A medium voltage vacuum contactor

A vacuum contactor and medium-voltage technology, which is applied in high-voltage air circuit breakers, stepless relays, high-voltage/high-current switches, etc., can solve the problems of mutual positioning defects of contacts, affecting the electrical life of contactors, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

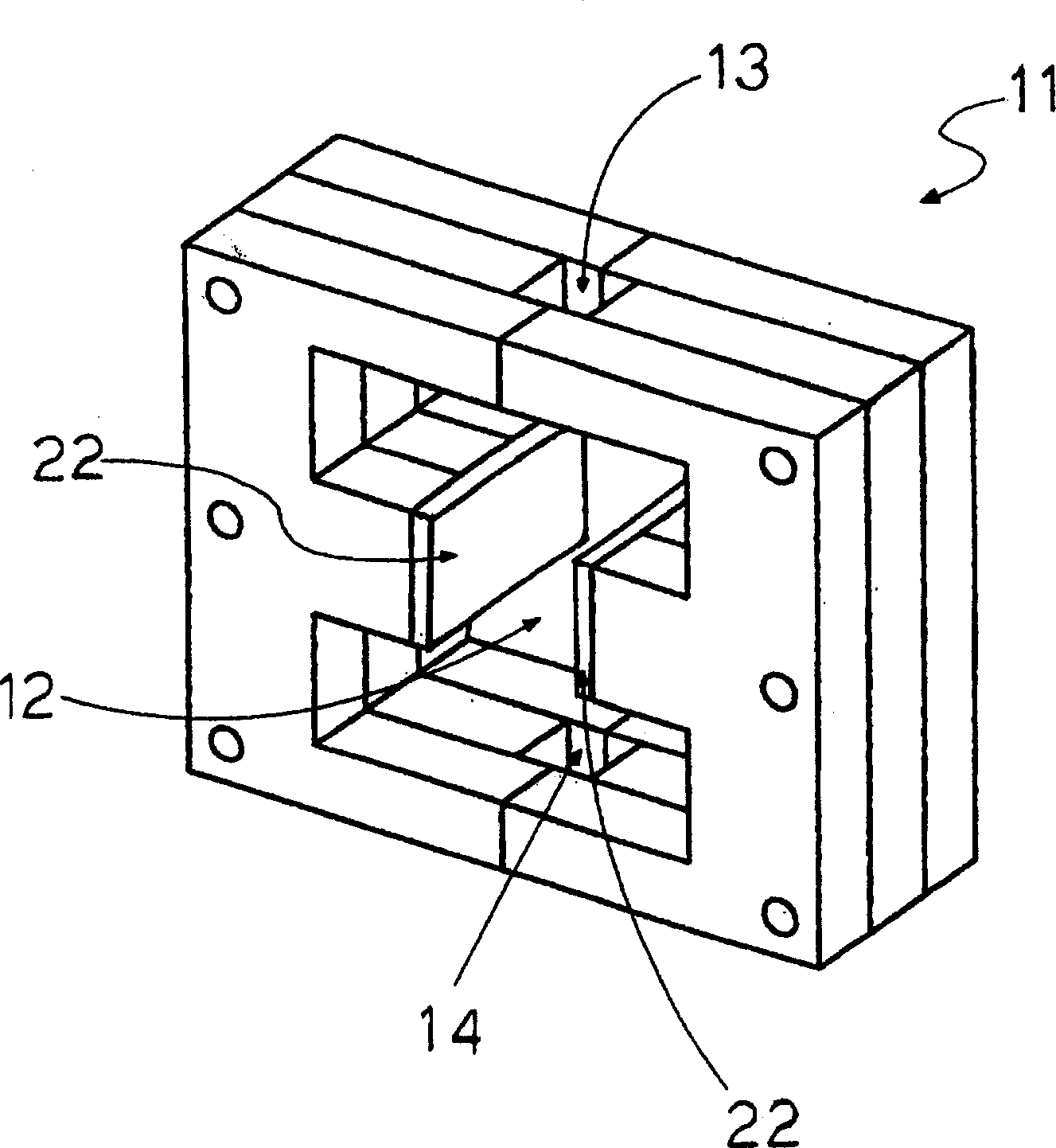

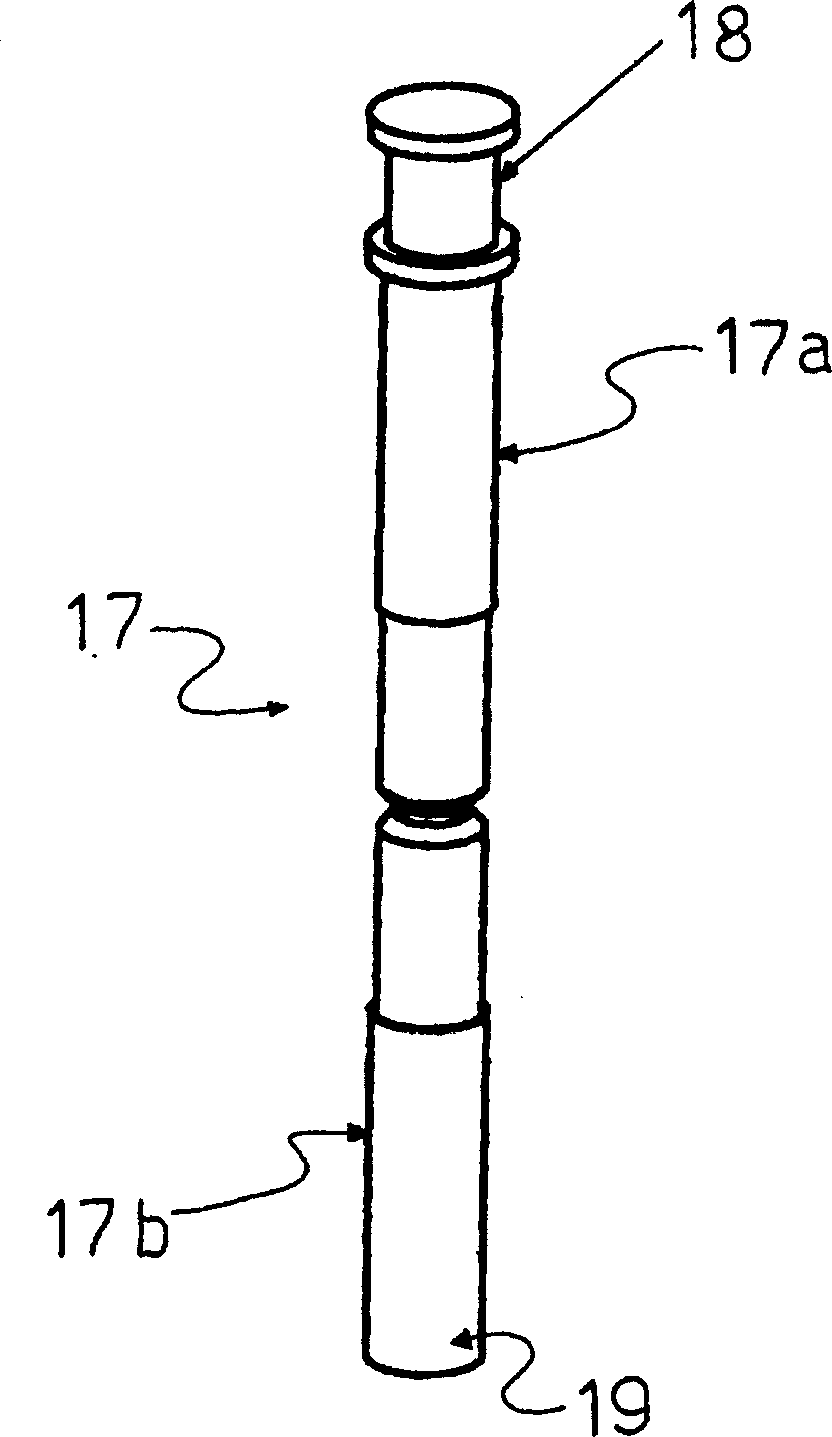

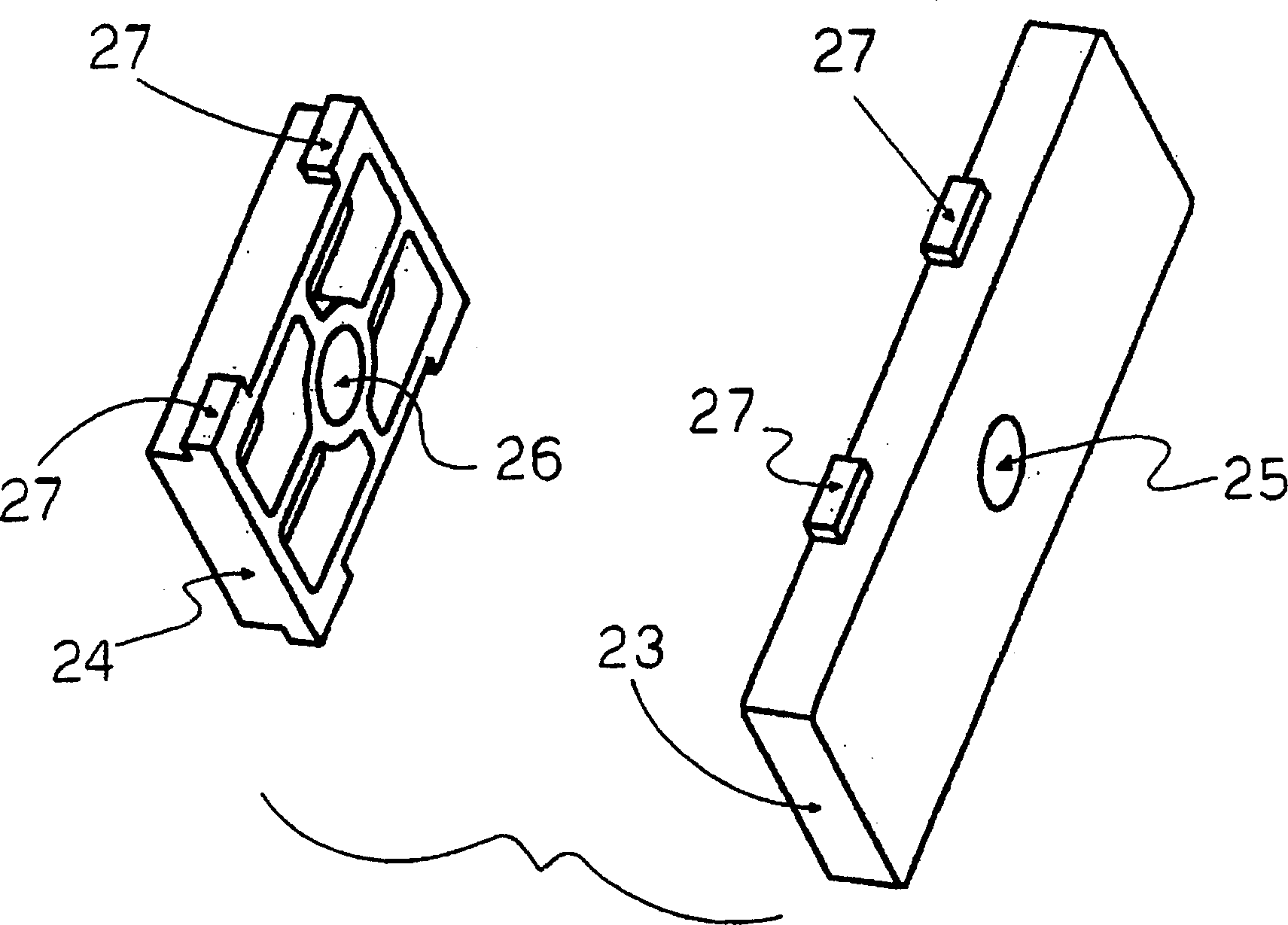

[0018] Figure 5 with Image 6 A three-pole medium voltage vacuum contactor is shown, generally indicated by reference numeral 100 . Each pole of the contactor 100 has a vacuum shell 1, such as a vacuum cover or a vacuum spherical shell, which contains a fixed contact 2 and a corresponding movable contact 3, for the sake of simplicity, only one pole is given A diagram is shown; the possible structural implementation of the vacuum housing 1 and the way of maintaining the vacuum therein are well known in the art, and thus will not be described in detail. According to a well-known solution, each movable contact 3 is connected to an actuating lever 4 to which is associated a contact compression spring 5 .

[0019] The contactor 100 also includes an actuating device, which is operatively connected to the movable contact 3 and provides for moving the movable contact 3 and allowing the movable contact 3 to operate relative to the corresponding fixed contact. Point 2 Electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com