Blended color yarn spun by pure spinning or blended spinning of corn fiber and its production method

A corn fiber and production method technology, applied in the field of mixed-color spinning yarn, can solve the problems of inability to adapt to individual consumption, single color structure of the yarn, etc., and achieve the effects of smooth cloth surface, light and comfortable wearing, and good drape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

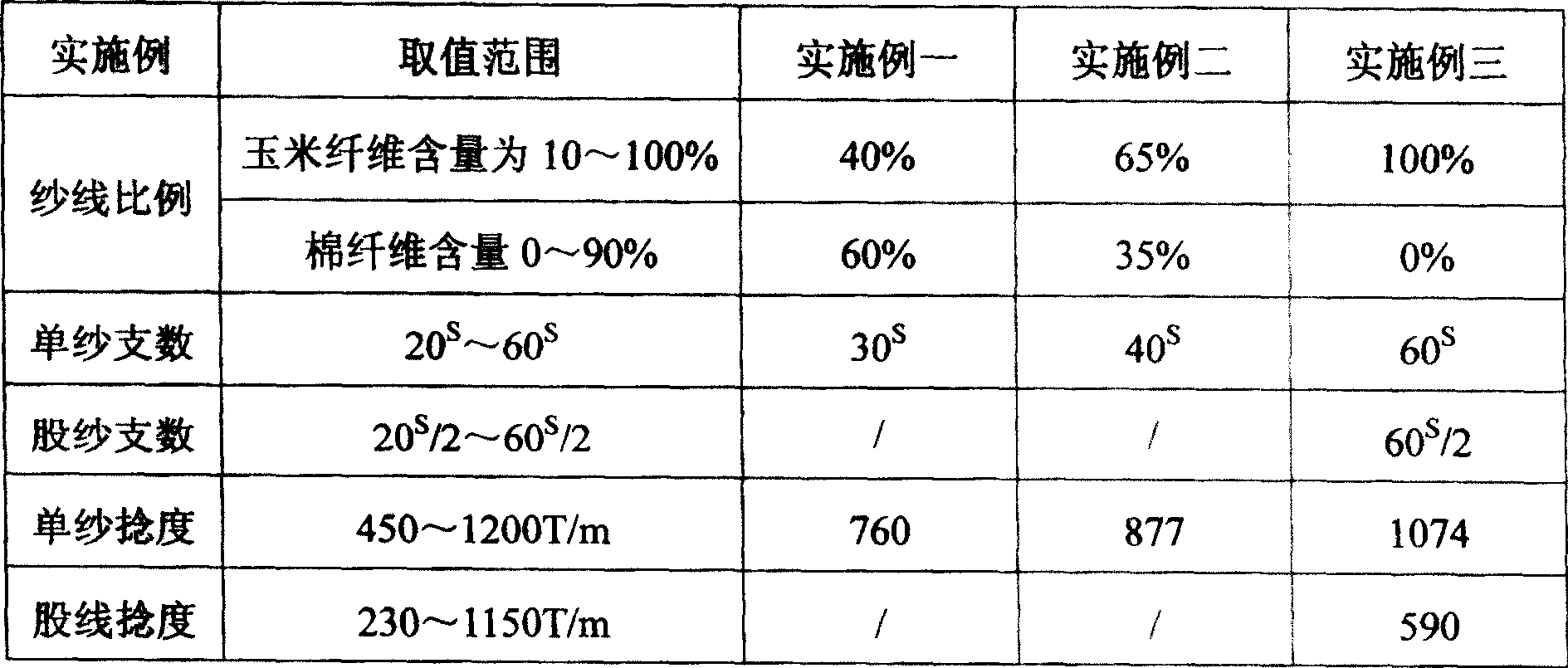

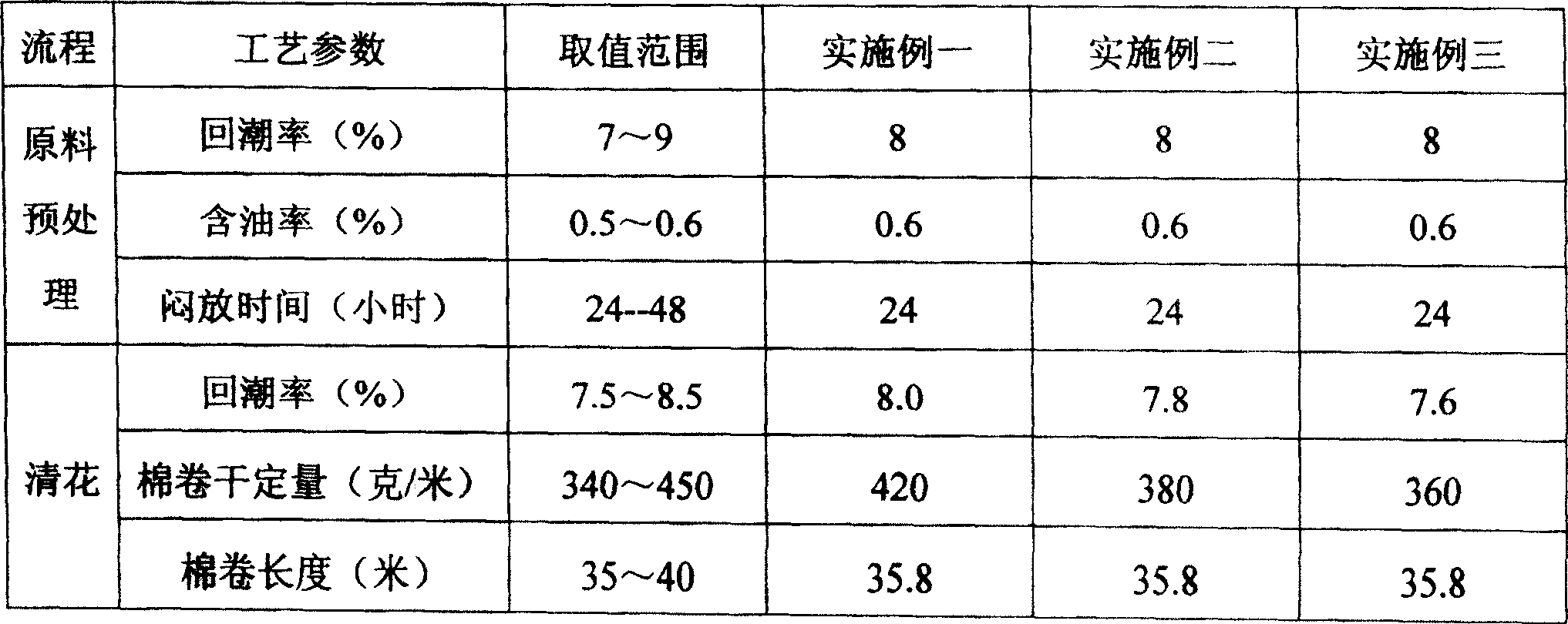

