Modular staircase system

a modular, staircase technology, applied in the direction of stairway-like structures, building construction, construction, etc., can solve the problems of high labor intensity, high cost of materials, and high cost of materials in even the most basic staircase systems, and achieves high design tolerances, high design efficiency, and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

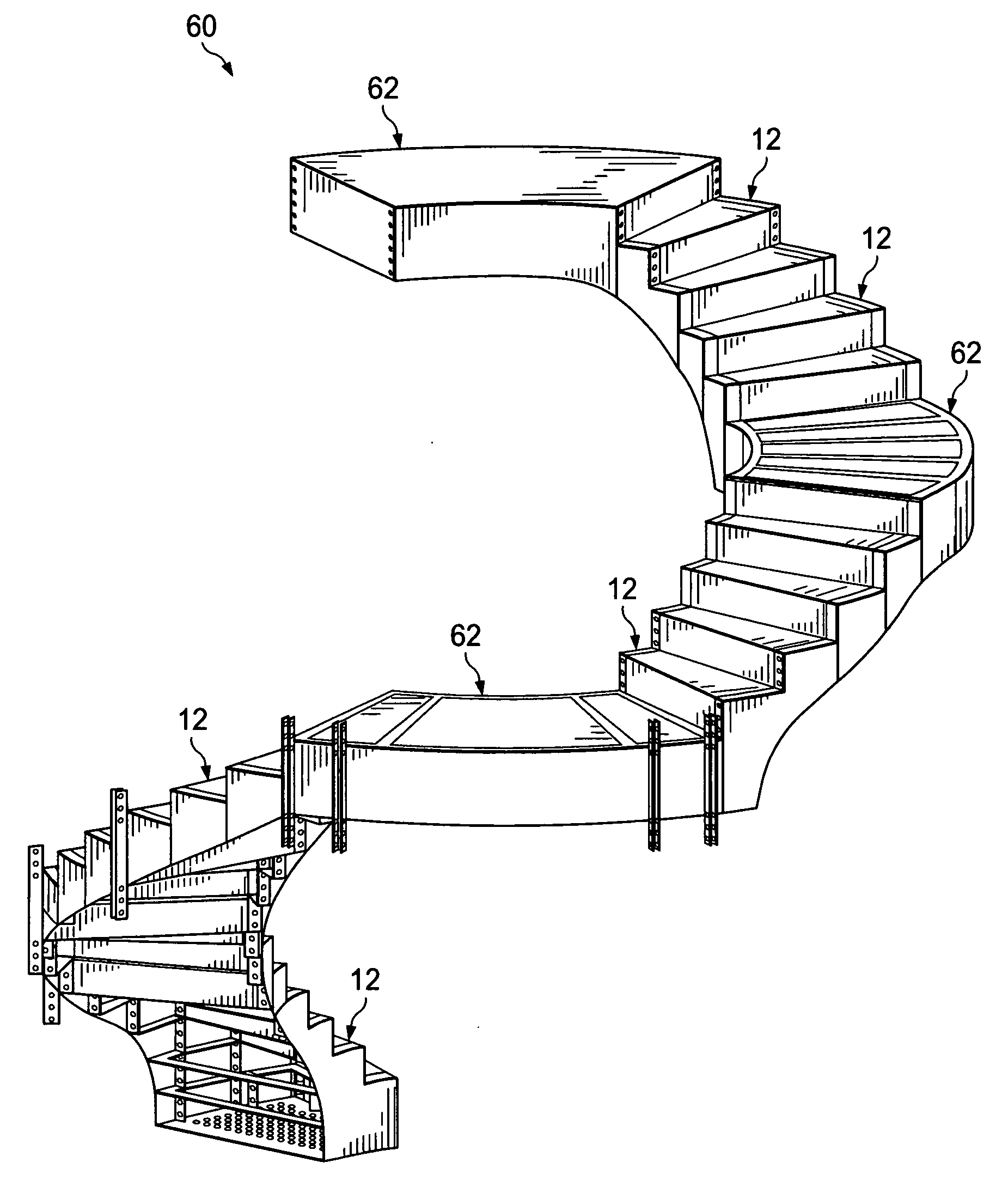

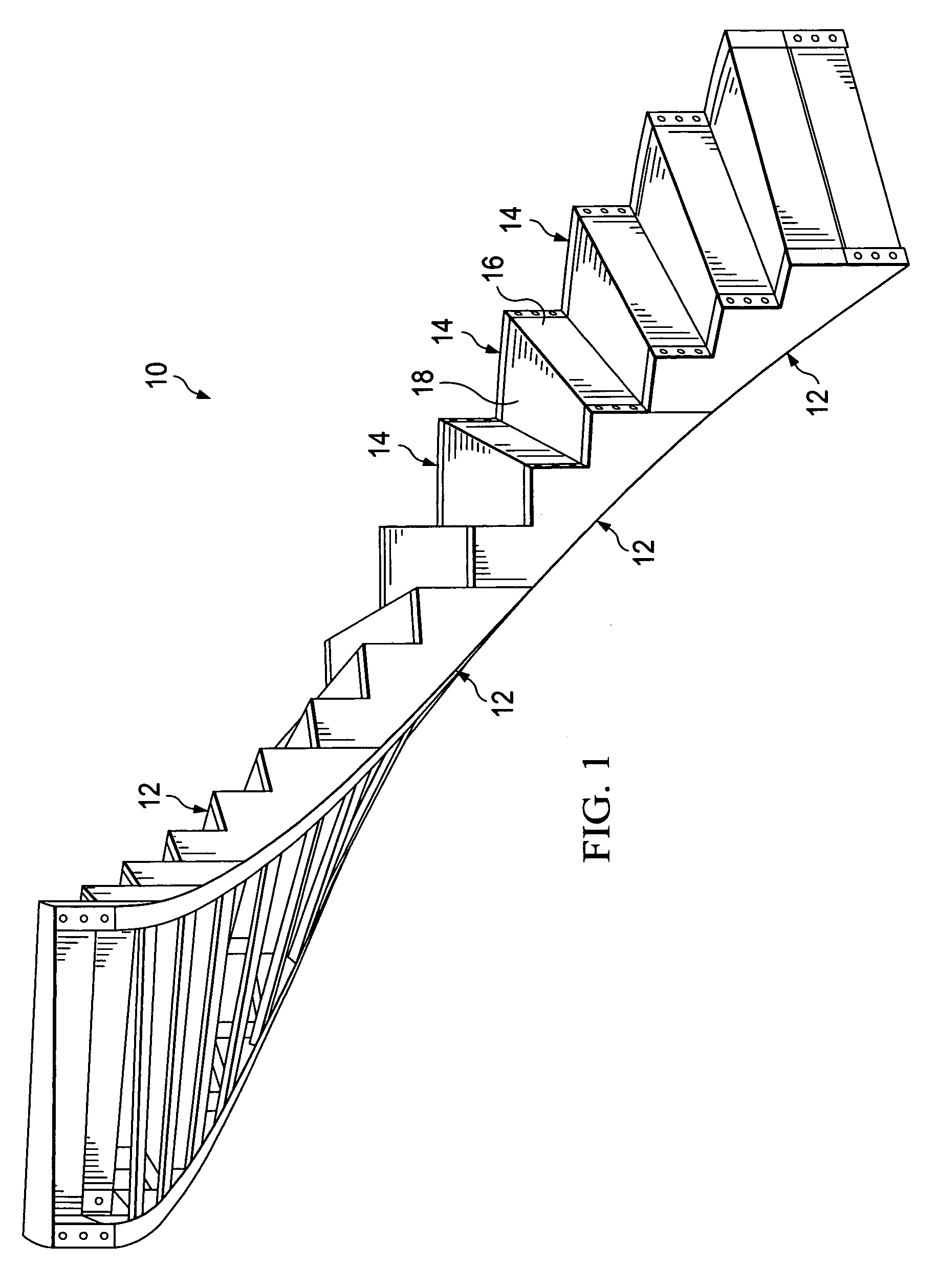

[0015]Referring now to FIG. 1, there is generally shown at 10 a modular staircase system according to one preferred embodiment of the present invention. System 10 is seen to be comprised of a plurality of stair sections generally shown at 12 assembled and secured to one another to create a floating staircase with continuous ascending steps generally shown at 14. Each step 14 has a riser portion 16 and a tread portion 18, as shown. In this preferred embodiment, each stair section 12 has three steps 14, although more or less steps could be included in the stair section 12 as desired and as a function of the overall staircase design. Staircase system 10 derives technical advantages in that a complex staircase system can be achieved utilizing modular stair sections, each section being tooled to very tight tolerances, configured to support great weight including premium stair materials including cast stone, marble and granite, as well as itself, at a relatively moderate cost.

