Patents

Literature

76results about How to "Improve the running force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

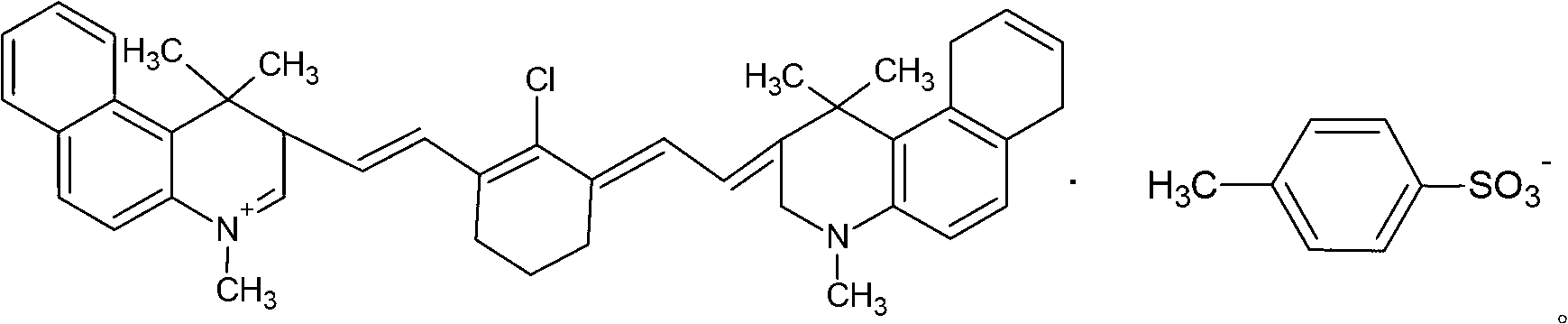

Image-forming composition for heat-sensitive CTP image base, acid generating source for the composition and preparation thereof

InactiveCN1603956AIncreased sensitivityHigh resolutionPhotosensitive material processingForme preparationHeat sensitiveCross linker

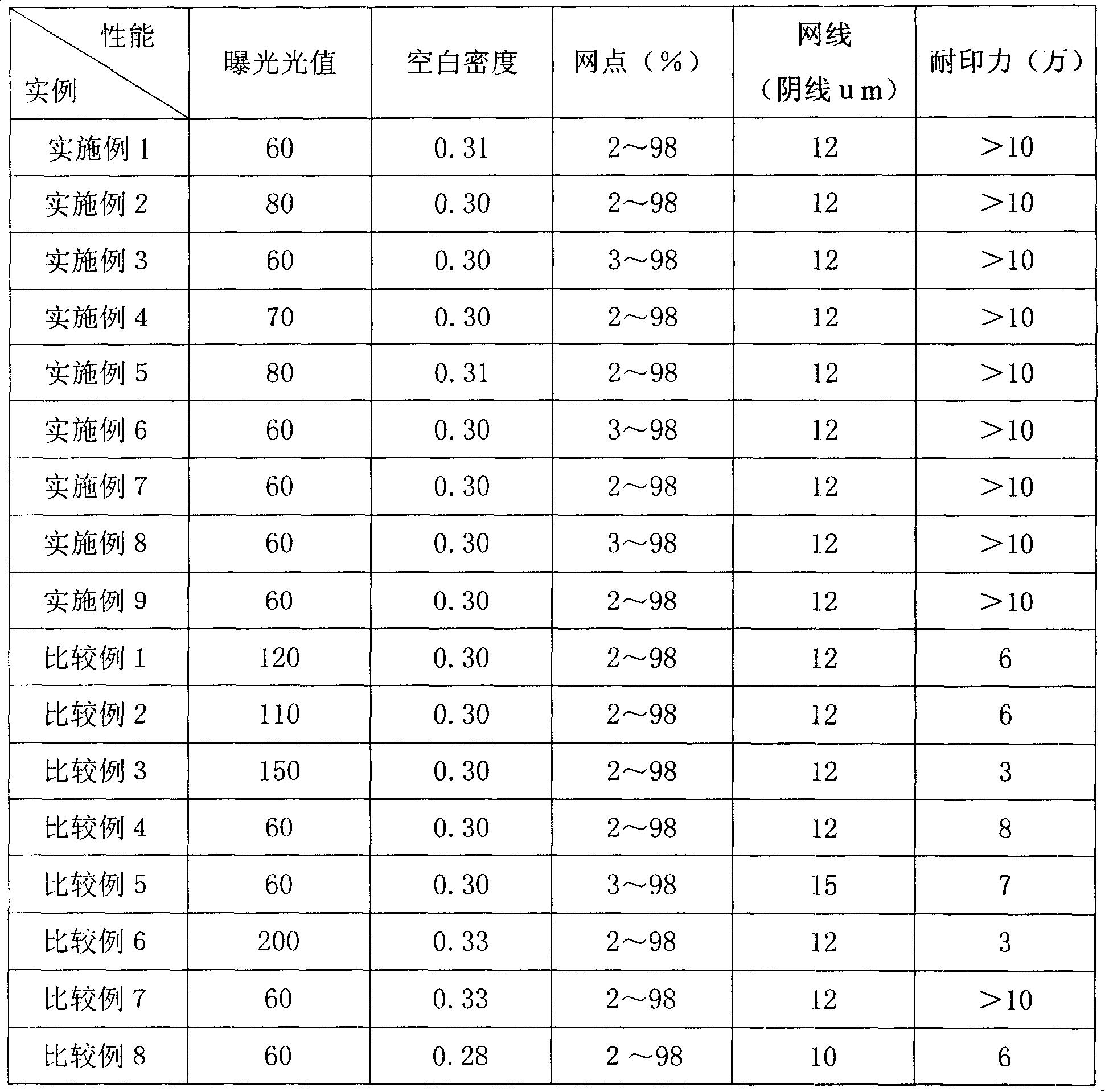

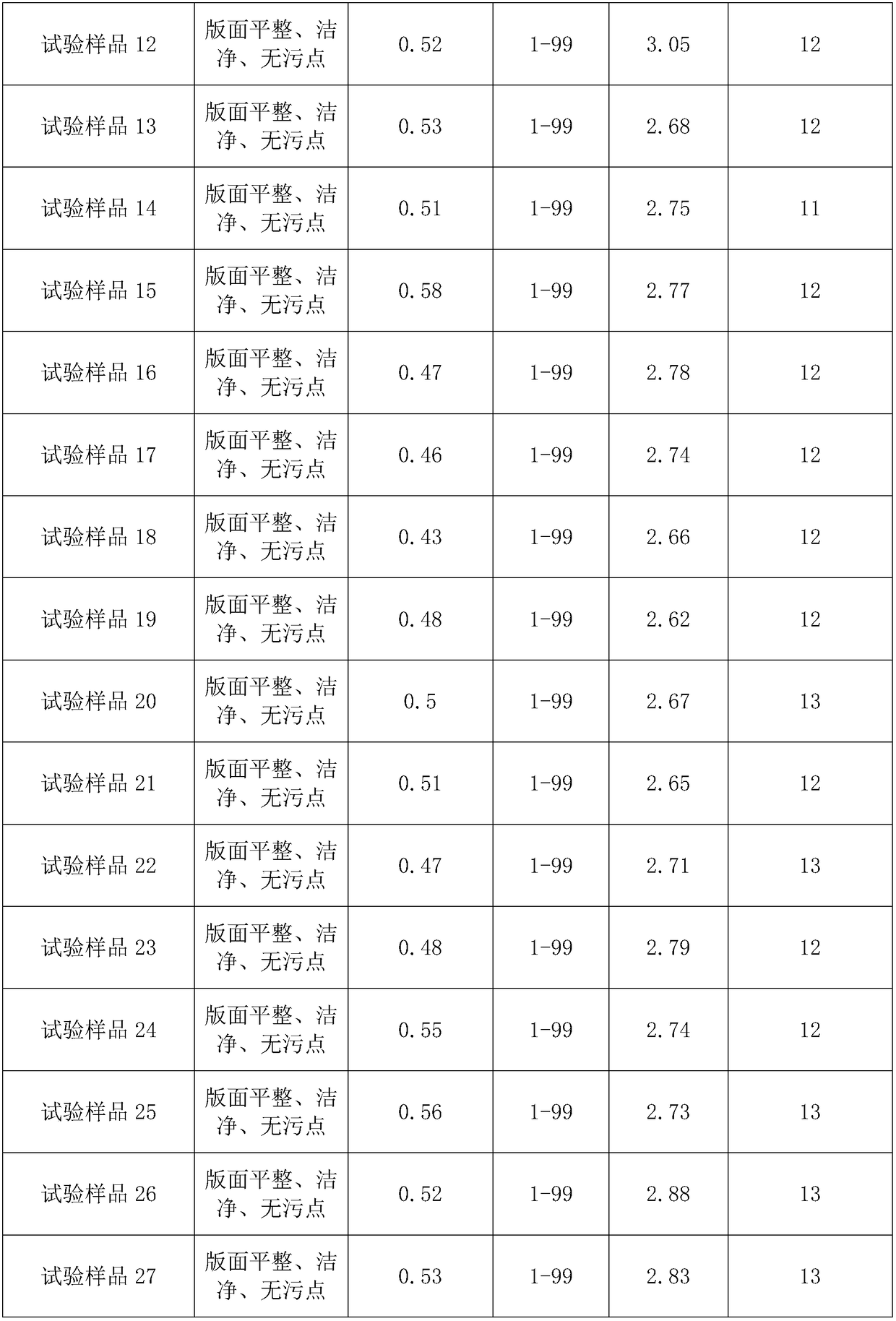

This invention provides a high sensitivity image forming composition used in heat sensitive CTP plate and its acid generating source preparation method. The said composition comprises the following countered by weight: 1 to 20 percent of heat acid generating source; 50 to90 percent of filming resin; 1 to 20 percent of cross linker; 1 to 10 percent of light to heat translation substance; 0.2 to 2 percent of color dye; and 10 to 30 percent of solvent, wherein the said weight percent values are based on the composition total mass.

Owner:BEIJING NORMAL UNIVERSITY +1

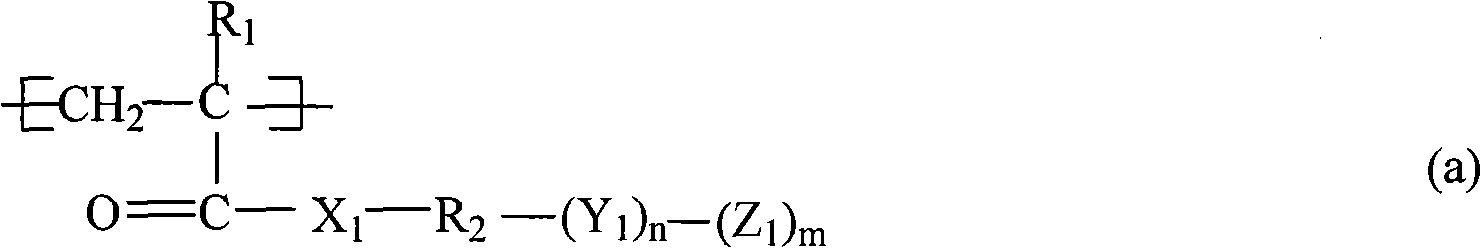

Chemical processing-free negative graph photosensitive composition suitable for UV-CTP and planographic printing plate manufactured therefor and planographic printing plate manufacture method

ActiveCN101192004AGood votiveImprove lipophilicityPhotosensitive materials for photomechanical apparatusChemical treatmentUltraviolet lights

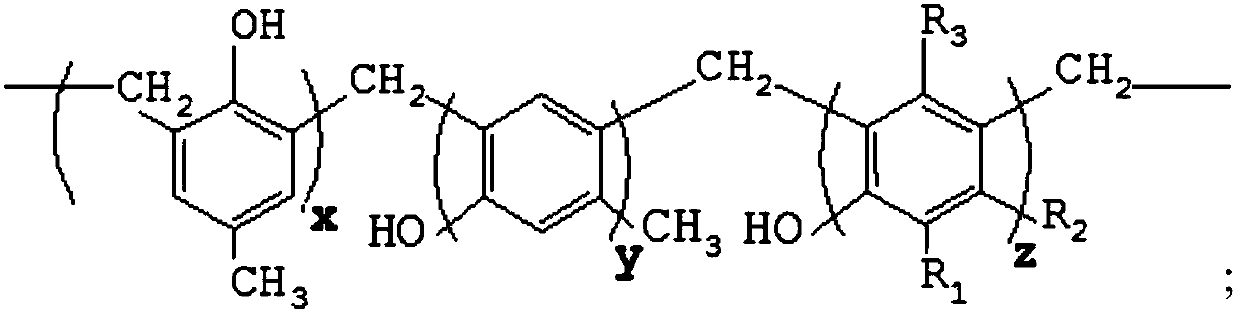

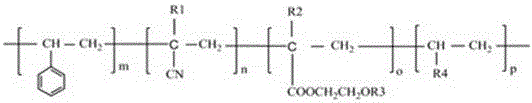

The present invention discloses a chemical treatment free negative photosensitive component suitable for UV-CTP and a lithograph plate using the same as well as lithograph plate manufacturing method, mainly comprising: (1) an unsaturated water-soluble polymer in a -(X)-(Y)-(Z)- structure which is characterized in that: X represents a copolymerized unit of sulfonic group; Y represents a carboxylic acid copolymerized unit of a branched chain containing two unsaturated double bonds; Z represents a acrylate copolymerized unit of a branched chain containing an unsaturated double bond; as well as (2) a photopolymerisable prepolymer, (3) a polyfunctional monomer, (4) one or more than one species of photopolymerization initiators and (5) one or more than one species of dyes or pigments. The present invention is suitable for the lithograph plate of UV-CTP plate-making machines. The lithograph plate of the present invention is high in photosensibility and good in network node reducibility, can be directly washed by tap water after ultraviolet light source exposure or can be used on machines for printing without any washing-processing step, and can gain high printing resistance, which is especially suitable for UV-CTP plate-making machines.

