Efficient air purification equipment for paint spray booth

A technology for air purification equipment and spray booths, which is applied in spray booths, mechanical equipment, climate change adaptation, etc., can solve the problems of time-consuming and laborious installation and disassembly of filter layers, reduced permeability of adsorption cotton, and reduced purification efficiency. The effect of convenient movement, simple structure, quick and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments. Based on embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative work, are within the scope of protection of the present invention.

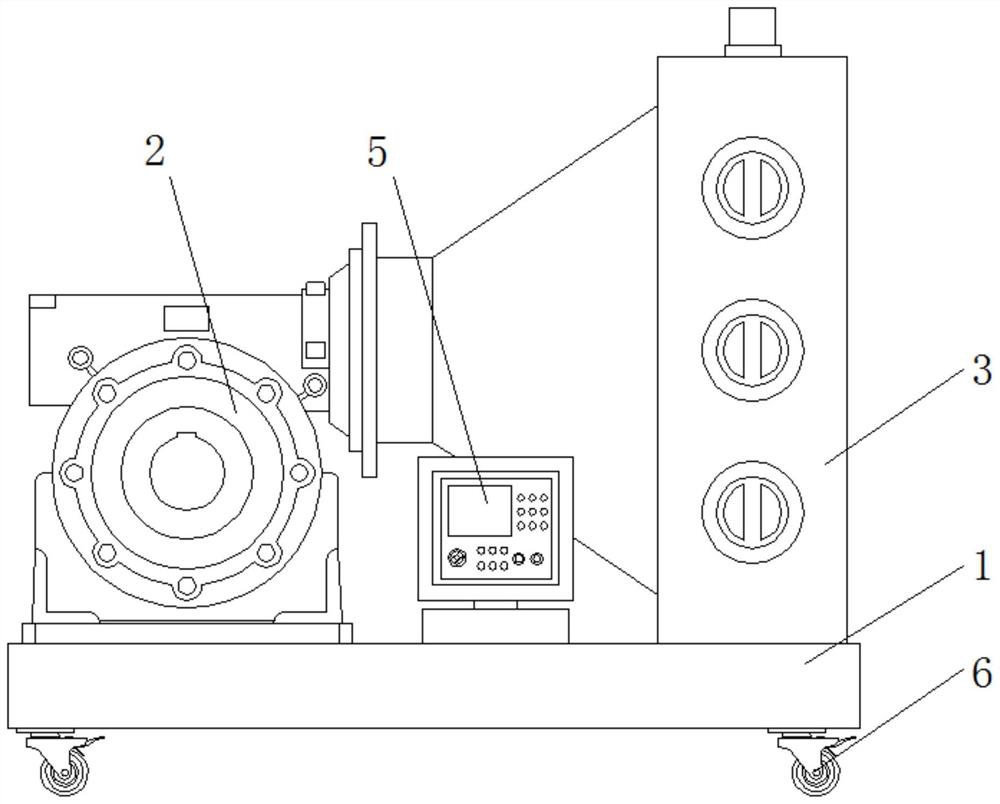

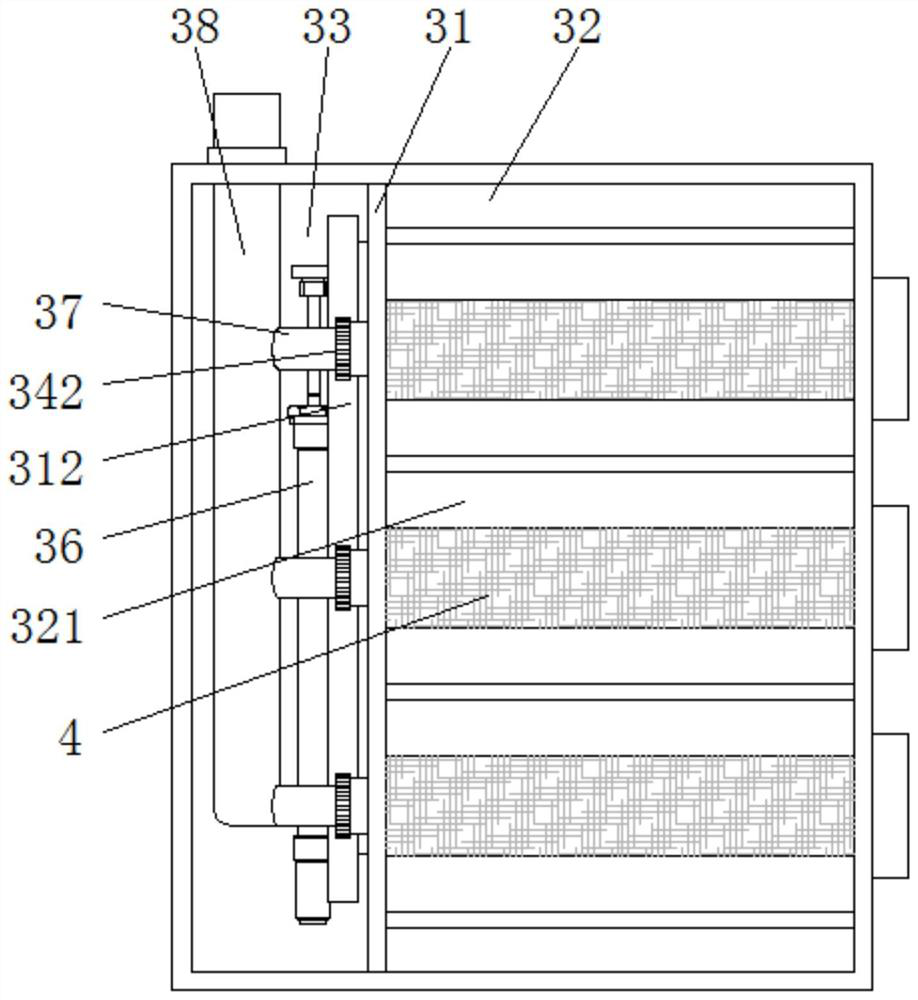

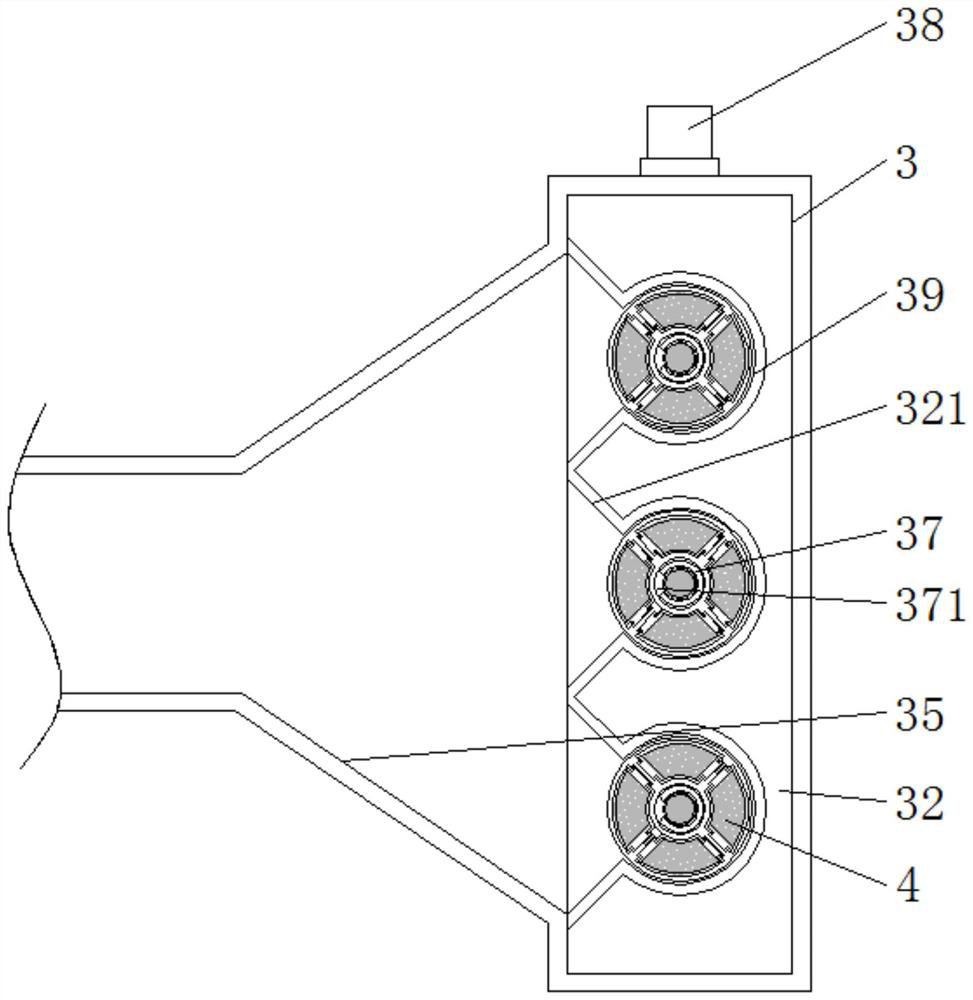

[0029] See Figure 1-9

[0030] At the same time, the contents not described in detail in this specification belong to the prior art known to those skilled in the art.

[0031] When used, through the display control panel 5 to start the centrifugal fan 2, centrifugal fan 2 to absorb the gas inside the paint room, and then through the centrifugal fan 2 to absorb the gas through the outlet pipe 38 into the conical intake cylinder 321, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com