Patents

Literature

188results about How to "Moderate weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

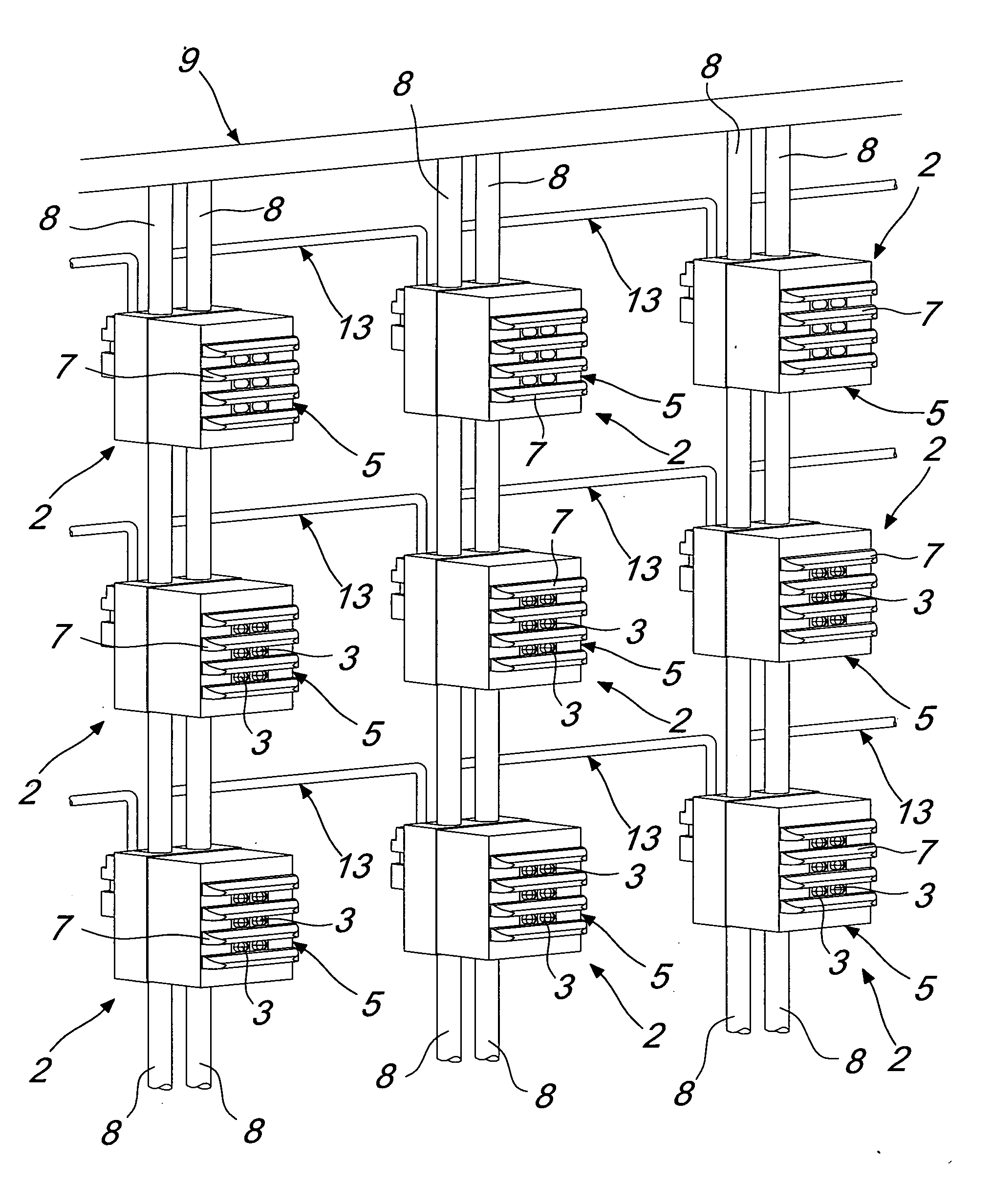

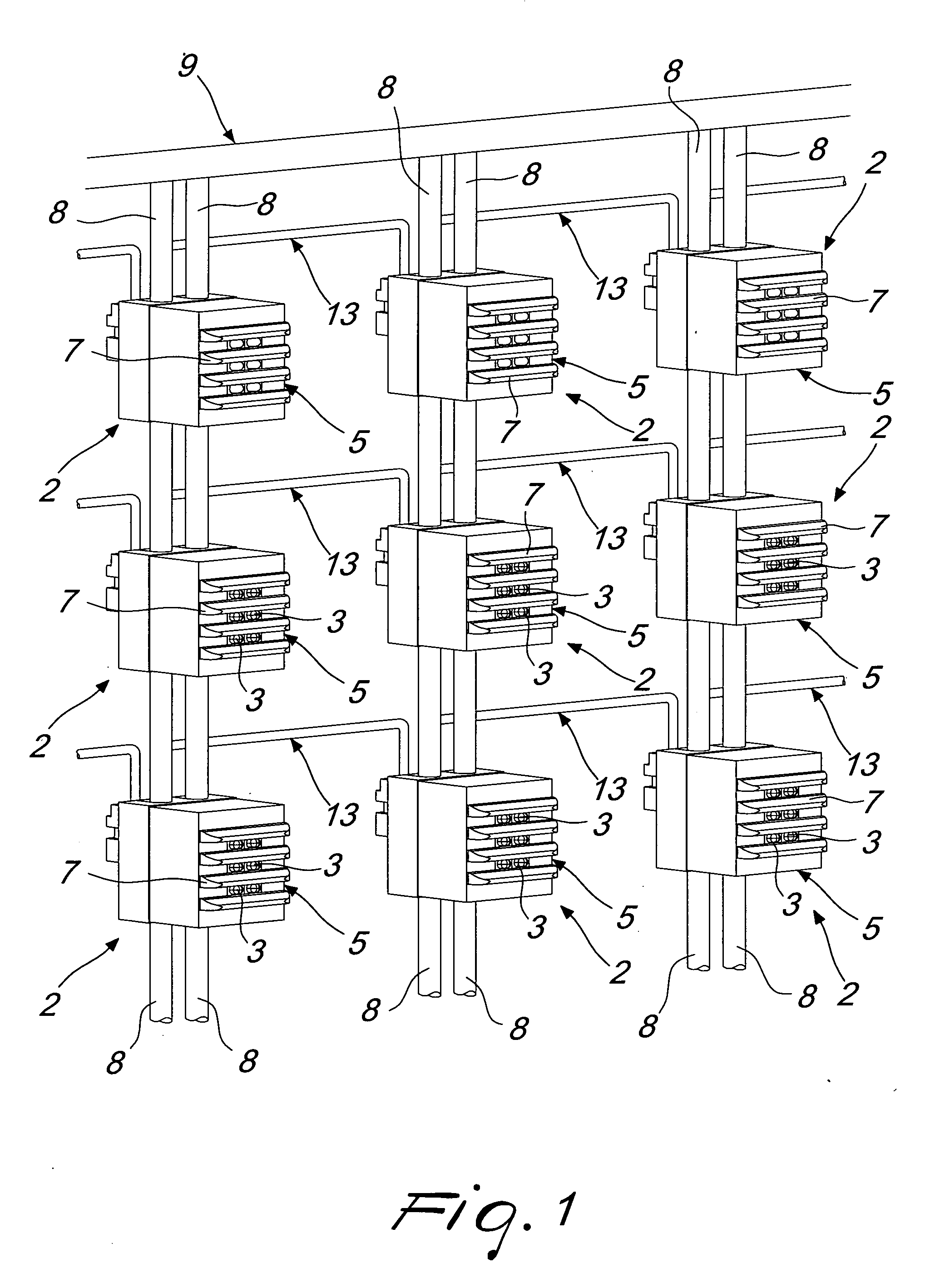

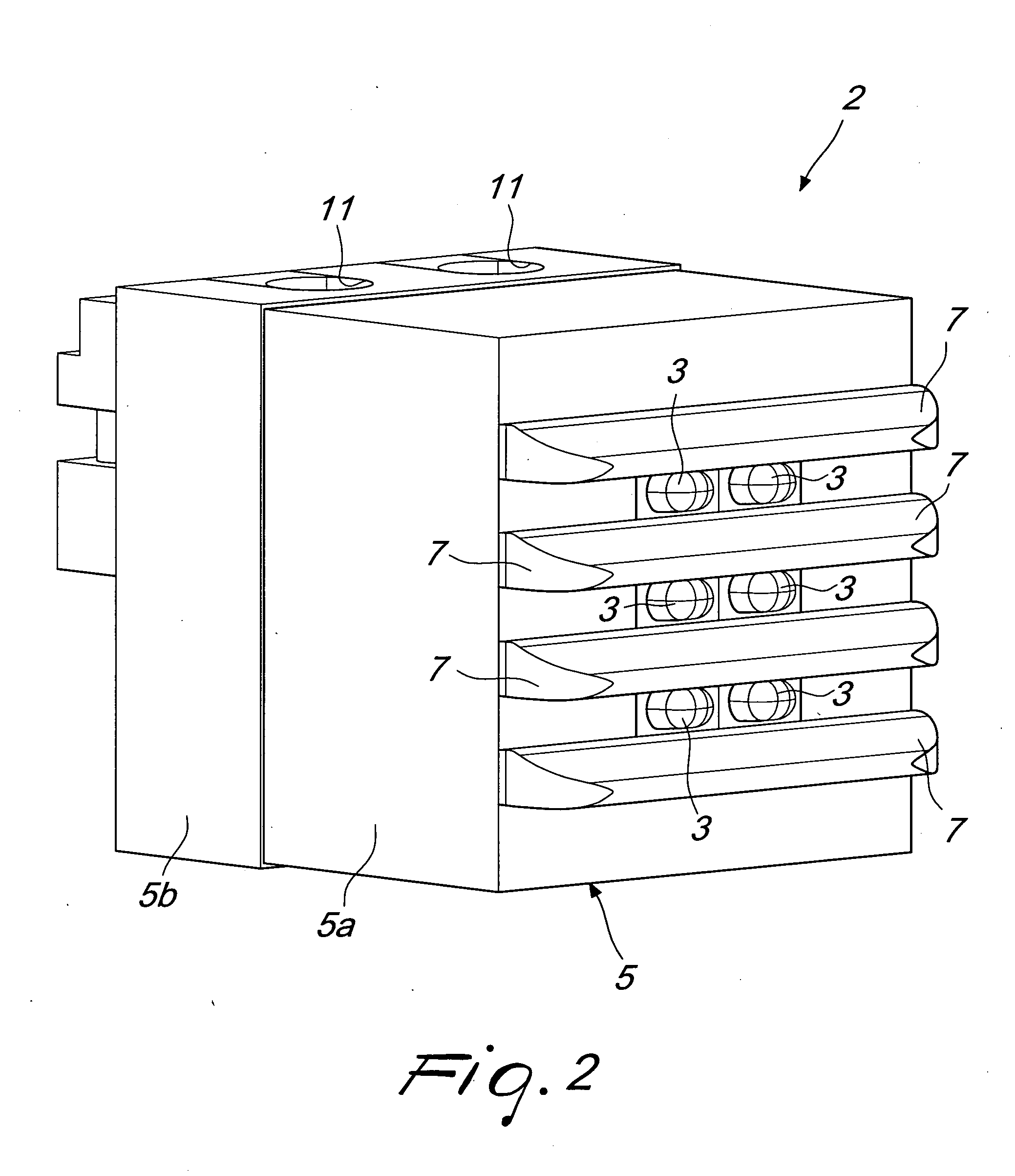

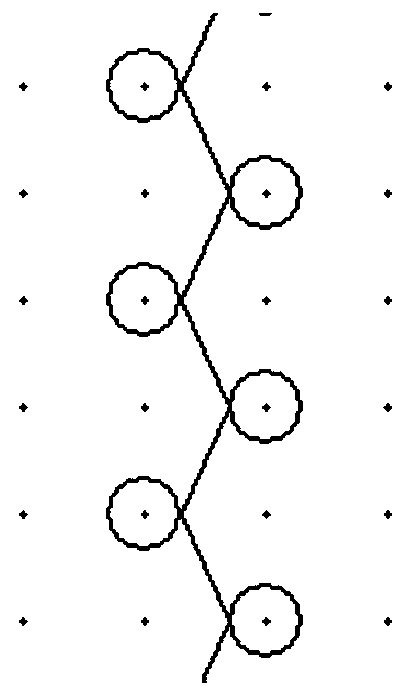

LED luminous screen, particularly for mega screens

InactiveUS20110134640A1Maximize transparencyResistance of effect of windLighting support devicesElectric lightingGraphicsEffect light

“An LED luminous screen, particularly for mega screens, giant graphical video screens, lighting effects and the like, comprising a plurality of pixels arranged according to an array, each pixel being formed by a plurality of LEDs which are associated with a printed circuit contained in a main body that forms the individual pixel; the screen comprises, for each column of the array, at least one supporting cable that can be fixed between the main bodies or to each one of the main bodies that belong to the same vertical row of the array by way of fixing means and extend substantially at right angles to an upper supporting bar, which can be arranged horizontally; the main bodies belonging to adjacent columns are mutually connectable by way of connection means in order to keep the main bodies substantially on a same plane and at a given distance between the elements.”

Owner:BERTELE MARCO

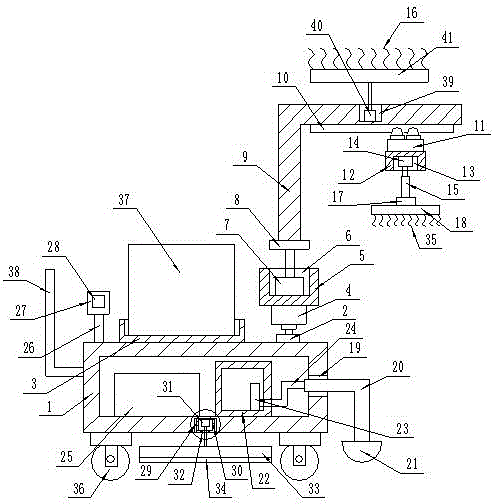

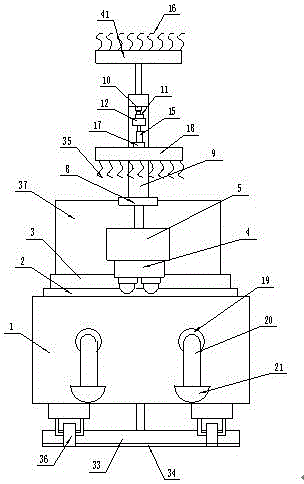

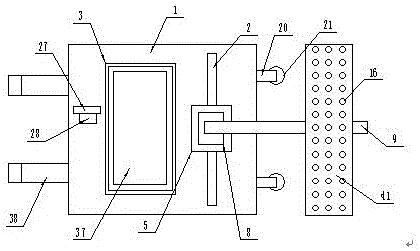

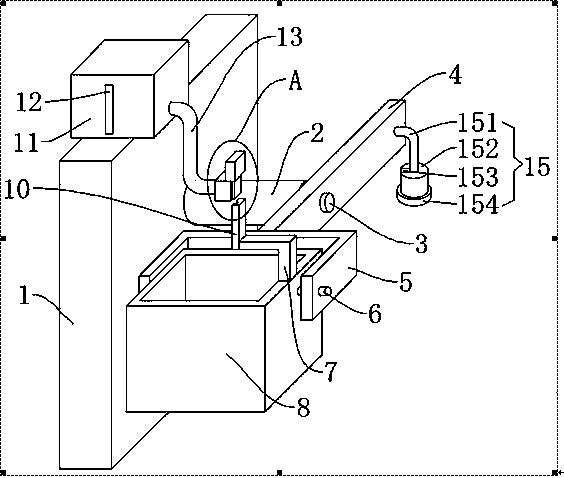

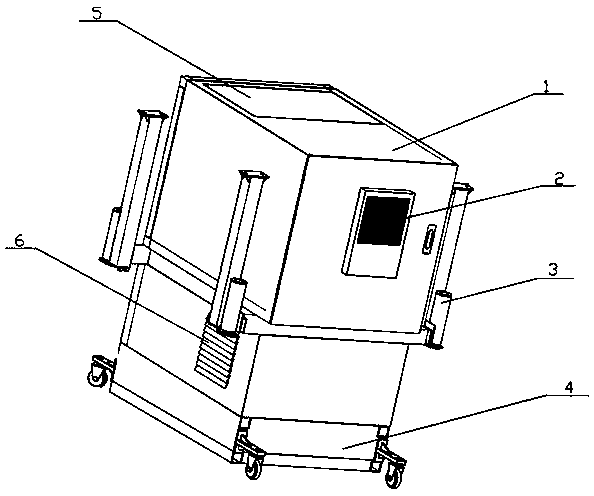

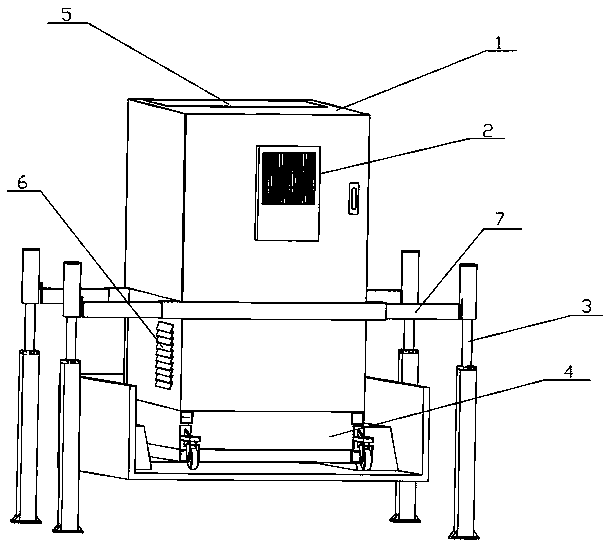

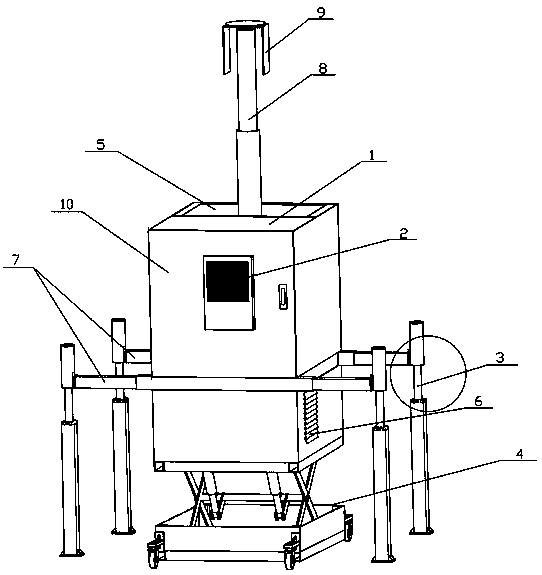

Hospital cleaning apparatus

ActiveCN106040649AEasy to operateReduce maintenance costsCarpet cleanersFloor cleanersEngineeringElectric trolley

The invention discloses a hospital cleaning apparatus which comprises a loading board with internal cavity structure. A slide is arranged on one side of the upper surface of the loading board; a u-shaped holder is arranged on the other side of the upper surface of the loading board. A first electric trolley is arranged on the slide and provided with a mount on the upper surface. An accumulator is arranged on one side of a water storage bucket and on the internal lower surface of the loading board. An upright rod is arranged on the upper surface of the loading board and disposed on one side of the u-shaped holder, a vertical mounting board is arranged on the upper surface of the upright rod, and a controller is arranged on the front surface of the vertical mounting board. A power terminal of the controller is connected with the accumulator through a conductor wire, and an output end of the controller is connected with the first electric trolley, an electric pusher, a second electric trolley, a second electric pusher and a water pump via conductor wires respectively. The hospital cleaning apparatus has the advantages of wide cleaning range including ceiling, high work efficiency, capability of liberating manpower, and moderate weight.