Owner:LUCKY HUAGUANG GRAPHICS

Positive-image PS-version and CTcP lithographic plate printing plate material

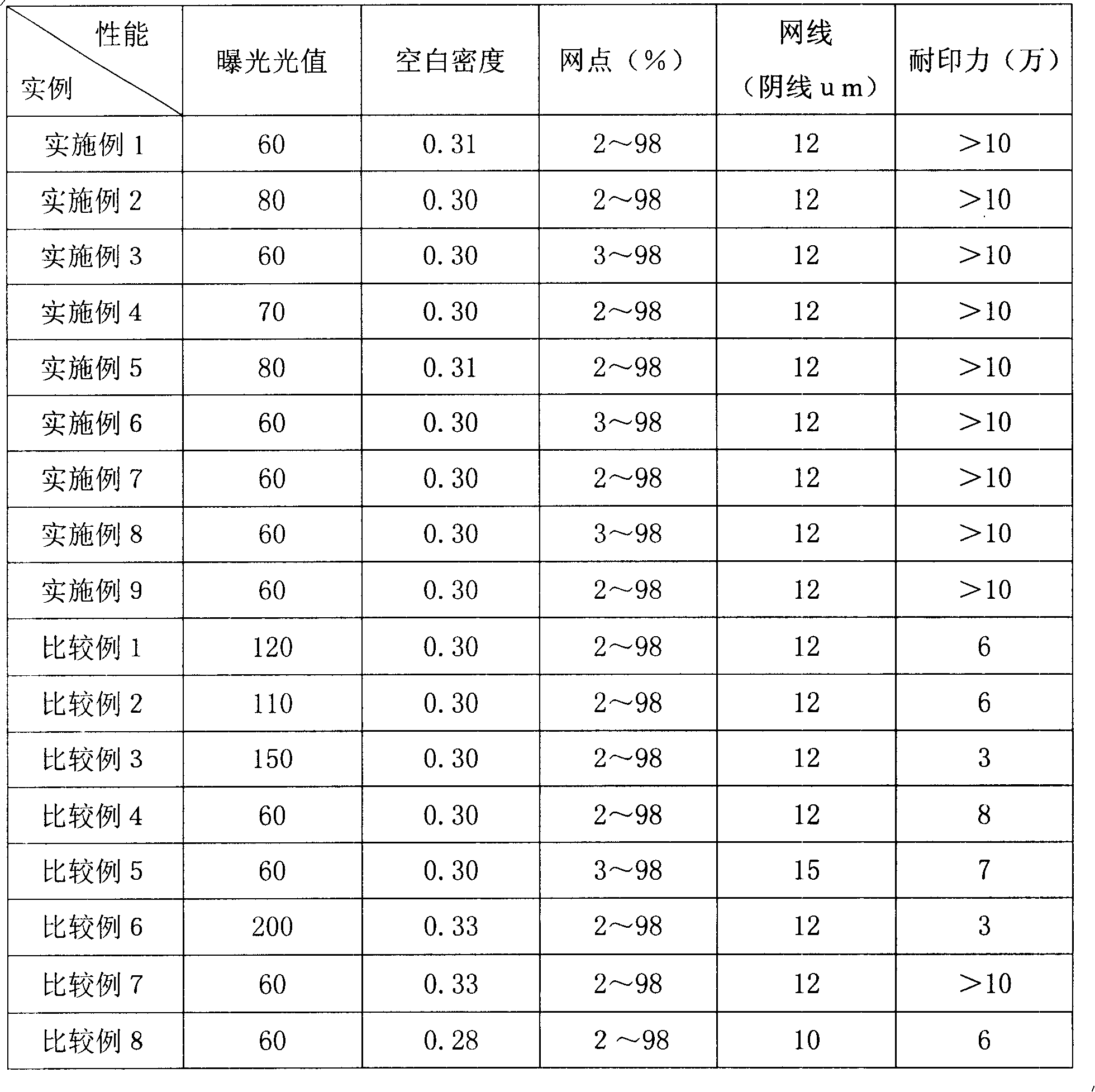

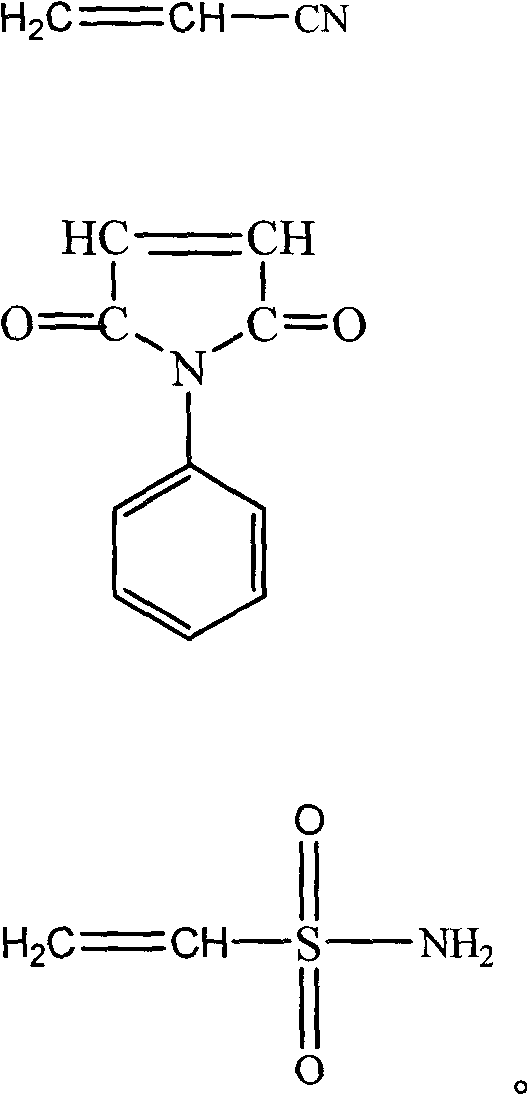

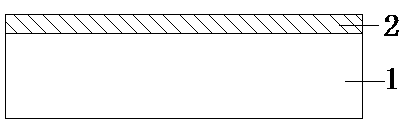

InactiveCN104503204AGood solvent resistanceIncreased sensitivityPhotosensitive materials for photomechanical apparatusSolventCorrosion

The invention provides a positive-image PS-version and CTcP lithographic plate printing plate material. The plate material comprises a hydrophilic support body, a bottom layer and a top layer, wherein the bottom layer and the top layer cover the hydrophilic support body and are capable of being dissolved by alkali after exposure. A bottom layer photosensitive composition comprises chemical resistant functional resin, a photosensitive compound and background coloring dye, wherein a branch chain carbon atom of the chemical resistant function resin is provided with benzylsulfonyl amino and N-aromatic maleimide circulating units. The molecular weight is between 1000 and 100000. A top layer photosensitive composition consists of film-forming resin, a photosensitive compound, a photoacid generator and background coloring dye. The bottom layer and the top layer are sensitive to visible light and ultraviolet light, after being exposed by the visible light and / or ultraviolet light, the bottom layer and the top layer are developed in an alkaline solution. An exposure area is eliminated after being dissolved, and the non-exposure area is insoluble or subjected to slight corrosion and remains. The positive-image PS-version and CTcP lithographic plate printing plate material has excellent solvent resistance, high sensitivity, high resolution and good developing tolerance level and is applicable to the UV ink printing.

Owner:QINGDAO LANFAN NEW MATERIAL

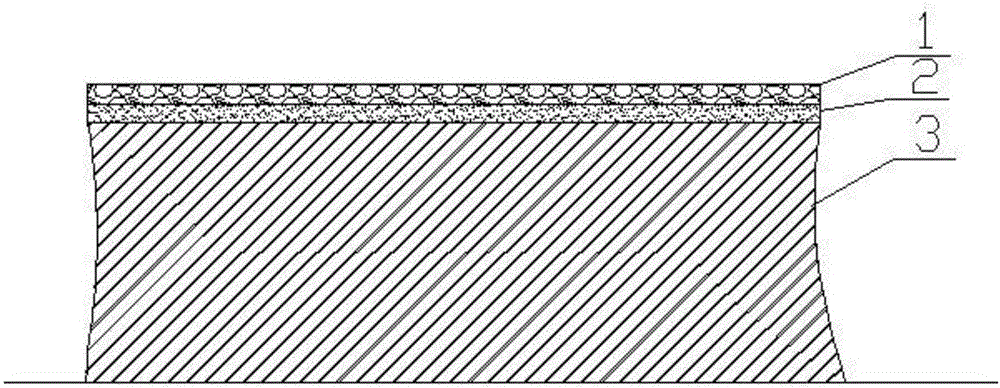

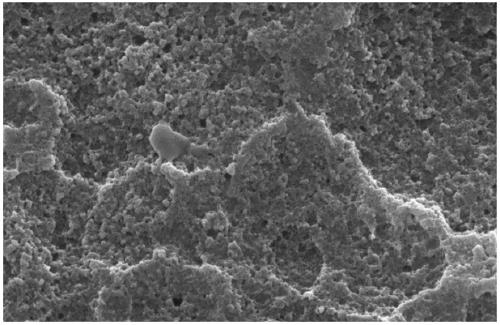

Negative image treatment-free lithograph plate

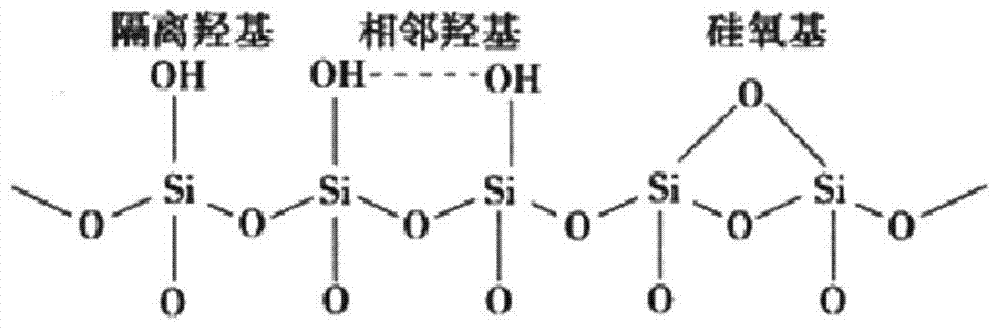

ActiveCN104730865AGuaranteed Aggregatable PropertiesInhibit aggregationPhotosensitive materials for photomechanical apparatusNano sio2Laser scanning

The invention provides a negative image treatment-free lithograph plate. The lithograph plate comprises a base, an imaging layer on the base and a protective layer on the imaging layer, wherein the imaging layer includes a polymer binder, an initiation system capable of initiating polymerization / cross-linking during imaging exposure and polymerisable / cross-linkable components, and the polymerisable / cross-linkable components comprise nanometer SiO2 / polyurethane acrylate prepolymer. The treatment-free lithograph plate can be directly installed on a printing machine for printing without developing after infrared laser scanning exposure. With the treatment-free lithograph plate and a printing method provided by the invention, the disadvantage of insufficient pressrun of treatment-free lithograph plates prepared by other methods is overcome, high pressrun is realized while high quality dots are guaranteed, and the number of transferring paper in starting of a machine is reduced.

Owner:LUCKY HUAGUANG GRAPHICS +1

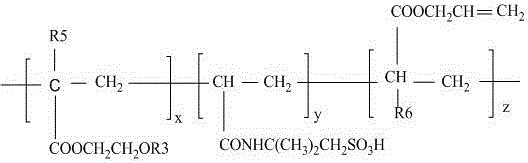

Water-developable photopolymerization type lithographic printing material containing two photosensitive layers and application thereof

ActiveCN104985914AImprove plate fastnessGood water developabilityPhotomechanical apparatusPrinting pre-treatmentWater solubleLength wave

The invention discloses a water-developable photopolymerization type lithographic printing material containing two photosensitive layers and an application thereof. The material comprises a support body, a photosensitive hydrophilic bottom layer and an oleophilic photosensitive layer, wherein the photosensitive hydrophilic bottom layer is arranged on the support body and comprises 50 to 99 parts of water soluble resin by mass, 0 to 49 parts of hydrophilic thinners by mass and 1 to 50 parts of hydrophilic polymerization initiating systems by mass, and the oleophilic photosensitive layer is arranged on the photosensitive hydrophilic bottom layer and comprises 10 to 60 parts of film forming resin by mass, 30 to 90 parts of crosslinking agents by mass, 0 to 40 parts of thinners by mass, 0.1 to 30 parts of polymerization initiating systems by mass and 0.1 to 10 parts of background coloring dye by mass. The lithographic printing material is suitable for exposure in laser with 350 mm to 450 mm of wavelength, is a photosensitive lithographic printing plate with high sensitivity and high pressrun in a CTP mode and can be developed with water or with a fountain solution on a printing machine.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink

ActiveCN103879169AIncreased sensitivityHigh developing latitudePlate printingFoil printingDouble coatingHeat sensitive

The invention discloses positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink. The positive image thermo-sensitive CTP printing plate material made by high-quality aluminum plate base and double coatings comprises a plate material support body. A resin layer good in solvent resistance and alkaline solubility coats the support body. A positive image thermo-sensitive photosensitive layer coats the resin layer. The main film forming resin also called polymer binder in the resin layer is independently researched and developed by the inventor company, and the photosensitive layer is modified by traditional single-layer thermo-sensitive CTP of the inventor company. The plate material is high in photosensitivity, excellent in screen dot reduction, large in plate making operation tolerance, stable in performance and high in printing adaptability. The plate material can be specially used for UV ink printing and also be used as the long-printing-process plate material of traditional solvent ink printing, and better printing durability is achieved when the plate material is applicable to the mentioned printing after baking.

Owner:LUCKY HUAGUANG GRAPHICS +1

Sensible heat composition for positive thermosensitive CTP plate without preheating and plate-making method by using same

InactiveCN101738856AGood plate appearanceIncreased sensitivitySemiconductor/solid-state device manufacturingPhotosensitive material processingComputer to plateHeat sensitive

The invention relates to a sensible heat composition for a thermosensitive CTP (Computer to Plate) plate. The thermosensitive composition comprises a perether compound of one or more low molecular phenolic compounds as a dissolution inhibitor or a solutizer, and the molecular weight of the low molecular phenolic compound is 100-400. Furthermore, the invention also relates to a method for preparing the positive thermosensitive CTP plate without preheating. The method comprises the following steps of: (1) sequentially carrying out rough treatment, anodic oxidation treatment and sealing treatment on an aluminum plate base; (2) carrying out plate coating on the aluminum plate base through the sealing treatment by using the thermosensitive CTP (Computer to Plate) plate; (3) carrying out two-section drying on the coated aluminum plate base obtained in the step (2), wherein the first section is dried by using a far infrared ray to heat, while the second section is dried by using forced hot blast, thereby obtaining the positive thermosensitive CTP plate without preheating. The plate produced in the invention has favorable appearance, higher sensitivity, favorable development latitude and higher print run and can be used in cooperation with photographic developers universally utilized at home and abroad.

Owner:GUANGXI YULIN JINLONG PS PLATE PRINTING MATERIAL

Heat-sensitive CTP heat-sensible image-forming liquid with carboxyl phenolic resin active ester and etherate as dissolving inhibitor

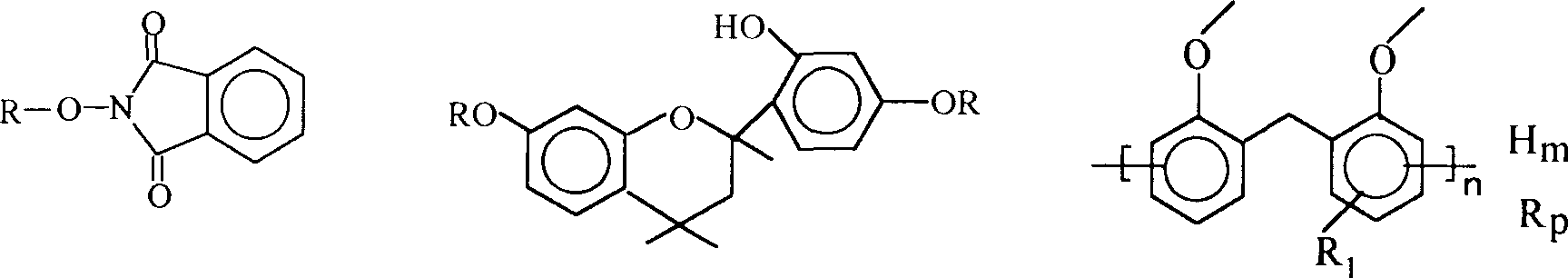

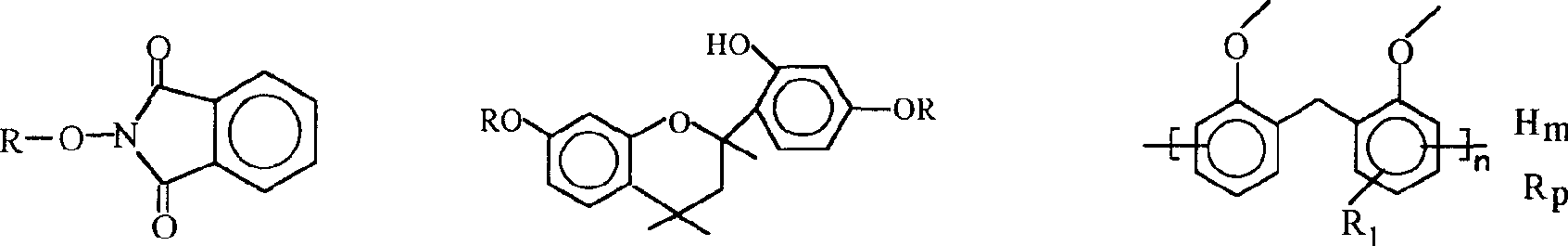

InactiveCN101762974ABig difference in solubilityImprove developmentPhotosensitive materials for photomechanical apparatusInfraredImage resolution

The invention discloses a heat-sensitive CTP heat-sensible image-forming liquid with carboxyl phenolic resin active ester and etherate as dissolving inhibitor, belonging to the application technology field of optical information recording material. The image-forming liquid comprises film forming resin, dissolving inhibitor, infrared dye, coloring background dye, photoacid generator, additive and solvent. The dissolving inhibitor is carboxyl phenolic resin active ester and etherate, and the dissolving inhibitor can be decomposed under the action of proton acid generated in the exposed area, to release alkali-soluble groups, e.g. carboxyl or phenolic hydroxyl, thus the dissolving difference between the exposed and unexposed areas is large, and the developing and imaging performance of the plate material is improved. Utilizing the dissolving inhibitor can obtain positive preheating-free heat-sensitive CTP plate material with high sensitivity and good resolution and pressrun.

