GAS mixing pump, particularly for heating system

A heating system, mixing pump technology, applied in control/regulation systems, air handling equipment, temperature control without auxiliary power supply, etc., can solve problems such as no pumping effect and no suction allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

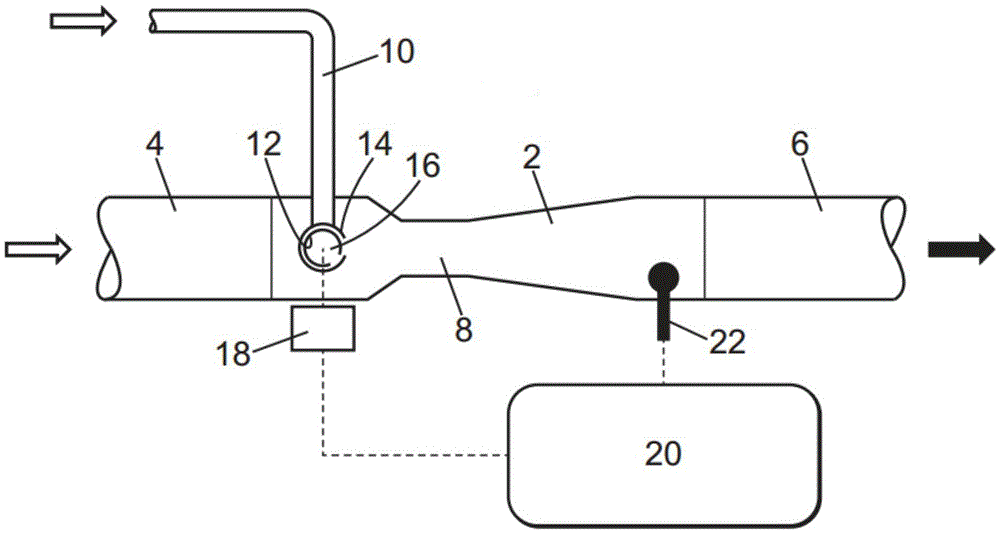

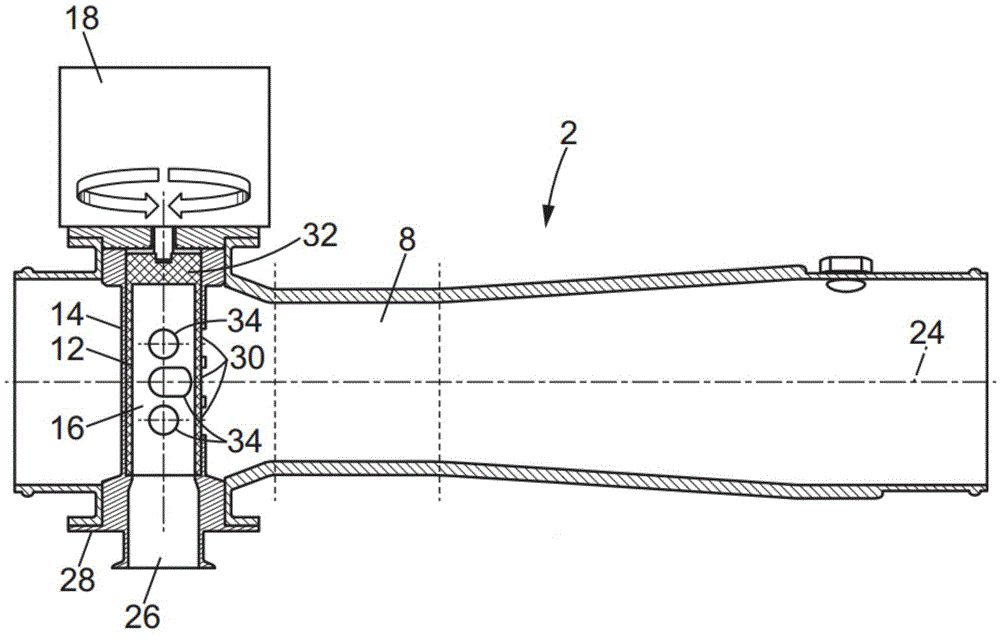

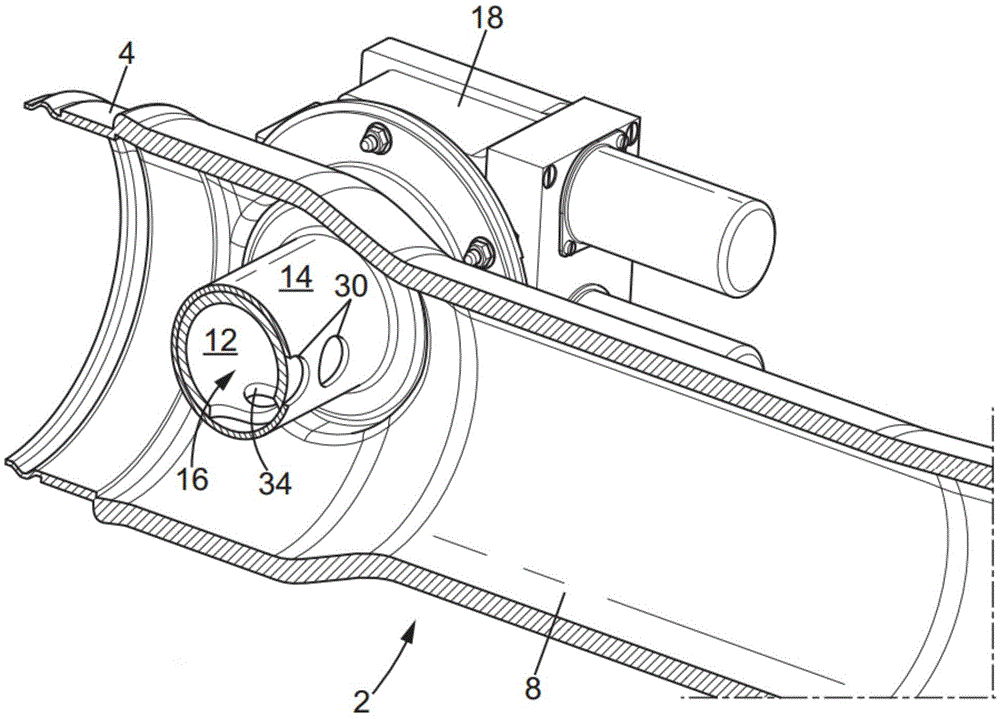

[0028] figure 1 The general structure of a preferred embodiment of a mixing pump 2 according to the present invention is explained.

[0029] The mixing pump 2 shown is installed downstream of the cool air inlet 4 and upstream of the warm air outlet 6 . It comprises a main duct, a mixing section 8, a hot air inlet 10, and means for mixing the air flow from the cold air inlet 4 with the air flow directed by the hot air inlet 10 to the mixing pump 2 located in said main within the pipeline. The mixing tool includes a valve 12 disposed in a sleeve 14 and defining a chamber 16 .

[0030] An actuator 18 is provided for adjusting the position of the valve 12 in the sleeve 14. The actuator 18 is controlled by an acquisition and control system 20 , which is in particular associated with a temperature sensor 22 . The actuator 18 is preferably electrical. However, depending on the circumstances, it is also possible, for example, to have a pneumatic device with, for example, a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com