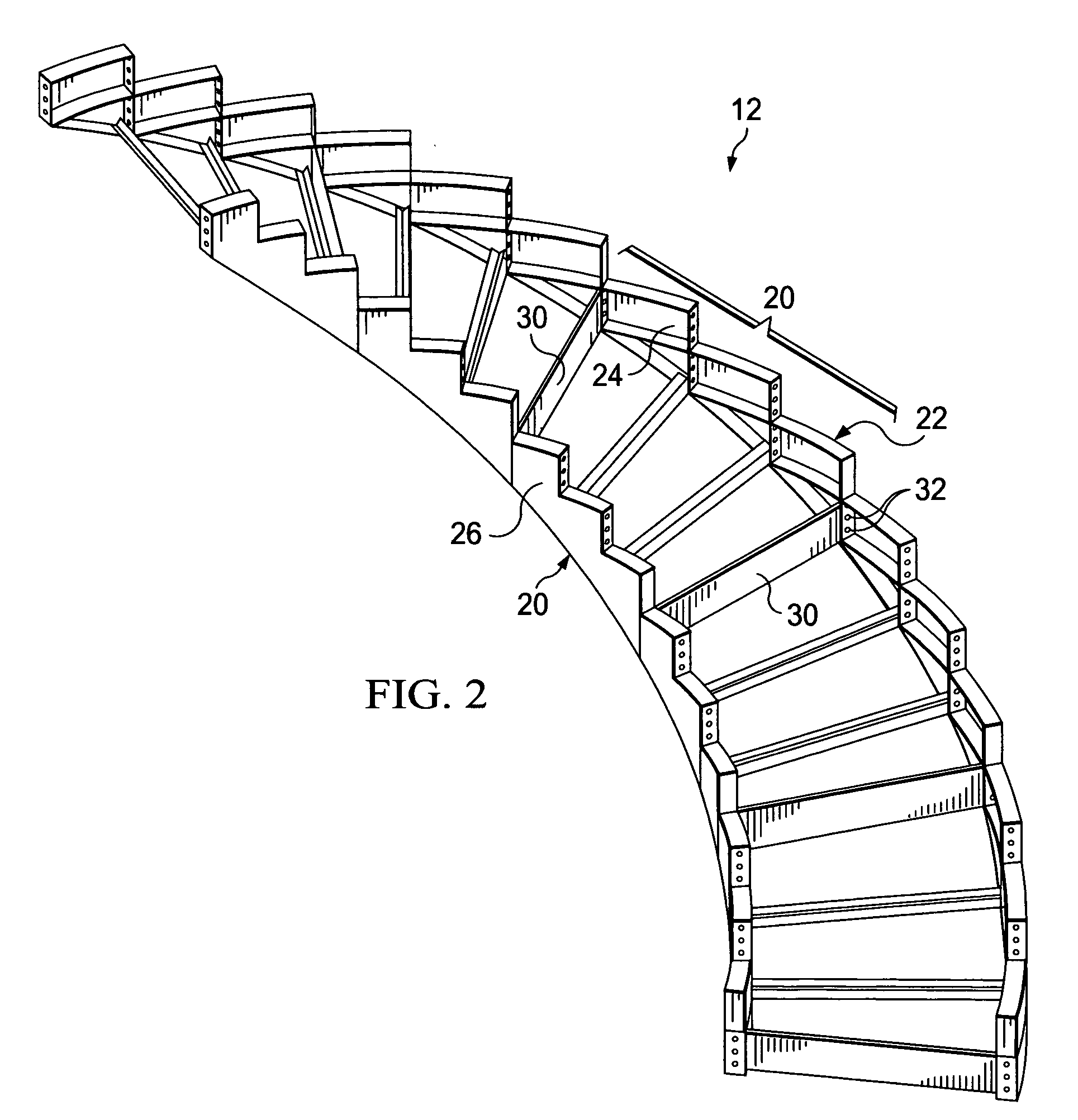

[0016]Referr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com