Owner:TAIXING CITY ORIENT IND +1

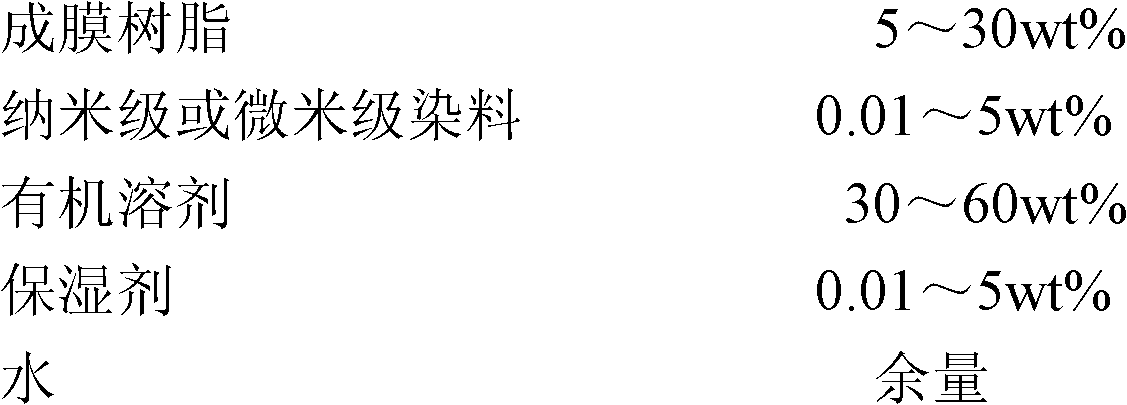

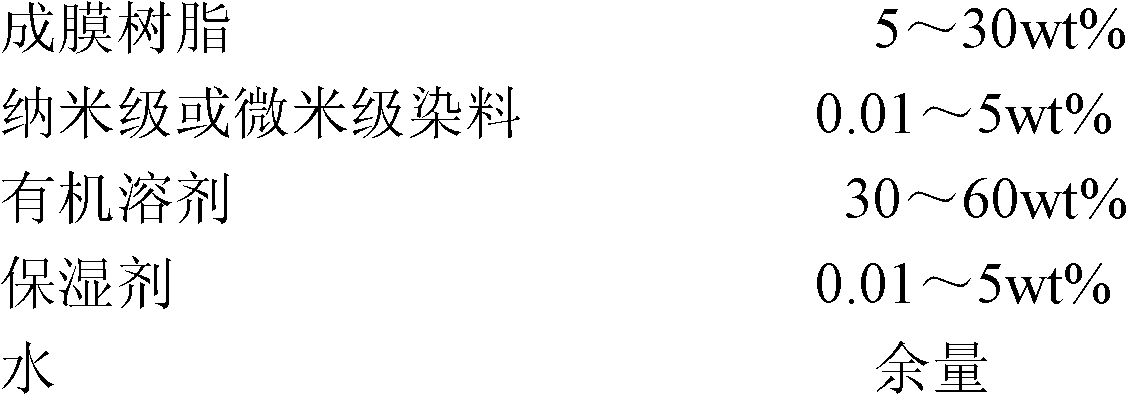

Ink for printing and directly making plate used in nanometer material and preparation method thereof

The invention belongs to ink for printing plate making, relates to a material for directly making a plate by jetting ink and printing based on a nanometer material, in particular to ink for printing and directly making a plate used in a nanometer material and a preparation method thereof. The method comprises the following steps of: uniformly stirring and mixing 5-30 percent by weight of film-forming resin, 0.01-5 percent by weight of a nano-grade or micron-grade dye, 30-60 percent by weight of an organic solvent, 0.01-5 percent by weight of a humectant and the balance of water at the room temperature on the basis of the total weight of ink; and after the film forming resin is dissolved completely, performing multi-stage filtration for removing impurities and / or undissolved substances from a mixed solution to obtain a filtrate, i.e., the ink provided by the invention. The ink is jetted onto the surface of a metal substrate through an ink jet printer for forming printing patterns, and can be directly printed after curing, so that the chemical pollution and a post-treatment process are reduced, the printing resistance of a printing plate can be up to 100,000 and the resolution is up to 175lpi.

Owner:INST OF CHEM CHINESE ACAD OF SCI

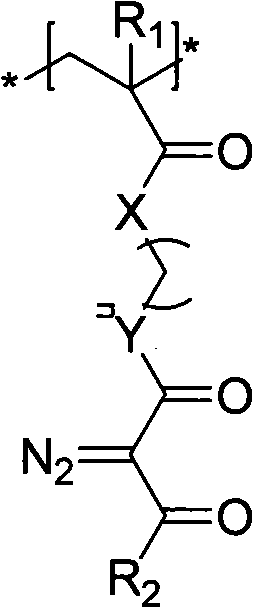

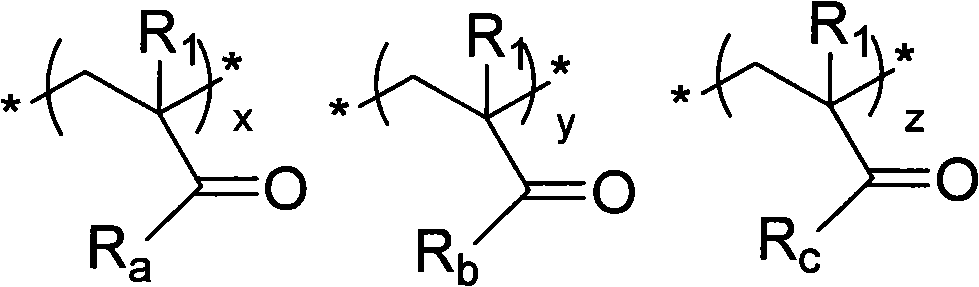

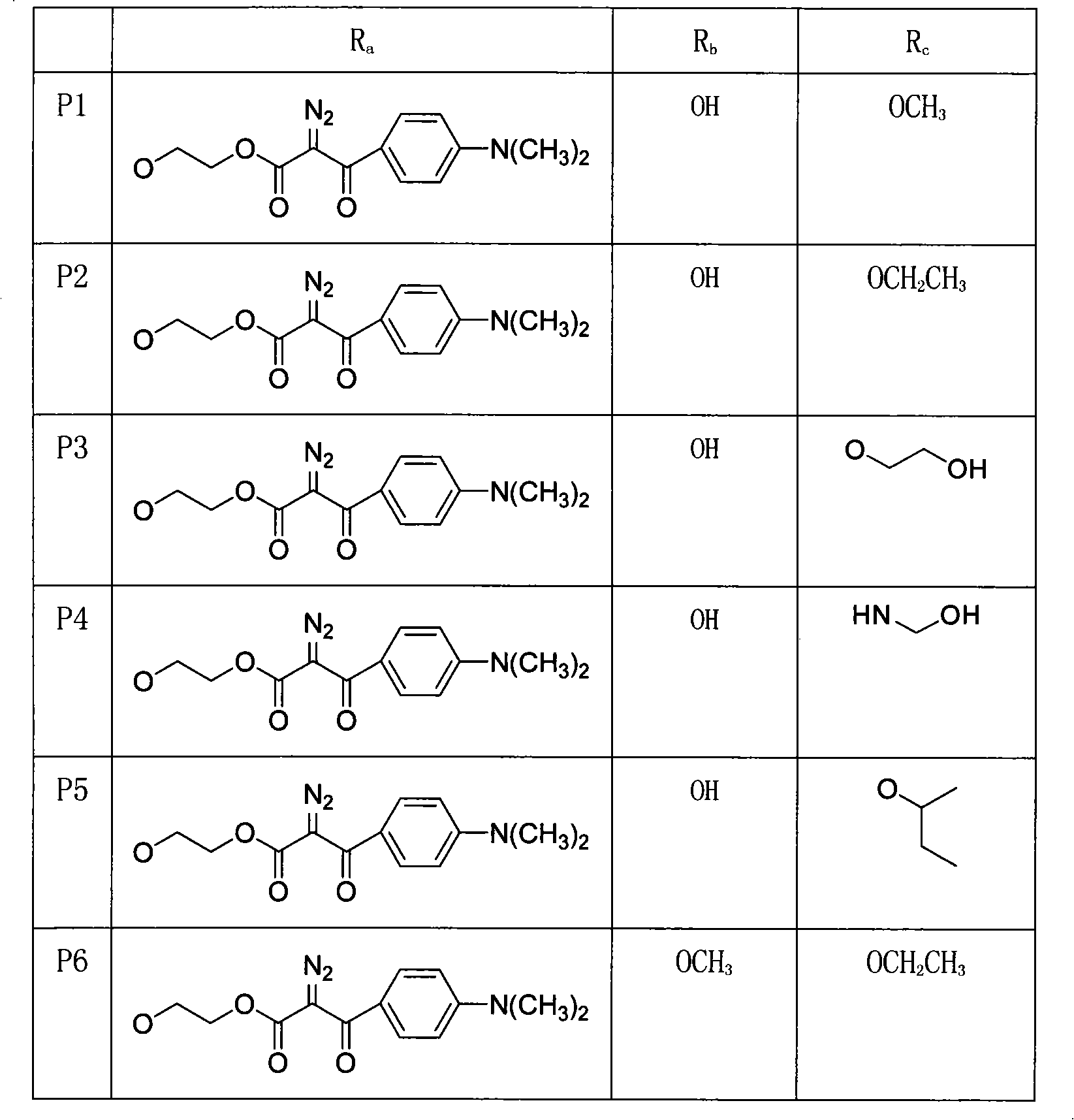

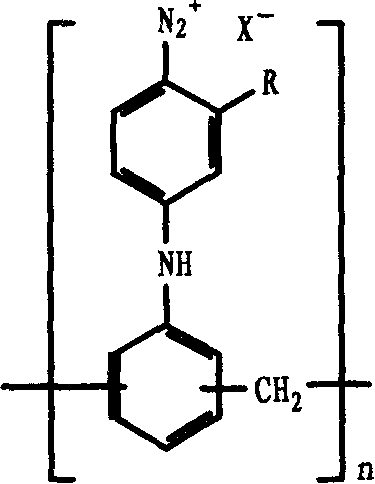

Photosensitive imaging liquid containing alpha-diazonium-1,3-diketone structure and used for photosensitive macromolecule flat printing plate

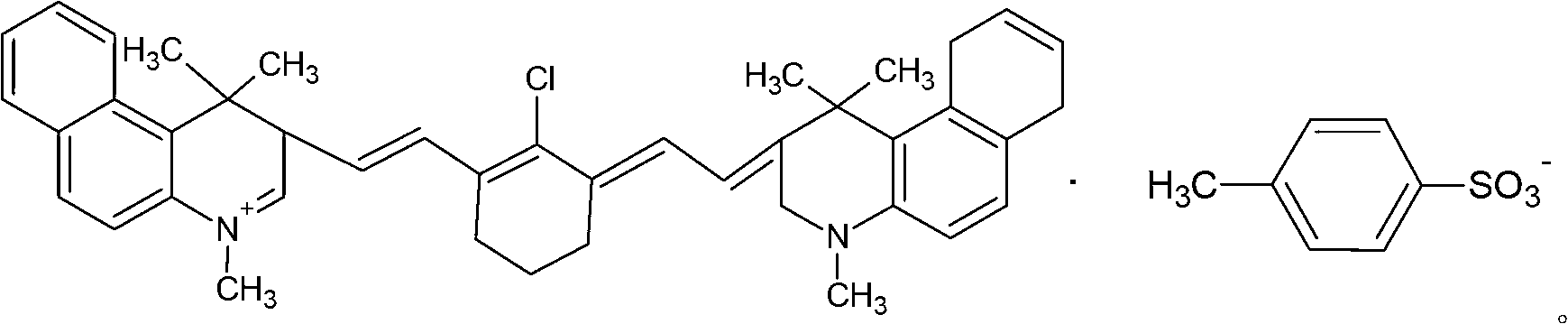

InactiveCN101930175AIncreased sensitivityImprove the running forcePhotomechanical apparatusDiketoneImage resolution

The invention discloses a photosensitive imaging liquid containing an alpha-diazonium-1,3-diketone structure and used for a photosensitive macromolecule flat printing plate, belonging to the field of applied technologies of optical information recording materials. The imaging liquid comprises film forming resin, photosensitive resin, an acid generating agent, coloring background dye and a solvent, wherein the photosensitive resin contains the alpha-diazonium-1,3-diketone structure, the maximum absorption wavelength is 250-400 nm, a decomposition and rearrangement reaction occurs after ultraviolet irradiation or scanning, and the plate is changed to be hydrophilic and oleophylic after development. Because no free radical polymerization occurs, a protective layer needs not to be coated on the photosensitive imaging liquid containing the photosensitive resin and sensing ultraviolet light. A positive photosensitive CTP plate and a negative photosensitive CTP plate with high sensitivity, good resolution and high pressrun can be obtained by using the photosensitive imaging liquid.