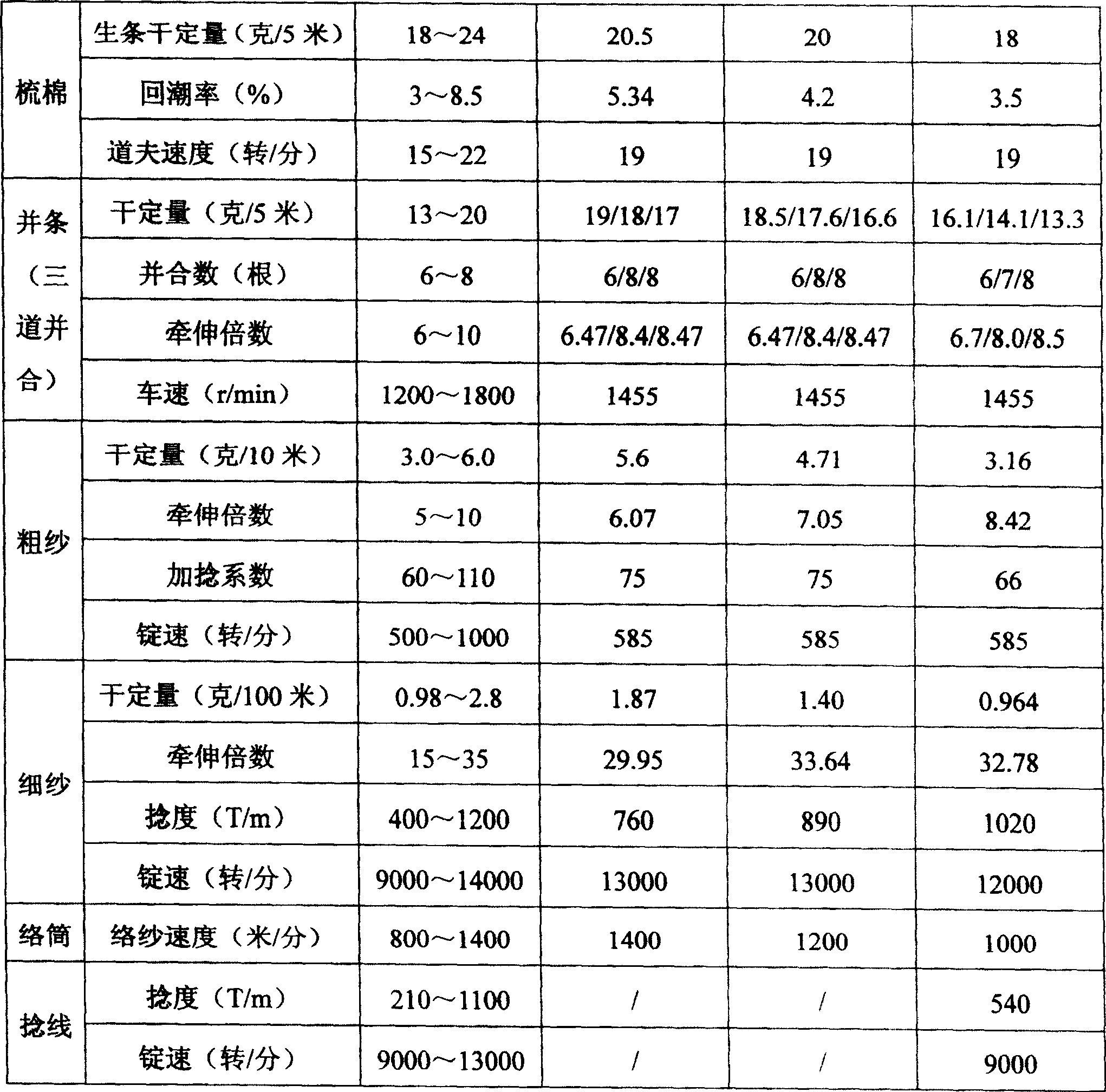

[0023] The present invention is further described below in conjunction with three embodiments. Embodiment one, two, three are all through corn fiber pre-opening, dyeing (pure cotton natural color combed cotton web dyeing, corn fiber dyeing), dyed corn fiber spinnability treatment, weighing, mixing, cleaning, combing Cotton, first parallel, two parallel, three parallel, roving, spun yarn, winding process. Wherein the third embodiment is after the winding process, and then through the twisting and winding process of the combined twisting machine. The specific process parameters are listed in the following table:

[0024] Example parameter table of corn fiber melange spinning yarn:

[0025]

[0026] Corn fiber mixed color spinning yarn embodiment process design table:

[0027]

[0028]

[0029] The main technical measures when the automatic bobbin winder (Auto Coner-338) is wound into a conical bobbin: a. The speed of the grooved drum is reduced to 1000 m / min; b. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com