A positive thermal CTP plate with UV ink resistance

A technology of positive working and plate materials, applied in the field of double-layer positive working heat-sensitive lithographic printing plates, which can solve the problems of poor chemical resistance, low tolerance, and low heat sensitivity of double-coat positive working

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

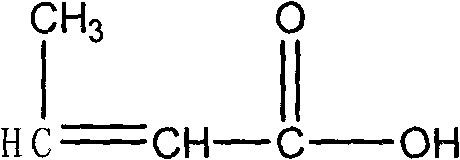

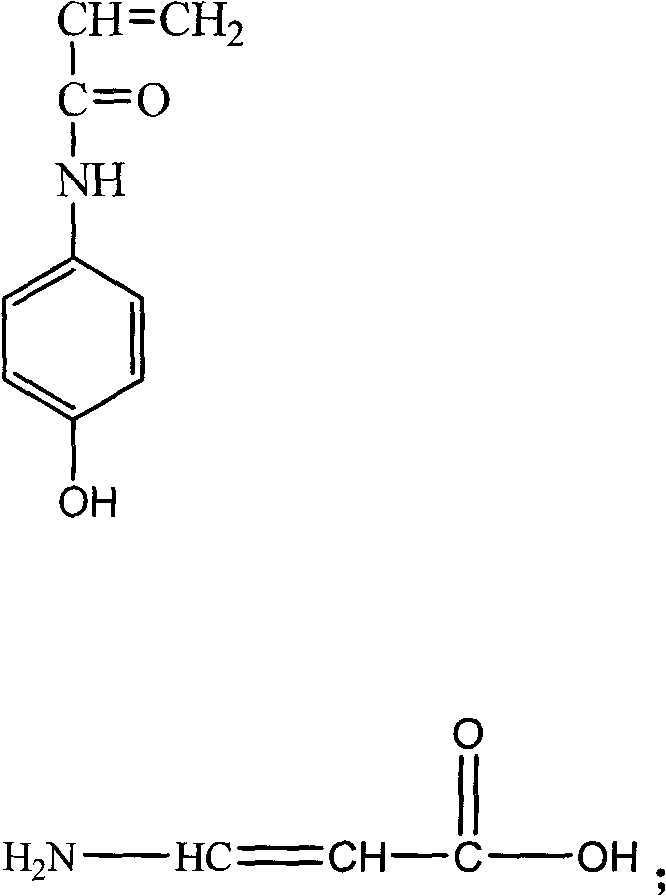

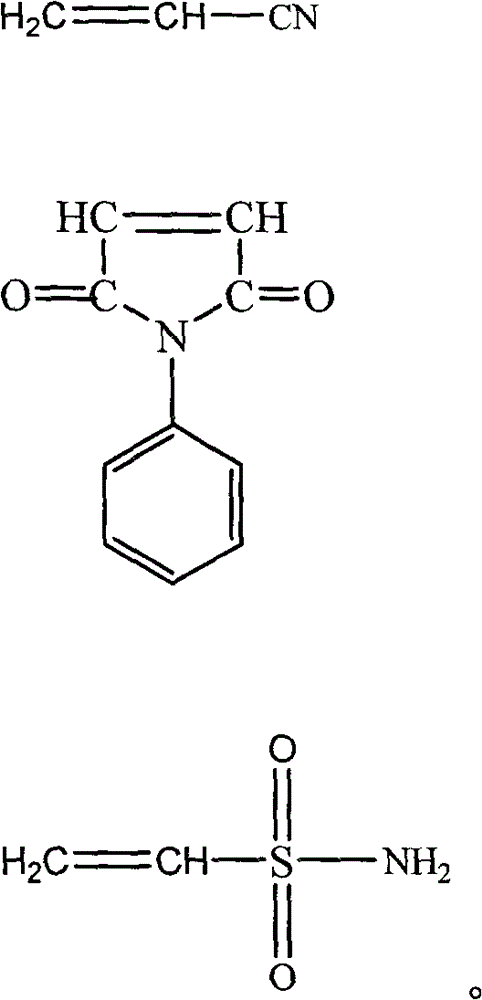

[0101] The synthetic method of the good film-forming resin of solvent resistance and alkali solubility in the present invention is as follows:

[0102] The synthesis of the following copolymers are all synthesized by the method of homopolymer, all in a container with stirring and condenser (it is best to pass nitrogen gas to exclude oxygen in the bottle), and add the solvent used to dissolve the monomer, generally N, N-dimethylformamide, then add a small part of the monomers used for copolymerization in proportion, and add an appropriate amount of initiator (the initiator is a kind of azo or organic peroxide), stir Dissolve for 10-20 minutes. Dissolve until the solution is nearly transparent, start to heat up to 70-80°C, and after one hour of reaction, add the remaining part dropwise with a funnel, preferably within one hour, continue to react for 4-5 hours, cool down to room temperature, add 0.5g hydroquinone (dissolved in 50ml ethyl cellosolve), stirred for 10 minutes, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com