Owner:山东国九堂制药集团股份有限公司

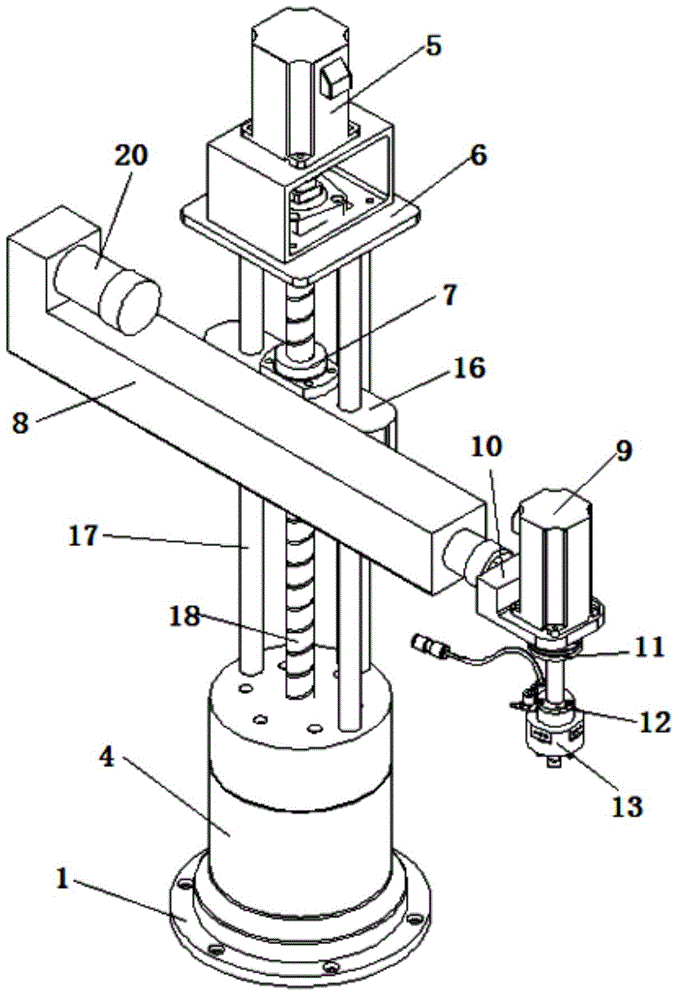

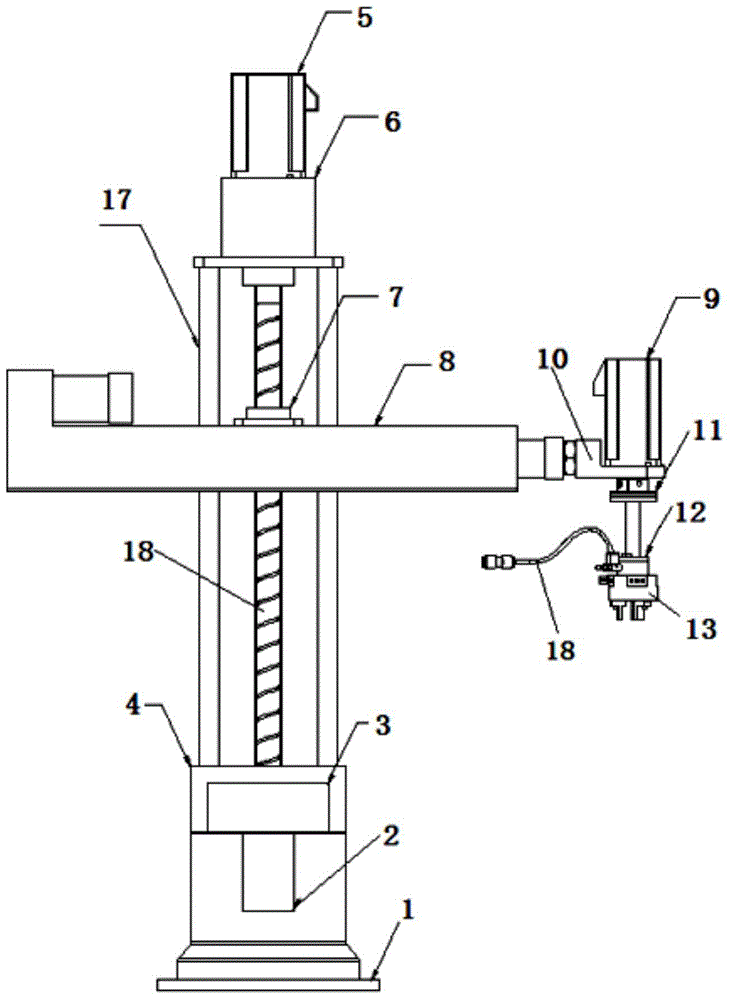

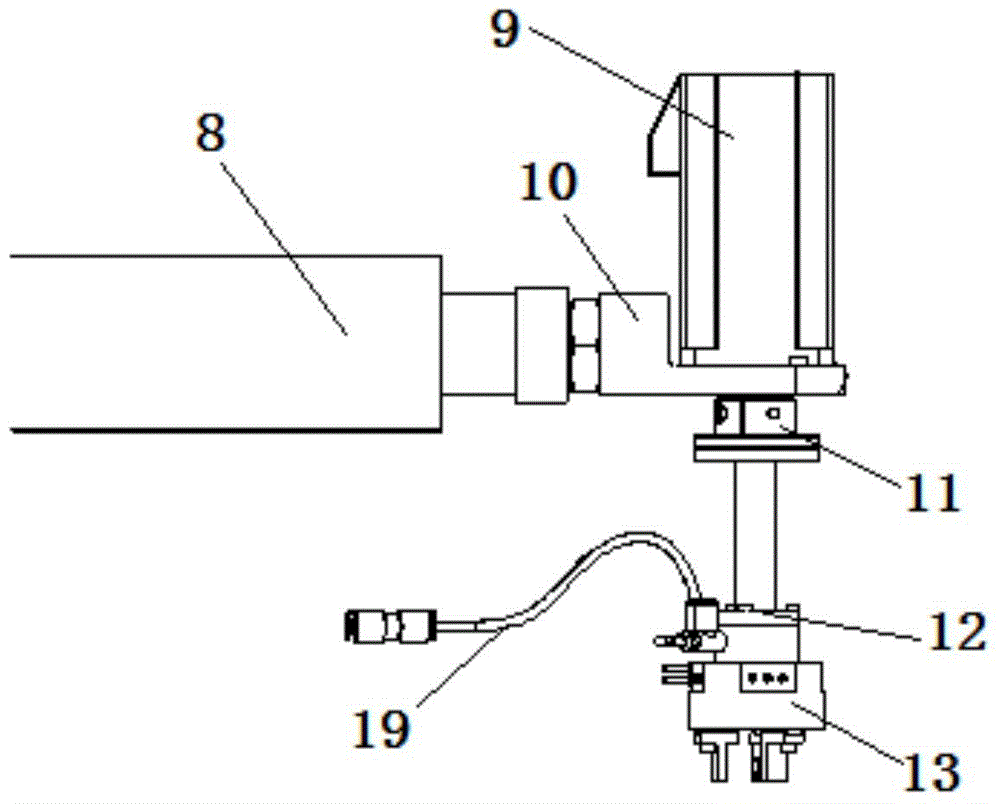

Cylindrical coordinate type robot

InactiveCN104786215AVariable programFlexibleProgramme-controlled manipulatorSmall footprintEngineering

The invention discloses a cylindrical coordinate type robot which comprises a base (1) and a guide mechanism vertically arranged on the base (1). A telescopic arm mechanism capable of horizontally and telescopically moving is connected to the guide mechanism, and the telescopic arm mechanism can do vertical ascending and descending motion along the guide mechanism. The front end of the telescopic arm mechanism is connected with a grabbing mechanism, and a base rotating mechanism driving the whole to rotate is arranged on the base (1). The cylindrical coordinate type robot is simple in structure, low in cost, small in occupied area, large in moving range, high in universality and suitable for medium and small batch automatic production with production varieties changed constantly.

Owner:CHERY AUTOMOBILE CO LTD

Nutrient medium and application for soilless culture

InactiveCN101717310ALow costWide variety of sourcesFertilising methodsAgriculture gas emission reductionSulfurNutrient solution

The invention belongs to the field of nutrient medium for soilless culture and a method for making the nutrient medium. The medium comprises a solid part and a nutrient solution. The making method comprises the steps of: pulverizing cotton seed shells and coal cinders, placing into two fermenting tanks, adding the nutrient solution until the materials absorb saturatedly, coating and fermenting for 8-14m; adding 2-4kg of 70% dexon raw powder into the decomposed cotton seed shells and the coal cinders per ton, uniformly stirring and airing; mixing the decomposed cotton seed shells and the coal cinders according to the volume ratio of 3:1-12:1; mixing 25-35kg of cake fertilizer to the mixed medium per ton, adding urine until the saturate state, re-coating and re-fermenting for 5-7m to enable the pH of the nutrient medium to be 7.0-7.5 when the fermentation is stopped, finally, adding a proper amount of sulfur powder to adjust the pH of the nutrient medium to be 6.0-7.5 so as to adapt the requirements of different plants. The nutrient medium has rich nutrient, favorable permeability, water retention, fertilizer retention, convenient making and wide raw material sources, and is suitable for various flowers and vegetables growing.

Owner:HUAZHONG AGRI UNIV

Rubber foaming shoe bottom, rubber foaming plates and pieces, and fabricating method of molding with cloth being added

InactiveCN1872531AModerate weightLow costFlat articlesMetal working apparatusPolymer scienceFoam rubber

Owner:珠海经济特区珠瑞橡胶化学工业有限公司

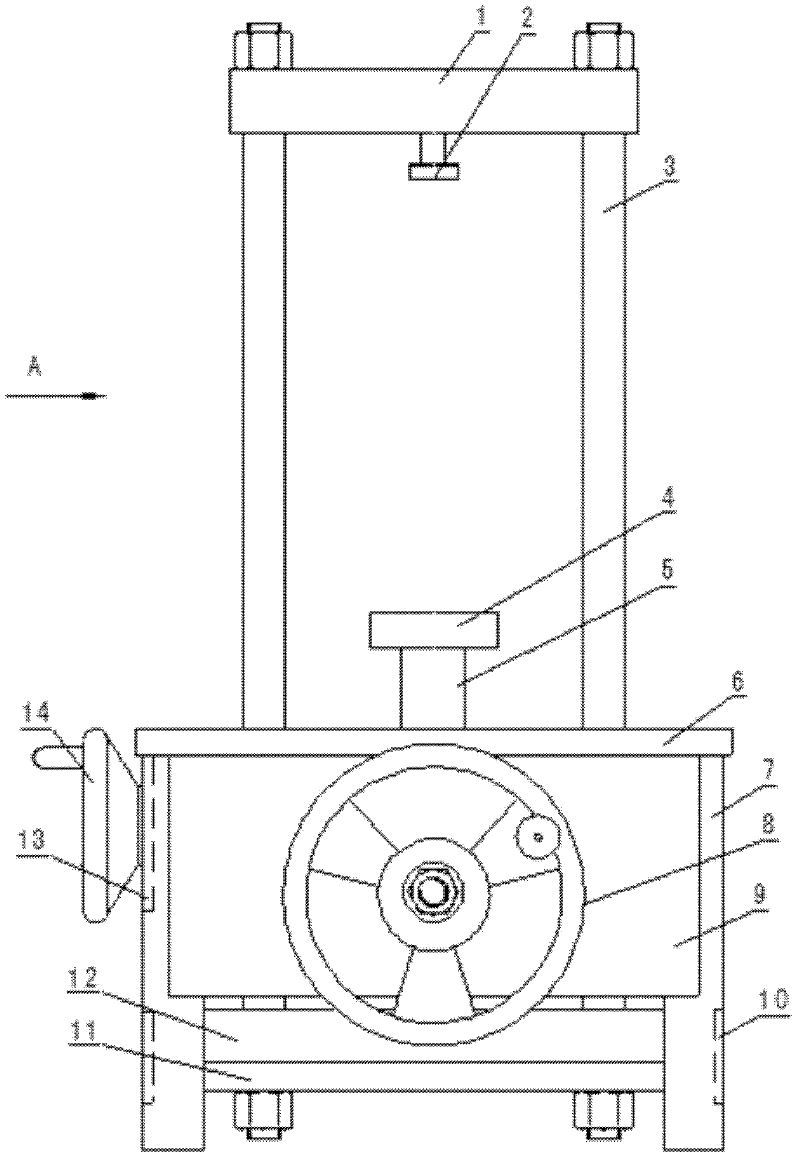

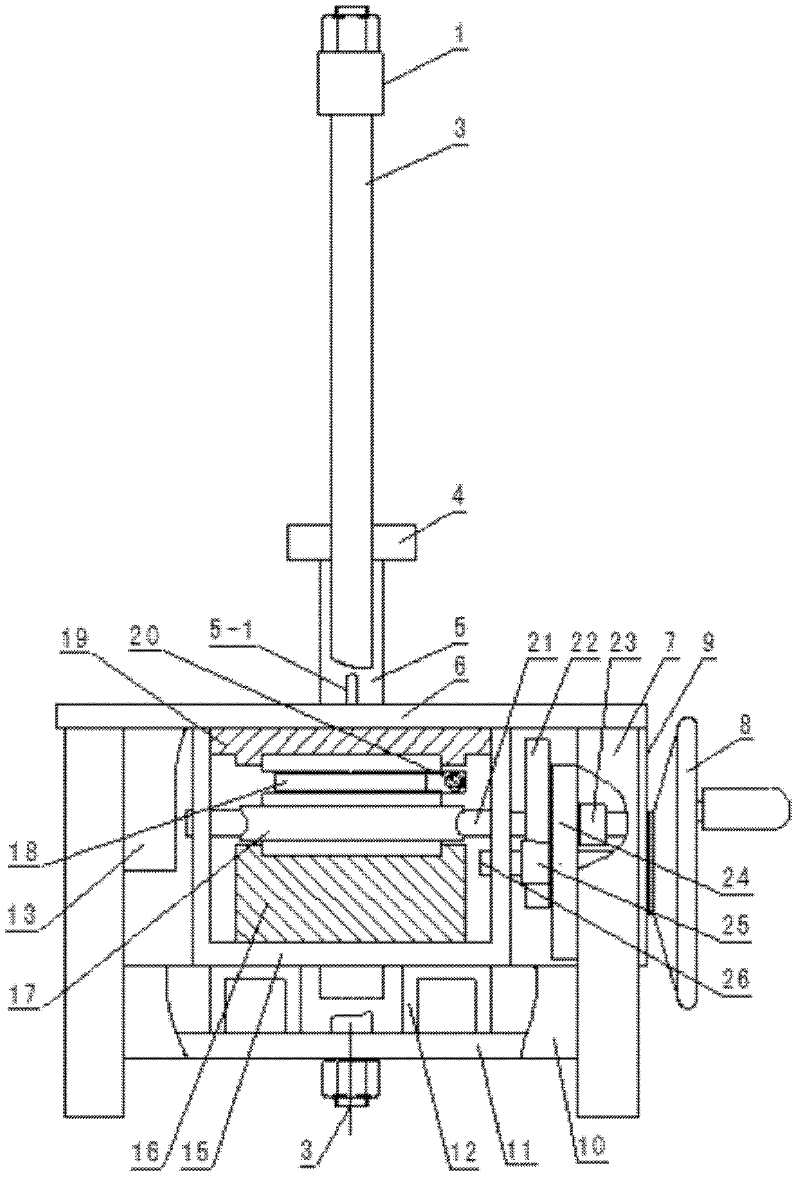

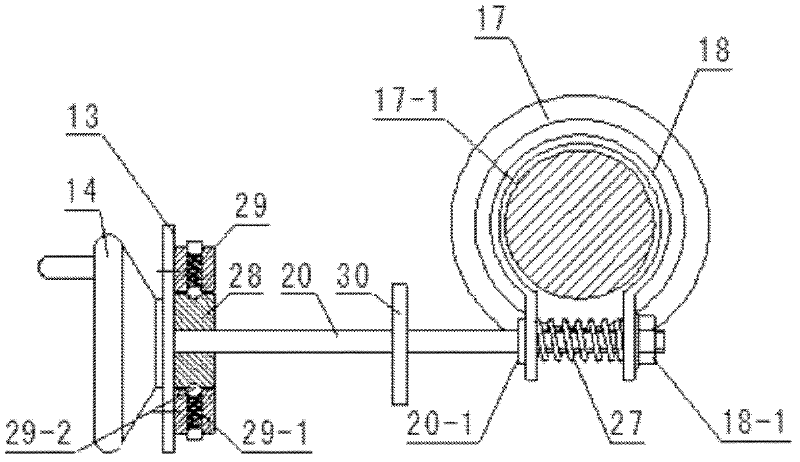

Pressure test calibration mechanical loading device for earthwork testing

ActiveCN102507086AWide applicabilityIncrease in sizeForce/torque/work measurement apparatus calibration/testingGear wheelScrew thread

The invention discloses a pressure test calibration mechanical loading device for earthwork testing. A workbench is arranged at the lower part of a portal frame; a joint in suspended connection witha tested pressure measuring element is in threaded connection to the center of an upper beam of the portal frame; the workbench is internally provided with a worm wheel and worm deceleration mechanism; the worm wheel is provided with a vertical lifting toothed bar, the central screw hole of which is in threaded connection with the joint of the upper beam of the portal frame; the vertical lifting toothed bar is in up-and-down correspondence with the joint; the workbench is provided with a driving main shaft which is parallel with the worm, slides axially and is provided with a hand wheel at the outer end per se; the driving main shaft is provided with an accelerating driving gear and a decelerating driving gear; and the accelerating driving gear and the decelerating driving gear are arranged at the optical shaft section of the worm. According to the pressure test calibration mechanical device, a complete counter-force frame is composed by the portal frame and the workbench; as a vertical force pressurization and deceleration force-increasing driving mechanism is arranged in the workbench, a standard force measurement gauge and a tested pressure measuring element both fixed between the joint of the portal frame and the vertical lifting toothed bar can be stressed at the same time; and the calibration purpose is realized by observing and comparing numerical readings of the standard force measurement gauge and the tested pressure measuring element.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

