Combined doctor blade chamber

一种刮墨刀、组合的技术,应用在刮墨刀腔系统,刮墨刀腔系统的应用,制备包括两个组合型材的组合刮墨刀腔领域,能够解决增强、渗透到刮墨刀和夹轨之间以及刮墨刀和刮墨刀腔之间、油墨不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

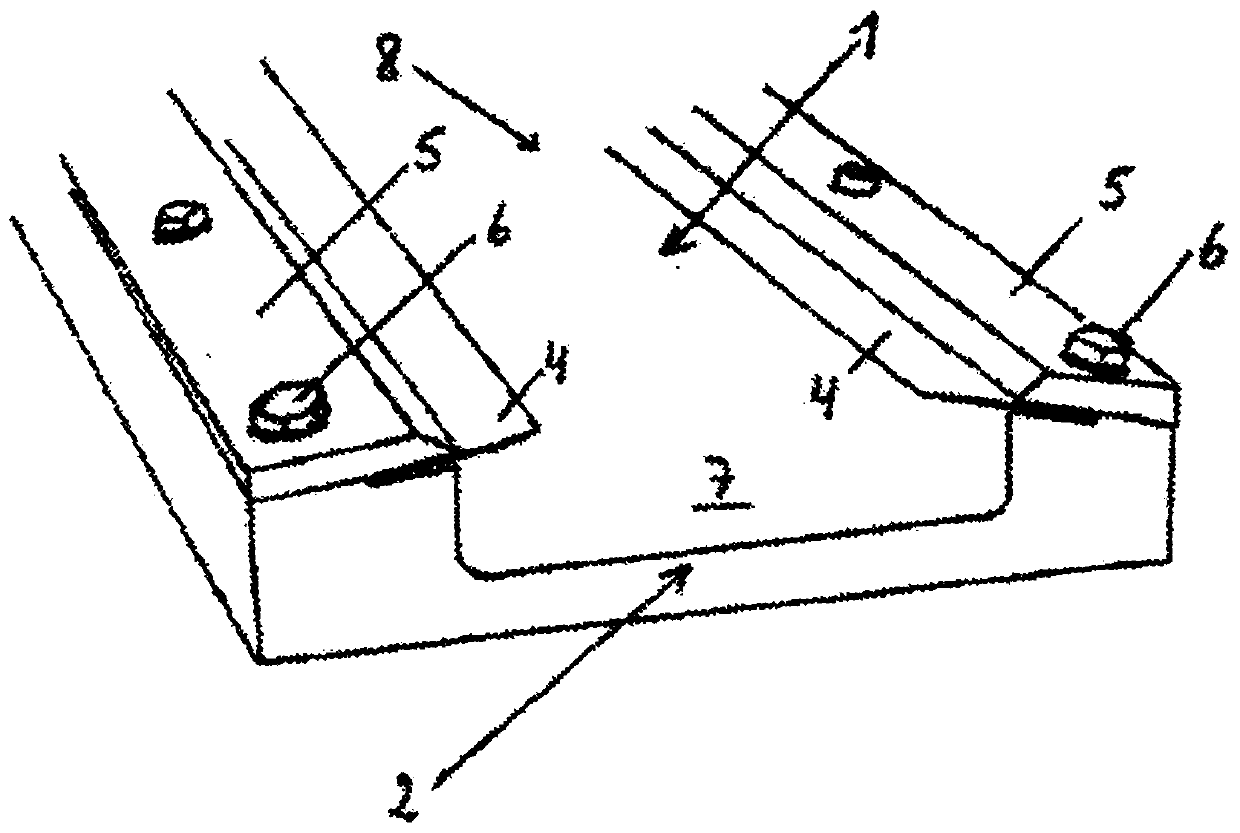

[0121] figure 1 It is a perspective view of a part of the doctor blade chamber 1 according to the prior art. For illustration, the doctor blade chamber 1 is shown without an end cap, which normally seals the end 2 so that ink does not flow out of the doctor blade chamber 1. The doctor blade 4 sandwiched between the clamping rail 5 and the doctor blade chamber 1 is mounted on the doctor blade chamber 1. Screw the clamp rail 5 to the doctor blade chamber 1 with bolts 6. The doctor blade chamber 1 and the doctor blade 4 together constitute the wall of the ink 7. When the doctor blade cavity 1 is aligned with the transfer roller, the open channel 8 between the doctor blades 4 is closed.

