Antiskid wear-resistant shoe material and preparation method thereof

A shoe material and anti-skid technology, applied in the direction of shoe soles, footwear, coatings, etc., can solve the problems of affecting the health of operators, poisonous glue, troublesome operation, etc., and achieve the effect of light and comfortable wearing, industrialization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

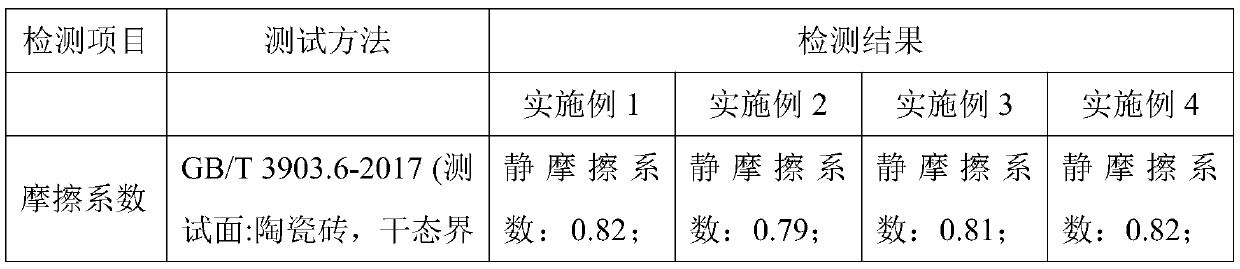

Examples

preparation example Construction

[0040] A preparation method for an anti-slip and wear-resistant shoe material, comprising:

[0041] Preparation steps of anti-slip masterbatch: uniformly mix the anti-slip agent and TPU granules in the formula amount, granulate, and obtain anti-slip masterbatch;

[0042] Preparation steps of wear-resistant masterbatch: uniformly mix the wear-resistant agent and TPU particles in the formula amount, granulate, and obtain wear-resistant masterbatch;

[0043] Mixing and drying step: mix the TPU main material, color masterbatch, anti-slip masterbatch, wear-resistant masterbatch and additives evenly, dry and dehumidify, and obtain the mixed material;

[0044] Casting step: Send the mixed material to the hopper of the casting machine. After the mixed material is heated by the five heating zones, the connecting zone and the screen changing zone of the casting machine, a molten TPU mixture is obtained, and the molten TPU mixture is passed through the casting process. Die extrusion to ...

Embodiment 1

[0055] A non-slip and wear-resistant shoe material, prepared according to the following method:

[0056] Preparation steps of anti-slip masterbatch: use olefin polymer as (ethylene-vinyl acetate-carbonyl (E / VA / CO)) anti-slip agent, and mix the anti-slip agent and thermoplastic TPU particles according to the weight ratio of 40:60 evenly , set the processing temperature of the granulator to 150°C to make anti-slip masterbatch;

[0057] Preparation steps of wear-resistant masterbatch: use silicone resin as wear-resistant agent, mix wear-resistant agent and thermoplastic TPU particles evenly according to the weight ratio of 40:60, set the processing temperature of granulator to 150°C, and make wear-resistant masterbatch ;

[0058] Mixing and drying step: TPU granules, color masterbatch, anti-slip masterbatch, wear-resistant masterbatch, anti-UV agent (2-hydroxy-4-n-octyloxybenzophenone) according to the weight ratio of 80:4:4: 2:2 mixing, stirring evenly; then transported to a d...

Embodiment 2

[0062] A non-slip and wear-resistant shoe material, prepared according to the following method:

[0063] Preparation steps of anti-slip masterbatch: use olefin polymer (ethylene-n-butyl acrylate-carbonyl (E / NBA / CO)) as anti-slip agent, and mix anti-slip agent and thermoplastic TPU particles in a weight ratio of 30:70 Mix evenly, set the processing temperature of the granulator to 140°C, and make anti-slip masterbatch;

[0064] Preparation steps of wear-resistant masterbatch: use polytetrafluoroethylene micropowder as wear-resistant agent, mix wear-resistant agent and thermoplastic TPU particles evenly at a weight ratio of 35:65, set the processing temperature of the granulator to 160°C, and make wear-resistant masterbatch grain;

[0065] Mixing and drying step: TPU granules, color masterbatch, anti-slip masterbatch, wear-resistant masterbatch and anti-UV agent (2-hydroxy-4-n-octyloxybenzophenone) according to the weight ratio of 86:5:4: 3:2 mixing, stirring evenly; then conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com