Imaging liquid for thermosensitive CTP (cytidine triphosphate) plate

An imaging solution and plate technology, which is applied in the direction of photosensitive materials used in optomechanical equipment, can solve the problem that the printing endurance needs to be improved, and achieve the effects of improving the printing endurance, saving production costs and good application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Preparation of imaging liquid of the present invention

[0030] Get 75g film-forming resin, 2g infrared dye, 5g polyamide, 2g crosslinking agent, 1g surfactant, 2g colored background dye, 704g of mixed solvent of 70% propylene glycol methyl ether and 30% butanone, each component is dissolved in In the mixed solvent, the imaging liquid is obtained;

[0031] Wherein, the film-forming resin is BTB-25 phenolic resin;

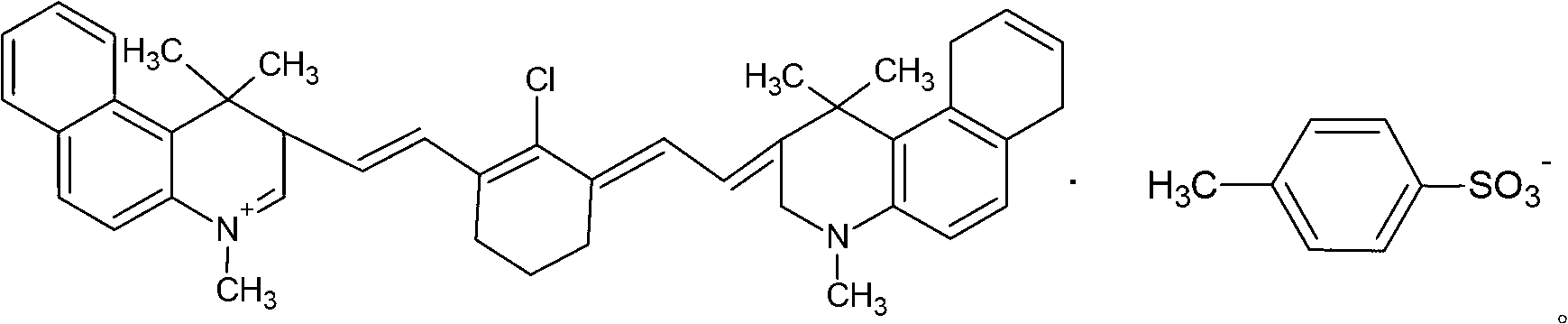

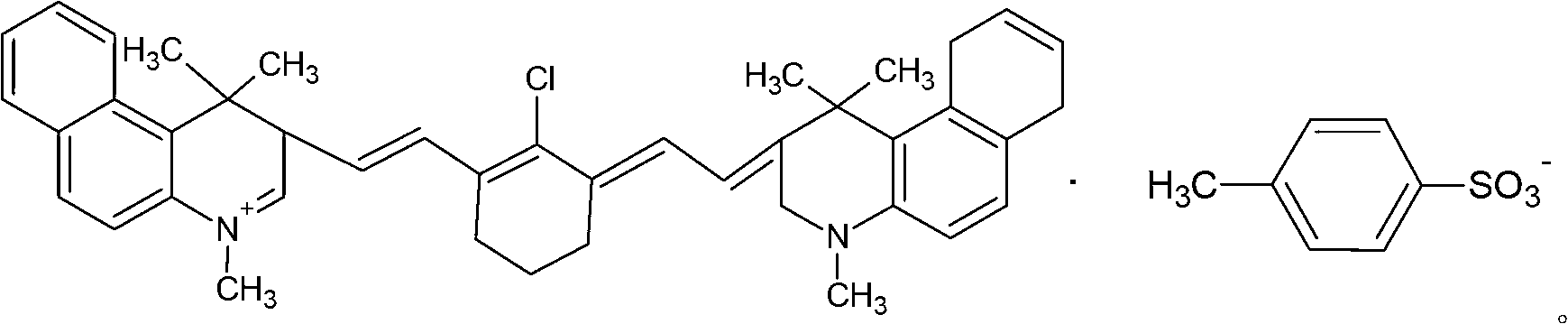

[0032] The infrared dye is (model: TR-8131)

[0033]

[0034] Polyamide is an acid generator with a weight average molecular weight of 1200~4000.

[0035] The crosslinking agent is a copolymer of methyl methacrylate and ethyl methacrylate, and its weight average molecular weight is 6800~12000.

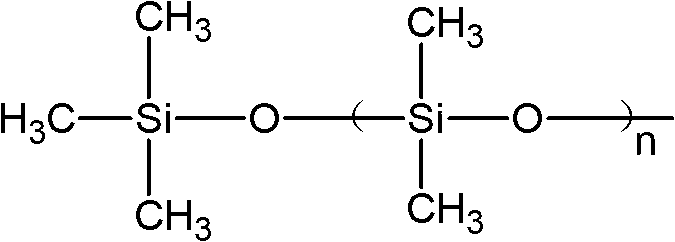

[0036] Surfactant is siloxane, and its structural formula is as follows:

[0037]

[0038] n is 15-25.

[0039] The coloring background dye is crystal violet.

Embodiment 2

[0040] Embodiment 2 Preparation of imaging liquid of the present invention

[0041] As in Example 1, wherein the film-forming resin is BTB-26G, and the colored background dye is Basic Brilliant Blue. The beneficial effects of the present invention will be specifically described below through test examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com