Anti-glare film, manufacturing method of anti-glare film, anti glaring anti-reflection film, polarizing plate, and display

An anti-glare and glare technology, applied in the direction of polarizing element, diffusing element, transportation and packaging, etc., can solve the problem of not achieving anti-glare or anti-reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0478] [Production of cellulose ester film 1]

[0479] A cellulose ester solution (dope) was prepared using the following cellulose ester, plasticizer, ultraviolet absorber, fine particles, and solvent, and a cellulose ester film 1 was produced by a solution casting film-forming method.

[0480] Cellulose ester (cellulose triacetate, acetyl substitution degree is 2.9, Mn=160000, Mw / Mn=1.8) 100kg

[0481] Plasticizer (trimethylolpropane tribenzoate) 5kg

[0482] Plasticizer (ethyl phthalate · ethyl glycolate) 5kg

[0483] Ultraviolet absorber (Chiubin 109, manufactured by Chiba Specia Litei-Chemicals Co., Ltd.) 1.0 kg

[0484] Ultraviolet absorber (Chiubin 171, manufactured by Chiba Specia Litei-Chemicals Co., Ltd.) 1.0 kg

[0485] Microparticles (Aerosil R972V, manufactured by Japan Aerosil Co., Ltd.) 0.3kg

[0486] Solvent (ethyl acetate) 440kg

[0487] Solvent (ethanol) 110kg

[0488] A cellulose ester solution (dope) is prepared using the above-mentioned cellulose est...

Embodiment 2

[0631] In the seamless resin printing plate produced in Example 1, except that the laser-engraved image was changed to a height of 0.3 μm of the ink adhesion part (convex part) after printing, a size of the convex part (long side) of 15 μm, and a distance between the convex parts A resin printing plate was produced in the same manner except for the uneven structure of 30 μm.

