Patents

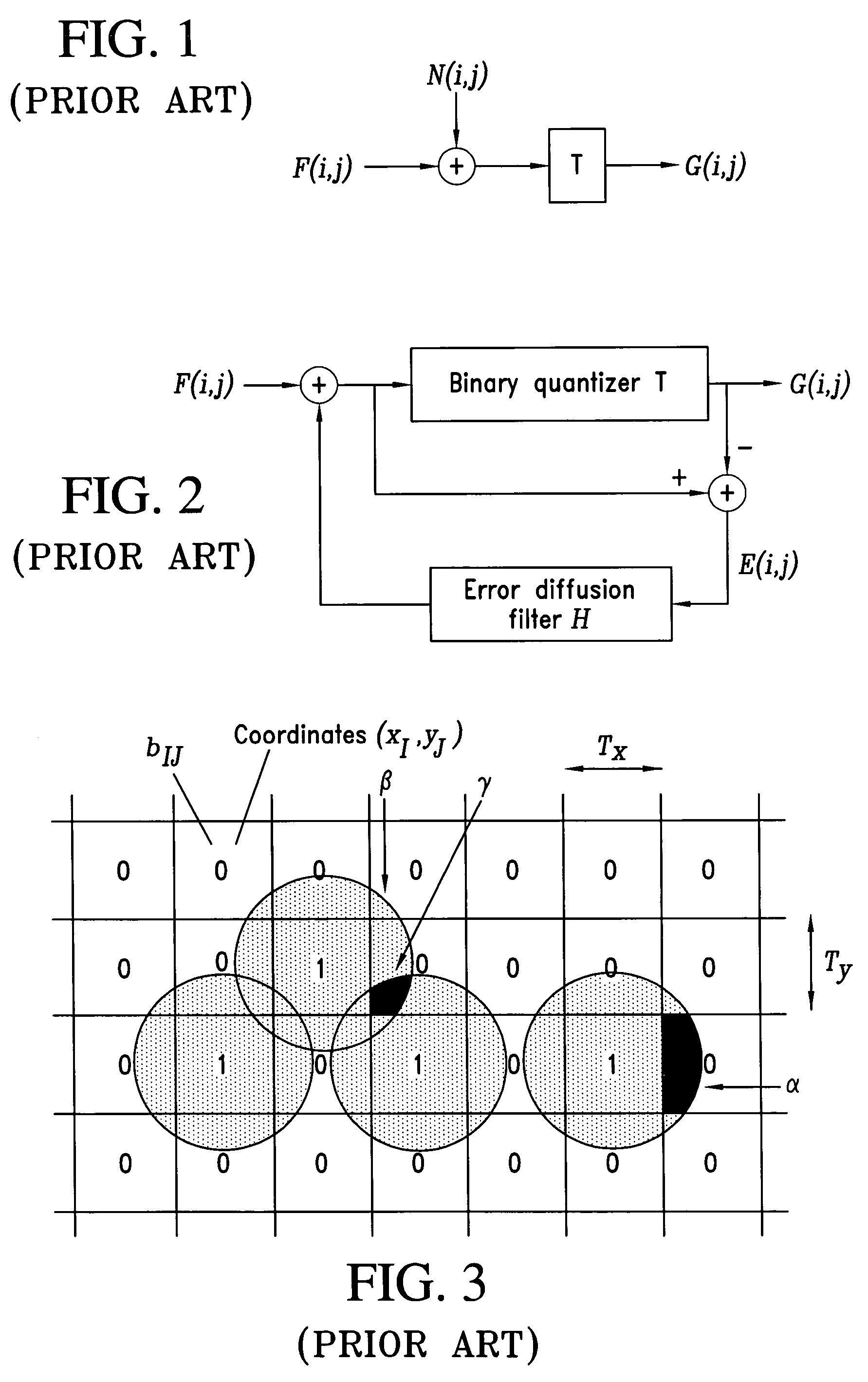

Literature

232 results about "Screentone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screentone is a technique for applying textures and shades to drawings, used as an alternative to hatching. In the conventional process, patterns are transferred to paper from preprinted sheets, but the technique is also simulated in computer graphics, notably in Flipnote Studio and Macpaint. It is also known by the common brand names Zip-A-Tone (1937, now defunct), Chart-Pak (1949), and Letratone (1966, from Letraset).

Methods and compositions for ink jet printing of pressure sensitive adhesive patterns or films on a wide range of substrates

InactiveUS20020128340A1Minimize dot gainLow viscosityAdhesive processesImpression capsDot gainFluid composition

Owner:3M INNOVATIVE PROPERTIES CO

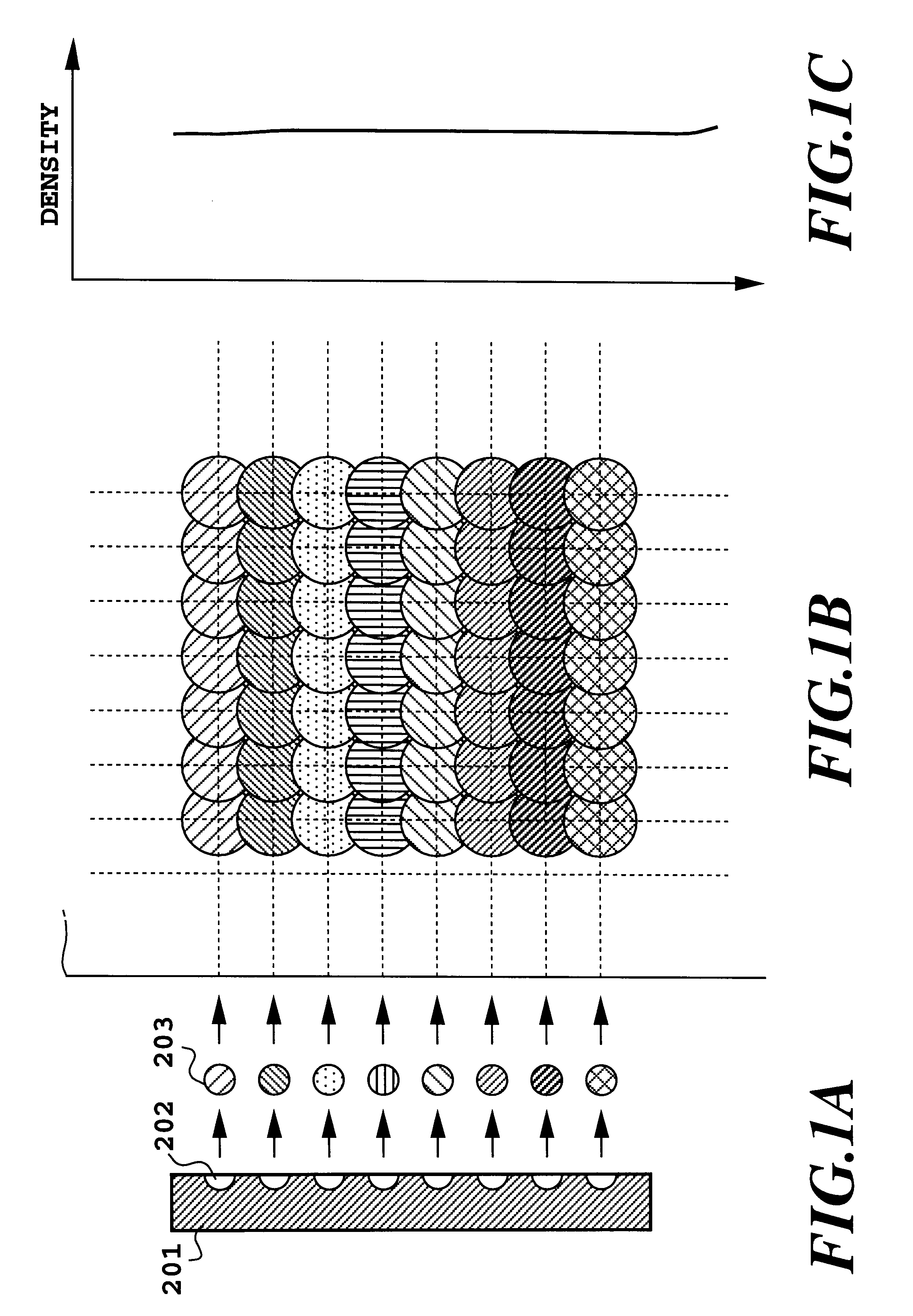

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6257143B1Guaranteed uptimeLow costCylinder pressesPlaten pressesEngineeringPrinting registration

A plurality of patterns respectively having different area factor of dot formation area are formed by forward and reverse scanning printing of a print head, and then optical characteristics of the plurality of formed patterns are measured. A function representing the relationship between the printing position offset between the forward and reverse printings is determined from the optical characteristics. Then, respective pattern having a predetermined area factor of dot formation area is formed by means of forward and reverse scanning where the speed is differentiated according to the mode of a printing apparatus, and then the optical characteristics of this pattern is measured. By applying this measured optical characteristics to the function, an adjustment value of the dot formation position conditions between the forward and reverse scans is obtained for each mode. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

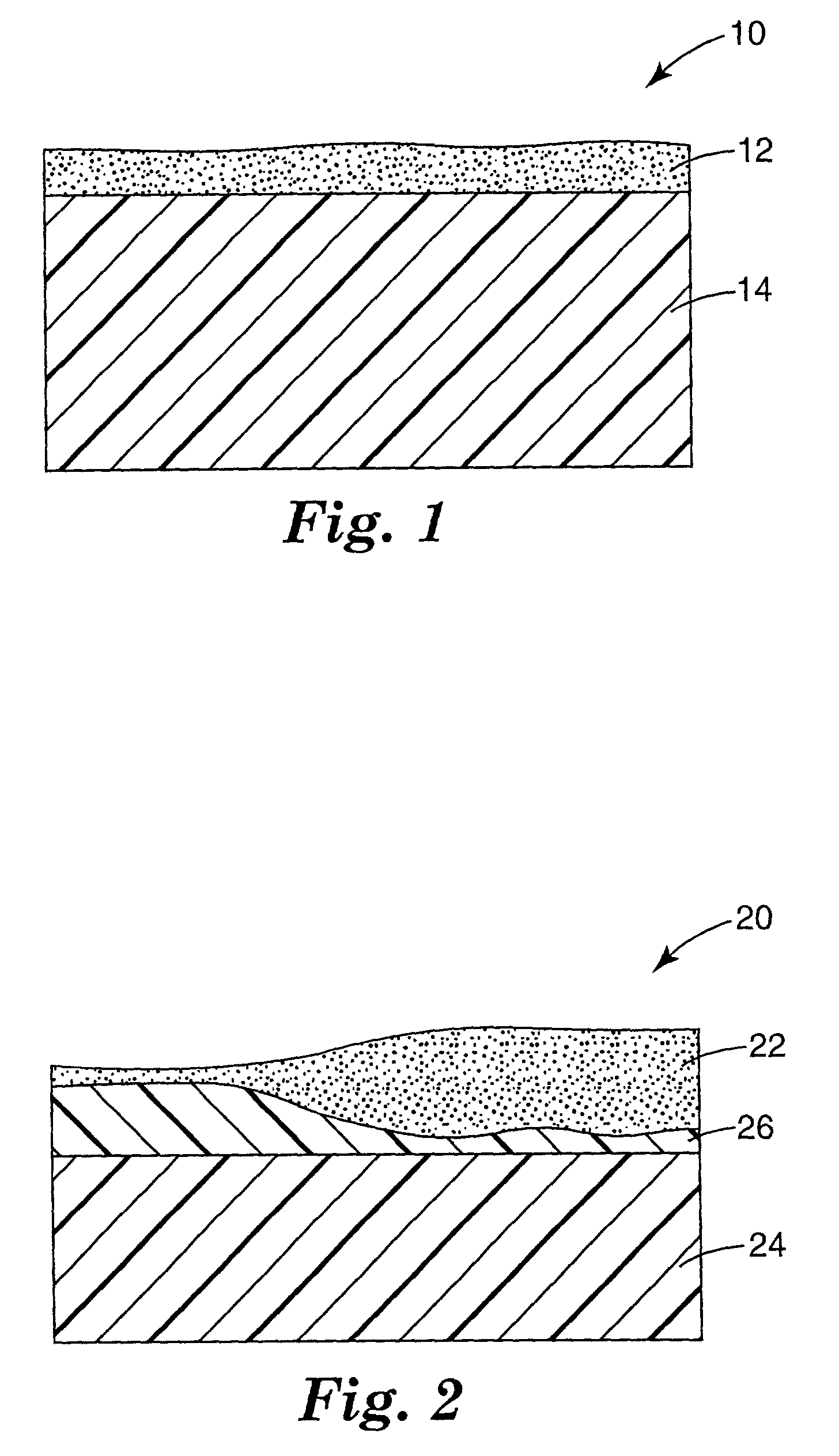

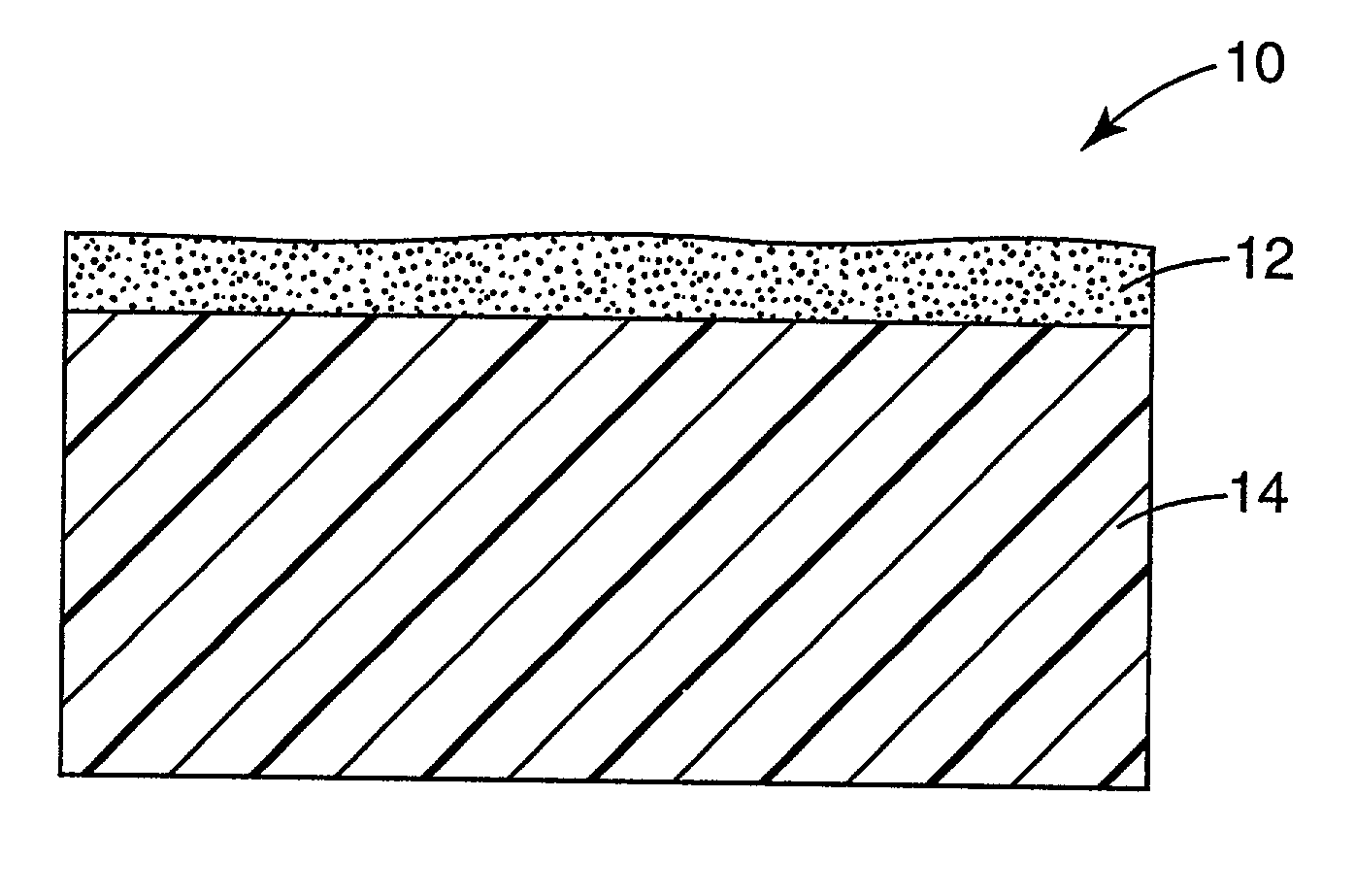

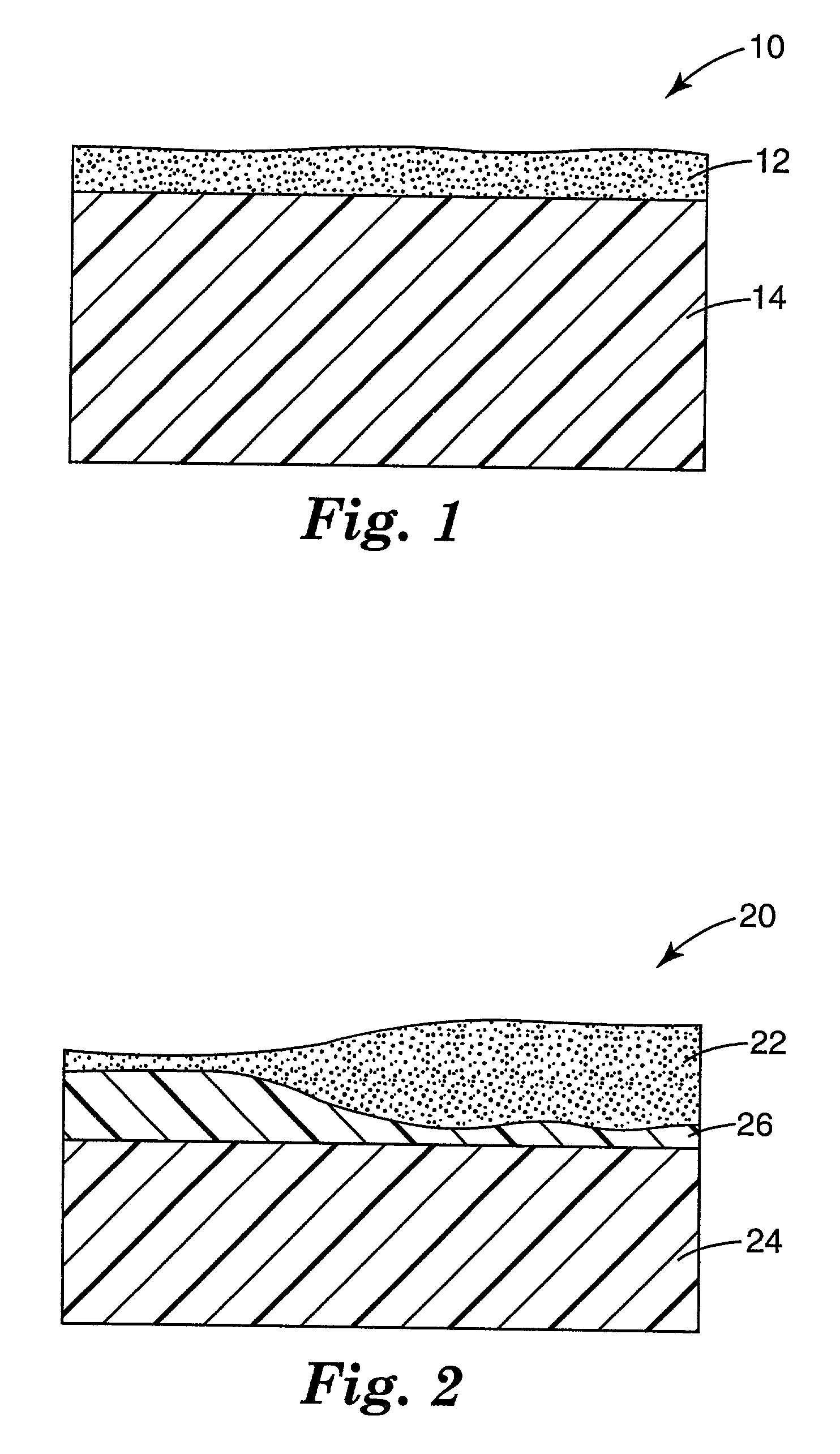

Imaged articles comprising a substrate having a primed surface

InactiveUS20030054139A1Decorative surface effectsSynthetic resin layered productsSolubilityImaging quality

The present invention relates to an imaged article comprising a substrate having a primed surface layer. The primed surface layer is comprised of a base polymer having a solubility parameter, molecular weight (Mw) and glass transition temperature within a specified range. The presence of the primer improves the overall image quality by improving at least one property including ink uptake, dot gain, color density and / or ink adhesion. Preferred primer compositions are soluble at least in part in the ink composition resulting in an increase in ink layer thickness that further improves the durability and / or day / night color balance. A variety of substrates may be primed including various sheeting for traffic control signage and commercial graphic films for advertising and promotional displays.