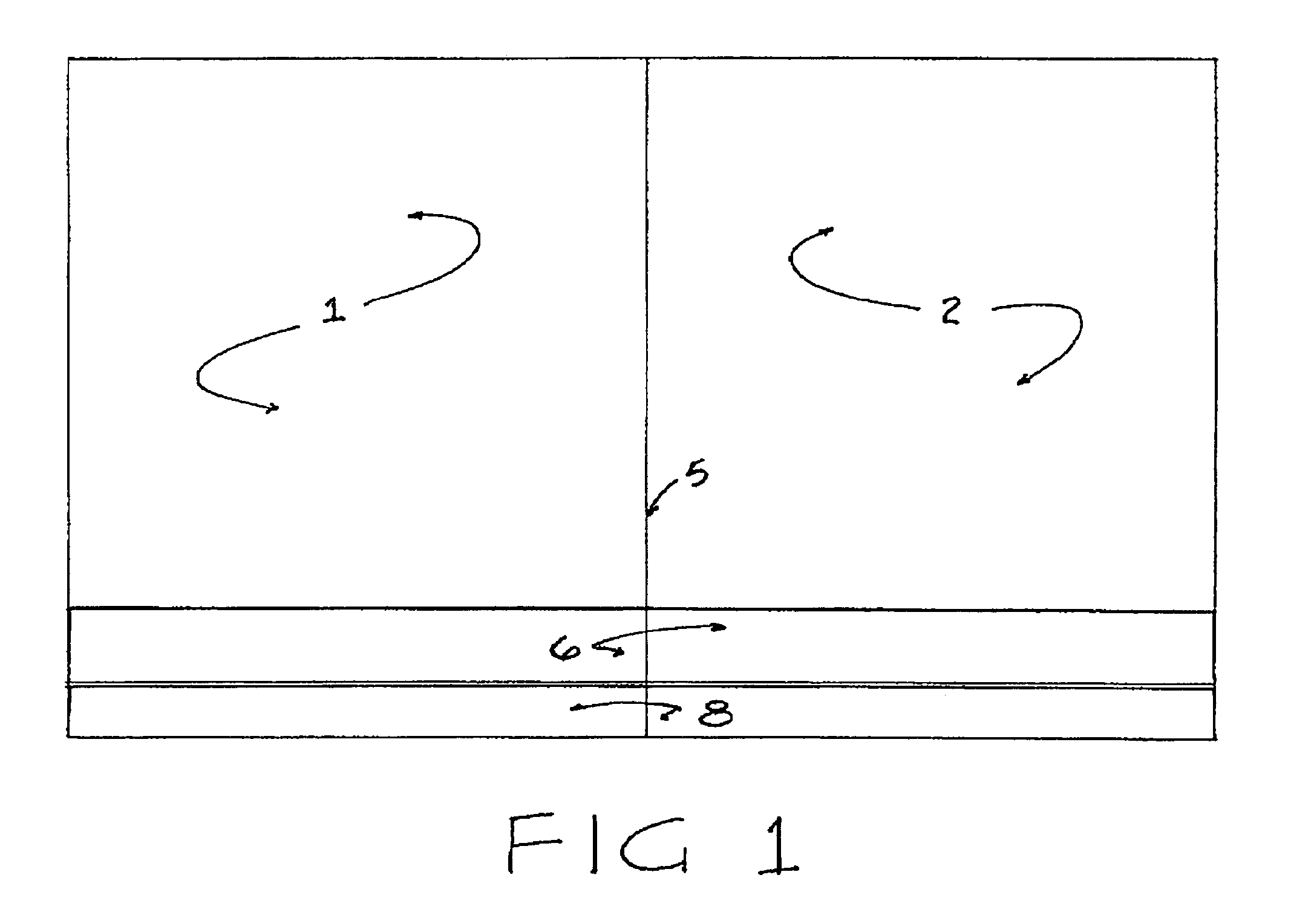

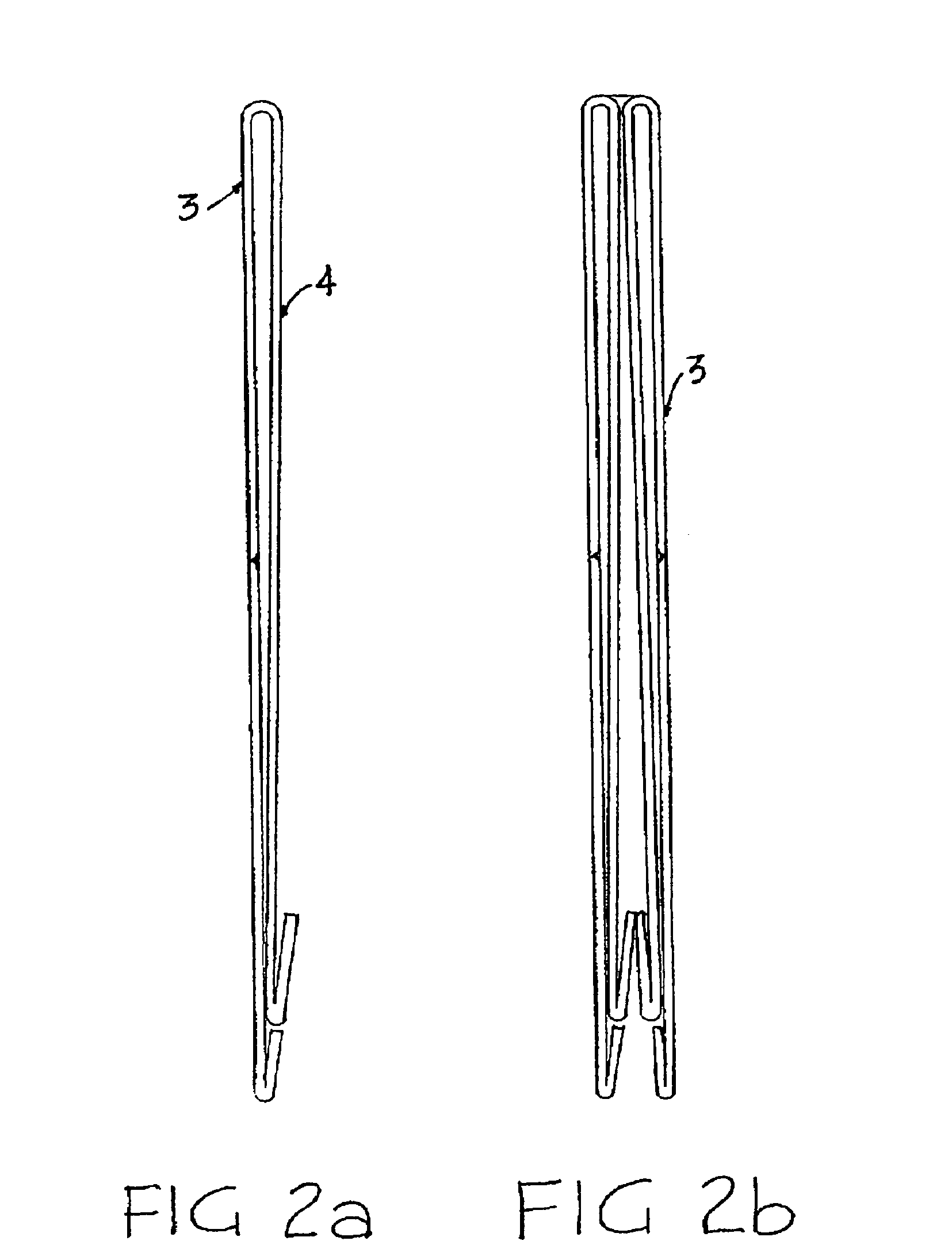

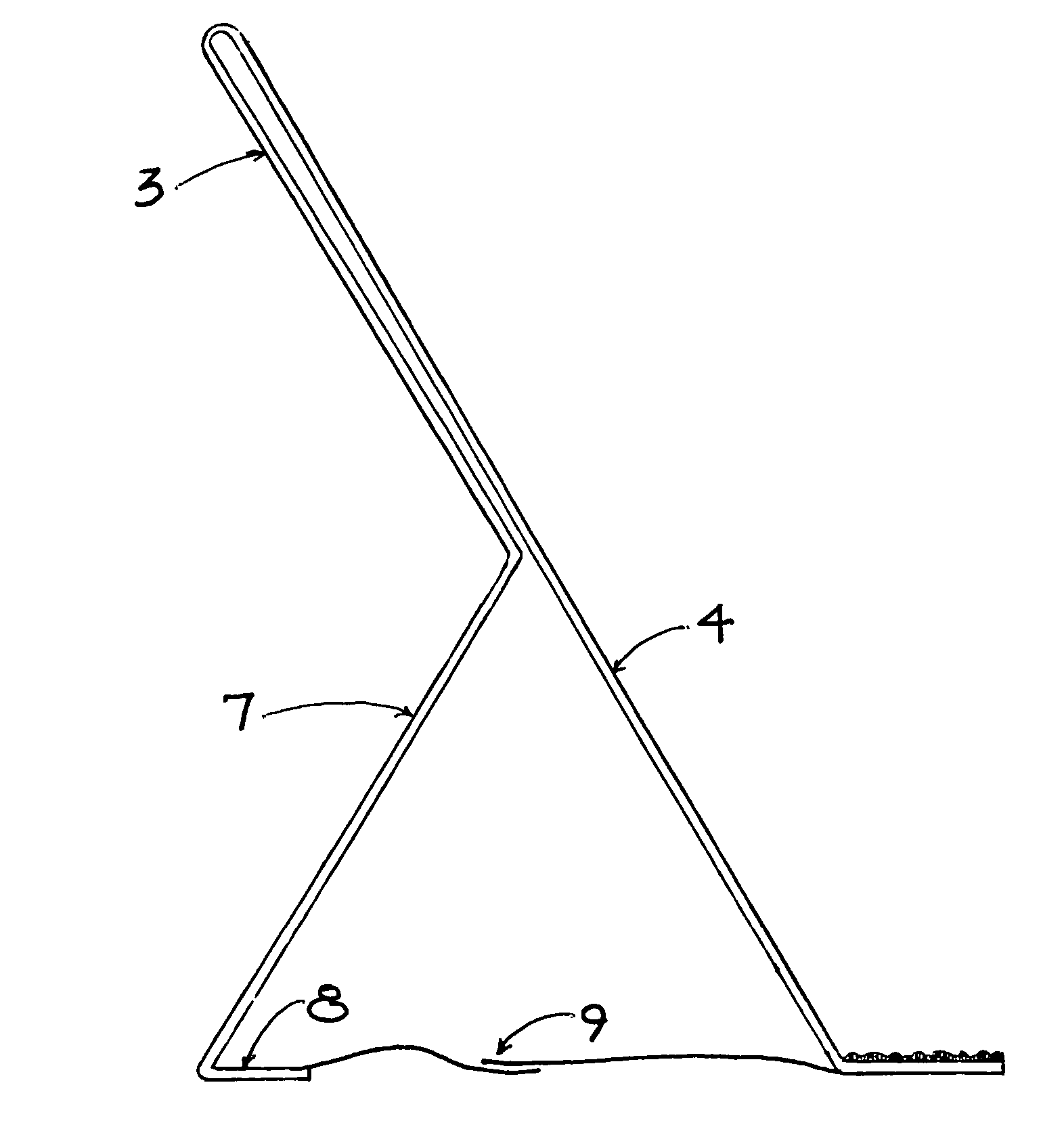

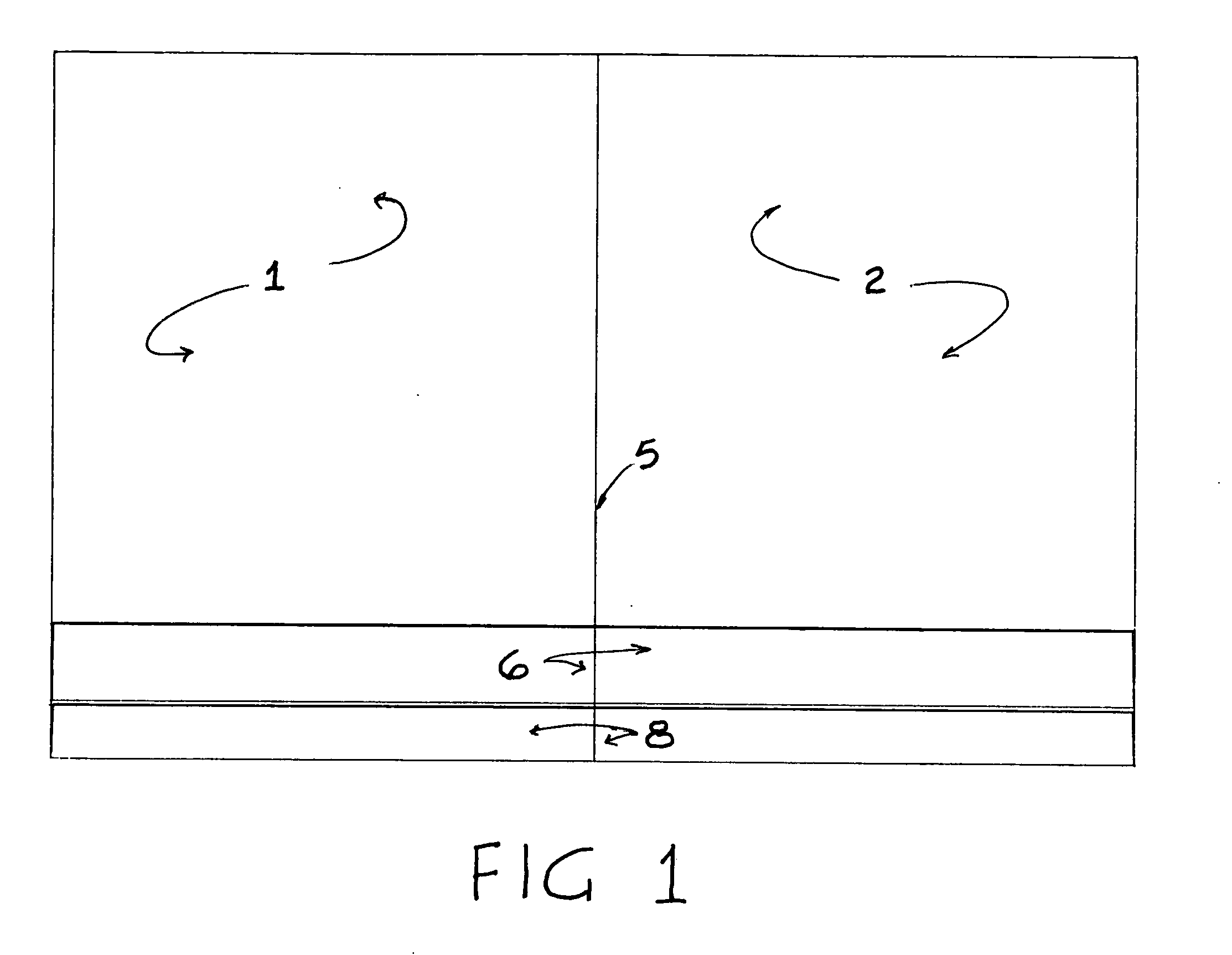

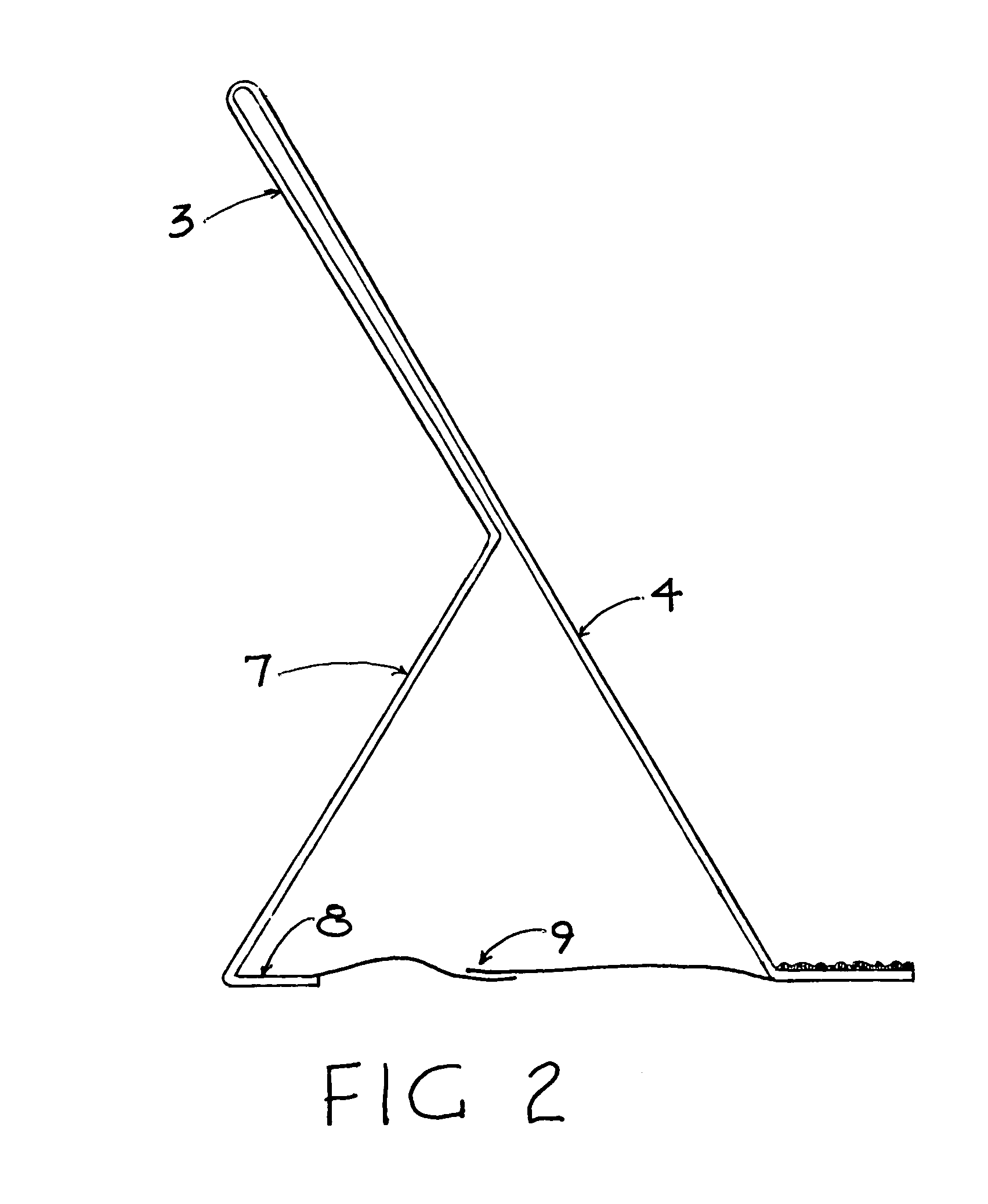

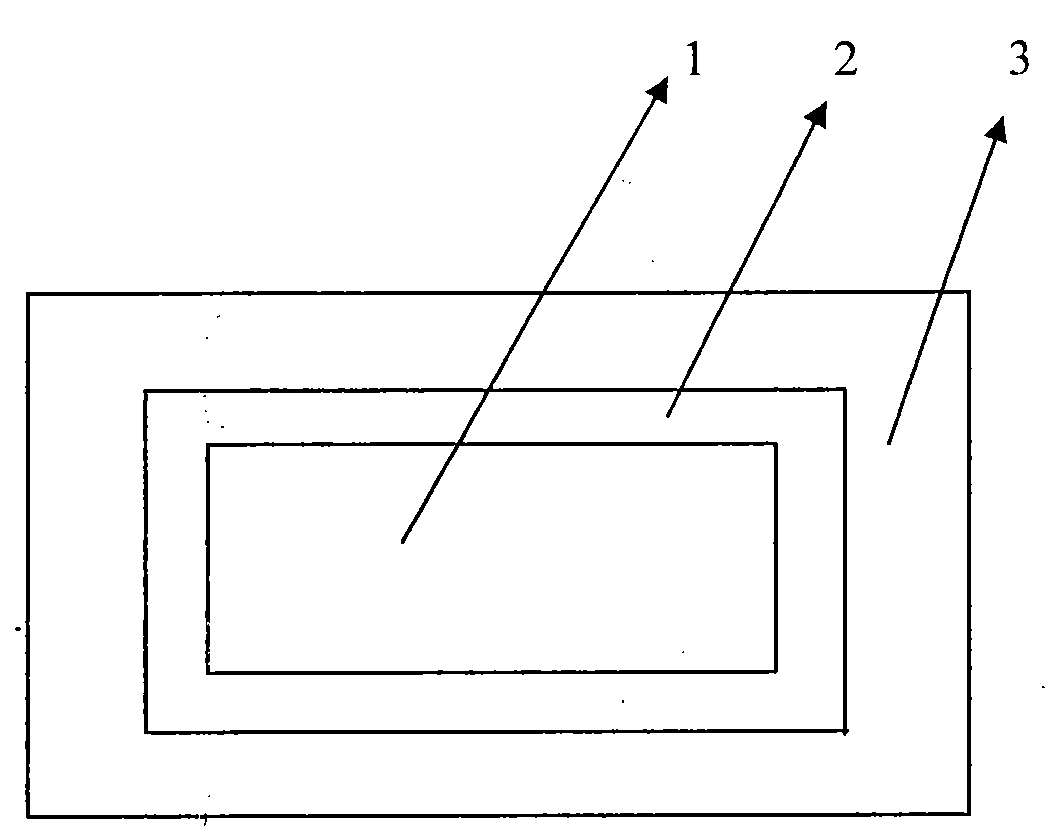

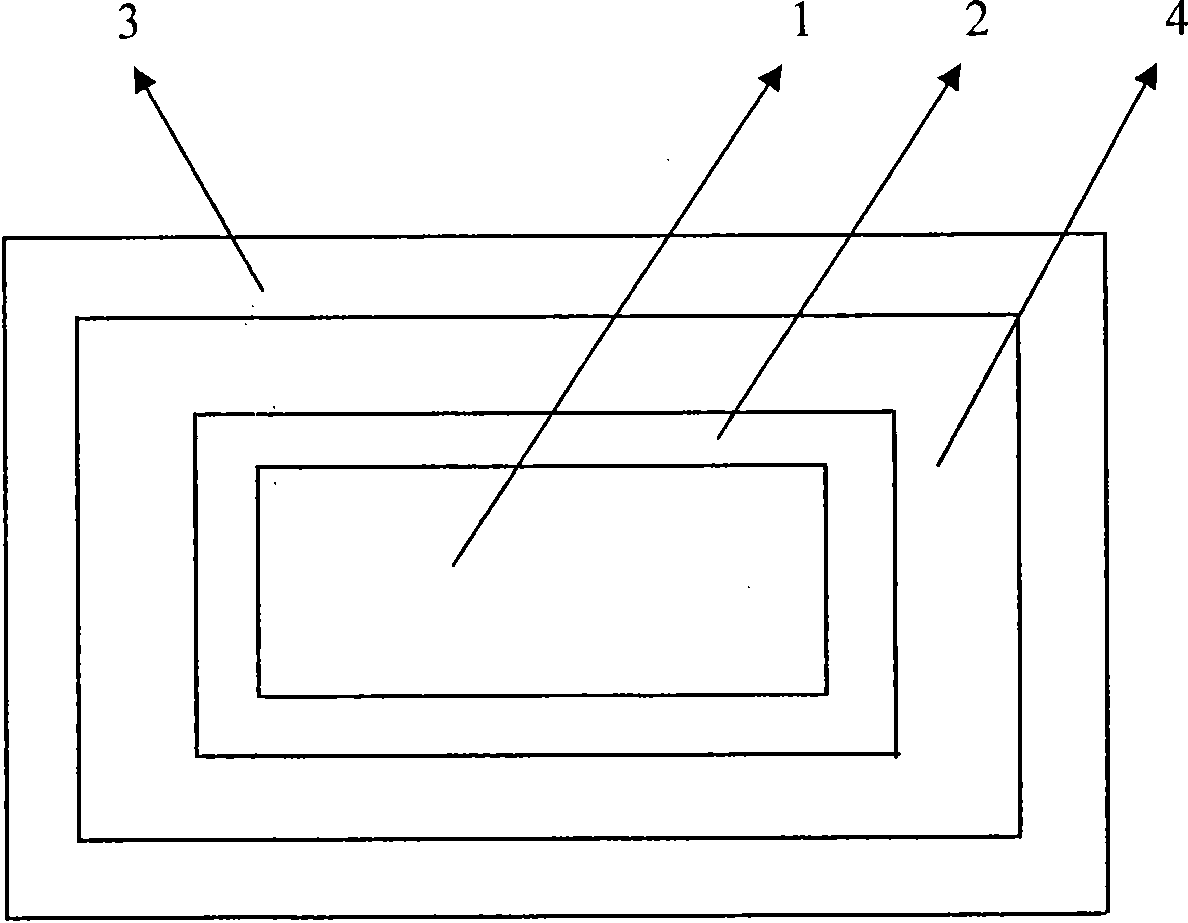

Lightweight combined folder and variable position display/book stand

InactiveUS7537192B2Effective document support toolEasy to transportHanging devicesPicture framesHinge lineEngineering

A multi-purpose portfolio formed from a sheet of rigid card with transverse hinged lines dividing the card into a number of panels that may be completely folded into its closed or carrying position, partially unfolded to access pen, pad, and the likes, and fully erectable for use as a podium, book holder or display stand. The major front panel and major back panel are secured together at their upper edges by a hinge line, and each has a narrow panel hinged along its bottom edge. In its fully erect position, the major front panel is inclined to hold books. Each panel has a hinge line along its bottom edge that secures a narrow panel.

Owner:AL HALEEM ABDEL KHALID +1

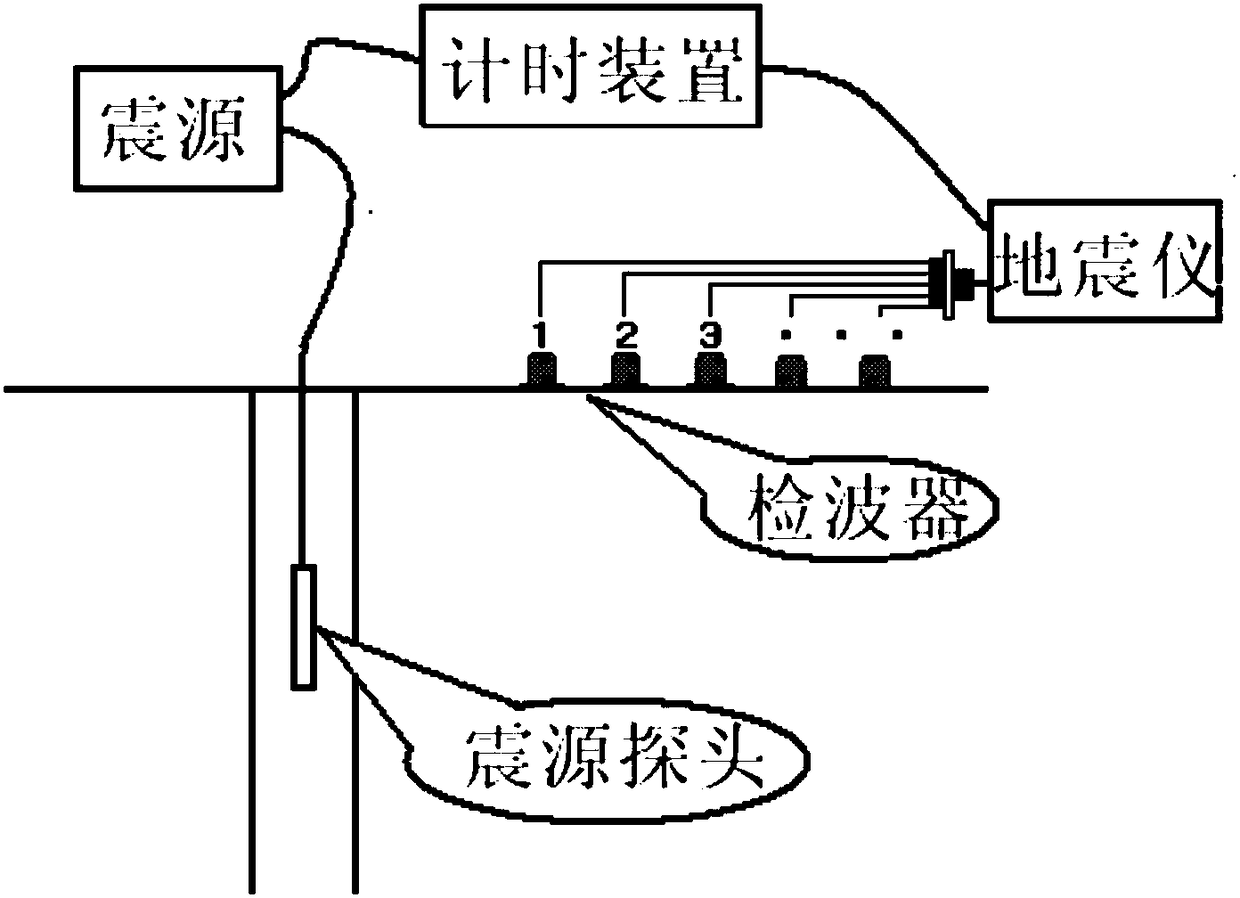

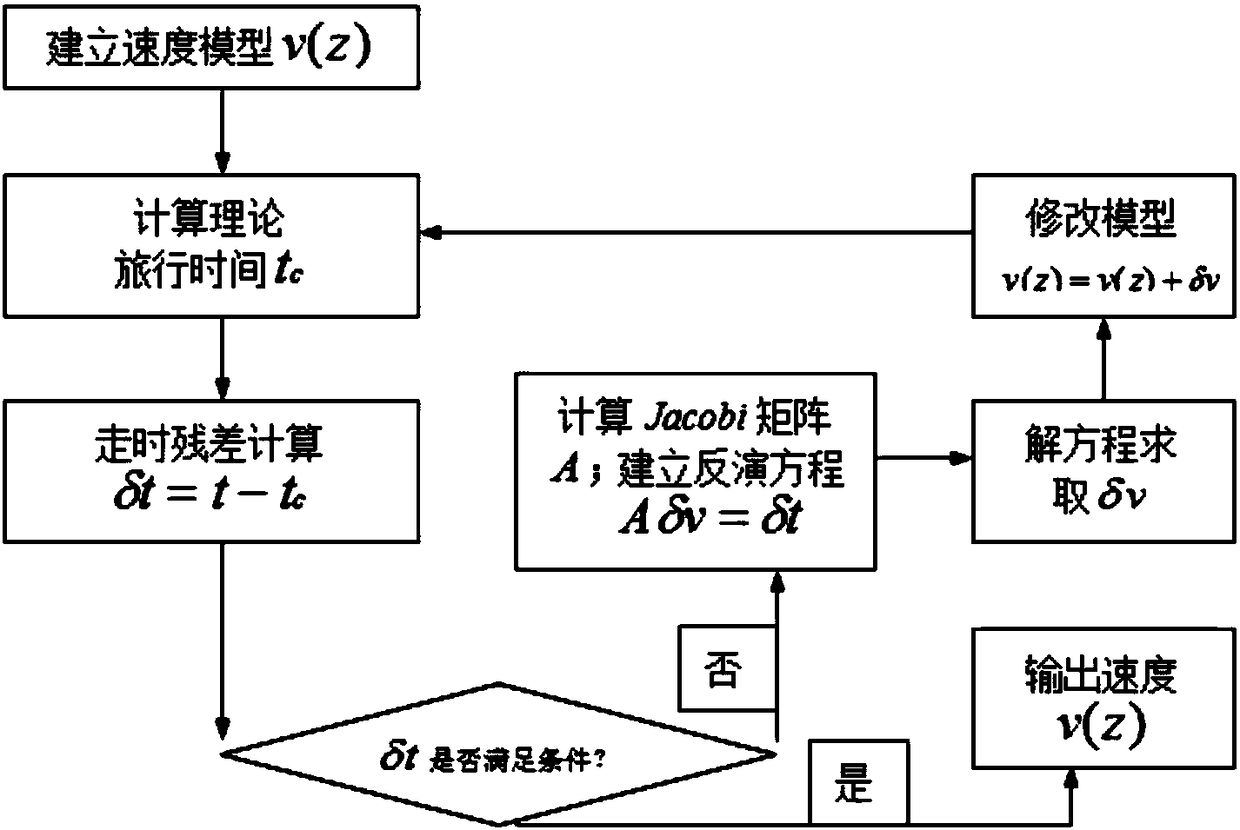

Formation speed test system and test method

ActiveCN108267778AHigh frequencyHigh Acquisition Speed AccuracySeismic energy generationSeismic signal receiversLongitudinal waveHigh energy

