Process for manufacturing cotton-polyester interwoven warp knitted fabric

A manufacturing process and warp knitting technology, which is applied in the manufacturing process of comfortable elastic cotton-polyester interwoven warp-knitted twill fabrics, can solve the problems of easy sticking of yarns, poor adaptability of raw materials, and low strength of spun yarns, and achieve obvious twill effect, Moderate weight, comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A cotton-polyester interwoven warp-knitted fabric, which is composed of the following components: 32s compact spun cotton yarn is 72.3%, 75D / 72F PBT filament is 27.7%, and the warp yarn of the fabric is protruded on the reverse side of the process to form twill floating lines. The twill dimples are formed where the knitting chain is looped, thus forming the twill effect.

[0032] The manufacturing process of described cotton polyester interwoven warp knitted fabric is:

[0033] 1. Preparation process: select 21s~60s compact spinning cotton yarn and 40~75D PBT filament;

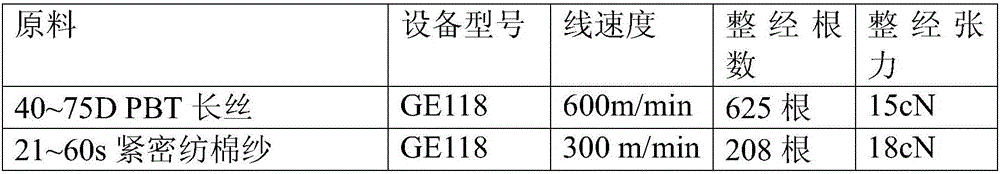

[0034] 2. Warping process: temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, relatively high and stable temperature and humidity are conducive to the stability of twisting and soft surface of cotton yarn, and avoid entanglement with each other , which is beneficial to the production of warp knitted products;

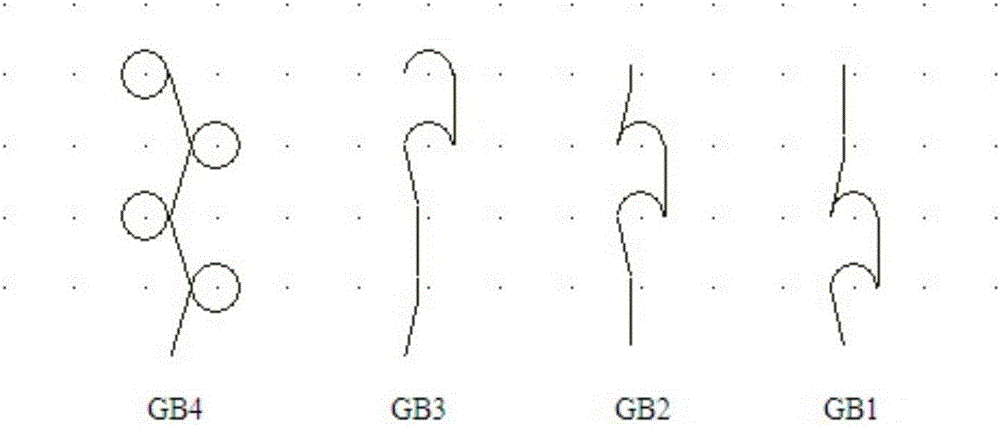

[0035] According to the conventional warping operat...

Embodiment 2

[0062] A cotton-polyester interwoven warp-knitted fabric, which is composed of the following components: 32s compact spun cotton yarn is 83.4%, 75D / 72F PBT filament is 16.6%, and the warp yarns of the fabric are protruded on the reverse side of the process to form twill floating lines. The twill dimples are formed where the knitting chain is looped, thus forming the twill effect.

[0063] The manufacturing process of described cotton polyester interwoven warp knitted fabric is:

[0064] 1. Preparation process: select 21s~60s compact spinning cotton yarn and 40~75D PBT filament;

[0065] 2. Warping process: temperature and humidity at the warping site: temperature 25±1°C, relative humidity 65±5%, relatively high and stable temperature and humidity are conducive to the stability of twisting and soft surface of cotton yarn, and avoid entanglement with each other , which is beneficial to the production of warp knitted products;

[0066] According to the conventional warping operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com