Owner:3M INNOVATIVE PROPERTIES CO

Imaged articles comprising a substrate having a primed surface

Owner:3M INNOVATIVE PROPERTIES CO

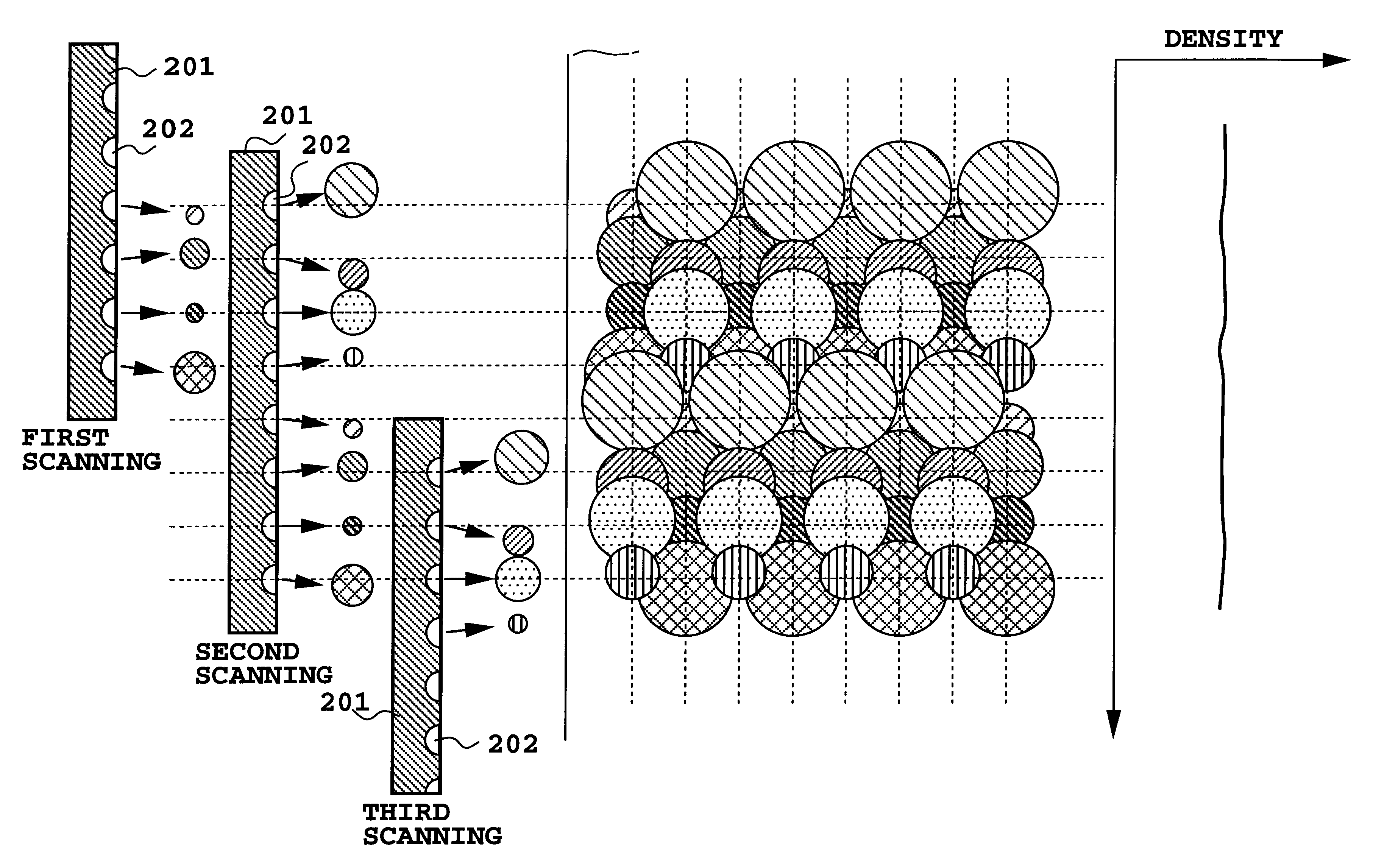

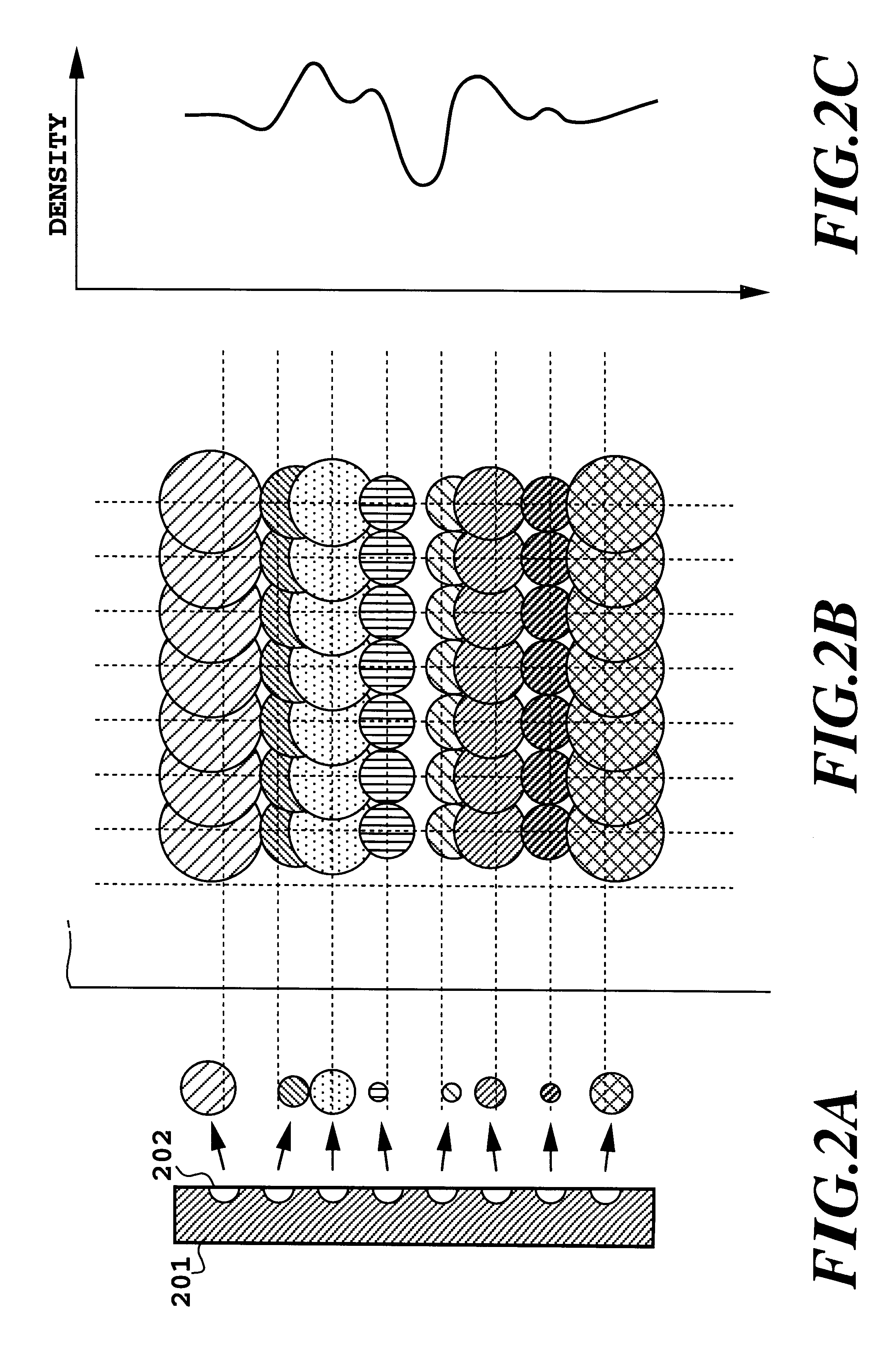

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6464319B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusSmall dropletPrinting registration

In the case where an image is formed with a mixture of large and small droplets by bi-directional printing in an ink jet printing apparatus in which ink is ejected in the form of, e.g., a droplet for printing operation while scanning by a print head, misalignment caused by a difference in ejection speed between the large and small droplets is prevented. For this purpose, there is provided a printing registration method according to the present invention comprises the steps of forming reference dots with the large and small droplets in forward scan printing, forming shifted dots in reverse scan printing on changed registration conditions, acquiring a adjustment value of the condition of dot forming positions on the basis of optical characteristics according to a plurality of shifting amounts of the relative printing positions between forward scanning and reverse scanning, controlling the order of formation of the large and small dots in the forward scanning and the reverse scanning, and correcting the adjustment value according to the offset amount of the small dot forming positions on the basis of the difference in ejection speed or the like.

Owner:CANON KK

Method of generating proof data and method of generating proof

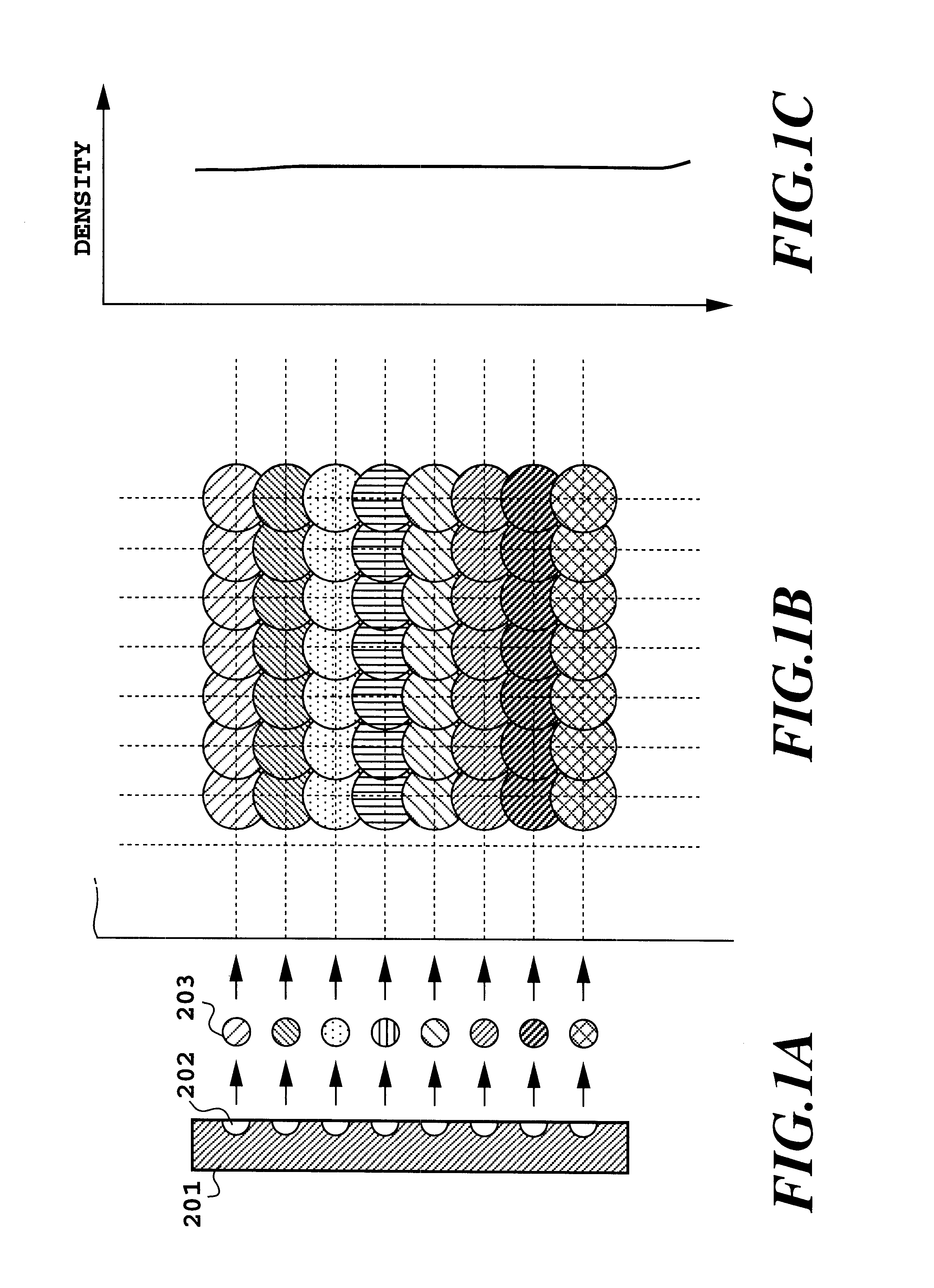

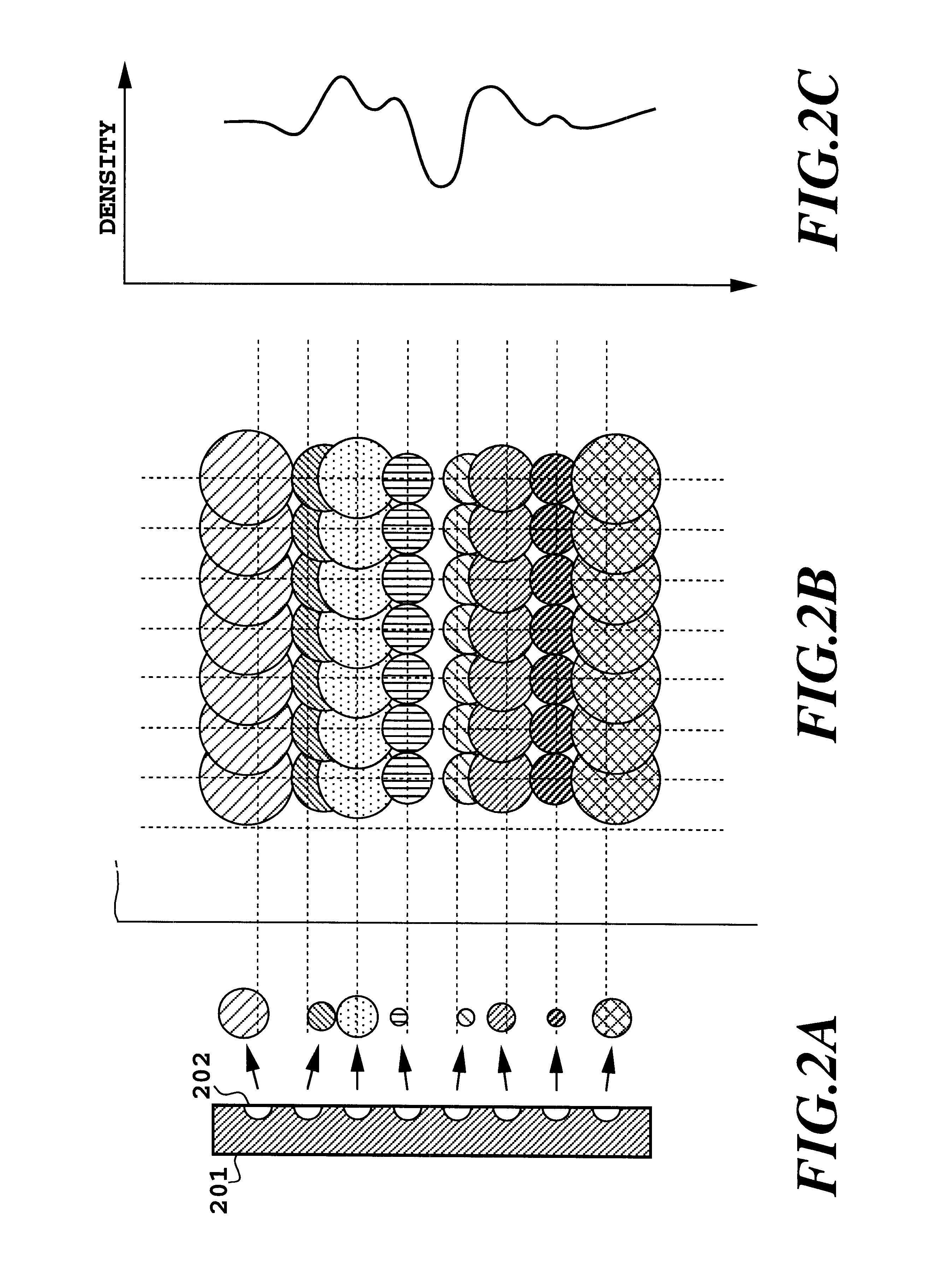

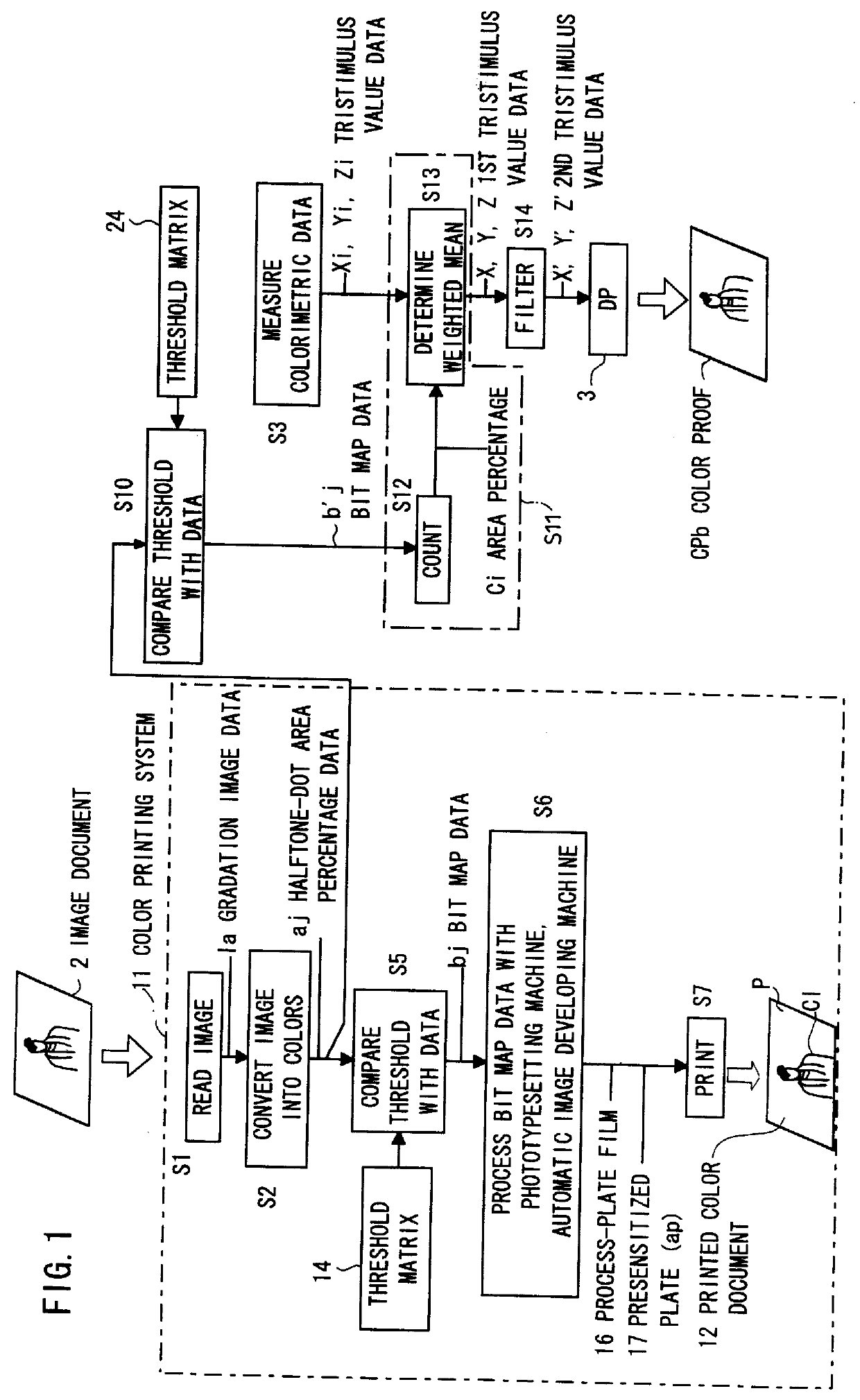

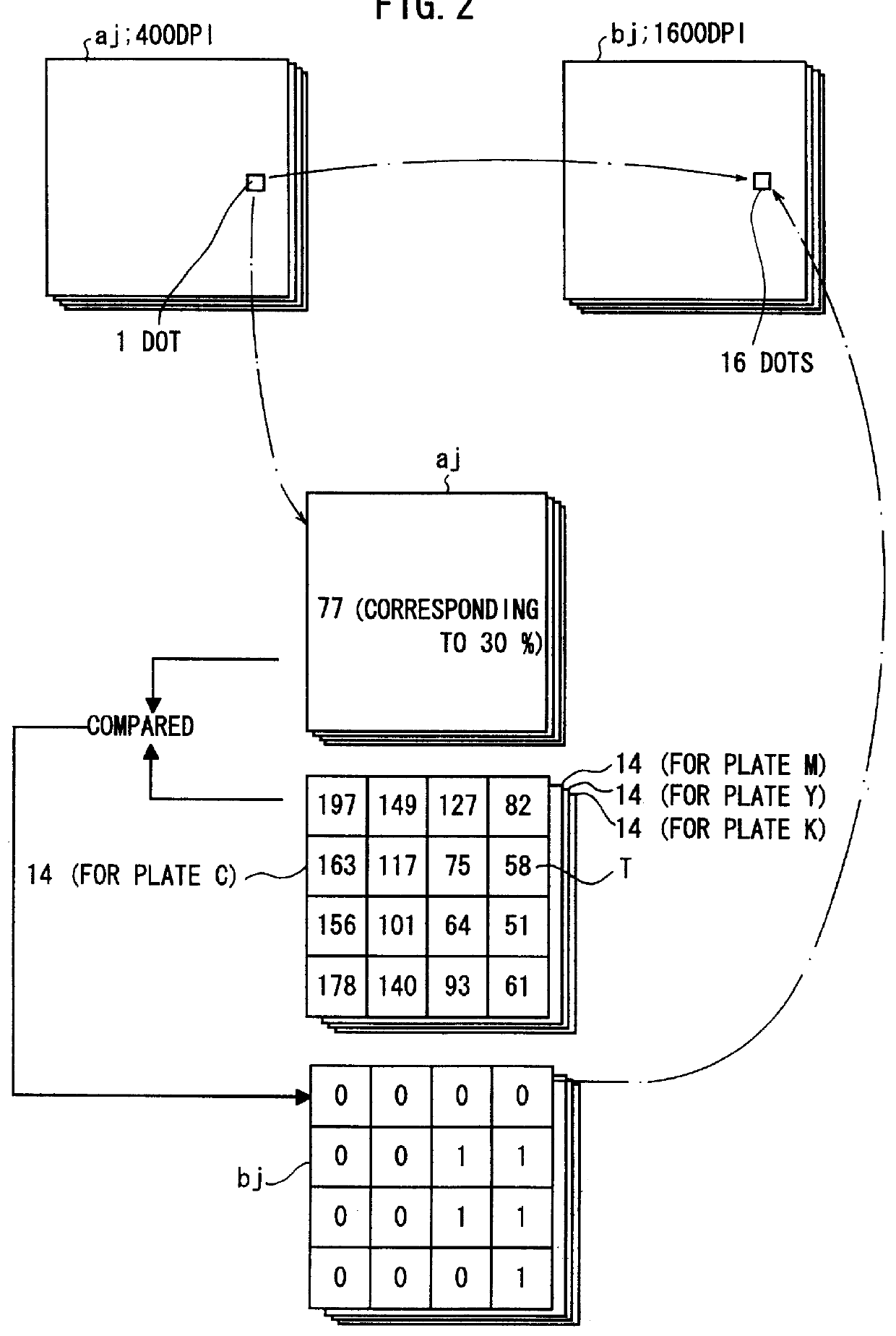

InactiveUS6072588ADigitally marking record carriersDigital computer detailsAnti-aliasingImage resolution

Cumulative histograms generated based on threshold matrixes with respect to halftone-dot area percentage data of the four plates C, M, Y, K are referred to for thereby determining the existential probability of halftone dots. Then, average colorimetric data are calculated from predetermined colorimetric data with respect to every 2n colors using the area percentage as a weighting coefficient. An anti-aliasing filtering process is effected on the average colorimetric data to produce device-independent image data for a color printer. The cumulative histograms are emphasized and the average colorimetric data are emphasized to accurately reproduce a peculiar pattern such as a rosette image which will appear on a printed document on a proof which is outputted from a low-resolution color printer. A process is provided for changing the halftone-dot area percentage data based on the type (wood-free paper, art paper, or the like) of paper of a print sheet of the printed document and the halftone-dot area percentage data on presensitized plates, when the halftone-dot area percentage data are converted into bit map data for the color printer, for thereby reproducing "impression irregularity" and "harshness" out of the visual irregular qualities of paper.

Owner:FUJIFILM CORP +1

Manufacturing method and product for nickel screen die roll for fabric printing

InactiveCN101559662AImprove bonding fastnessExtended service lifePlate printingFoil printingDynamic balanceLaser engraving

The invention relates to a manufacturing method and a product for a nickel screen die roll for fabric printing. The process comprises the following steps: machining, electroplating, copper grinding and polishing, glue coating, description and typesetting, corrosion, and detection. The manufacturing method is characterized in that: the procedure of the description and typesetting is followed by laser engraving; the laser engraving has the concentricity jump of a calibrated printing roll less than or equal to 0.02, printing roll rotating speed of 700 r / min, dynamic balance less than 2, laser power of 20W and engraving length of 2,220 mm; the laser engraving is centrally symmetric; the shape of the nickel screen die roll is a hexagonal, square, diamond or circular mesh point die roll rotating15 degrees; mesh points are U-shaped; and a screen wall is fine and is almost perpendicular. The manufacturing method adopts a jointless laser engraving technique and a controllable corrosion process. The product has the U-shaped mesh points with a large bottom area so as to greatly improve the strength of binding with stuffed insulating rubber, prolong the service life of the die roll, and having relatively stable nickel screen aperture ratio and fewer changes.

