Hermetic compressor

一种压缩机、密闭型的技术,应用在压缩机、制冷机、机械设备等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

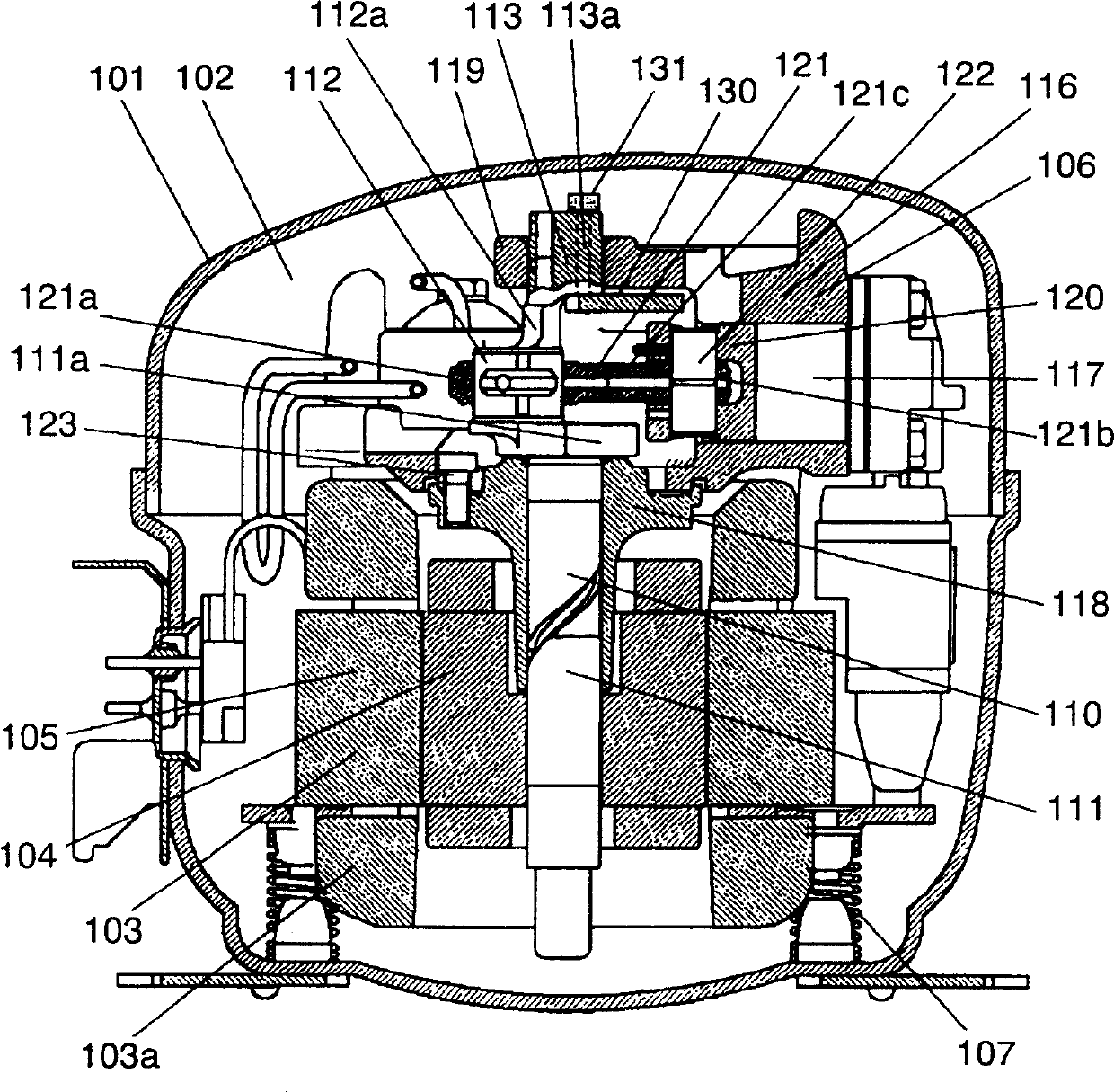

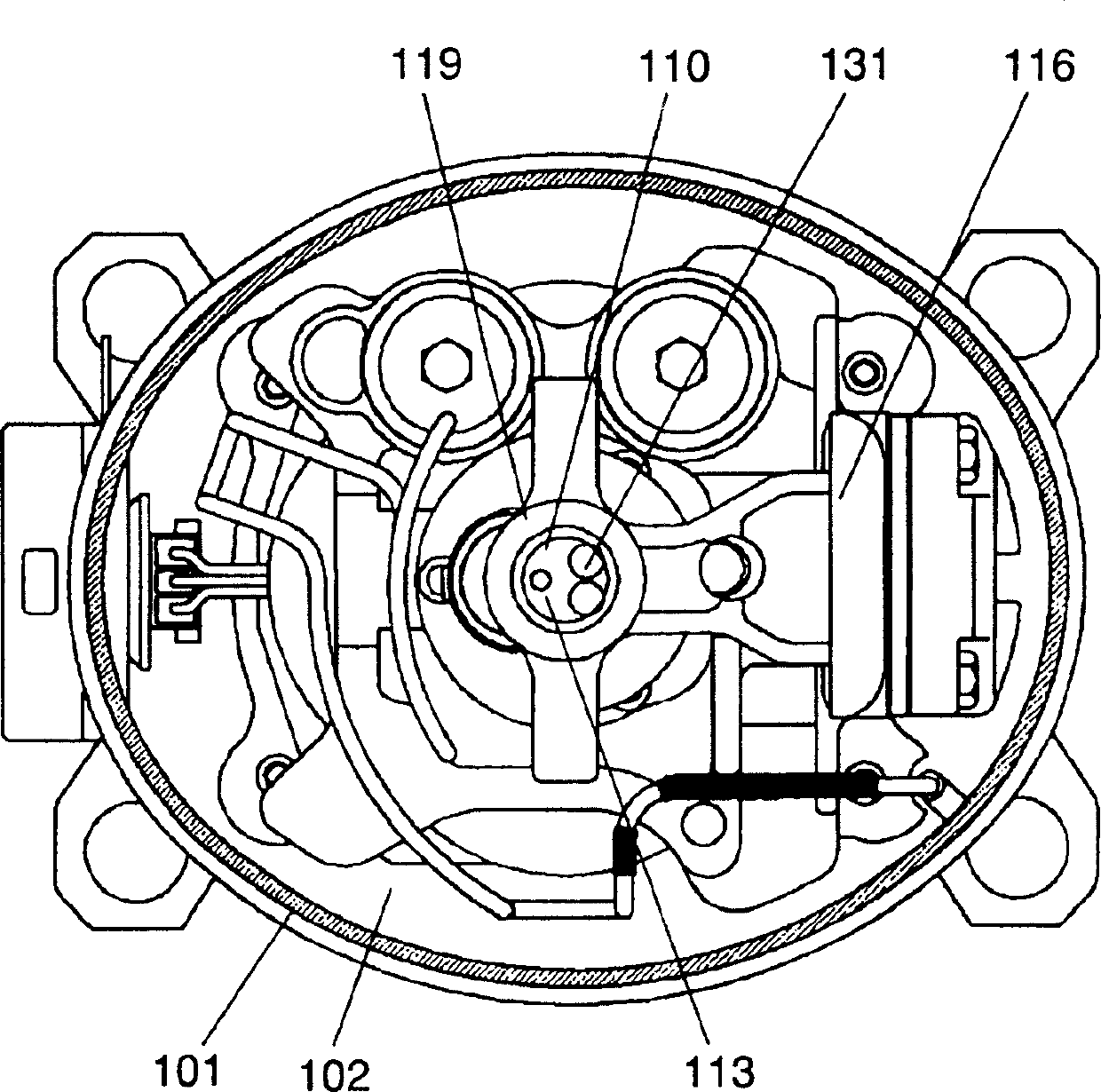

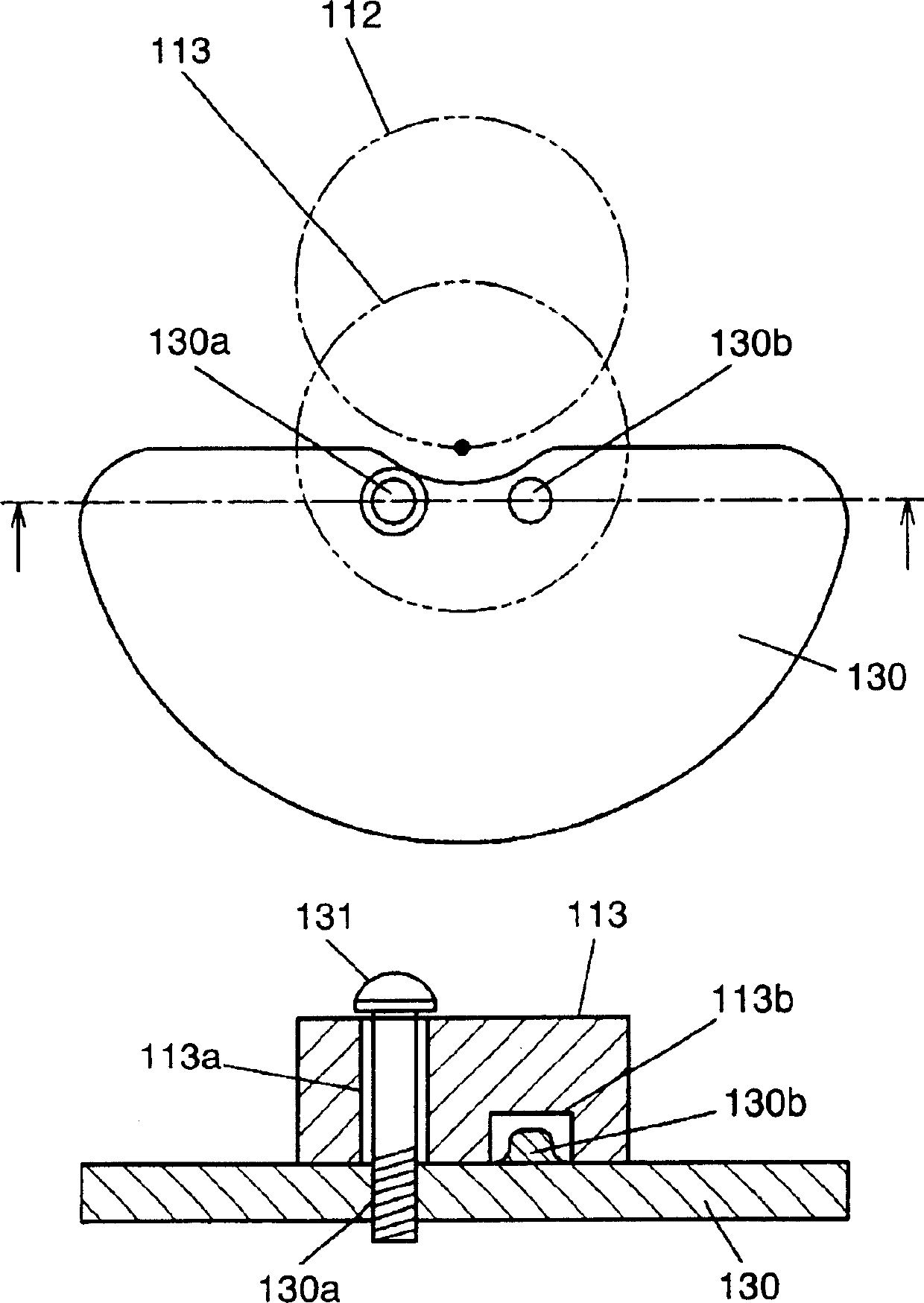

[0025] Fig. 1 is a vertical sectional view of a hermetic compressor according to a preferred embodiment 1 of the present invention. Fig. 2 is a horizontal sectional view of this embodiment. Fig. 3 is an expanded view of the main body of this embodiment. Figure 4 is a perspective view of the body of this embodiment. Fig. 5 is a sectional view of the main body of this embodiment.

[0026] In FIGS. 1 to 5 , the airtight container 101 is filled with refrigerant 102 . The electric element 105 is composed of a stator 103 and a