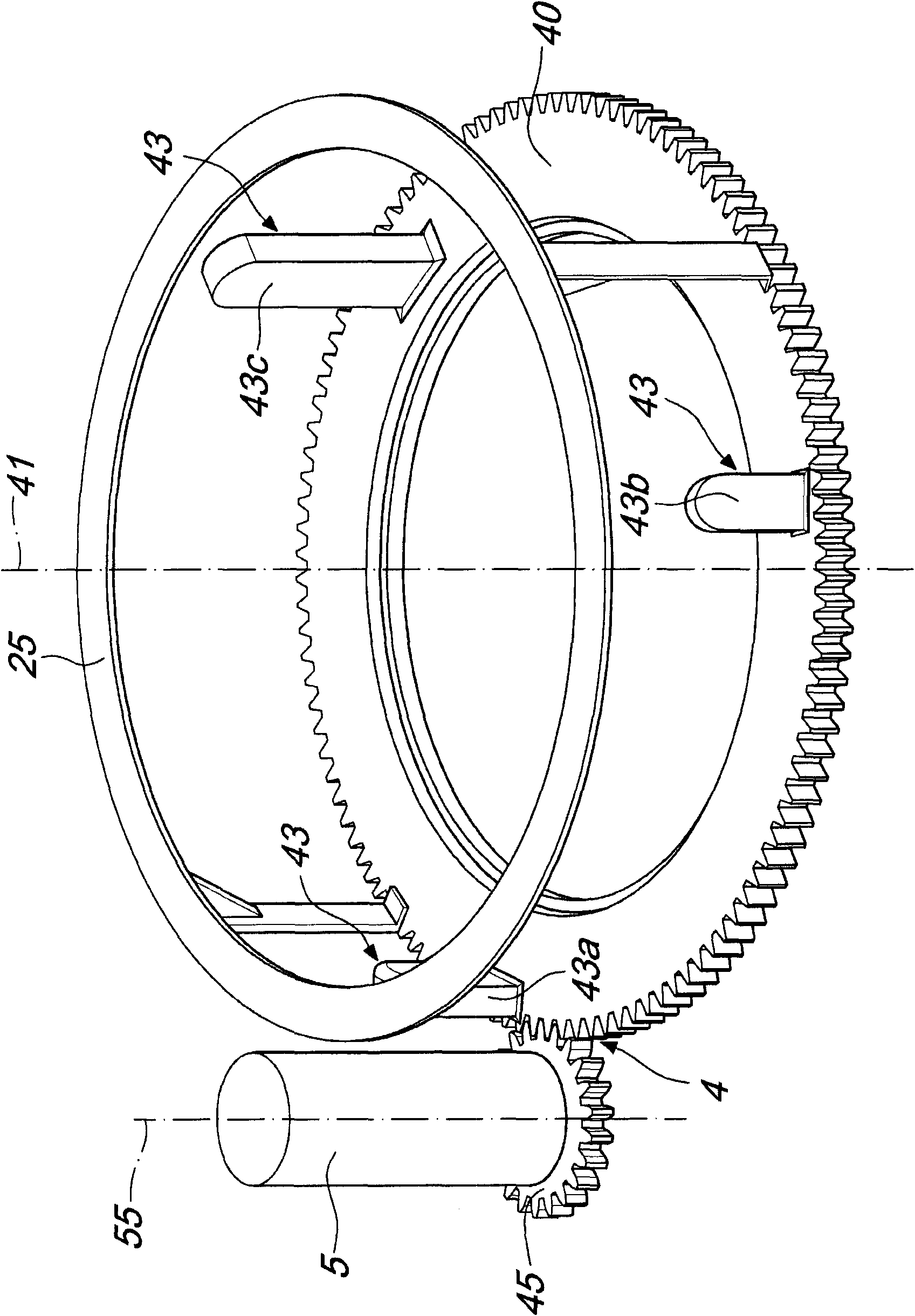

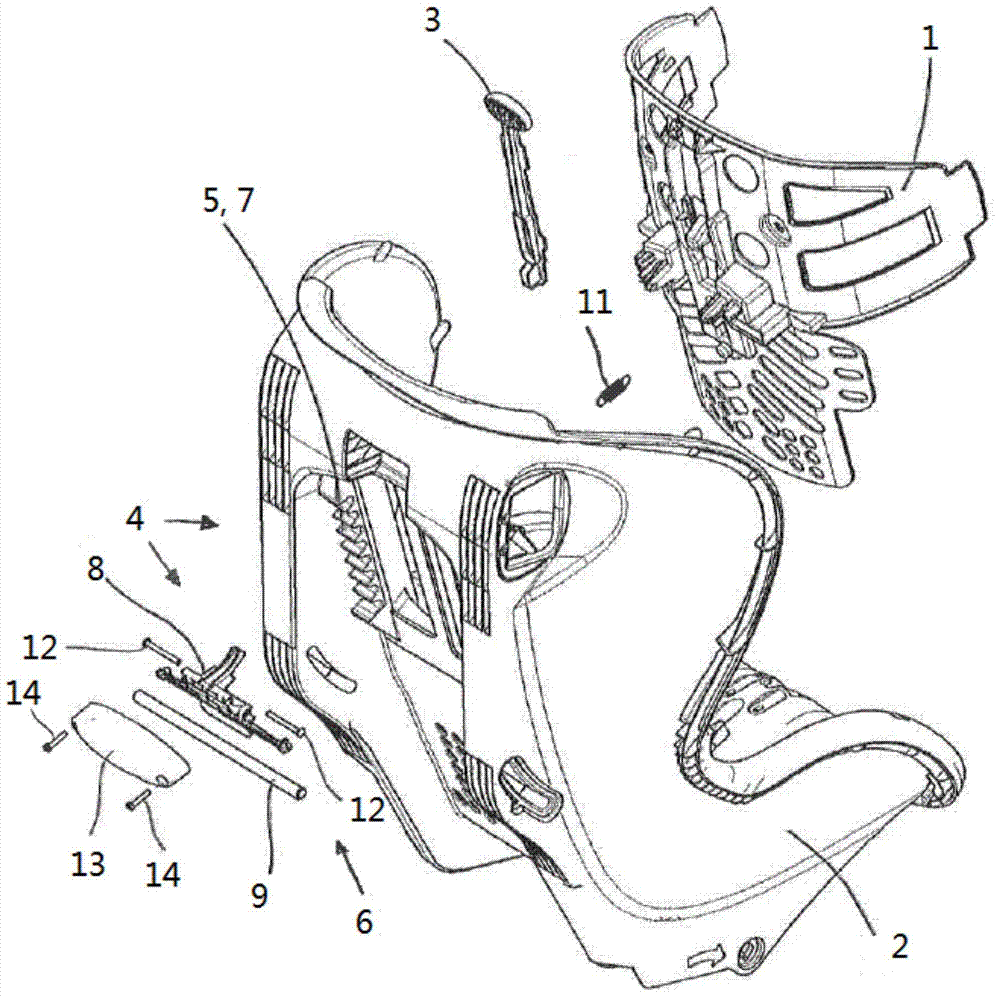

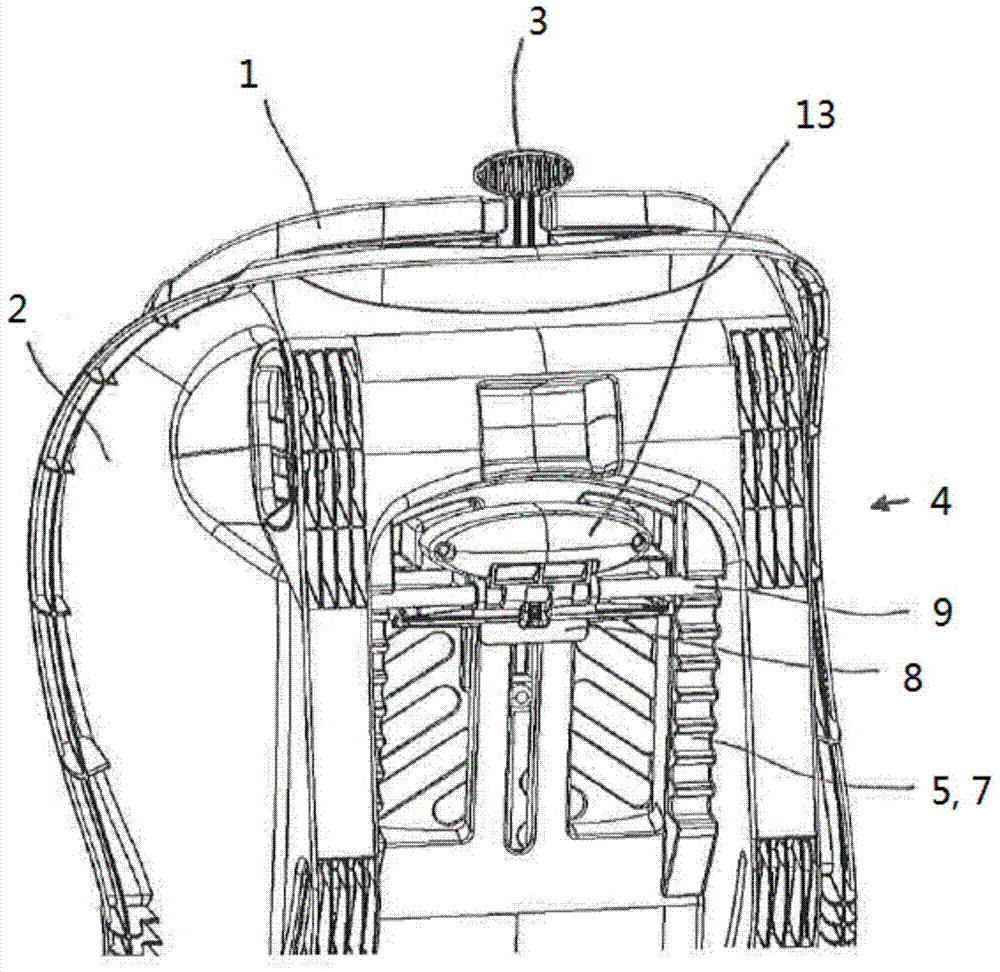

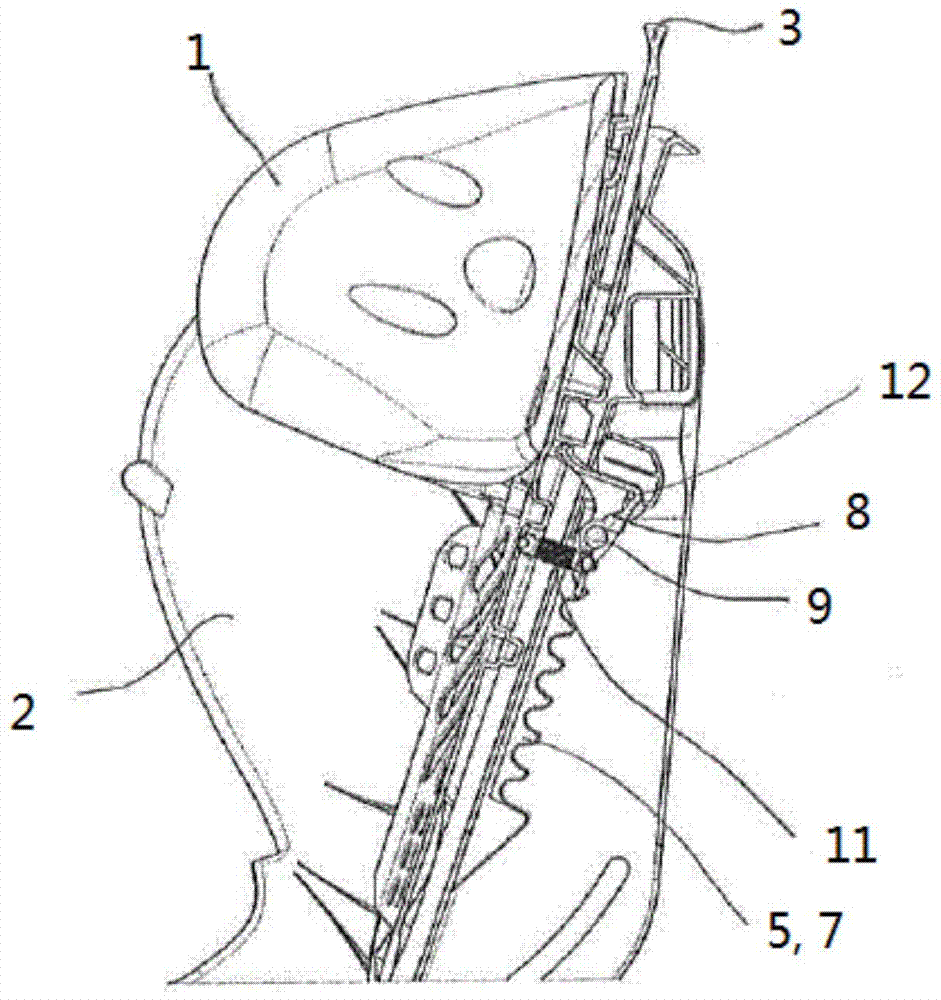

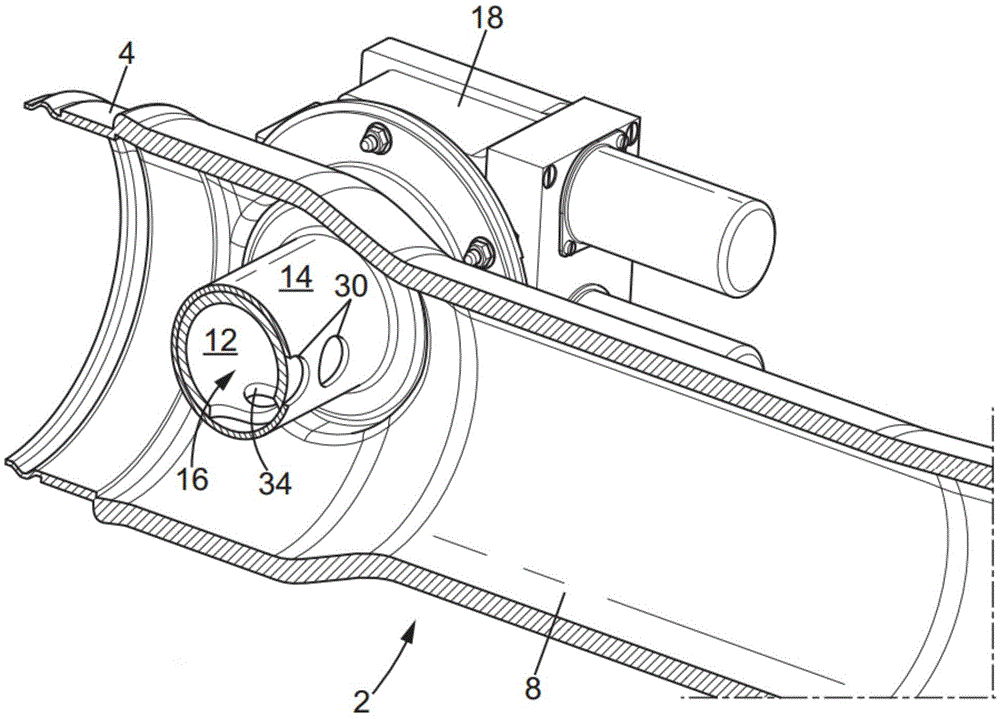

Child safety seat

The present invention discloses a height adjusting mechanism for adjusting a headrest (1) of a child safety seat. The child safety seat includes a seat body (2) and the headrest (1). The headrest (1) is slidably mounted on the seat body (2) and can slide up and down. The adjusting mechanism includes an actuator (3) and a locking means (4), wherein the locking means (4) is used for releasably locking the headrest (1) at a preselected height, and the actuator (3) is used by itself action to release the locking means (4) so that the height of the headrest (1) can be adjusted. The actuator (3) is located between the headrest (1) and the seat body (2) and extends outside the headrest (1). Preferably, the locking means (4) comprises a first component (5) mounted on the seat body (2) and a second component (6) mounted on the headrest (1), wherein the second component (6) and the first component (5) are releasably engaged.

Owner:BRITAX ROMER KINDERSICHERHEIT

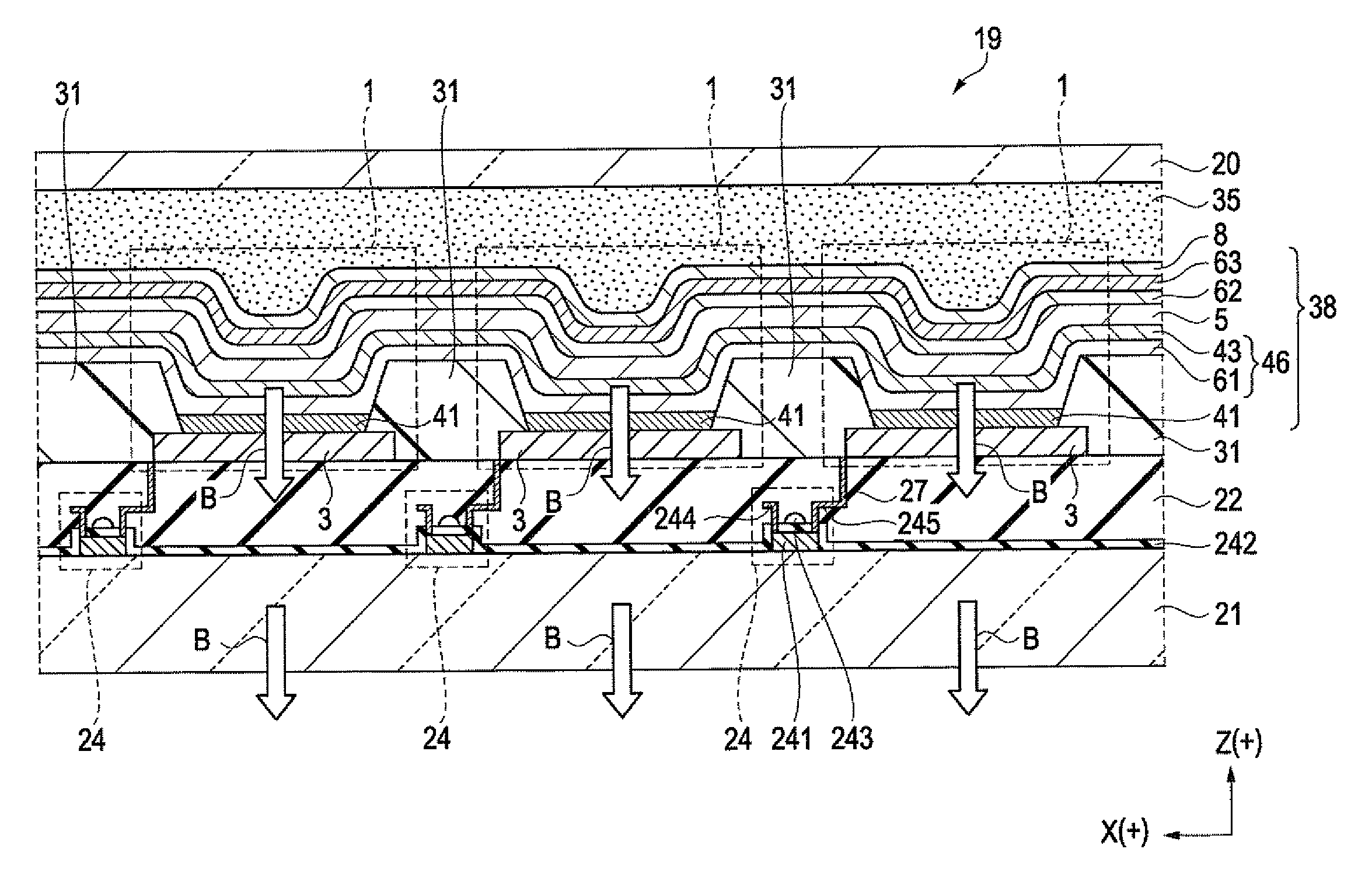

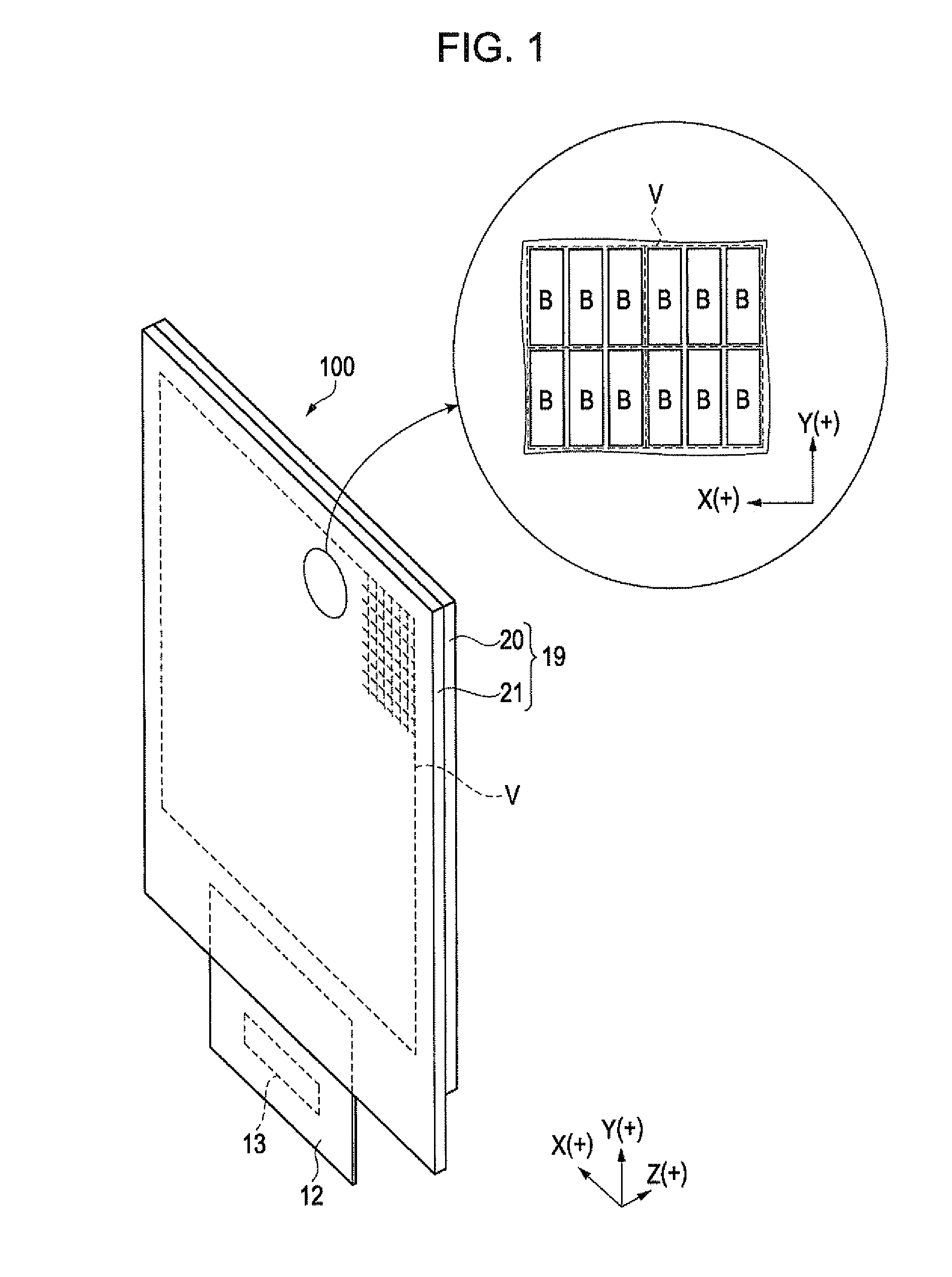

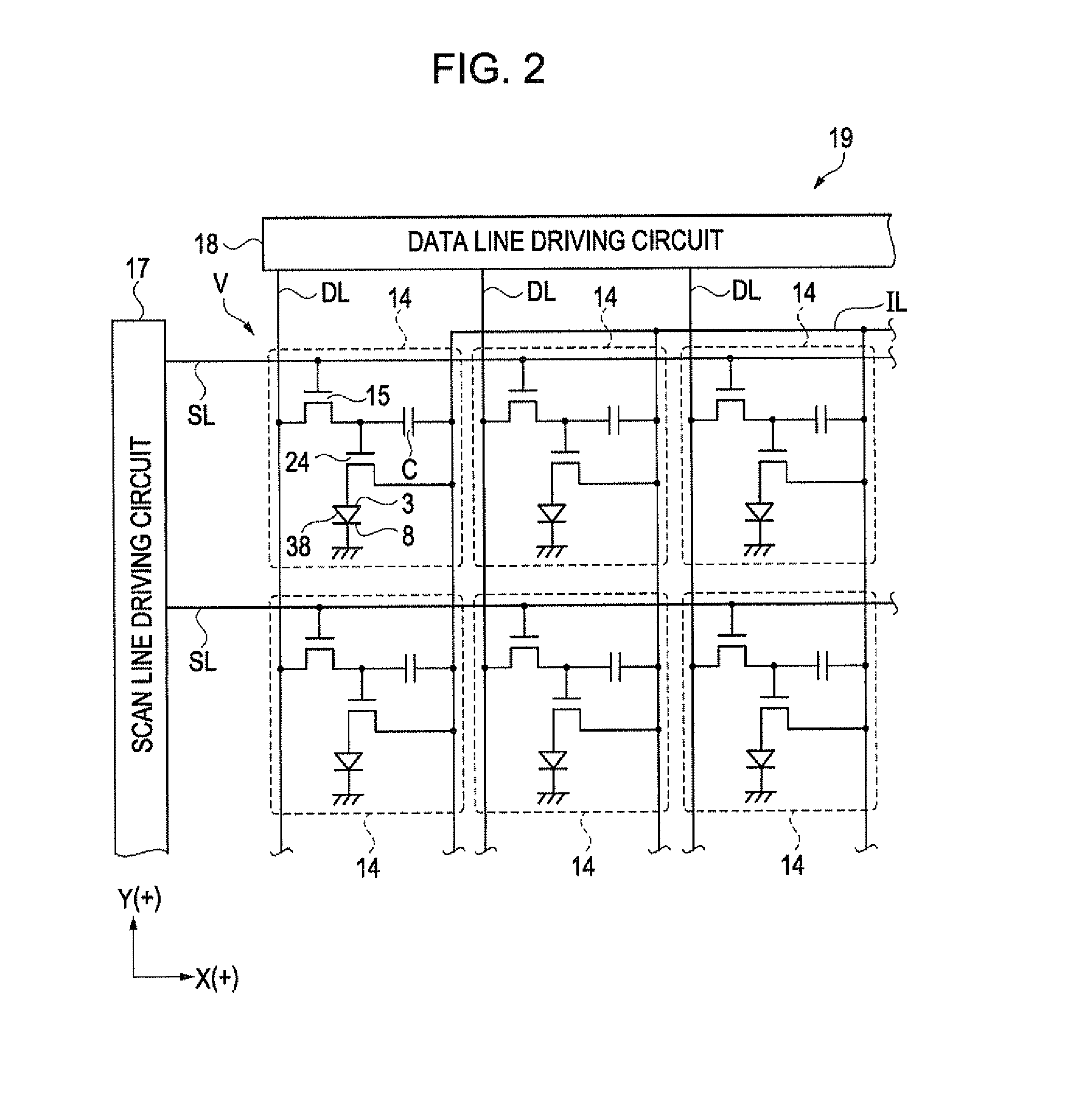

Light emitting device, display apparatus, and electronic apparatus

ActiveUS20120146062A1Highly reliableEasy to transportSolid-state devicesSemiconductor lamp usageElectric devicesHole injection layer

In a display panel, a first electron injection layer is formed between an anode and a light-emitting functional layer, and a hole injection layer is formed between the anode and the first electron injection layer. In other words, the hole injection layer, the first electron injection layer, and the light-emitting functional layer are configured to be laminated on the anode in this order. An electron injection material used for the first electron injection layer is diffused into the hole injection layer, and the diffused electron injection material inhibits or promotes hole transportation of the hole injection layer, so that the amount of holes transported to a light-emitting functional layer is adjusted. As a result, the carrier balance is improved.