Owner:TAIXING CITY ORIENT IND +1

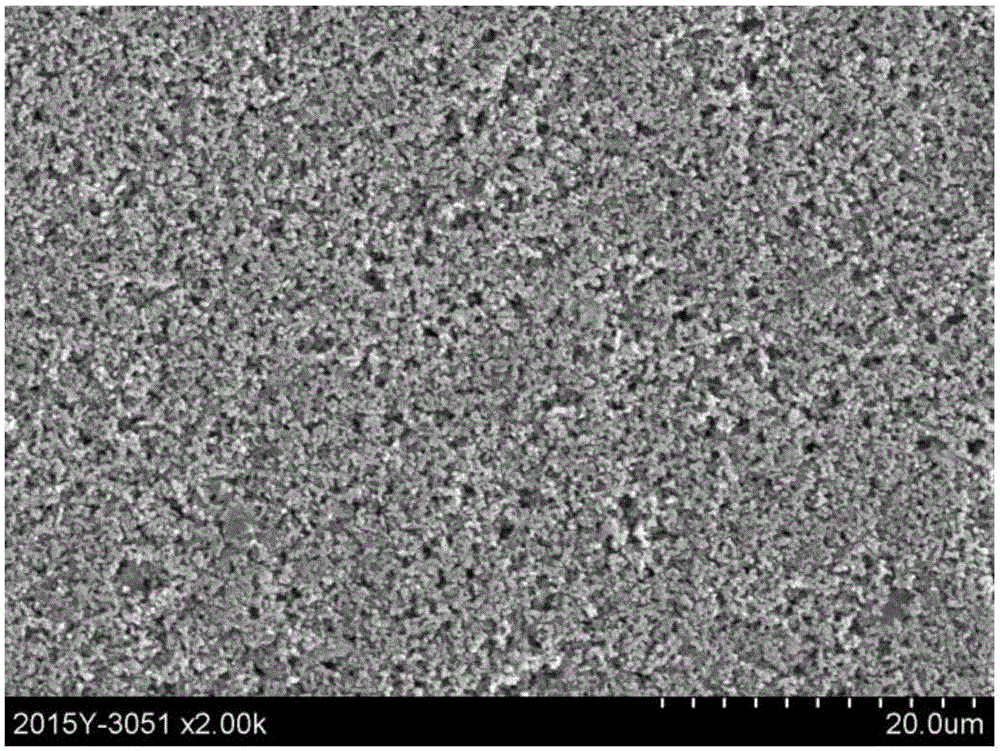

Grain-free metal printing plate base and preparation method thereof

ActiveCN106364208AOptimizing componentsIncrease contentNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesInorganic particleAdhesive

The invention discloses a grain-free metal printing plate base. The grain-free metal printing plate base comprises a metal plate material, an adhesive layer and a hydrophilic layer; the mass of inorganic particles accounts for 90% or more of that of the hydrophilic layer; the surface of the hydrophilic layer is subjected to hole sealing treatment by using a hole sealing material; the adhesive layer is formed by drying and curing after the metal plate material is coated with a coating liquid with great adhesive force to the metal plate material; the hydrophilic layer is formed by drying and curing after an inorganic nano or micro particle with a small amount of an adhesive is coated with a coating liquid. A preparation method for the grain-free metal printing plate base disclosed by the invention avoids the defects of high energy consumption and high pollution of the conventional grain plate base, can effectively reduce cost, and can be applied to the printing fields, such as a PS plate or a CTP plate.

Owner:CHINA LUCKY FILM CORP +1

Quick drying ink used for ink-jet printing direct plate making as well as preparation method and application thereof

The invention relates to quick drying ink used for printing plate making, in particular to quick drying ink used for ink-jet printing direct plate making and a preparation method thereof. In the quick drying ink, 0.1-35wt% of thermoplastic resin, 0.1-20wt% of curing agent, 0.01-10wt% of nano-scale dye and / or micron-scale dye and the balance of organic solvent are mixed, and filtered to remove insoluble particles and impurities in the mixed liquor to obtain the quick drying ink. The quick drying ink is sprayed onto the surface of a printing plate through an ink-jet printer controlled by a computer to form images, then the printing plate is heated to 60-300 DEG C, and the thermoplastic resin is cross-linked and cured under the effect of the curing agent in the quick drying ink, so the drying temperature is reduced, and simultaneously the wiping capacity of resistant cleaning plate paste containing alcohol of the image part of the obtained printing plate is improved; and the obtained printing plate has good printing printability and higher printing resistance in computer printing, and the image resolution of printed matter is better.

Owner:INST OF CHEM CHINESE ACAD OF SCI

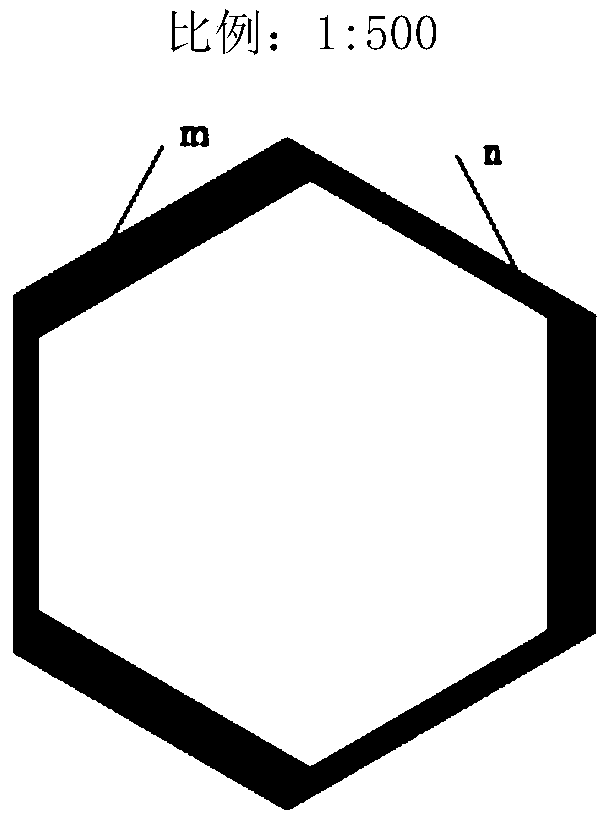

Benzene ring network structure for intaglio printing

The invention discloses a novel benzene ring network structure for intaglio printing, and aims at solving the problems of poor drying, plate blocking, ripples and the like occurring when an existing printing plate is used for net printing of water-based ink. Under the condition of not influencing the printing durability, the net hole area can be increased, the net hole depth can be reduced, the ink transfer rate can be increased, and the phenomenon of ripples can be reduced. According to the benzene ring network structure for intaglio printing, net holes are hexagonal, and in every six net walls between each net hole six adjacent net holes around, three connected net walls are thick edge net walls, two net walls connected with the three thick edge net walls are thin edge net walls, and thenet wall between the two thin edge net walls is a thick edge net walls. The width of the thick edge net walls is two times that of the thin edge net walls.

Owner:NANJING FORESTRY UNIV +1

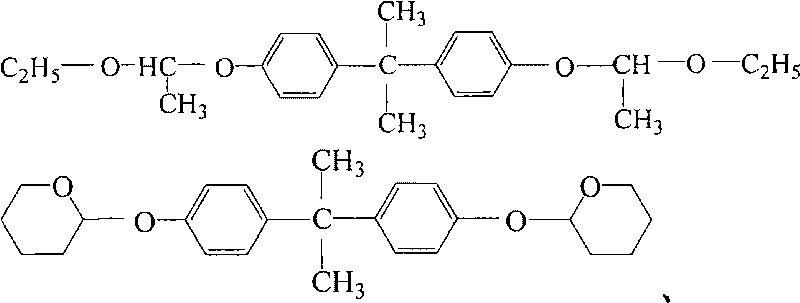

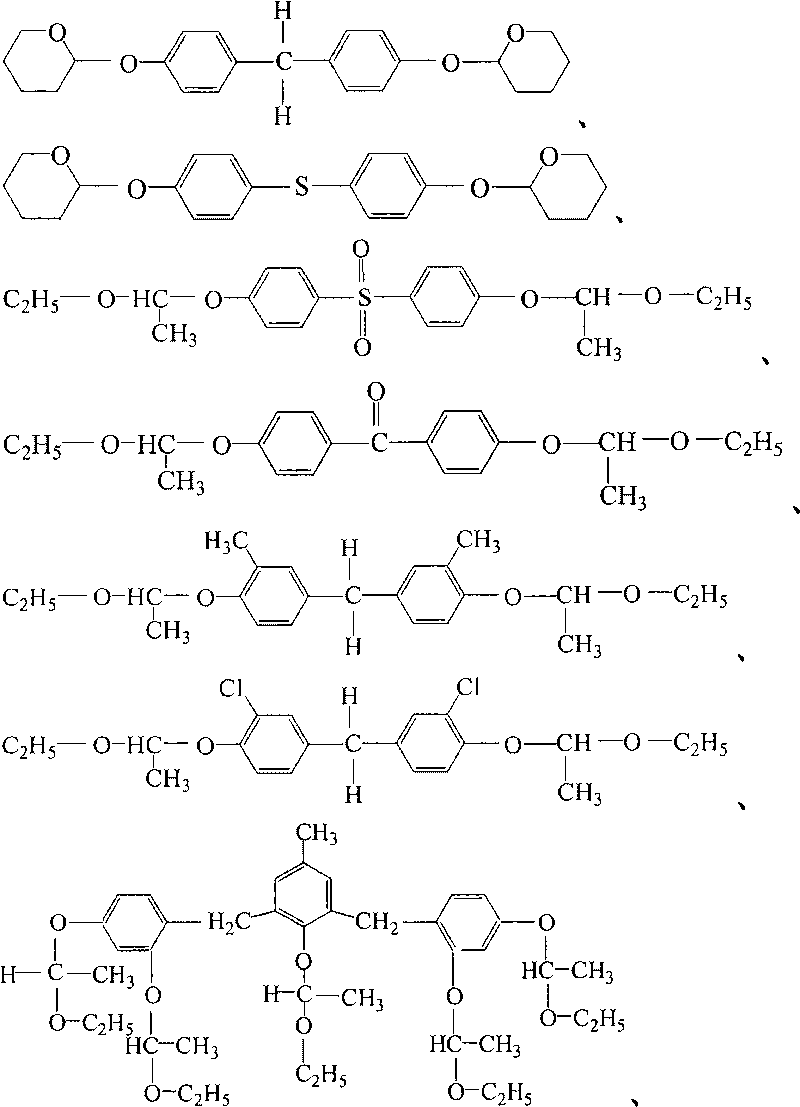

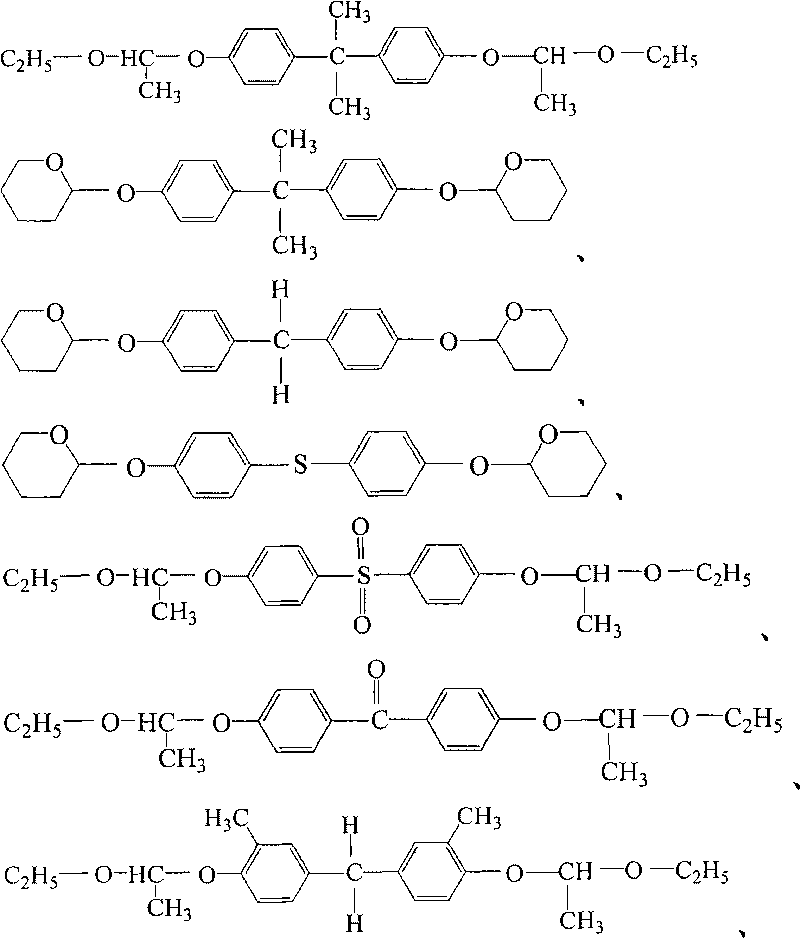

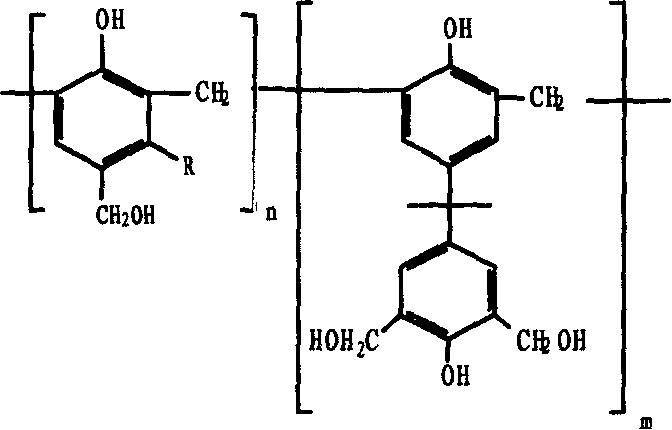

Photosensitive composition and lithograph plate made of same

ActiveCN1595295AImprove the running forceIncreased sensitivityLiquid surface applicatorsPhotomechanical coating apparatusPolymerPhotochemistry

This invention discloses a light sensitive compound and the lithoprint plate using the compound. The light sensitive compound comprises the following as weight percent: 30 t0 60 percent of resin, 5 to 20 percent of infrared absorbing compound, 30 to 60 percent of potential protonic acid, 0 to 10 percent o f acid breeding agent. The lithoprint plate comprises base with a base coating layer of hydrophilicity polymer attached with the above light sensitive layer on. The sample in this invention can get print plate 1 images more than one hundred thousand times through the multiple printing plate experience. If the plate is baked under a temperature of 220 degrees for ten minutes, the printing time can be three hundred times. The printing plate 2 can achieve one hundred times, If the plate is baked under a temperature of 220 degrees for ten minutes, the printing time can achieve five hundred times.

Owner:LUCKY HUAGUANG GRAPHICS

Computer to conventional plate (CTcP) photosensitive resist, preparation method of the CTcP photosensitive resist and CTcP prepared from the CTcP photosensitive resist

InactiveCN102486608AImprove alkali resistanceImprove solvent resistancePhotosensitive materials for photomechanical apparatusResistSulfonyl chloride

The invention discloses a computer to conventional plate (CTcP) photosensitive resist and a preparation method thereof. The preparation method of the CTcP photosensitive resist comprises that m-cresol-formaldehyde resin, poly(epoxy acrylate) resin and 2-diazo-1-naphthoquinone-5-sulfonyl chloride undergo an esterification reaction to produce an esterified material; and the esterified material is prepared into the CTcP photosensitive resist. The invention also discloses a CTcP prepared from the CTcP photosensitive resist. Through the CTcP photosensitive resist obtained by the preparation method, the CTcP pressrun is improved and is more than 150000.