rotor 104 including a coil portion 103a. The compression element 106 driven by the electric element 105 and the electric element 105 are elastically held in the airtight container 101 by the suspension spring 107 .

[0027] The shaft 110 has (i) a main shaft portion 111 in which the rotor 104 is pressed and fixed, (ii) an eccentric shaft portion 112 formed with a certain degree of eccentricity with respect to the main shaft portion 111, (iii) an eccentric ...

Embodiment 2

[0047] Fig. 6 is a perspective view of a main body of a hermetic compressor according to a preferred embodiment 2 of the present invention. 7 is a sectional view of a main body of a hermetic compressor according to Embodiment 2. FIG.

[0048] The basic structure of the hermetic compressor in this preferred embodiment 2 is the same as that indicated in FIGS. 1 to 5 . Also, for the same structures as some structures in Preferred Embodiment 1, the same symbols will be used, and detailed explanations thereof will be omitted.

[0049] In FIGS. 6 and 7 , the first counterweight 130 of the hermetic compressor is fixed to the subshaft portion 113 by pressing with rivets 151 .

[0050] An explanation will be given below of the method of assembling the hermetic compressor constructed as described above.

[0051] The piston 120 is integrated with the coupling mechanism 121 by means of a piston pin 122 and then inserted into the compression chamber 117 of the cylinder block 116 . After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com