Photosensitive composition suitable for heat-sensitive positive computer to plate (CTP) and lithographic plate containing same

A heat-sensitive positive image and composition technology, applied in the field of lithographic printing plates, can solve the problems of affecting the plate durability, poor wear resistance, and low thermal stability, and achieve excellent drug resistance, large developing latitude, and high resistance to printing. Alkaline good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

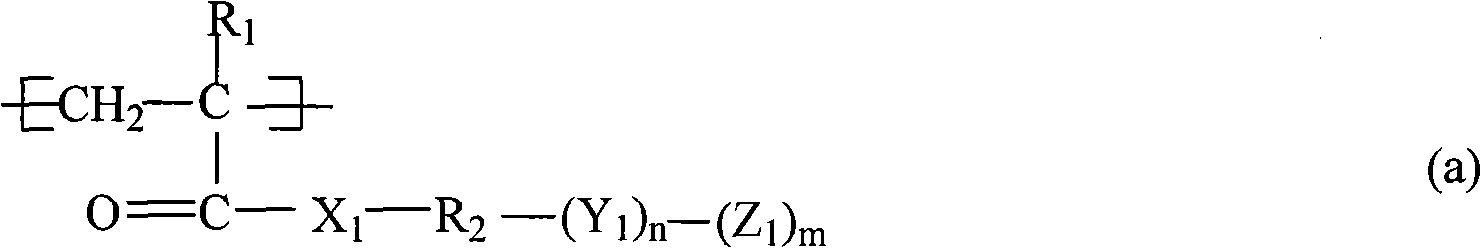

Method used

Image

Examples

Synthetic example 1

[0070] In a 500ml three-neck flask equipped with a stirrer, a reflux tube, and a dropping funnel, add 20g of N,N-dimethylformamide and 2.2g of benzoyl peroxide. Use a hot water bath while heating to 78 ° C, while passing nitrogen protection. Add dropwise from 20gN, N-dimethylformamide, 70g N-(4-hydroxybenzene) methacrylamide, 29g N-(4-sulfonamidobenzene) maleimide, 1g N-(4- Acetoxyphenyl) maleimide mixed solution, 2 hours dropwise. React at constant temperature for 10 hours. After the reaction was completed, 200 g of methanol was added, cooled, added to 2 L of water with stirring, and filtered and dried after stirring for 1 hour to obtain 90.66 g of a white solid. The weight-average molecular weight (polystyrene standard) of the high molecular weight polymer measured by silica gel permeation chromatography was 40,000.

Synthetic example 2

[0072]In a 500ml four-neck flask equipped with a stirrer, a reflux tube, and a dropping funnel, add 20g of N,N-dimethylformamide and 2.2g of benzoyl peroxide. Use a hot water bath while heating to 78 ° C, while passing nitrogen protection. Add dropwise by 130g N, N-dimethylformamide, 1g N-(4-hydroxybenzene) methacrylamide, 1g N-(4-sulfonamidobenzene) maleimide, 50g N-(4 -Acetoxyphenyl) maleimide, the mixed solution that 48g methyl methacrylate forms, dropwise in 2 hours. React at constant temperature for 10 hours. After the reaction was completed, 200 g of methanol was added, cooled, added to 2 L of water with stirring, and filtered and dried after stirring for 1 hour to obtain 90.68 g of a white solid. The weight-average molecular weight (polystyrene standard) of the high molecular weight polymer measured by silica gel permeation chromatography was 50,000.

Synthetic example 3

[0074] In a 500ml four-neck flask equipped with a stirrer, a reflux tube, and a dropping funnel, add 20g of N,N-dimethylformamide and 2.2g of benzoyl peroxide. Use a hot water bath while heating to 78 ° C, while passing nitrogen protection. Add dropwise from 130g N, N-dimethylformamide, 70g N-(4-hydroxybenzene) methacrylamide, 20g N-(4-sulfonamidobenzene) maleimide, 1g N-(4 -Acetoxyphenyl) maleimide, the mixed solution that 9g methyl methacrylate forms, dropwise in 2 hours. React at constant temperature for 10 hours. After the reaction was completed, 200 g of methanol was added, cooled, added to 2 L of water with stirring, stirred for 1 hour, filtered and dried to obtain 89.00 g of a white solid. The weight-average molecular weight (polystyrene standard) of the high molecular weight polymer measured by silica gel permeation chromatography was 60,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com