The invention relates to a formation speed test system and test method. The system comprises a high-energy electric spark source, a plurality of ground detectors, one to two receiving lines, a seismograph and a triggering timing device. According to the formation speed test system of the invention, high-energy electric spark is excited in a hole, and the plurality of detectors are linearly arranged on the ground to receive seismic waves. The test system has strong excitation energy and high main frequency; the test system receives longitudinal wave first arrivals in a multi-channel manner, which realizes easiness in distinguishing; the test system can pick up first arrivals in a common-excitation point and common-receiving interactive pickup manner, so that longitudinal and transverse wavefirst arrival time can be picked up; a speed obtained through a tomographic inversion method has high precision; the formation speed test system and test method are not only suitable for soil layers,but also suitable for rock formations; and a formation speed acquired by the test system and test method is accurate and reliable and is similar to a result obtained by an in-situ wave speed test.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

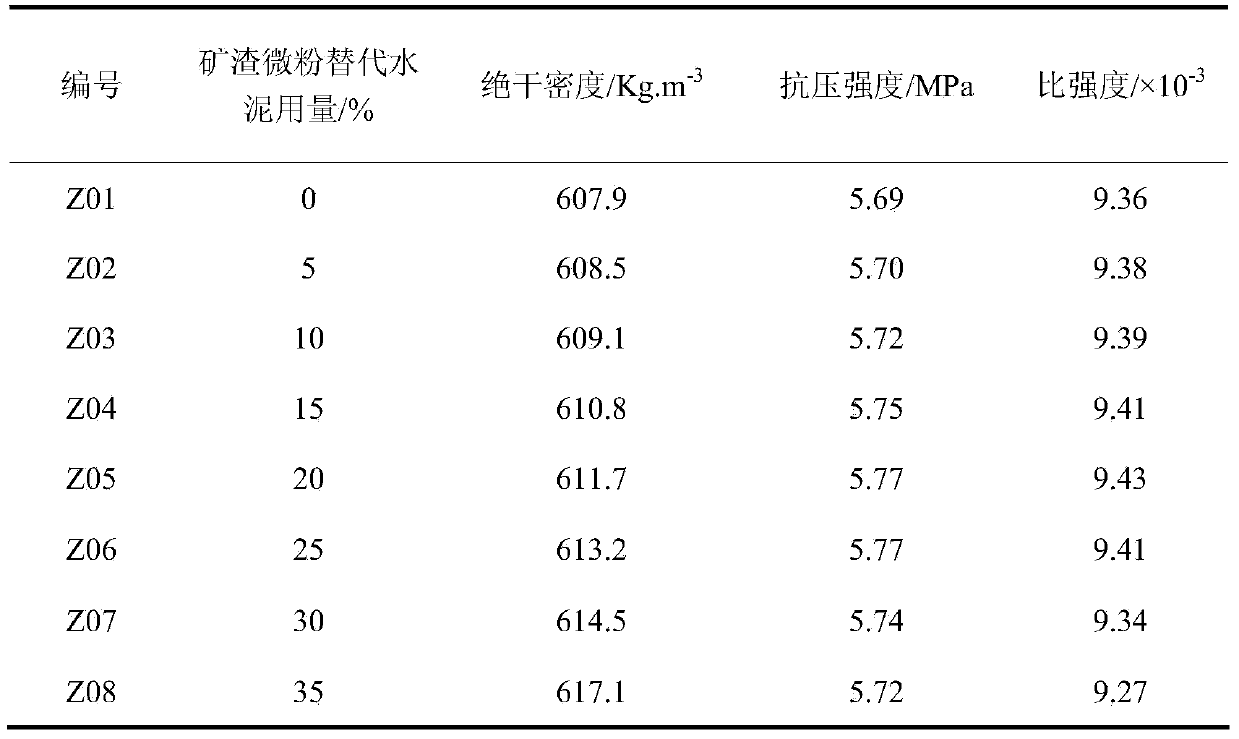

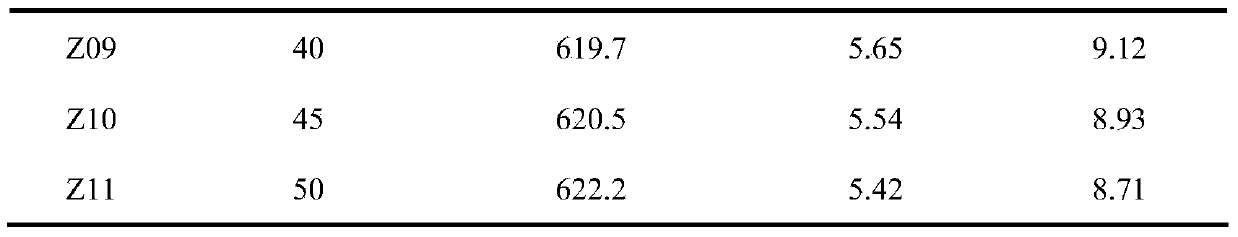

Light and high strength aerated concrete prepared with glass powder and preparation method thereof

ActiveCN103723988AFor high load-bearing requirementsThe high demands on load-bearing capacity meet theCement productionCeramicwareEconomic benefitsUltimate tensile strength

The invention discloses a light and high strength aerated concrete prepared with glass powder and a preparation method thereof. The inventor further improves kaolin tailings aerated concrete, and uses the glass powder to substitute partial tailings so as to remarkably enhance product strength. In addition, regulation of the use amount of aluminum powder and external addition of an early-strength agent CaCl2 effectively improve product density without losing overmuch strength; the bodying and gas forming expansion are coordinated by regulating time for agitation, and finally, the light and high strength aerated concrete with good heat-insulated performance, proper weight and higher strength is prepared. The light and high strength aerated concrete and the preparation method thereof fully utilize resources, lower production cost, have good economic benefits, improve the strength and keep lower intensity on the basis of ensuring the heat-insulated performance of the aerated concrete building blocks, can meet the high requirement of the present buildings on the bearing performance of the aerated concrete, and meanwhile satisfy the demand of environmental-friendly buildings.

Owner:GUANGXI UNIV

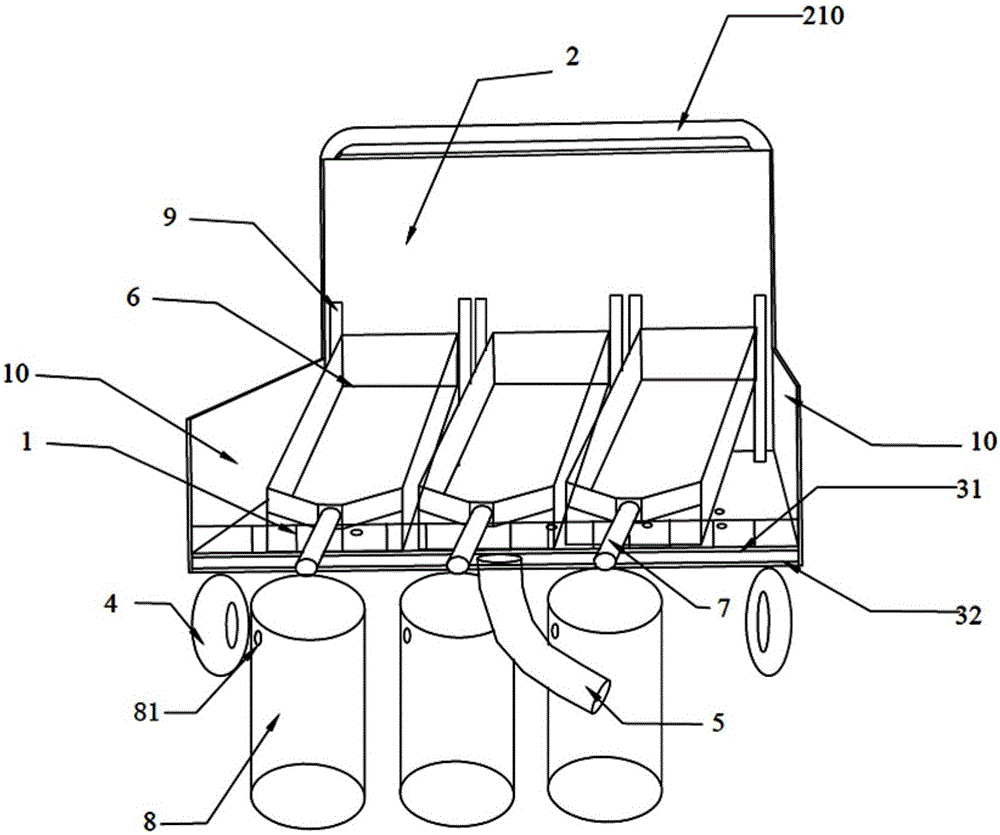

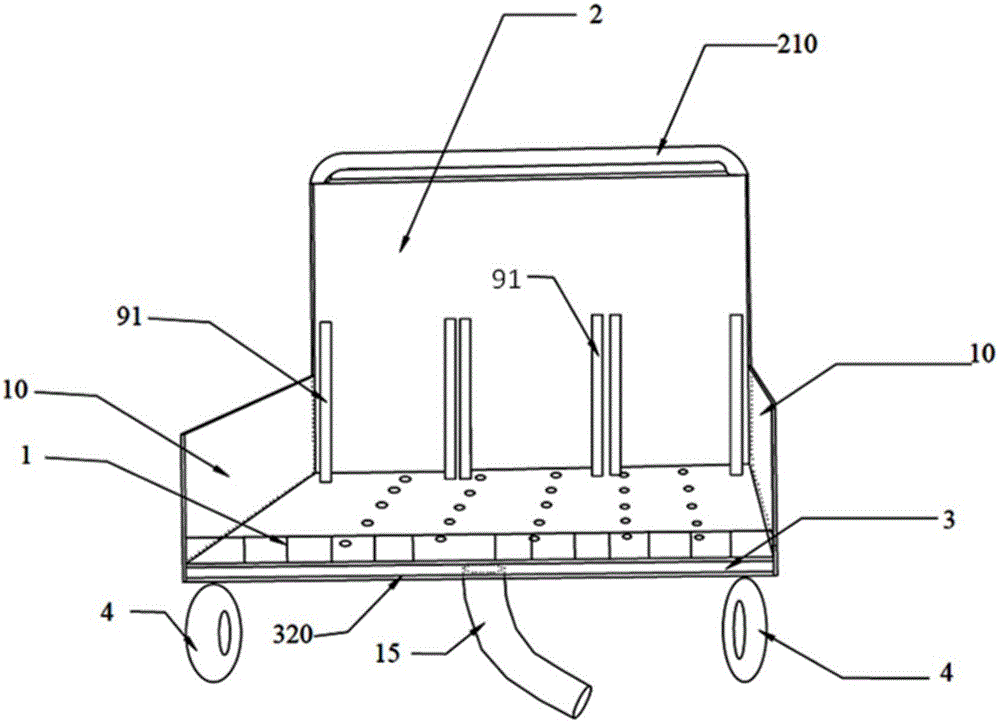

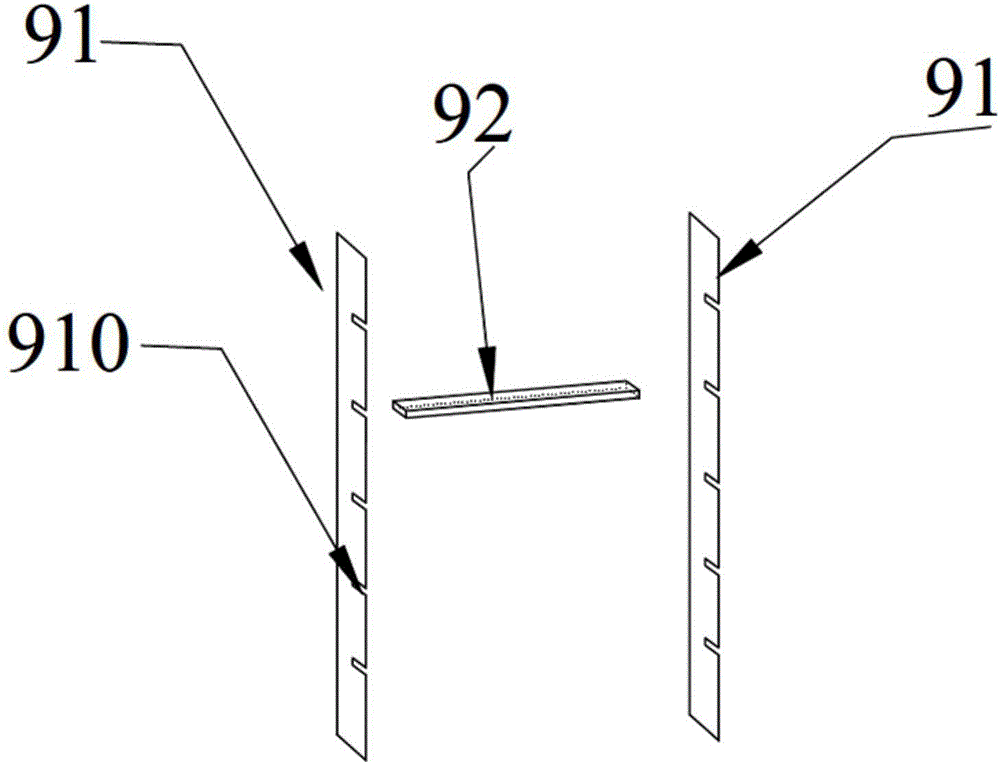

Movable rainfall simulating and flow collecting device

The invention relates to a movable rainfall simulating and flow collecting device which comprises a bearing trolley, multiple slope position supports, multiple runoff plots, flow collecting barrels and flow guide pipes. Universal wheels are arranged at the bottom of the bearing trolley. The bearing trolley comprises a front wall, two side plates, a rear plate and a bottom compartment used for collecting rainwater. The bottom compartment is of a two-layer structure and comprises an upper plate and a lower plate. The upper plate of the bottom compartment is a porous plate. A rainwater outlet is formed in the lower plate of the bottom compartment and connected with a rainwater recovery pipe. The slope position supports are located on the upper plate of the bottom compartment. The rear ends of the runoff plots are located on the slope position supports. The front ends of the runoff plots abut against the front wall. Flow guide holes are formed in the front ends of the runoff plots and connected with one ends of the flow guide pipes. The other ends of the flow guide pipes extend out from the upper side of the front wall, and the flow collecting barrels are arranged below the other ends, extending out of the upper side of the front wall, of the flow guide pipes. The movable rainfall simulating and flow collecting device has the advantages of being light in weight, convenient to carry, resistant to corrosion and not prone to rusting, and moving fast.

Owner:INST OF WATER RESOURCES FOR PASTERAL AREA MINIST OF WATER RESOURCES P R C +1

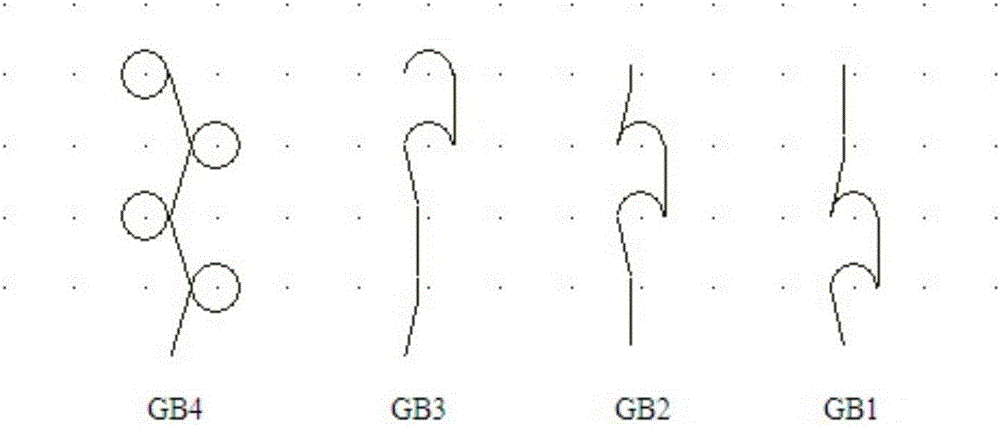

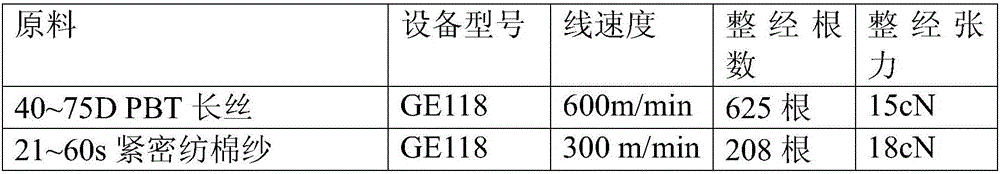

Process for manufacturing cotton-polyester interwoven warp knitted fabric

InactiveCN106436000AModerate weightGood dimensional stabilityWarp knittingTextile shapingPolyesterEngineering

The invention relates to a process for manufacturing a cotton-polyester interwoven warp knitted fabric. The process is characterized by comprising the following steps: (1), selecting materials, namely, selecting cotton yarns and PBT long yarns; (2) performing warping, namely, performing warping on the cotton yarns and the PBT long yarns on a warping machine; (3) weaving, namely, weaving by using a tricot warp knitting machine, wherein the yarn threading mode of a guide bar is that 1 cotton yarn is threaded and one internal is preserved in one GB guide bar, one cotton yarn is threaded and one interval is preserved in 2 GB guide bars, and 4 GB guide bars are fully threaded with the PBT long yarns; or 1 cotton is threaded and 2 intervals are preserved in one GB guide bar, 1 cotton yarn is threaded and 1 internal is preserved in 2 GB guide bars, 2 cotton yarns are threaded and 1 interval is preserved in 3 GB guide bars, and 4 GB guide bars are fully threaded with the PBT long yarns; and (4) performing aftertreatment, namely, performing singeing, scouring and bleaching, dyeing and shaping on a woven blank fabric, and cooling, thereby obtaining the cotton-polyester interwoven warp knitted fabric. The process is simple in process and low in cost, comfort and elasticity are provided for the fabric due to a warp knitted coil structure, and the elasticity resilience is improved.

Owner:JIANGNAN UNIV

Lightweight combined folder and variable position display/book stand

InactiveUS20060249646A1Effective document support toolEasy to transportHanging devicesPicture framesHinge lineEngineering

A multi-purpose portfolio formed from a sheet of rigid card with transverse hinged lines dividing the card into a number of panels that may be completely folded into its closed or carrying position, partially unfolded to access pen, pad, and the likes, and fully erectable for use as a podium, book holder or display stand. The major front panel and major back panel are secured together at their upper edges by a hinge line, and each has a narrow panel hinged along its bottom edge. In its fully erect position, the major front panel is inclined to hold books. Each panel has a hinge line along its bottom edge that secures a narrow panel.