Owner:上海希尔彩印制版有限公司

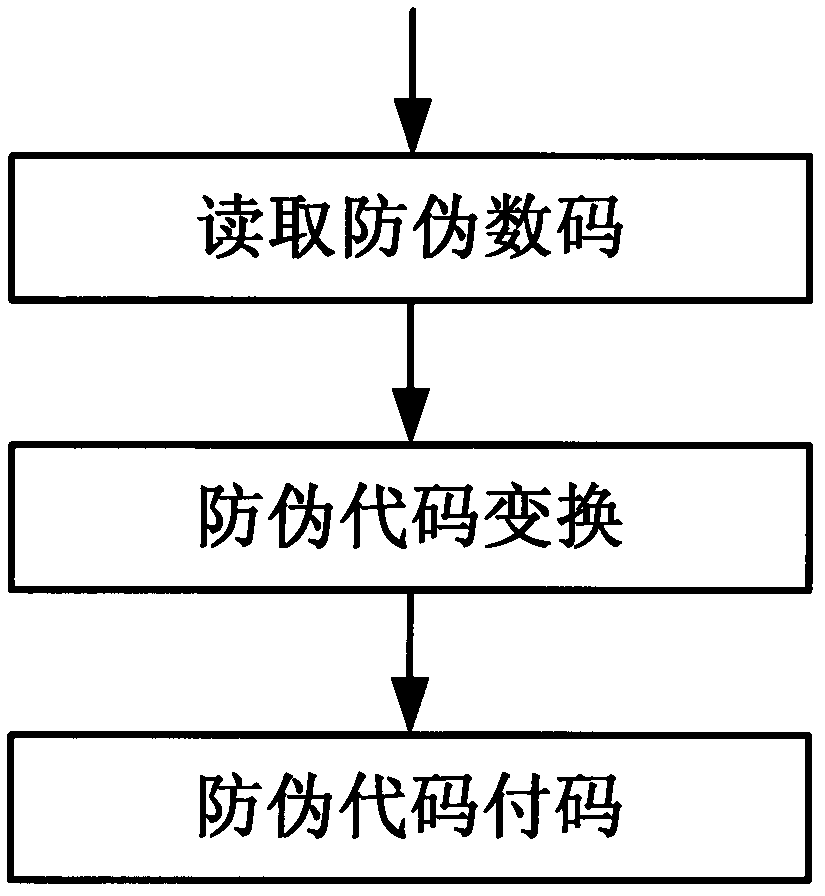

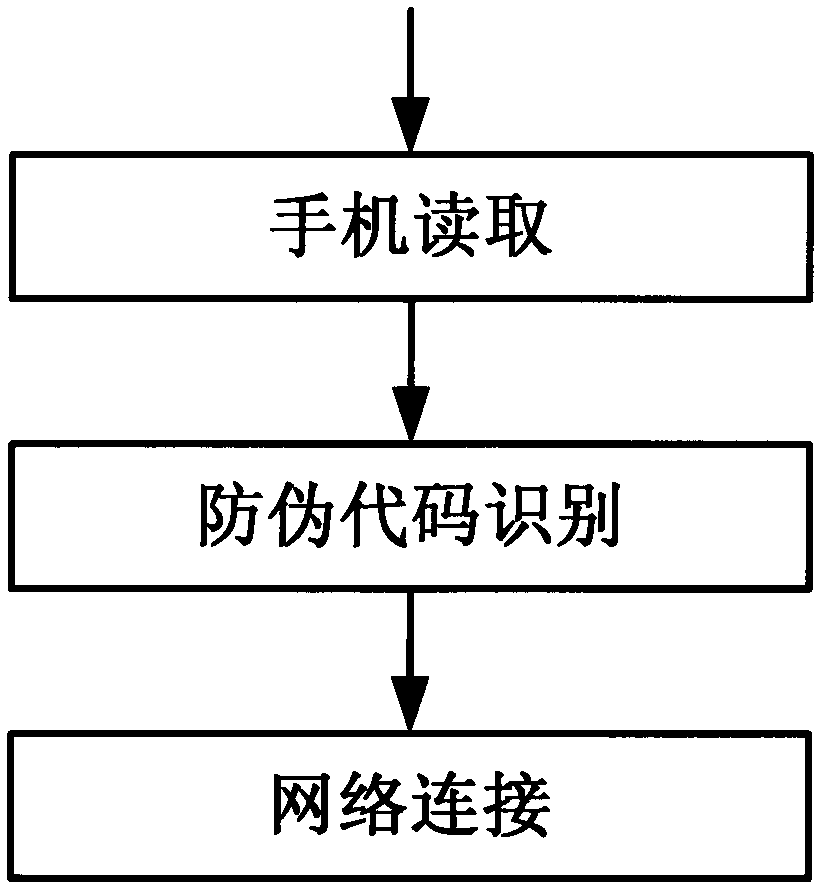

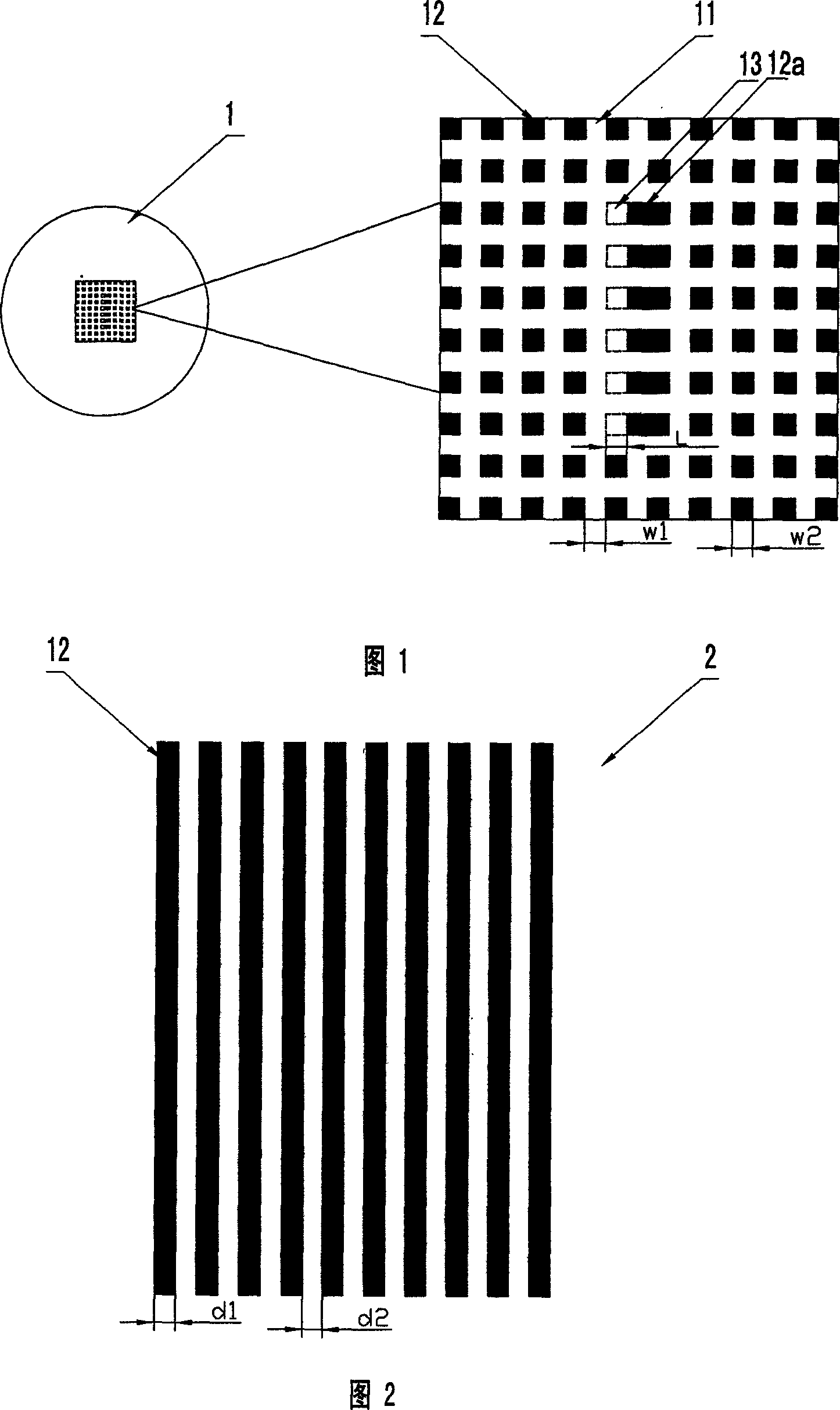

Method for generating dot matrix pattern capable of recording multiple-bit information

ActiveCN103390146AResolve identifiabilityRecording efficiency optimizationPictoral communicationSensing by electromagnetic radiationInformation processingDot matrix

The invention relates to a method for generating a dot matrix pattern capable of recording multiple-bit information in the field of information processing. According to the method, a point with a website can record the multiple-bit information, only one reference dot matrix line needs to be set on a 45-degree inclination angle, correction of position printing errors on a printing machine can be achieved, and efficiency of information recording can be improved. The invention also provides another dot matrix pattern capable of recording the multiple-bit information. The gray value of the dot matrix pattern is only 1 / 4 the maximum gray value of a common two-dimensional bar code, in addition, the information amount is large, network addresses, anti-fake information and the like can be hidden in a commodity logo, the dot matrix pattern capable of recording the multiple-bit information is especially suitable for being recognized and read by public cell phones and can serve as a network inlet of Internet of Things, and any commodity can be connected with the network. The invention further provides a method for obtaining randomly-distributed variable information only through common printing, therefore, printing cost is reduced, anti-fake grades are improved, and popularization is facilitated.

Owner:TIANJIN APOLLO ELECTRONICS

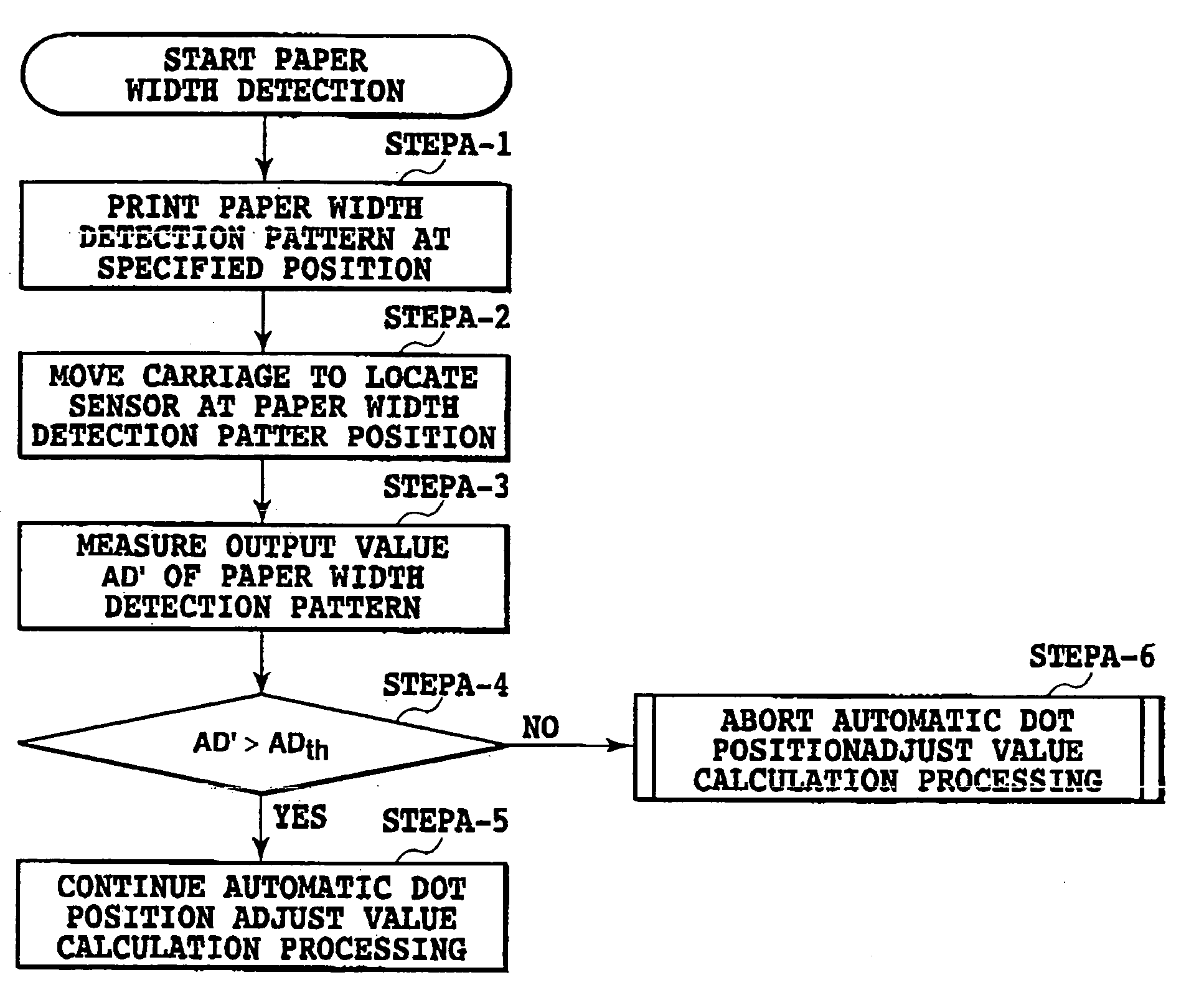

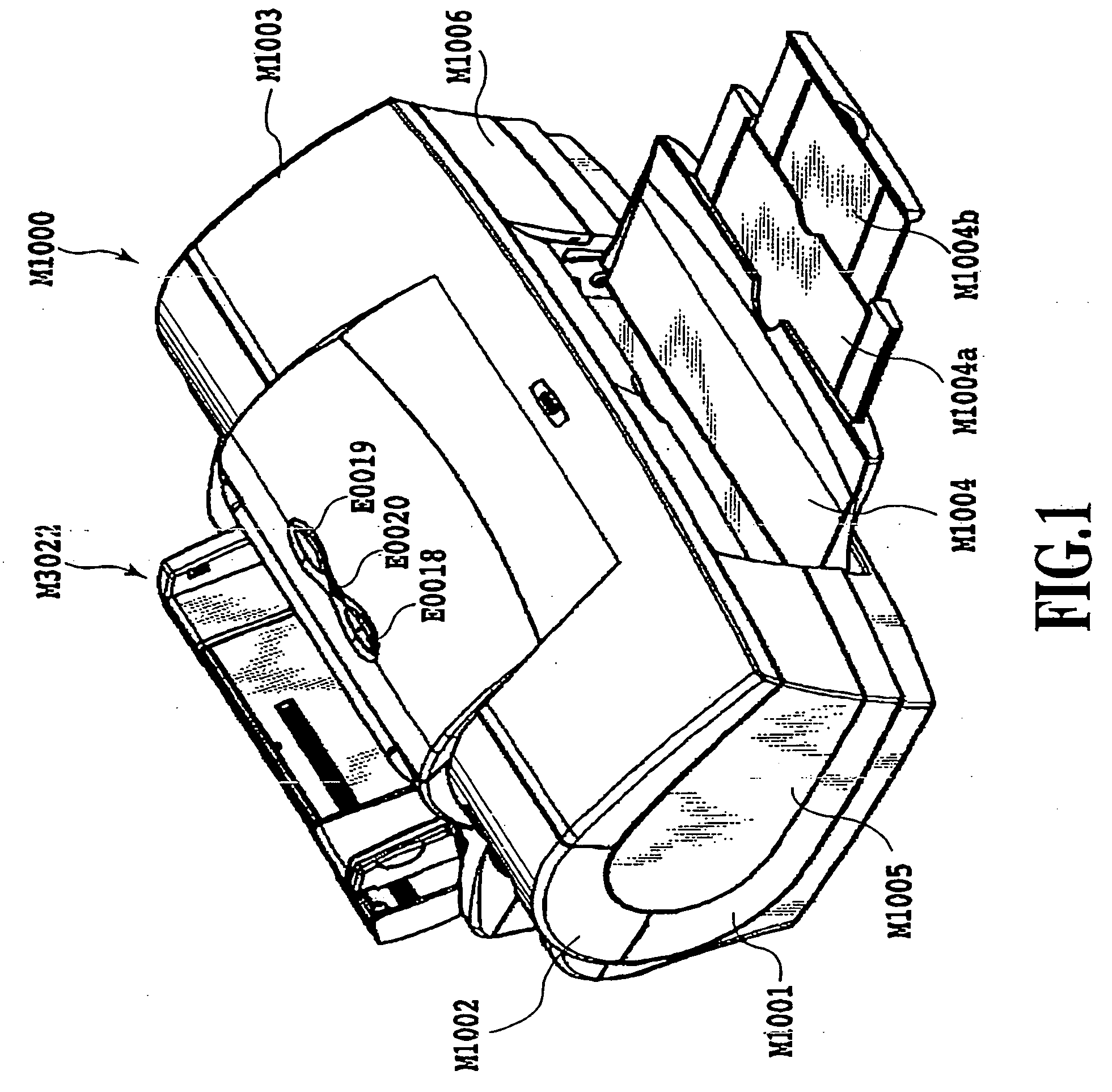

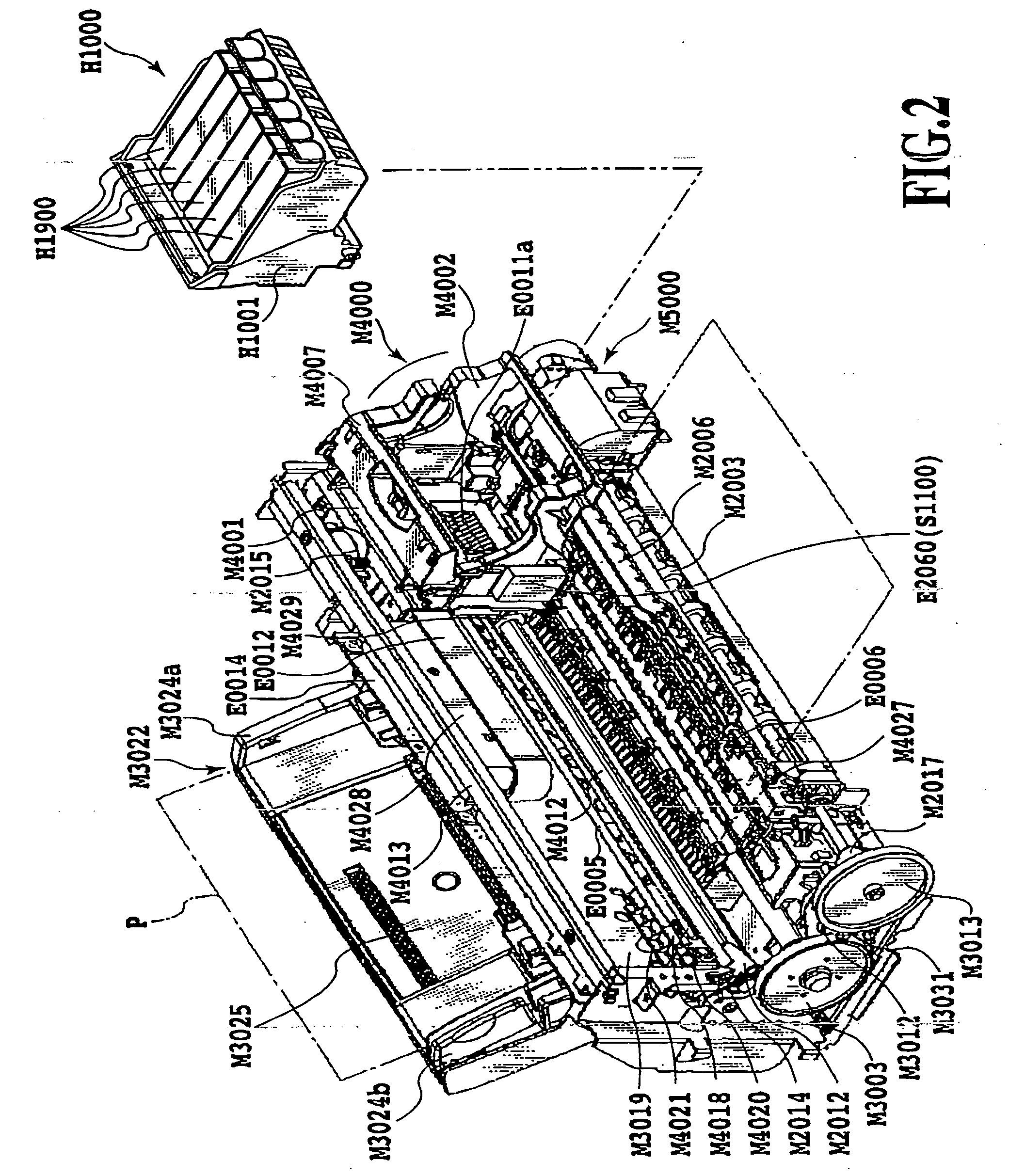

Printing apparatus and dot position adjusting method

ActiveUS20050046657A1Overcomes drawbackOther printing apparatusElectrical and Electronics engineeringEngineering

A printing apparatus and a print position aligning method are provided which can execute a dot position adjust value calculation mode normally and smoothly without requiring the user to make decisions or adjustments. A test pattern to check the width of a print medium is printed and is detected by an optical sensor to decide whether or not a dot position adjustment pattern can be printed. Before the dot position adjustment pattern is printed, a decision is made as to whether the print medium supplied is appropriate or not. If the print medium supplied is smaller than a size specified for the dot position adjust value calculation processing, the print medium is discharged without being printed with the dot position adjustment pattern. This eliminates a possibility of a wasteful consumption of print mediums and of contaminating the interior of the printing apparatus.

Owner:CANON KK

Method for engraving gravure grinding roller by laser

InactiveCN102935755AControl thicknessUniform ink contentPrinting pre-treatmentForme preparationScreentoneLaser engraving

The invention relates to a method for engraving a gravure grinding roller by laser, which is applied to realizing gravure grinding printing. The method comprises the following specific manufacturing steps of (1) rubber coating, (2) rubber sintering, (3) corroding, (4) rubber removing, (5) chromium plating, and (6) checking. The method for engraving a gravure grinding roller by laser, disclosed by the invention, has the advantages that the depth requirement is strict, and 0.05mesh of net points can be controlled so that the printing ink content of each net point is uniform in a printing process; after the printing ink is subjected to gravure transfer printing, the thickness of a whole layout can be uniform, the leveling is good, the concave-convex feeling can be generated; compared with a silk screen manner, the gravure printing manner has the advantages of good third dimension, large printing format, high speed and high efficiency; and the thickness of the printing oil can be precisely controlled, the waste is reduced and the environment protection is realized.

