Hybrid golf club shaft

a golf club shaft and hybrid technology, applied in the field of hybrid golf club shafts, can solve the problems of dampening vibration but also stiffening the club, and achieving the effects of moderate swing weight, high torsional stiffness, and optimal overall club performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

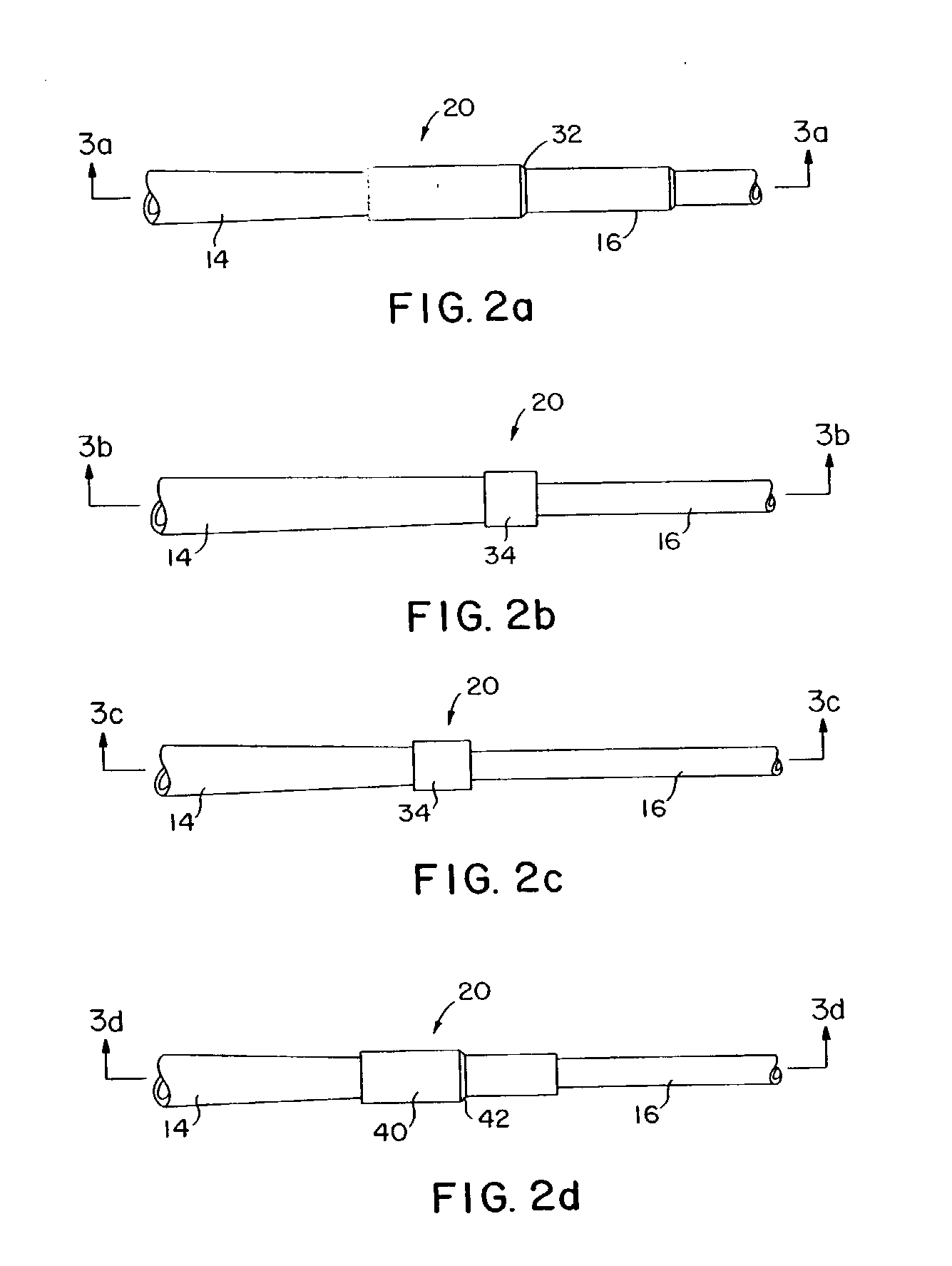

[0055] Referring now to the figures, a discussion of the above features with respect to preferred embodiments is provided below. It should be understood that such embodiments are for illustrative purposes, and should not be construed as limiting the scope of the invention.