Owner:AL HALEEM ABDEL KHALID +1

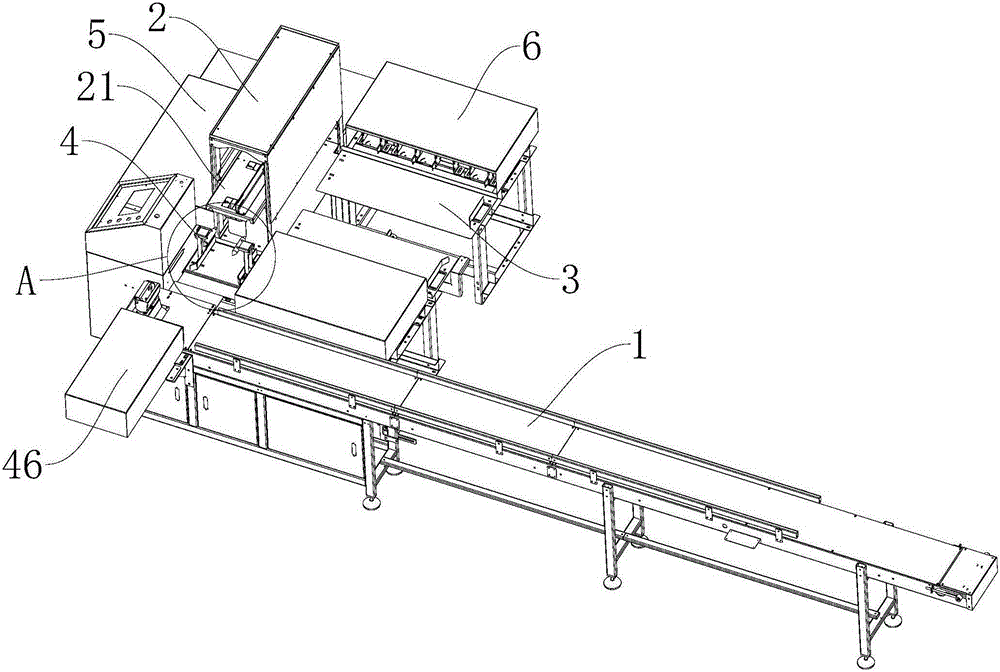

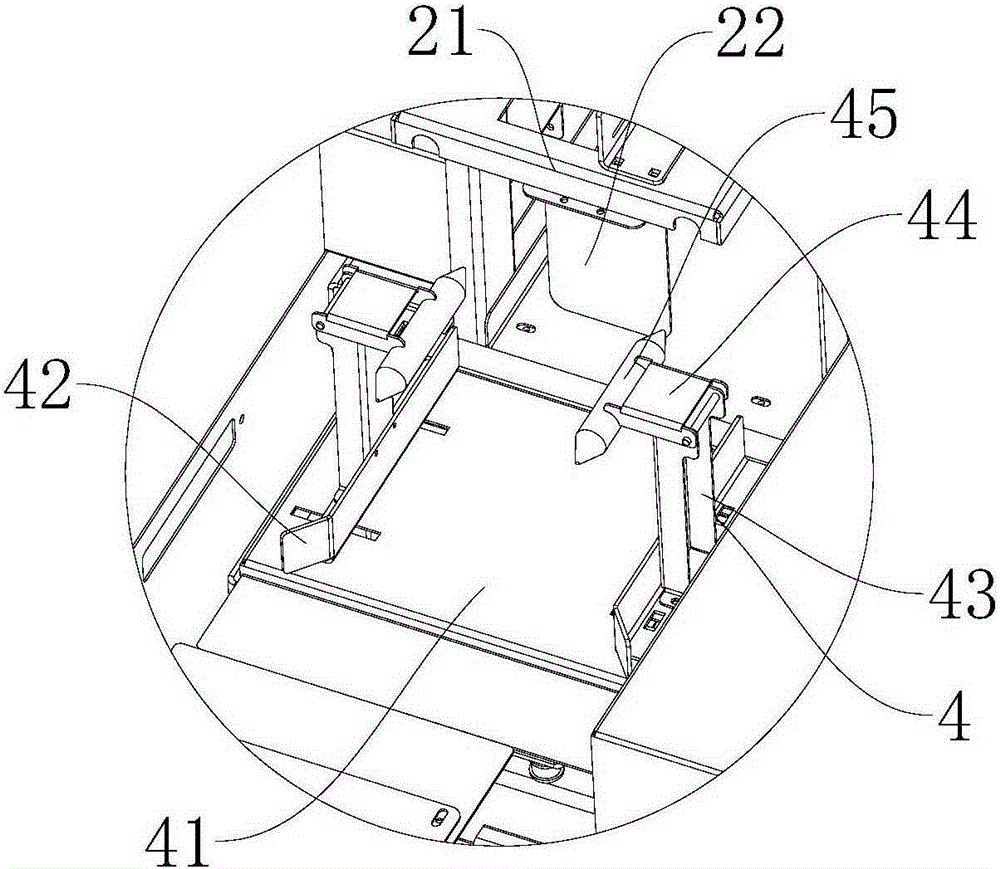

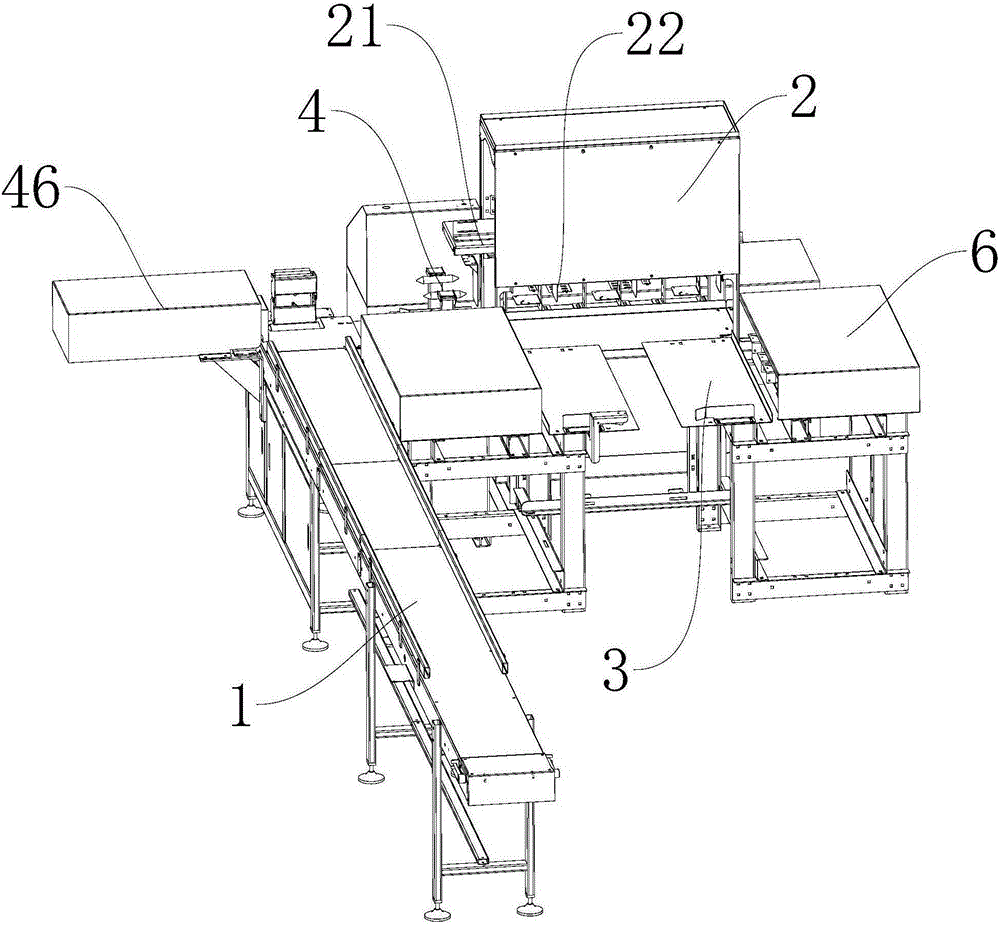

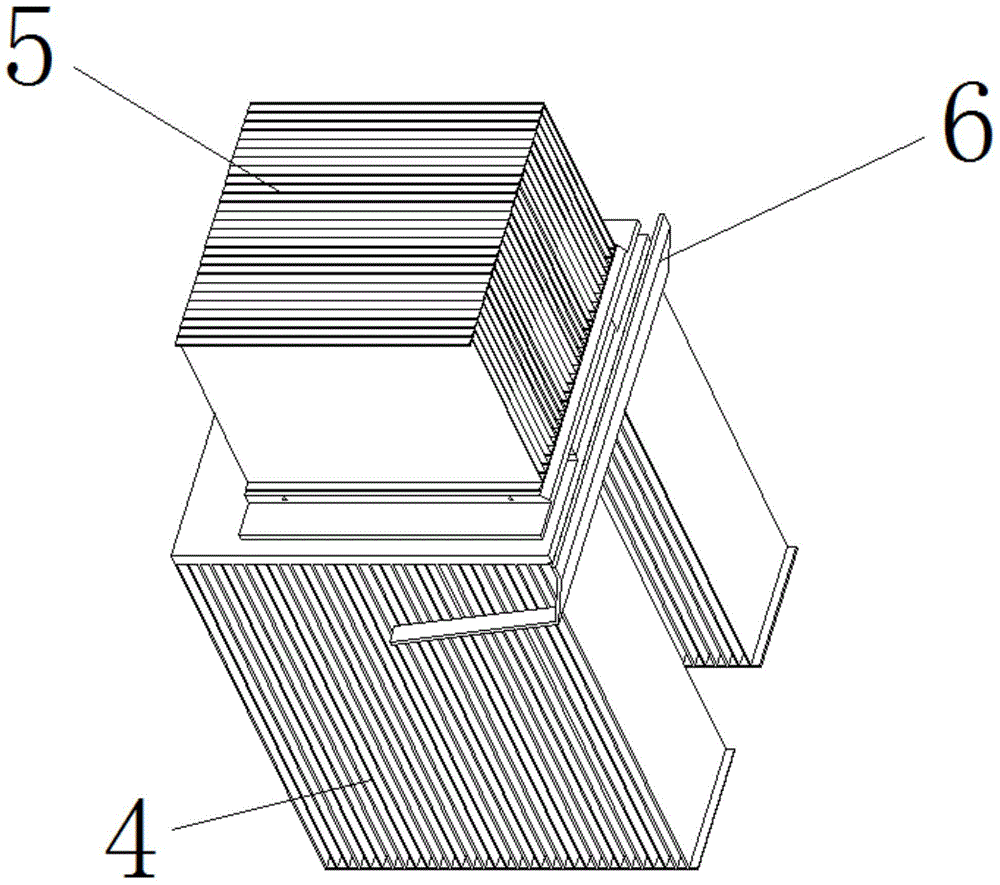

Full-automatic intelligent constant weight machine for cone yarn pre-treatment

InactiveCN105173686ATroubleshoot logging issuesModerate weightSolid materialConveyor partsYarnFull life cycle

The invention discloses a full-automatic intelligent constant weight machine for cone yarn pre-treatment. The full-automatic intelligent constant weight machine comprises a cone yarn input conveying belt and an allocation device. A cone yarn compressing station-entry weighing system is arranged between the cone yarn input conveying belt and the allocation device. A left cone yarn temporary storage region, a qualified cone yarn output region and a right cone yarn temporary storage region are formed between two cone yarn receiving plates. The problem that in traditional manual sorting, too heavy or too light cone yarn is difficult to treat properly is solved, production efficiency can be greatly improved, huge economic value can be created after accumulation, and labor cost is reduced; and a guarantee is provided for automatic intelligent production of cone yarn in a full life cycle, and the basis of practical application value is achieved in the constant weight step at the earlier stage of the whole packaging link of the cone yarn..

Owner:江苏晨阳机械有限公司

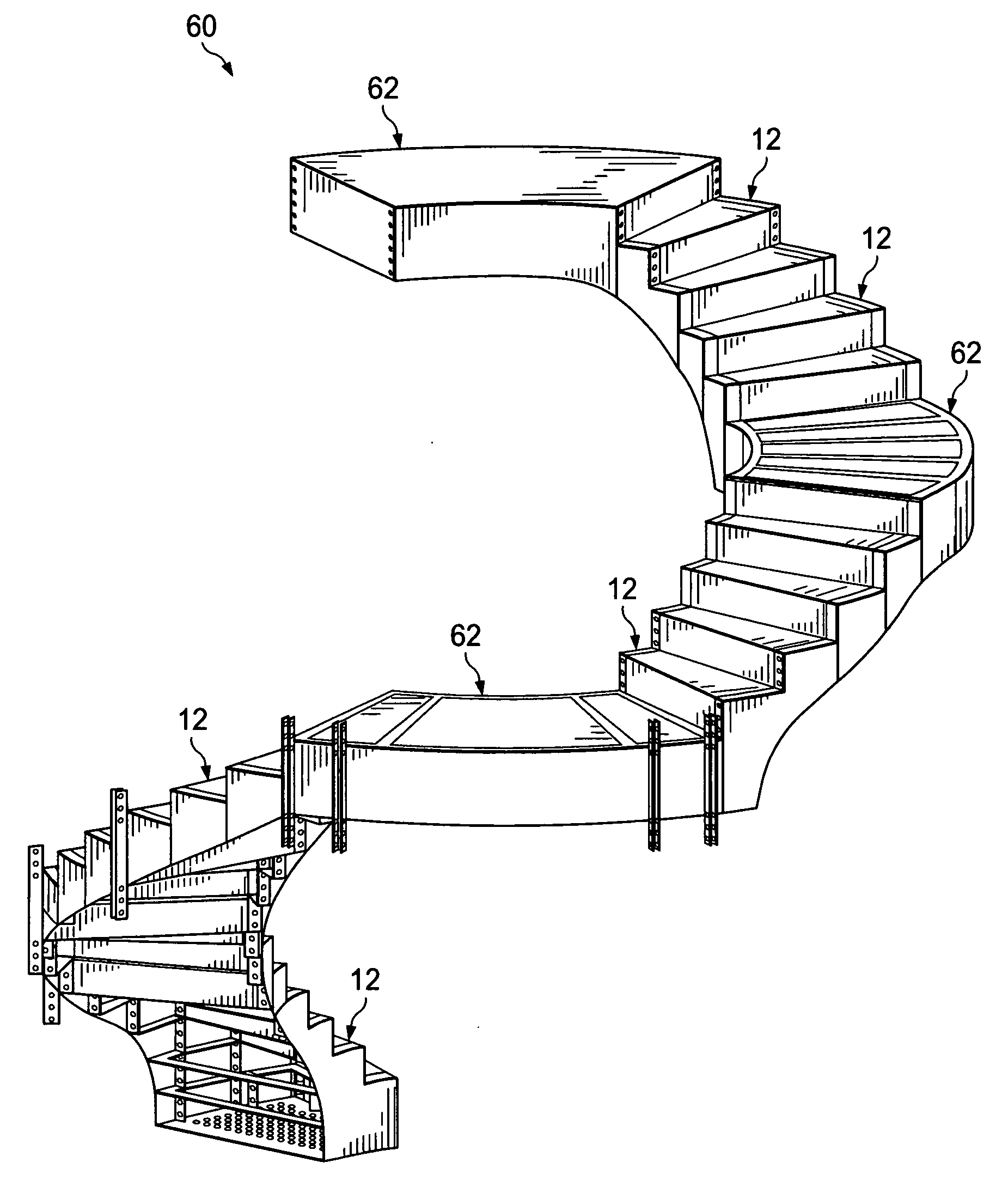

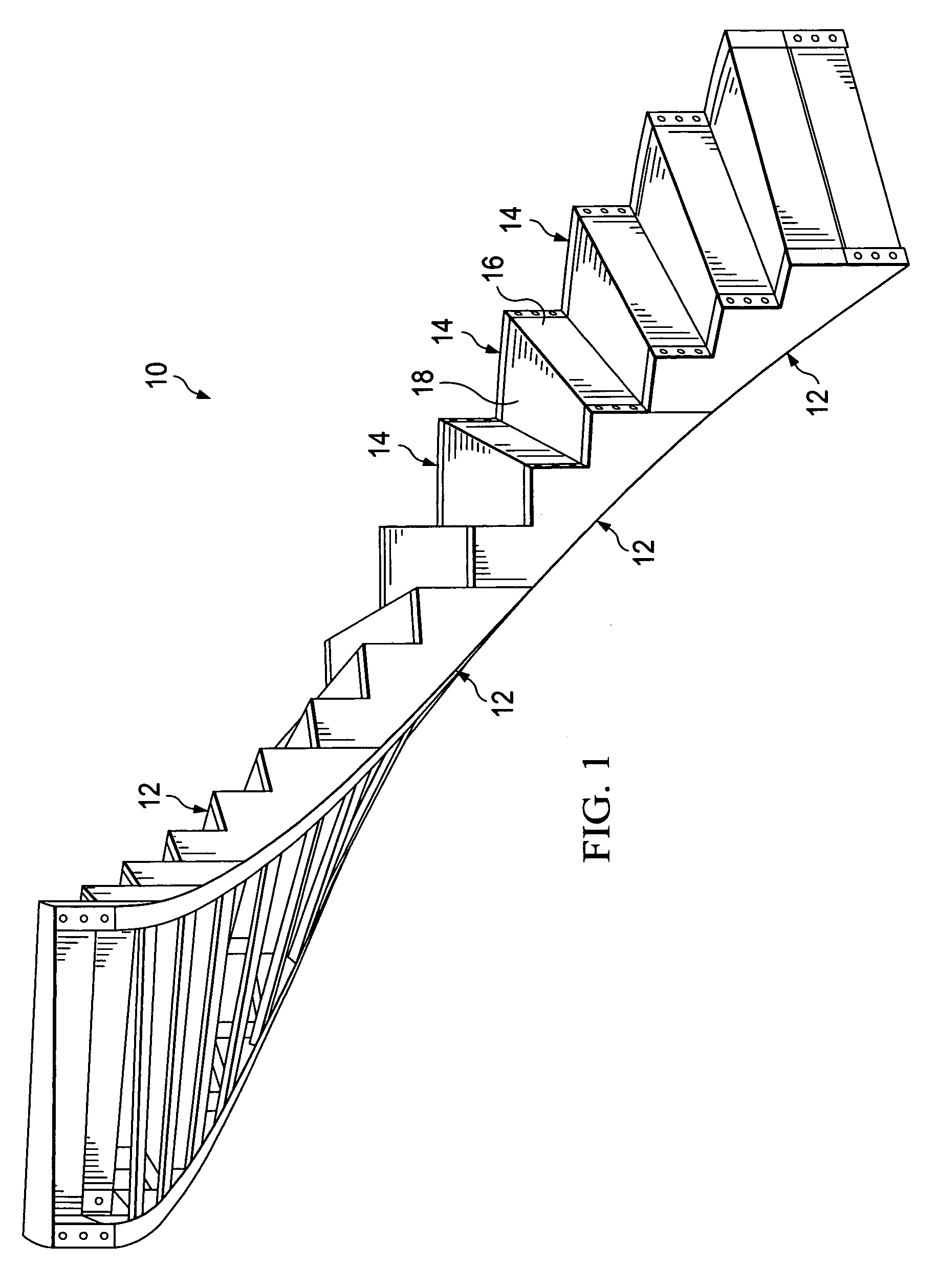

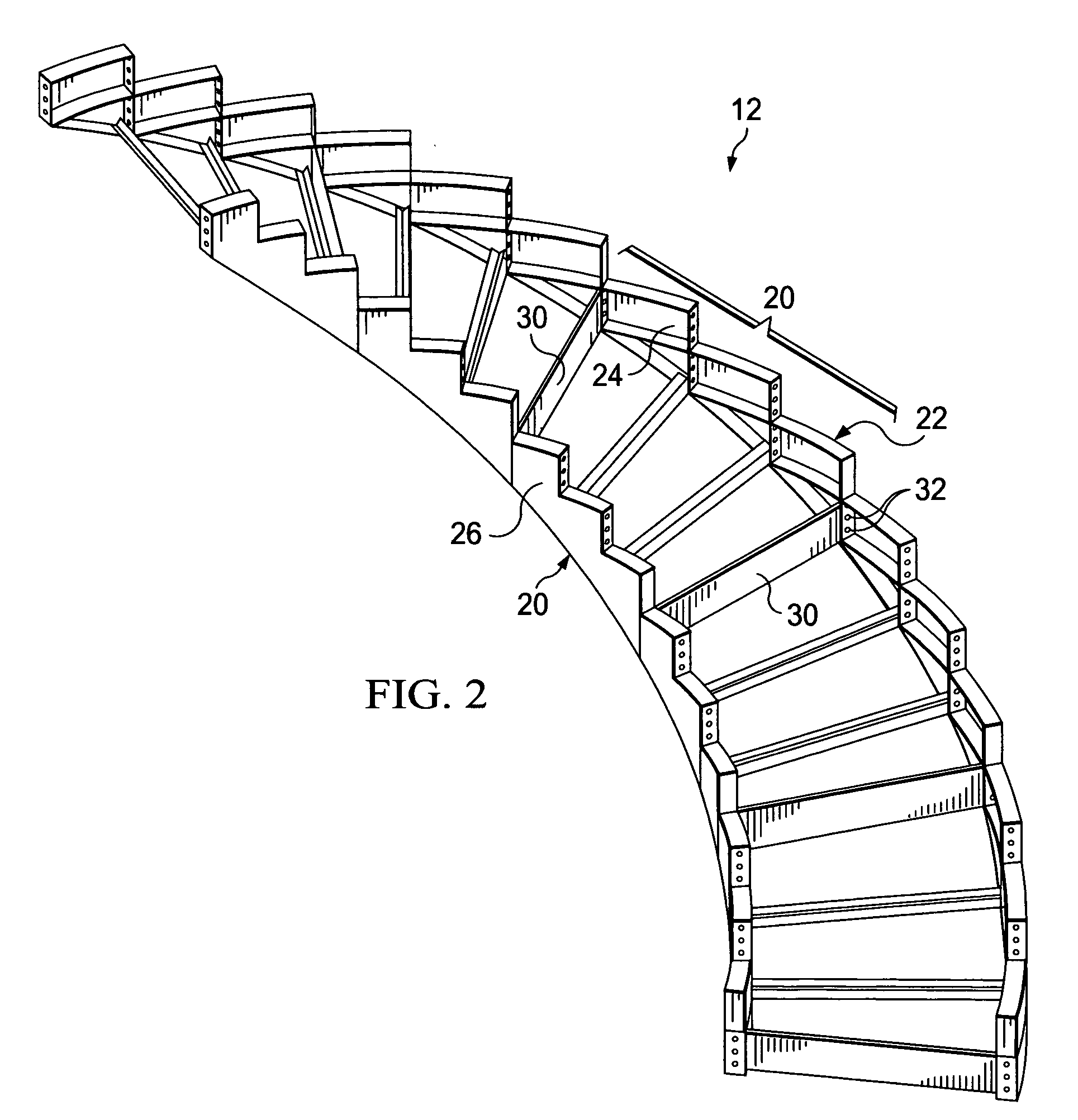

Modular staircase system

InactiveUS20100132277A1Reduced strengthMaterial is heavyStairway-like structuresEngineeringUltimate tensile strength

A modular staircase system configured to form a curved staircase, support extremely heavy finishing materials, having higher design tolerances, and can be achieved at a relatively moderate cost. A plurality of stair modules are configured to secure to one another to form a complete staircase system, each which has an elaborate stringer of significant strength and moderate weight configurable to create floating staircases at an affordable cost.