Owner:武汉东运制版有限公司

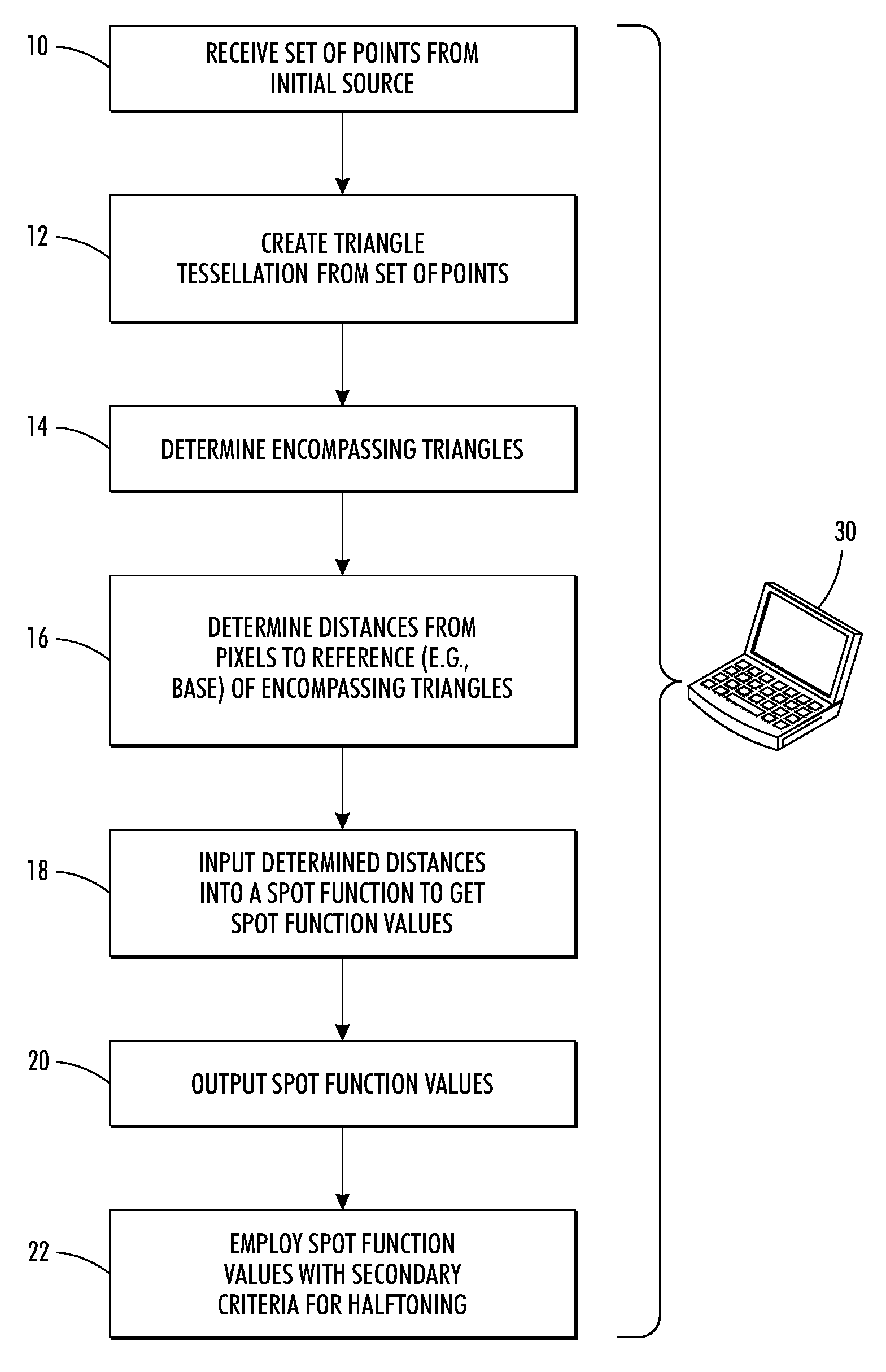

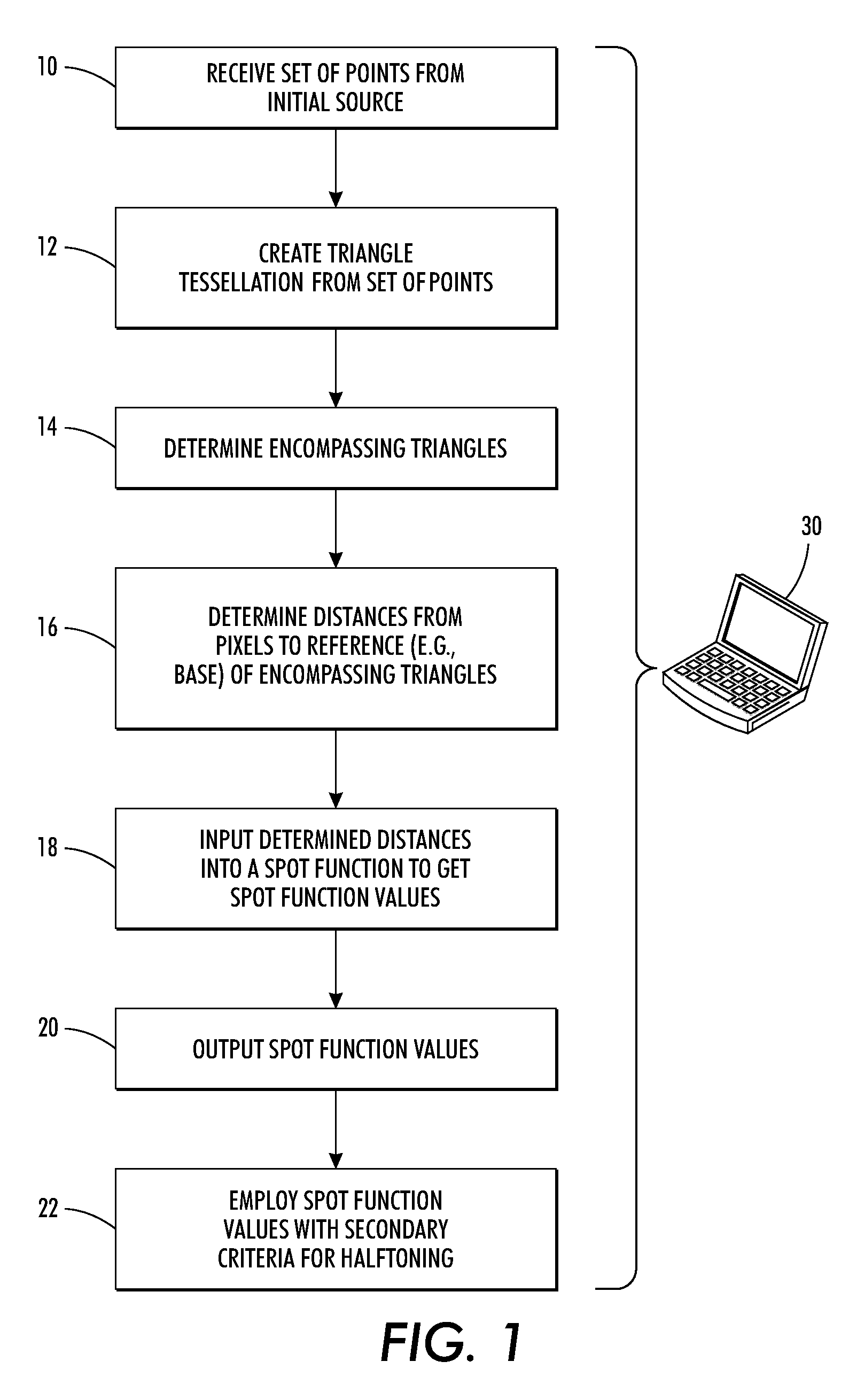

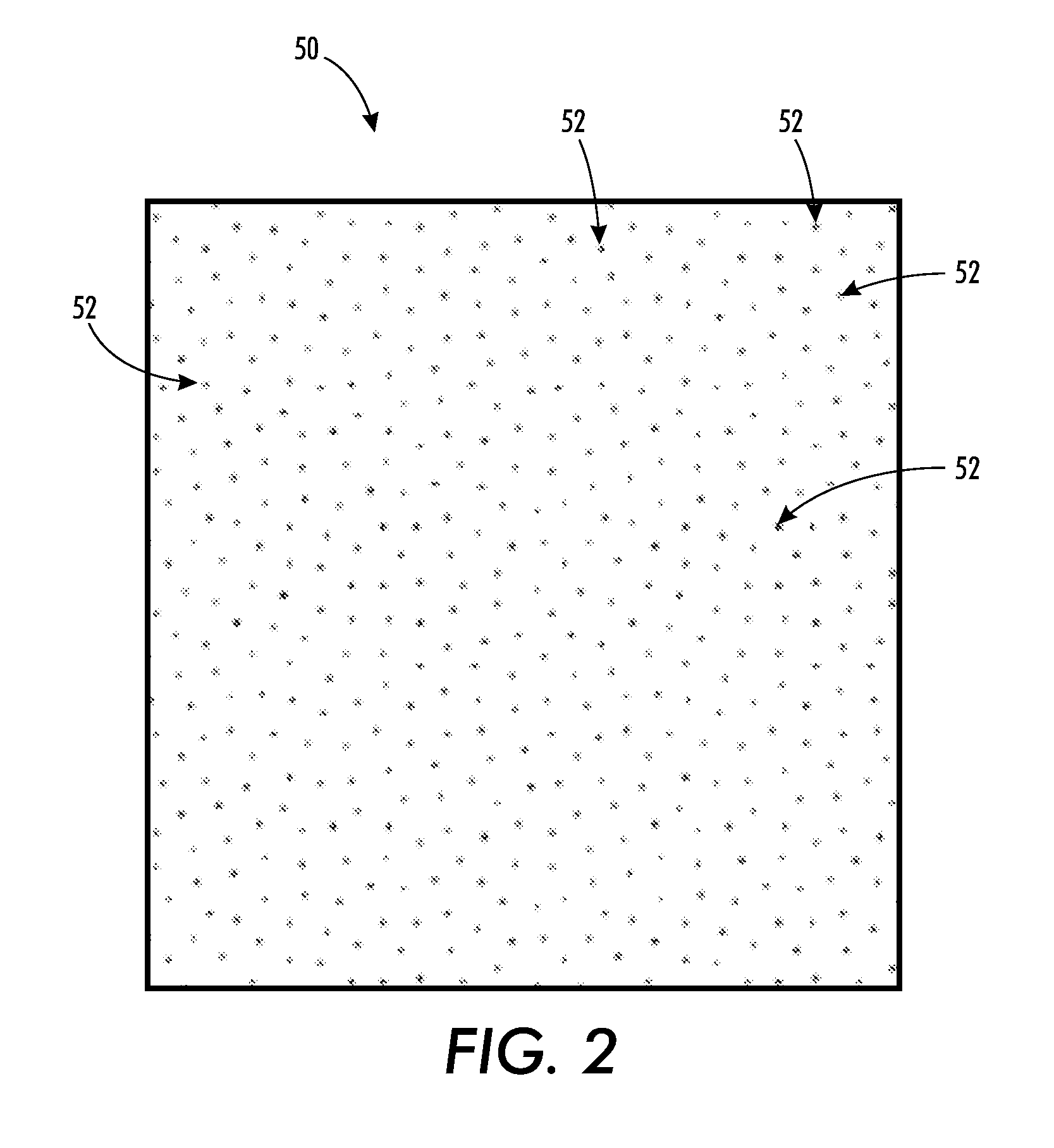

Parametrically controlled halftone spot function for an irregular halftone grid

InactiveUS20120274985A1Promote generationVisual presentationForme preparationRegular gridGrowth control

As set forth herein, computer-implemented methods and systems facilitate halftoning using a parametrically controlled spot function based on triangle tessellation, which in turn facilitates dot growth control of periodic halftone using an irregular seed structure. The spot function determines the shape of the halftone dot used to reproduce a given pixel. The spot function is well suited for growing halftone dots arrayed on a non-regular grid and can also be used for grids with regular order. The spot function includes adjustable parameters for controlling its sharpness and slope.

Owner:XEROX CORP

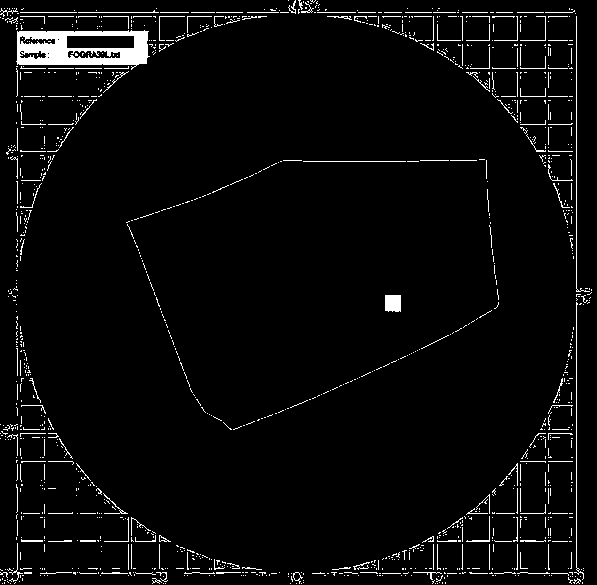

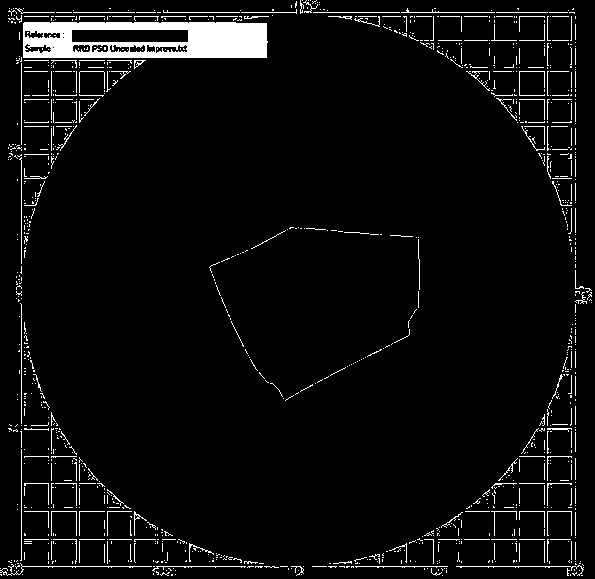

Color management method and device of maximized uncoated paper printing color gamut

ActiveCN107757166AGood ink absorptionIncrease the amount of inkMounting boardsOther printing apparatusContrast levelVolumetric Mass Density

The invention discloses a color management method and device of a maximized uncoated paper printing color gamut. The method comprises the following steps: (1) setting a dot shape to be compound screening through prepress setting; (2) increasing dots for reducing CMYK to 13%-16% through prepress compensating curve setting for increasing image contrast level; (3) increasing the density values of C,M, Y and K to 1.20-1.25, 1.20-1.25, 0.95 and 1.25-1.30 separately for increasing color saturation; (4) increasing a rubber blanket by adjusting the press setting for increasing the pressure between apress tape cylinder and an impression cylinder and improving the ink absorption performance of uncoated paper; and (5) adding 2%-4% of viscosity reducers in amount to original color ink by adjusting CMY ink viscosity. According to the color management method disclosed by the invention, the inking amount is increased by improving the paper ink absorbency, and the contrast level is increased by matching with the prepress treatment for increasing the color gamut. The printing color gamut is increased by 30% than the printing color gamut in ISO, so that the publication and production are convenient, and the uncoated paper production is easy apply; the manufacturing procedures of coated paper and the cost are reduced, and the method is friendly-environment.

Owner:DONGGUAN DANGNA PRINTING CO LTD

Invisible code graphics, processing method thereof and anti-fake application

The invention discloses invisible code graphics, a processing method of the invisible code graphics and anti-fake application and belongs to the field of information processing. The processing method includes a processing method with the image hiding technology and the coding technology combined. Images are divided into two parts, two different screening manners are adopted for screening the two parts of the images respectively, amplitude-modulating screening is conducted on an information hiding part, frequency modulating screening is conducted on the other part of the images, and meanwhile coding information is recorded according to the sequence of exposing pixel points in a grid of an area needing information hiding so that the purpose of information hiding can be achieved. The hidden code graphics serves as anti-fake labels, after the labels are copied by a common copying machine, the images with amplitude-modulating dot screening can be well shown, however, the images with amplitude-modulating dot screening cannot be completely shown, and therefore the code graphics can be shown and initial fake prevention is achieved. Meanwhile, buried coded messages can be obtained through an image sensor, and therefore authenticity is identified after the coded messages are compared with content on certificates and securities.

Owner:广东绿之彩科技股份有限公司

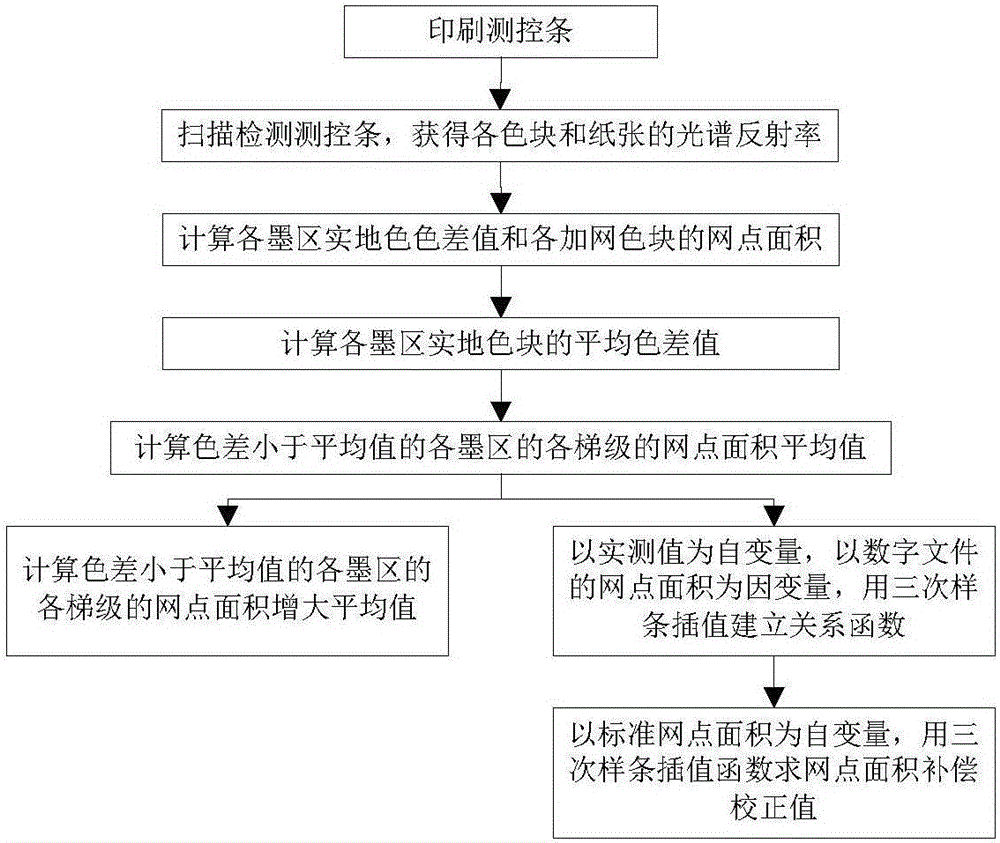

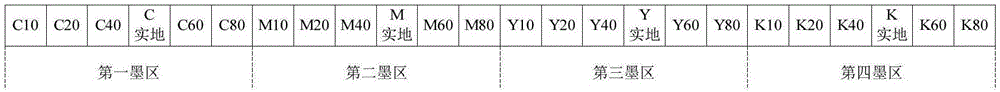

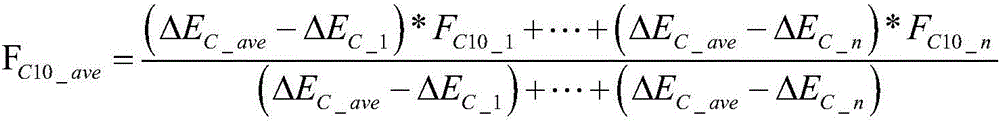

Detection and correction method for printing dot area increase values

ActiveCN106585090AEasy to operateImprove efficiencyMeasurement devicesPrinting press partsReflectivityChromatic contrast

The invention discloses a detection and correction method for printing dot area increase values. A detection strip on which multiple sections of screening step wedges are arranged for each color is attached to each printing sheet; multiple of printing sheets of different time periods are extracted; each color block on the detection strips is detected in a scanning mode, so that the spectral reflectance of each color block is obtained; color difference values of L*a*b*values of green, pinkish red, yellow and black solid color blocks of different ink zones of different printing sheets and standard L*a*b* values are calculated; then simple arithmetic mean values of color differences are calculated; weighted average values of dot areas of screening color blocks of each step wedge of each ink zone of which the color differences are smaller than the average color difference values according to color differences; then the dot area increase values are calculated; and correction values which are needed by digital documents for dot area compensation are calculated according to the average values of dot areas. The dot area increase values obtained in the invention can represent a current dot representation state of a printer more reasonably; dot area correction is performed more correctly; and the detection method is simple for operation and high in efficiency.

Owner:南县好彩印务有限公司

Method of manufacturing anti-counterfeiting plate by virtue of electric plating and electric carving

InactiveCN102514355AIncrease volumeImprove color saturationPrinting pre-treatmentForme preparationScreentoneMetallurgy

The invention relates to a method of manufacturing an anti-counterfeiting plate by virtue of electric plating and electric carving. The method comprises the following steps: manufacturing a printing plate matrix and plating copper to a printing plate roller; plating chrome on the copper layer of the plate, wherein the thickness of the chrome coating is between 0.1 and 0.2mu m; manufacturing an printing plate image on the printing plate roller in an electric carving manner, forming a V-shaped internet point on the surface of the printing plate roller; corroding the printing plate roller with a carved V-shaped internet point, deepening and widening the printing plate copper layer corresponding to the V-shaped internet point by virtue of corrosion to expand the volume of the internet point; corroding copper by adopting 38wt% of ferric trichloride in electric plating for 10-15 seconds; cleaning chrome; plating chrome for the second time; and polishing chrome. In a gravure roller prepared by the method, the internet point volume and the ink capacity are large, the internet point ink content obtained by adopting the post-chrome corrosion method is 50 percent higher than that obtained by adopting a normal carving method according to measurement; and the color saturation of a print in transfer printing is good, and the printing quality is high, so that the method is good in economical benefit.