Owner:SEIKO EPSON CORP

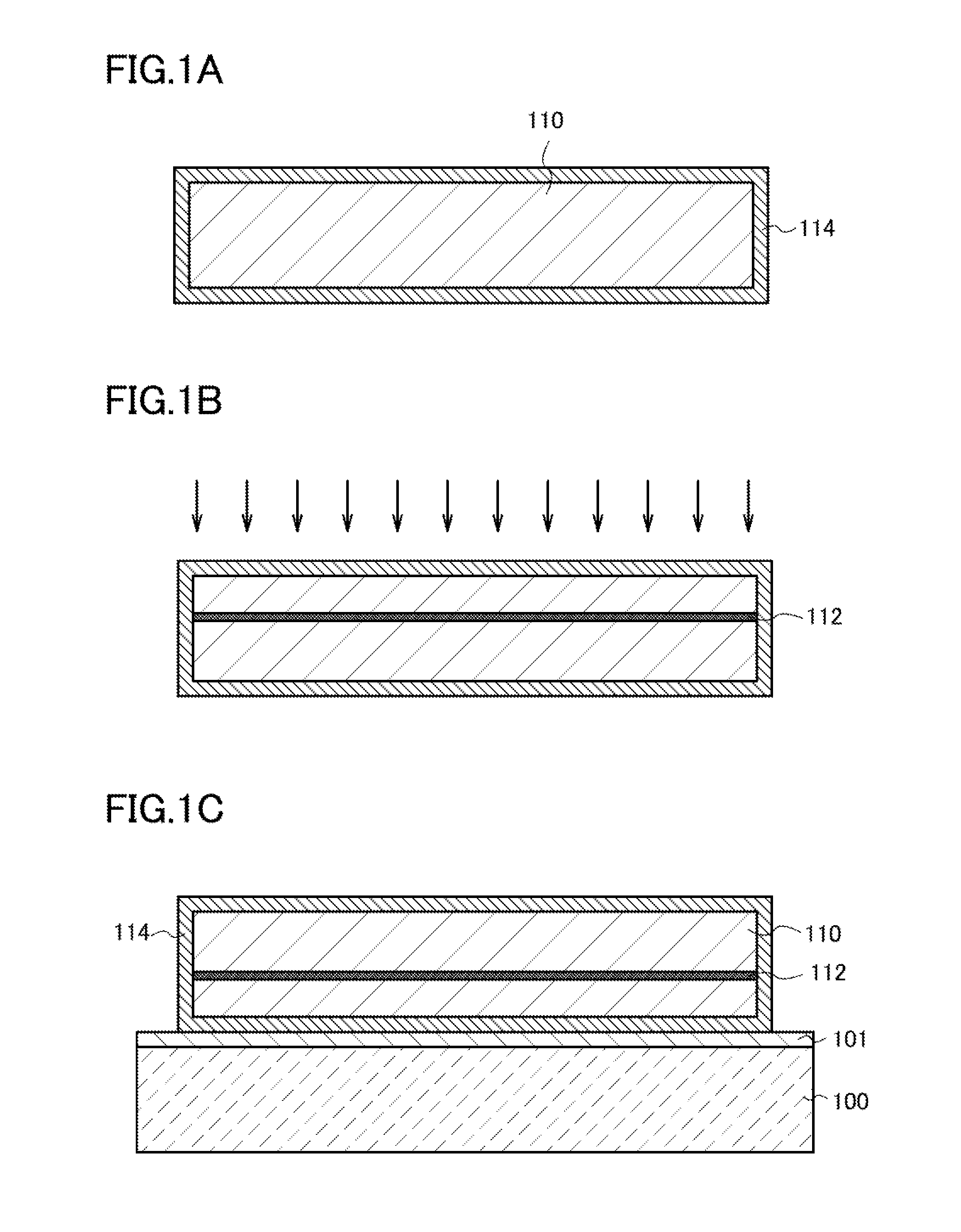

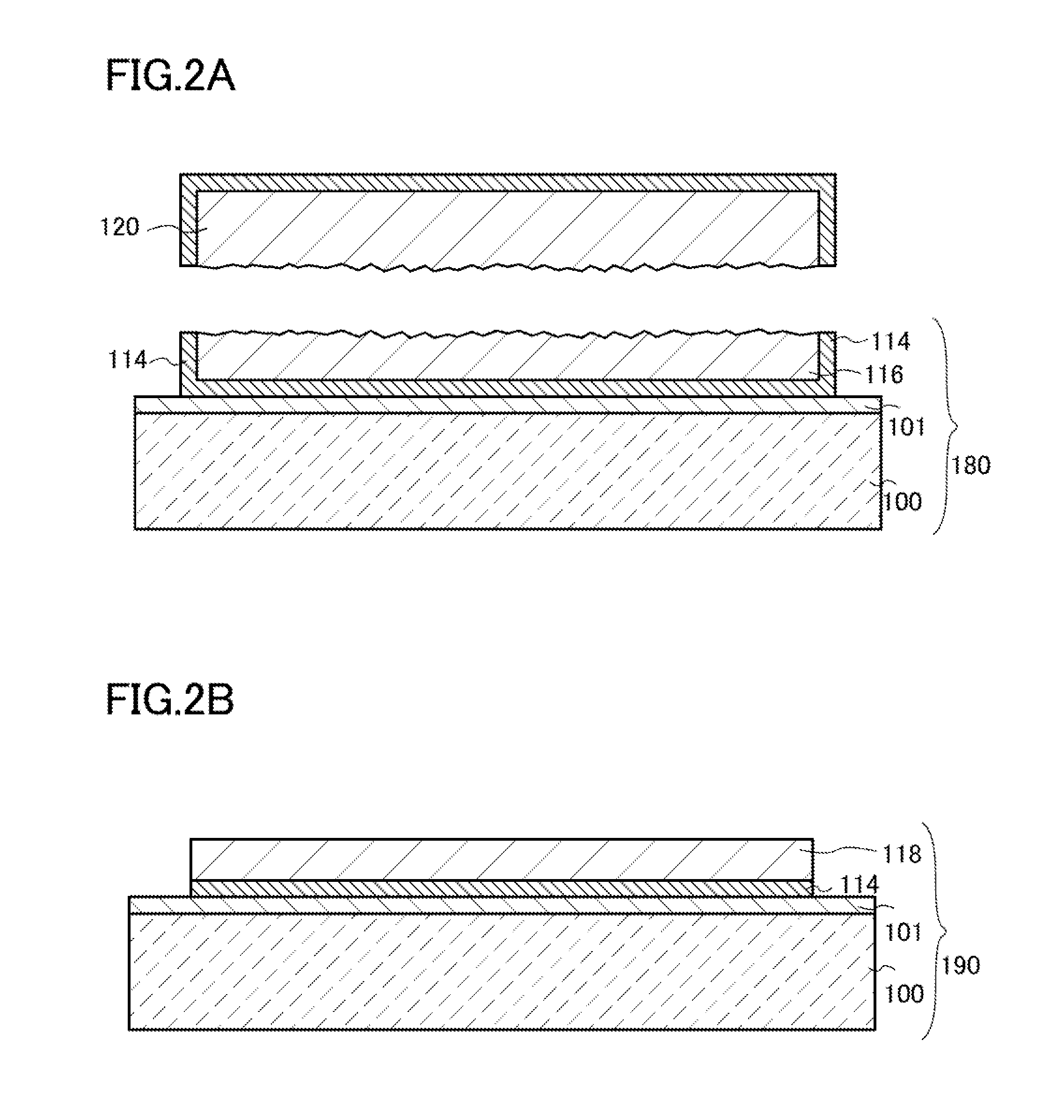

Semiconductor device and method for manufacturing the same

ActiveUS20120194756A1Highly reliableReduce numberStatic indicating devicesSolid-state devicesOxide semiconductorPhotolithography

The number of photolithography steps used for manufacturing a transistor is reduced to less than the conventional one and a highly reliable semiconductor device is provided. The present invention relates to a semiconductor device including a circuit including a transistor having an oxide semiconductor layer over a first substrate and a second substrate fixed to the first substrate with a sealant. A closed space surrounded by the sealant, the first substrate, and the second substrate is in a reduced pressure state or filled with dry air. The sealant surrounds at least the transistor and has a closed pattern shape. Further, the circuit is a driver circuit including a transistor having an oxide semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

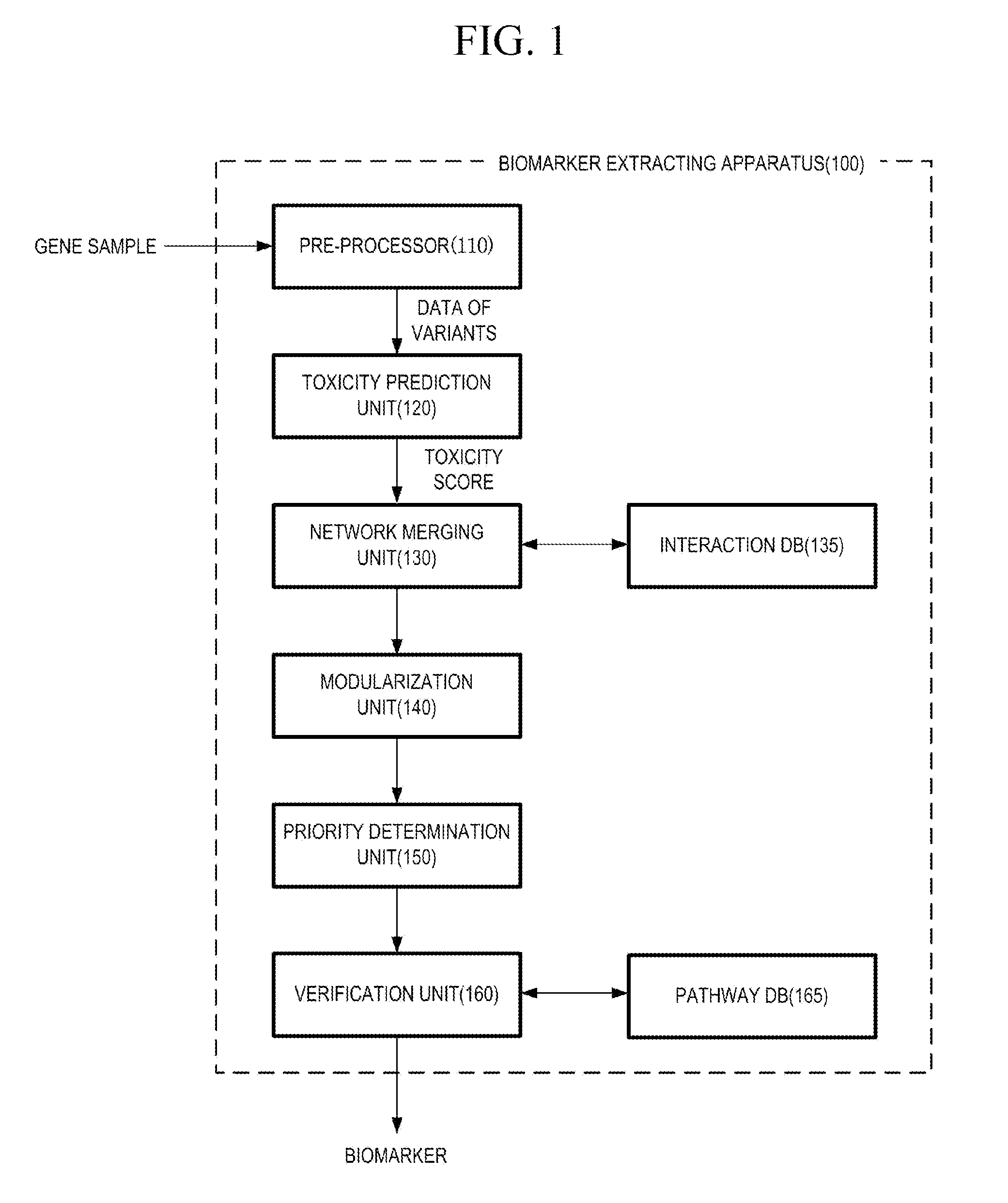

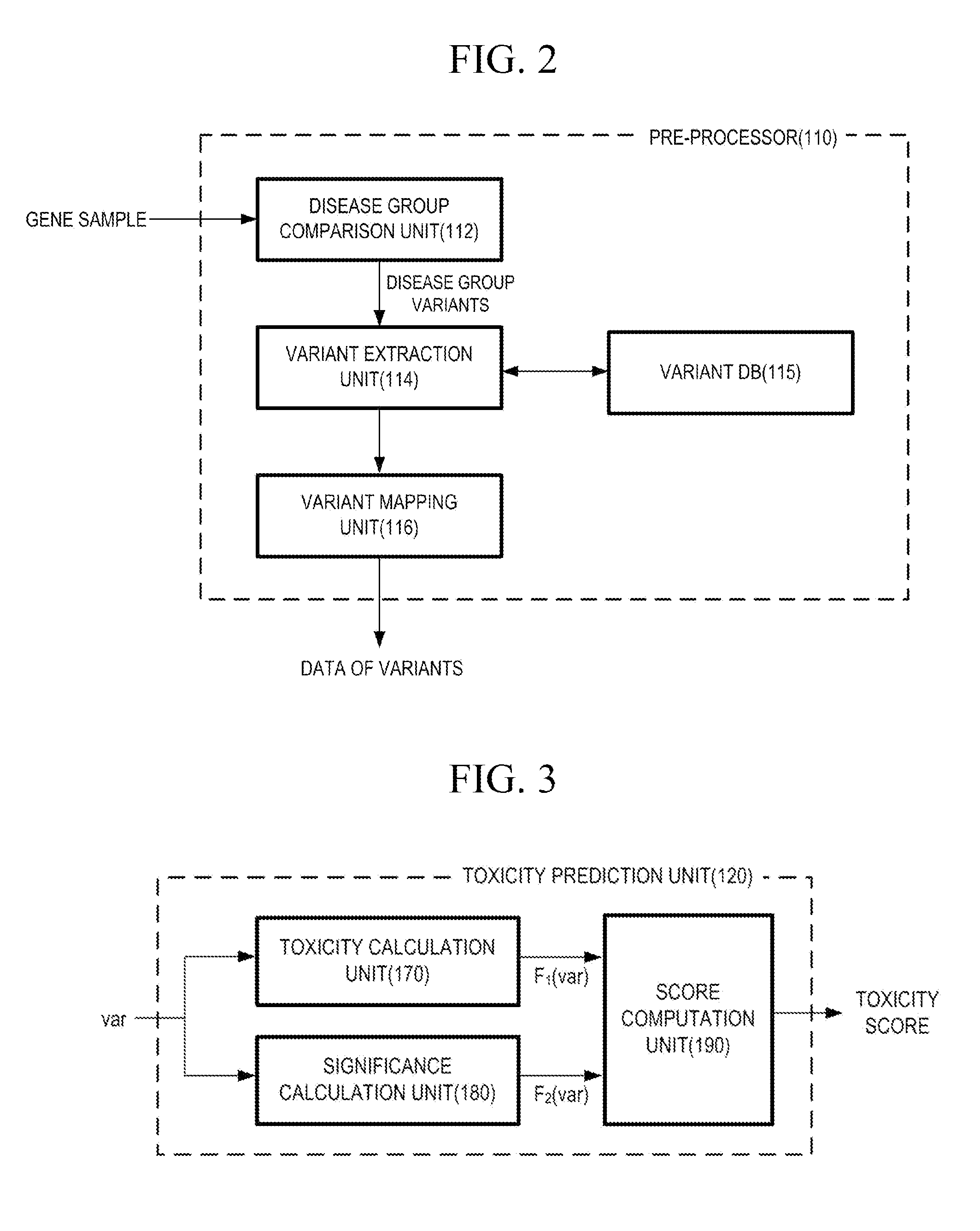

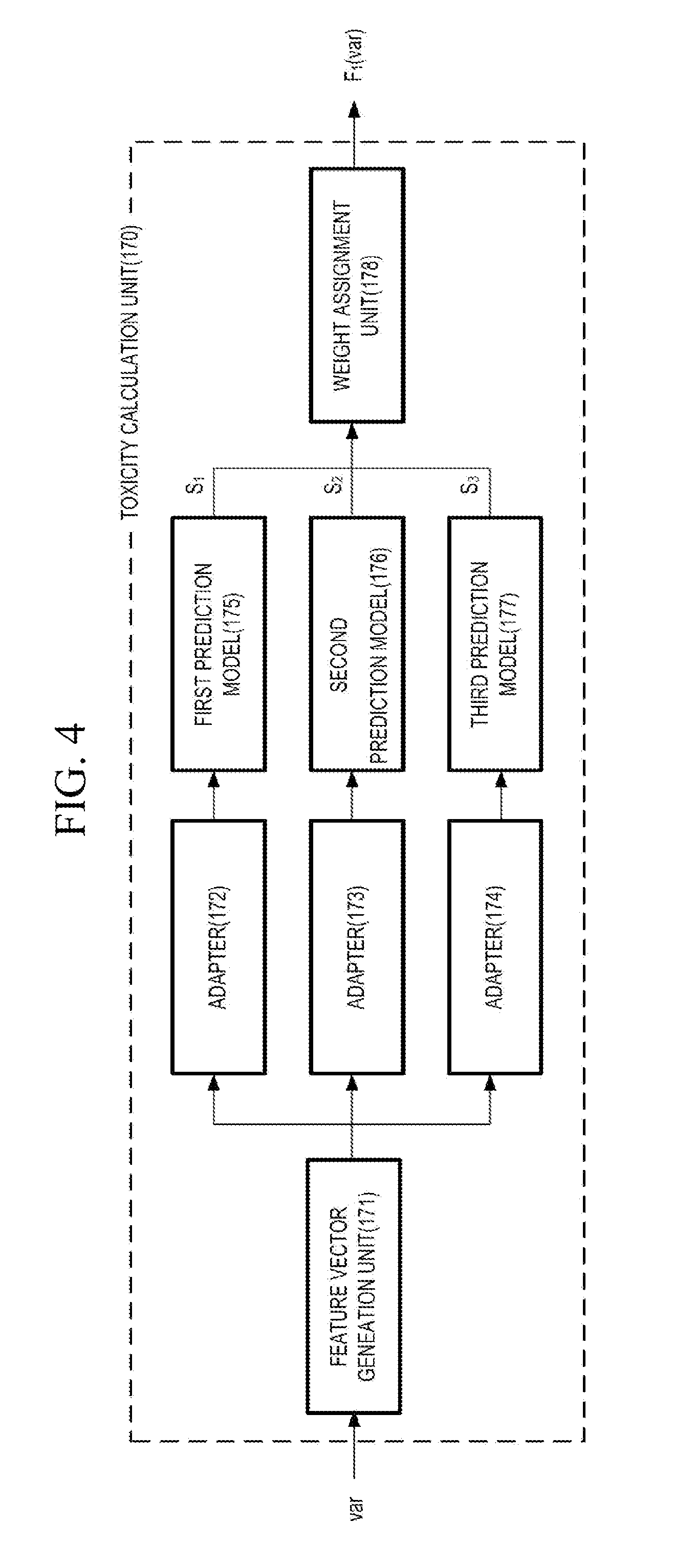

Apparatus and method for extracting biomarkers

InactiveUS20120109615A1Highly reliableMicrobiological testing/measurementAnalogue computers for chemical processesToxicityGenetic variation

An apparatus and method for extracting biomarkers with higher reliability by analyzing toxicity indicating how genetic variants appearing in sequences affect gene functions are provided. The apparatus includes a pre-processor that analyzes sequences of samples of genes and extracts data of genetic variants mapped to the genes, a toxicity prediction unit that obtains toxicity scores obtained by quantifying genetic dysfunctions affected by the data of genetic variants, and a modularization unit that searches for a least one sub-module including a set of genes whose toxicity scores exceed a predetermined critical value from a genetic network.

Owner:SAMSUNG SDS CO LTD

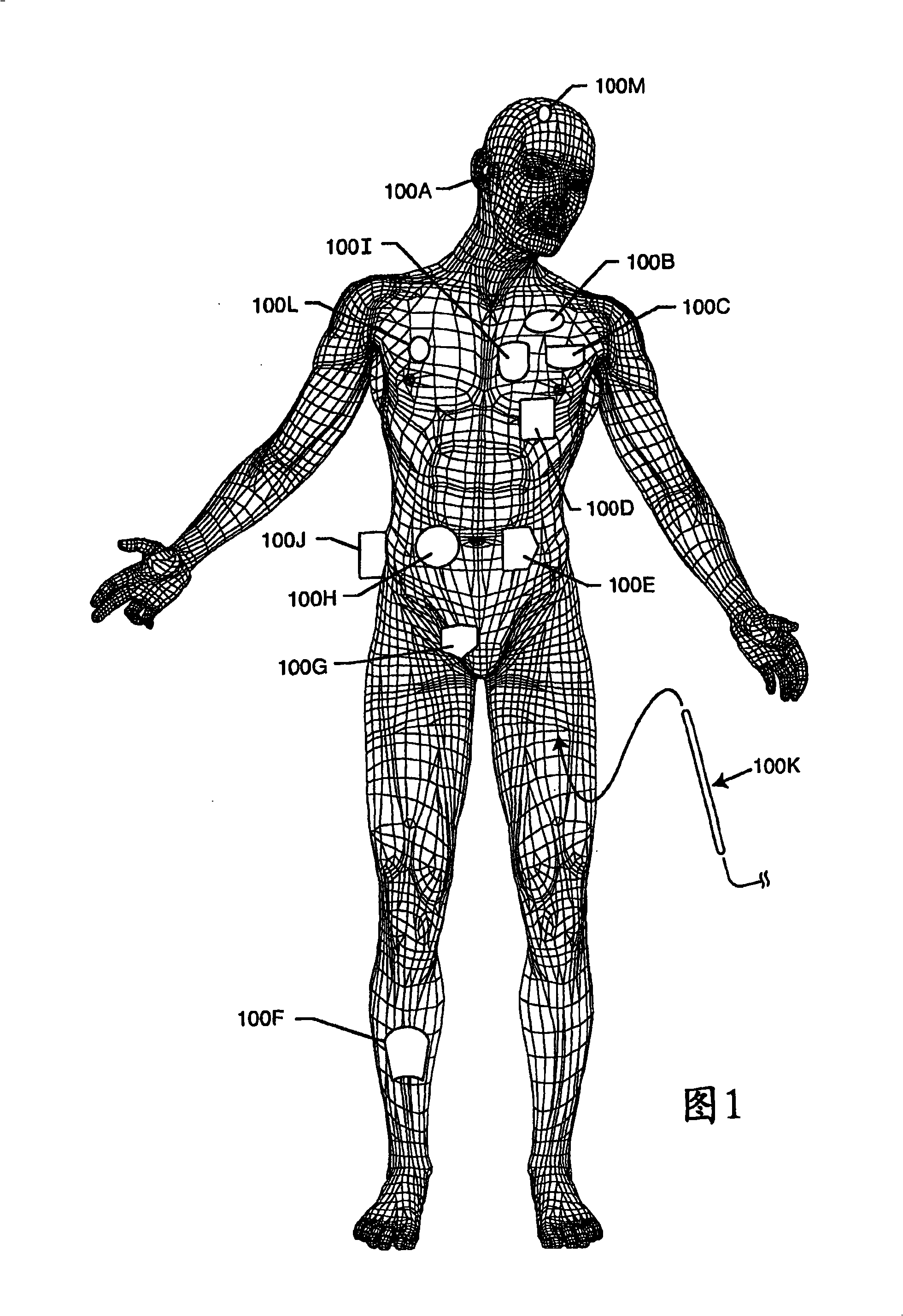

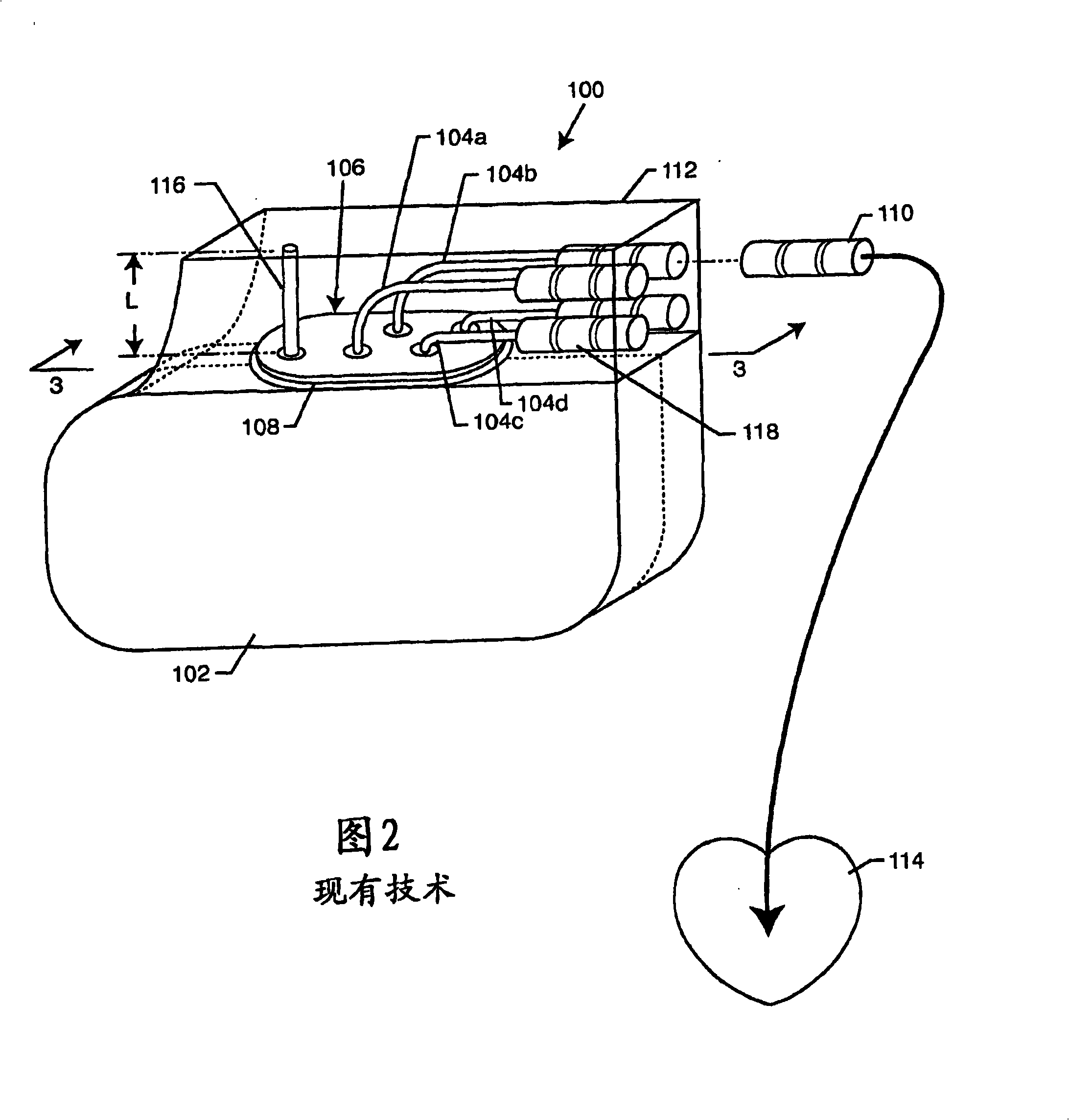

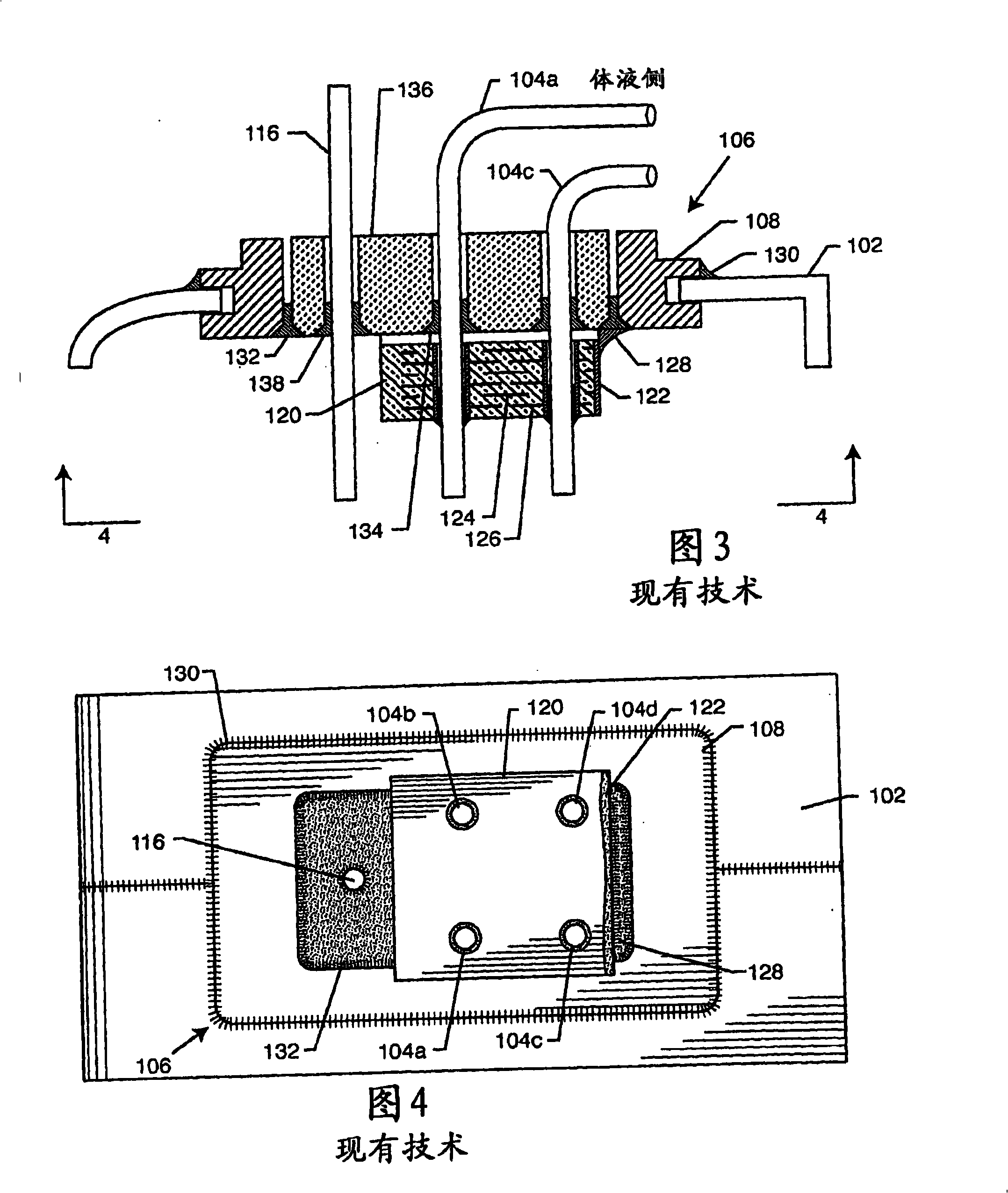

Tank filters placed in series with the lead wires or circuits of active medical devices to enhance MRI compatibility

A TANK filter is provided for a lead wire of an active medical device (AMD). The TANK filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the TANK filter is resonant at a selected frequency. The Q of the inductor may be relatively maximized and the Q of the capacitor may be relatively minimized to reduce the overall Q of the TANK filter to attenuate current flow through the lead wire along a range of selected frequencies. In a preferred form, the TANK filter is integrated into a TIP and / or RING electrode for an active implantable medical device.