Owner:上海琪川感光设备有限公司

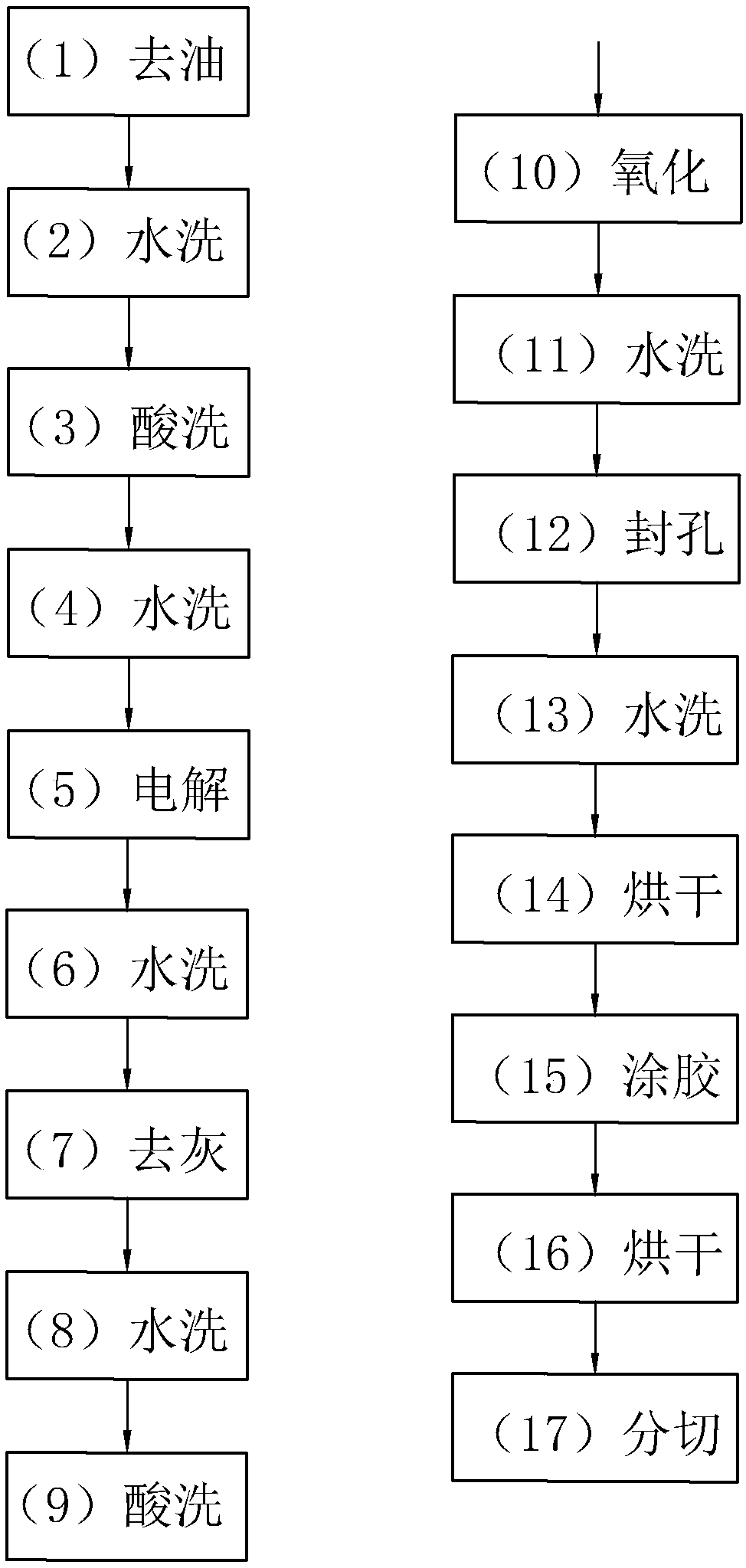

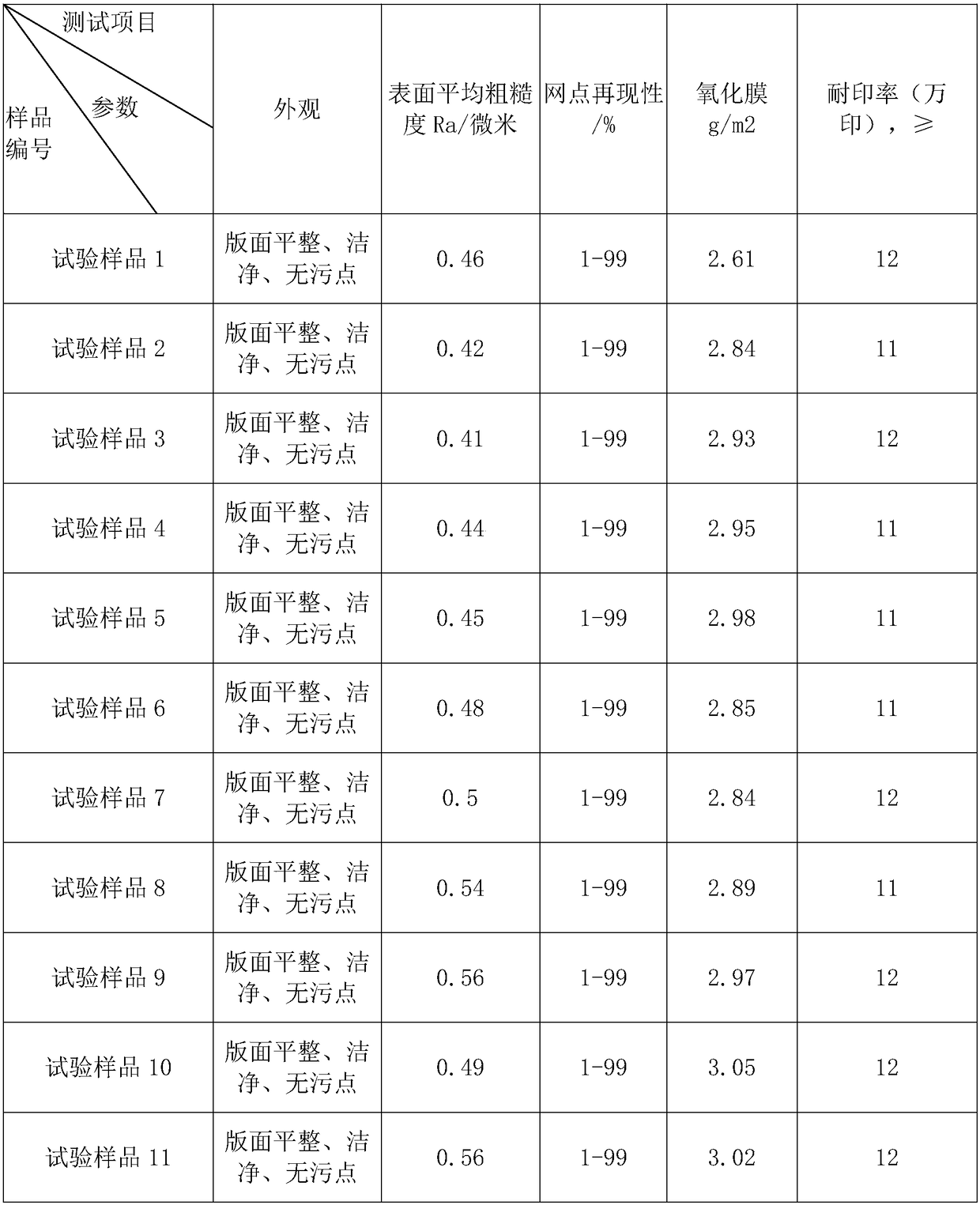

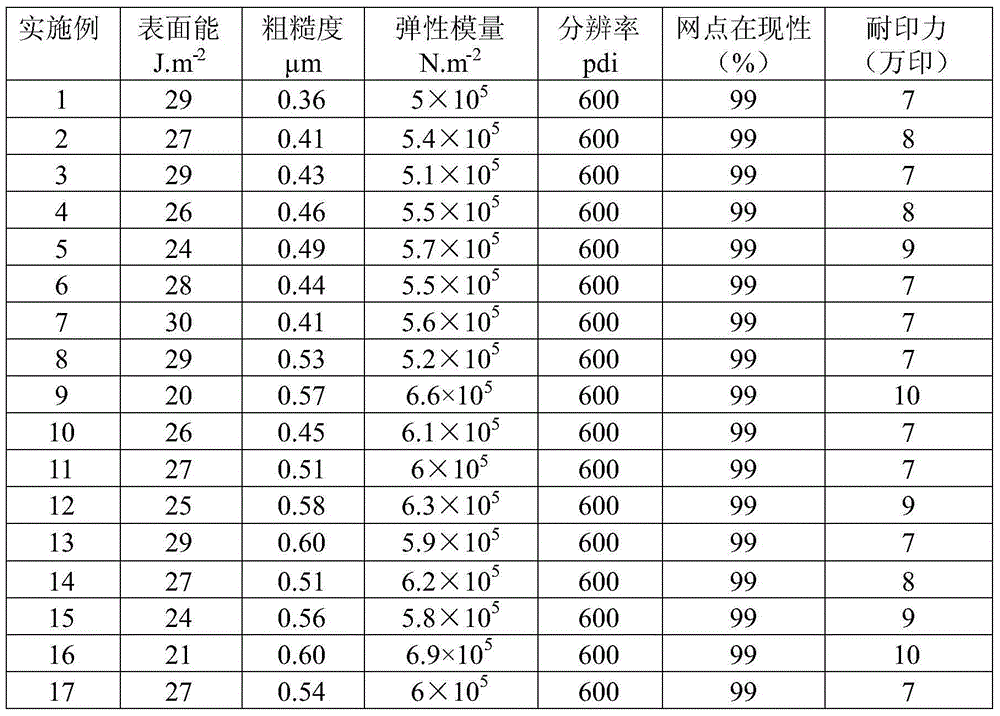

Thermosensitive CTP plate production technology

InactiveCN108374190AImprove dot reproducibility and run-timeImprove preservation performance and printing durabilityAnodisationPhotomechanical apparatusDark lineEngineering

The invention discloses a thermosensitive CTP plate production technology, and relates to the technical field of printing plates. The technology solves the problems that the dot reproducibility, the sensitiveness, the developing characteristic and the printing durability of an existing CTP plate are poor. The technology comprises the following steps of (1) removing oil; (2) carrying out water washing; (3) carrying out acid pickling; (4) carrying out water washing; (5) carrying out electrolysis; (6) carrying out water washing; (7) removing ash; (8) carrying out water washing; (9) carrying out acid pickling; (10) carrying out oxidizing; (11) carrying out water washing; (12) carrying out hole sealing; (13) carrying out water washing; (14) carrying out drying; (15) carrying out gluing; (17) carrying out drying; and (17) carrying out slitting. According to the technology, the technological steps and the parameters are adjusted, so that the dot reproducibility and the printing durability ofthe CTP plate can be improved, sand meshes can be more uniform and compact, a layer of compact and uniform oxidation film can be conveniently formed on the surface of an aluminum plate base material in the oxidation process, and therefore the storage performance and the printing durability of the plate can be improved; and the aluminum plate base material is white-bright, clean and free of dirt, and the defects such as the dirt and dark lines can be avoided

Owner:上海宝士嘉印刷器材有限公司

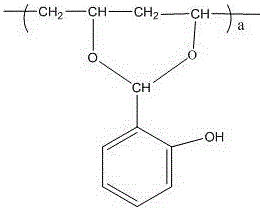

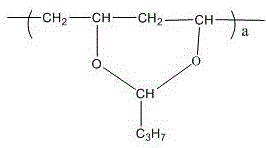

Photosensitive composition suitable for heat-sensitive positive computer to plate (CTP) and lithographic plate containing same

ActiveCN101770170AGood alkali resistanceLarge development latitudePhotosensitive materials for photomechanical apparatusAnti solventComputer to plate

The invention discloses a photosensitive composition suitable for heat-sensitive positive computer to plate (CTP) and a lithographic plate containing the same. The composition comprises the following components in part by weight: 30 to 80 parts of anti-solvent vinyl polymer, 3 to 20 parts of infrared absorbing dye, 5 to 35 parts of vinyl sulfonate polymer and 0.5 to 5 parts of cellulosic derivative. The lithographic plate consisting of the photosensitive composition has the characteristics of high photosensitivity, good storage stability, high development latitude, good abrasion resistance of plate coating, and high durability; besides, the plate coating has good chemical resistant performance and is suitable for UV ink printing. The durability of the plate using the photosensitive composition reaches over 200,000 printings by using the normal lithographic ink printing and 50,000 printings by using the UV oil printing; and pollution is avoided during printing.