Owner:ZHENGZHOU YUNCHENG PLATE MAKING

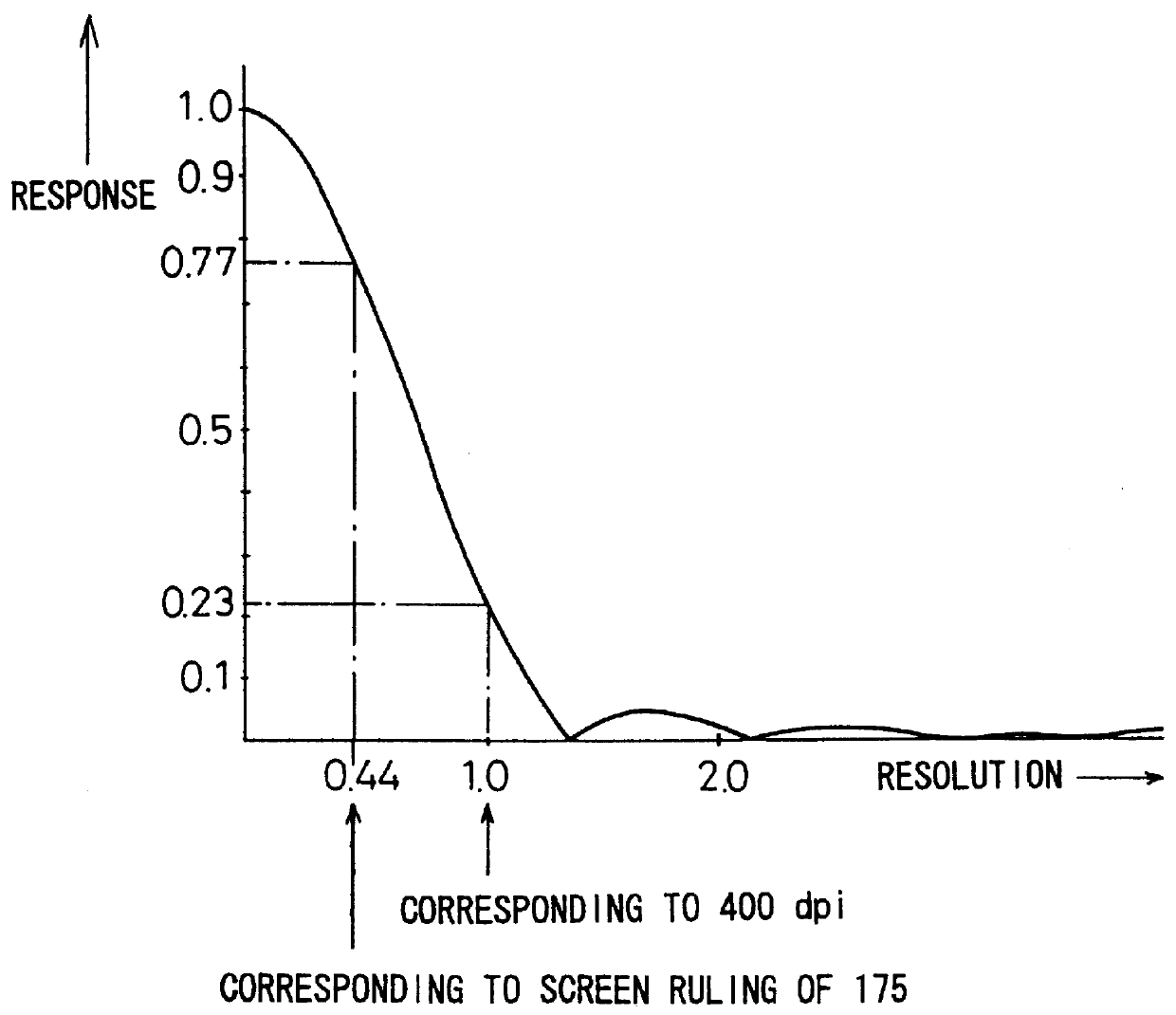

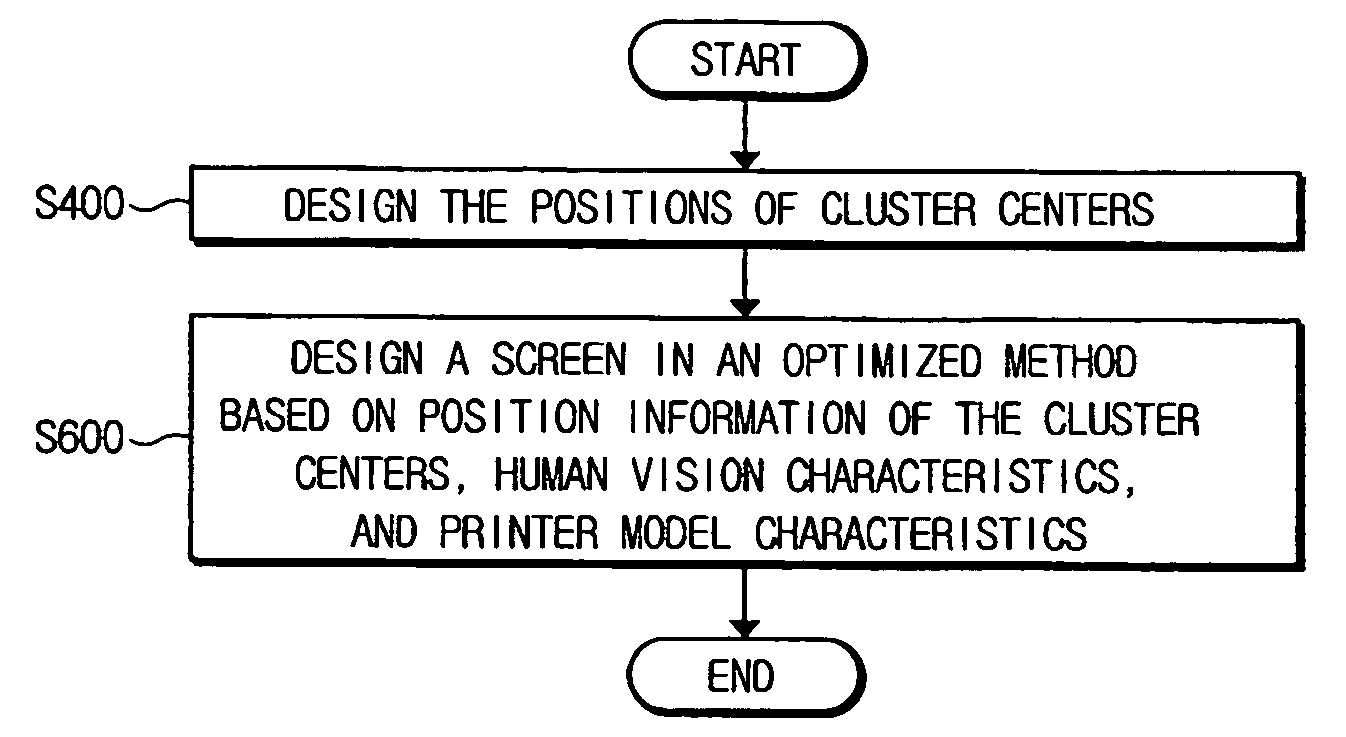

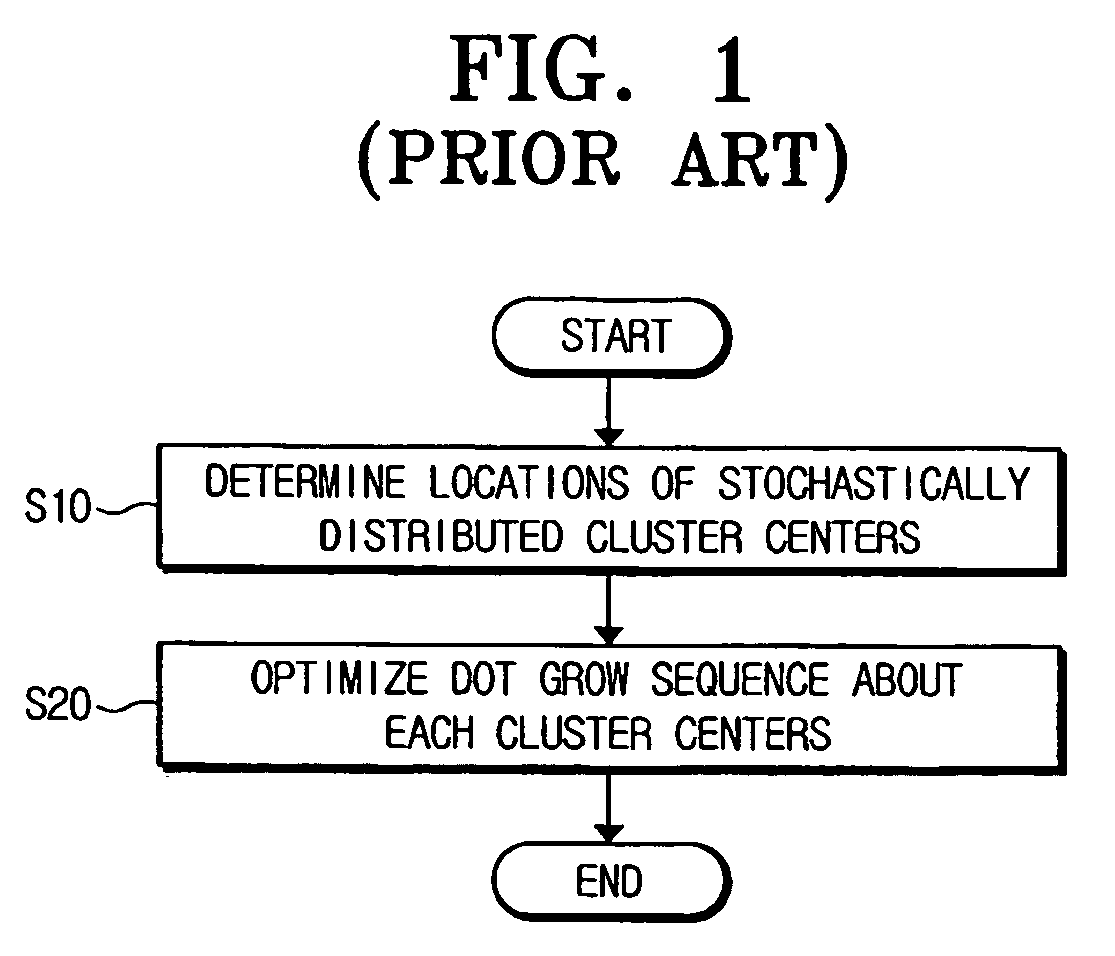

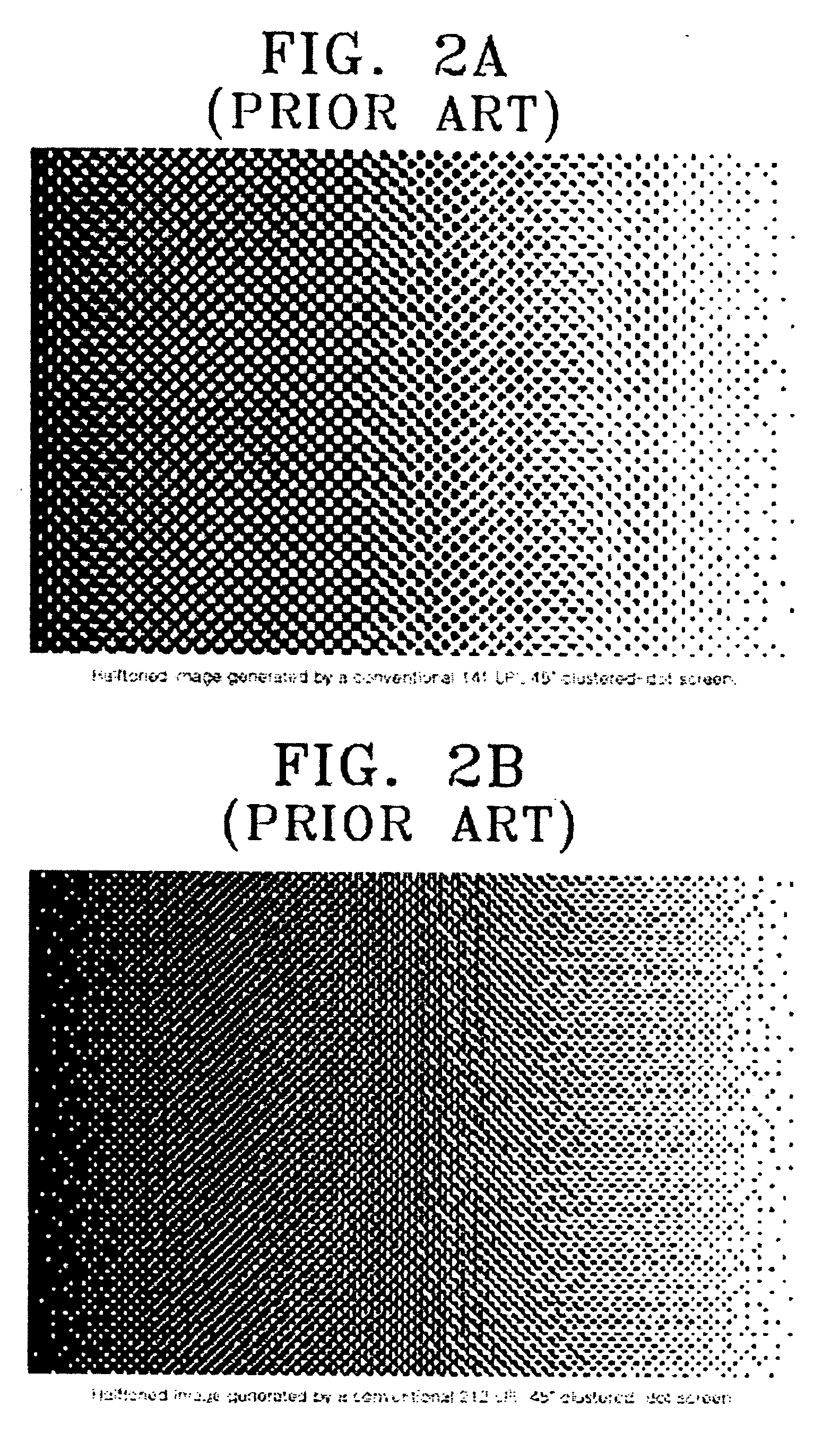

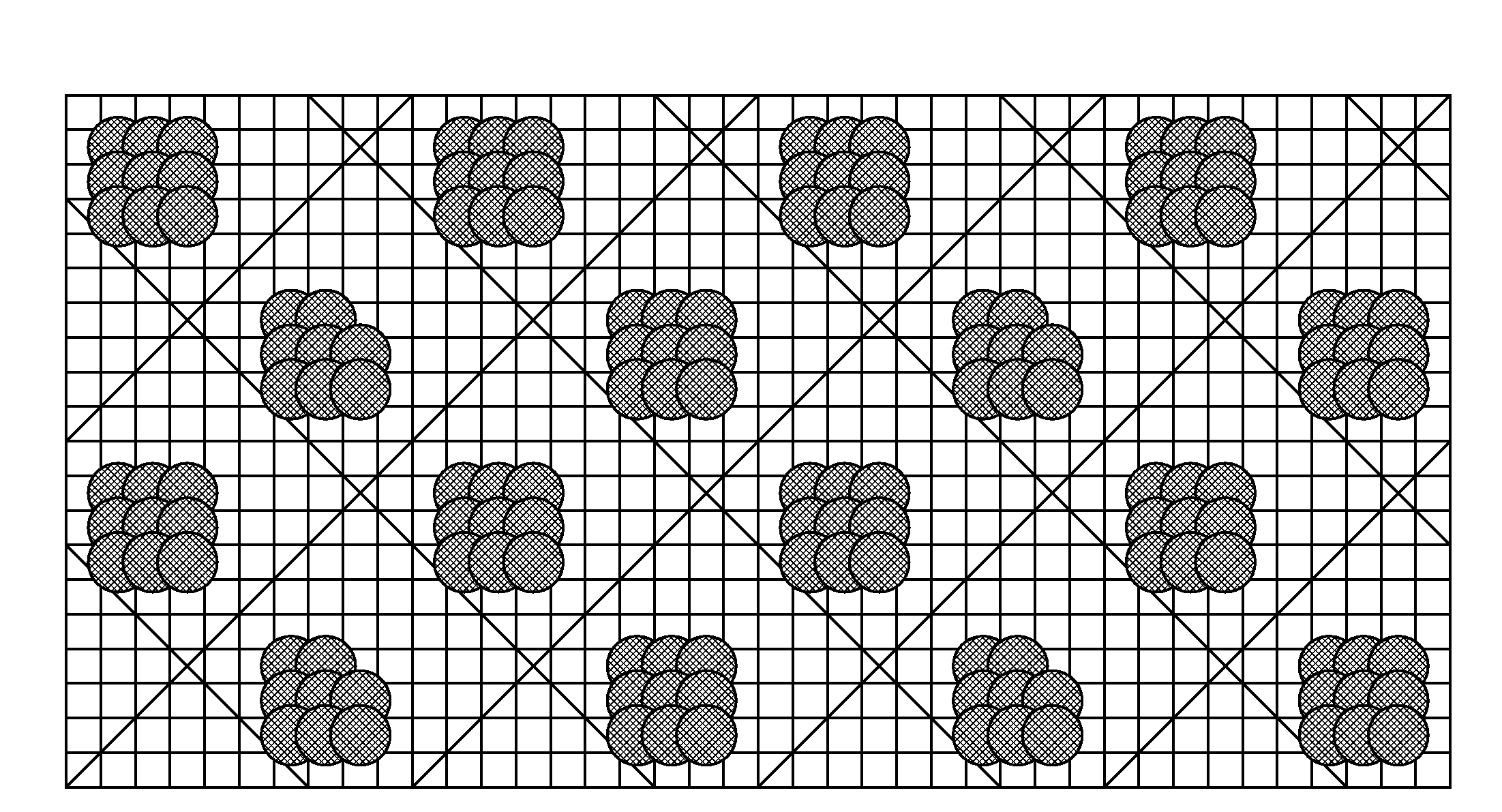

Clustered dot-screen design method, a device to perform the clustered dot-screen design method based on human vision and printer model characteristics, and an image-forming apparatus to output binary images on a designed screen

ActiveUS20060066908A1Minimize the differenceMinimize cost functionVisual presentationPictoral communicationEngineeringImaging equipment

A clustered-dot screen design method, a device to perform the clustered-dot screen design method based on human vision characteristics and printer model characteristics, and an image-forming apparatus to output binary images using designed screens. The clustered-dot screen design method based on the human vision characteristics and the printer model characteristics includes determining positions of a plurality of clustered-dot centers using a predetermined method, and designing a screen by growing specific sub-dots about the cluster centers using a predetermined algorithm according to position information of the cluster centers, the human vision characteristics, and the printer model characteristics. The clustered-dot design method has a high tolerance for defects of printers, since a dot growth sequence about the cluster centers is designed in an optimized method based on the human vision characteristics and the printer model characteristics to have an optimized image quality in output images of the printers, and the dots are clustered about the cluster centers.