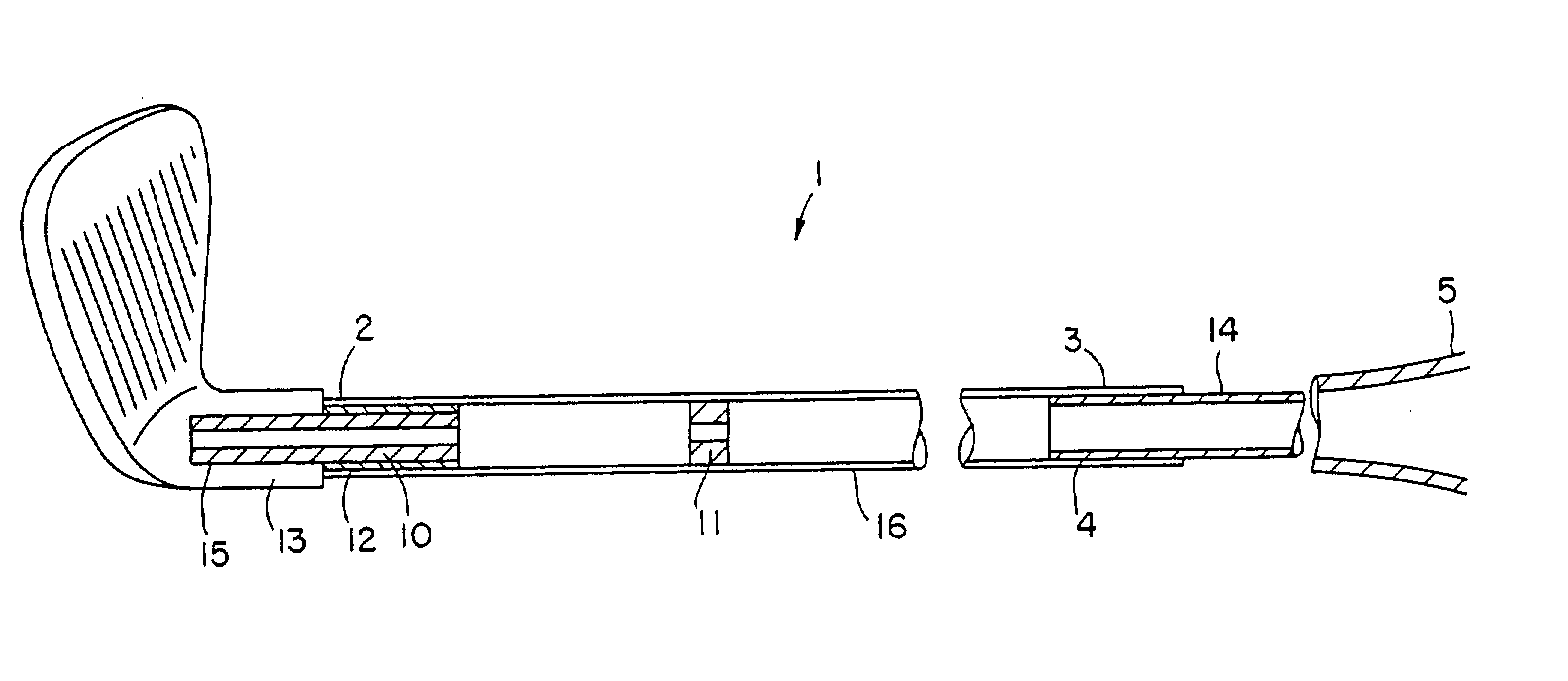

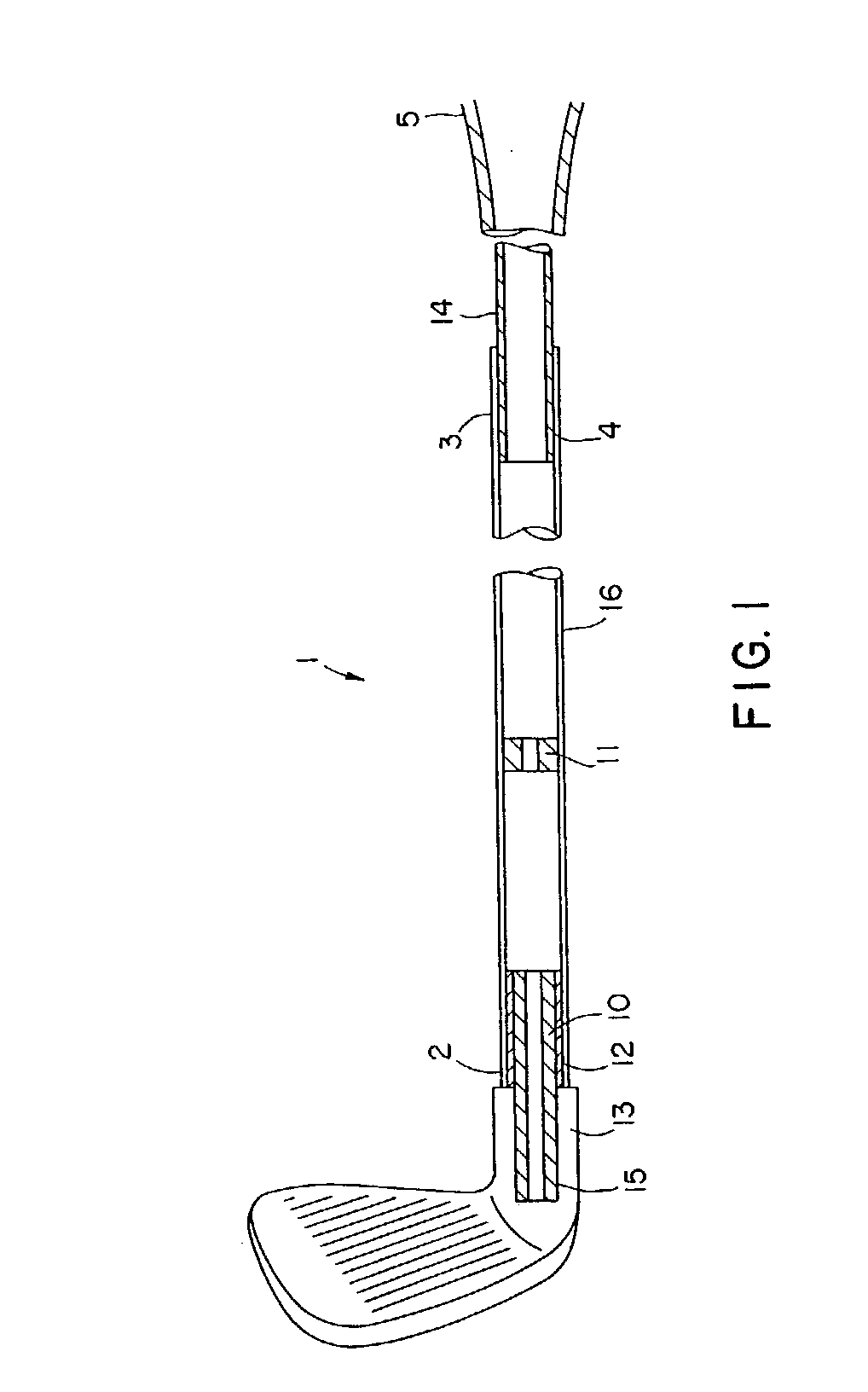

[0056] FIG. 1 illustrates a preferred embodiment of a hybrid shaft 1 which can be used with a driver (wood) or an iron. The hybrid shaft 1 comprises a first section 16 and a second section 14. The first section 16 has a hossel end 2 and a joint end 3. The hossel end 2 is connected to a hossel 13 of a club head 6 via a connector 15. The first section has a linear weight less than that of a comparable section of a conventional steel shaft and comprises a material having a shear modulus greater than that of the material of the second section. The second section comprises a lightweight material and has a joint end 4 which connects to the joint end 3 of the first section 16 and a butt end 5.

[0057] The first section impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com