Owner:BUSH RICHARD

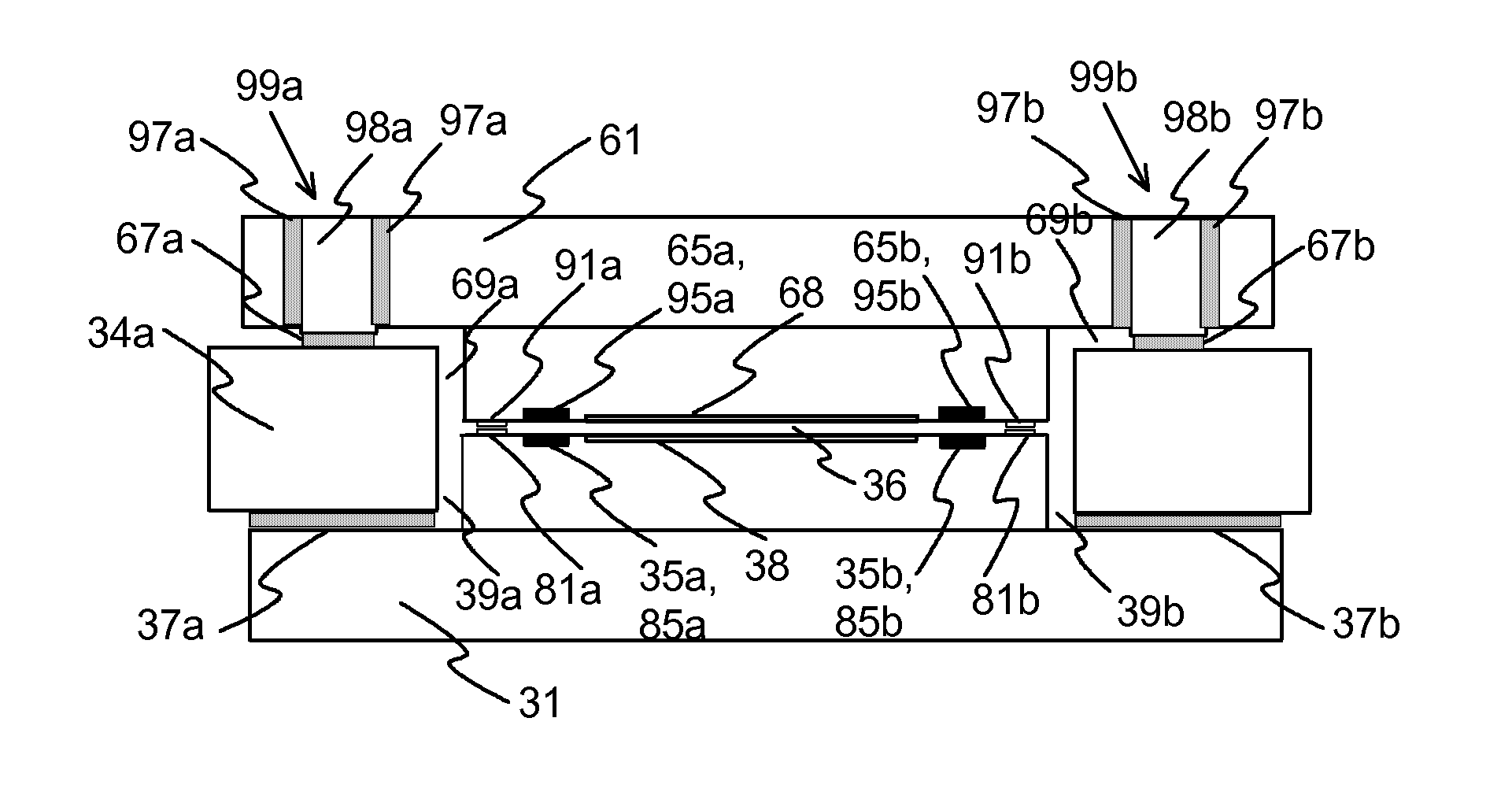

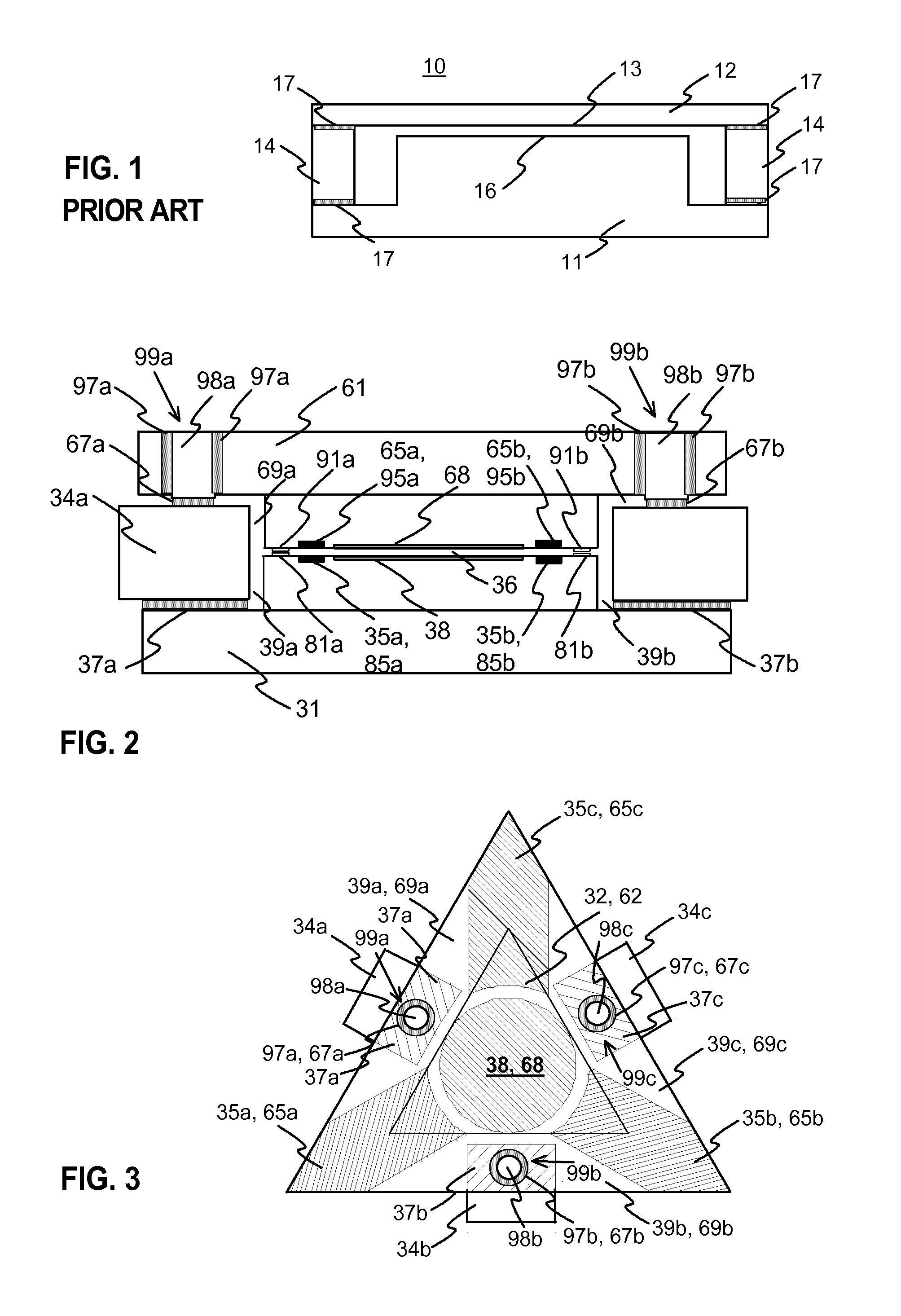

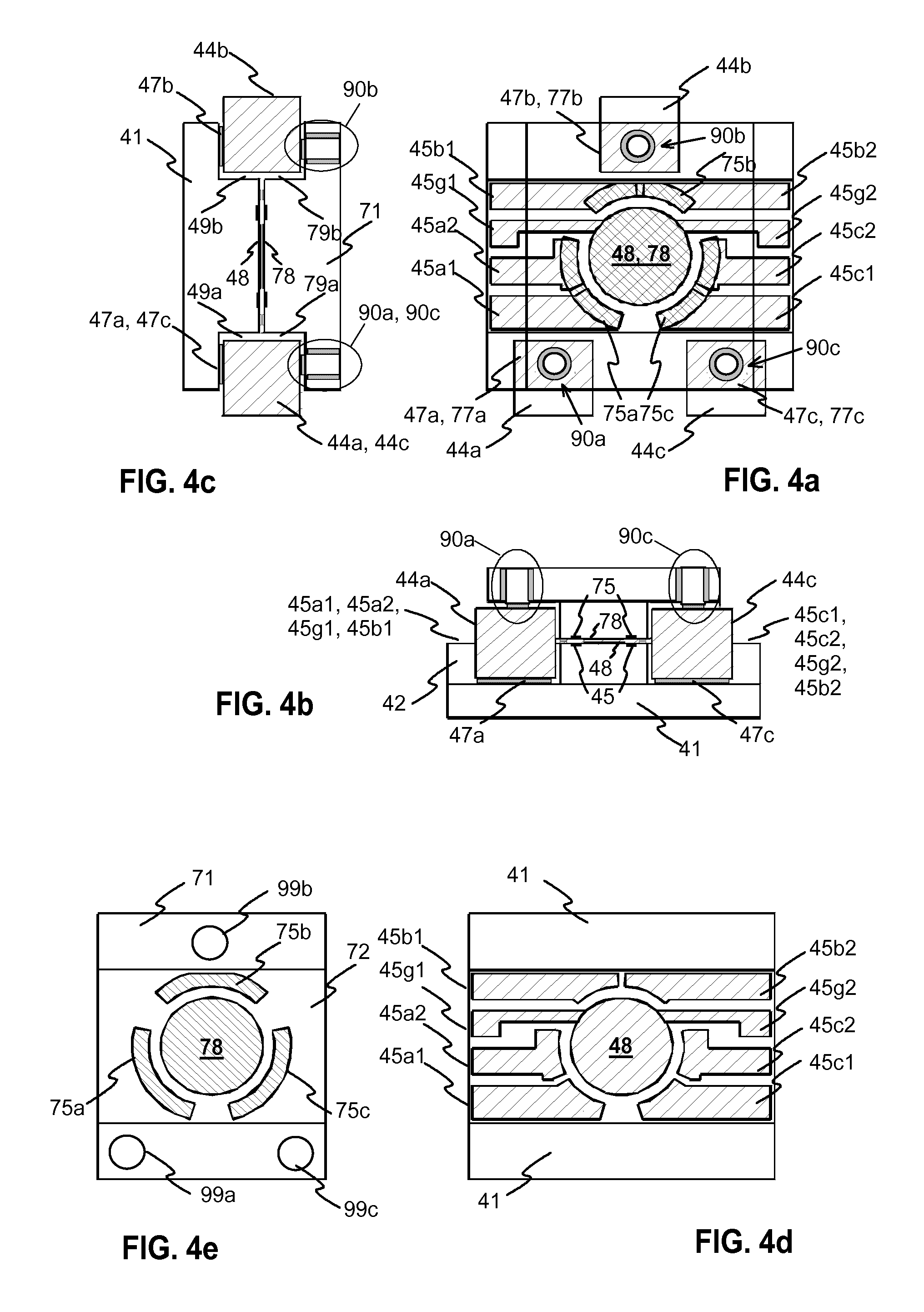

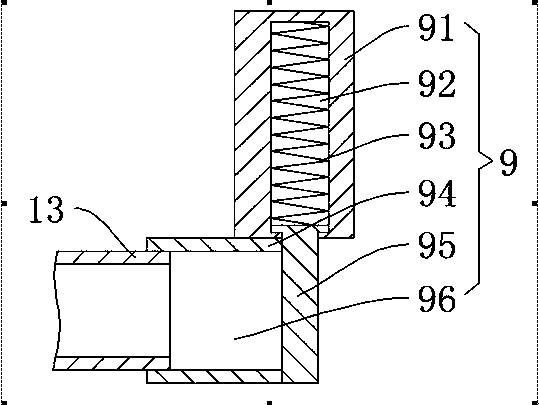

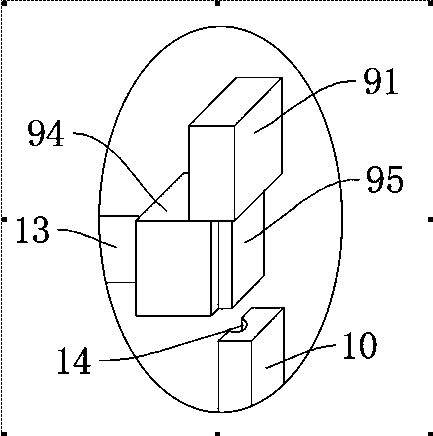

Fabry-Perot interferometer and a method for producing the same

ActiveUS20150124263A1Disadvantage is reduced and avoidedSmall and uniform gapInterferometersSpectrum generation using multiple reflectionEngineeringActuator

The invention relates to a Fabry-Perot interferometer and a method for producing the same. More specifically, the invention relates to Fabry-Perot interferometers which are controllable with one or several actuators, such as piezoelectric, electrostrictive or flexoelectric actuators. In prior art technology there is a problem to achieve a sufficiently small and uniform gap between mirrors. In the present invention an intermediate structure (85a, 85b, 95a, 95b, 81a, 81b, 91a, 91b, 98a, 98b) is used between a mirror and an actuator or between two mirrors. The method of production also includes measuring the width distribution of the gap in several phases, and providing pre-actuation of actuators.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Coated sustained release tablets of a hygroscopic compound for once-a-day therapy

InactiveUS20030215509A1Moderate weight and volumeEasy to swallowBiocideAnimal repellantsProlonged-release tabletExcipient

The present invention provides coated sustained release tablets of a hygroscopic compound for once-a-day therapy, said tablets having a moderate weight and volume and comprising-(a) a core comprising the hygroscopic compound and pharmaceutically acceptable excipients, (b) a first coating layer comprising a polymer selected from the group consisting of water-insoluble polymers, pH dependent polymers or a mixture thereof, and (c) a second coating layer comprising a water-insoluble polymer.

Owner:SUN PHARMA INDS

Comfortable non-ironing cotton warp knitted shirt fabric and production method thereof

ActiveCN109487430AGood value for moneyModerate weightWarp knittingHeating/cooling textile fabricsPolyesterYarn

The invention discloses a comfortable non-ironing cotton warp knitted shirt fabric and a production method thereof. The fabric comprises the following raw materials by mass: A: 55-60% of 60S cotton yarn and B: 40-45% of 50D half-gloss polyester; or A: 16-20% of 30D polyester, B: 16-20% of 40S cotton yarn, C: 29-33% of 75D half-gloss cationic polyester and D: 29-33% of 75D matt polyester. The cotton yarn and the polyester yarn are first used as development raw materials of the comfortable non-ironing cotton warp knitted shirt fabric, and the differentiated cost-effective comfortable non-ironingcotton warp knitted shirt fabric is formed through the organic integration of the new raw material ratio, the new pattern design and the new structure selection. Mainstream products of woven and warpknitted shirt fabrics are supplemented to make up and balance the shortcomings of weft-knitted or woven fabrics, and a new comfortable non-ironing cotton warp knitted shirt fabric system is established.

Owner:JIANGYIN FUBO TEXTILE CO LTD

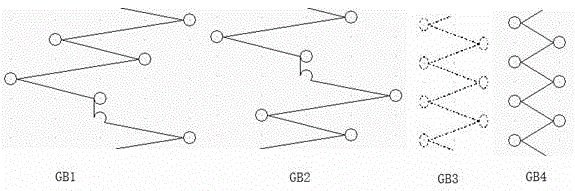

Warp-knitting elastic zigzag-design thermal fabric and production method thereof

The invention discloses warp-knitting elastic zigzag-design thermal fabric. The warp-knitting elastic zigzag-design thermal fabric is prepared from, by mass, 28-31% of 30-32 s white ACR yarn, 28-31% of 30-32 s black cotton yarn and 38-44% of 75D40D polyester package spandex. The fabric is has a single-combing weave structure of GB1 combing and GB2 combing, wherein the white ACR yarn and the blackcotton yarn are adopted for GB1 combing and spaced, and the 75D40D polyester package spandex is adopted for GB2 combing. The warp-knitting elastic zigzag-design thermal fabric is simple in technologyand low in cost, the flexibility of existing woven zigzag-design fabric and the dimensional stability of existing weft-knitting zigzag-design fabric on the market are improved, the elastic recovery ofthe weft-knitting zigzag-design fabric is improved, and the warp-knitting elastic zigzag-design thermal fabric is comfortable to wear, fitting and attractive; thanks to the dual-way elasticity, lightness and comfort of the warp-knitting elastic fabric, a user does not feel constrained when wearing the warp-knitting elastic zigzag-design thermal fabric, and the warp-knitting elastic zigzag-designthermal fabric does not bulge or deform.