Owner:HEWLETT PACKARD DEV CO LP

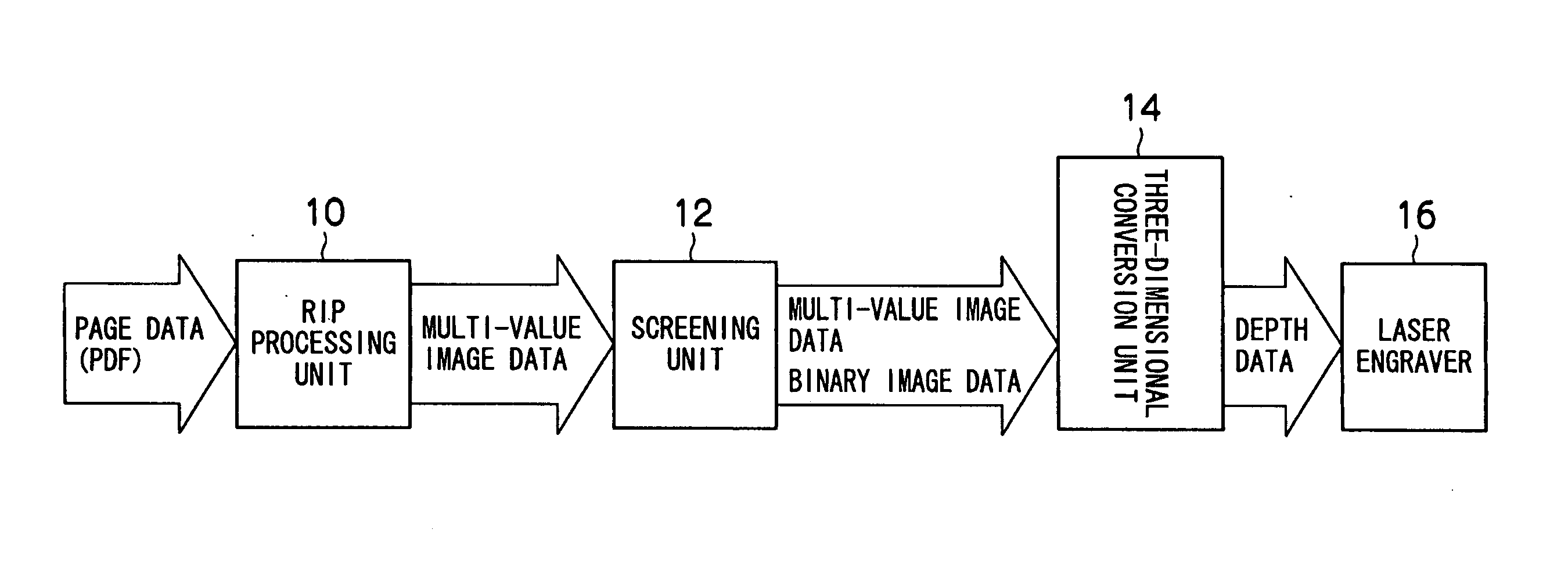

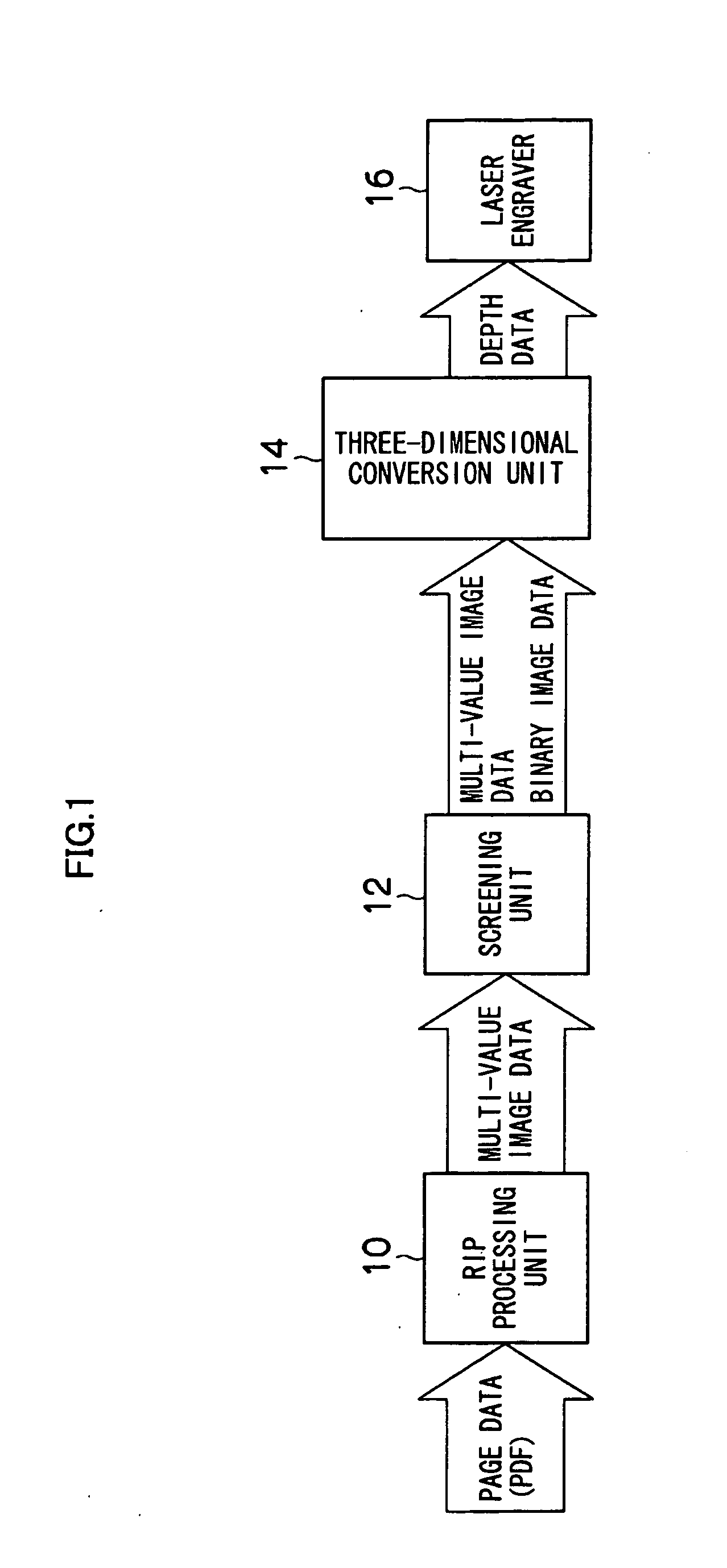

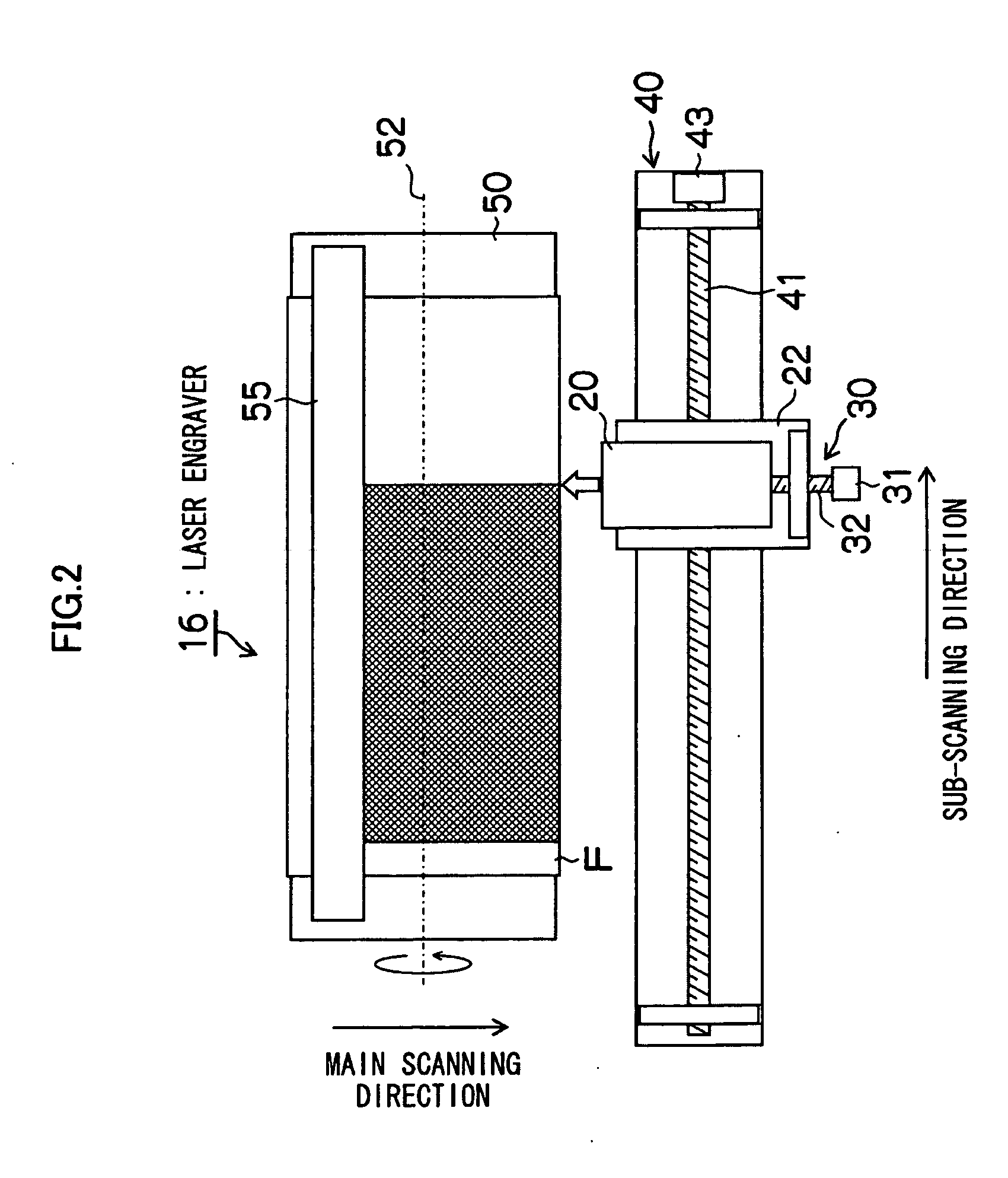

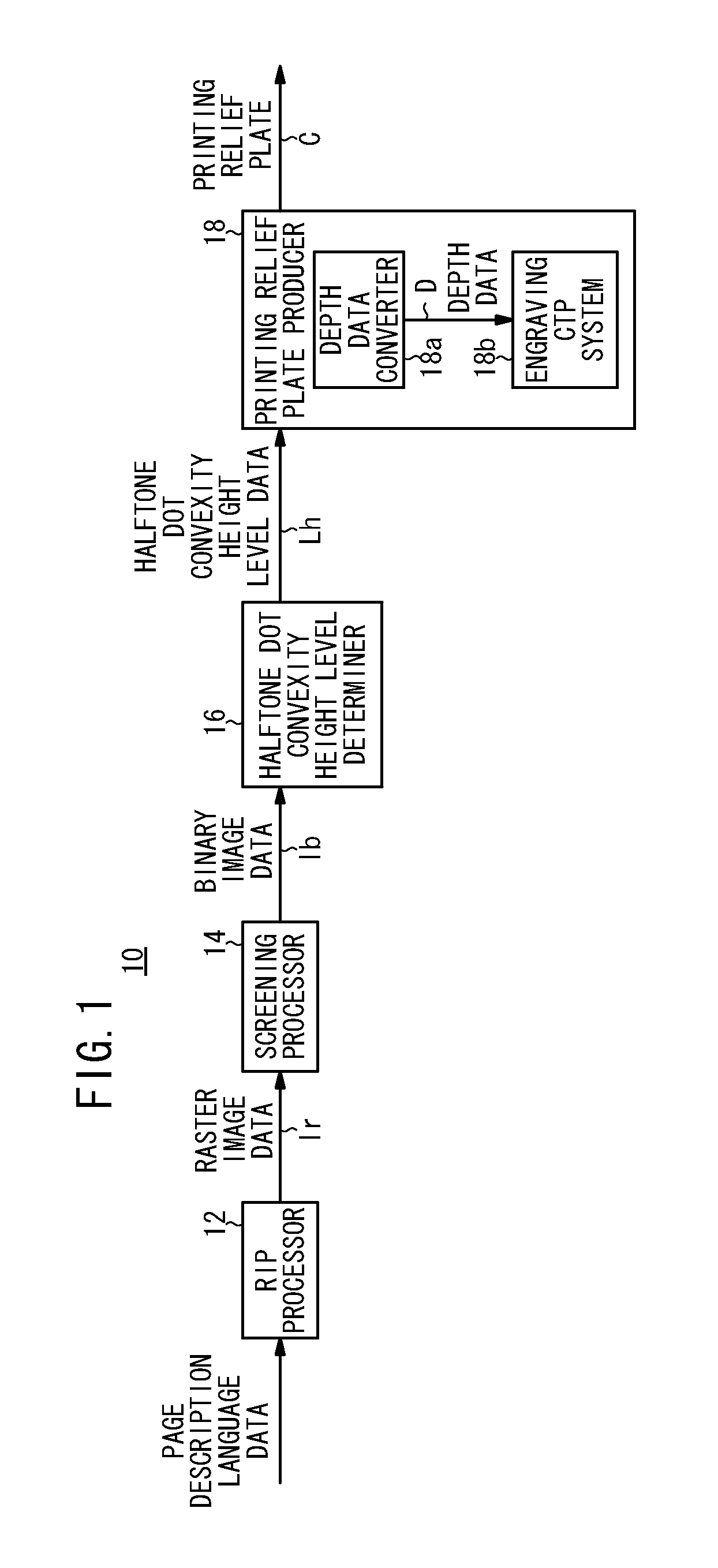

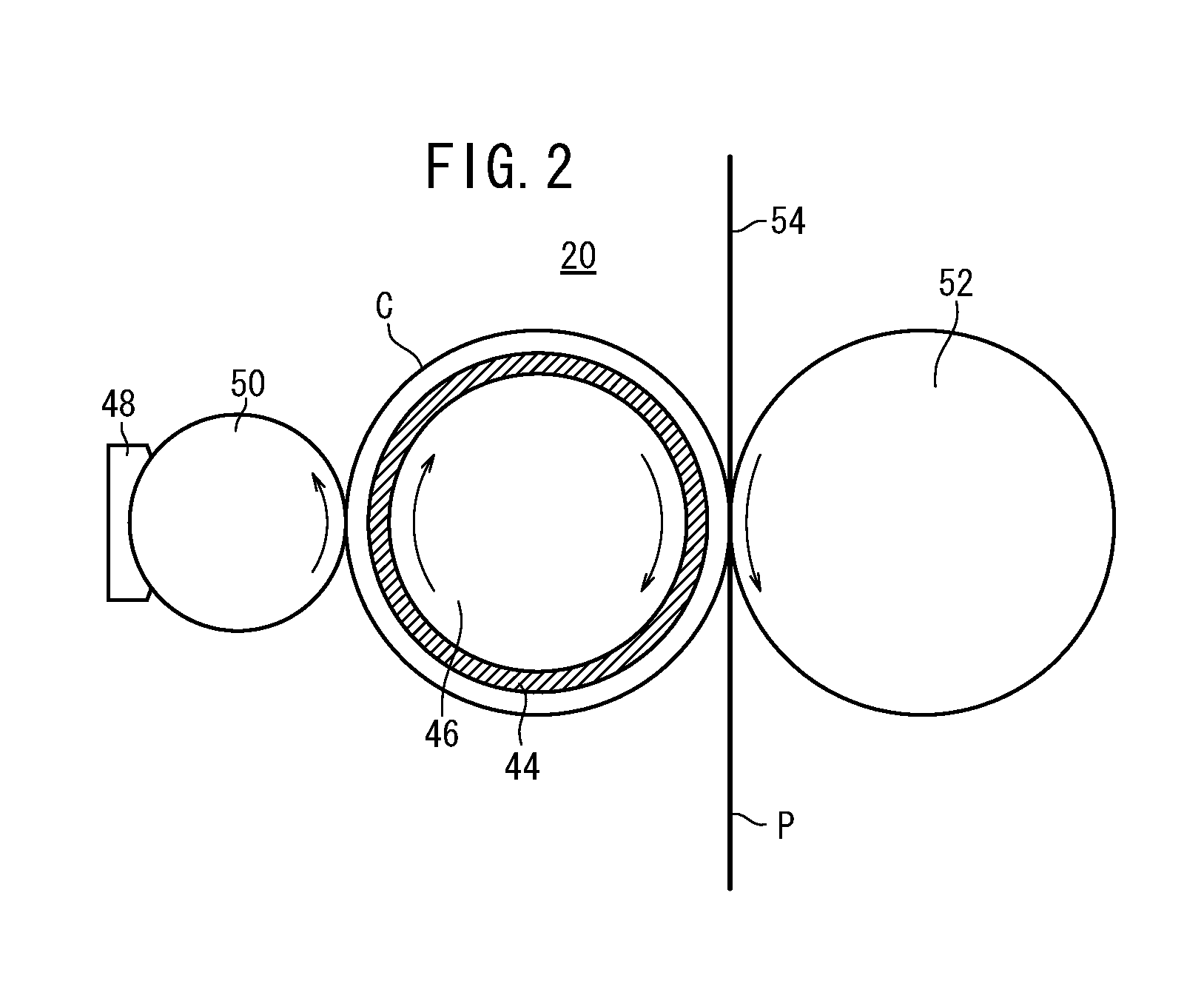

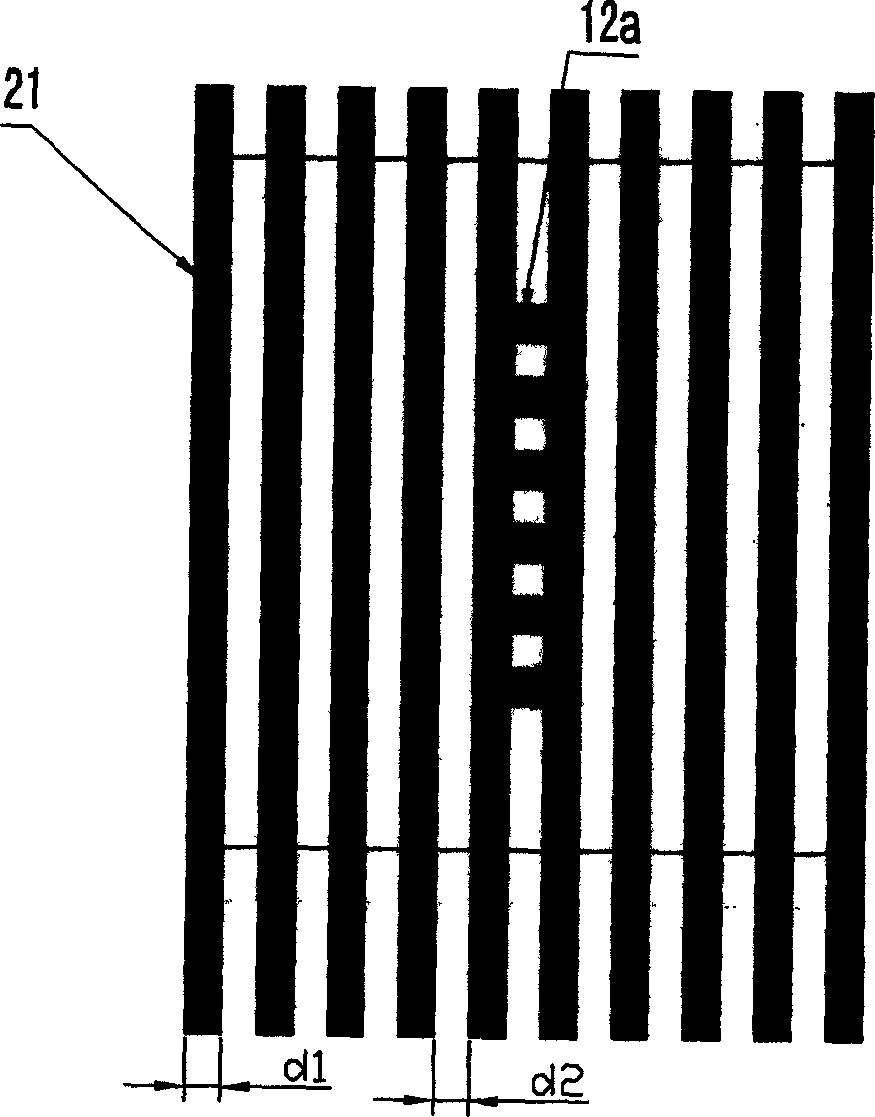

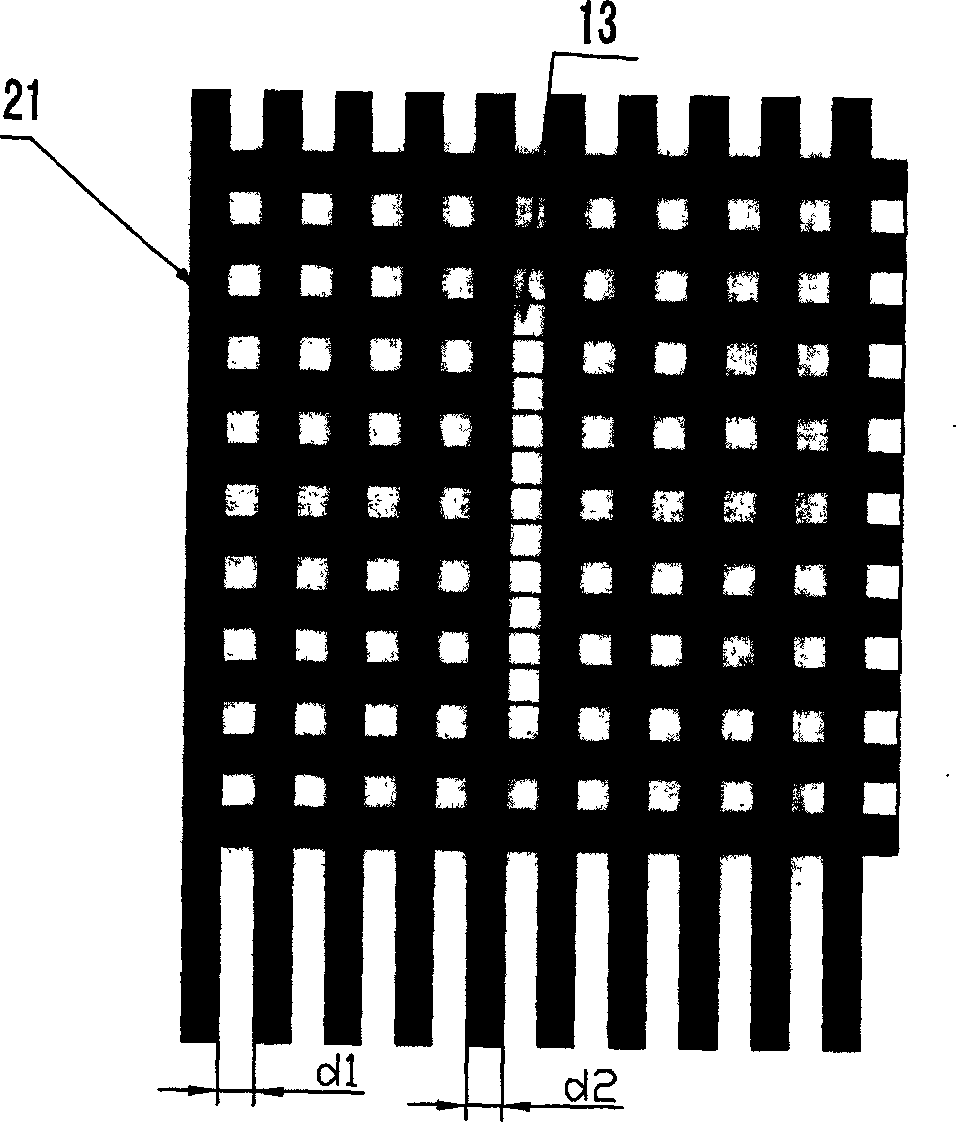

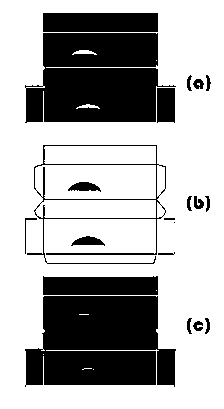

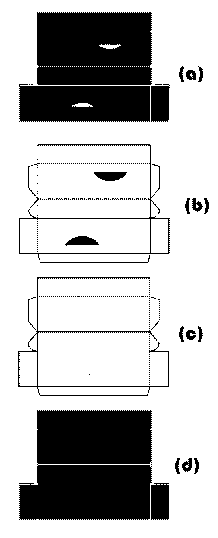

Relief printing plate, plate-making method for the relief printing plate and plate-making apparatus for the relief printing plate

InactiveUS20120055360A1ReproducedImprove stress resistancePlate printingVisual presentationEngineeringRelief printing

In a relief printing plate according to an aspect of the present invention, the relief can be formed to have resistance to pressure applied to the apex thereof thanks to the depth (d) and the ridge tilt angle (x). In particular, the resistance to pressure against a relief serving as a highlight halftone dot can be improved to prevent the relief from falling over by the pressure applied to the apex of the relief. Thereby, the relief serving as a highlight halftone dot can be made not to be dipped in a cell of the ink roller (e.g., anilox roller).

Owner:FUJIFILM CORP

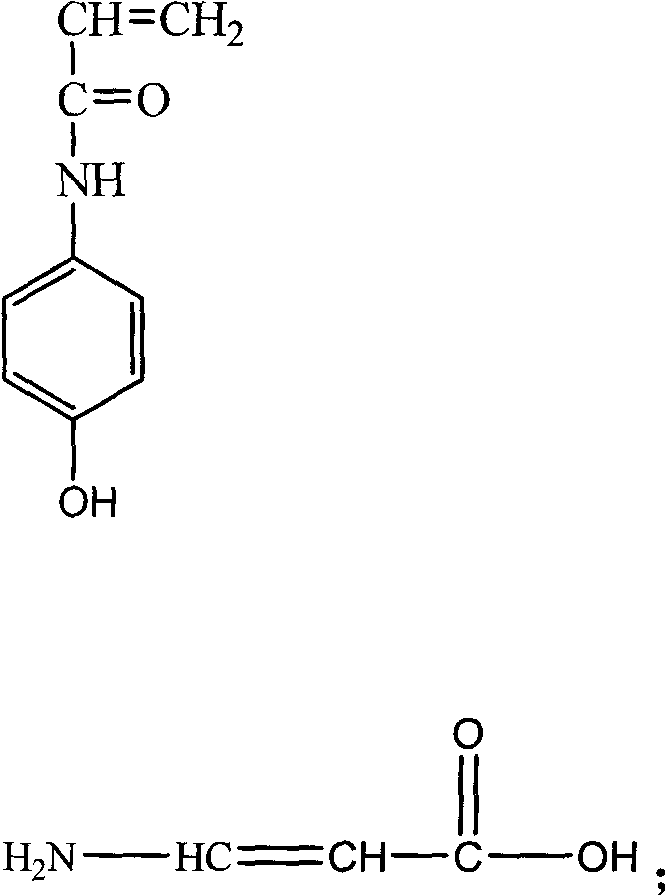

Positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink

ActiveCN103879169AIncreased sensitivityHigh developing latitudePlate printingFoil printingDouble coatingHeat sensitive

The invention discloses positive image thermo-sensitive CTP printing plate material capable of resisting UV printing ink. The positive image thermo-sensitive CTP printing plate material made by high-quality aluminum plate base and double coatings comprises a plate material support body. A resin layer good in solvent resistance and alkaline solubility coats the support body. A positive image thermo-sensitive photosensitive layer coats the resin layer. The main film forming resin also called polymer binder in the resin layer is independently researched and developed by the inventor company, and the photosensitive layer is modified by traditional single-layer thermo-sensitive CTP of the inventor company. The plate material is high in photosensitivity, excellent in screen dot reduction, large in plate making operation tolerance, stable in performance and high in printing adaptability. The plate material can be specially used for UV ink printing and also be used as the long-printing-process plate material of traditional solvent ink printing, and better printing durability is achieved when the plate material is applicable to the mentioned printing after baking.

Owner:LUCKY HUAGUANG GRAPHICS +1

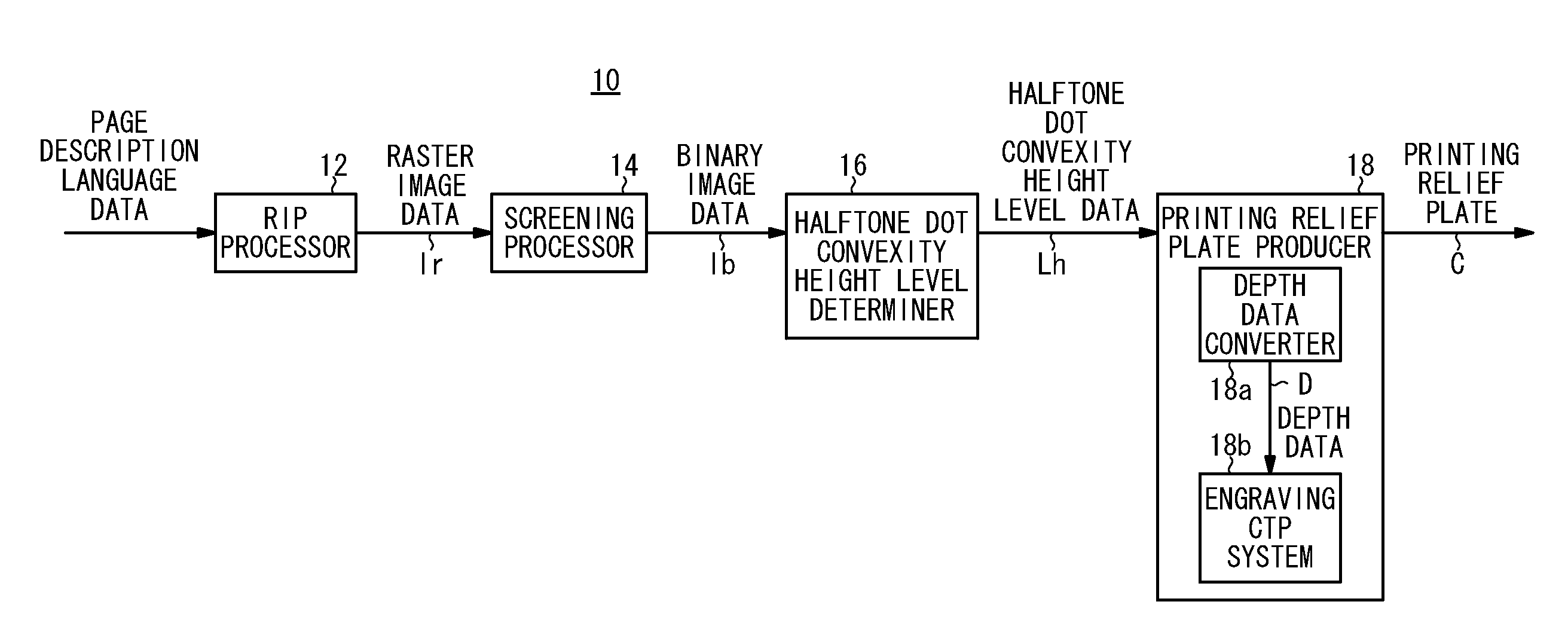

Printing relief plate

InactiveUS20110252990A1Avoids localized enlargementReduce generationMounting boardsForme preparationComputer graphics (images)Halftone

A printing relief plate, within a screen tint region, includes main halftone dot convexities, halftone dot convexities, and other halftone dot convexities, in which the heights of printing surfaces of the halftone dot convexities to which ink is applied differ from each other in a plurality of halftone dot convexity height levels.