Owner:WILSON GREATBATCH LTD

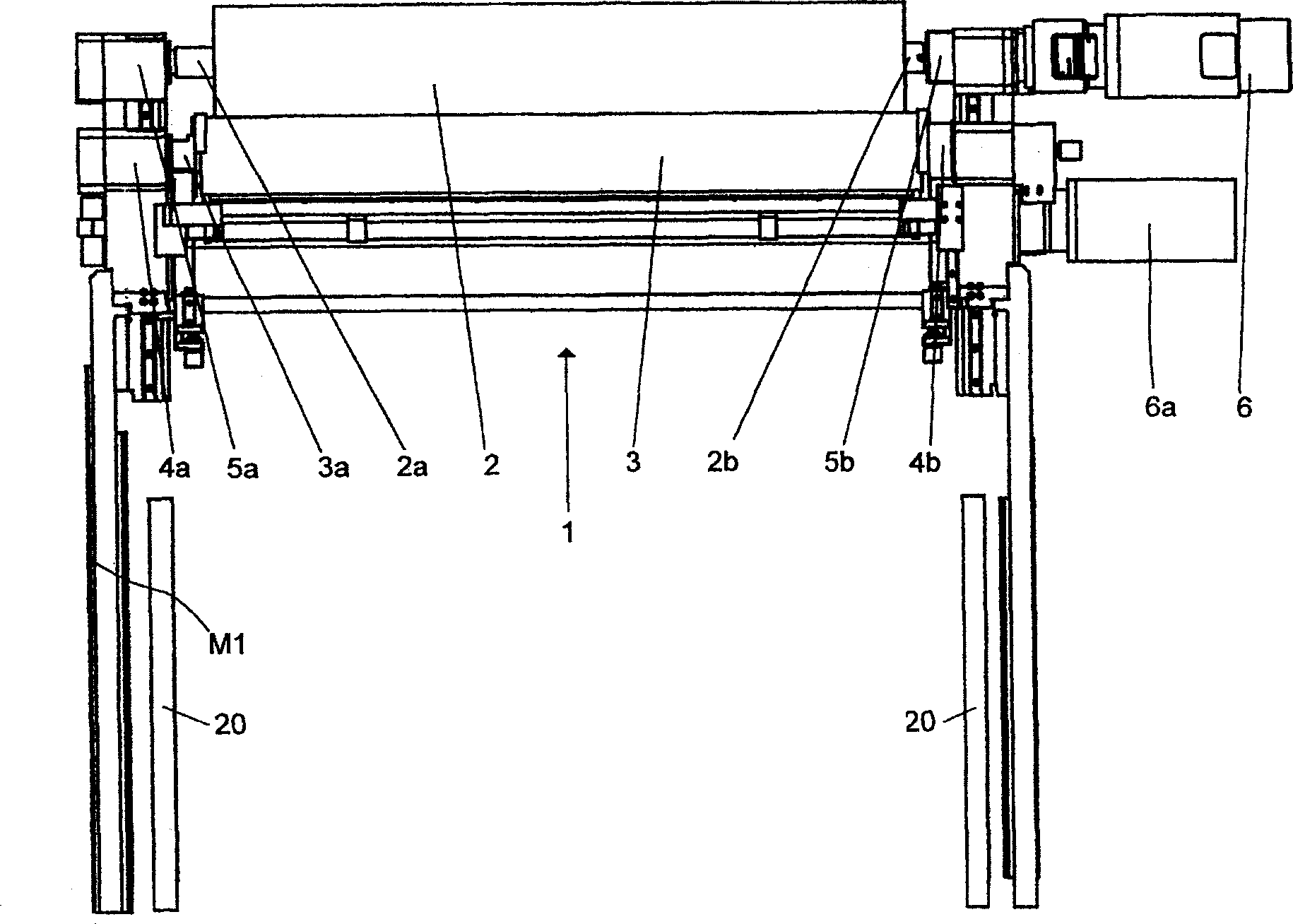

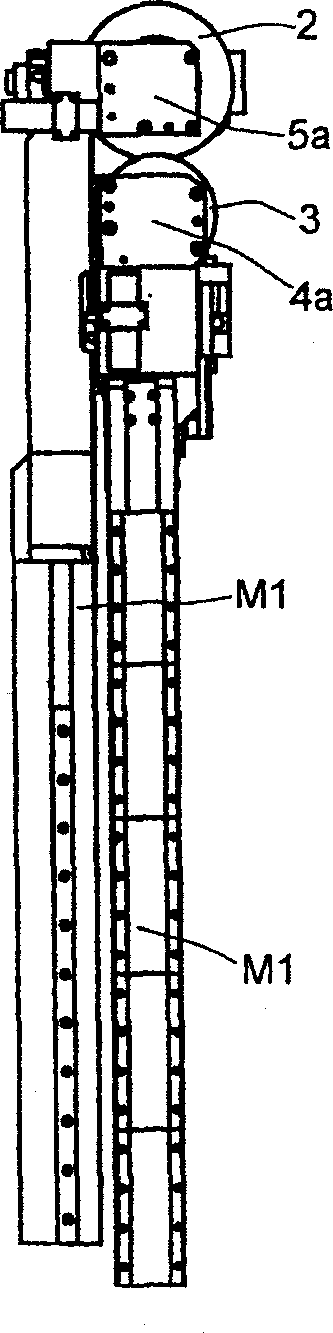

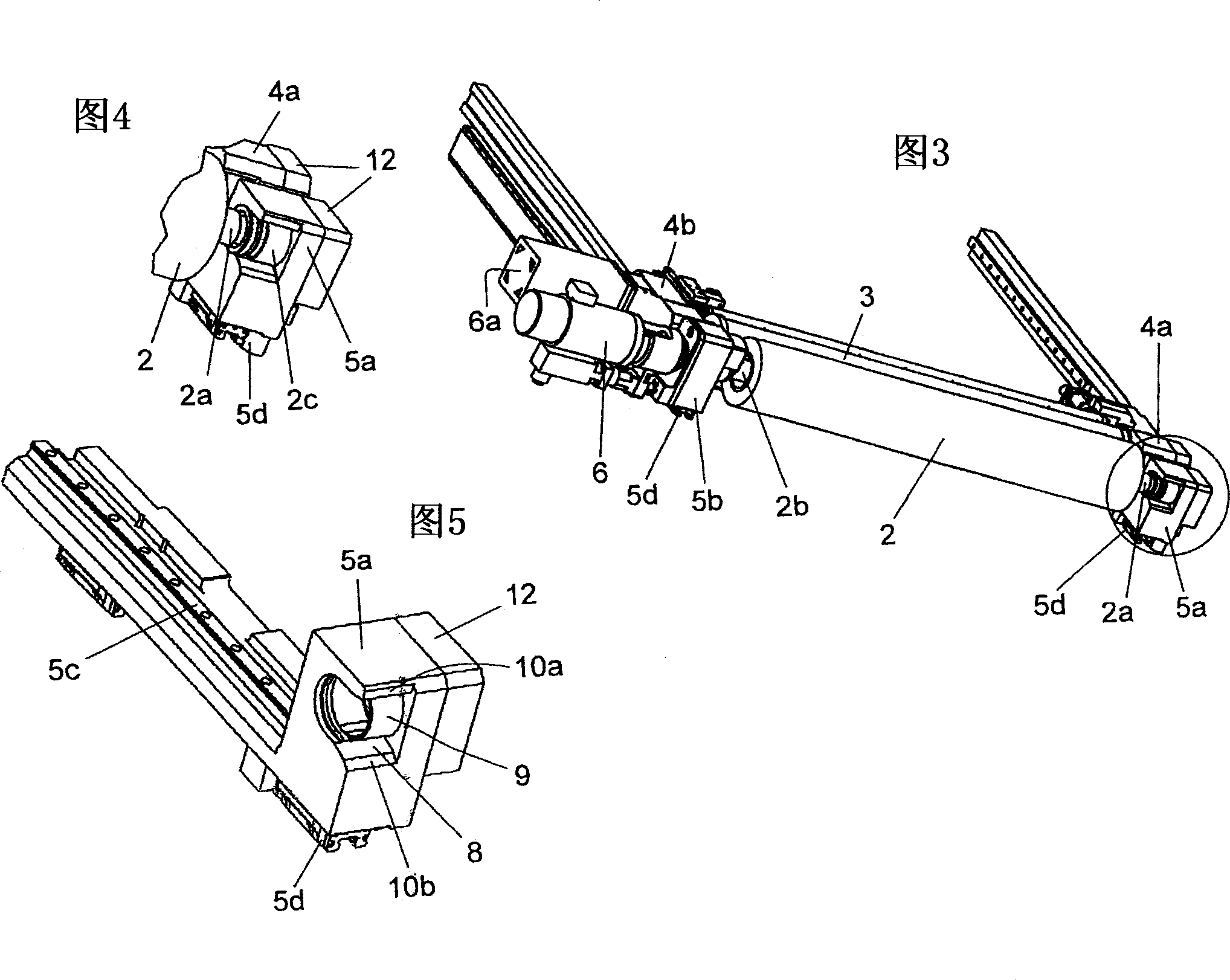

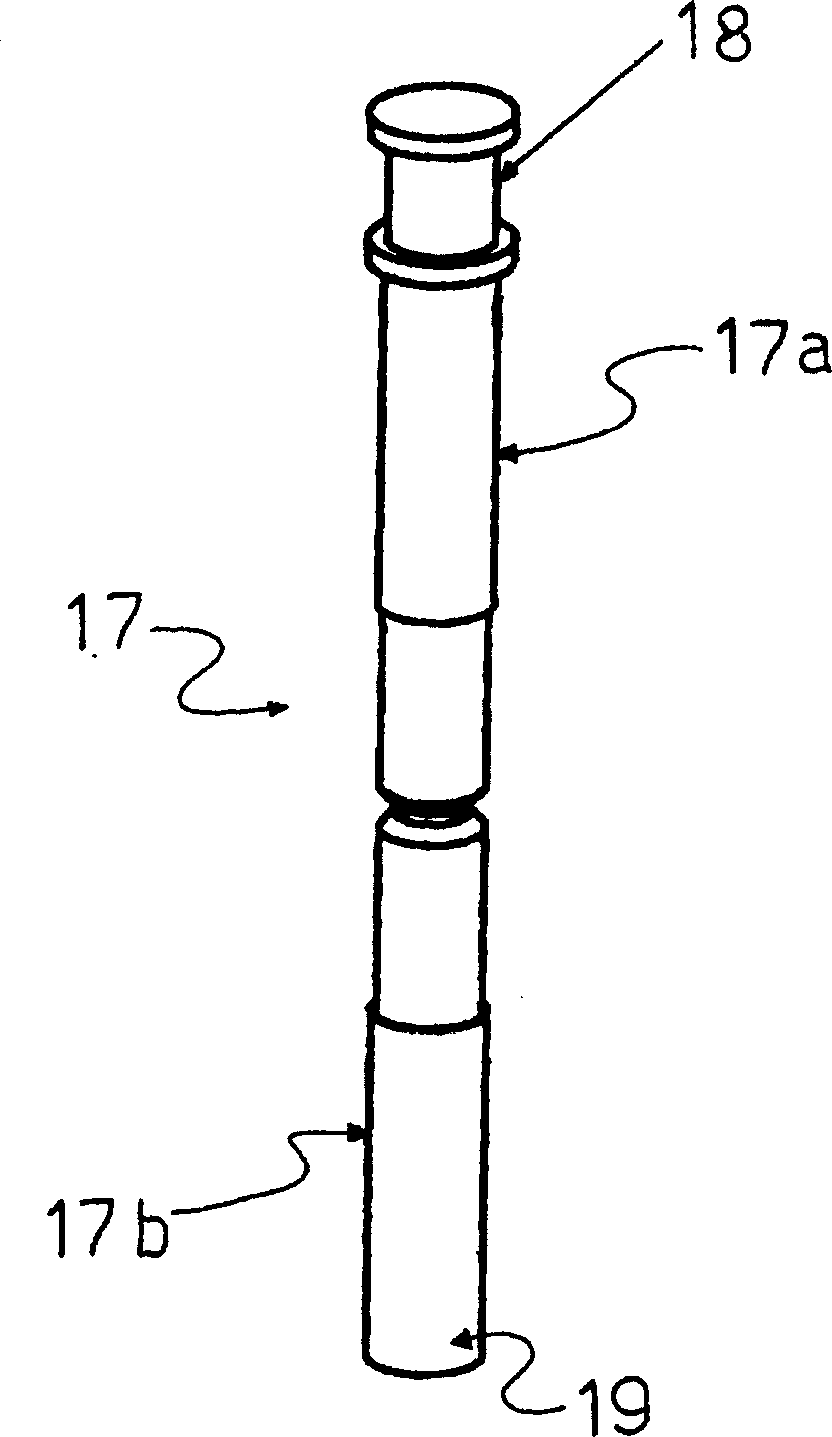

Supporting and releasably holding device for a printing cylinder hub

InactiveCN1746025AHighly reliableSolution to short lifeRotary letterpress machinesRelief printingMechanical engineering

A printing machine colour assembly having a main or clich-carrying cylinder (2) and an interlocking or screened cylinder (3), each carried at its hubs (2a, 2b; 3a, 3b) by first (4a; 5a - operator side) and second (4b; 5b - motor side) slidable supports positioned on different sides of the printing machine and parallel displaceable independently from one another. The first support (5a) of at least the main cylinder (2) is detachable from the respective hub (2a) to cantileverwise position the main cylinder (2) on the second support (5b) thereby carrying out sleeve replacement on the main cylinder (2). At least one auxiliary supporting means (17) at the second support (5b) of at least the main cylinder (2) is designed to engage with, and assist in supporting, it when cantileverwise positioned for replacing a sleeve.

Owner:马里亚·格拉齐亚·瓦伦蒂尼

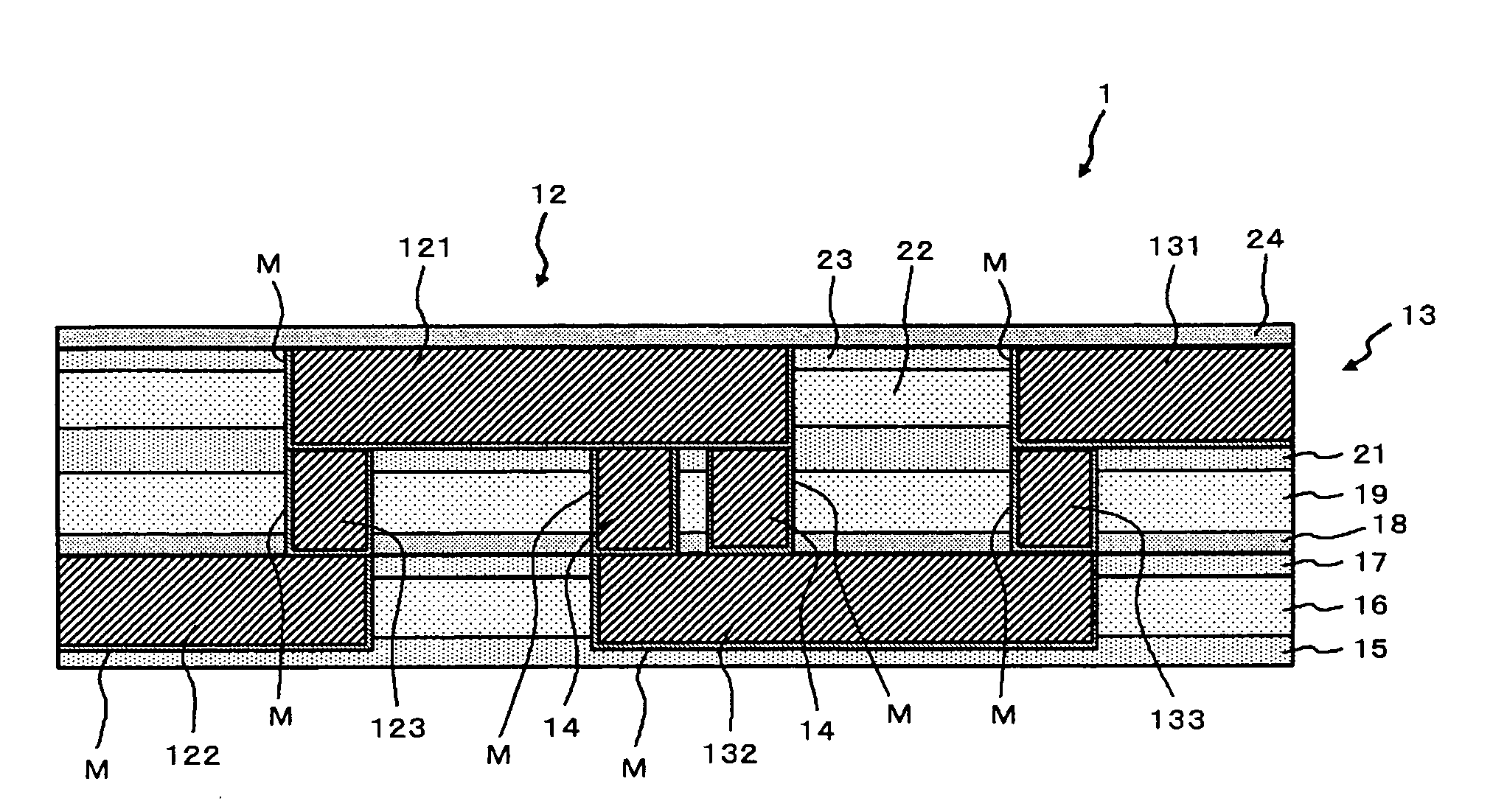

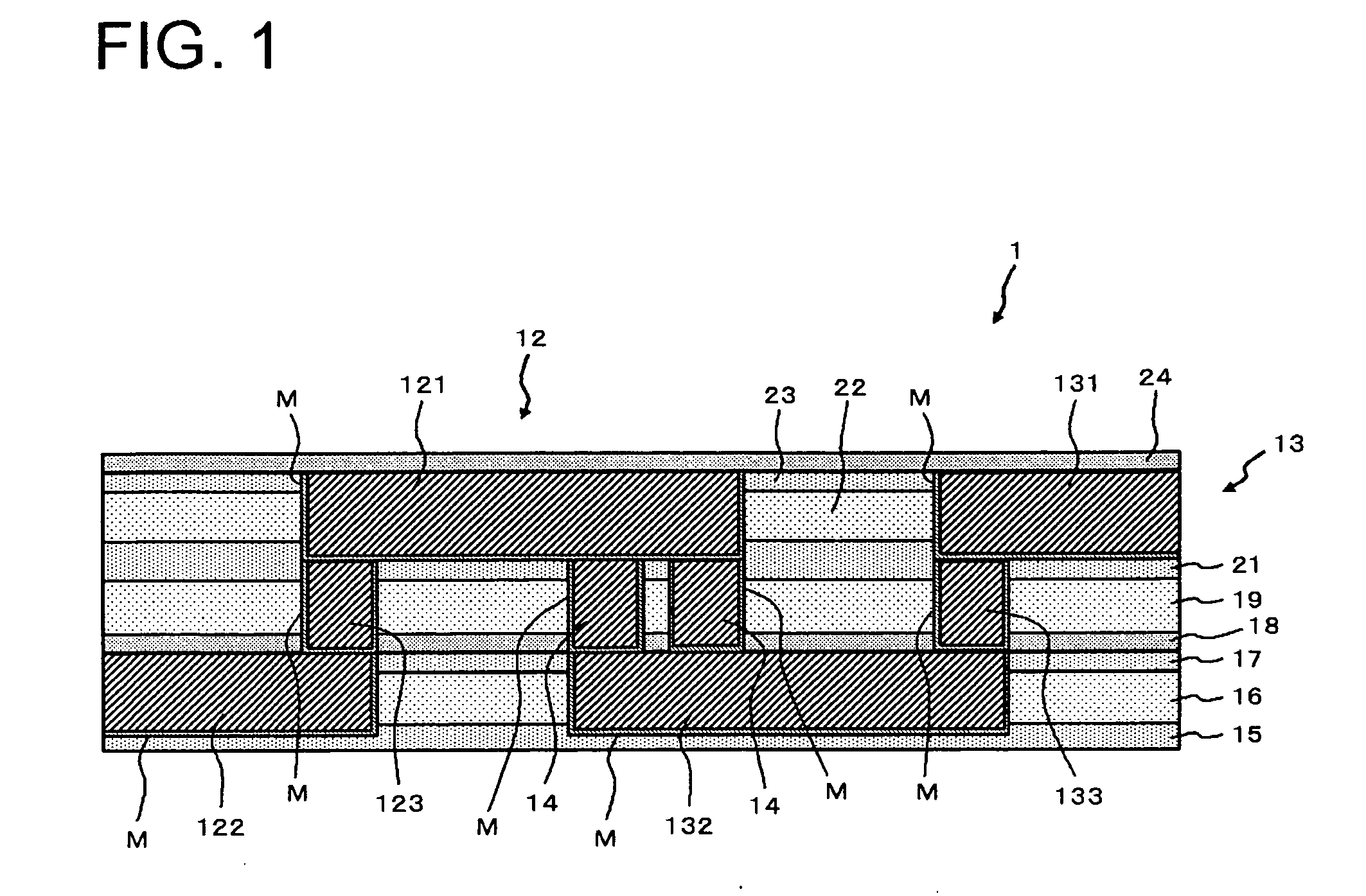

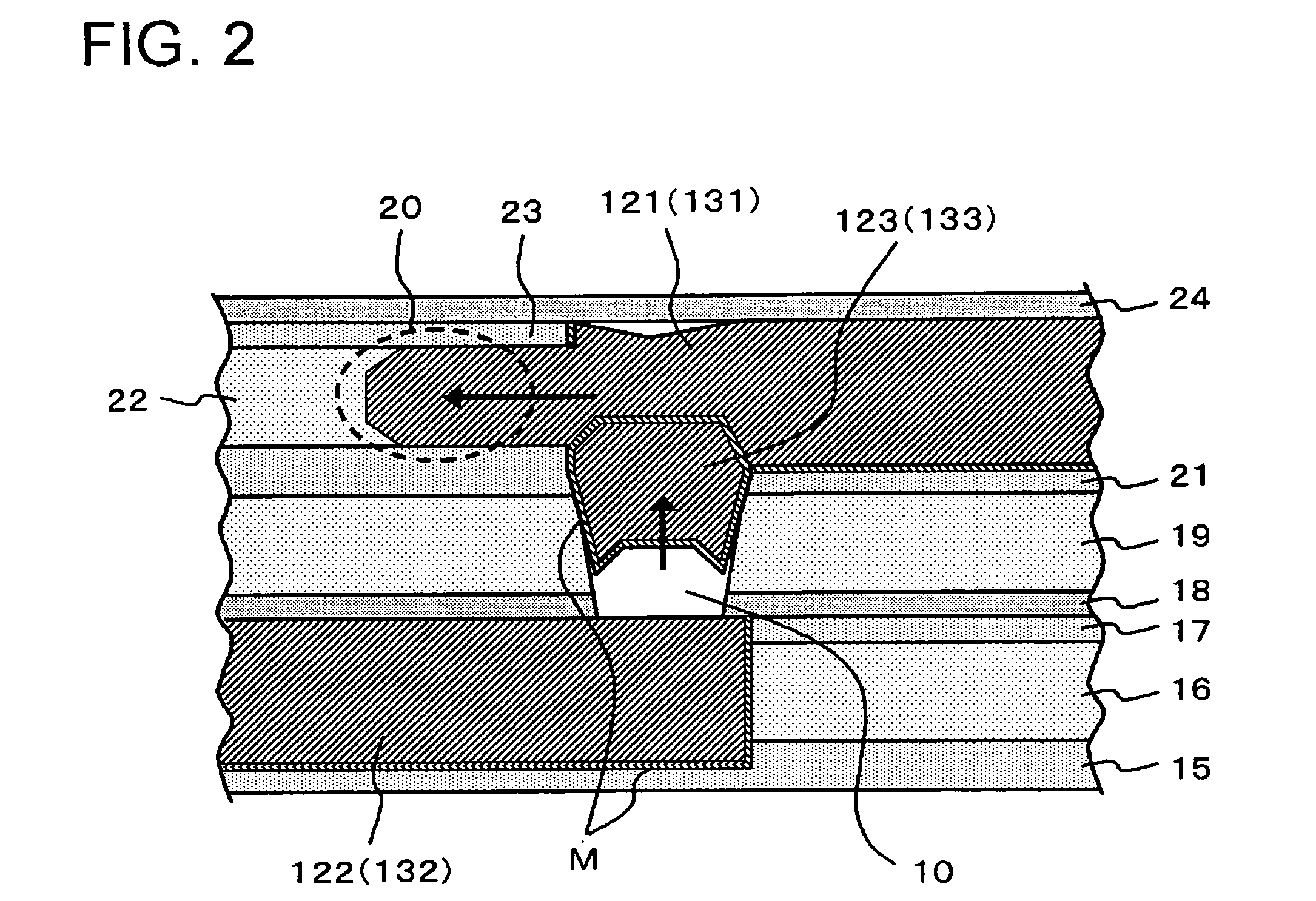

Semiconductor device

InactiveUS20090251275A1Highly reliableInconsistency in resistance value can be preventedSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A semiconductor device 1 has a semiconductor substrate and a first electrical fuse 12 and a second electrical fuse 13, which are provided on the semiconductor substrate. The first electrical fuse 12 has a first upper layer wire 121 and a first lower layer wire 122 formed in different wire layers, and a via 123 for connecting the first upper layer wire 121 to the first lower layer wire 122. The second electrical fuse 13 has a second upper layer wire 131 and a second lower layer wire 132 formed in different wire layers, and a via 133 for connecting the second upper layer wire 131 to the second lower layer wire 132. The semiconductor device 1 has a connection portion 14 for connecting the above described first upper layer wire 121 of the first electrical fuse 12 to the second lower layer wire 132 of the second electrical fuse 13. The connection portion 14 connects the first electrical fuse 12 and the second electrical fuse 13 in series.

