Warp knitting moisture absorption and sweat releasing shirt fabric and preparation method thereof

A moisture-wicking, warp knitting technology, applied in warp knitting, dyeing, fabric surface trimming, etc., can solve the problem of difficulty in ensuring wearing comfort, lightness and breathability, woven fabric elasticity, poor extensibility, and wearing comfort. Insufficient sex and other problems, to achieve the effect of excellent body and color effect, good wrinkle resistance and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Warp-knitted moisture-absorbing and sweat-wicking shirt fabric, the fabric contains the following raw materials and mass percentages: A: 10.4% of 30D polyester FDY, B: 9.9% of 75D matte special-shaped cross-section polyester DTY; C: 13.3% of 60s blue cotton yarn; D: 58.4% 60s white cotton yarn.

[0054] Spinning process: adding 2%-3% matting agent, cooling and cutting, dry blending, spinning assembly filtration, profiled spinning (using the required H-type or four-lobed spinneret holes), cooling and oiling , one roll, two rolls and winding forming, and finally obtain the desired warp.

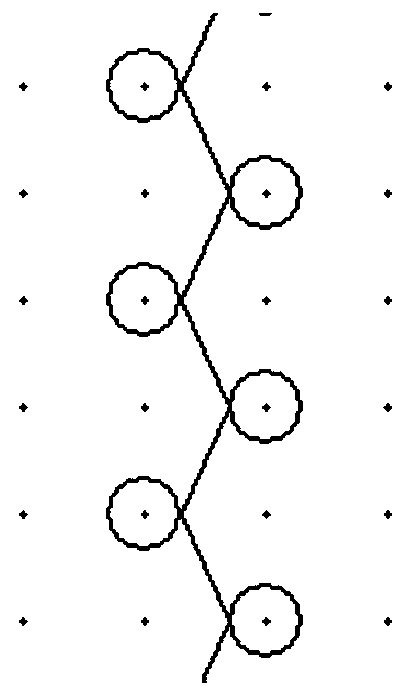

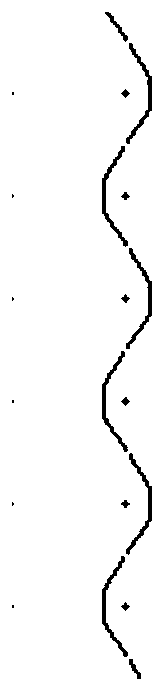

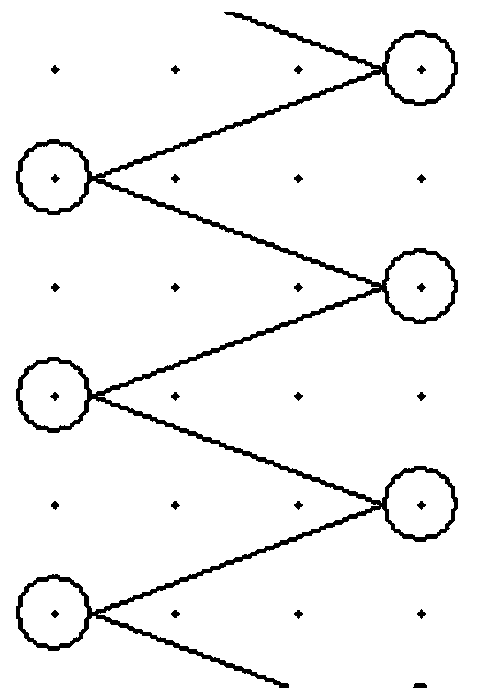

[0055] The single-comb weave structure and threading mode of the fabric are:

[0056] GB1 comb: 1-0 / 1-2 / / , 12A;

[0057] GB2 comb: 1-1 / 0-0 / / , 12B;

[0058] GB3 comb: 1-2 / 1-0 / / , (1C, 1 empty) × 3, (1D, 1 empty) × 3;

[0059] GB4 comb: 3-4 / 1-0 / / , (1 empty, 1D) × 6

[0060] That is, GB1 comb: 30D polyester FDY; GB2 comb: 75D matte special-shaped cross-section polyester DTY; GB3 comb: ...

Embodiment 2

[0063] Cotton warp knitted moisture-absorbing and sweat-wicking shirt fabric, the fabric contains the following raw materials and mass percentages: A: 18.4% of 30D polyester FDY, B: 9.9% of 75D matte special-shaped cross-section polyester DTY; C: 35.8% of 60s blue cotton yarn ;D: 35.8% 60s white cotton yarn.

[0064] Spinning process: adding 2%-3% matting agent, cooling and cutting, dry blending, spinning assembly filtration, profiled spinning (using the required H-type or four-lobed spinneret holes), cooling and oiling , one roll, two rolls and winding forming, and finally obtain the desired warp.

[0065] The single-comb weave structure and threading mode of the fabric are:

[0066] GB1 comb: 1-0 / 1-2 / / , 2A;

[0067] GB2 comb: 1-1 / 0-0 / / , 2B;

[0068] GB3 comb: 1-2 / 1-0 / / , 1C, 1 empty;

[0069] GB4: comb: 3-4 / 1-0 / / , 1 empty, 1D;

[0070] That is, GB1 comb: 30D polyester FDY; GB2 comb: 75D semi-gloss moisture-absorbing and sweat-wicking special-shaped polyester DTY; GB3 co...

Embodiment 3

[0073] Cotton warp knitted moisture-wicking shirt fabric, the fabric contains the following raw materials and mass percentages: A: 18.9% of 30D polyester FDY, B: 17.7% of 40s natural color cotton yarn; C: 31.7% of 75D matte cationic dyeable special-shaped cross-section Polyester DTY; D: 31.7% 75D matte profiled polyester DTY.

[0074] Spinning process: adding 2%-3% matting agent, cooling and cutting, dry blending, spinning assembly filtration, profiled spinning (using the required H-type or four-lobed spinneret holes), cooling and oiling , one roll, two rolls and winding forming, and finally obtain the desired warp.

[0075] The single-comb weave structure and threading mode of the fabric are:

[0076] GB1 comb: 1-0 / 1-2 / / , 2A;

[0077] GB2 comb: 1-1 / 0-0 / / , 2B;

[0078] GB3 comb: 2-3 / 1-0 / / , 1C, 1 empty;

[0079] GB4: comb: 2-3 / 1-0 / / , 1 empty, 1D;

[0080] That is, GB1 comb: 30D polyester FDY; GB2 comb: 40s cotton yarn; GB3 comb: 75D matte cationic dyeable special-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com