Owner:FUJIFILM CORP

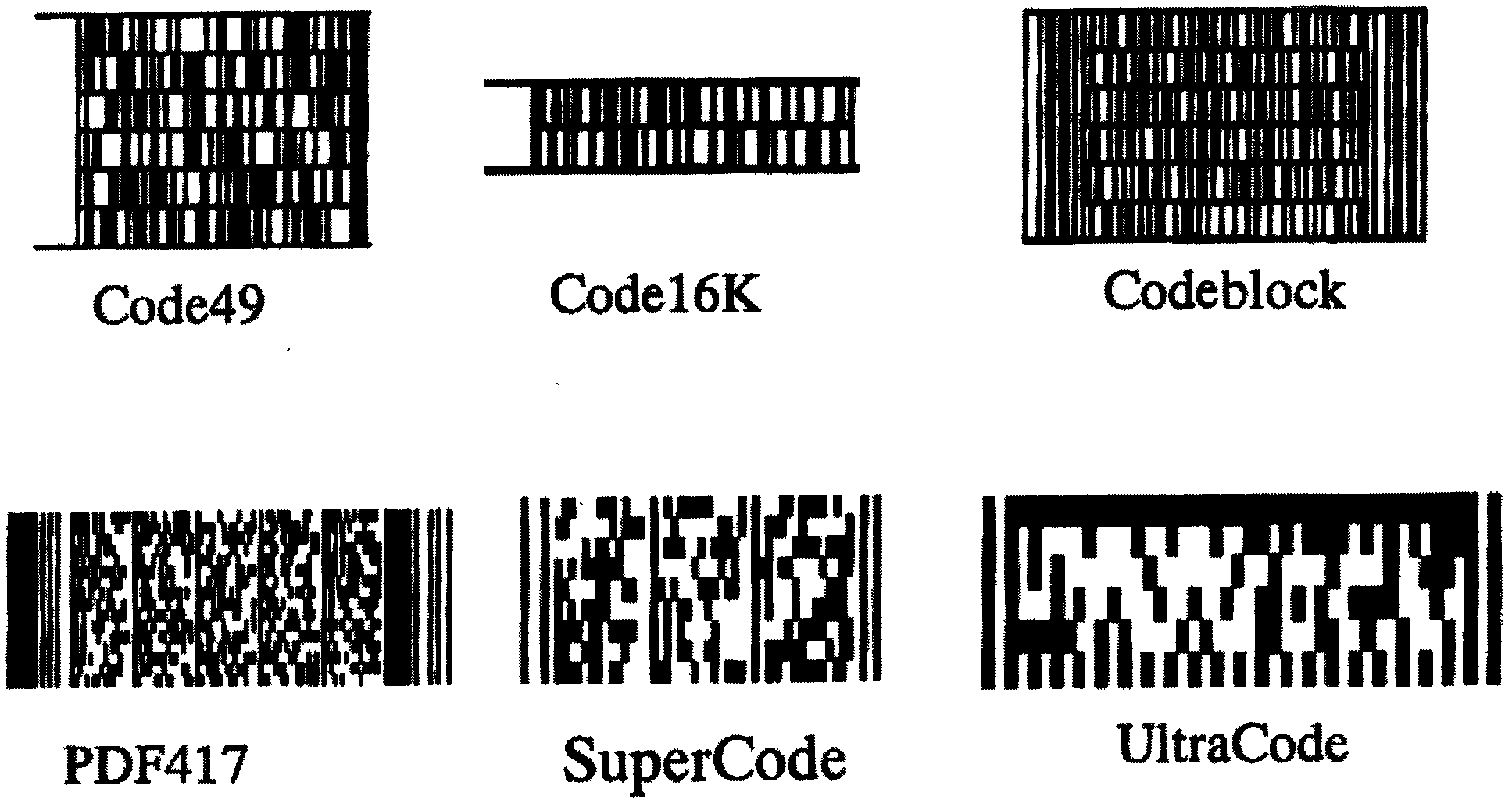

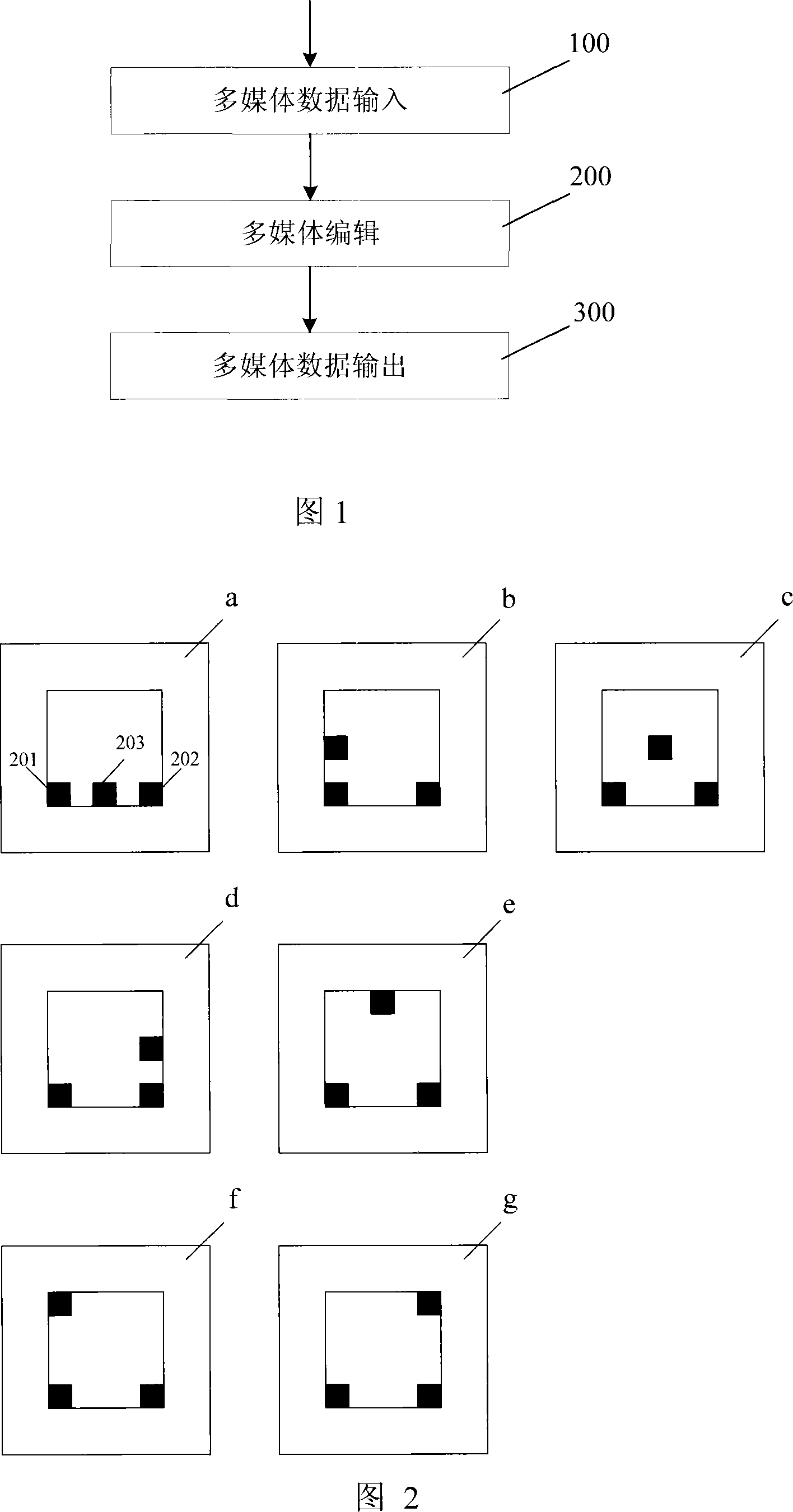

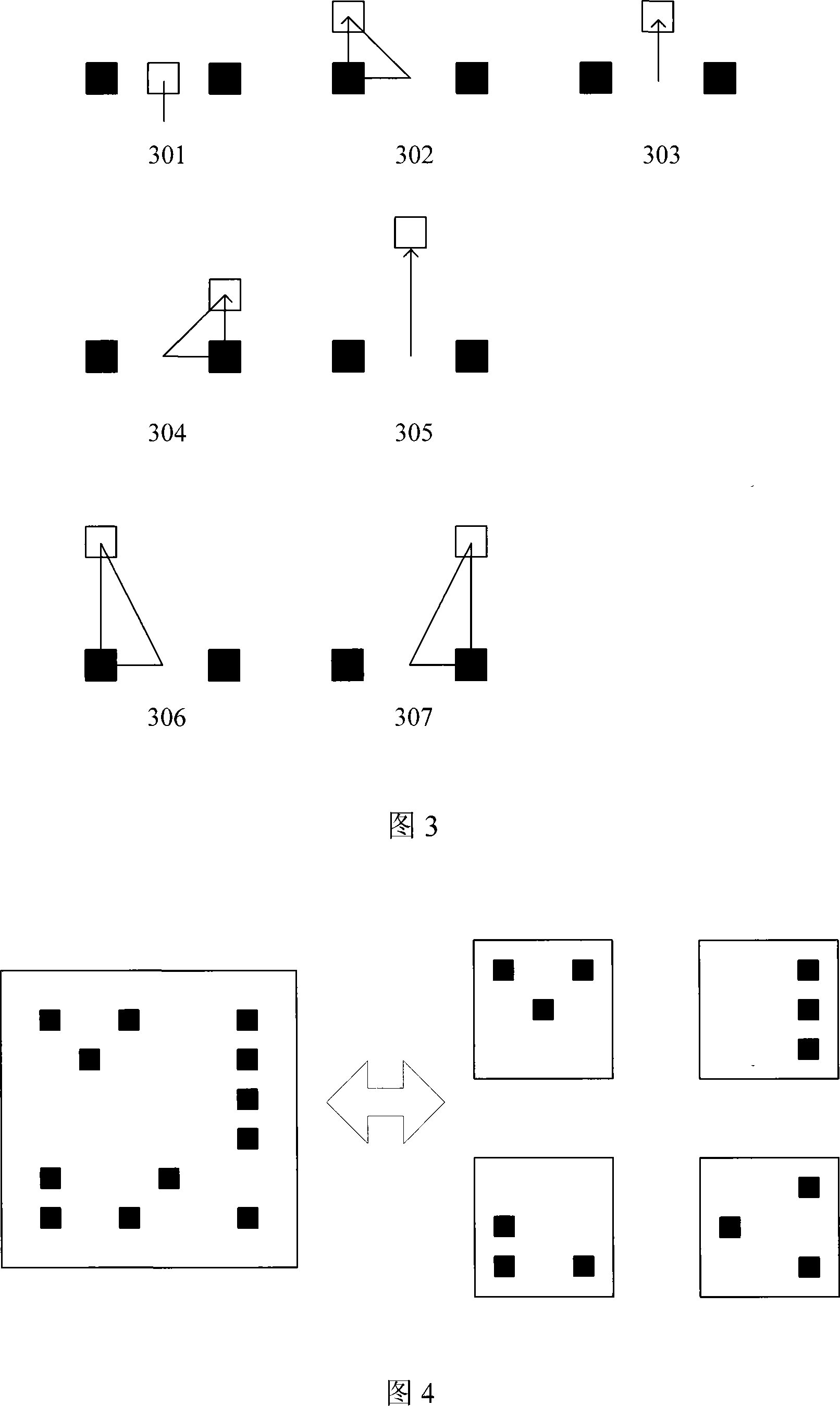

Multimedia printing system realization method for multi-resolution printer

ActiveCN101101631ASolve the problem that the number of lattices cannot be too largeQuick identificationCo-operative working arrangementsPictoral communicationComputer graphics (images)Imaging quality

The invention discloses a method for forming new type mesh code for identification, an information embedded method for multimedia print, and a method for constituting multimedia print system. The said new type mesh code uses following parts: different geometric distributions including displacement, direction, and shape of mesh point to record information directly; different physical distributions including phase modulation of 2D image, propagation direction of mesh point to record information directly; and method for partitioning mesh points on mesh screen. Features are: even gray scale of mesh point, small size of mesh point, and large capacity of information. The small size of mesh point is in favor of recognizing codes, and suitable to embed information to any printing image as well as gives small influence on image quality after information is embedded.

Owner:天津市阿波罗信息技术有限公司

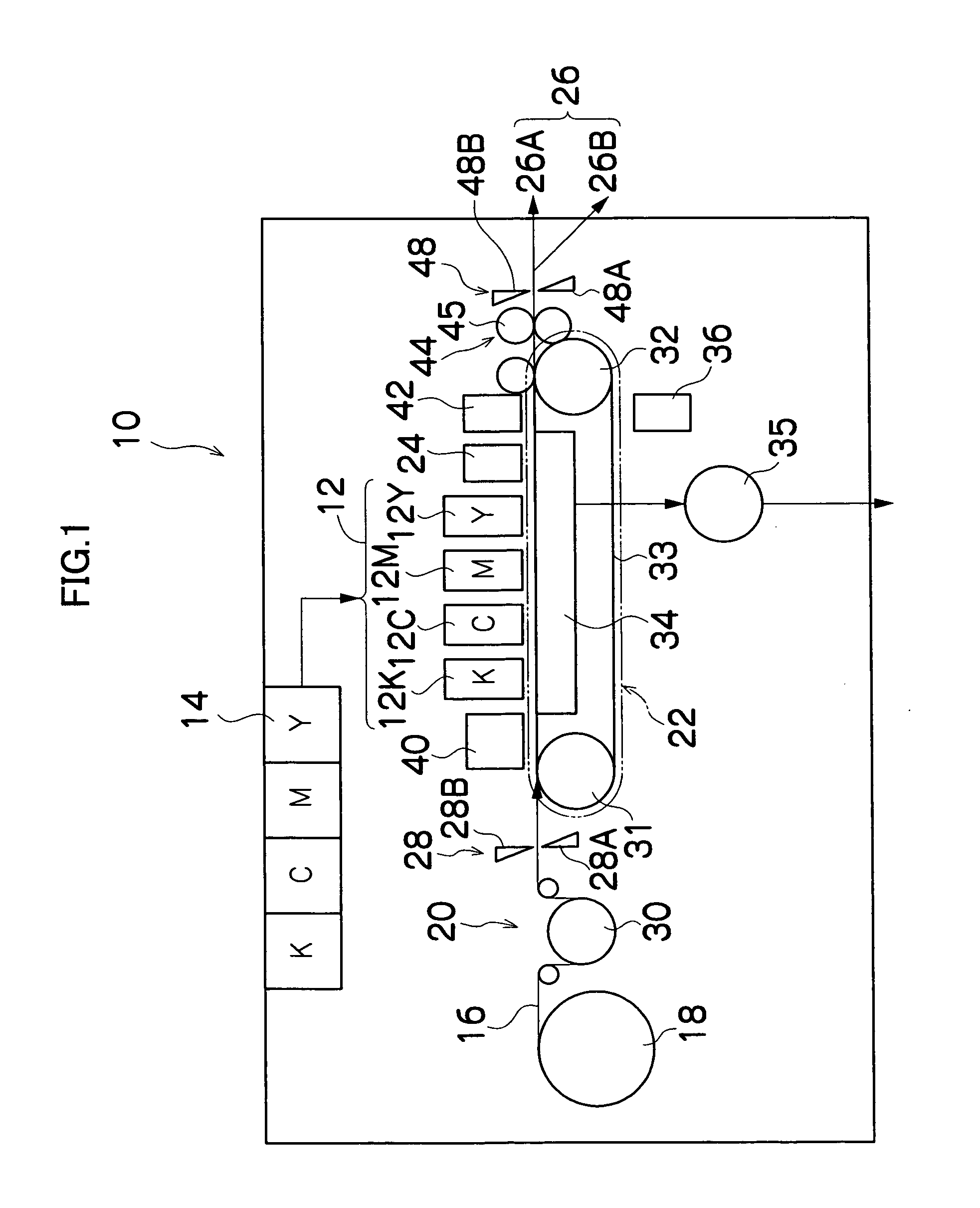

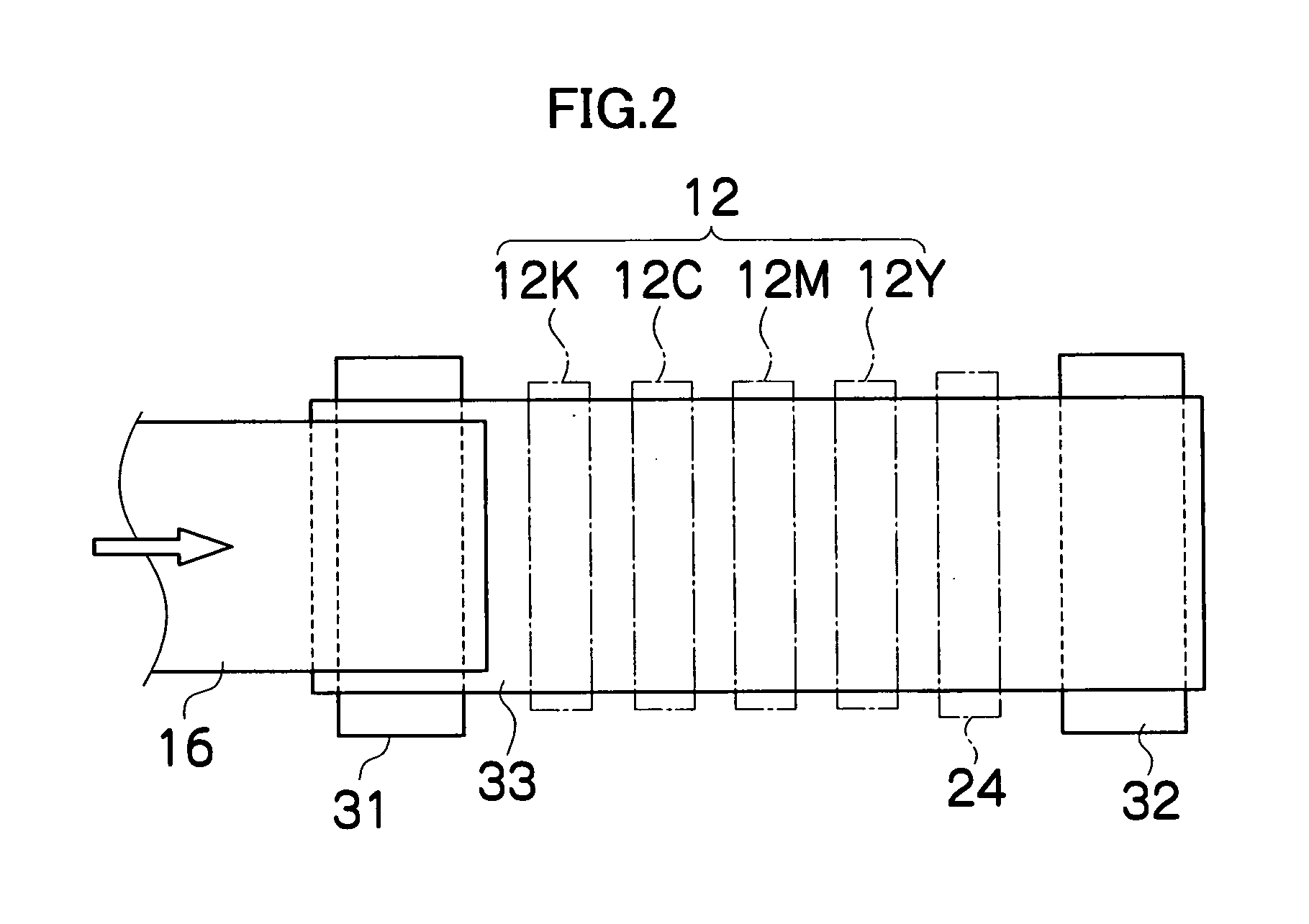

Image processing method and apparatus, and image forming apparatus

InactiveUS20050219295A1High-quality image recordingStrong visual impactOther printing apparatusPictoral communicationImaging processingComputer science

The image processing method for specifying dot arrangements for respective ink components according to image data, when forming an image on a recording medium by means of dots of inks of n colors, where n is any positive integer, the method comprises the steps of: calculating color correlation and spatial frequency components from the image data; specifying a dot overlap function for controlling overlapping between dots of the ink components, according to the calculated color correlation and spatial frequency components; calculating an ink recording rate of each of the inks from the image data; specifying the dot arrangement of a first ink component by means of a prescribed method, according to the ink recording rate; and determining a dot arrangement for the inks of the n colors, in such a manner that, taking k to be an integer where 2≦k≦n, the dot arrangement of the kth ink component is specified according to the ink recording rate of the kth ink component, and the previously specified dot arrangement and dot overlap function of the first ink component through to the (k−1)th ink component.

Owner:FUJIFILM CORP

Lithographic printing plate material, lithographic printing plate, method for preparing lithographic printing plate, and method for printing by lithographic printing plate

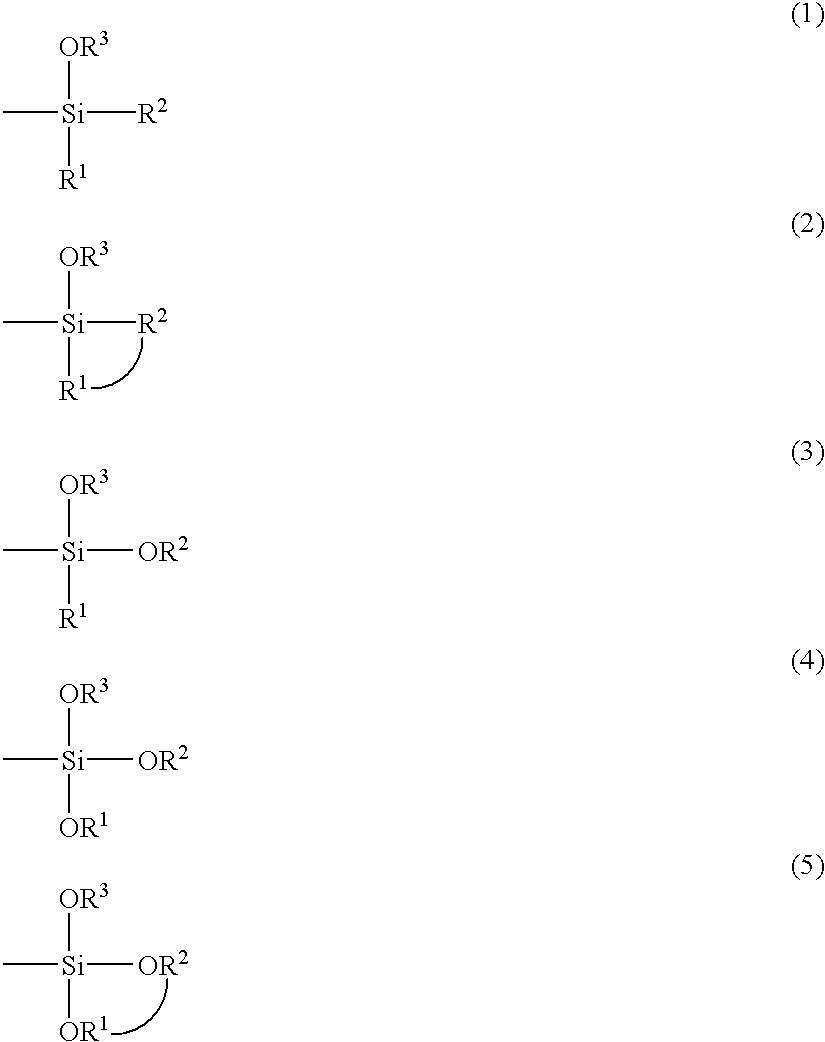

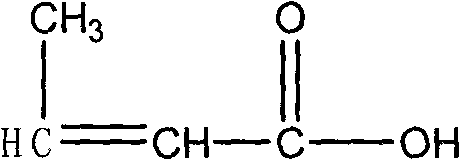

InactiveCN101316721AExcellent ink smudge removal performanceQuality improvementInksPlate printingOligomerPrinting ink

This invention provides a lithographic printing plate material that is excellent in contamination recovery and halftone dot quality and is less likely to cause printing troubles by dust adherence or the like. The lithographic printing plate material comprises an aluminum base material and an image forming function layer provided on the aluminum base material, the image forming function layer containing a photo-thermal conversion material, a photopolymerizable compound, and a polymerization initiator. The lithographic printing plate material is characterized in that the image forming function layer in its non-image part can be removed by, after image-wise exposure, supplying a printing ink containing at least one material selected from polymerizable monomers and polymerizable oligomers. There are also provided a lithographic printing plate, a method for preparing the lithographic printing plate, and a method for printing by a lithographic printing plate.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Ancient fresco duplicating process in original color and original size

The process of duplicating ancient fresco in original color and original size includes the following steps: taking the picture of ancient fresco and making color code after making mark lines on the fresco; repairing in computer through scanning the taken film, processing image with the image processing software, inputting electronic files to computer, assembling, regulating color, splitting colors to make single color negative pictures and outputting spot-free negative pictures with laser films; making color codes; making single frame printing plates; printing and mounting. The said process may be used in duplicating ancient fresco in original color and size and no spots with less damage to original.