Owner:RENESAS ELECTRONICS CORP

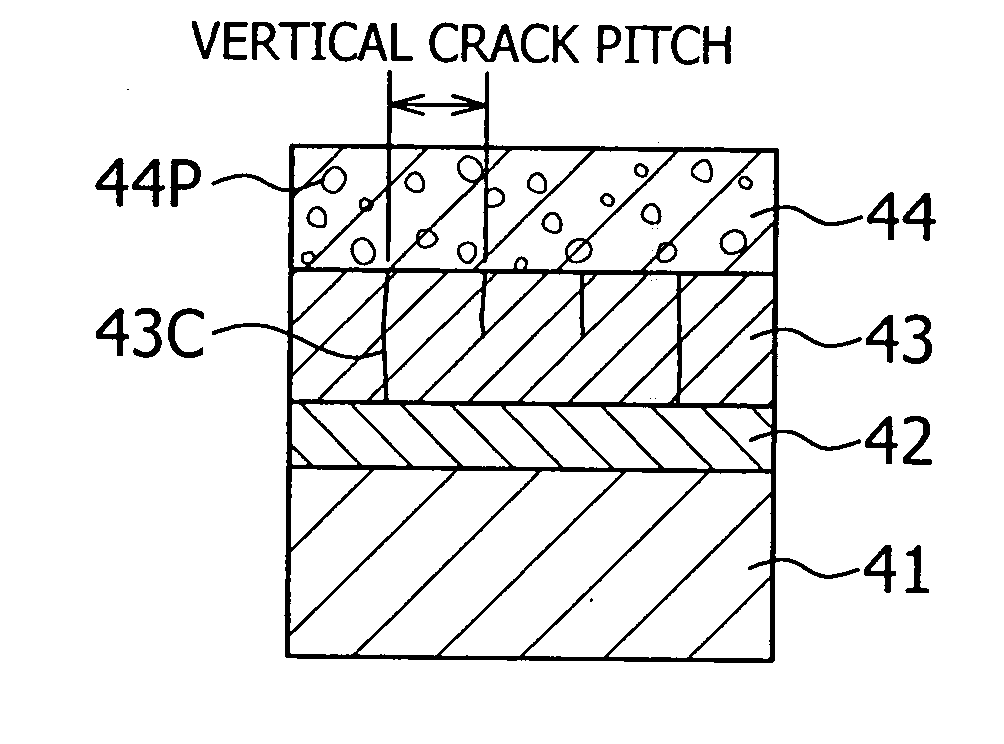

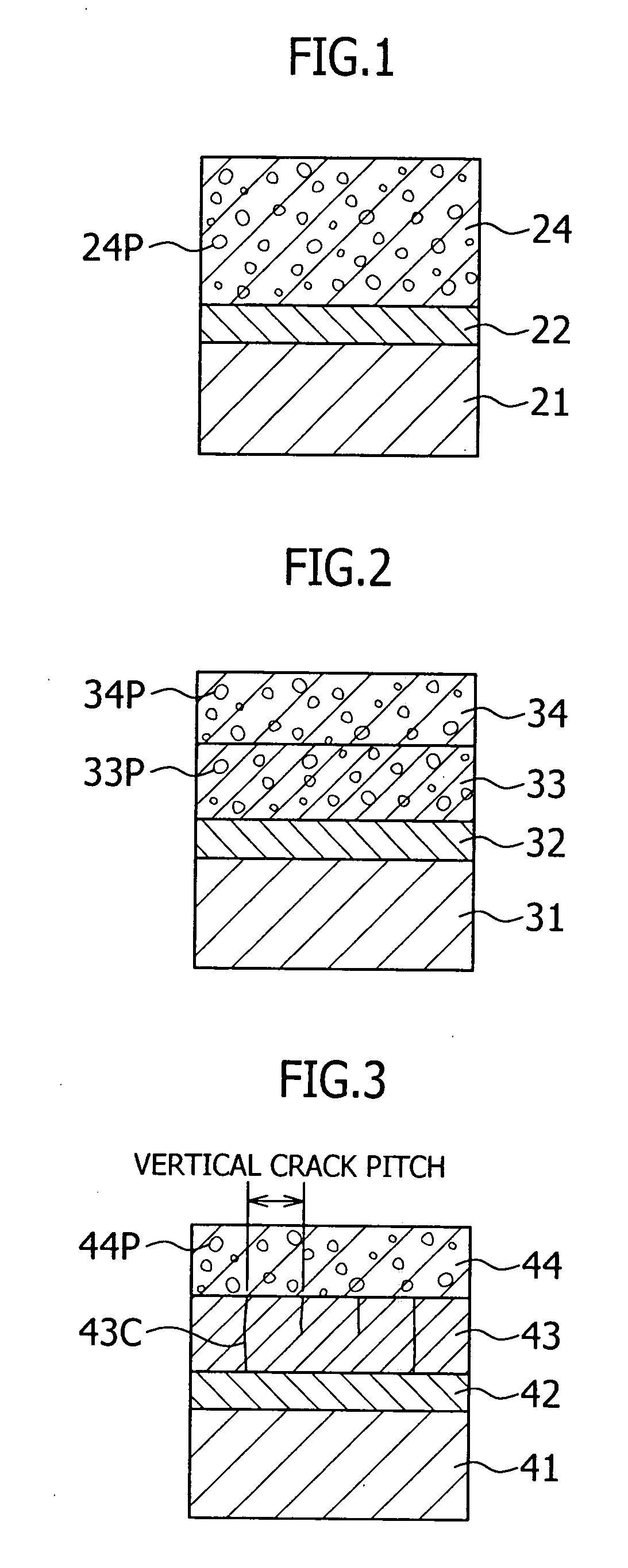

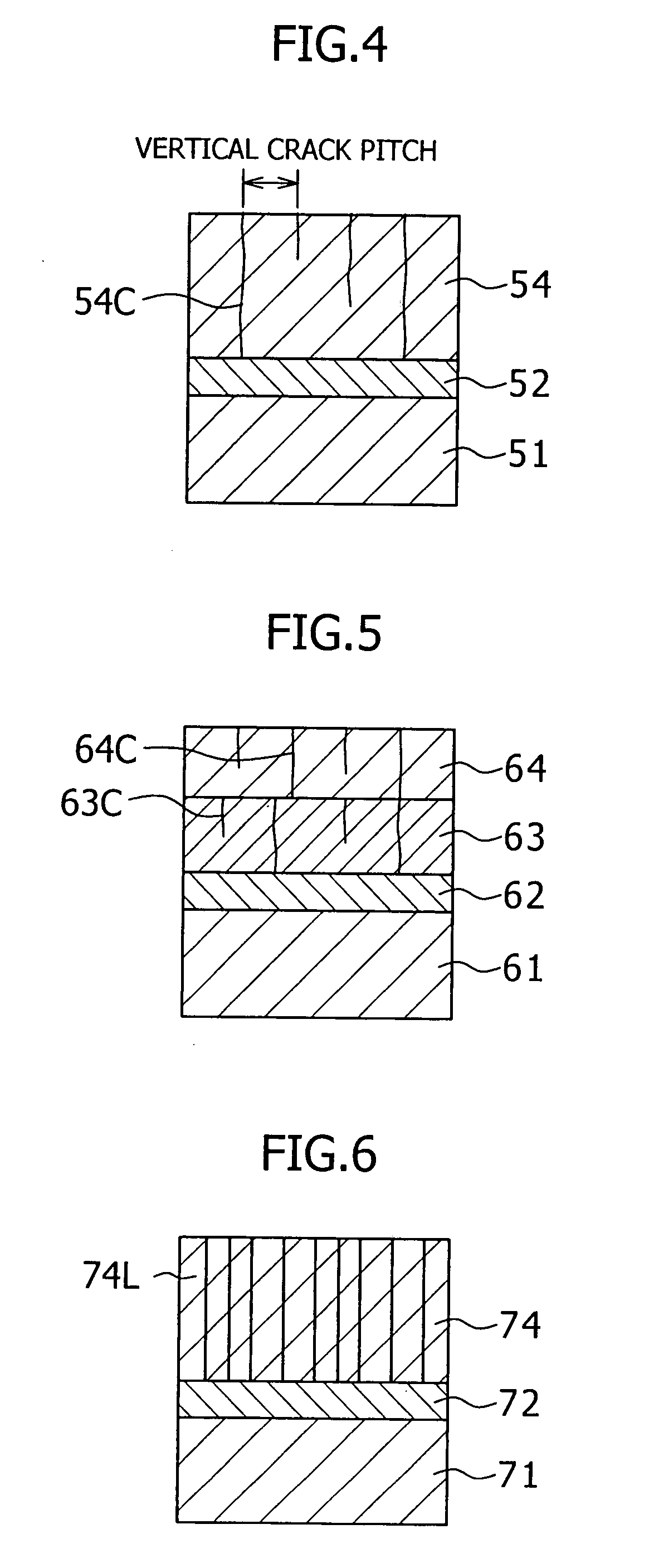

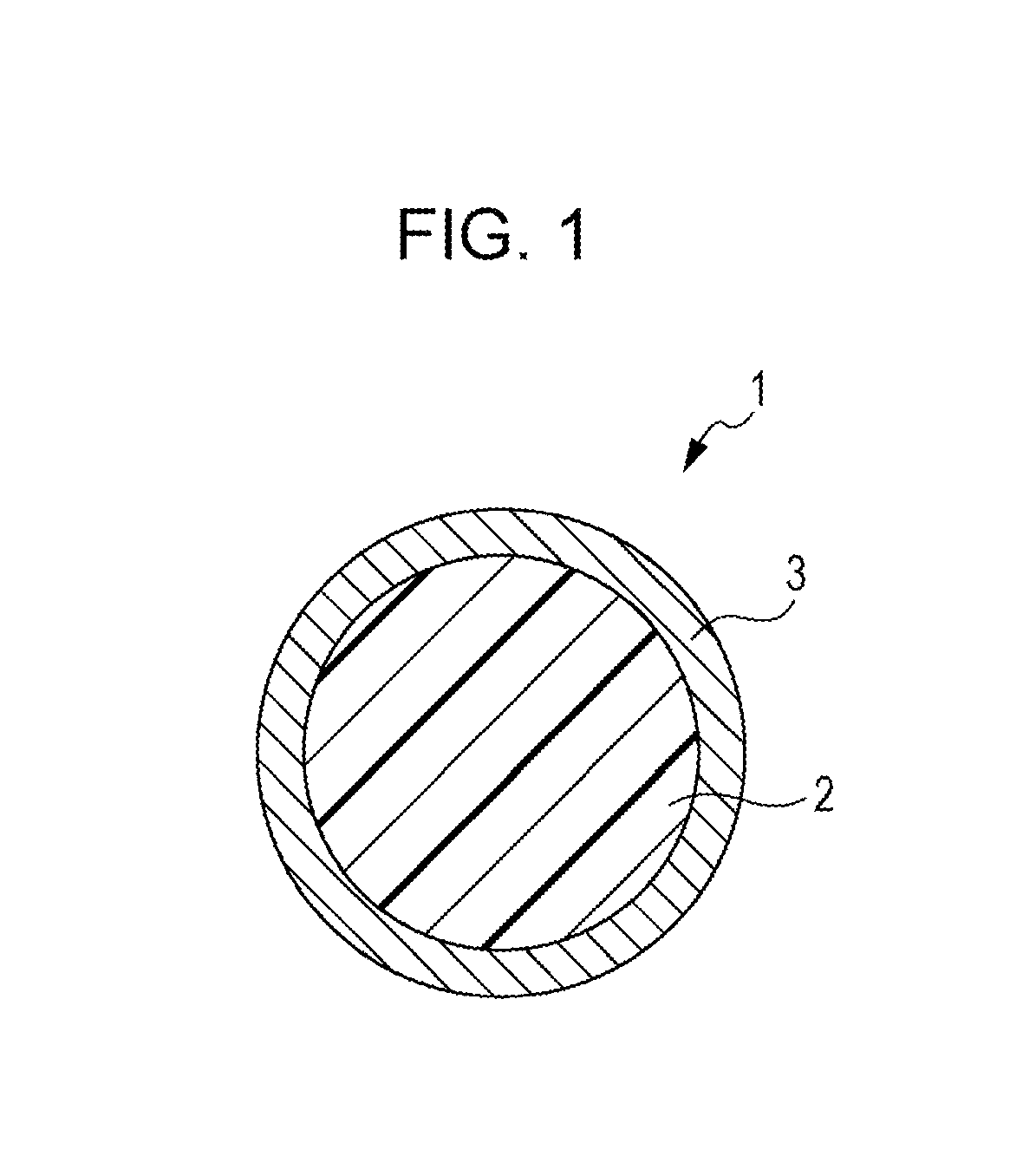

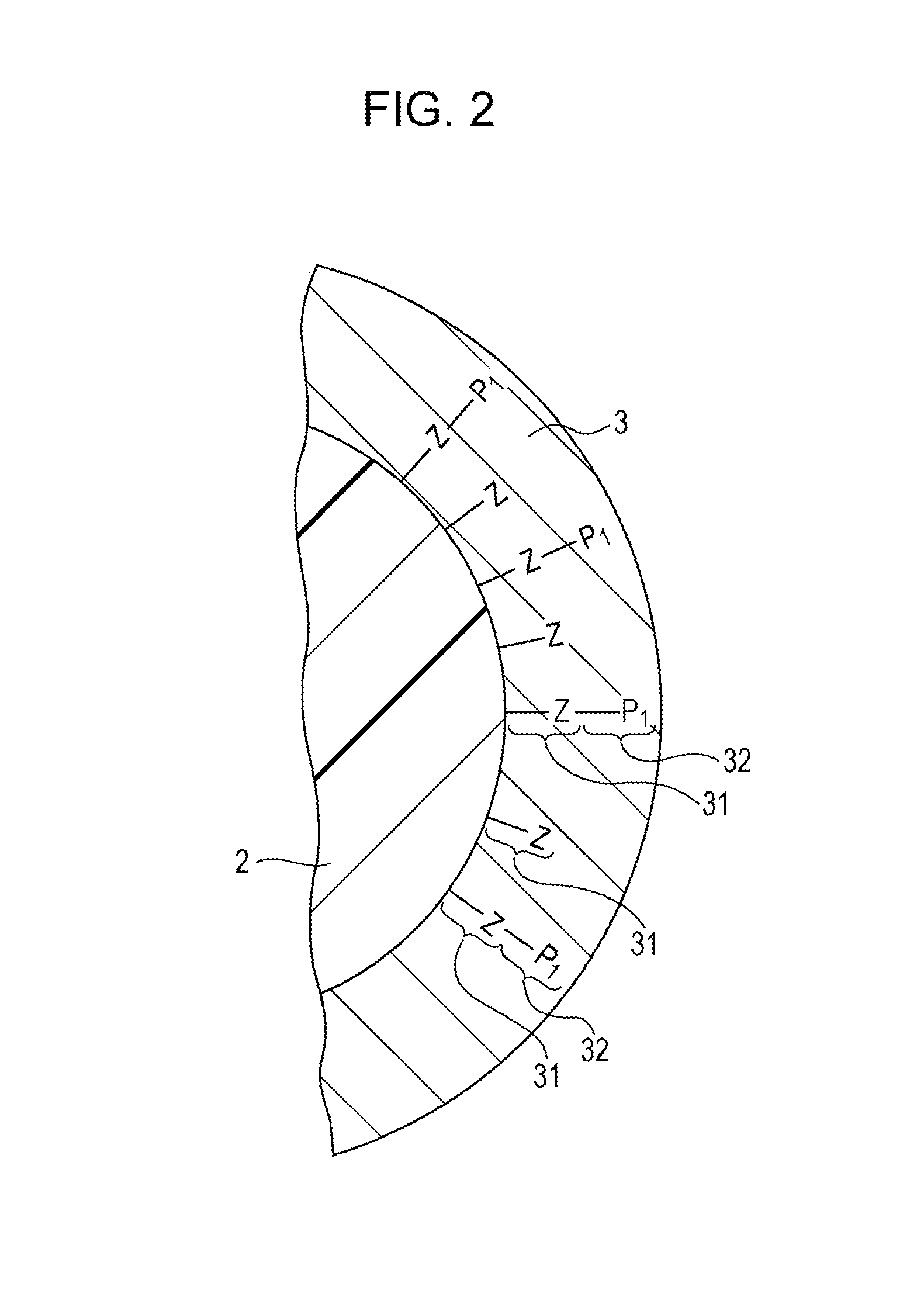

Thermal barrier coating material, thermal barrier member, and member coated with thermal barrier and method for manufacturing the same

InactiveUS20080131608A1Excellent thermal cycle durabilityHighly reliableLiquid surface applicatorsEfficient propulsion technologiesRare-earth elementTotal thickness

Provided are a thermal barrier coating material and a member coated with thermal barrier that can suppress the separation when used at a high temperature, and have a high thermal barrier effect; a method for manufacturing the member coated with thermal barrier; a turbine member coated with the thermal barrier coating material; and a gas turbine. More specifically provided are a shield coating member comprising a heat-resistant substrate, a bond coat layer formed on the heat-resistant substrate, and a ceramic layer formed on the bond coat layer, wherein the ceramic layer comprises a ceramic represented by a general formula A2Zr2O7, wherein A denotes a rare earth element, and the ceramic layer has (a) a porosity of 1 to 30%, (b) cracks in a thickness direction in pitches of 5 to 100% the total thickness of layers other than the bond coat layer on the heat-resistant substrate, or (c) columnar crystals.

Owner:MITSUBISHI HEAVY IND LTD +1

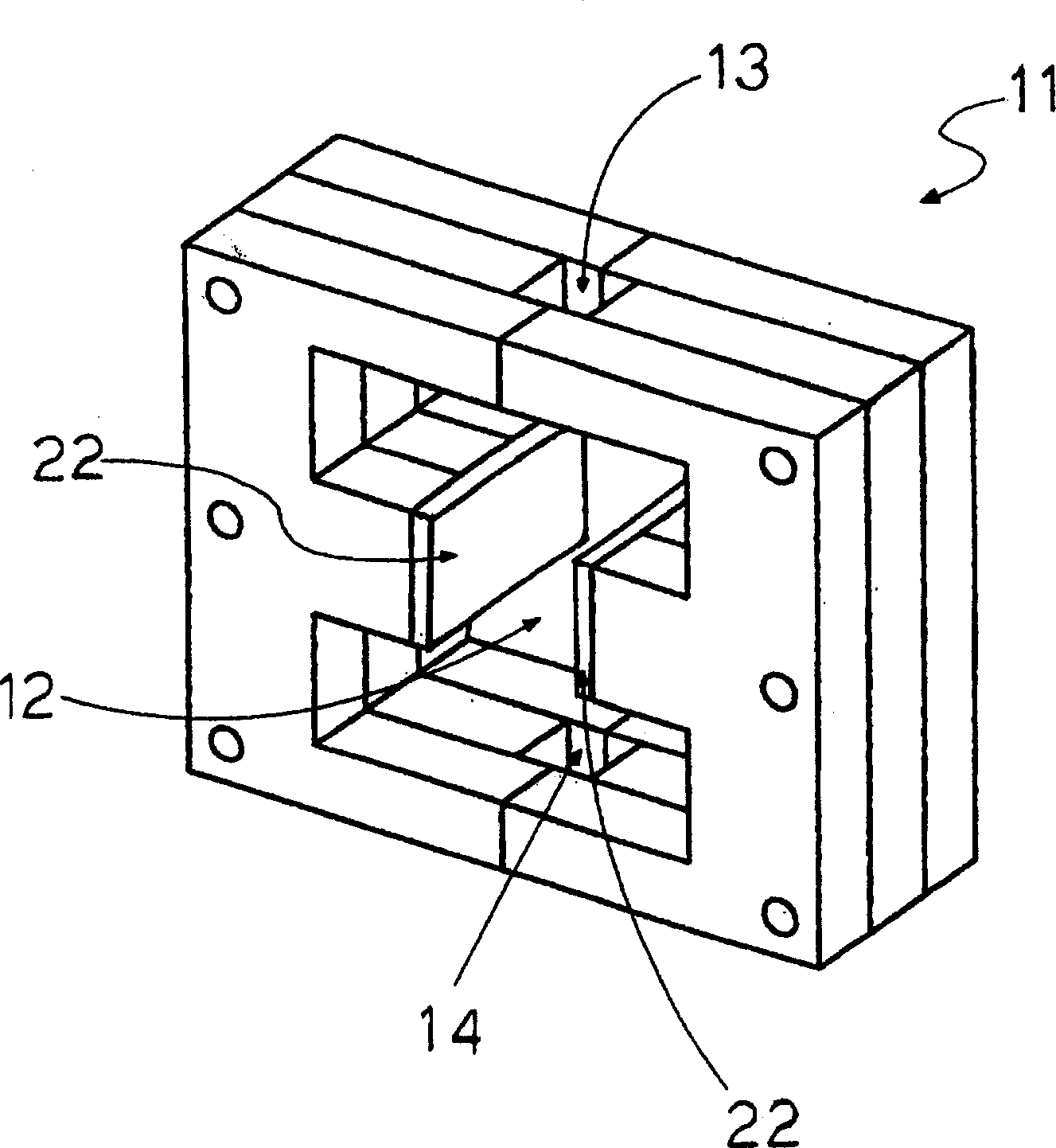

A medium voltage vacuum contactor

InactiveCN1722333ASimple structureImprove performanceHigh-tension/heavy-dress switchesAir-break switchesCouplingElectromagnetic actuator

A medium voltage vacuum contactor comprising for each pole, a vacuum envelope which contains a fixed contact and a corresponding movable contact; and actuating means providing the energy required to move the movable contacts, characterized in that said actuating means comprise an electromagnetic actuator having: a magnetic yoke which has an inner cavity communicating with the outside through at least a first opening; at least one coil accommodated in the cavity; a movable armature which is operatively connected to at least one movable contact through coupling means, and is mounted axially displaceable in the cavity with at least one end protruding from the first opening; at least one permanent magnet devoted to directly hold the movable armature in two stable positions. Further, there are provided means for guiding the movement of the movable armature which are positioned outside the yoke in correspondence of at least the first opening.

Owner:ABB (SCHWEIZ) AG

Positive-type photosensitive resin composition, cured film, protective film, insulating film, and semiconductor device

ActiveUS20100239977A1Highly reliableLow temperatureDiazo compound compositionsPhotosensitive material processingStructural unitPolymer chemistry

A positive-type photosensitive resin composition includes (A) a polyamide resin that includes a structural unit shown by the following formula (1) and a structural unit shown by the following formula (2), and (B) a photosensitive compound, the polyamide resin (A) having a weight average molecular weight (Mw) of 5000 to 80,000, and a cured film obtained by curing the positive-type photosensitive resin composition at 250° C. having a tensile modulus of elasticity of 2.0 to 4.0 GPa and a tensile elongation of 10 to 100%.According to the present invention, a positive-type photosensitive resin composition that can be cured at a low temperature and a highly reliable semiconductor device including a cured film of the positive-type photosensitive resin composition can be provided.