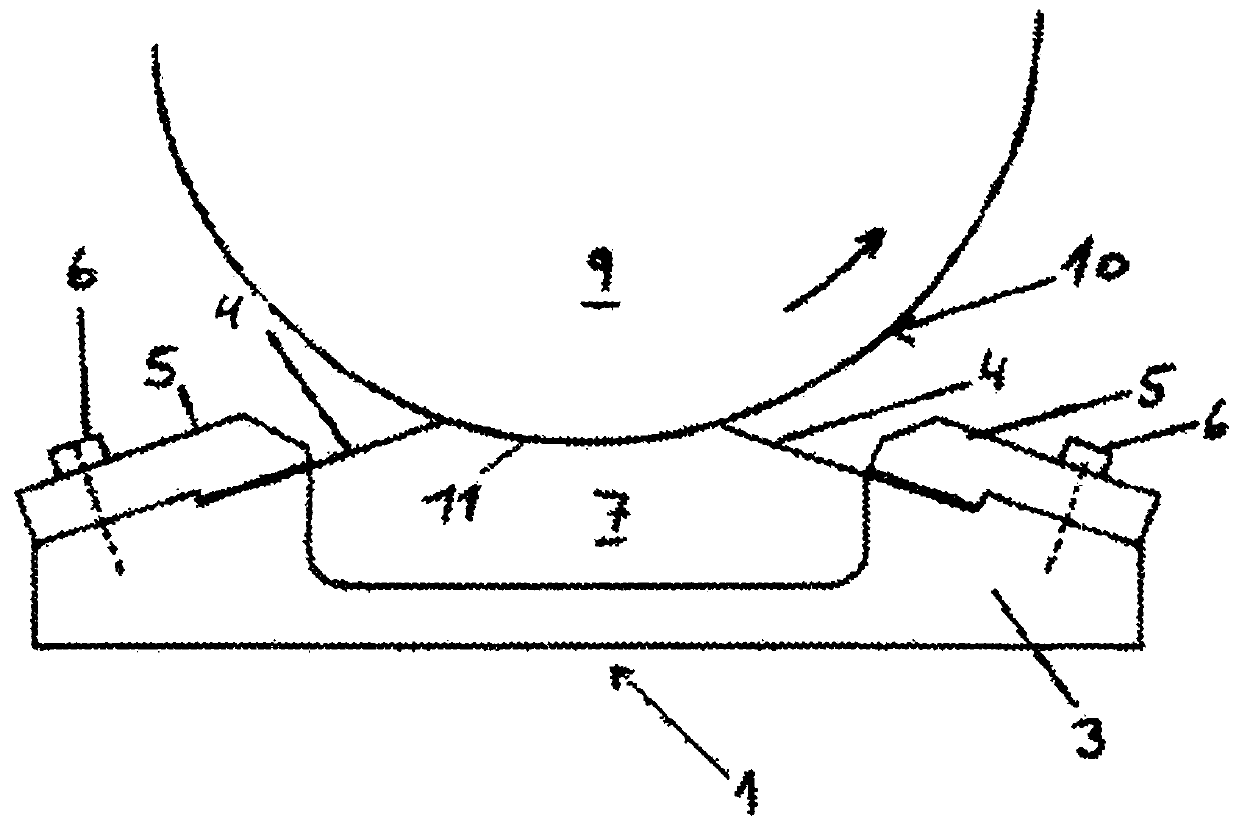

[0122] figure 2 A cross-sectional view of the doctor blade chamber 1 and the transfer roller 9 according to the prior art is shown. When the two doctor blades 4 contact the roller surface 10, the ink chamber 7 is substantially closed. When the ink transfer roller 9 rotates along its axis, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com