Owner:北京邦普制版印刷有限公司

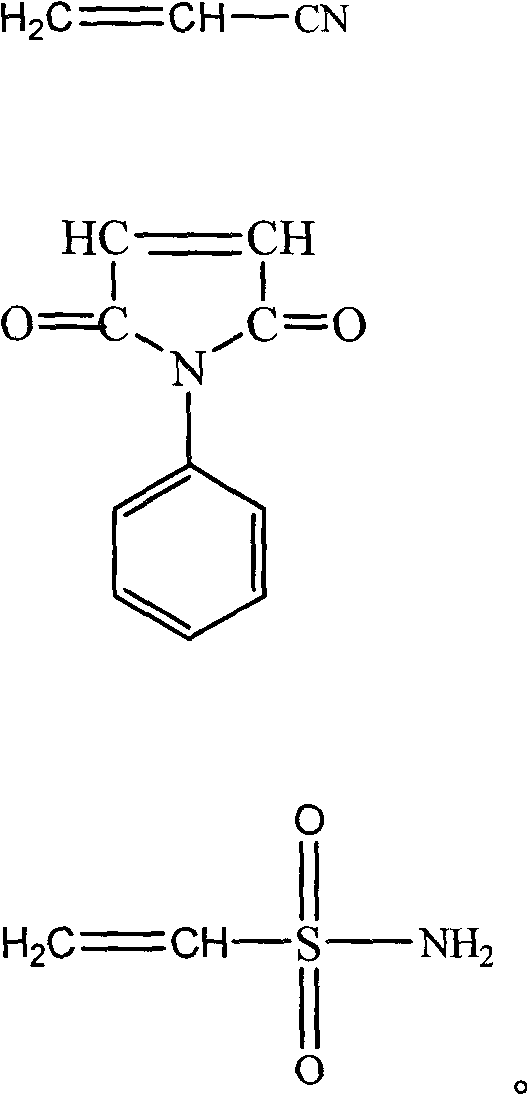

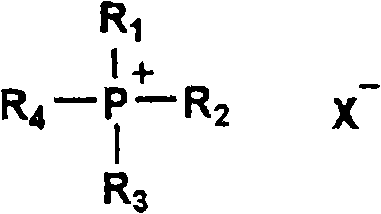

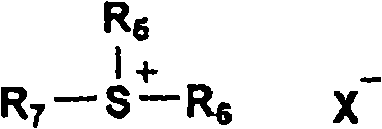

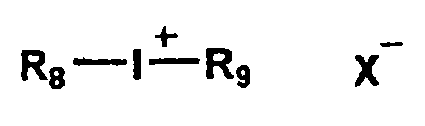

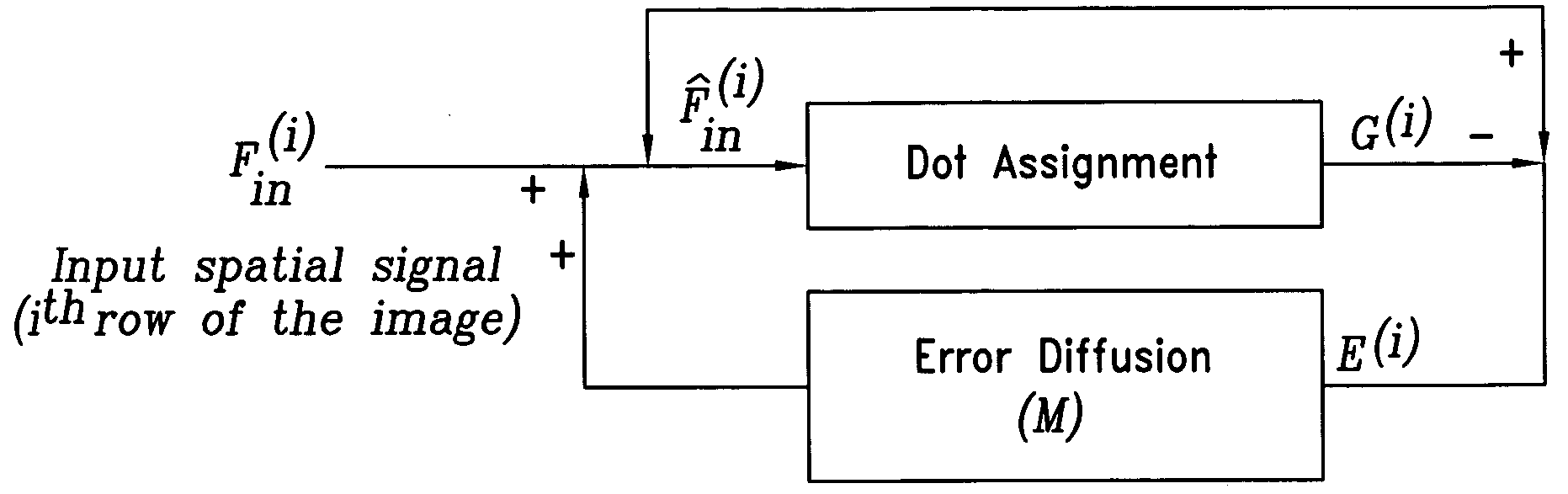

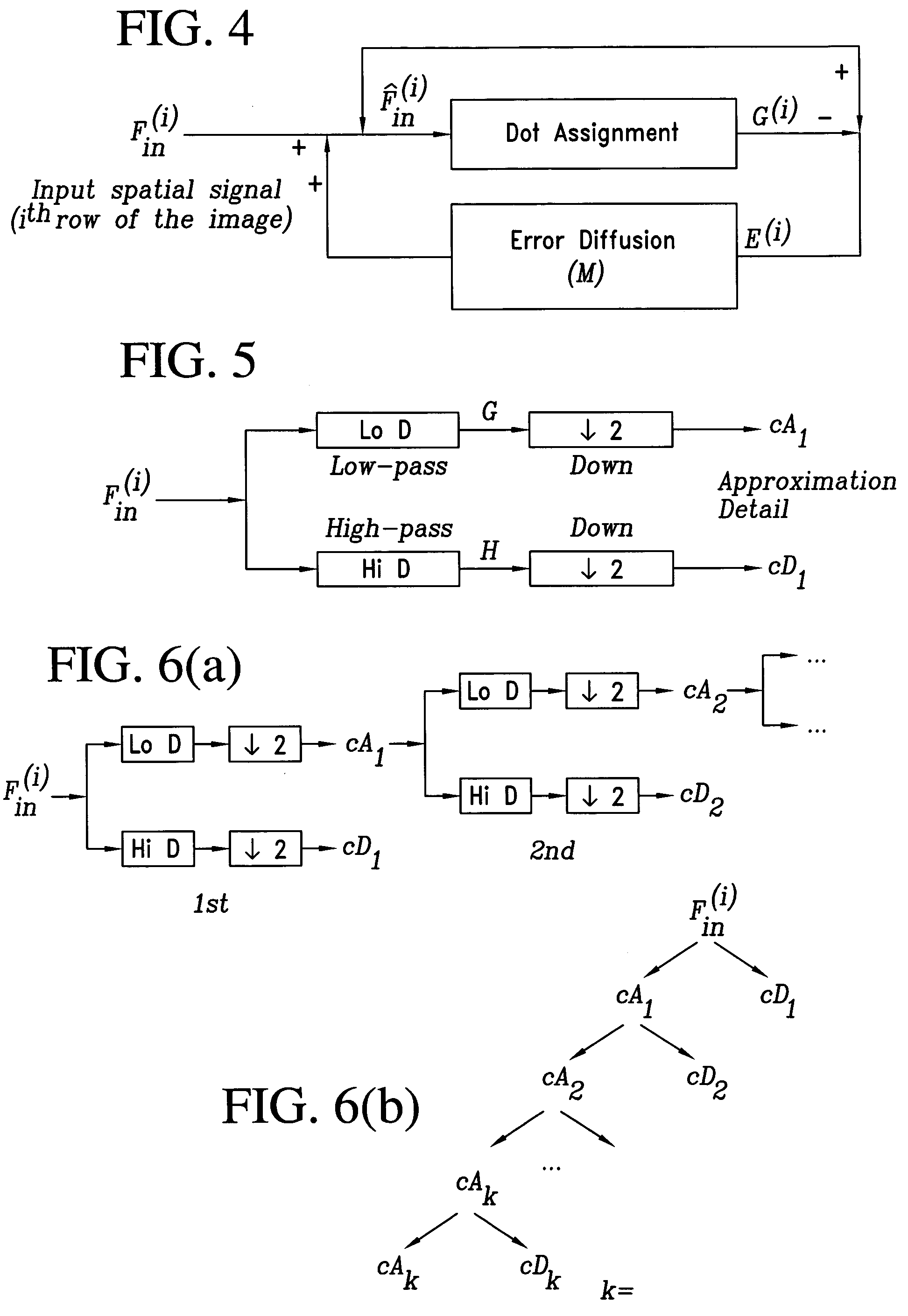

Digital halftoning technique based on 1-D multi-scale dot assignment

InactiveUS7580074B2Improve visual effectsEfficient implementationTelevision system detailsColor television detailsScreentoneAlgorithm

A line-based digital halftoning technique uses both a wavelet transform and multi-scale dot assignment concepts in which the dots are assigned in a top-down fashion and error diffusion is also adopted to fine tune the halftoned images and compensate for errors generated by the implicit quantization. 1-D processing makes the implementation easy while the top-down multiscale dot assignment can produce a multi-resolution halftoned image, which provides a good approximation of the original in multiple scales.

Owner:PRIMAX ELECTRONICS LTD

Method of silk screen printing

InactiveCN1615221AWith concave-convex surfaceGood touchScreen printersPattern printingScreen printingScreentone

Disclosed is a method of silk screen printing. The printing method includes coating a diagonal screen made of a screen fabric having a mesh count of 200-300 with a light sensitive emulsion, drying the coated screen, placing a film of 40-60 lines and 60-70 dot percentage on the screen, exposing the screen having the film placed thereon to ultra-violet light for 1-2 min, washing out the screen areas which have not been exposed to the light, and performing screen printing.

Owner:崔容硕

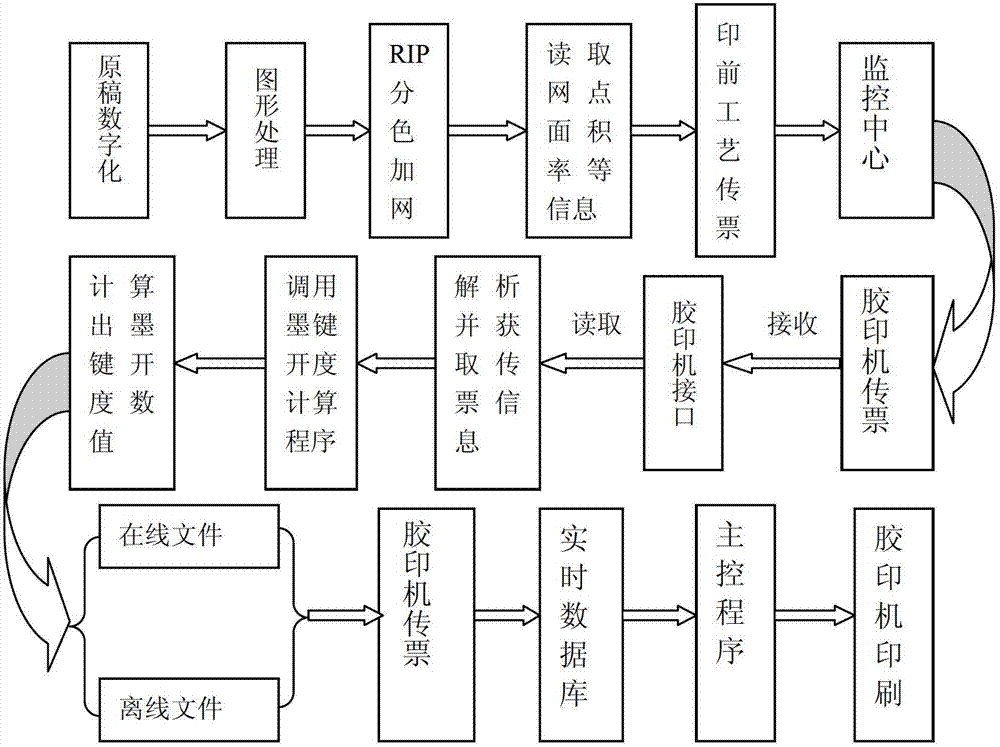

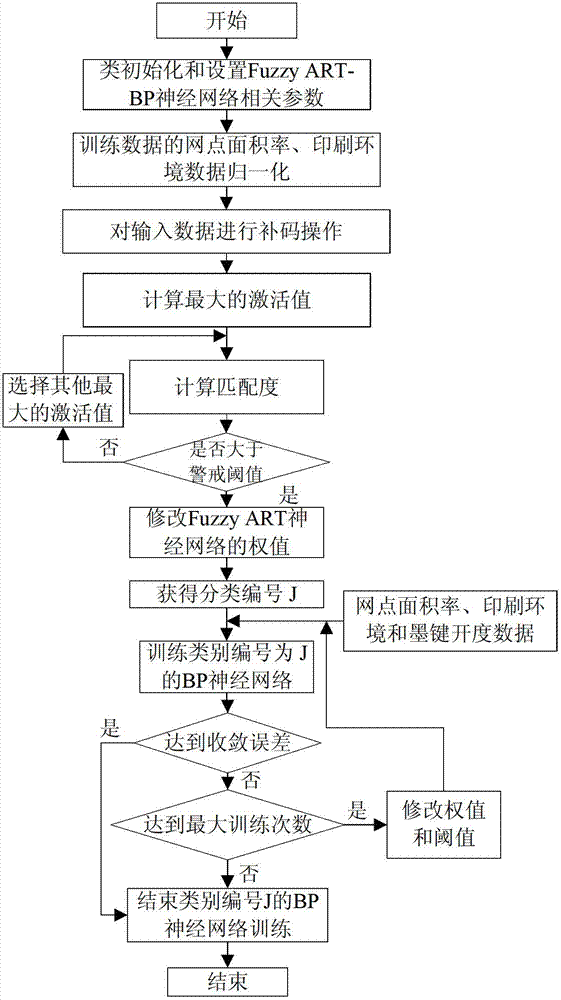

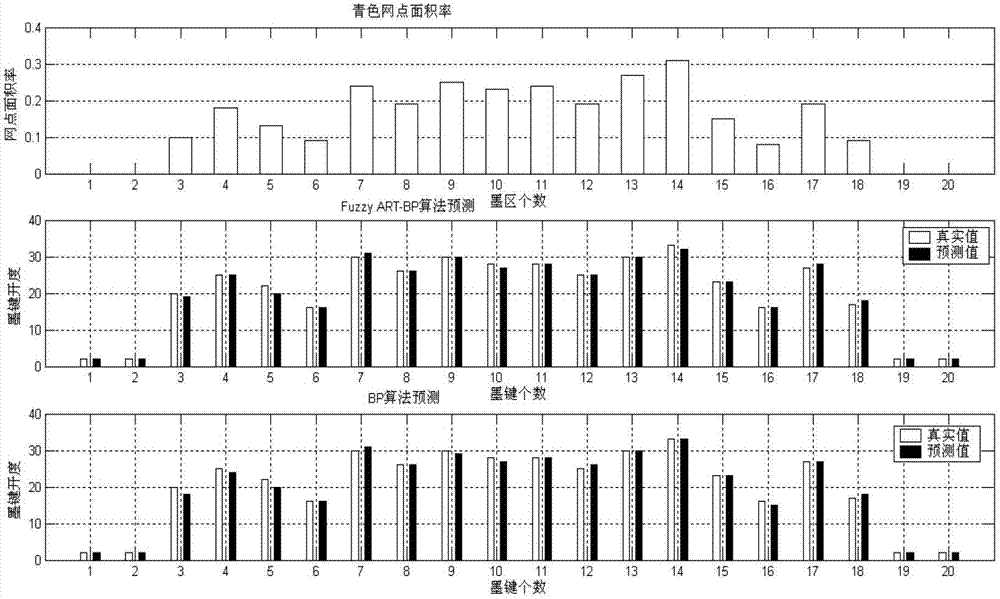

Ink key opening forecasting method having increment type learning capacity

The invention relates to a method for presetting digital printing ink and provides an ink key opening forecasting method based on a Fuzzy ART-BP mixed neural network algorithm of a Fuzzy ART neural network and a BP neural network. An input vector is stably classified by fully utilizing the self-learning, self-organizing and information fuzzy processing capacities of the Fuzzy ART neural network by the network; for each classification, nonlinear mapping is performed on the input and output vectors of a training sample by utilizing the BP neural network, namely, a mapping relation between image-text digital information and ink key control parameter of the training sample is established by taking printing on-site temperature, humidity, a printer rotating speed and a website area rate corresponding to an ink area as input vectors and an ink key opening value as an output vector; and a converged network is used for forecasting the ink key opening value of a new sample. The network learning is higher in pertinence, the iteration times of the BP network is reduced, the network has the increment type learning capacity and the generalization of the network is increased.

Owner:BEIJING UNIV OF TECH

Method for manufacturing gravure with laser anti-counterfeit lines

InactiveCN102416789AThick linesLines without linesPrinting pre-treatmentForme preparationMicrometerCopper plating

The invention relates to a printing roll manufacturing technique, in particular to a method for manufacturing gravure with laser anti-counterfeit lines. The process comprises the following steps: mechanical processing, copper plating, grinding, manuscript making, frictioning, laser engraving, corroding and chrome plating. Compared with the prior art, the method has the advantages that: thick lines with a thickness of less than 0.06 millimeter are engraved in form of dotted lines; the thickness and length of the solid lines and the dotted lines are well controlled; the solid lines serving as lattice points and dotted lines serving as lattice wall are directly engraved by laser; the etch depth is 0.015 to 0.018 millimeter; after etching, the final distance between solid lines is 1 to 3 micrometers; and that the printed lines are thick and not broken can be ensured.

Owner:上海希尔彩印制版有限公司

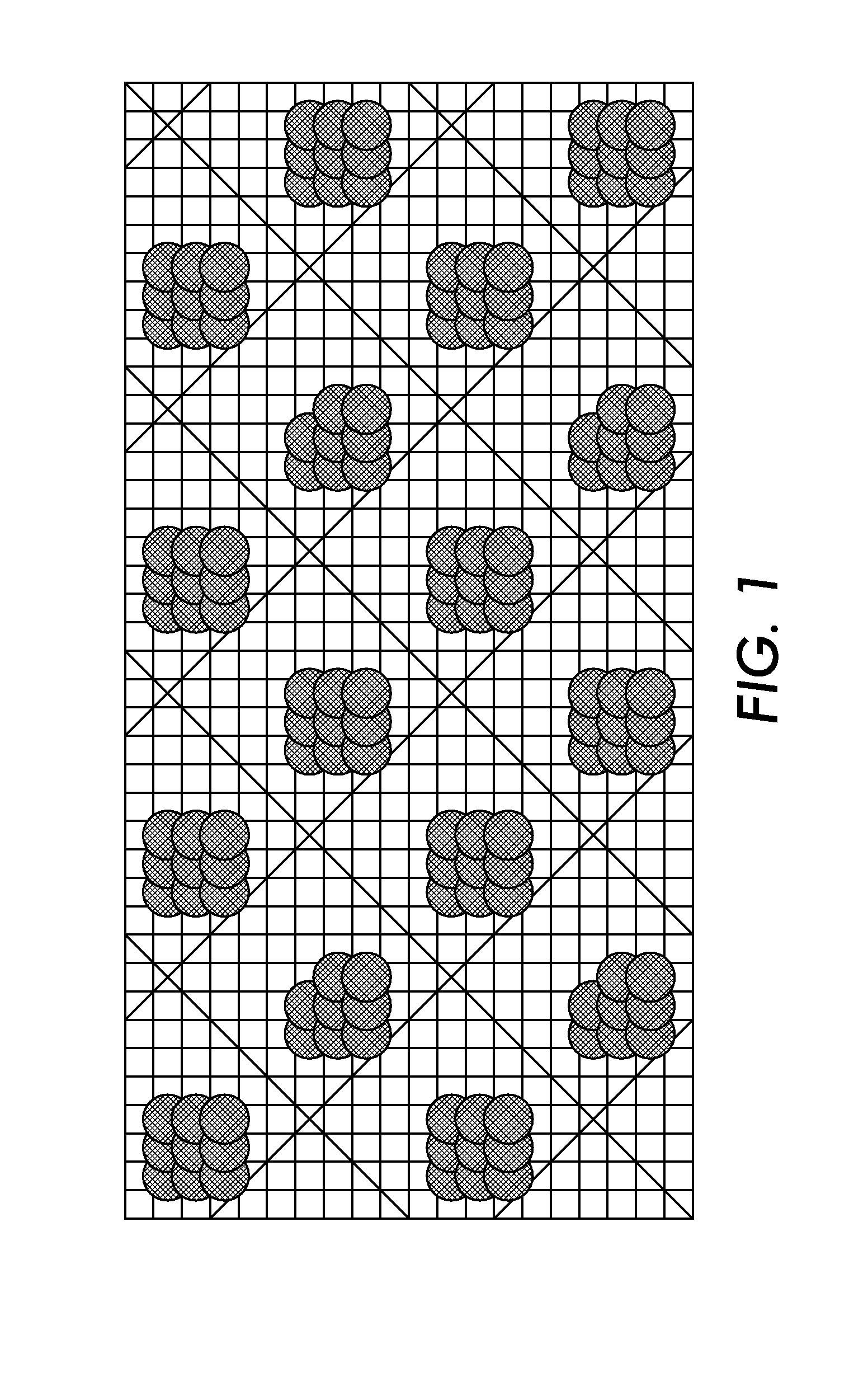

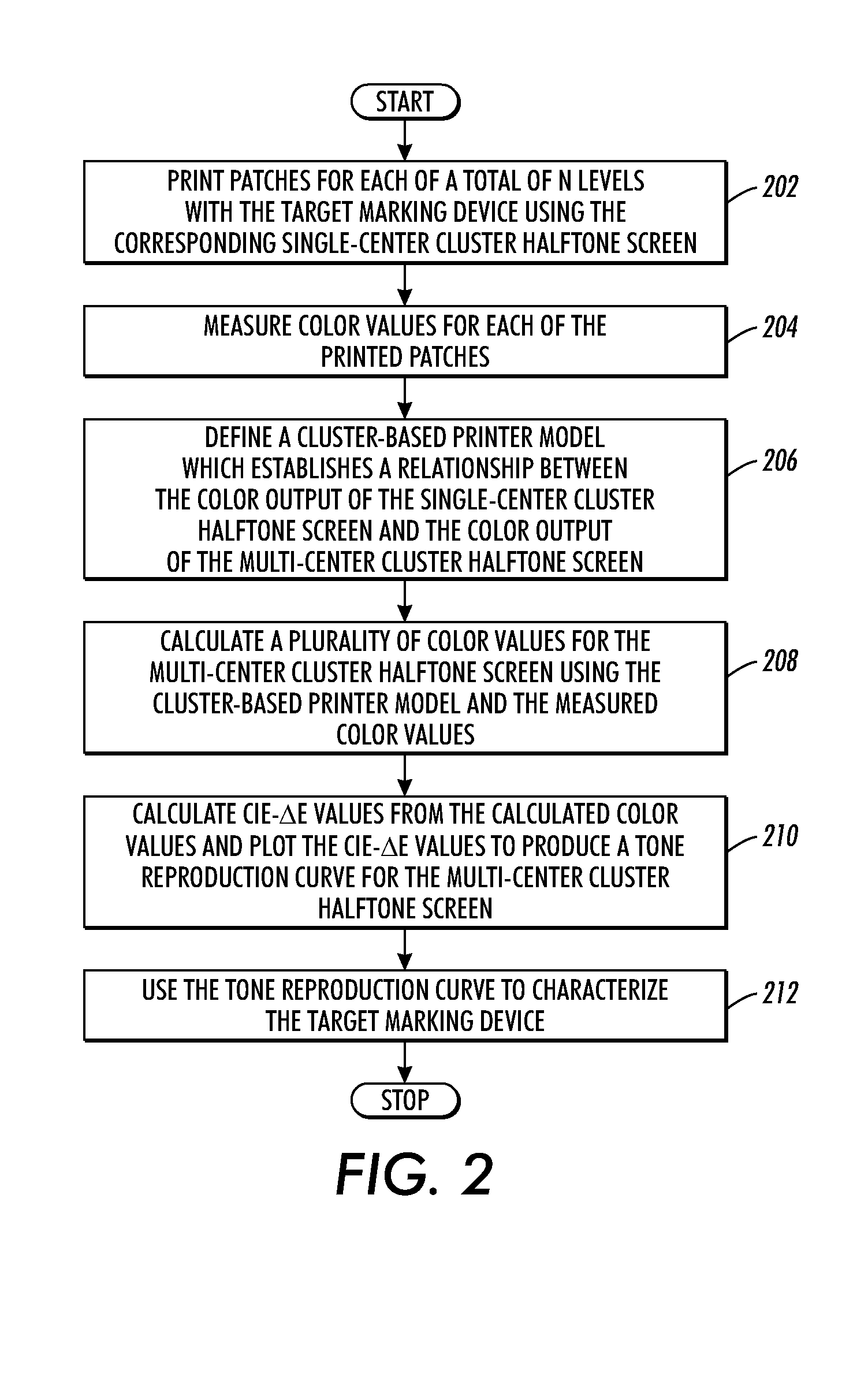

Cluster-based printer model for tone reproduction curve estimation

ActiveUS20100039657A1Efficiently and accurately estimatingImprove accuracyDigitally marking record carriersDigital computer detailsPattern recognitionSingle Center

What is disclosed is a system and method for efficiently and accurately estimating the complete TRC for a color marking device equipped with a multi-center cluster halftone screen which has a similar halftone tiling geometry and a similar growth specified by a corresponding single-center cluster halftone screen. The present method introduces a cluster-based printer model which establishes a relationship between a color output of a single-center cluster halftone screen and a color output of a multi-center cluster halftone screen. The present cluster-based printer model determines the complete TRC for the multi-center cluster halftone screen using the measurements for the single-center cluster halftone screen. Results of halftone dot linearization with different printing devices demonstrates that high accuracy can be achieved using the reduced measurements from the single-center cluster halftone screen. The present method finds its uses in characterization processes for a wide variety of color marking devices known in the arts,

Owner:XEROX CORP

Perspective information anti-fake print and its verifying tool and verifying method and anti-fake stamp

InactiveCN1588430AImprove concealmentSimple structureCharacter and pattern recognitionValidation methodsComputer engineering

Owner:DONGGUAN HUIFENG COMML CO LTD

Method for printing on-site and transitional-layer images and texts in color-overlapped manner by gravure plate

InactiveCN102700273AIncrease the scope of applicationImprove application efficiencyOther printing apparatusScreentoneEngineering

The invention provides a method for printing on-site and transitional-layer images and texts in a color-overlapped manner by a gravure plate. The method comprises the following steps: firstly printing on-site and transitional-layer dot images and texts and printing large-area on-site images and texts and basic transitional layer dots, wherein a gravure plate is made in an on-site-to-highlight transition manner, and ink cell angles are square dots; and overprinting transitional-layer dot images and texts, wherein the transitional layer dots of the gravure plate are made in a manner of highlight-to-middle tone-to-highlight transition, and ink cell angles are elongated dots. With the application of the method, a gravure press can be used for successfully printing products with on-site and transitional-layer images and texts in one time, the traditional printing manner combining gravure with offset printing is not used, and the application scope and the production efficiency of the gravure technology can be improved effectively.

Owner:CHONGQING HONGSHENG PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com