Owner:SUMITOMO BAKELITE CO LTD

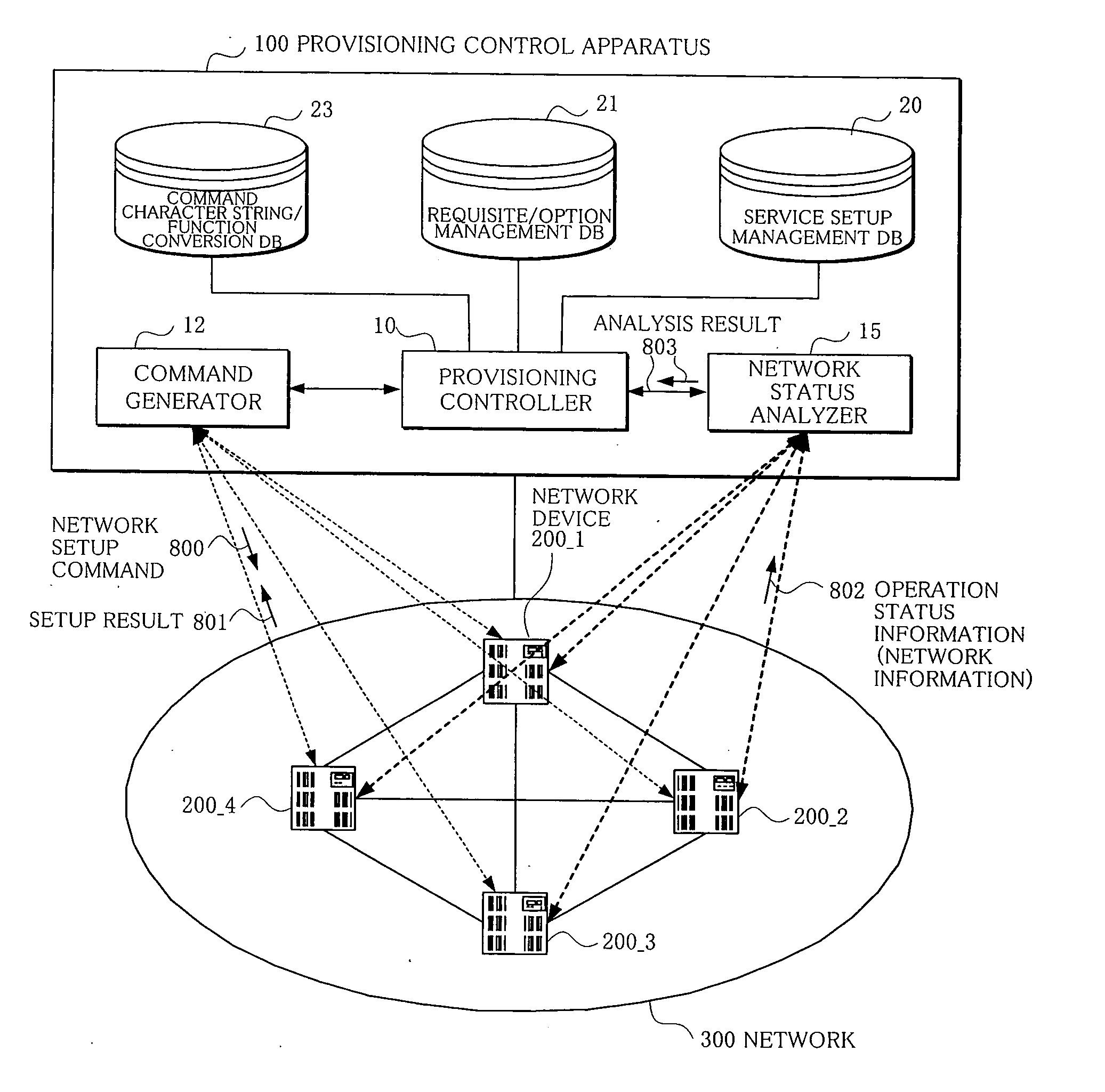

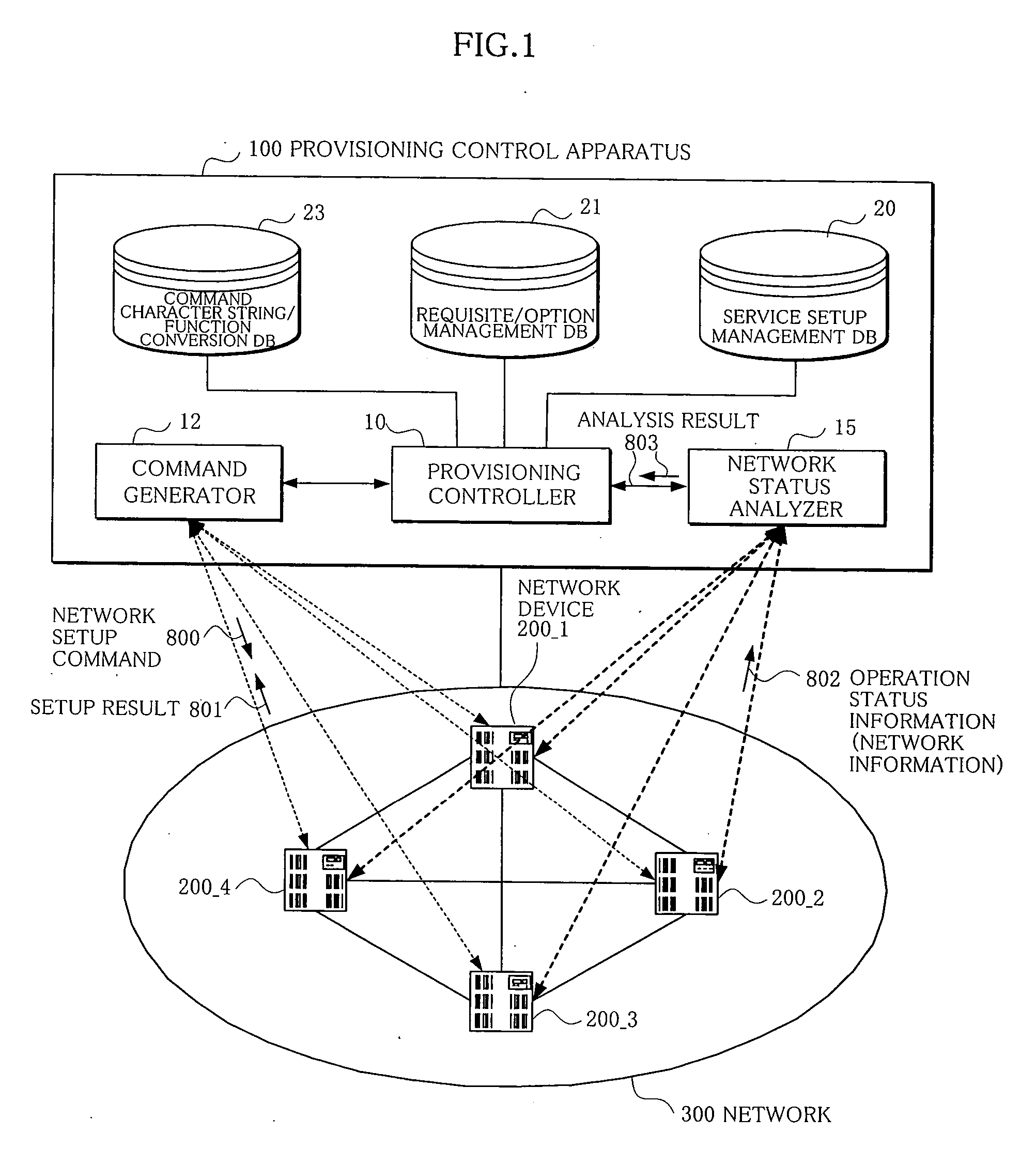

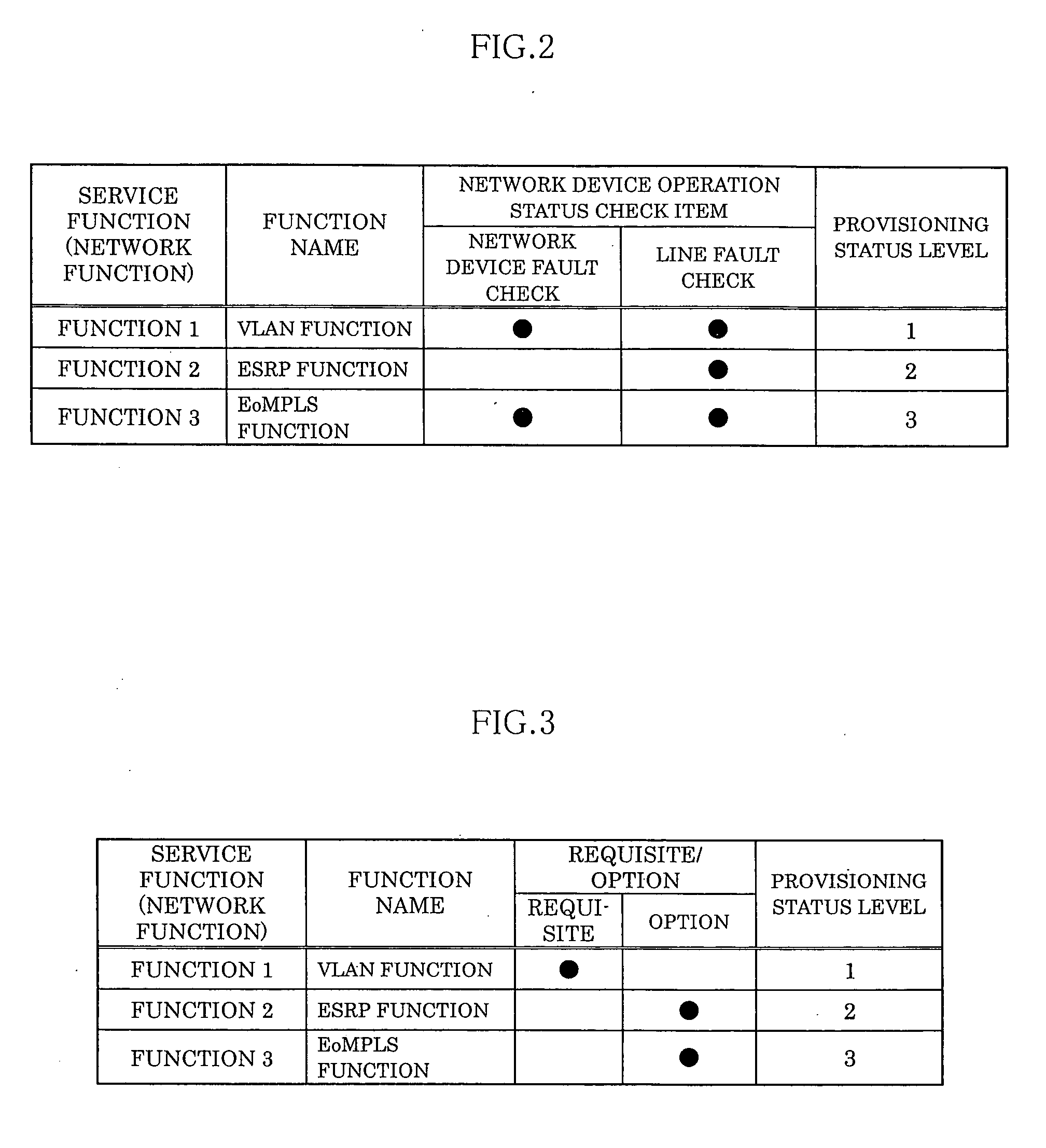

Provisioning control apparatus

InactiveUS20050207347A1Highly reliableImprove reliabilityError preventionTransmission systemsInformation analysisNetwork architecture

In a provisioning control apparatus which performs provisioning of network devices in order to construct a predetermined network architecture on a network composed of the network devices, a command generator generates a network setup command for making the predetermined network architecture to be provided to the network devices, a network status analyzer acquires operation status information of the network devices determined based on the setup result, and analyzes a network architecture state based on operation status information. A provisioning controller determines the network setup command based on the analysis result and demands the command generator to generate the command.

Owner:FUJITSU LTD

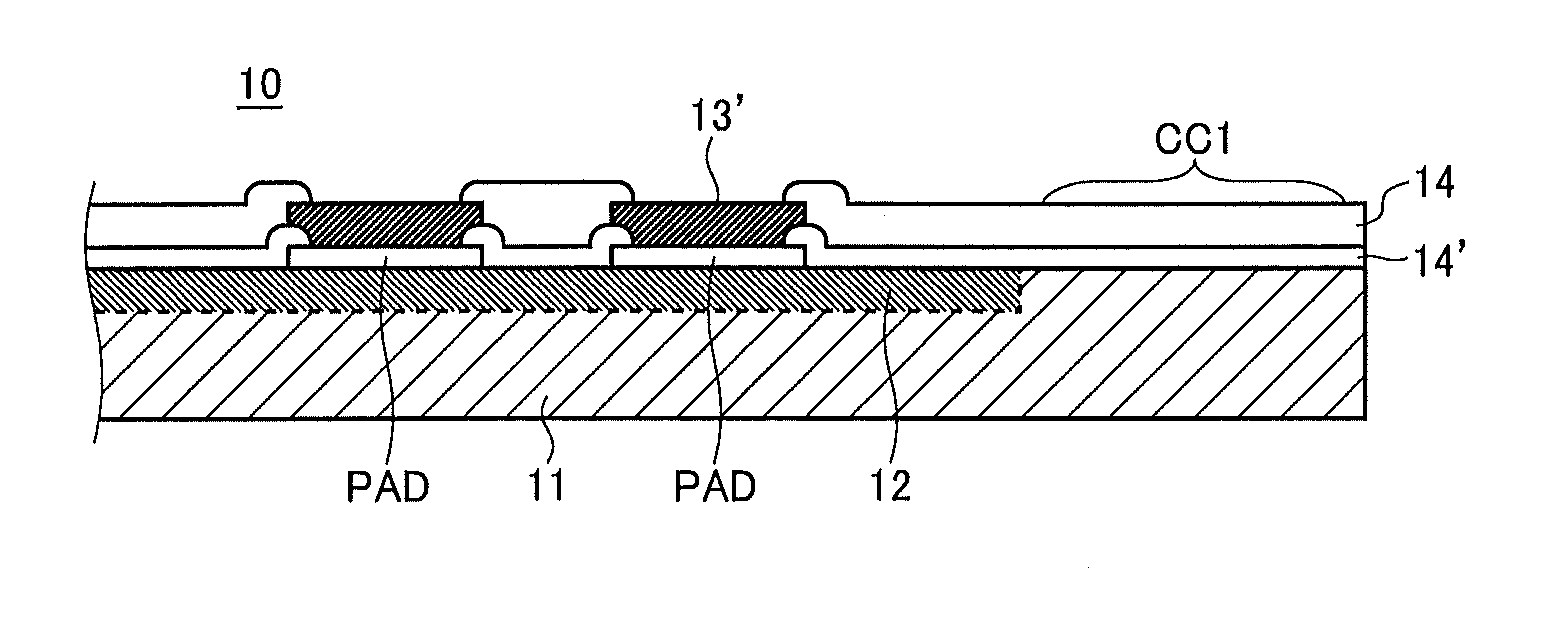

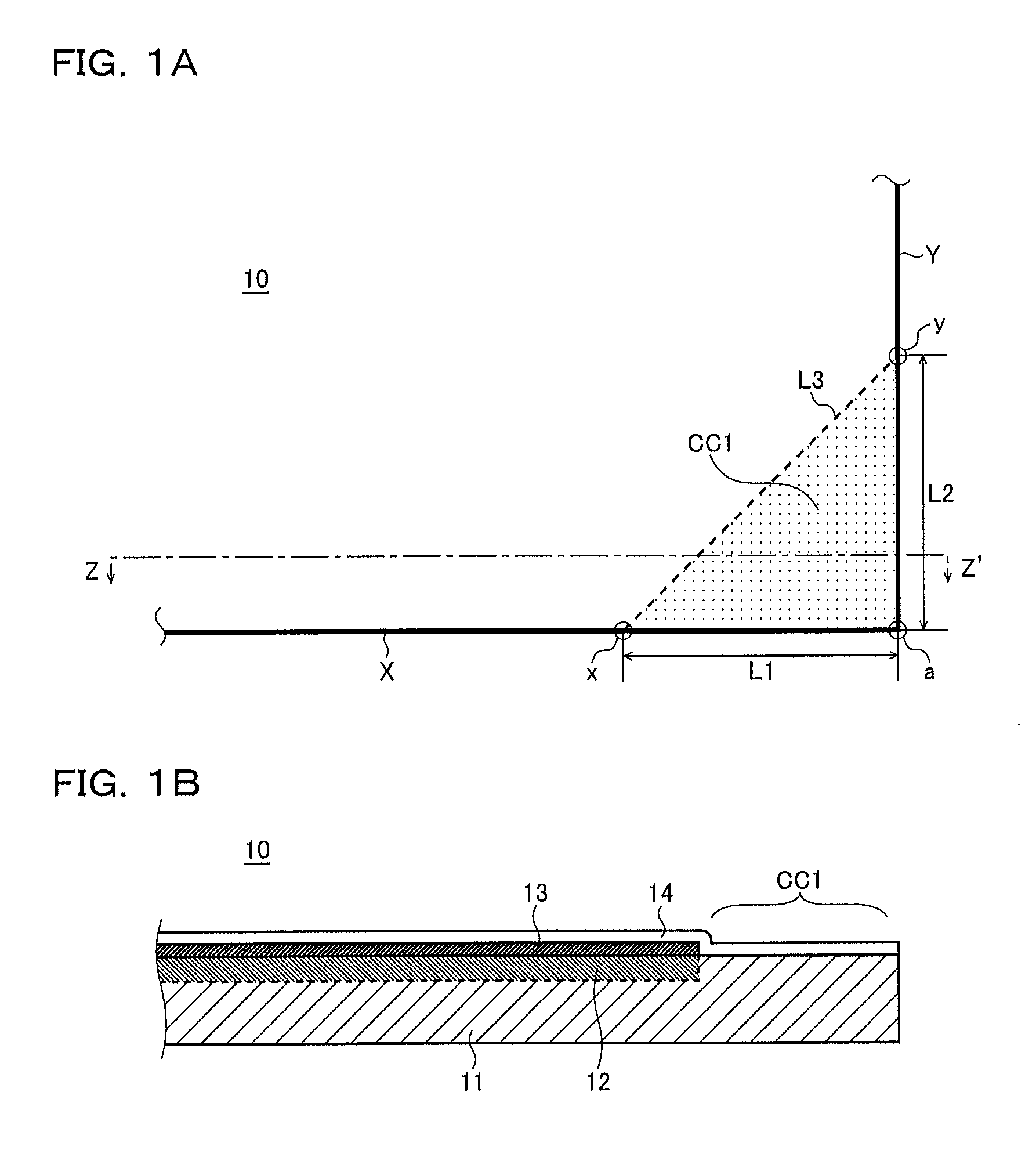

Semiconductor integrated circuit device

ActiveUS20120241969A1Highly reliableImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

A semiconductor integrated circuit device includes: a rectangular shaped semiconductor substrate; a metal wiring layer formed on or over the semiconductor substrate; and a passivation layer covering the metal wiring layer. A corner non-wiring region where no portion of the metal wiring layer is formed is disposed in a corner of the semiconductor substrate. A slit is formed in a portion of the metal wiring layer which is close to the corner of the semiconductor substrate. The passivation layer includes a first passivation layer which is formed on the metal wiring layer and a second passivation layer which is formed on the first passivation layer. The first passivation layer is formed of a material that is softer than a material of the second passivation layer.

Owner:ROHM CO LTD

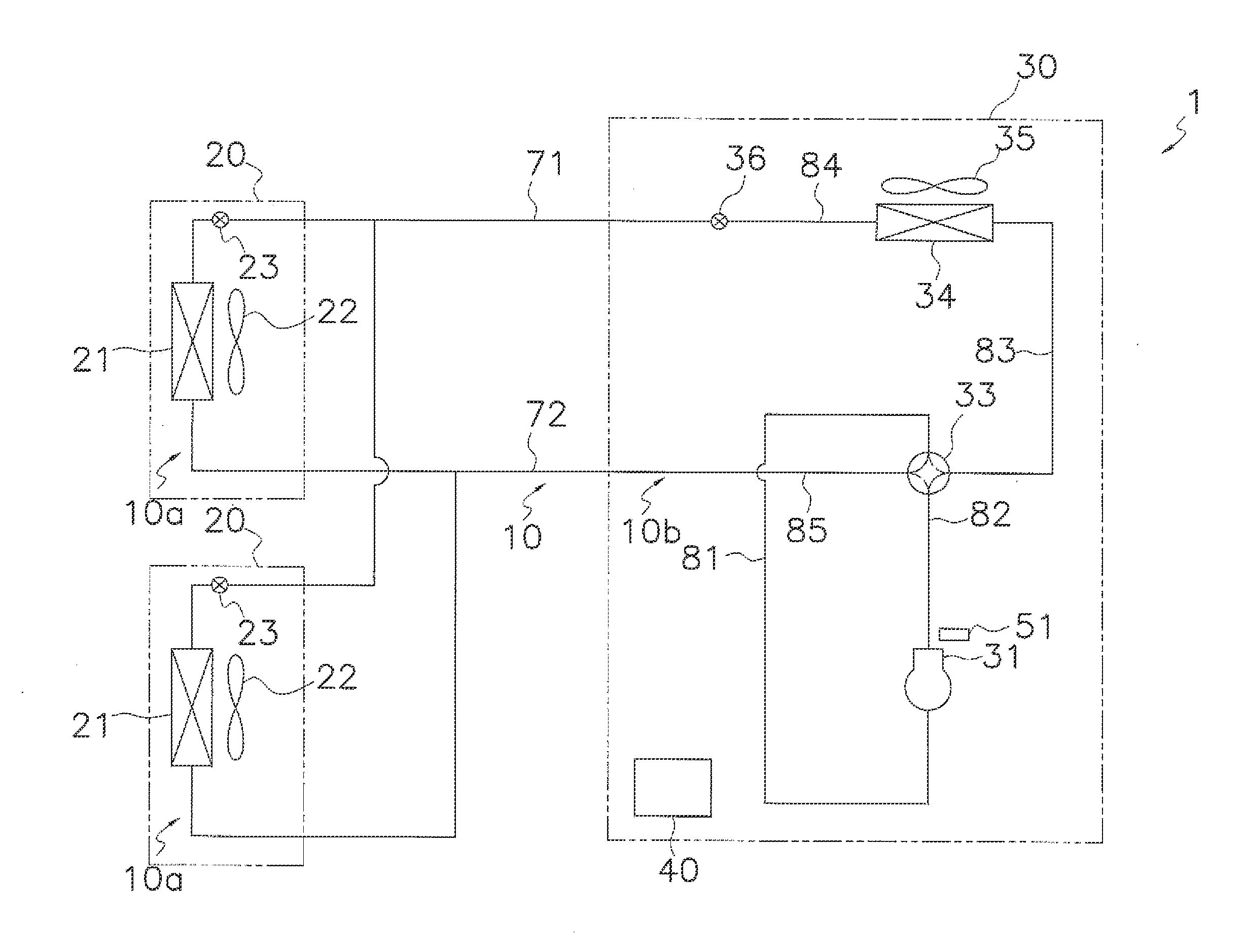

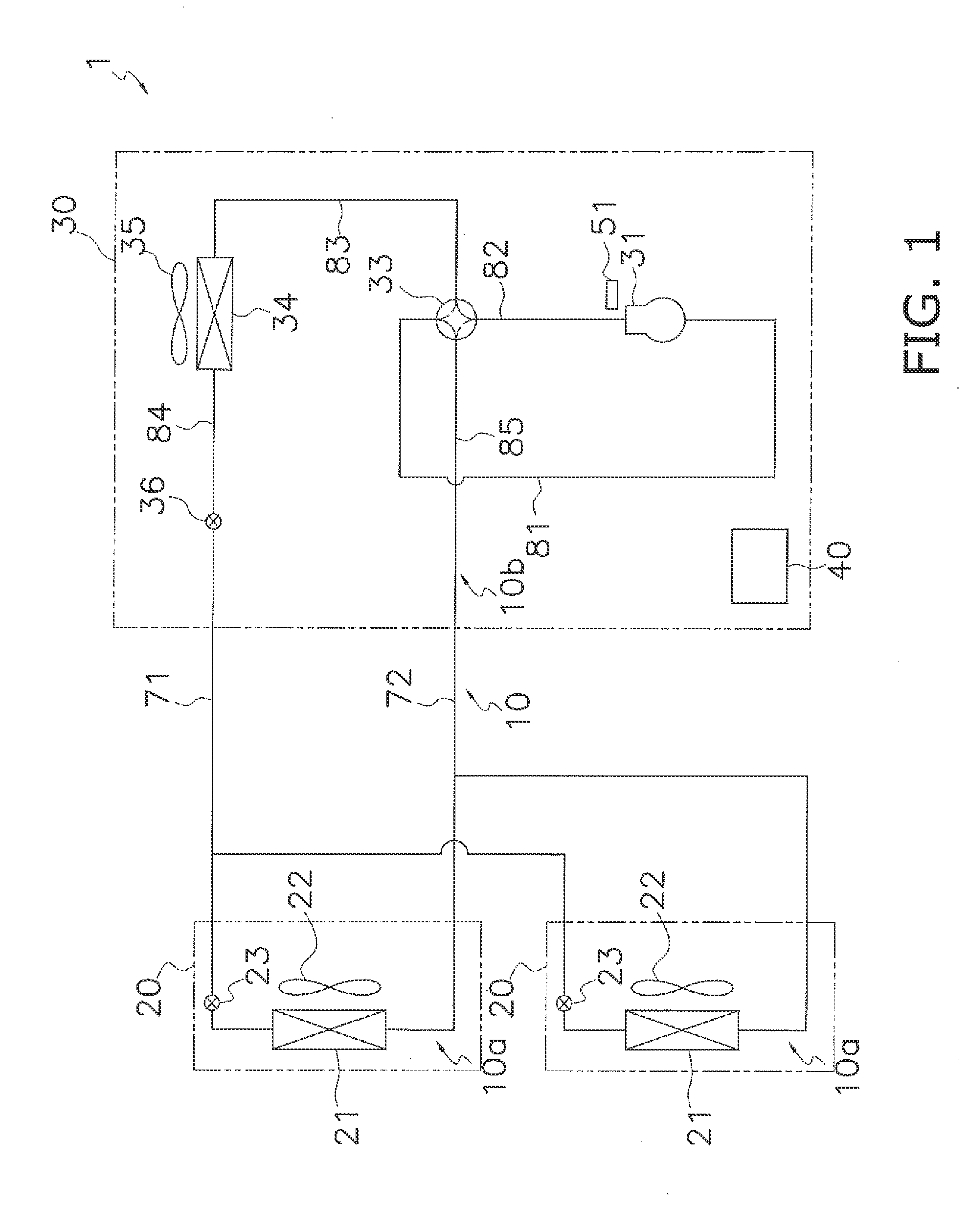

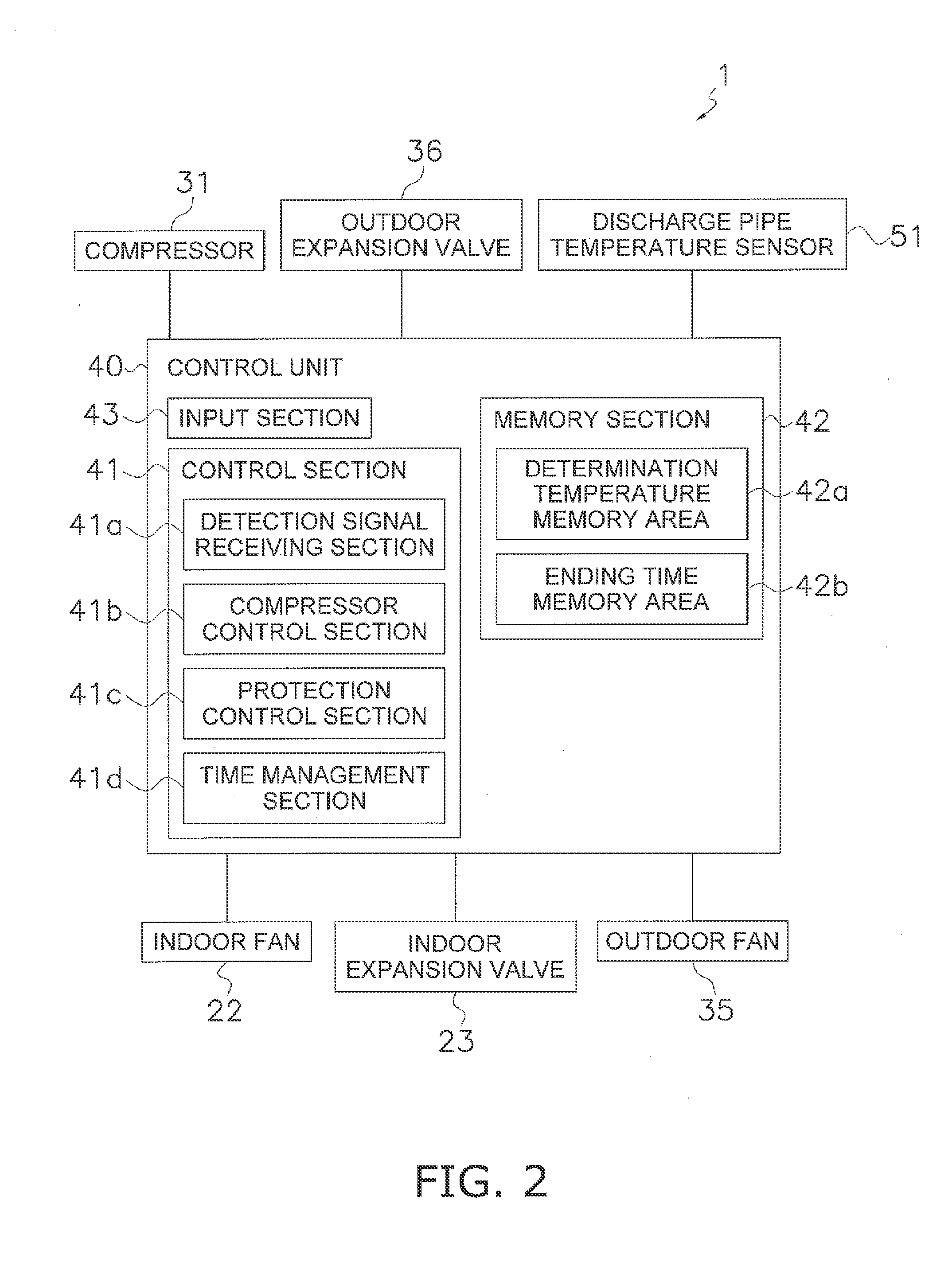

Refrigerating device

ActiveUS20150153085A1Highly reliableAppropriate controlCompression machines with non-reversible cycleCompression machines with reversible cycleRefrigerantEngineering

A refrigerating device includes a compressor, a temperature detector and a protection control section. The compressor compresses a refrigerant. The temperature detector detects a temperature of the refrigerant discharged from the compressor on an outside of the compressor. The protection control section judges that a transition following a starting of the compressor is in effect and that a steady state following an end of the transition in which a state of the refrigerant is stable is in effect, performs protection control on the compressor when a detected temperature detected by the temperature detector exceeds a first determination temperature during the transition, and performs the protection control on the compressor when the detected temperature exceeds a second determination temperature during the steady state.