Owner:JIANGYIN FUBO TEXTILE CO LTD

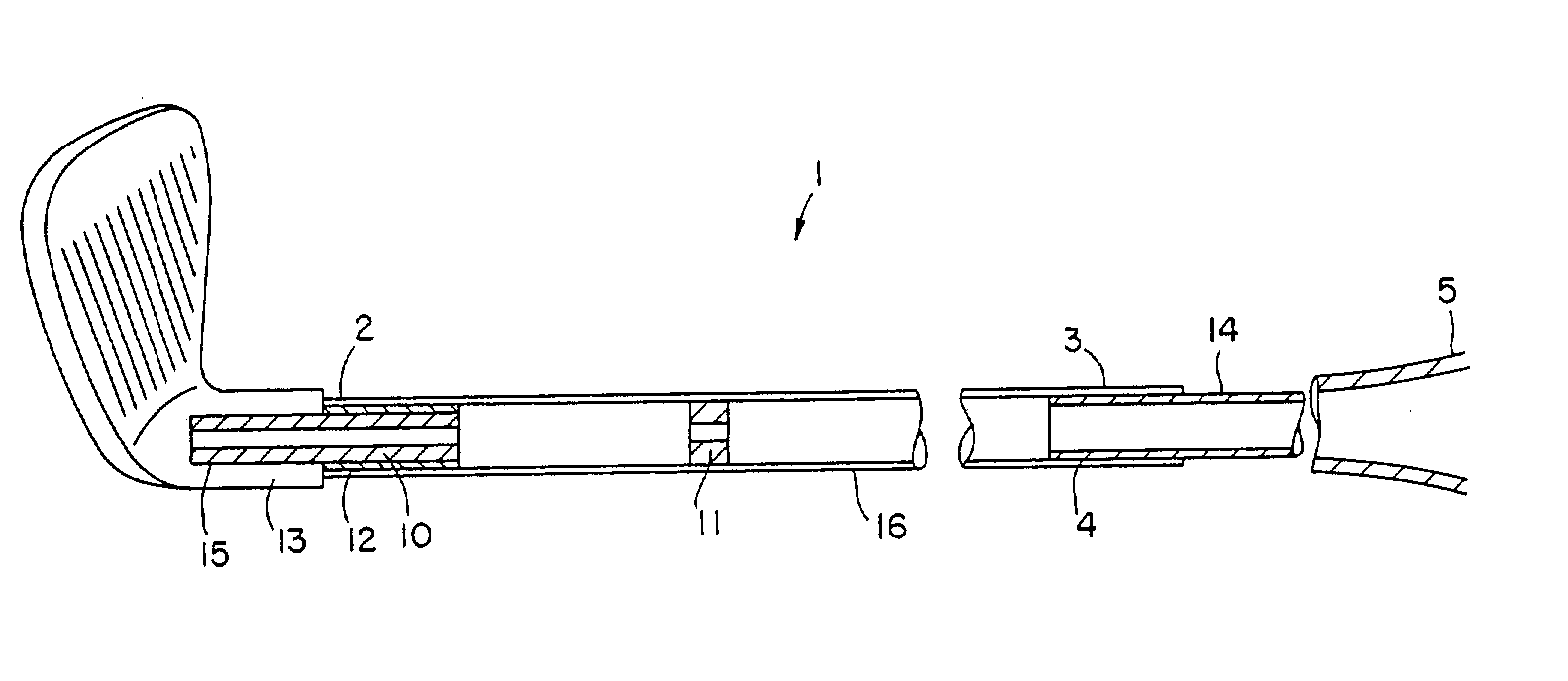

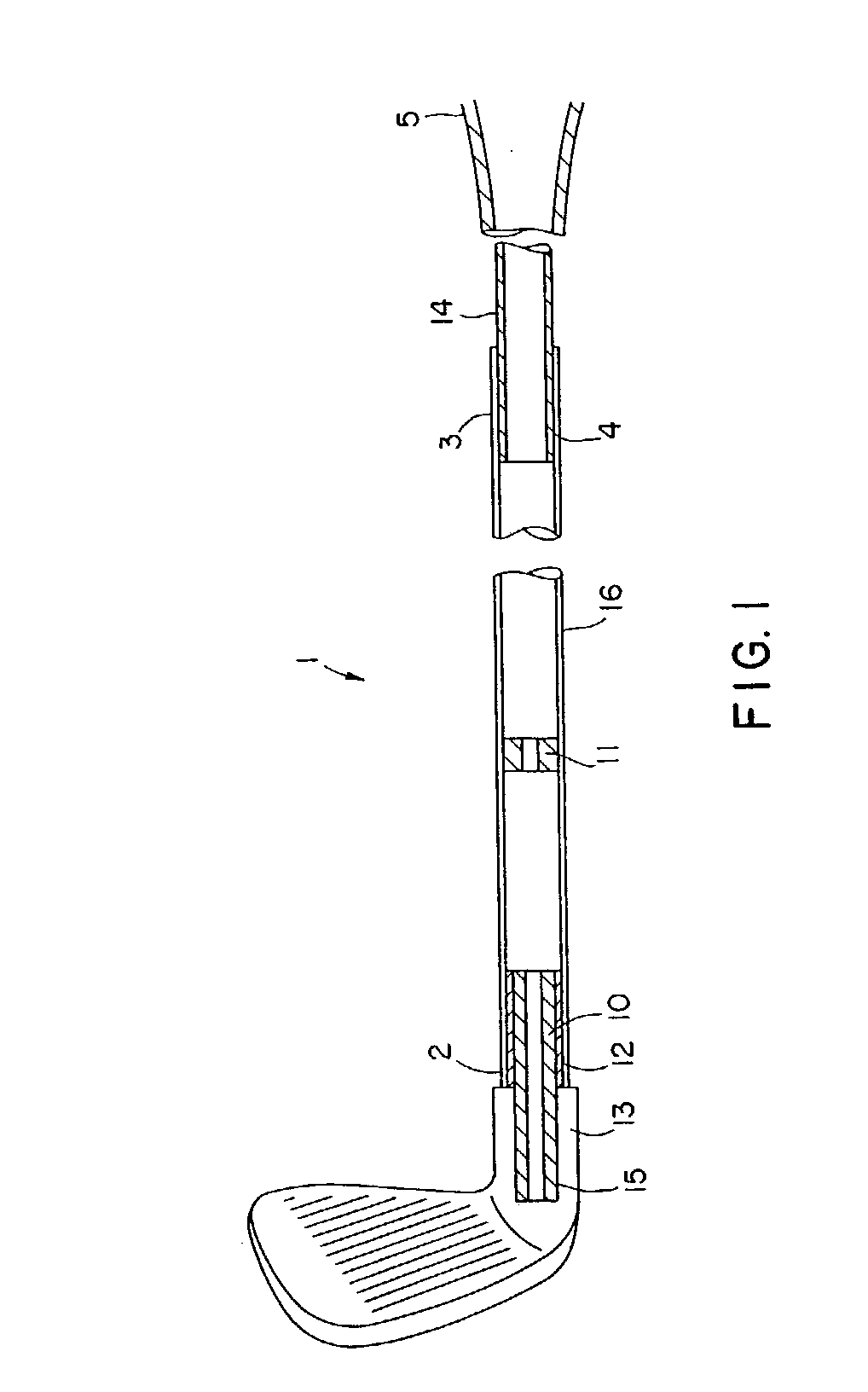

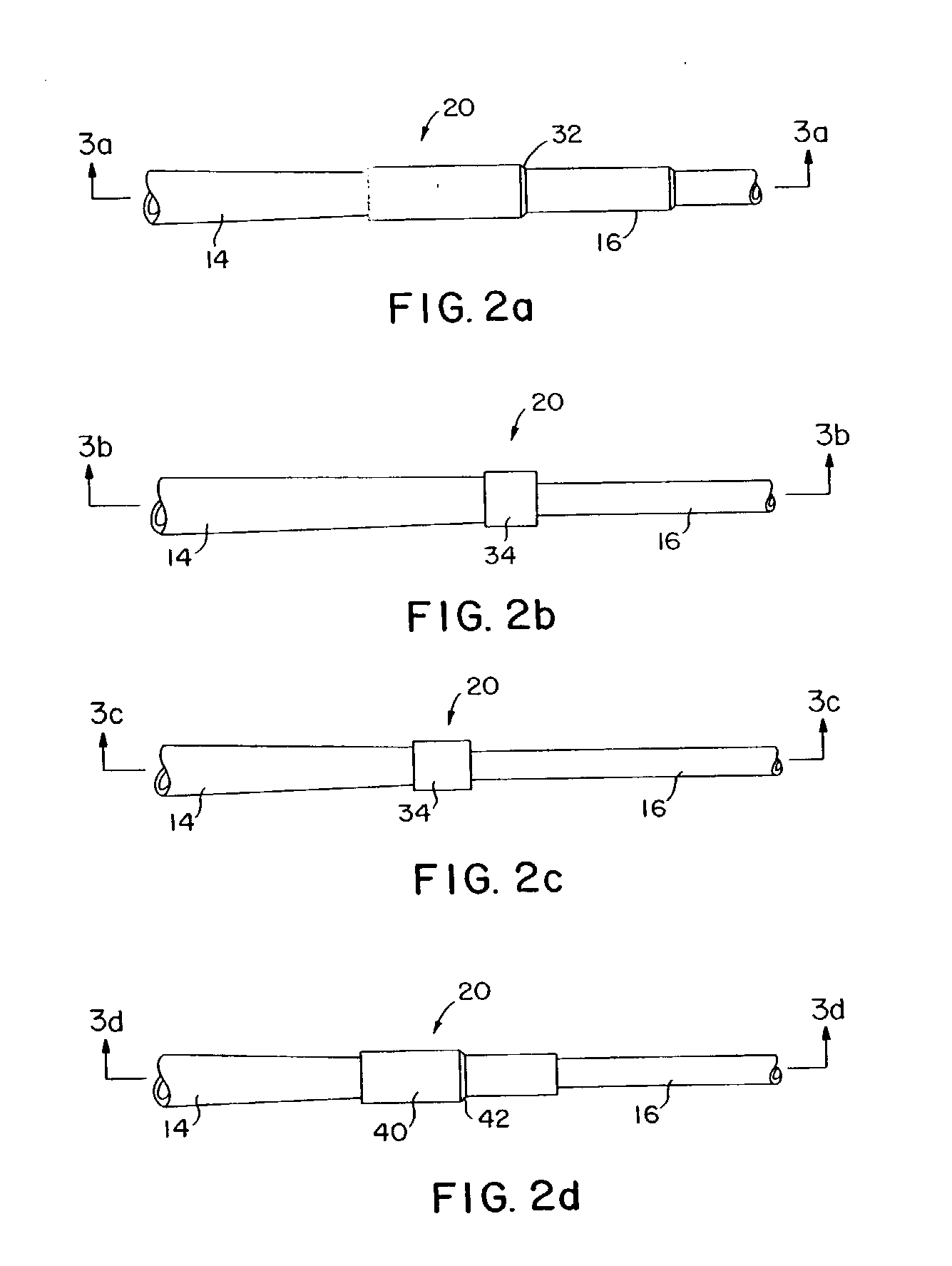

Hybrid golf club shaft

InactiveUS20030176236A1Optimal overall club performanceIncreased torsional stiffnessGolf clubsRacket sportsShear modulusEngineering

A golf shaft for attachment to a hossel of a club head, said shaft comprising: (a) a first section comprising a first material and having a hossel end and a first joint end, said first section having a linear weight no greater than 2.4 g / in; (b) a second section comprising a second material and having a butt end and a second joint end, said second joint end being connected to said first joint end; (c) wherein said second material is less dense than said first material; and (d) wherein said first material has a shear modulus greater than that of said second material.

Owner:FENDEL EDWIN B

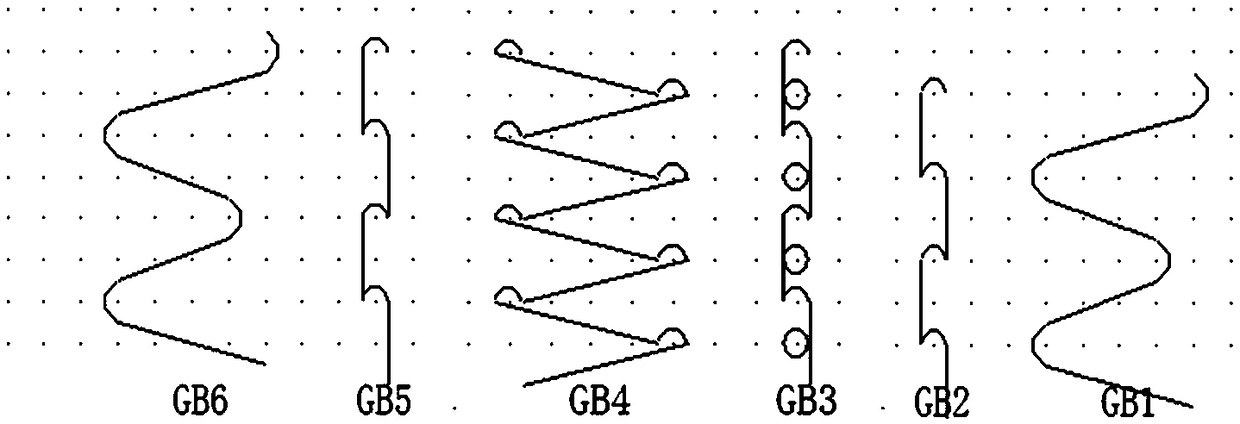

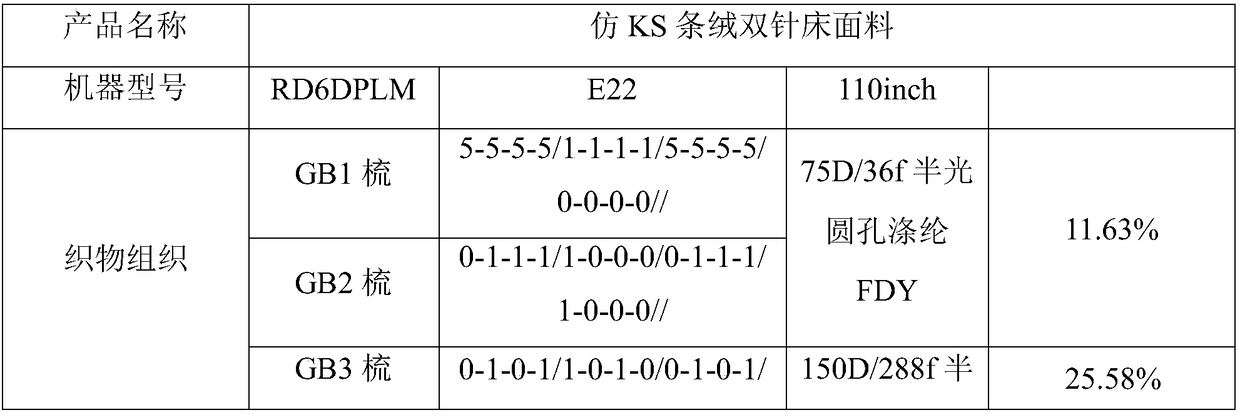

KS-corduroy-simulation double-needle bar fabric and production method thereof

The invention discloses a KS-corduroy-simulation double-needle bar fabric and a production method thereof and belongs to the field of textiles. According to the fabric, a corduroy fabric is combined with fashionable warp-knitting double-needle jacquard weave flannelette, by designing and improving a yarn threading mode, the made KS-corduroy-simulation double-needle bar fabric product is stable instructure and good in size stability, the fabric is not easily loosened, the plush height of the fabric is low, and the fabric is non-lodging, high in pressure resistance, good in straight effect andmoderate in weight per gram; the weight of a finished product can be controlled below 330 g / m<2>, compared with the corduroy fabric on a KS machine, the fabric has more full handfeeling, the softnessof the fabric is improved, the elastic feeling of the suede is improved, the fabric is non-lodging and high in wrinkle resistance, the shrinkage rate after water washing is small and is only about 2%generally, 4 widths of gray fabric can be produced at the same time, the production efficiency is improved, and the fabric is suitable for industrial application.

Owner:苏州吴坤纺织品有限公司 +1

Manufacturing process of composite sleeper

ActiveCN101850622AThere will be no interstory shear failureImprove securityGlass fiberUnsaturated polyester

The invention relates to a manufacturing process of a composite sleeper which can be used for supporting a railway rail. The invention selects an inner core of a wood material or an inner core of a composite material, wherein the outside of the inner core of the wood material is provided with an unsaturated polyester resin reinforcement glass fibre roving layer; and the outside of the unsaturated polyester resin reinforcement glass fibre roving layer or the inner core of the composite material is wrapt with glass fibre multi-axial cloth after the surface treatment of a coupling agent, polyurethane resin is sprayed to the glass fibre multi-axial cloth, the glass fibre multi-axial cloth is soaked and foamed fully by utilizing the polyurethane resin, and a polyurethane resin reinforcement glass fibre multi-axial cloth layer is formed. The manufacturing process of the composite sleeper avoids the problem of easy rupture and damage of a sleeper, which is caused by the unidirectional arrangement of the glass fibre.

Owner:北京交跃通达检测科技有限公司

High-survival-rate feed for 15-45-day-old loach

InactiveCN105851704AFull of nutritionGood digestion and absorptionFood processingClimate change adaptationChrysomyaDigestion

The invention discloses high-survival-rate feed for 15-45-day-old loach. The feed is prepared from, by weight, 40-60 parts of fish meal, 10-20 parts of silkworm chrysalis meal, 5-15 parts of shrimp meal, 2-10 parts of snail meal, 2-10 parts of scallop rims, 2-10 parts of kelp powder, 5-15 parts of earthworms, 20-30 parts of fermented soybean meal, 2-6 parts of oil bran, 5-15 parts of millet powder, 1-3 parts of olive oil, 1-3 parts of granulesten oil, 2-7 parts of flos chrysanthemi dregs, 1-2 parts of honey, 1-2 parts of choline chloride, 1-3 parts of monocalcium phosphate, 1-2 parts of sepiolite powder, 1-2 parts of Chinese herbal medicine and 1-2 parts of a premix compound. The feed is applicable to the young loach which is 15-45-day old and is complete in nutrition, and the loach is good in digestion and absorption, fast in growth and high in survival rate.

Owner:SUSONG FUMIN AQUATIC PROD CULTURE CO LTD

Diagonal bi-directional elastic indigo warp knitted jean fabric and preparation technology

ActiveCN105525430ATwo-way elasticModerate weightWarp knittingHeating/cooling textile fabricsPolyesterEngineering

The invention relates diagonal bi-directional elastic indigo warp knitted jean fabric and a preparation technology, and provides the diagonal bi-directional elastic indigo warp knitted jean fabric with a stable structure and good elasticity. The diagonal bi-directional elastic indigo warp knitted jean fabric is prepared from the following components in percentage by weight: 55 to 75 percent of indigo yarn, 25 to 40 percent of polyester (DTY), and 5 to 10 percent of spandex; the preparation technology comprises the steps of beaming, weaving and setting, when weaving in a tricot warp knitting machine, a first guide bar and a second guide bar are the indigo yarn, a third guide bar is the polyester (DTY), and a fourth guide bar is the spandex, by utilizing the indigo yarn threaded by the previous two guide bars, modified locknit stitch is performed to form diagonal cords on the back side of the craft, by utilizing empty threading of the previous two guide bars to form concave strips and realize the diagonal effect, and by utilizing the final spandex guide bar to perform two-stitch tricot to enable the fabric surface to generate elasticity in the vertical and horizontal directions; the back side of the craft is taken as the right side of garment of the fabric; the diagonal bi-directional elastic indigo warp knitted jean fabric and the preparation technology belong to the technical field of textile; a finished product of the diagonal bi-directional elastic indigo warp knitted jean fabric is 280 to 360g / m<2>.

Owner:JIANGYIN FUBO TEXTILE CO LTD

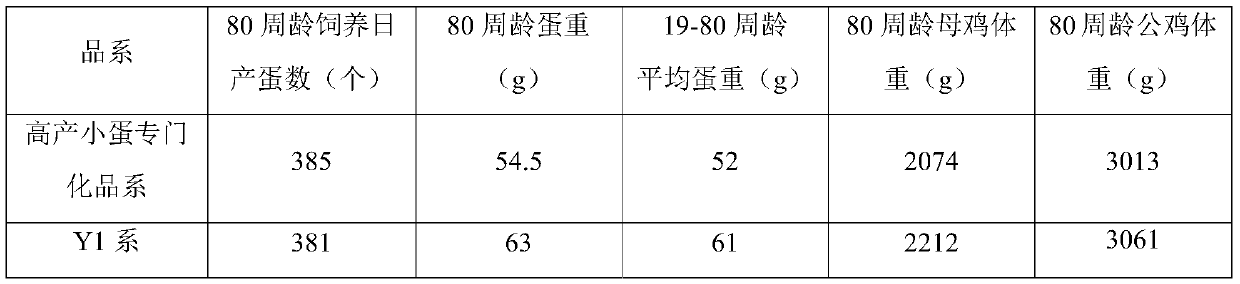

Seed production method of non-short high-yield small-egg layer synthetic line

The invention relates to a seed production method of a non-short high-yield small-egg layer synthetic line. The seed production method includes following steps: S1, forming an underlying group, and producing a pure-line chicken group: taking egg weight as a main option character for screening, and screening a rooster and a hen from existing high-yield layer lines to form a family for expanding propagation to obtain the pure-line chicken group; S2, performing closed flock continuous progeny breeding on the obtained pure-line chicken group, and obtaining a high-yield small-egg specialized line through breeding of four generations in a row; S3, taking the high-yield small-egg specialized line as a male parent and other layer lines of about 60g in average egg weight in the whole process of egglaying as a female parent, and matching to obtain a goods-generation layer new synthetic line, namely the non-short high-yield small-egg layer synthetic line. Goods-generation chickens have the advantages of small egg weight, high egg yield and moderate body weight, comprehensive benefit of layers is increased, domestic high-yield layer variety type is enriched, and brand layer development needscan be met.

