Method for printing on-site and transitional-layer images and texts in color-overlapped manner by gravure plate

A technique of stacking color printing and gravure plate, which is applied in the field of gravure printing machine printing and transitional level graphics and text, which can solve the problems of inability to realize transitional level graphic printing, long cycle time, and high transformation cost, so as to improve the application range and product quality. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

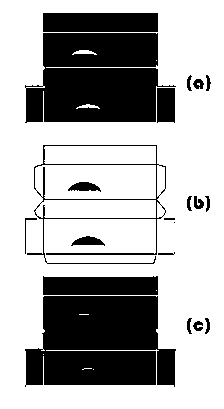

[0016] Example 1 , taking the printing and processing of a certain type of cigarette packaging box as an example, the main printing graphics are a large area of red solid ground plus two transitional graphics in the same direction similar to the moon shape, and the dots of the transitional graphics are about 80%. That is to say, to realize the transition from 100% solid to 80% level, the following process steps are adopted:

[0017] (1) For the first printing, solid-field printing plus transition-level dot graphics, the gravure plate production method is transition from solid to bright tone, that is, 0.3 to 0.4 times the number of dots required for 100% transition from solid to bright tone graphics. The angle is a square dot, and the number of screen lines is 70 lines / cm. At the same time, it completes large-area solid graphics and texts and foreshadowing transitional dot printing. The effect is as follows: figure 1 as shown in (a);

[0018] (2) Second printing, at figur...

Embodiment 2

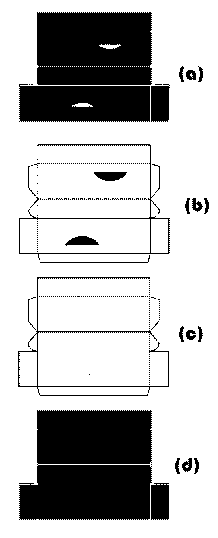

[0020] Example 2 , taking the printing and processing of a cigarette packaging box as an example, the main printing graphic is a large area of red solid ground plus two moon-like transitional graphics in the opposite direction, and the bright tone part of the transitional graphics is still about 80%. , but to realize the level transition from 100% to 80% on the ground in two opposite directions, the rest are the same as in Example 1, and adopt the following process steps:

[0021] (1) For the first printing, solid-field printing plus transition-level dot graphics, the gravure plate production method is transition from solid to bright tone, that is, 0.3 to 0.4 times the number of dots required for 100% transition from solid to bright tone graphics. The angle is a square dot, and the number of screen lines is 70 lines / cm. At the same time, it completes large-area solid graphics and texts and foreshadowing transitional dot printing. The effect is as follows: figure 2 as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com