Owner:DAIKIN IND LTD

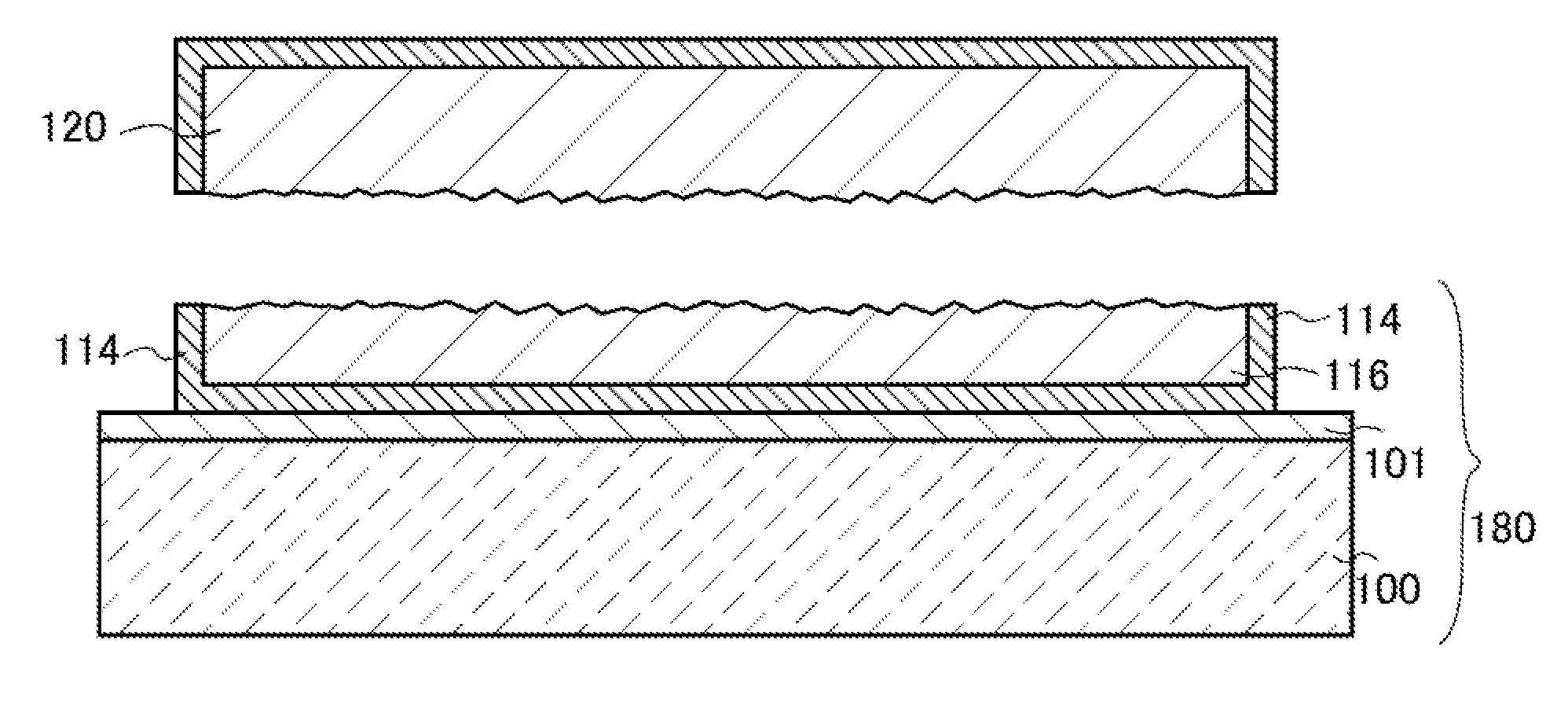

Method for manufacturing soi substrate

InactiveUS20120190171A1Few defectHighly reliableSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsIon beam irradiation

An SOI substrate is manufactured by the following steps: a semiconductor substrate is irradiated with an ion beam in which the proportion of H2O+ to hydrogen ions (H3+) is lower than or equal to 3%, preferably lower than or equal to 0.3%, whereby an embrittled region is formed in the semiconductor substrate; a surface of the semiconductor substrate and a surface of a base substrate are disposed so as to be in contact with each other, whereby the semiconductor substrate and the base substrate are bonded; and a semiconductor layer is separated along the embrittled region from the semiconductor substrate which is bonded to the base substrate by heating the semiconductor substrate and the base substrate, so that the semiconductor layer is formed over the base substrate.

Owner:SEMICON ENERGY LAB CO LTD

Device for winding watches, in particular self-winding watches

InactiveCN102135753AReduce weightReduce volumeNormal windingAutomatic windingEngineeringMechanical engineering

Owner:MCM MILANO

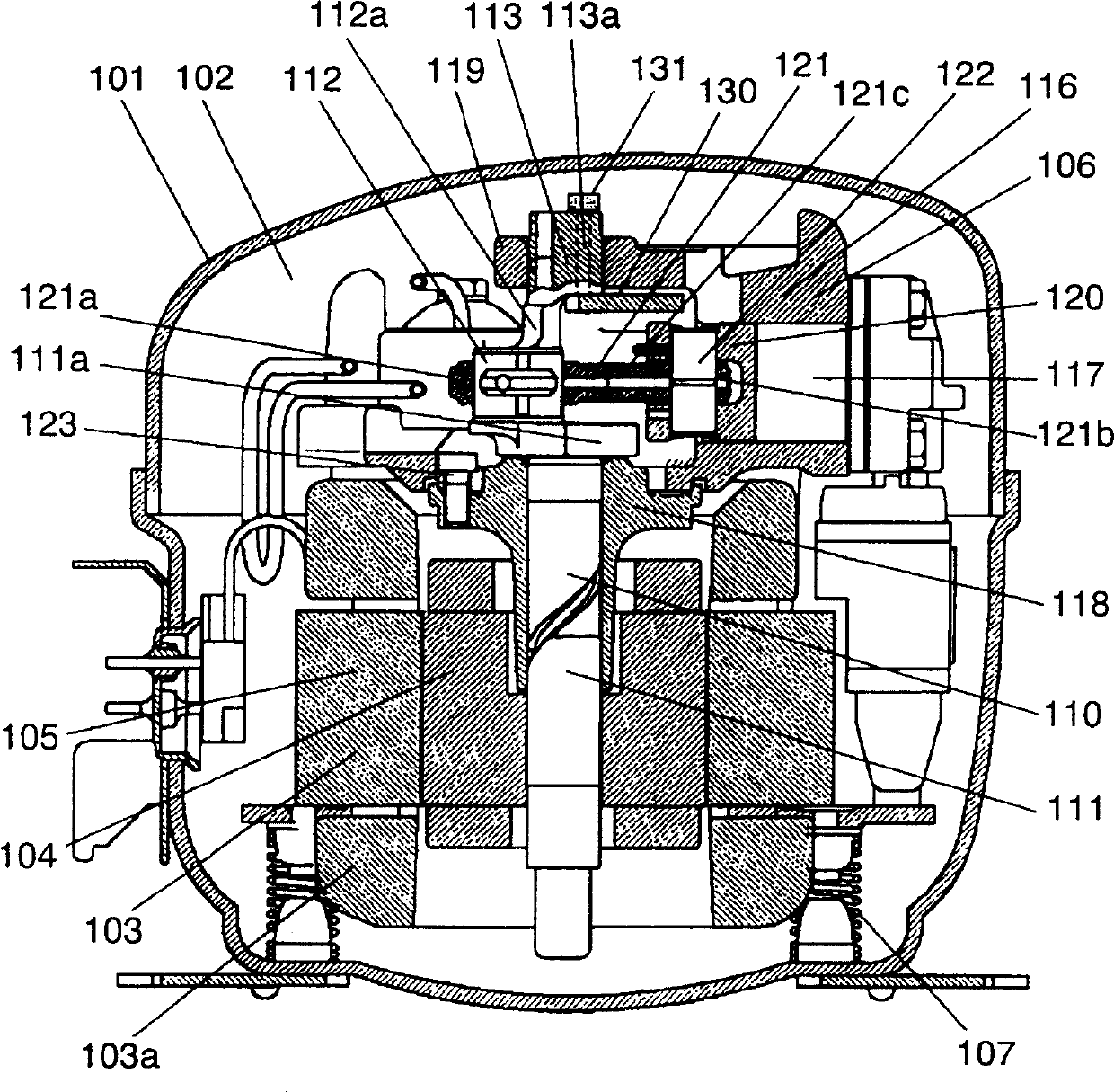

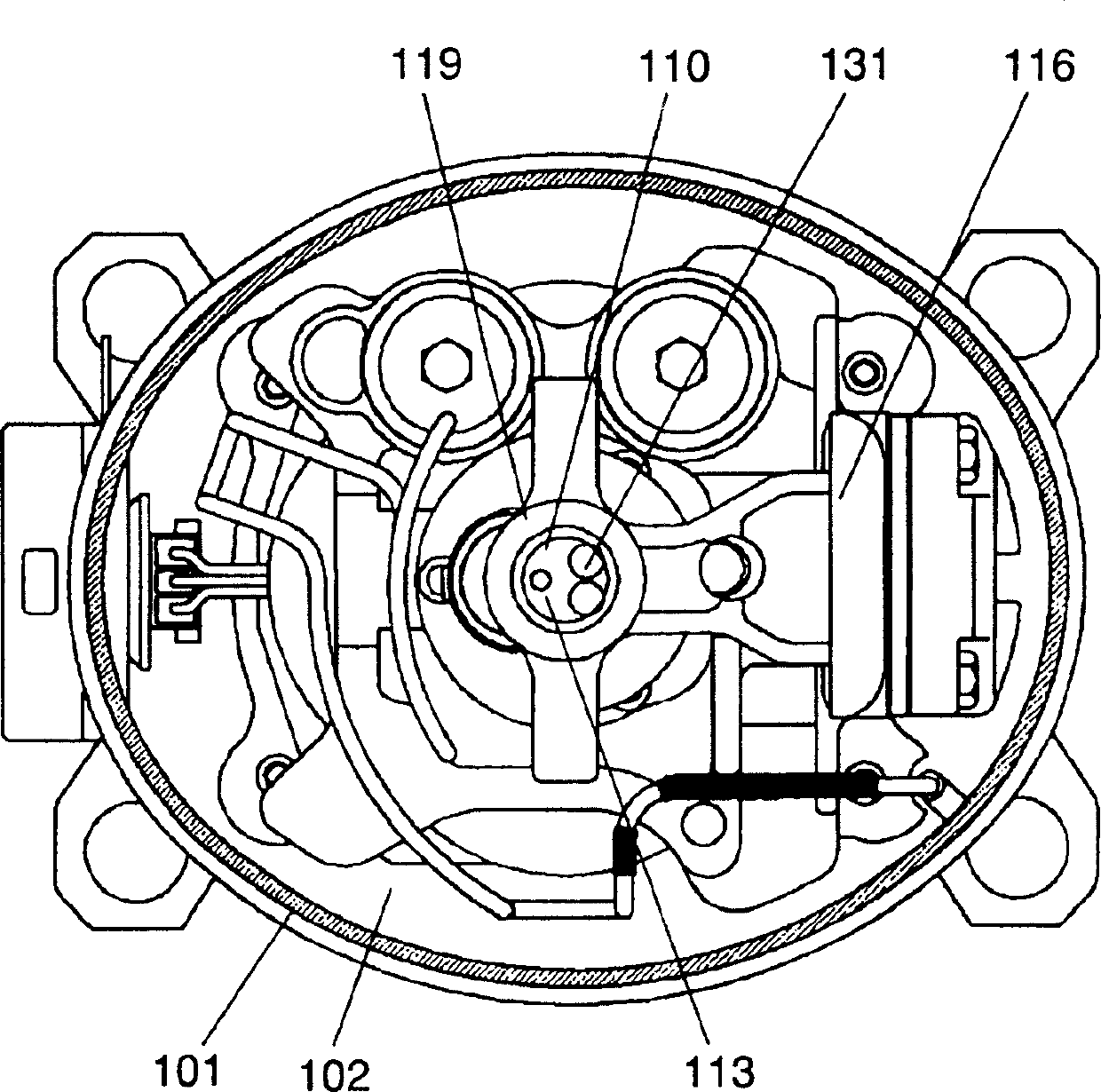

Hermetic compressor

InactiveCN1701181AReduce vibrationEasy to processCompressorPositive displacement pump componentsEngineeringMechanical engineering

Owner:PANASONIC CORP

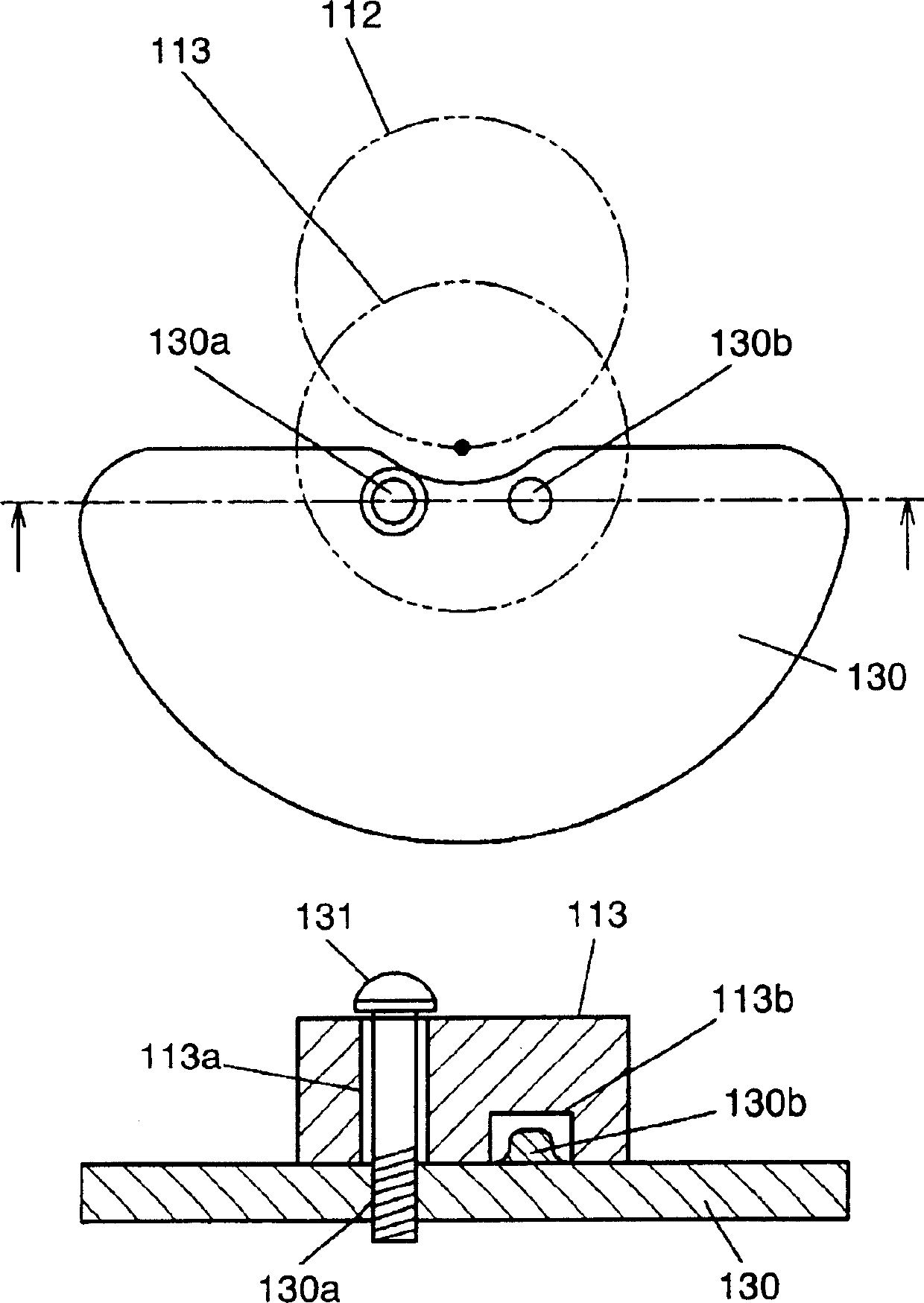

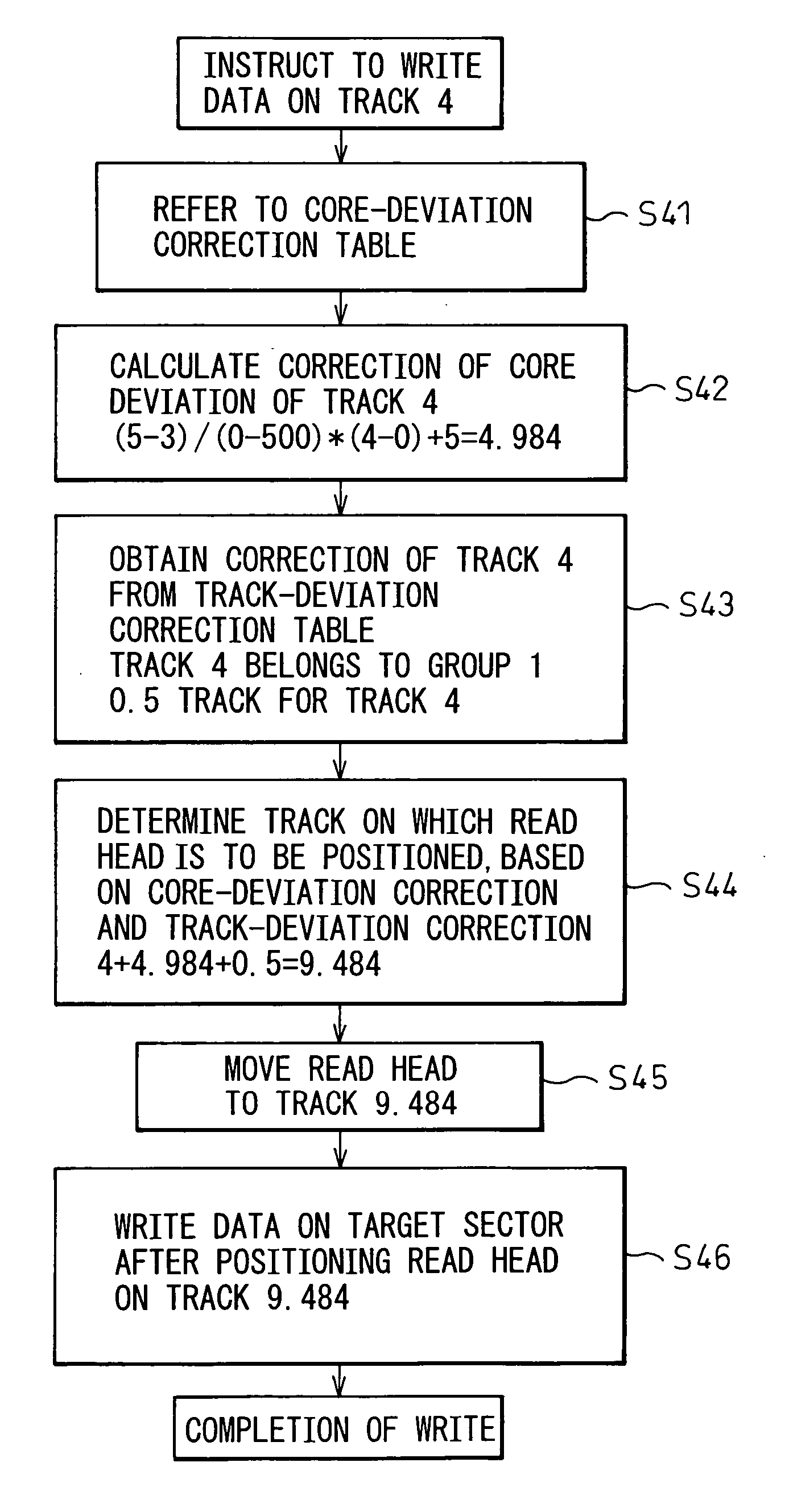

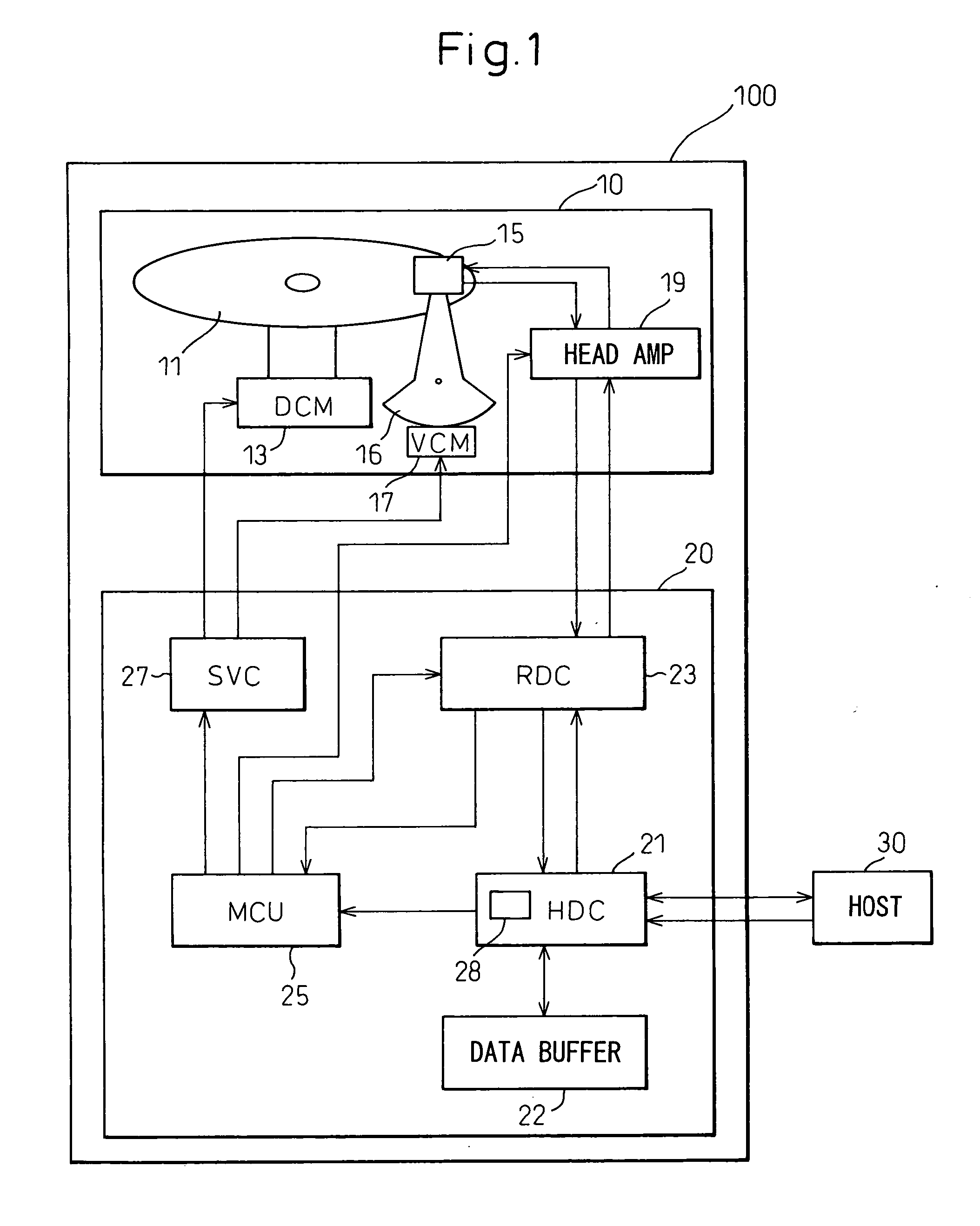

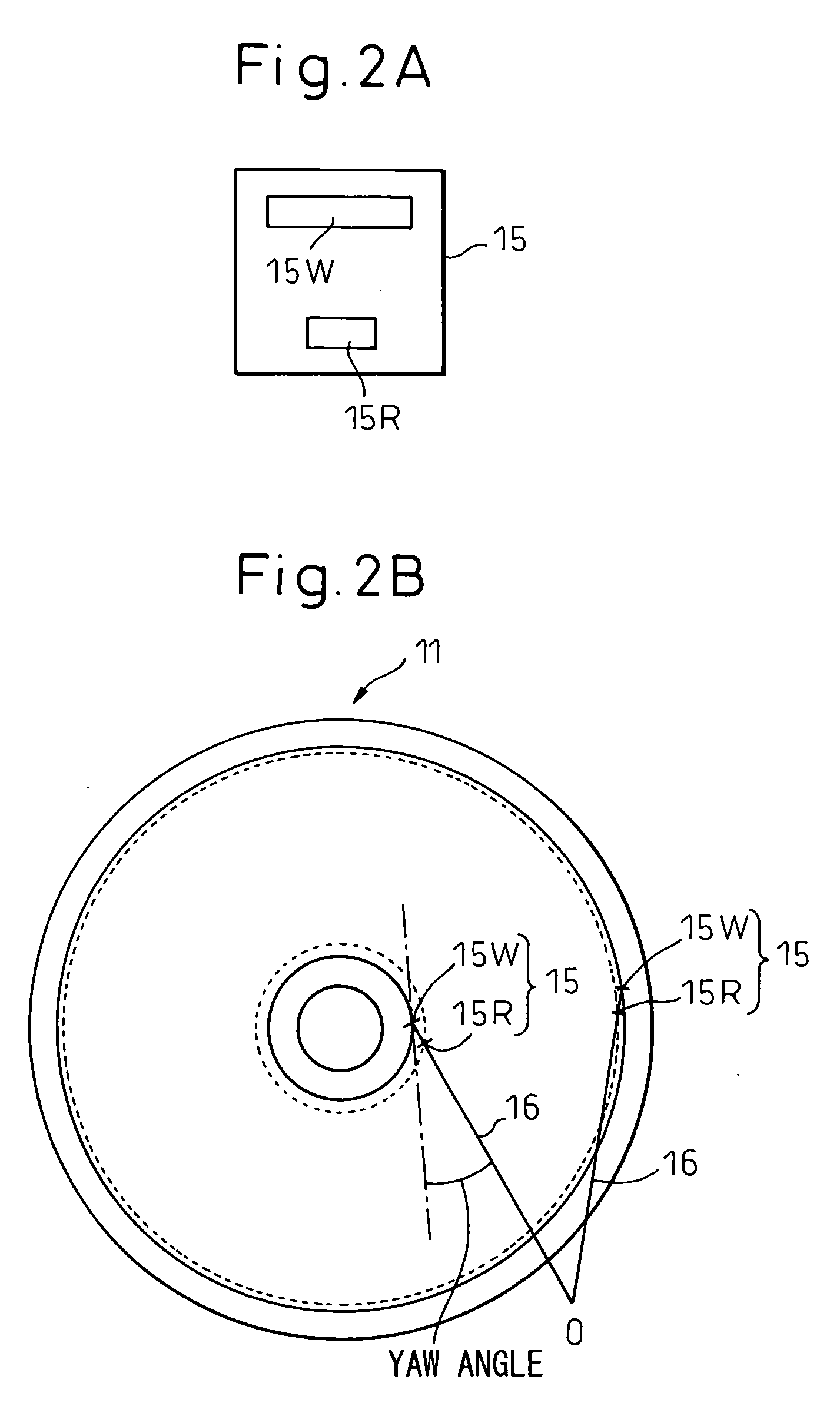

Magnetic storage device and method of correcting magnetic head position

InactiveUS20070133120A1Highly reliableEffectively write dataRecord information storageAlignment for track following on disksMagnetic coreHead position

A head position is corrected based on track deviation information read from a storage unit that stores the information on track deviation due to an abnormal pitch of a servo track. At the time of writing data, a track on which a read head R is to be positioned, which is determined based on correction of core deviation of a write head, is further corrected based on correction of track deviation information.