Owner:BEIJING HUADU YUKOU POULTRY

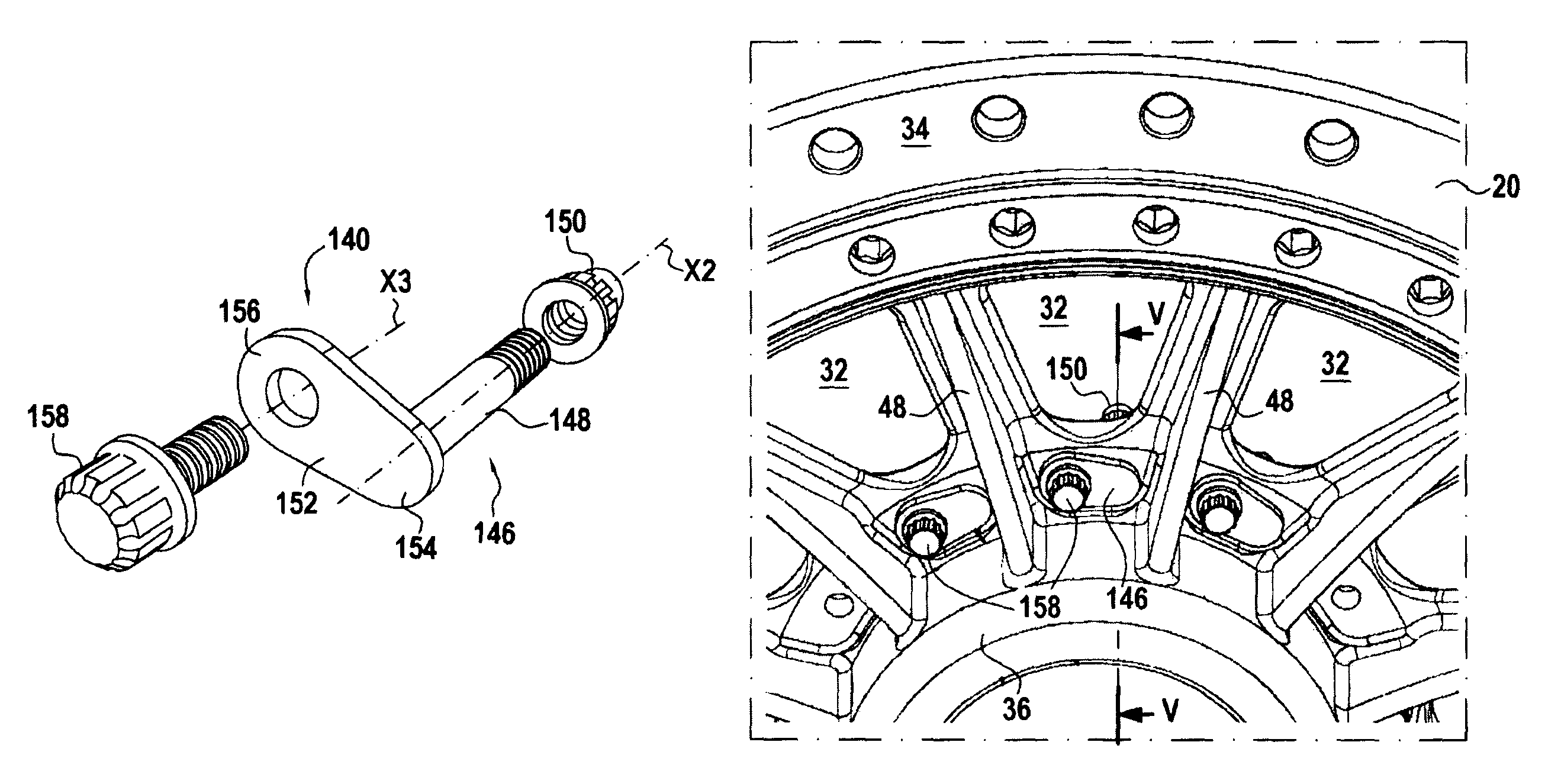

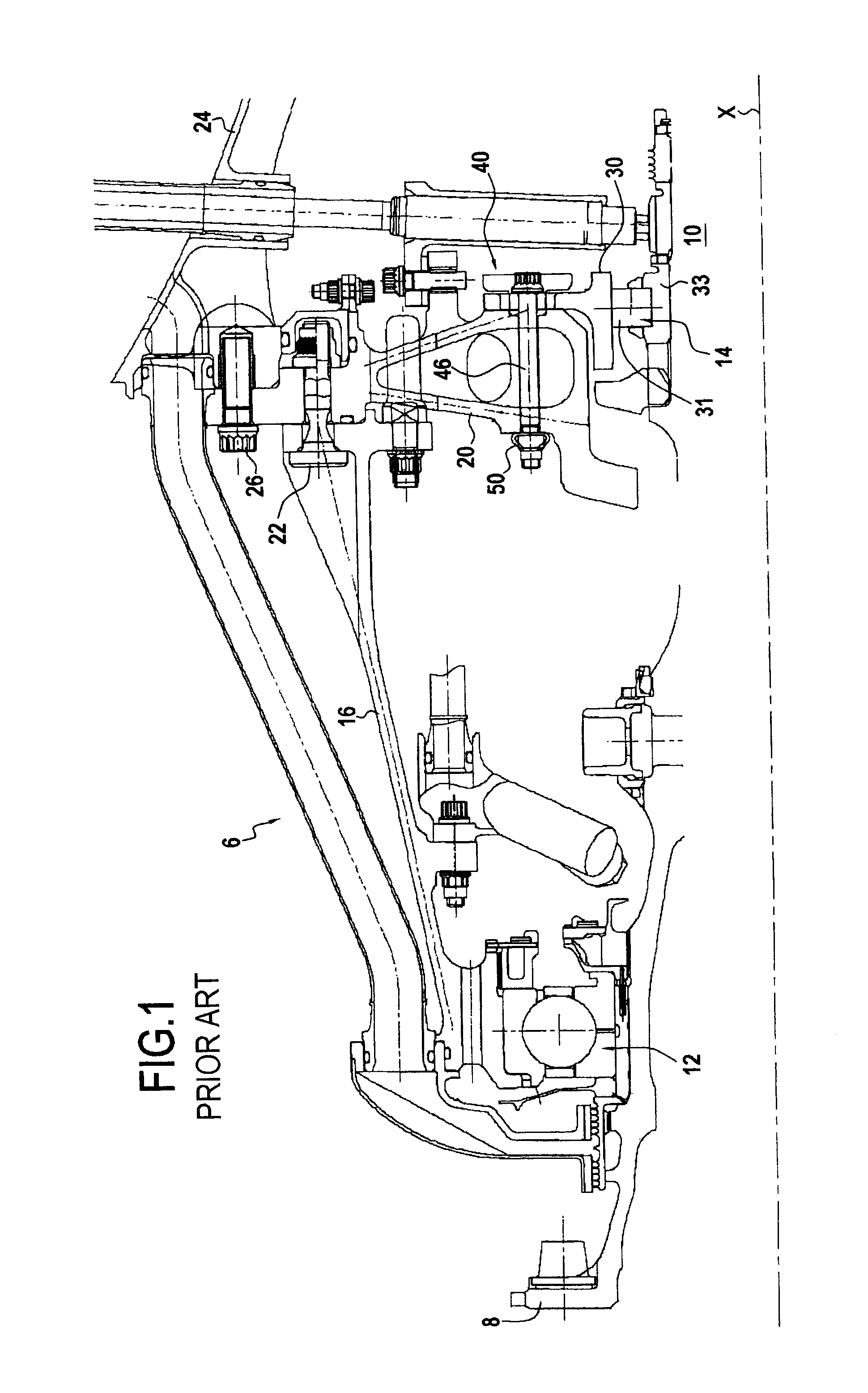

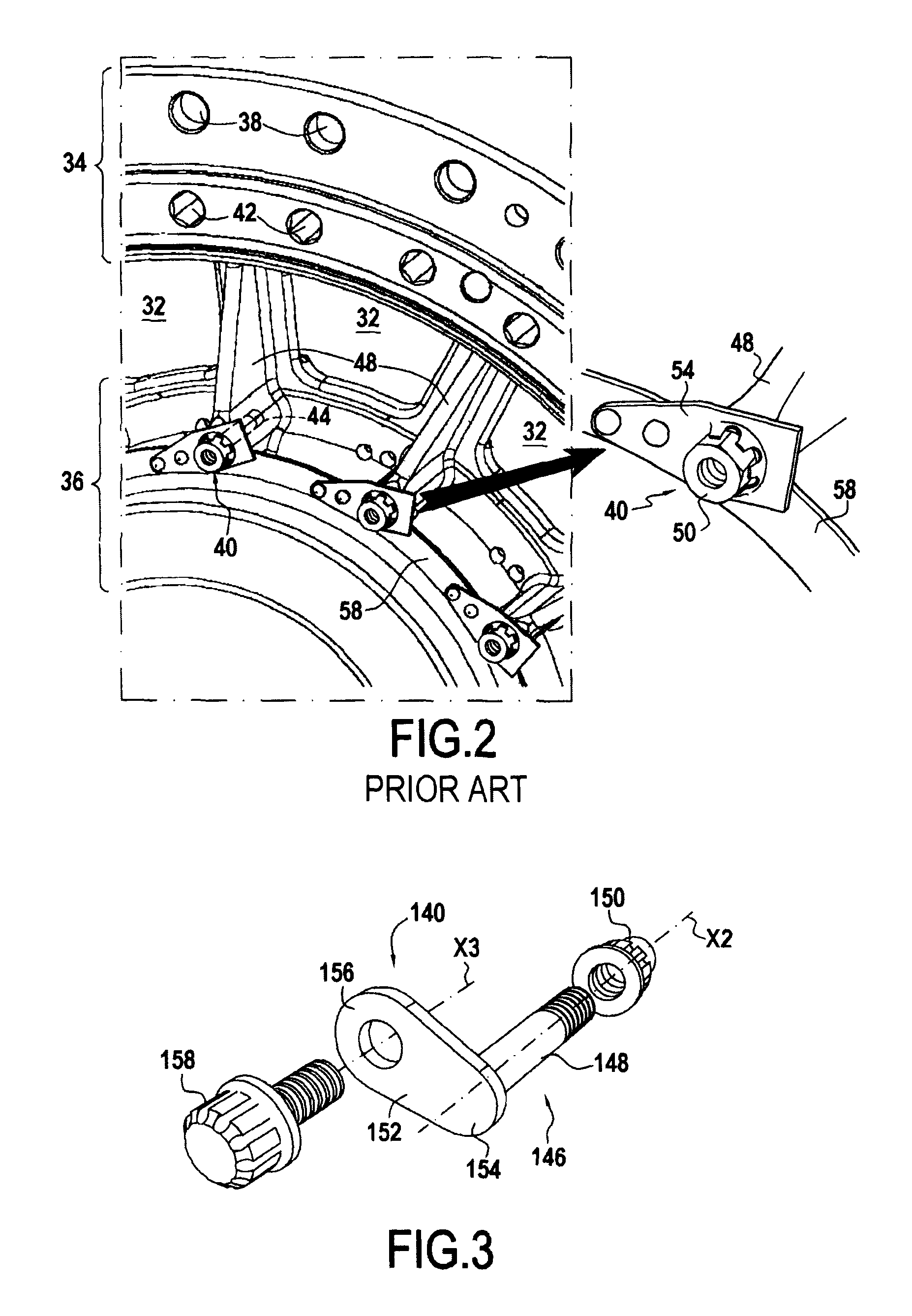

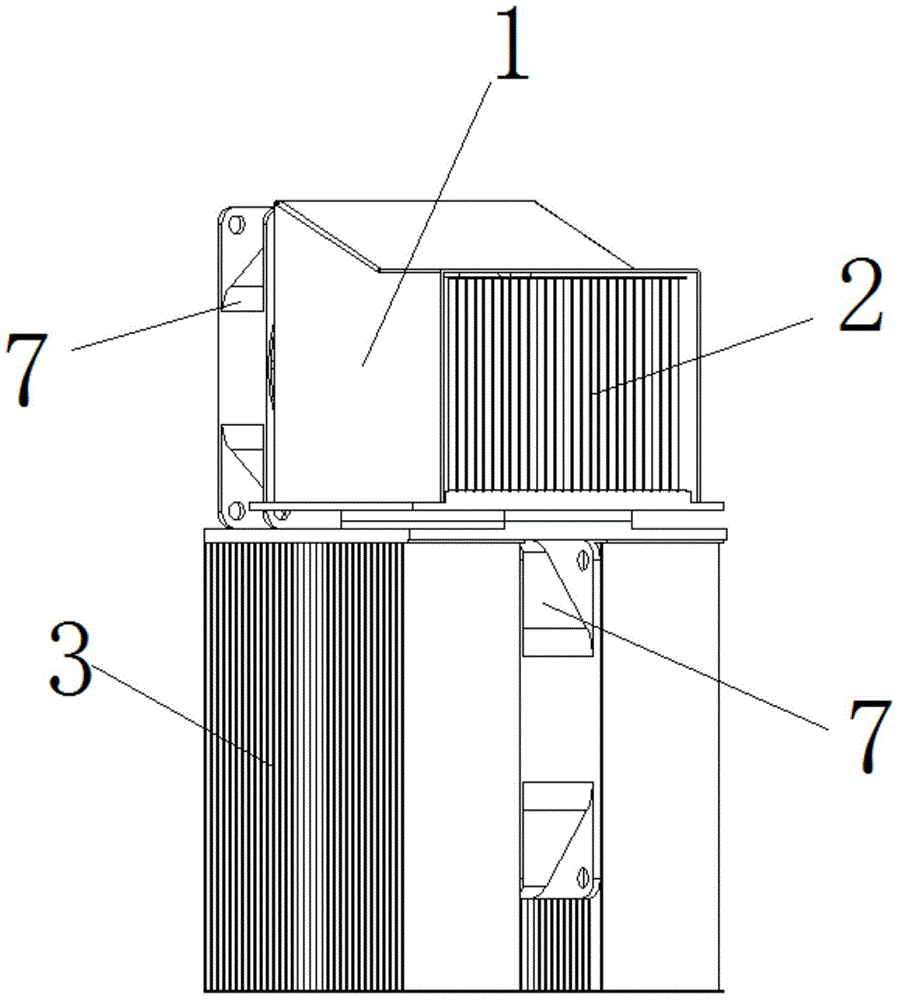

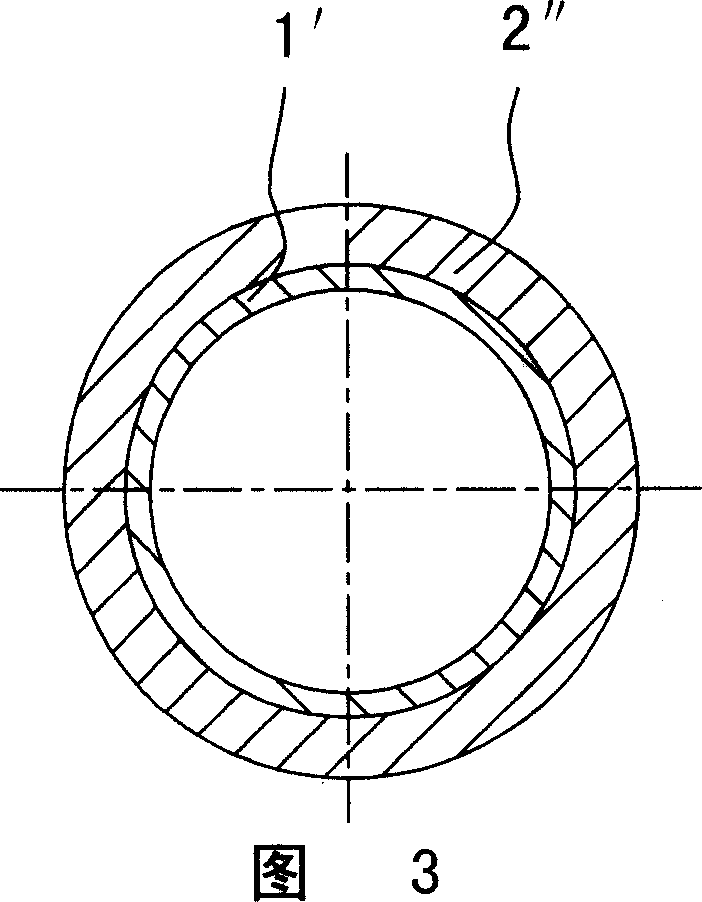

Turbomachine optimized for fastening a rotary shaft bearing, A method of mounting said bearing on said turbomachine

A turbomachine including a shaft, a bearing for supporting the shaft and including an outer ring, and a support for the bearing, the support having a flange to which the outer ring is fastened by fasteners, is provided. Each fastener includes a fastener bolt and a nut screwed together. The turbomachine further includes, for each fastener, a position-retention device for retaining the bolt, and suitable for retaining the bolt in a position that is stationary relative to the bearing support or the outer ring, even in the absence of the nut. The head of the fastener bolt and the position-retention device may be of small dimensions, thereby enabling the fastening of the flange to the bearing support to be optimized, and in particular enabling the weight of the fastening to be optimized. A method of mounting the bearing of the turbomachine is also provided.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

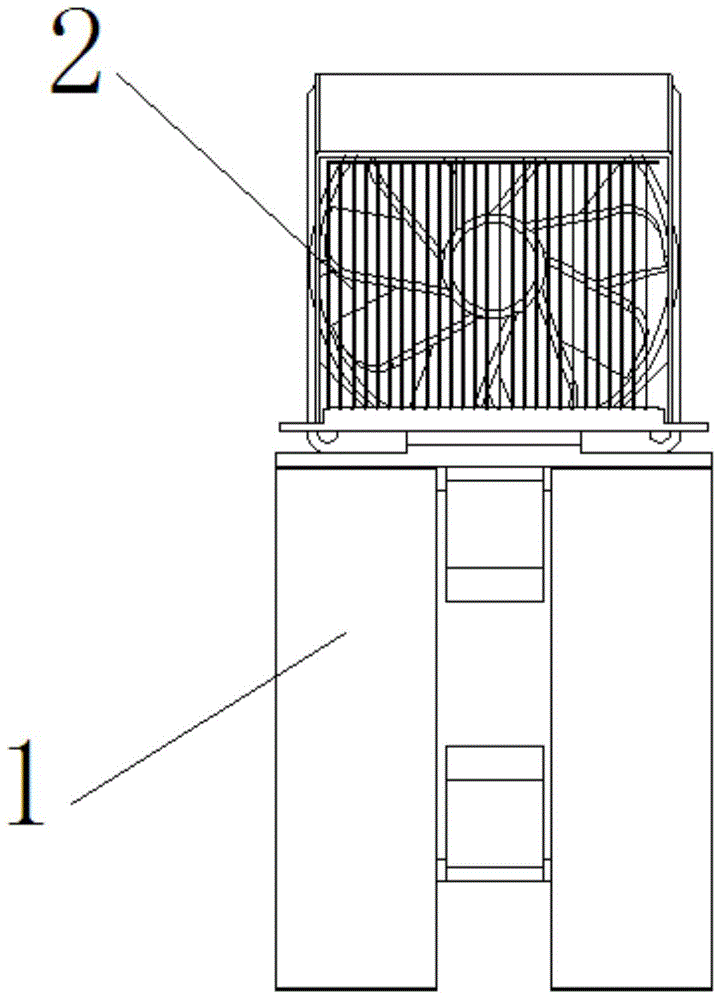

Novel integrated refrigeration fan

InactiveCN104930750AReduce volumeImprove heat dissipationMachines using electric/magnetic effectsAir conditioning systemsEngineeringCold air

The invention relates to a novel integrated refrigeration fan which comprises a cold air duct shell, a semiconductor refrigeration component, an air outlet mesh guard, an air inlet mesh guard, fan bodies and a circular control system. The cold air duct shell is divided into an upper refrigeration layer and a lower radiating layer, the semiconductor refrigeration component comprises a semiconductor refrigeration chip, a hot end aluminum radiator and a cold end aluminum radiator, the hot end aluminum radiator is positioned in the radiating layer, the cold end aluminum radiator is positioned in the refrigeration layer, the hot end of the semiconductor refrigeration chip is connected with the hot end aluminum radiator, the cold end of the semiconductor refrigeration chip is connected with the cold end aluminum radiator, and the fan bodies are arranged on one side of the cold end aluminum radiator and one side of the hot end aluminum radiator. By the aid of the advantages of fine refrigeration effect, small size and light weight of the semiconductor refrigeration chip, the novel integrated refrigeration fan solves the problem of condensate water generated in the use process.

Owner:刘鸿飞

Automatic watering seedling breeding device

InactiveCN108934586AModerate weightRealize automatic wateringSelf-acting watering devicesCultivating equipmentsEngineeringAutomatic testing

The invention discloses an automatic watering seedling breeding device which comprises a support. A supporting rod is fixedly installed on the support. A first rotating shaft is installed on the end face of the supporting rod and sleeved with a rotating rod. One end of the rotating rod is connected with a connecting plate which is sleeved with a second rotating shaft. The second rotating shaft isfixedly connected with the outer wall of a seedling breeding pot side plate. The other end of the rotating rod is rotationally sleeved with a pressure device. A water tank is fixedly installed on thetop of the support. A water pipe is connected with the bottom of the water tank and sleeved with an on-off connector. A top plate is arranged at the bottom of the on-off connector and connected with aseedling breeding pot through a first connecting rod. Seeds are planted in the seedling breeding pot and watered with a proper amount of water, the rotating plate is made to be horizontal, when waterin the seedling breeding pot is lost, the weight of the seedling breeding pot is lowered, a gravity block moves down, the seedling breeding pot moves up, the top plate rises, the on-off connector isturned on, water is poured in the seedling breeding pot, the weight is increased after water is poured in the seedling breeding pot, the seedling breeding pot moves down, and when water in the seedling breeding pot restores the initial state, the rotating rod returns to be horizontal, and the on-off connector is turned off.

Owner:安庆市茂祥农业科技发展有限公司

Portable integrated emergency communication platform

PendingCN110049579AHigh degree of automationModerate weightStands/trestlesWireless communicationEngineering5G

The invention discloses a portable integrated emergency communication platform. The platform comprises an emergency box body, a bearing beam, a horizontal telescopic arm, a rotary supporting leg assembly, a telescopic walking device, a lifting mast, an antenna, a box body door, a ventilation blind window, a skylight, an air conditioner, in-box equipment and the like. Compared with a traditional emergency communication vehicle, a pull type emergency square cabin and a container square cabin, the minimum transport vehicle of the device is a pickup truck or a light truck, at least one person doesnot need to use external loading and unloading equipment or devices within a short time; the 4G or 5G communication base station can be quickly and flexibly opened by loading and unloading the vehicle, expanding and supporting, walking in a short distance and opening the base station communication platform only through the inseparable integrated function of the device, the defects of the existingemergency guarantee communication means are overcome, and economic and social benefits are achieved.

Owner:姜艳

Warp knitting moisture absorption and sweat releasing shirt fabric and preparation method thereof

InactiveCN110067076ALight and comfortable to wearIncrease elasticityWarp knittingHeating/cooling textile fabricsPolyesterEngineering

The invention relates to a warp knitting moisture absorption and sweat releasing shirt fabric and a preparation method thereof and belongs to the technical field of warp knitting shirt fabrics and production thereof. The fabric is made of 17-19% of polyester yarns, 13-75% of cotton yarns, 10-20% of extinction irregular cut polyester yarns and 0-35% of extinction cationic dyeable irregular cut polyester yarns through weaving by using a four-comb warp knitting machine. The warp knitting shirt fabric provided by the invention has the advantage of warp knitting textures made of cotton yarns and irregular cut polyester yarns in reasonable proportioning, the fabric has moisture absorption and sweat releasing functions, meanwhile, the amount of special yarns is reduced, the production cost can bereduced, and the fabric has the advantages of being light and thin, comfortable to wear, rich in color, smooth in hand feeling, moderate in elasticity, and the like.

Owner:JIANGNAN UNIV

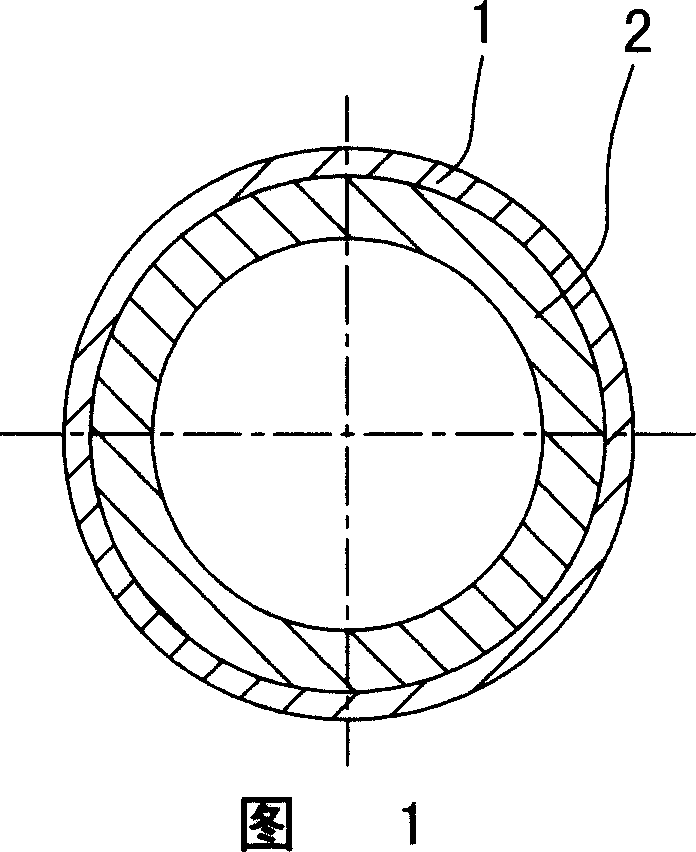

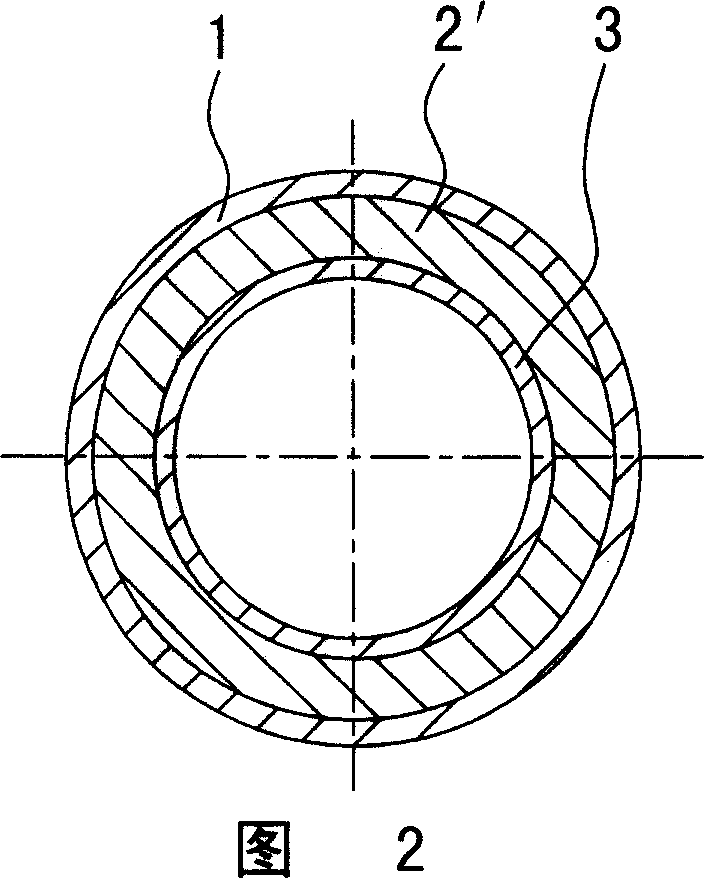

Copper and aluminium composite pipe

InactiveCN1932361AHigh mechanical strengthModerate weightLayered productsRigid pipesPipe layerElectrical equipment

The present invention relates to a copper-aluminium composite pipe made up by using seamless copper pipe and seamless aluminium pipe. Said composite pipe has two-layer pipe wall structure or three-layer pipe wall structure. Its two-layer structure is characterized by that its outer layer is seamless copper pipe layer and its inner layer is seamless aluminium pipe layer or its outer layer is seamless aluminium pipe layer and its inner layer is seamless copper pipe layer, and its three-layer structure is characterized by that its intermediate layer is seamless aluminium pipe layer and its outer layer and inner layer are seamless copper pipe layer.

Owner:台州市路桥巨科汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com