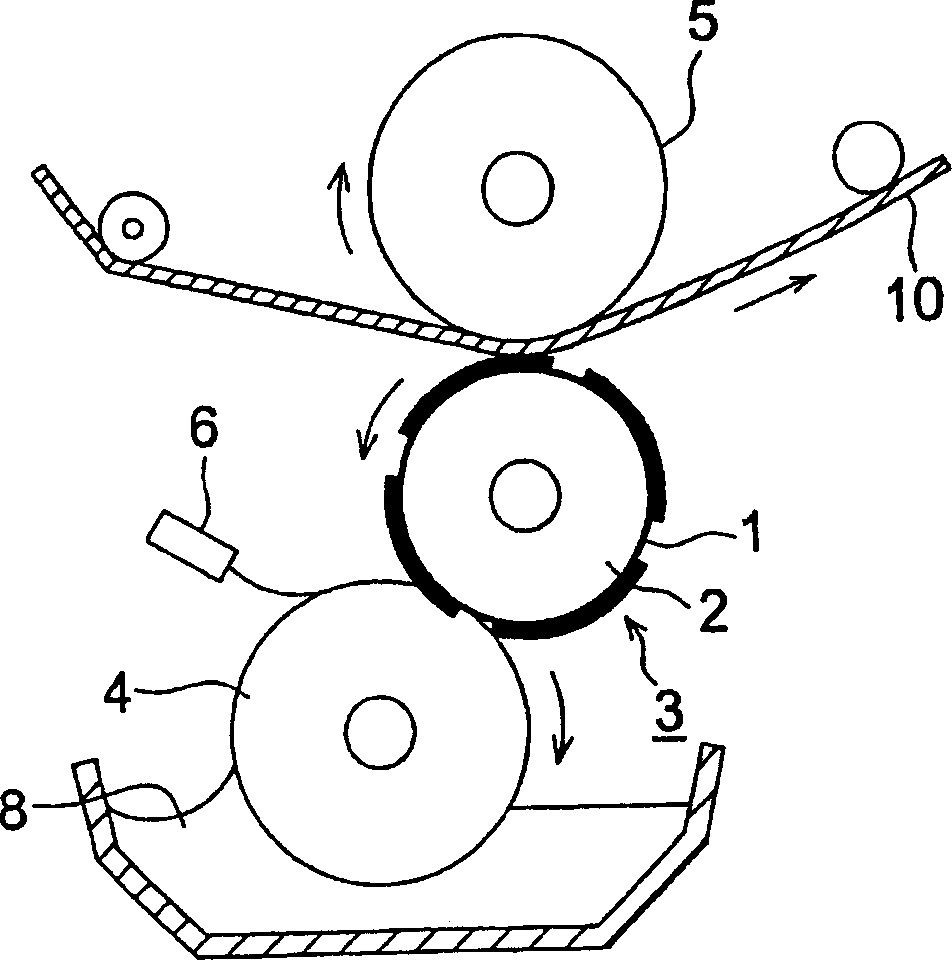

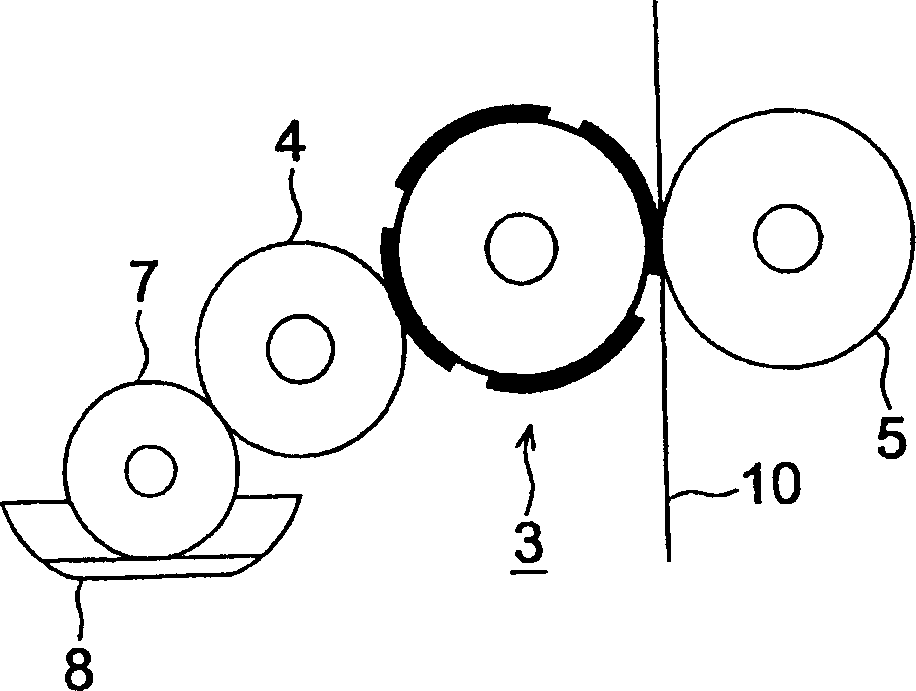

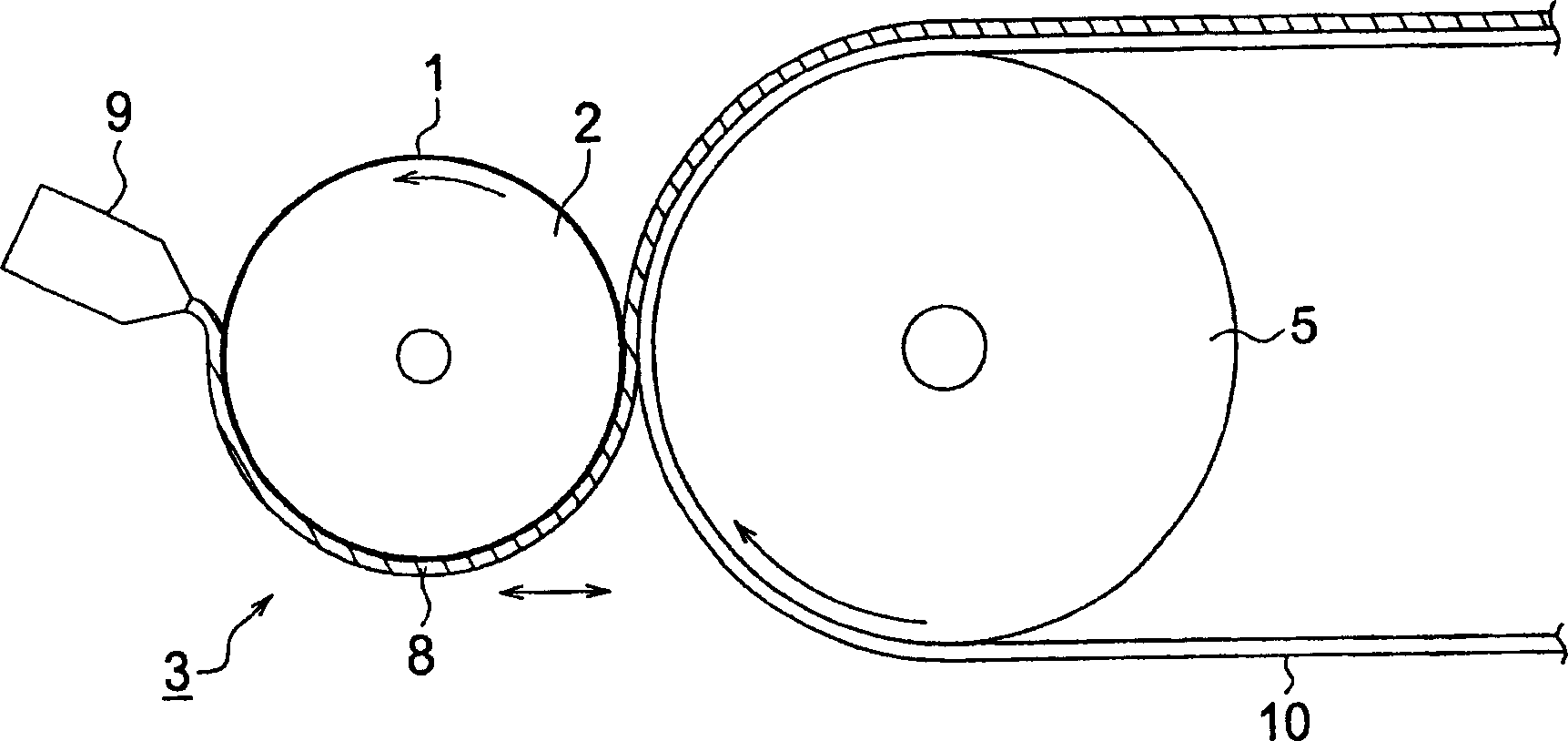

[0632]Next, instead of using Figure 8 In the manufacturing apparatus of (b), the flexographic printing part B uses the resin printing plate used in Example 1 (the diameter of the resin printing plate is 800 mm, and the rubber hardness is 50 degrees), and the flexographic printing part C uses the resin printing plate produced above, and Except the method of performing flexographic printing twice, it carried out similarly to Example 1, and produced the antiglare hard coat film. At this time, the diameter of the resin printing plate of the flexographic printing part C was 500 mm, and the rubber hardness w...

Embodiment 3

[0636] In embodiment 1, in the composition of anti-glare layer ink liquid 1, the amount of methyl ethyl ketone is adjusted to make the viscosity of ink liquid change to 0.05, 0.1, 1, 5, 8, 10, 11Pa·s, in order to prevent glare Under the conditions of the antireflection film 7, when the uneven structure was formed by flexographic printing, the viscosity of the ink liquid was in the range of 0.1 to 10 Pa·s, and it was confirmed that the desired uneven structure was formed. On the other hand, the height of the convex portion of the ink liquid of 0.05 Pa·s is reduced by 30%, and the size is increased by 40%, so it is difficult to obtain the desired concave-convex structure. In addition, it can be seen that the ink liquid of 11 Pa·s is slightly lacking in the convex portion, and the transferability of the ink is poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com