Pressure test calibration mechanical loading device for earthwork testing

A technology of pressure testing and mechanical addition, applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the problems of complex structure of hydraulic system, difficulty of precise control of manual oil injection pump, poor stability, etc. Achieve the effects of wide application, wide online detection and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

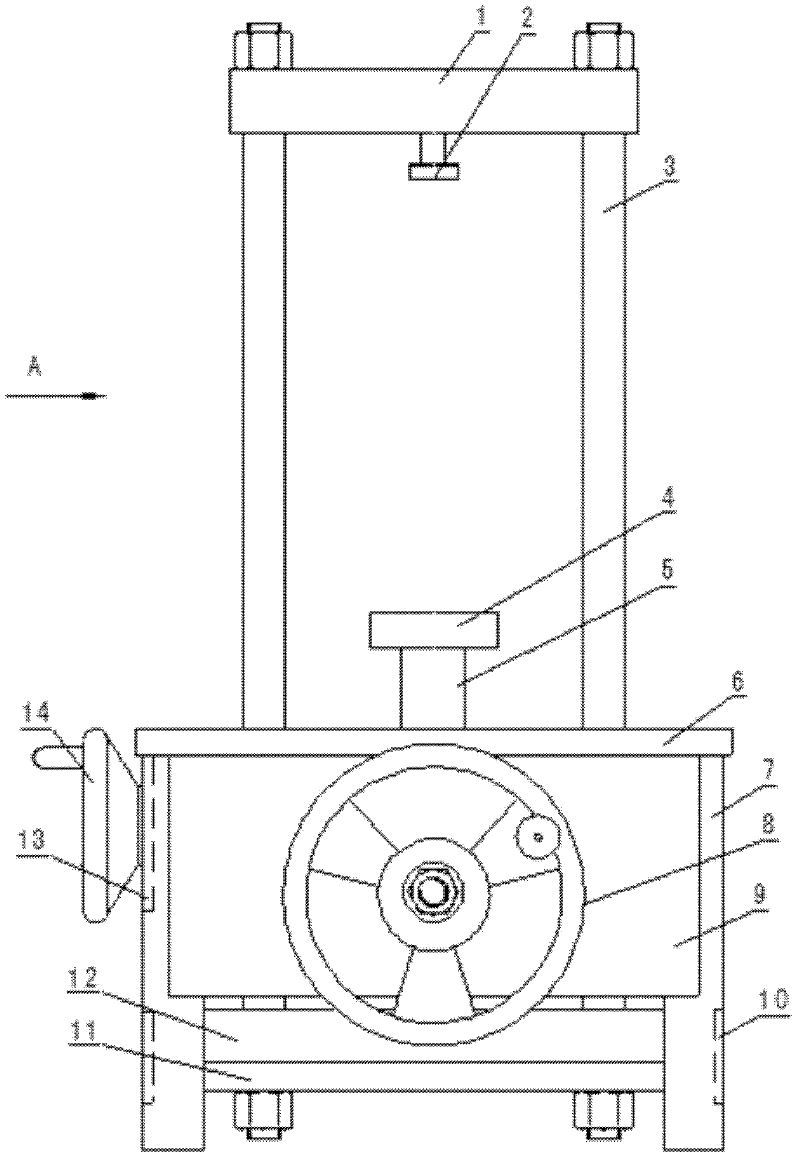

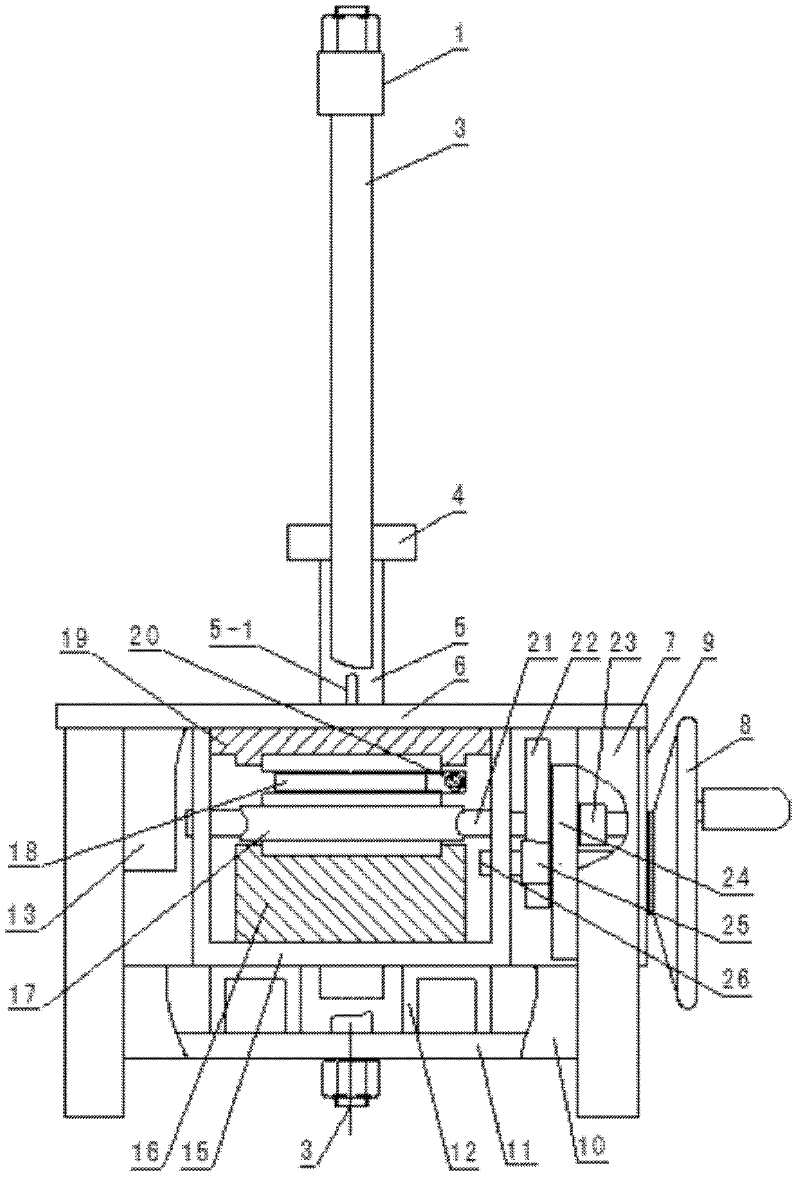

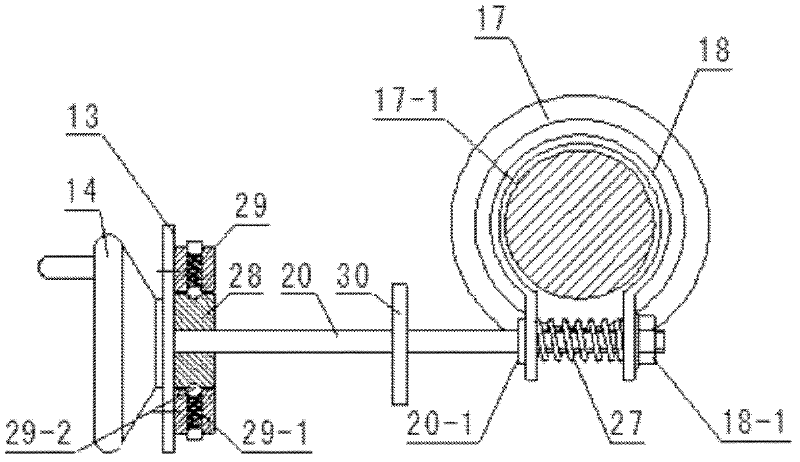

[0026] Such as figure 1 , 2 In the shown embodiment, the pressure test calibration mechanical loading device includes a gantry frame composed of two columns 3, an upper beam 1 and a lower beam. The connecting plate 10 between constitutes the workbench.

[0027] The two uprights 2 of the gantry frame pass through the corresponding holes on the workbench 6 and are connected to the lower beam. The lower beam is composed of a bottom plate 11 and two channel steels 12 symmetrically welded to the long axis of the bottom plate. The bottom ends of the two uprights 3 of the gantry frame are connected by nuts. The bottom plate is fixed between two channel steels. The two ends of the lower crossbeam made of welded one-body base plate and two channel steels are respectively welded and fixed with the connecting plate 10 between the pillars 7 on both sides of the workbench.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com