Owner:LUCKY HUAGUANG GRAPHICS

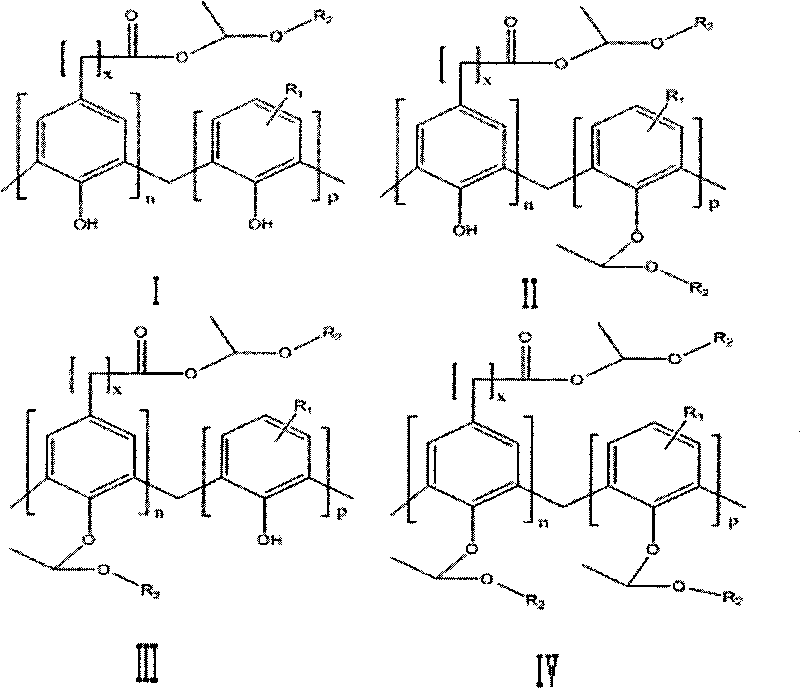

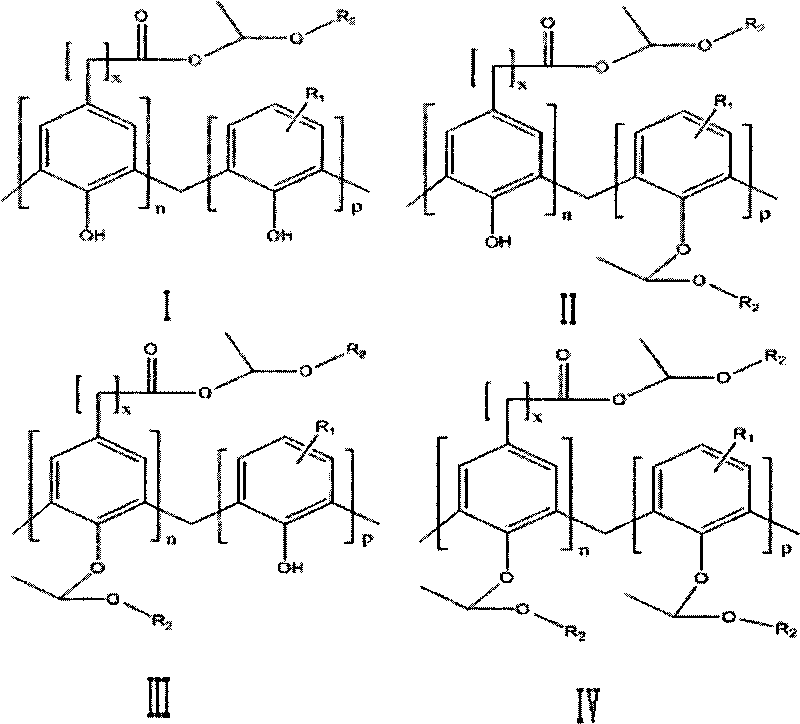

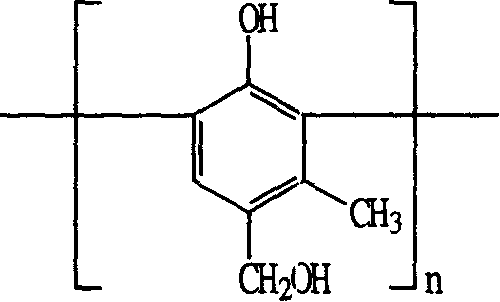

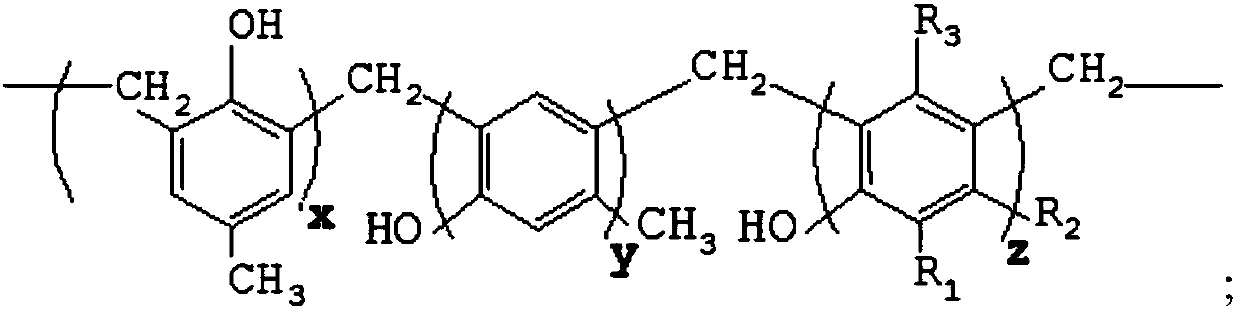

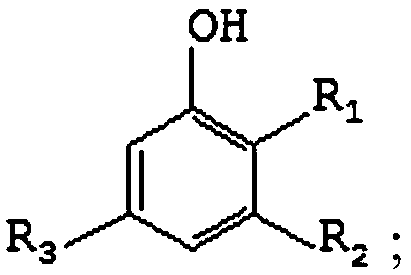

Phenolic resin and preparation method thereof, and photoresist

PendingCN111303362AImproved thermal stabilityImprove the running forcePhotosensitive materials for photomechanical apparatusPhotoresistPhenol Compound

The invention discloses a phenolic resin and a preparation method thereof, and a photoresist. The preparation method of the phenolic resin comprises the following steps: obtaining reaction raw materials p-cresol, m-cresol and a phenol compound; under the action of an acidic catalyst, carrying out an addition condensation polymerization reaction on the reaction raw materials and formaldehyde to obtain an intermediate product; and distilling the intermediate product to obtain the phenolic resin, wherein the chemical structural formula of the phenol compound is defined in the specification, R1 isselected from CH3, CH2CH3 and H, and R2 and R3 are both selected from H, CH3 and CH2CH3. The prepared phenolic resin has good thermal stability, has the advantages of narrow molecular weight distribution, adjustable and controllable dissolving speed in a developing solution and good developing performance, heat resistance and resolution, is suitable for preparing positive photoresist such as LCDpositive photoresist, and endows the positive photoresist with good thermal stability, high pressrun and good development performance and resolution.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

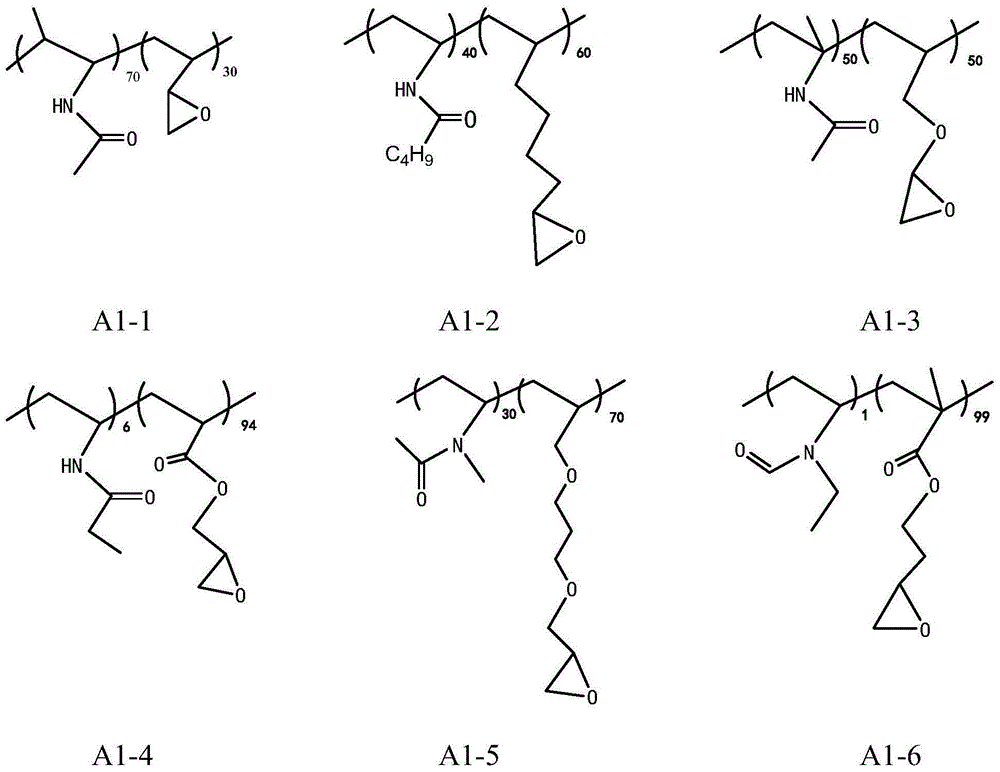

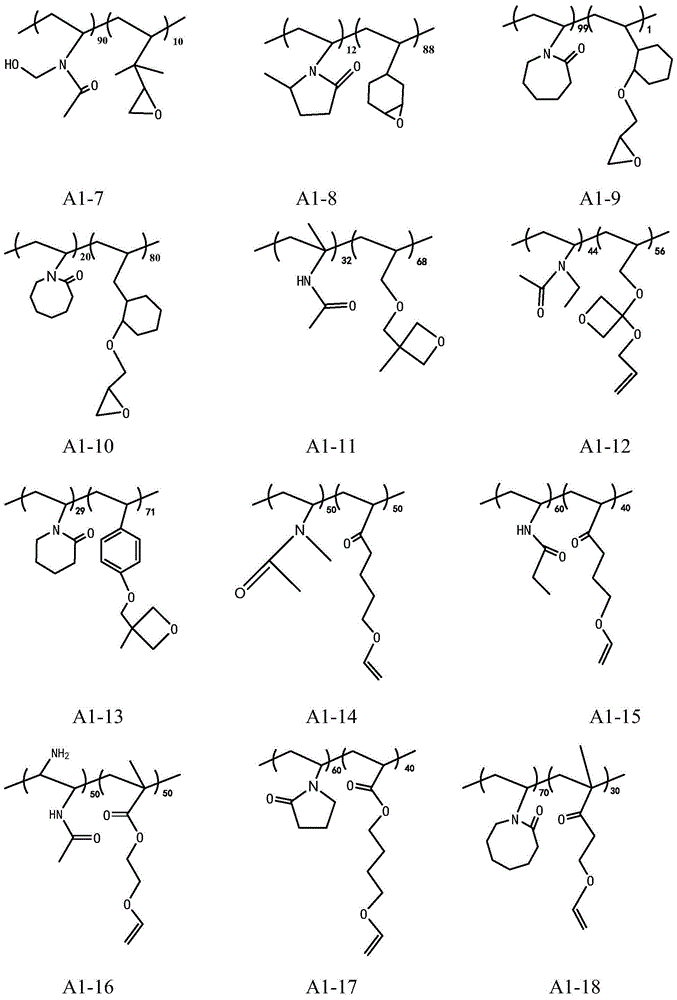

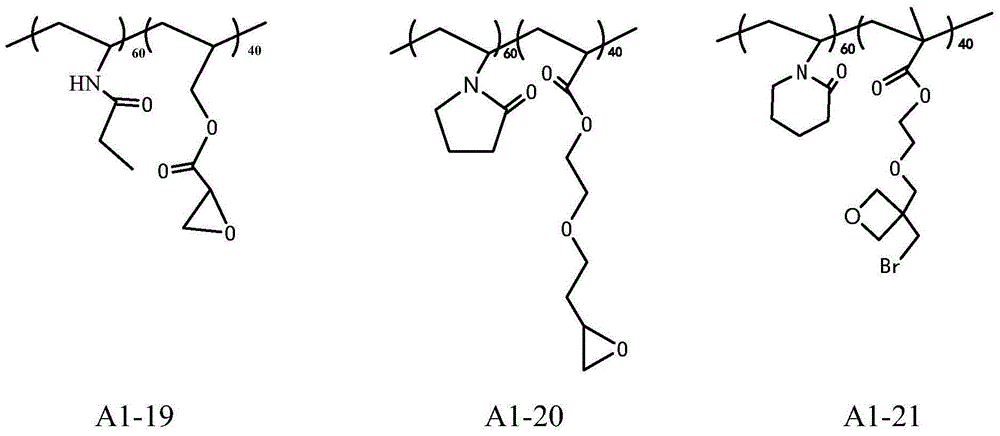

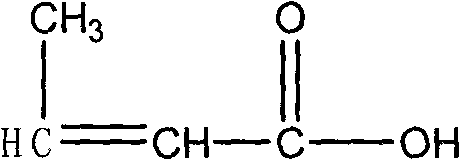

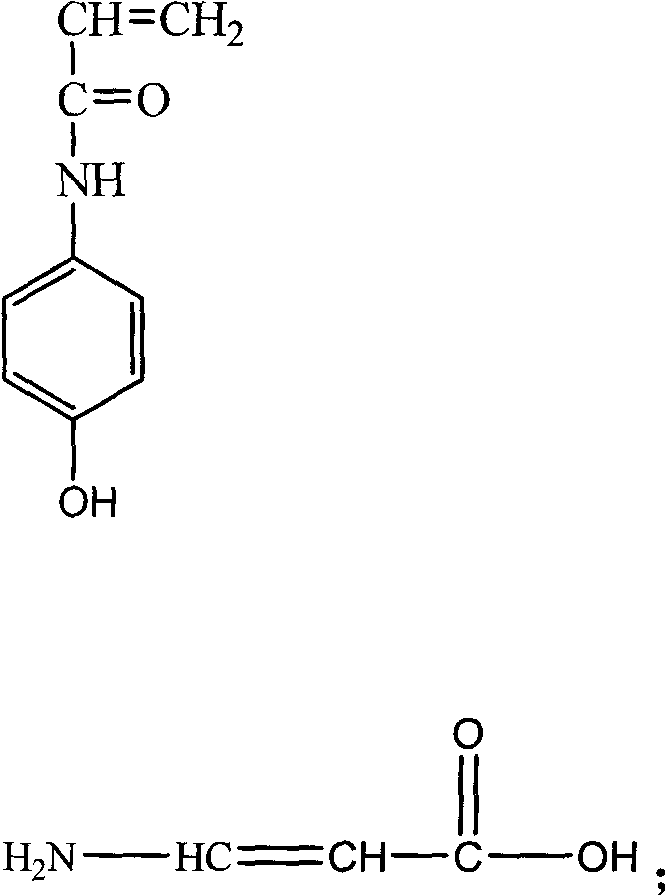

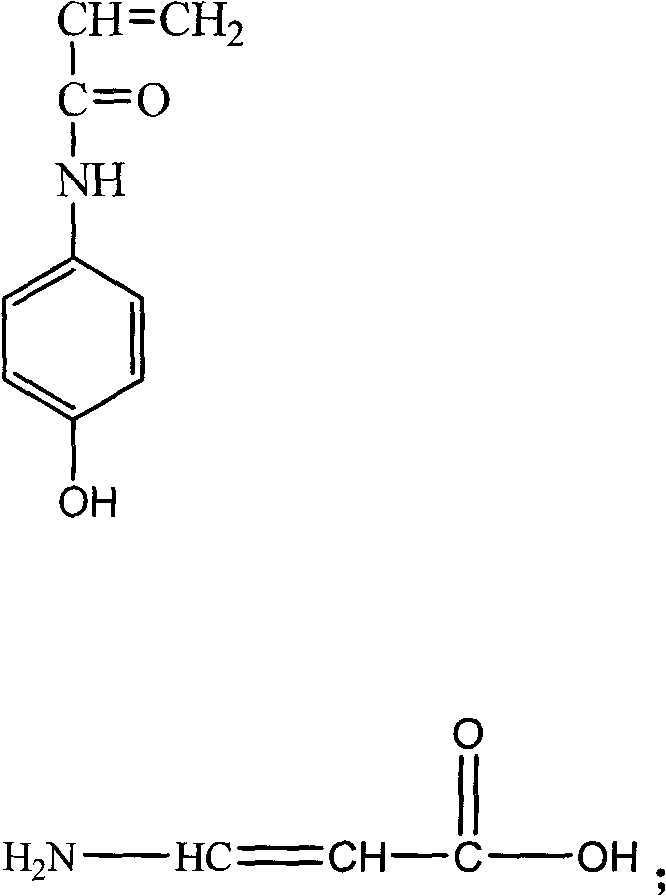

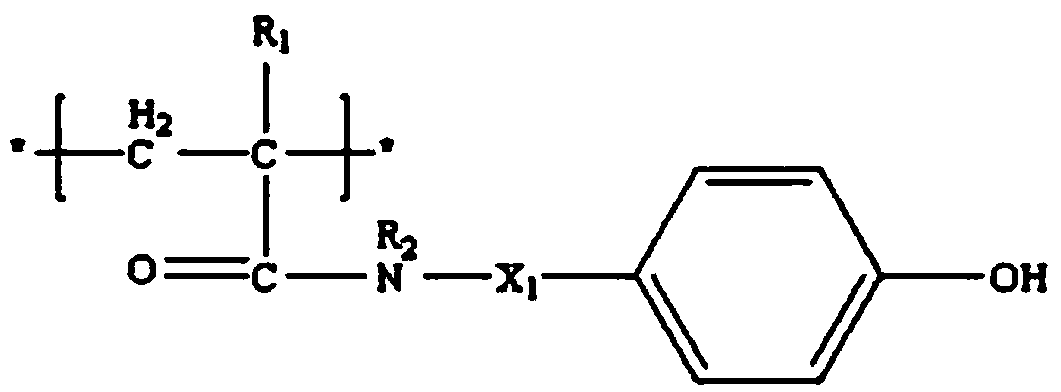

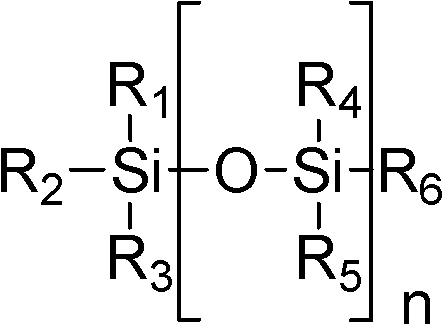

Elastomer composition used for water washing flexographic plate, and water washing flexographic plate containing elastomer composition and having excellent press life and affinity for ink

ActiveCN106324991AImprove toughnessStrong printing forcePhotosensitive materials for photomechanical apparatusElastomerWater soluble

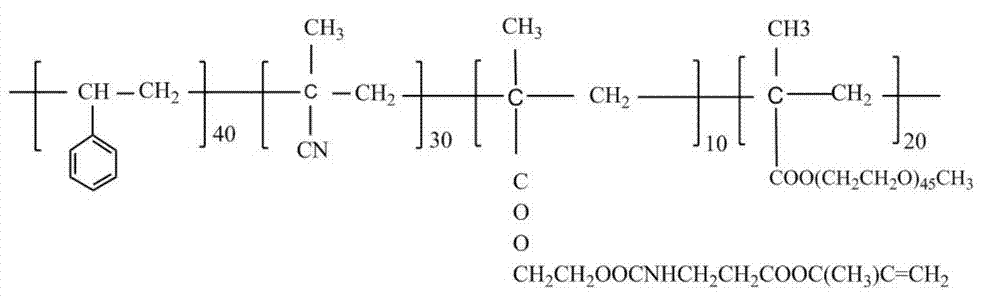

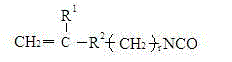

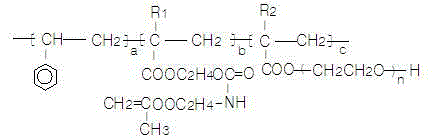

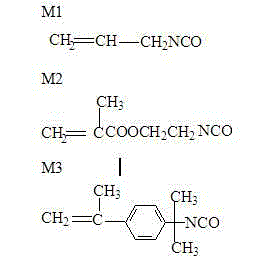

The invention relates to an elastomer composition used for a water washing flexographic plate. The elastomer composition contains a water-soluble copolymer with the branched chain being grafted with an active urethanated double bond, liquid polybutadiene with the end being grafted with an urethanated double bond, an unsaturated monomer containing at least one double bond, a photopolymerization initiator, a dye and other additives. The water washing flexographic plate has excellent press life and affinity for ink.