Owner:TOSHIBA STORAGE DEVICE CORP

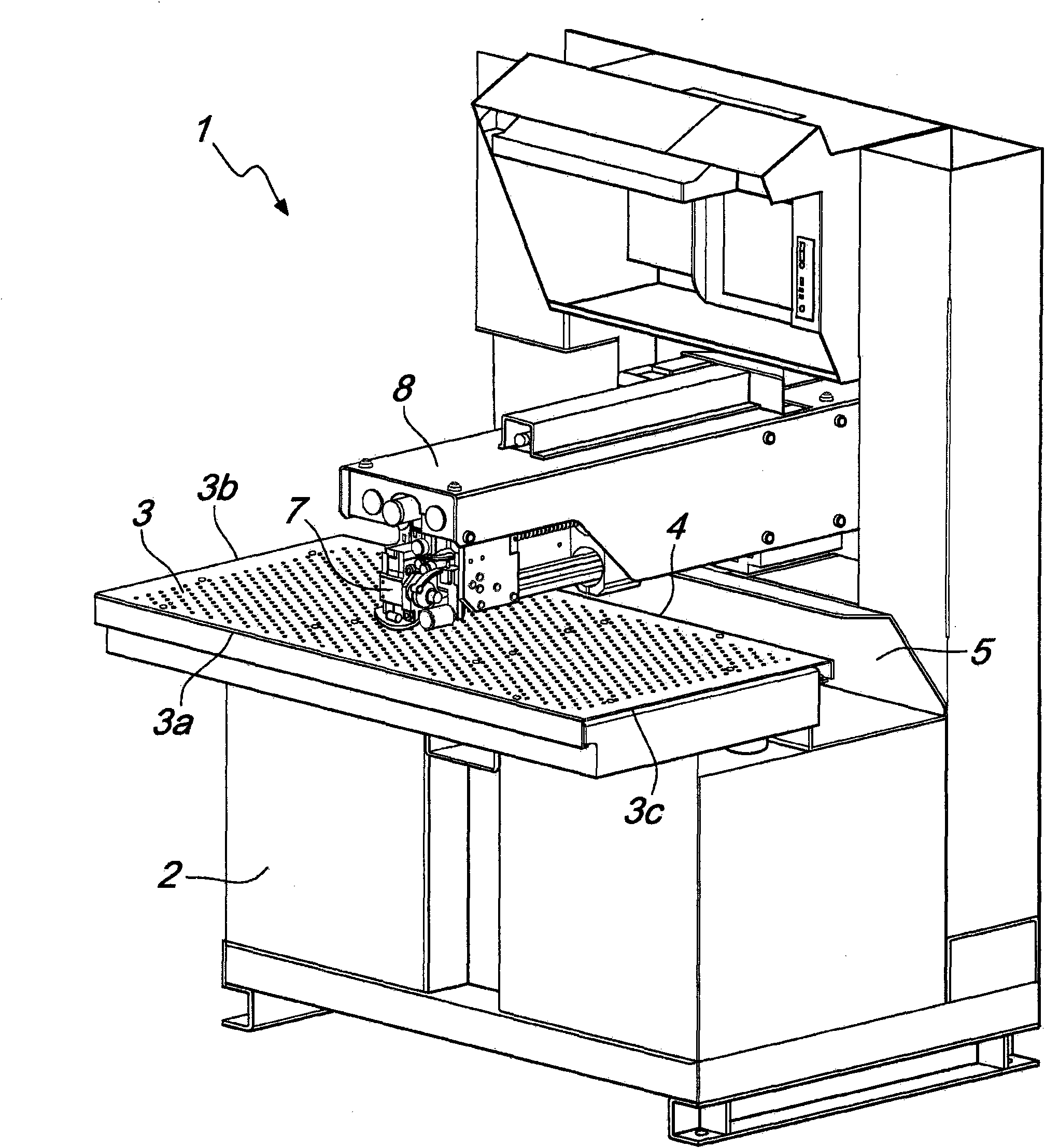

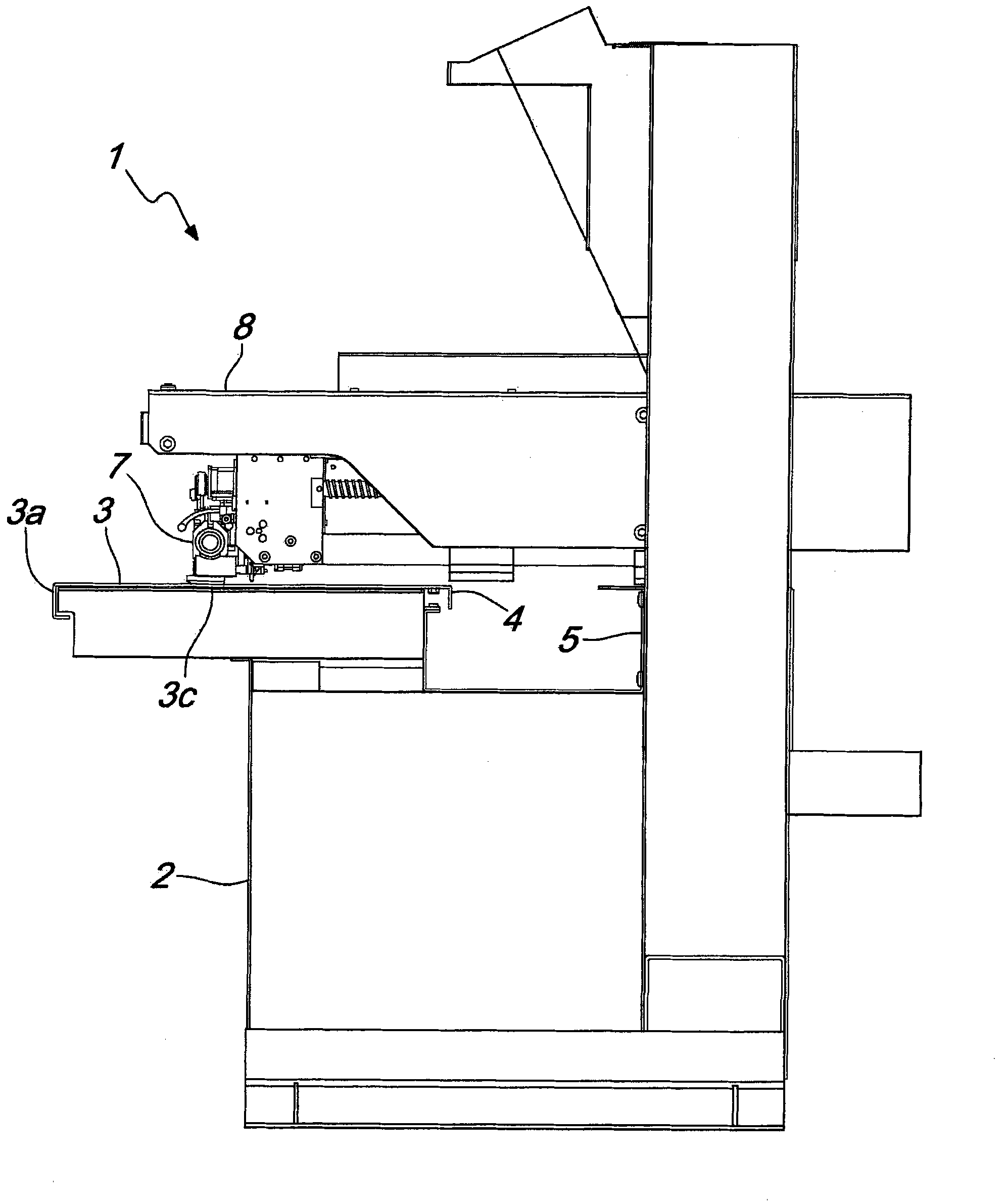

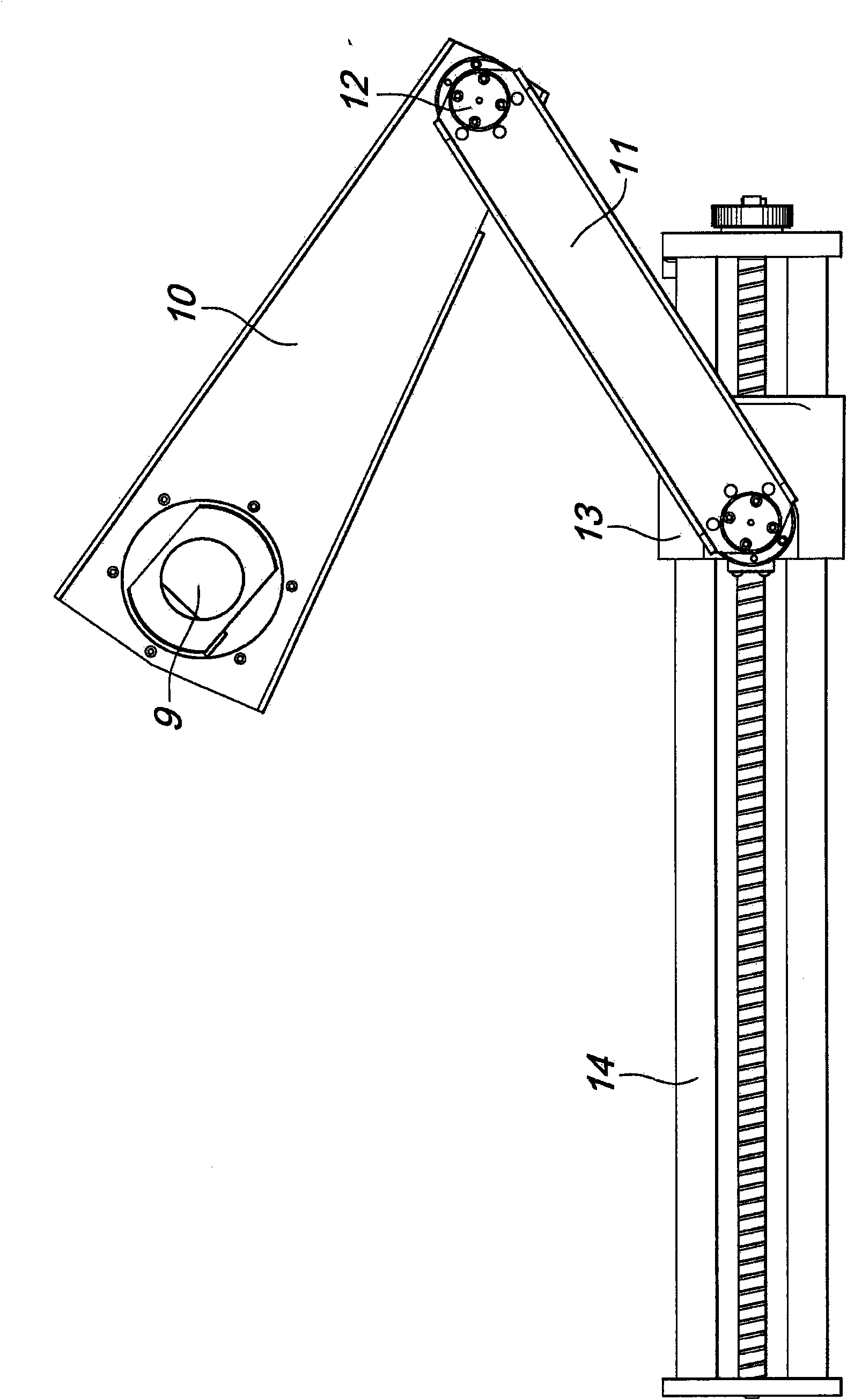

Machine for cutting hides and the like and sheet-like materials in general, with simplified-access worktable

ActiveCN101952092AEasy to provideHighly reliableLeather clicking/perforating/clickingMetal working apparatusCantileverMechanical engineering

Owner:COMELZ SPA

LED module

InactiveUS20170040510A1Highly reliableImprove efficiencySolid-state devicesSemiconductor devicesSecondary layerResist

A light emitting diode (LED) module which includes: a substrate; a resist including a plurality of layers above the substrate; and an LED element mounted above the substrate. The plurality of layers includes a second layer that is an uppermost layer and a first layer that is an underlying layer. The second layer that is the uppermost layer includes fluorine as a component.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

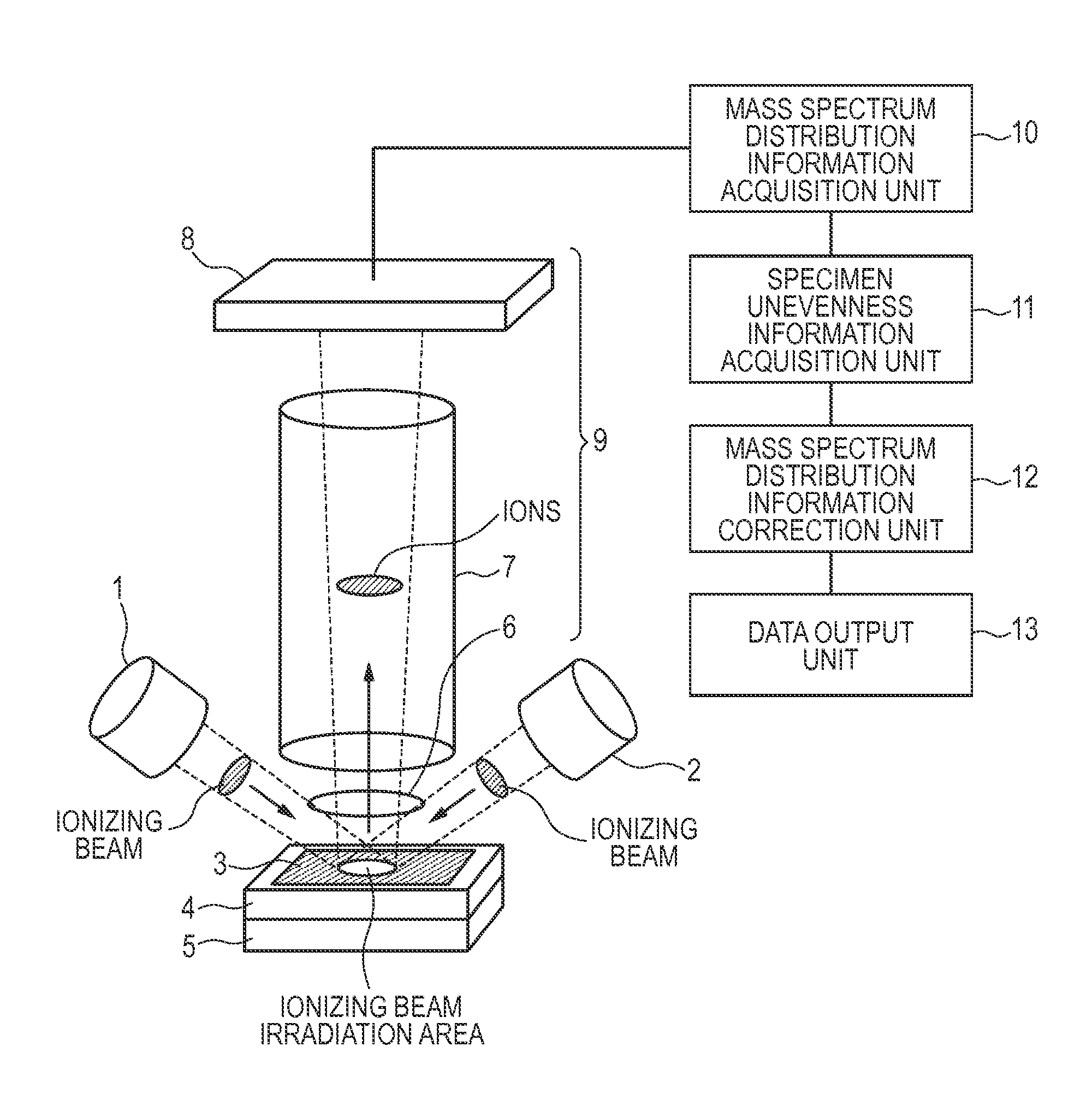

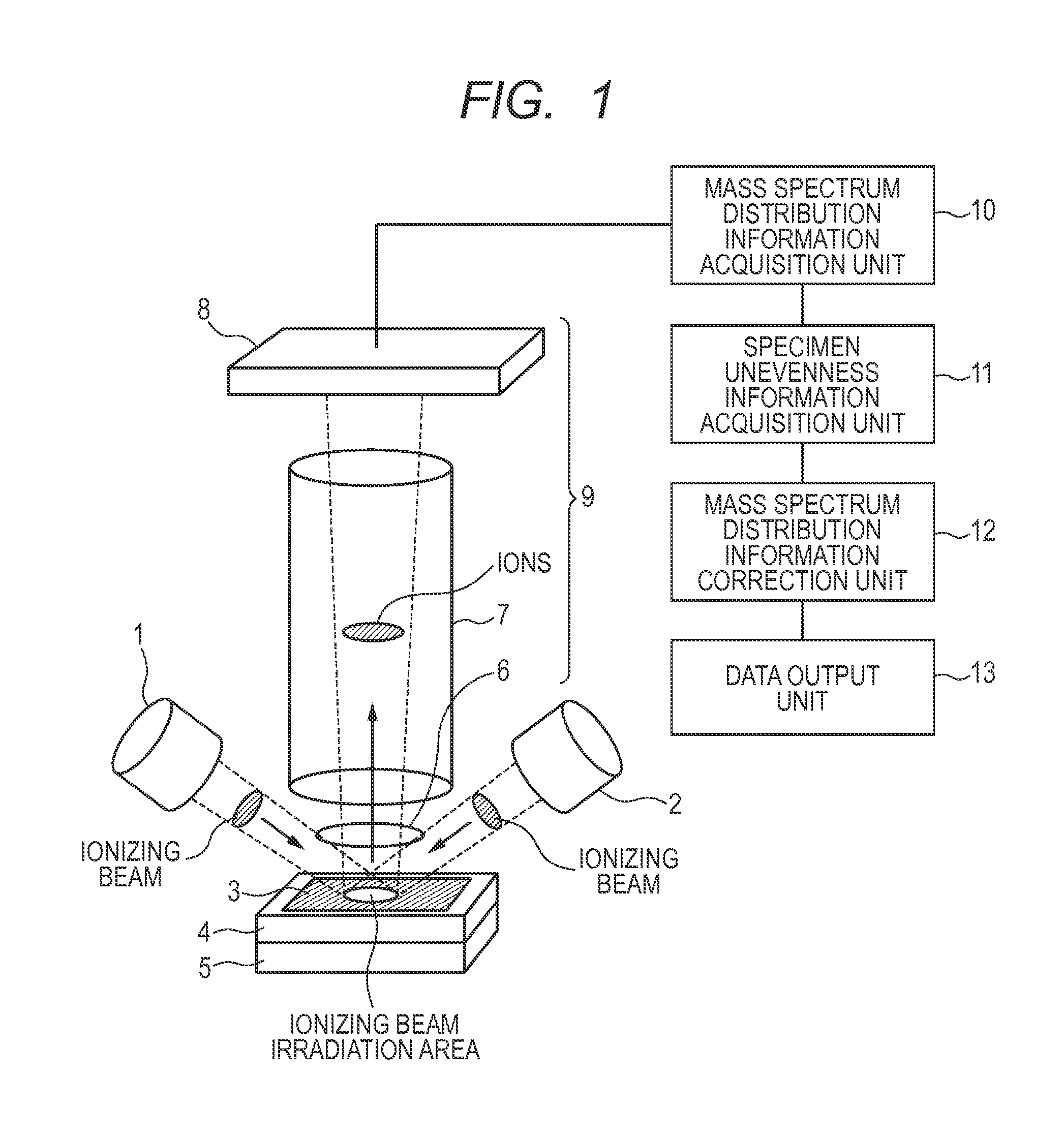

Mass distribution measurement method and mass distribution measurement apparatus

InactiveUS20150115148A1Suppress fallHighly reliableTime-of-flight spectrometersIsotope separationIonTime distribution

Projection TOF mass spectrum distribution information is acquired by irradiating a first ionizing beam onto a surface of a specimen to acquire first mass spectrum distribution information on secondary ions generated from the specimen, irradiating a second ionizing beam onto the same surface to acquire second mass spectrum distribution information on secondary ions generated from the specimen irradiation, and correcting the second mass spectrum distribution information by correcting time-of-flight distribution information of secondary ions in the second mass spectrum distribution information on the basis of detection time distribution of an arbitrary peak in the first mass spectrum distribution information.

Owner:CANON KK

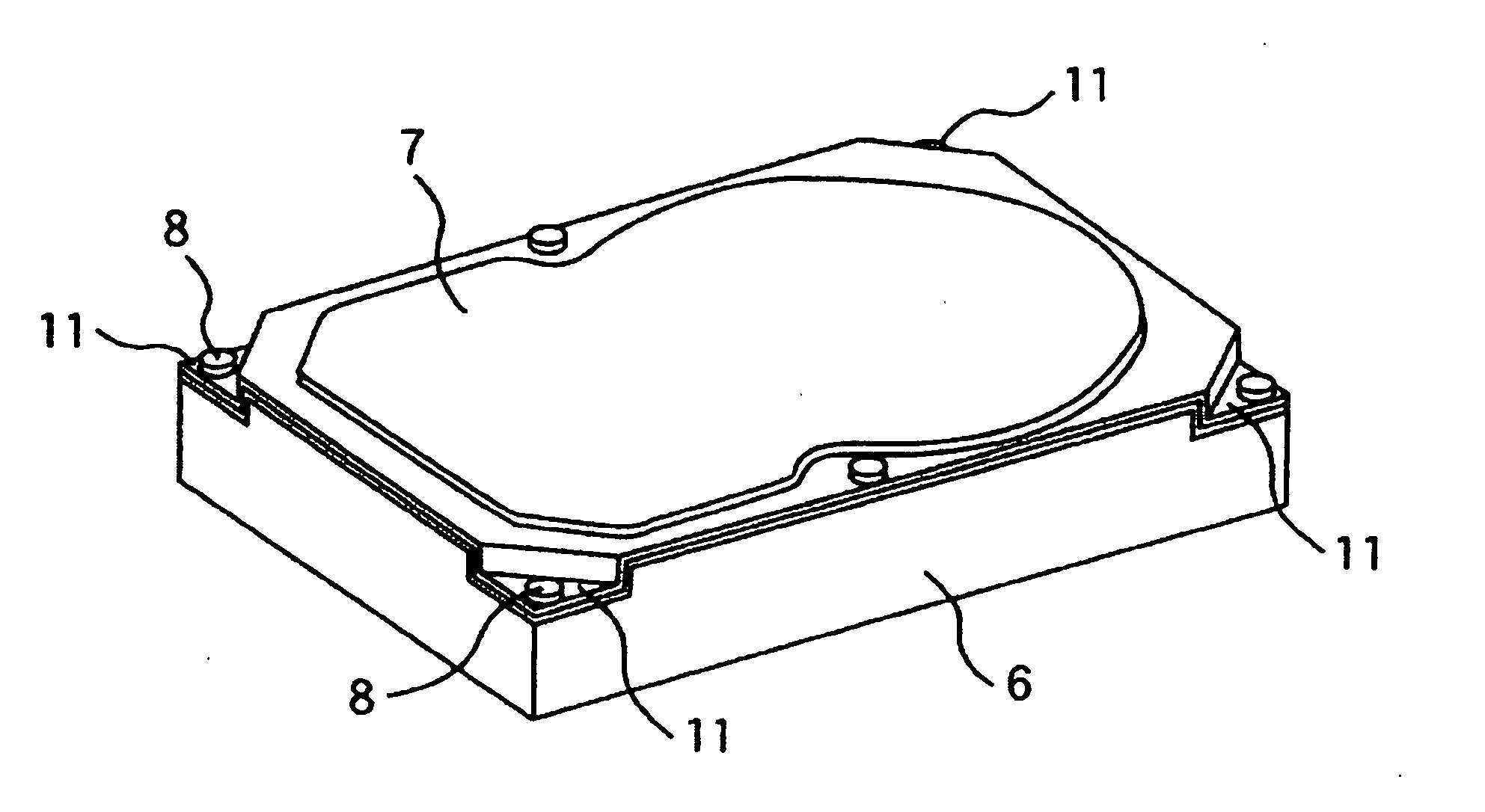

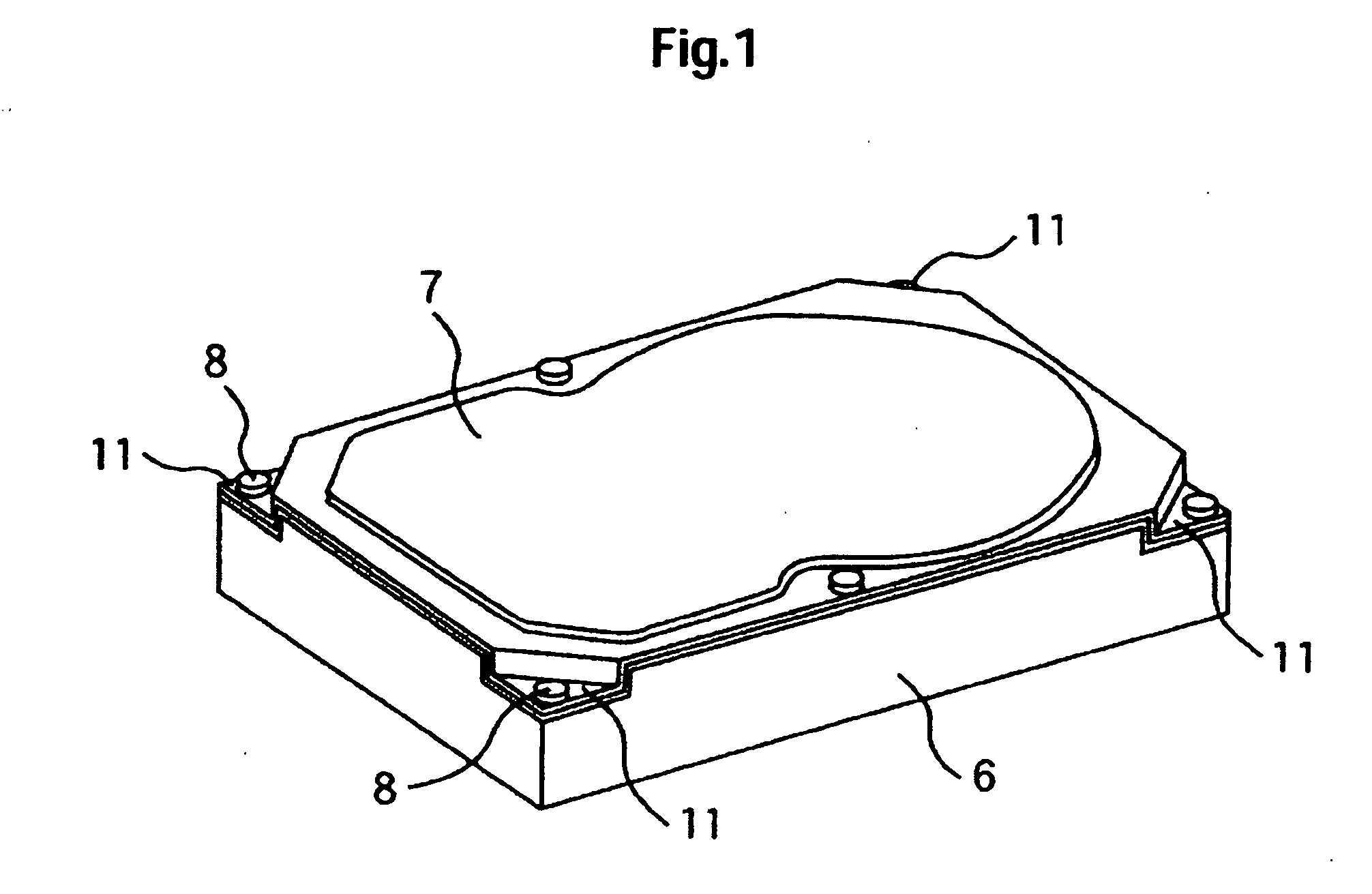

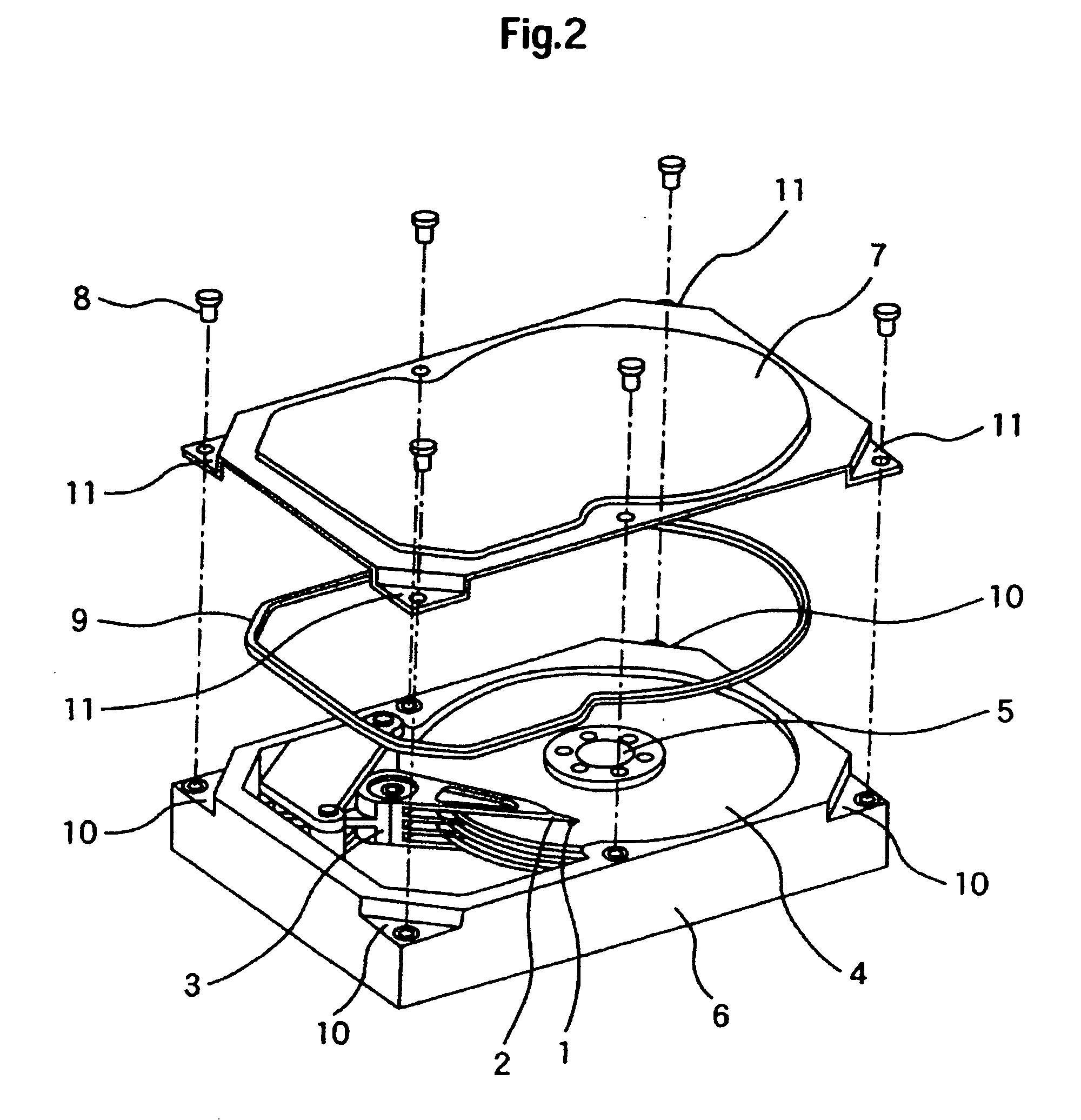

Magnetic disk drive

InactiveUS20080112299A1Highly reliableEnhance seal performanceRecord information storageSealing carrier gasketsMagnetic disksHead parts

