Method for printing substrate using anilox roll, ilox roll for printing method and printing apparatus

A technology of printing equipment and anilox rollers, which is applied in the field of use and formation of anilox rollers, can solve problems such as time-consuming and difficult, and achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

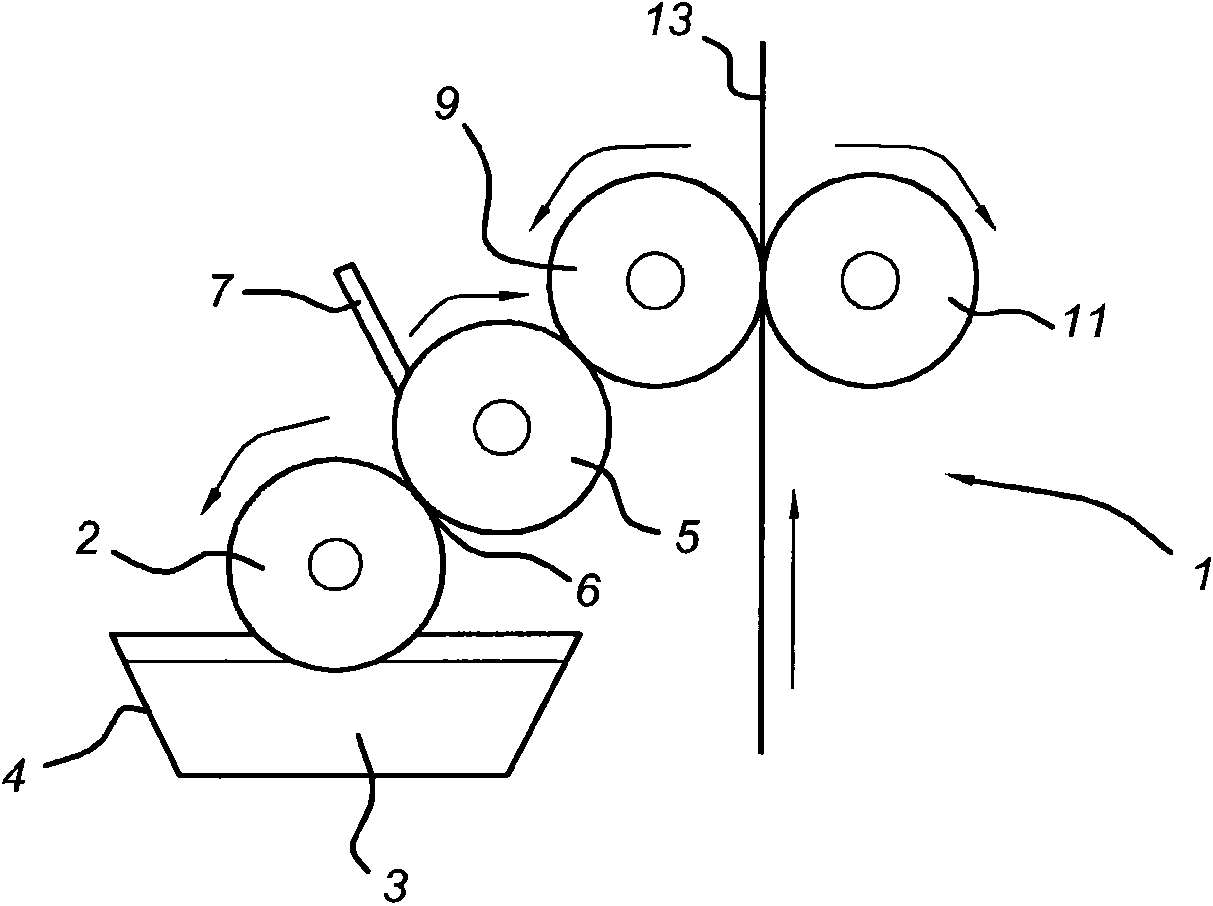

[0090] figure 1 A partial side view of a printing apparatus 1 as used in a flexographic printing process is shown. The printing device 1 may be part of a series of printing devices that print using different inks or various techniques. A person skilled in the art will be familiar with different embodiments of the printing device 1 . The printing apparatus 1 is adapted and arranged to apply ink to a substrate in a desired pattern.

[0091] In the illustrated embodiment, the printing device 1 comprises a dipping roller 2 partially immersed in an ink fountain 4 containing a quantity of ink 3 . The impregnation roll is rotatable and its outer surface may be rubber-coated.

[0092] A rotatable metering roll or anilox roll 5 is positioned beside the impregnation roll 2, wherein the longitudinal axis of the anilox roll 5 is parallel to the longitudinal axis of the impregnation roll. This results in the formation of contact points or contact lines 6 . The rollers 2 and 5 are in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com