Owner:LUCKY HUAGUANG GRAPHICS

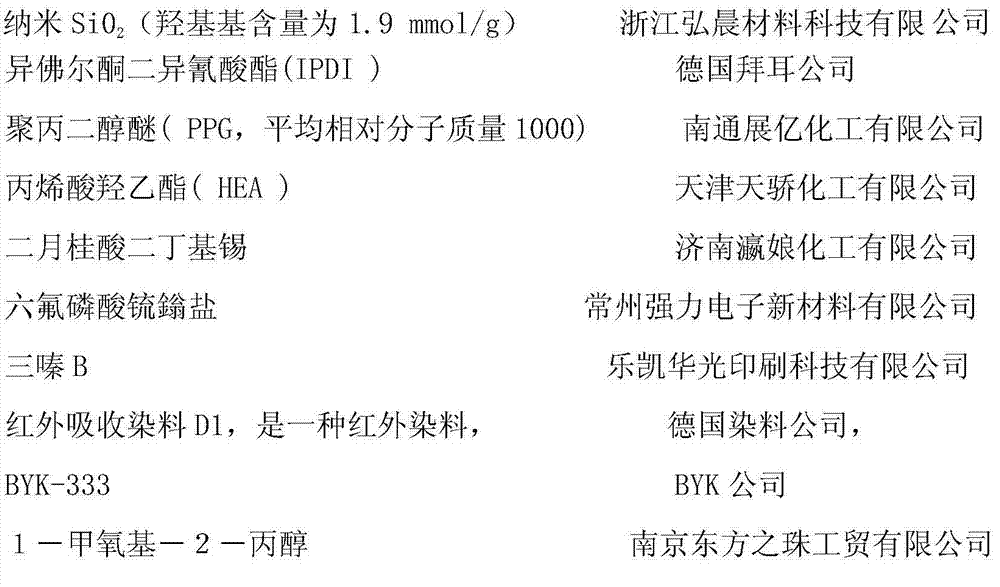

UV-cured plate base coating for ink-jet printing direct plate making and preparation method thereof

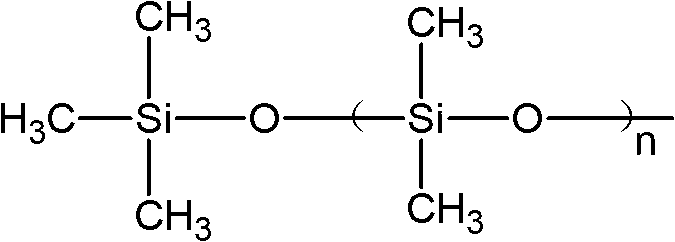

ActiveCN106336784AStable storageImprove the running forcePolyurea/polyurethane coatingsPolyether coatingsChemical reactionPhotoinitiator

The invention discloses a UV-cured plate base coating for ink-jet printing direct plate making and a preparation method thereof. The UV-cured plate base coating comprises, by mass, 5-70 parts of a UV-cured prepolymer, 10-50 parts of oxide particles, 0.01-10 parts of a photoinitiator and 1-30 parts of a UV-cured reactive monomer. The UV-cured prepolymer contains hydroxyl and / or carboxyl function groups. After UV curing, a part of the hydroxyl and / or carboxyl function groups are still retained. In ink-jet printing plate making, the hydroxyl and / or carboxyl function groups residual in the coating and plate making ink undergo a crosslinking chemical reaction so that the plate making ink is cured on the coating, plate pressrun is improved and a plate making precision is greatly improved. The UV-cured plate base coating has pressrun of 100000 after ink-jet plate making.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A positive thermal CTP plate with UV ink resistance

ActiveCN103879169BIncreased sensitivityHigh developing latitudePlate printingFoil printingSolubilityDouble coating

The invention discloses positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink. The positive image thermo-sensitive CTP printing plate material made by high-quality aluminum plate base and double coatings comprises a plate material support body. A resin layer good in solvent resistance and alkaline solubility coats the support body. A positive image thermo-sensitive photosensitive layer coats the resin layer. The main film forming resin also called polymer binder in the resin layer is independently researched and developed by the inventor company, and the photosensitive layer is modified by traditional single-layer thermo-sensitive CTP of the inventor company. The plate material is high in photosensitivity, excellent in screen dot reduction, large in plate making operation tolerance, stable in performance and high in printing adaptability. The plate material can be specially used for UV ink printing and also be used as the long-printing-process plate material of traditional solvent ink printing, and better printing durability is achieved when the plate material is applicable to the mentioned printing after baking.

Owner:LUCKY HUAGUANG GRAPHICS +1

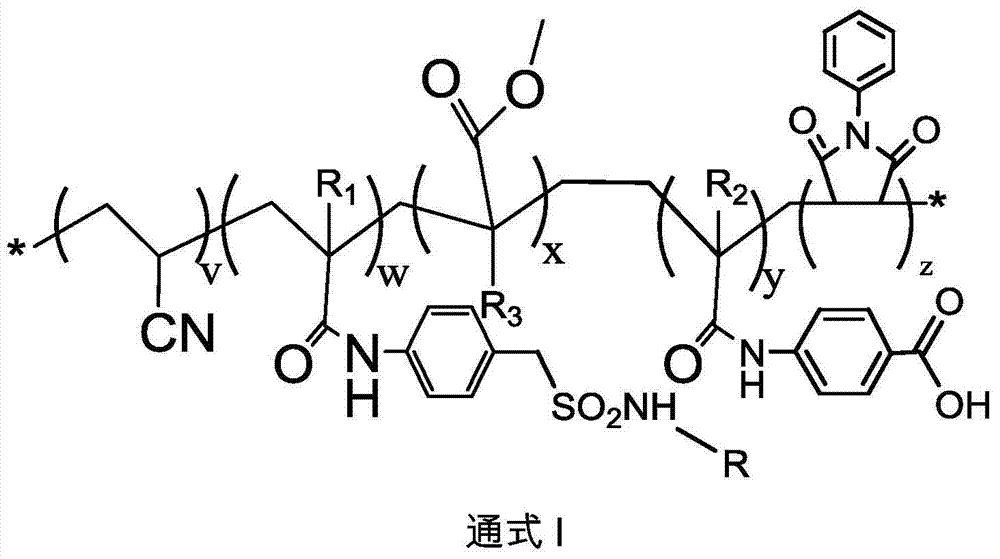

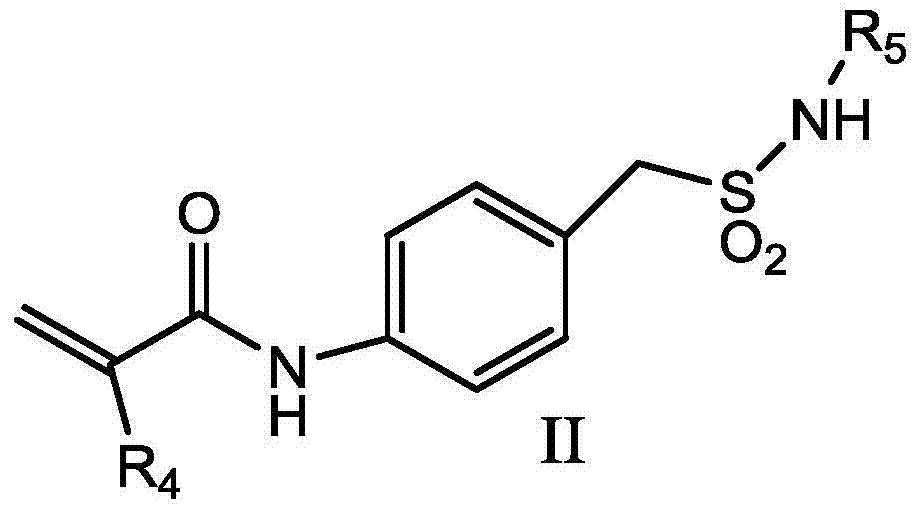

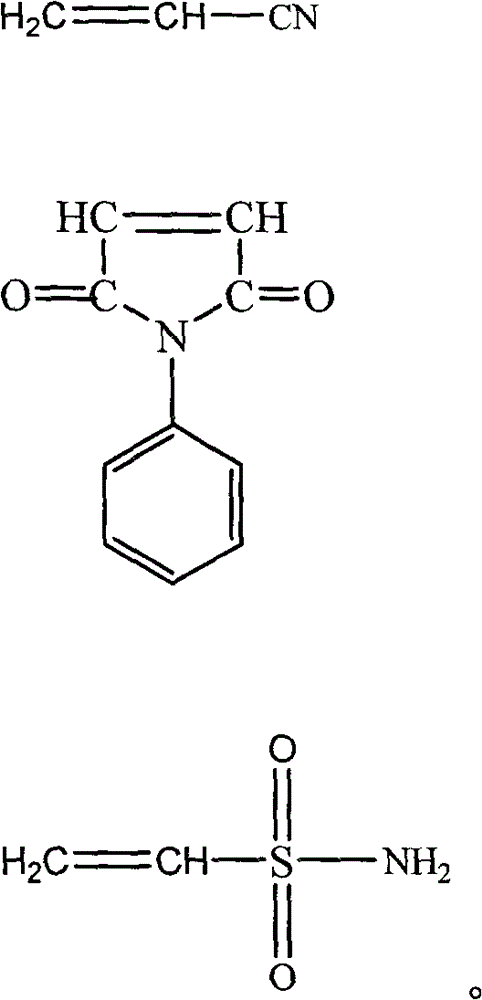

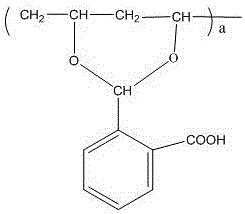

Positive image thermal-sensitive UV-resistant printing ink CTP material

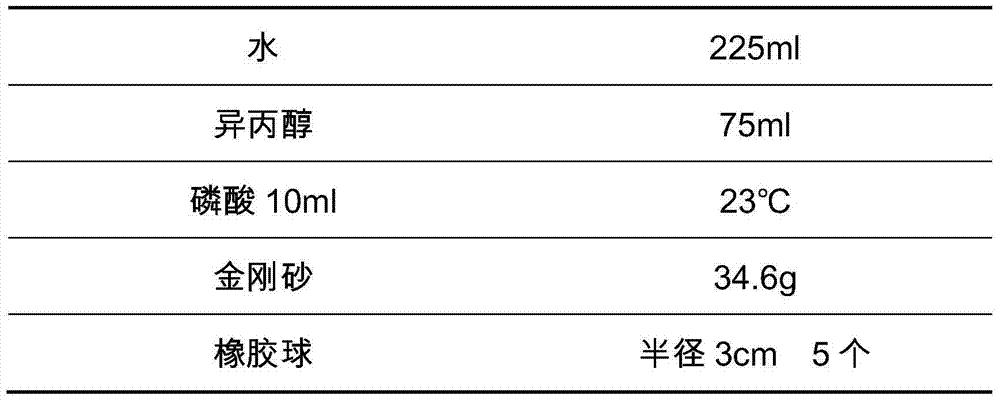

ActiveCN109774334AGood storage stabilityChange performancePlate printingFoil printingSolubilityAnti solvent

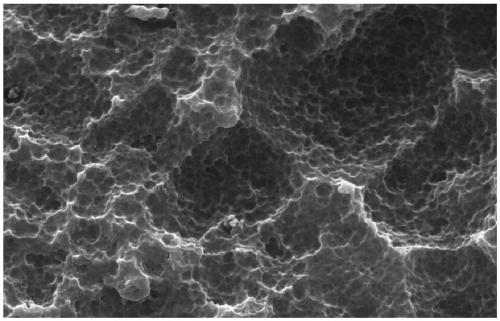

The invention discloses a positive image thermal-sensitive UV-resistant printing ink CTP material. The positive image thermal-sensitive UV-resistant printing ink CTP material comprises a plate material supporting body. A resin layer coats the plate material supporting body, and a positive image thermal-sensitive photosensitive layer coats the resin layer. The resin layer comprises an anti-solventtype vinyl polymer and background dye, wherein the anti-solvent type vinyl polymer is good in alkali solubility. The positive image thermal-sensitive photosensitive layer is a photosensitive layer which contains an olefinic copolymer and a polyvinyl acetal copolymer, wherein the olefinic copolymer contains a benzene sulfonamide group. The positive image thermal-sensitive UV-resistant printing inkCTP material has the beneficial effects that the positive image thermal-sensitive lithographic plate printing plate material which comprises the structure, the components and a honeycomb structure grained aluminum plate base processed by the special technology has the advantages of being high in chemical resistance, alcohol resistance, printing durability and scratch resistance.

Owner:LUCKY HUAGUANG GRAPHICS

Lithographic original plate and printing method thereof

ActiveCN104290483BAvoid scratchesAvoid ablationPlate printingPhotomechanical exposure apparatusCross-linkImage recording

The invention relates to an original edition of a lithograph plate, and the original edition comprises an image recording layer and a substrate, wherein the image recording layer includes an infrared absorber, an energy initiation cross-linking and / or polymerization initiator and a cross-linkable and / or polymerization multi-polymer, the image recording layer is the single-layer hydrophilic and oleophylic mixture, and the contact angle of the mixture with the water drop in air is less than or equal to 10 degrees. Through the original edition of the lithograph plate, the intensity and anti-chemical property of the image part can be greatly improved, thereby improving durability and achieving the excellent developing effect and durability.

