Detection and correction method for printing dot area increase values

A technique for increasing the dot area and area, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problem of inaccurate dot area compensation and correction, and achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

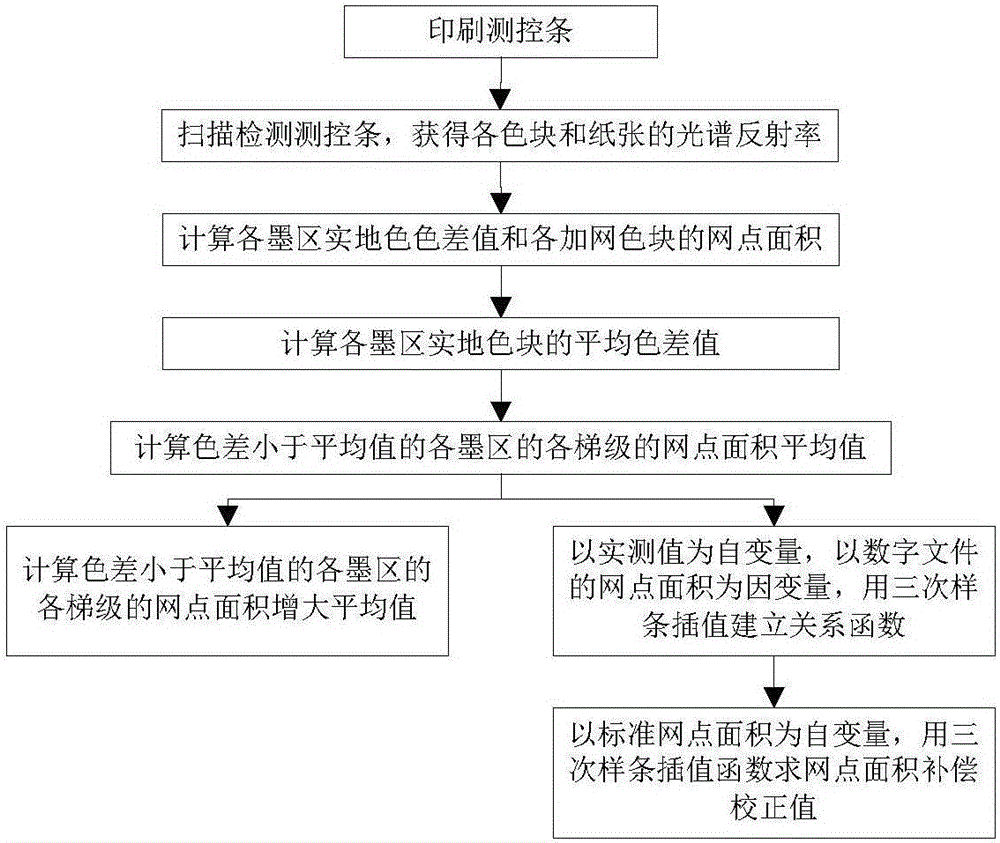

[0019]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

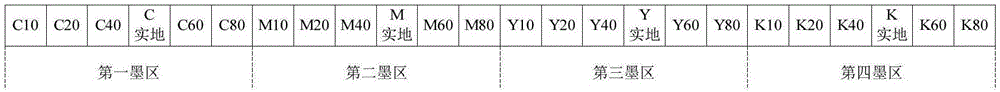

[0020] When the existing method detects the printing dot area, it is generally obtained by extracting a printed sheet and measuring the screened color block and the solid color block at a certain local position on the control strip. Because there are many factors that affect the increase of the dot area during printing In particular, the change of ink volume in the printing process will cause the change of dot area. The dot area detected by this method cannot represent the average characteristics under the current printing conditions. Based on the dot area obtained by this detection method, the grid It is often unreasonable to perform dot area compensation correction on digital files before digitalization.

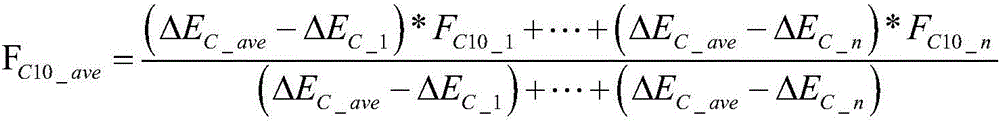

[0021] The present invention proposes a new method for detecting and correcting the dot area increase value of lithographic printing. By a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com