Embodiments of present invention help to realize a highly reliable magnetic disk drive by preventing a positional displacement between a magnetic head and a target track by decreasing restricting forces that a cover exerts on a base when the temperature is increased. According to one embodiment, a base is formed by aluminum die casting, has a concave, rectangular parallelepiped shape, and is formed with step portions at the four corners. A cover is a flat plate of stainless steel or iron. Four corner portions of the cover are bent to form step portions. The cover is fixed to the base at the four corners with bolts at two side positions (six positions in total). A gasket is inserted at that time to enhance the sealing performance. Since the gasket is a member like a rubber packing, it is necessary to press the gasket with the flat portions of the base and the cover To this end, the gasket is placed on top of the base step portions and the connection between the cover and the base at the four corners is made under the base step portions.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

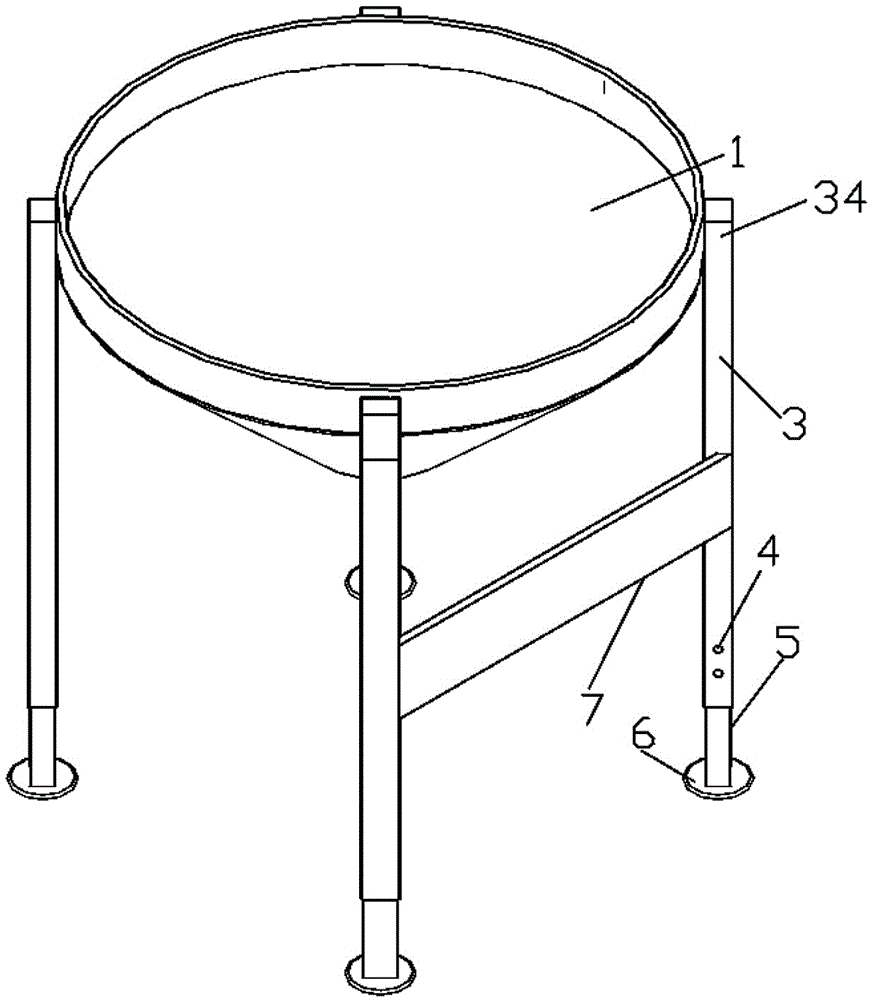

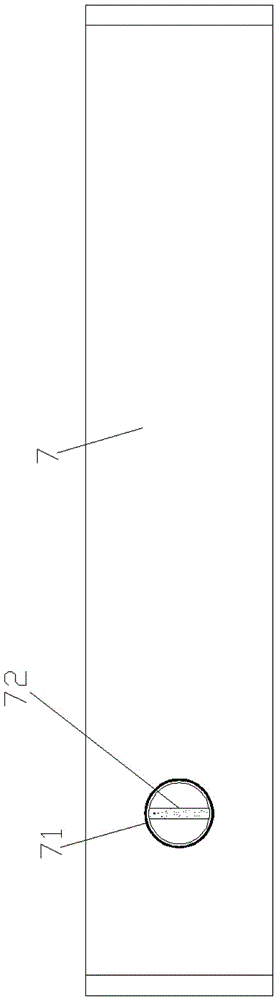

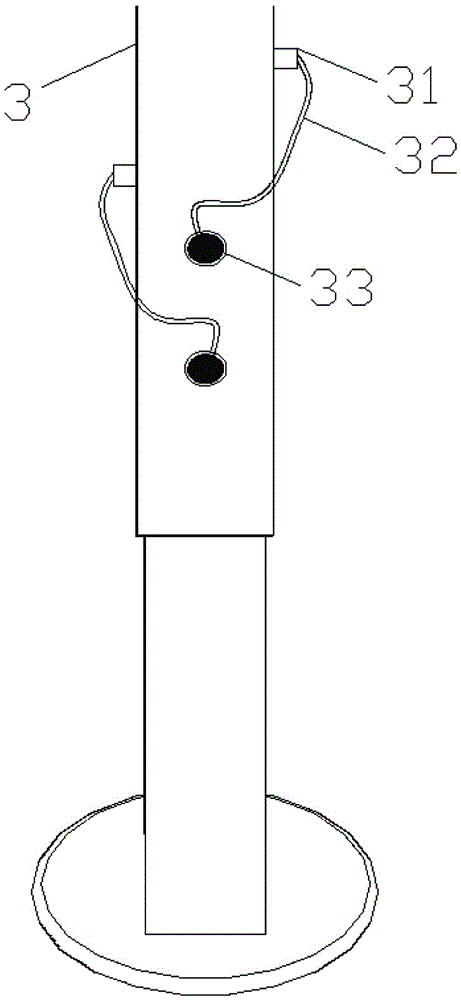

Telescopic type stove convenient for transportation

InactiveCN105650700AWill not be affectedAvoid wastingStoves/ranges foundationsDomestic stoves or rangesEngineeringCombustion process

The invention discloses a telescopic type stove convenient for transportation. The height of the stove can be adjusted, and the same stove is suitable for optimal use heights in steaming and frying processes. A stove bracket has an extremely good wind shielding effect to guarantee sufficient fire and high efficiency in a gas combustion process. The telescopic type stove comprises a supporting frame and the stove bracket which is arranged on the supporting frame and is used for placing cookware; the stove bracket is of a frustum structure with two through ends; the top edge of the stove bracket upwards extends to form an annular supporting ring; air vents are uniformly formed in the supporting ring; the supporting frame comprises four supporting legs which are uniformly distributed around the stove bracket and have adjustable heights; the supporting legs comprise fixed supporting legs fixed around the stove bracket and telescopic supporting legs assembled on the fixed supporting legs; and the bottoms of the telescopic supporting legs extend along the radial direction to form a supporting base plate.

Owner:陈圆丁

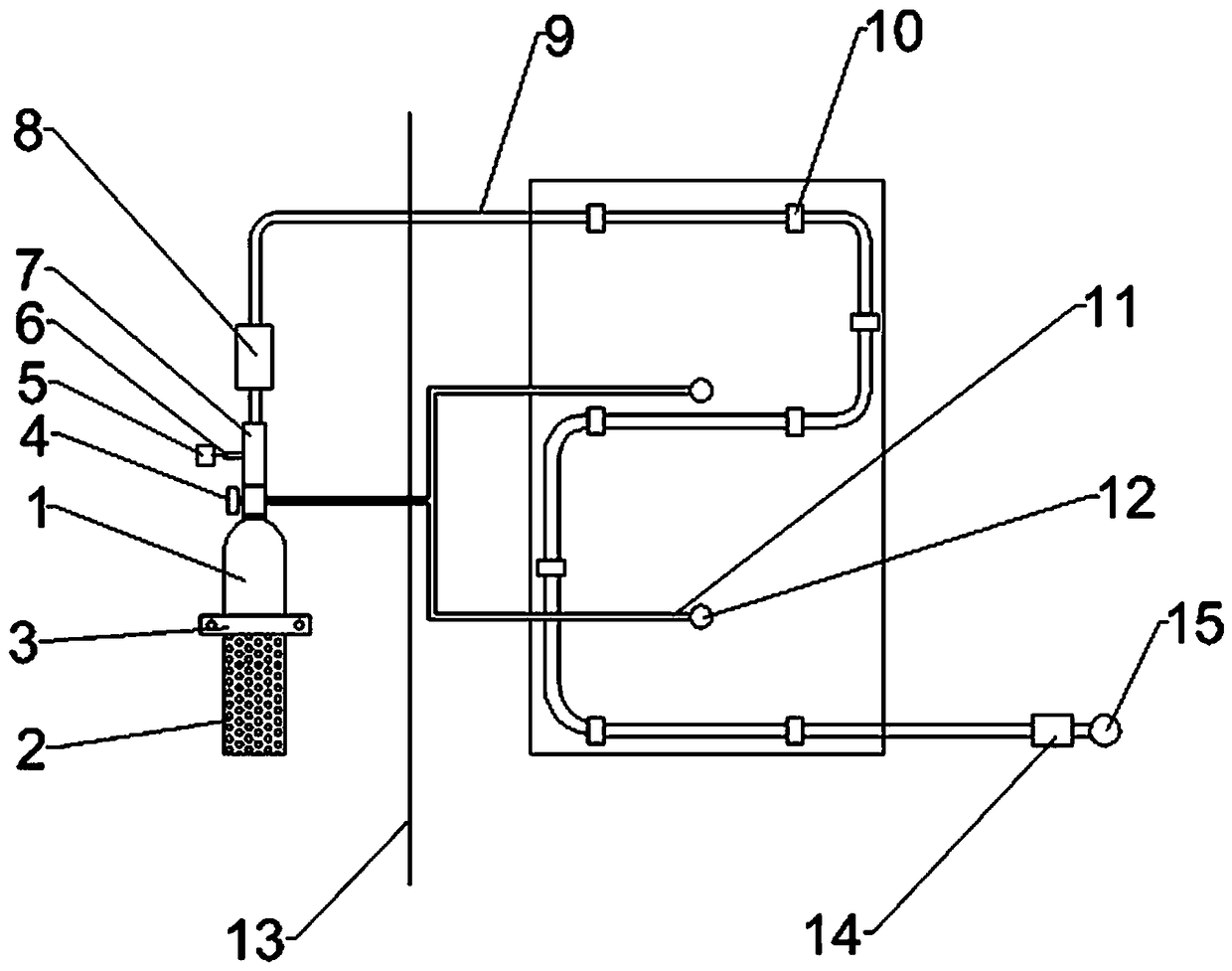

Automobile-mounted automatic powder extinguishing device

The invention relates to an automobile-mounted automatic powder extinguishing device, and belongs to the technical field of fire-fighting extinguishing devices. The invention relates to an automatic extinguishing system integrating fire detection with extinguishing. Rapid, accurate and effective detection for a fire source can be realized by pressure-charged fire detection pipe and container bottle group by virtue of the own pressure storage, the automatic extinguishing system has the advantages of being simple to design and calculate, simple and convenient to construct and install, rapid andeffective in extinguishing, purely mechanical in automatic control and start-up, and is an automatic extinguishing system which is low-carbon, environment-friendly, simple, low in cost, highly reliable and independent. According to the automobile-mounted automatic powder extinguishing device disclosed by the invention, container bottles are arranged outside an engine cabin, so that influence on the sealing performance of the container bottles when the temperature of the engine cabin part liable to cause fire, on an automobile, is high during the running of the automobile, is reduced; and moreover, the fire detection pipe is arranged in the form of S-shape, free from dead angles in fire prevention, capable of stretching into the engine cabin with a complex structure and really realizing nodead angles in safety protection, applicable to various occasions, and capable of realizing no blank in protection.

Owner:丁玉琴

Electrophoretic particle, method of manufacturing electrophoretic particle, electrophoresis dispersion liquid, electrophoresis sheet, electrophoresis device, and electronic apparatus

An electrophoretic particle includes a particle and a coating layer, in which the coating layer includes at least one of dispersibility and chargeability, and includes a polymer that connects to the particle, where the polymer includes a first functional group and is connected to the particle via a connected body, the connected body has a molecular weight of 500 or less and includes a second functional group and a third functional group, and the particle, the connected body and the polymer are connected via the chemical bond formed by reacting the first and second functional groups and the chemical bond formed by reacting the hydroxyl group and the third functional group.

Owner:E INK CORPORATION

child safety seat

The present invention discloses a height adjusting mechanism for adjusting a headrest (1) of a child safety seat. The child safety seat includes a seat body (2) and the headrest (1). The headrest (1) is slidably mounted on the seat body (2) and can slide up and down. The adjusting mechanism includes an actuator (3) and a locking means (4), wherein the locking means (4) is used for releasably locking the headrest (1) at a preselected height, and the actuator (3) is used by itself action to release the locking means (4) so that the height of the headrest (1) can be adjusted. The actuator (3) is located between the headrest (1) and the seat body (2) and extends outside the headrest (1). Preferably, the locking means (4) comprises a first component (5) mounted on the seat body (2) and a second component (6) mounted on the headrest (1), wherein the second component (6) and the first component (5) are releasably engaged.

Owner:BRITAX ROMER KINDERSICHERHEIT GMBH

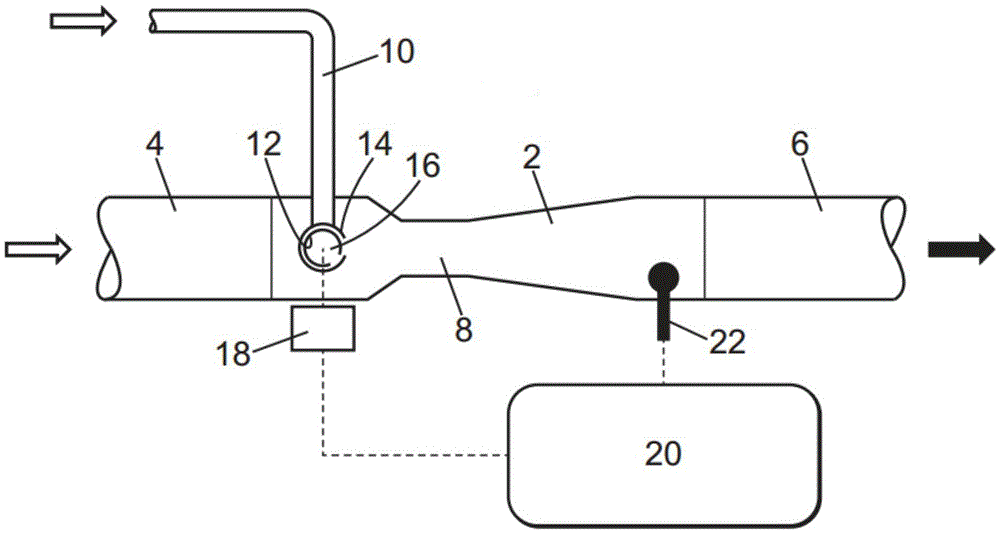

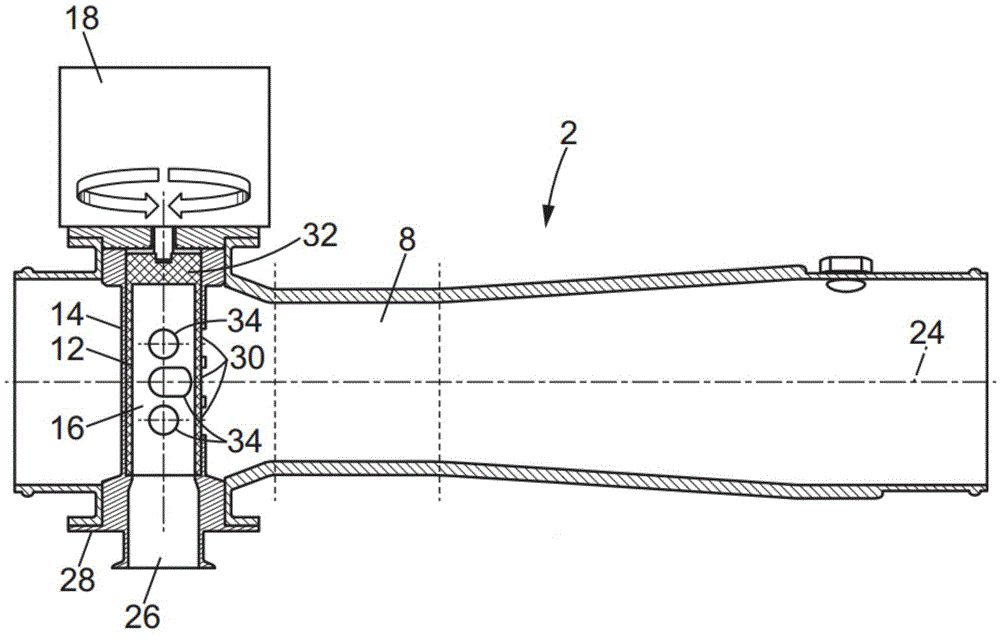

GAS mixing pump, particularly for heating system

InactiveCN105593777ASimple designSmall sizeTemperature control without auxillary powerAir-treatment apparatus arrangementsHeating systemGas mixing

Owner:LIEBHERR AEROSPACE TOULOUSE

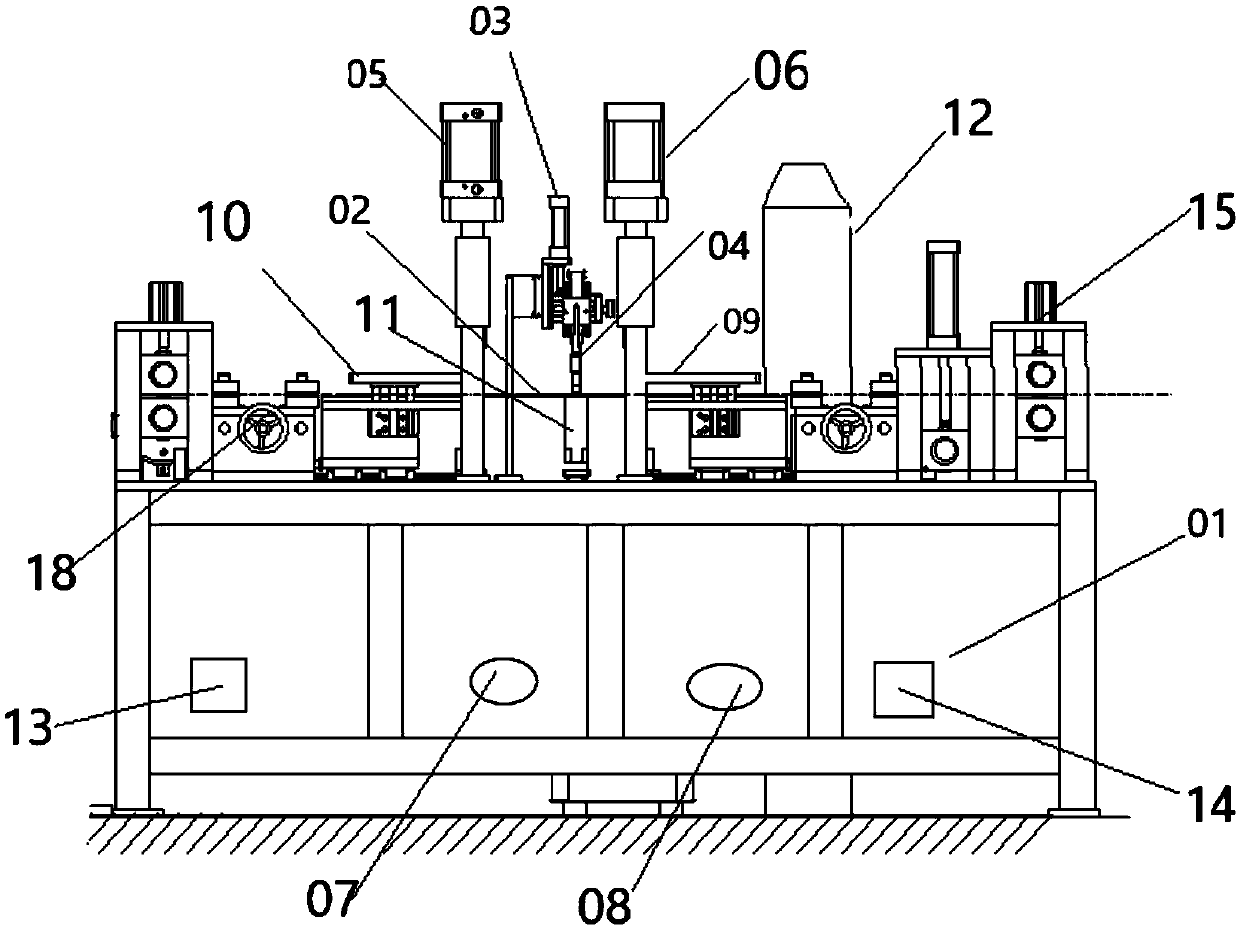

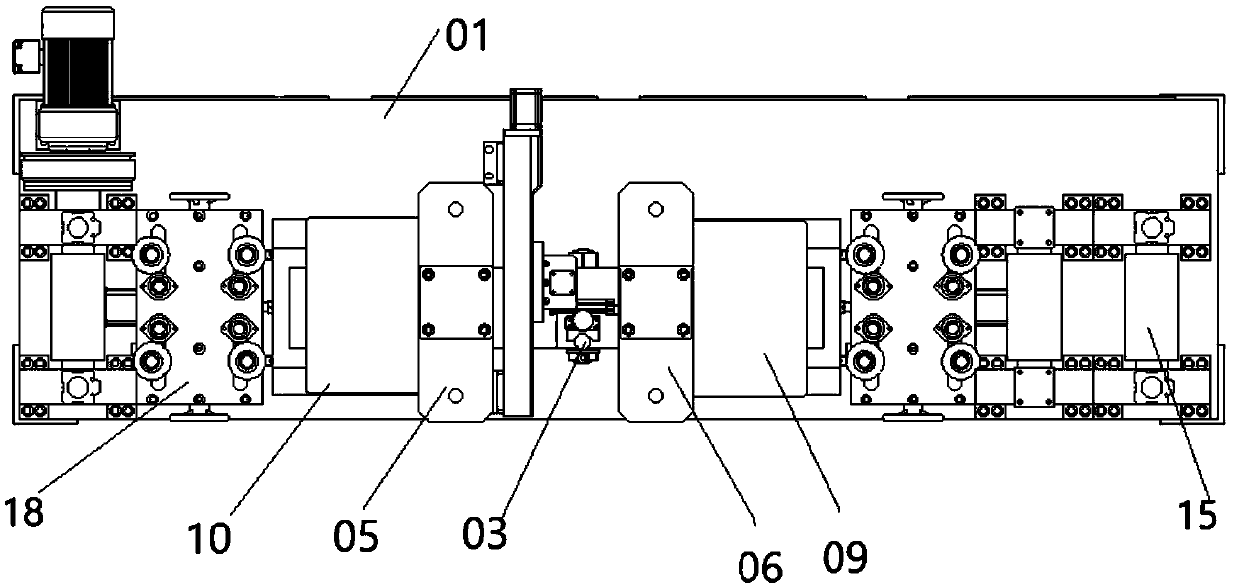

Semi-automatic welding device for steel belt production line

InactiveCN111085867AMeet production requirementsEasy to operateOther manufacturing equipments/toolsProduction lineMolding machine

The invention discloses a semi-automatic welding device for a steel belt production line. The semi-automatic welding device comprises a machine tool base (01), a welding operating table (02), a welding machine travelling mechanism (03), a first shearing mechanism (05), a second shearing mechanism (06) and a control module; a welding machine (04) is arranged on the welding machine travelling mechanism (03); the first shearing mechanism (05) is used for shearing a material head of a rear material; the second shearing mechanism (06) is used for shearing a material tail of a front material; the welding machine (04) is used for welding the shorn front material and rear material into a whole; and a first shearing switch (07) and a second shearing switch (08) are arranged on the machine tool base(01). According to the semi-automatic welding device for the steel belt production line, a front material steel belt and a rear material steel belt are welded into a whole, the front material steel belt drives the rear material steel belt to enter into a subsequent forming machine production process, and thus the current situation that the feeding angle of each steel belt is adjusted through manual operation to place the steel belts in a forming machine is changed.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com