Owner:LUCKY HUAGUANG GRAPHICS +1

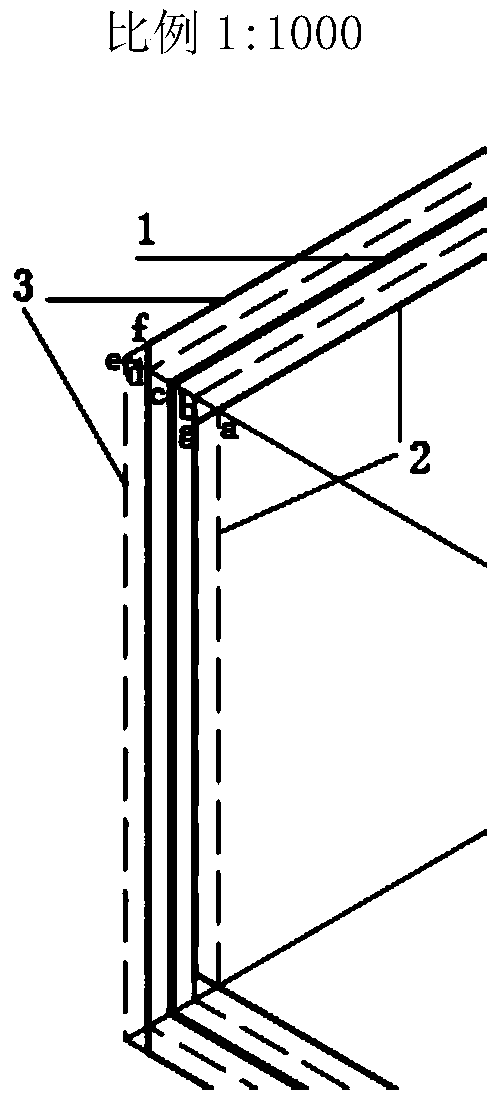

Processing method of high pressrun printing plate and printing plate material thereof

ActiveCN103395278AImprove wear resistanceImprove the running forcePlate printingFoil printingPhysical chemistryMaterials science

The invention relates to a processing method of a high pressrun printing plate, comprising: setting a photosensitive layer on a surface of a lipophilic substrate layer, irradiating the photosensitive layer with laser, to make the lipophilic substrate layer of the parts irradiated by the laser to be exposed after development; and then setting a metal hydrophilic layer on the exposed part of the lipophilic substrate layer, removing the residual photosensitive layer, and completing the process after maintaining and cutting. The process method has characteristics of simple preparation process, low environment pollution, high product quality and high pressrun of the obtained printing plate. Furthermore, a printing plate material can be formed by pre-setting the photosensitive layer on the surface of the lipophilic substate layer. By mass production of the printing plate material, making efficiency of the printing plate is higher, and quality is more stable.

Owner:CHINA BANKNOTE DESIGNING & ENGRAVING CO LTD

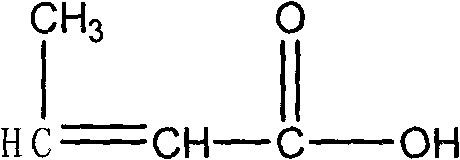

Positive-working thermosensitive lithography printing plate material

InactiveCN106292183AIncreased sensitivityGood dot qualityPhotomechanical apparatusLithographyScreentoneEngineering

The invention discloses a positive-working thermosensitive lithography printing plate material. The material comprises a hydrophillic layer base body and a thermosensitive layer covering the hydrophillic layer base body, wherein the main component alkali-soluble resin in the thermosensitive layer is composed of an IA repetitive unit, an IB repetitive unit, an IC repetitive unit and an ID repetitive unit. The material has the advantages that the plate material subjected to exposure and liquid alkali developing has high sensitivity, high screentone quality and high pressrun.

Owner:QINGDAO LANFAN NEW MATERIAL

Processless computer to plate precursor, and ultra-short pulse laser plate making method

ActiveCN106543860ANo pollution in the processHas a treatment-free effectPolyurea/polyurethane coatingsPlate printingChemistryEnvironmental resistance

The invention discloses a processless computer to plate precursor. The processless computer to plate precursor is composed of a metal substrate processed via roughening, and an ink-loving resin layer or an UV curable resin layer on the metal substrate, wherein the ink-loving resin layer and the UV curable resin layer contain no photoactive substance, and can be processed via laser ablation. It is not necessary for the coating layer of the processless computer to plate precursor to contain any complex photosensitive systems, coating of the metal substrate processed via roughening with the resin layer which can be processed via etching, and possesses ink resistance and ink-loving performance is enough. According to an ultra-short pulse laser plate making method, the coating layer is subjected to ultra-short pulse laser engraving so as to remove bland parts in an original pattern via ablation, form hydrophilic zones, and obtain ink-loving zones formed by images and texts, processless computer to plate with ink balance needed in lithography is obtained, and environment-friendly and pollution-free computer to plate production is realized.

Owner:LUCKY HUAGUANG GRAPHICS +1

Water-based ink printing plate material and preparation method for same

ActiveCN105818562AAvoid pollutionMeet elastic pressurePlate printingFoil printingWater basedEngineering

The invention discloses a water-based ink printing plate material and a preparation method for the same. The printing plate material structurally comprises a plate base, an ink-repulsive layer and an image-text layer from bottom to top, wherein the ink-repulsive layer is made from fluorinated polysiloxane nano-composite material and coated on the plate base via a spinning way with coating amount of 2.4 to 3.9g.m-2; the ink-repulsive layer is achieved when the fluorinated polysiloxane nano-composite material is solidified for 10 to 30 minutes at the temperature of 120 to 200 DEG C; and the image-text layer is achieved when ink is sprayed on the ink-repulsive layer with spraying amount of 0.8 to 2.5g.m-2 and solidified for 10 to 30 minutes at the temperature of 120 to 200 DEG C. A traditional planographic printing method is broken through and a water-oil mutual-exclusive principle is employed; an image-text area with hydrophic ink and a non-image-text area with water-repellent area are constructed on a planographic printing surface; and a technical scheme of traditional planographic printing material having to employing water or similar "fountain solution" to occupy a blank area can be avoided. With only water-ink (without of water or other fountain solution), water-based ink image-text area and non-water-based ink blank area can be separated on the plate material surface; and printing patterns can be formed when transferred to a printing material surface.

Owner:INST OF CHEM CHINESE ACAD OF SCI

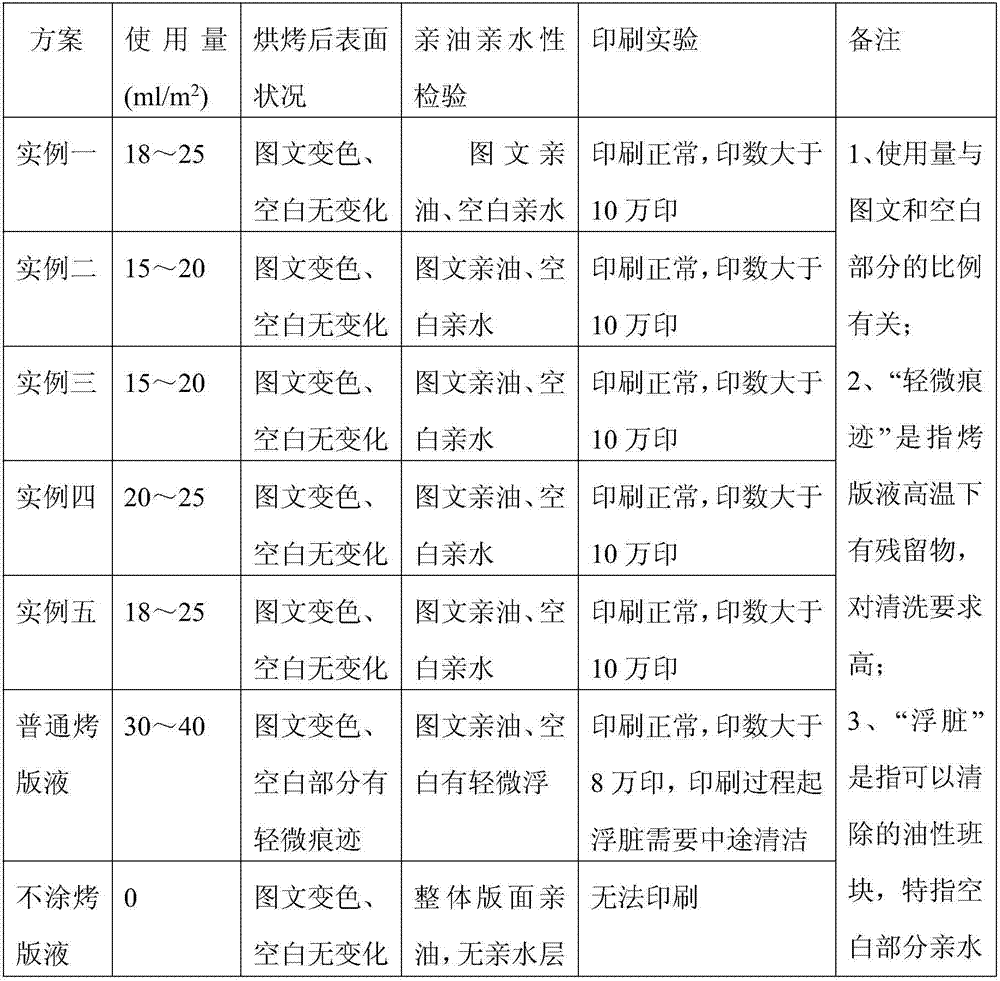

Protective solution for CTP plate material in the baking process

The invention belongs to the technical field of printing plate material production, in particular to a protective solution for a CTP printing plate material in the baking process. The protective solution comprises the following raw materials, by mass percentage, 1.0-7.0% of borate, 0.5-1.0% of a nonionic surfactant, 0.5-1.2% of an anionic surfactant, and the balance water, wherein the borate is at least one selected from ammonium pentaborate, sodium tetraborate, ammonium tetraborate and ammonium fluoborate, the nonionic surfactant is at least one selected from alkylphenol ethoxylates and fatty alcohol-polyoxyethylene ether, and the anionic surfactant is at least one selected from alkyl diphenyl ether disulfonate, fatty alcohol-polyoxyethylene ether sulfosuccinic acid half-ester disodium salt, alkyl ether sulfonated sodium succinate and sodium dodecyl benzene sulfonate. The protective solution for the CTP printing plate material in the baking process has the advantages that the pressrun of the printing plate material can be increased, and the layout can be ensured not to be dirty.

Owner:HUANGSHAN YINJIANG TECH +1

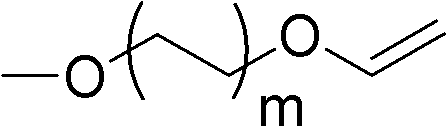

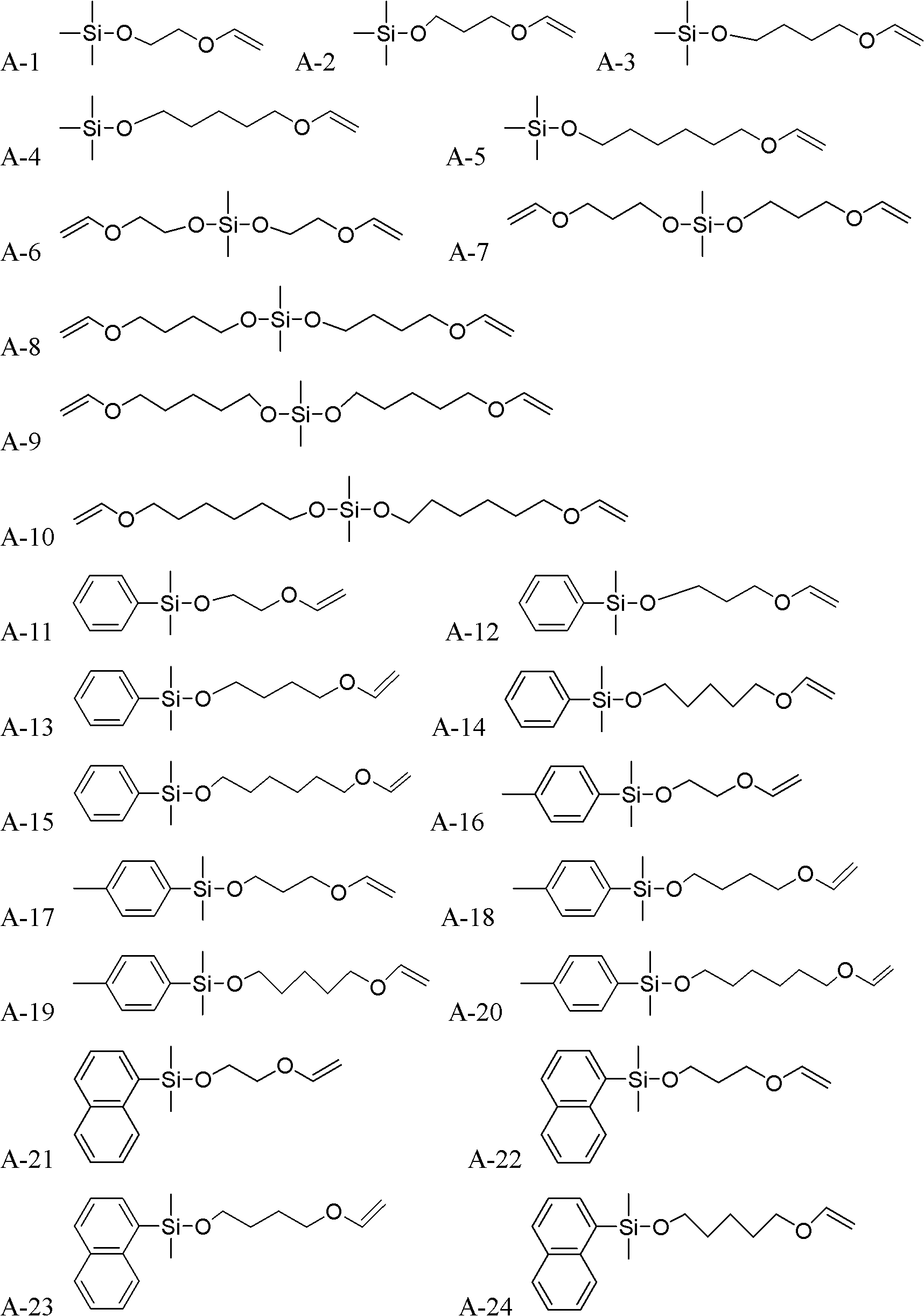

Cationic polymerization imaging composition for high-sensitive photopolymerization plate

ActiveCN102566277BIncreased sensitivityImprove the running forcePhotosensitive materials for photomechanical apparatusVinyl etherCationic polymerization

Owner:BEIJING NORMAL UNIVERSITY

Imaging liquid for thermosensitive CTP (cytidine triphosphate) plate

ActiveCN102841502AImprove the running forceGuaranteed imaging effectPhotosensitive materials for photomechanical apparatusSurface-active agentsSolvent

The invention provides an imaging liquid for a thermosensitive CTP (cytidine triphosphate) plate, which comprises the following components by weight: the solute of the imaging liquid comprising 75-90 parts of film forming resin, 2-5 parts of infrared dye, 5-10 parts of acid production agent, 2-6 parts of cross-linking agent, 1-2 parts of surface active agent, and 2-5 parts of background coloring dye solvent, and the imaging liquid with the weight ratio of the solute to the solvent being (10-15) to (85-90); and the acid production agent is polyamide. According to the imaging liquid, after components in the imaging liquid such as the acid production agent and the like are improved and on the basis that the imaging effect is ensured, the pressrun of the imaging liquid is effectively improved, and the production cost is greatly saved, therefore, the imaging liquid provided for the thermosensitive CTP plate has good application value.

Owner:成都星科印刷器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com