Grain-free metal printing plate base and preparation method thereof

A non-gritty, metal-free technology, applied in printing, printing plates, printing processes, etc., can solve the problems of insufficient water retention capacity of the coating, loss of use effect, easy to get dirty coating, etc., to achieve good hydrophilicity and water retention performance, Improve printing durability and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

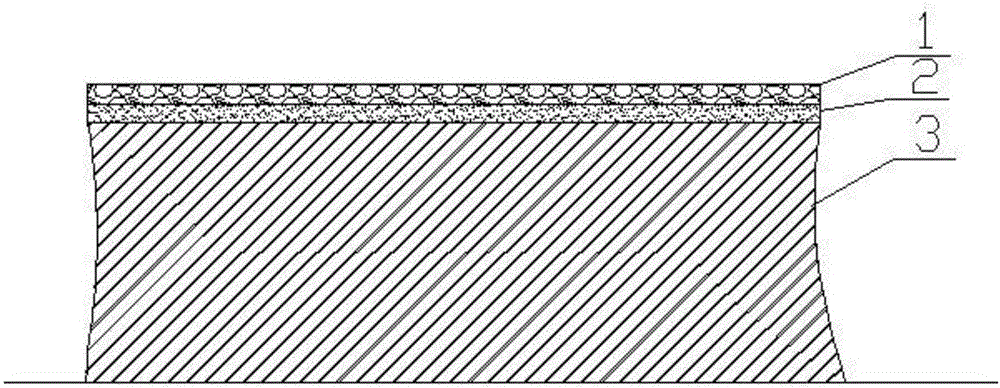

[0057] The preparation of a non-gritty metal printing plate base consists of four main steps:

[0058] (1) Metal plate pretreatment: use 1%-20% lye to degrease, wash and dry;

[0059] (2) Mix the bonding layer composition evenly to prepare a bonding layer coating solution; apply the bonding layer coating solution on the metal plate, and then dry it in an oven at 50°C-200°C for 3min-30min to obtain Metal plate with bonding layer;

[0060] (3) Mix the hydrophilic layer composition evenly to prepare a hydrophilic layer coating solution; apply the hydrophilic layer coating solution on the metal plate containing the bonding layer, and then heat it in an oven at 50°C-200°C Dry at ℃ for 3min-30min to obtain a metal printing plate base;

[0061] (4) Solvent-assisted sealing: put NaH 2 PO 4 According to the proportion of 65g / L~85g / L, NaF is dissolved in water according to the proportion of 550mg / L~750mg / L to make working solution and heated to 40℃~50℃, and the metal printing plate ...

Embodiment 1

[0066] Preparation of adhesive layer coating solution: 60g (30%) polyacrylate aqueous solution, 6g (30%) silica sol, 10g aziridine crosslinking agent, 8g ethylene glycol tert-butyl ether, 0.8g fluid The leveling agent and 15.2 g of deionized water were mixed evenly at room temperature.

[0067] Preparation of metal plate with bonding layer: Degrease the ungrained aluminum plate with 5% sodium hydroxide solution, wash it with clean water and dry it, and apply the bonding layer by spin coating The solution was coated on an aluminum plate and dried at 150° C. for 10 minutes.

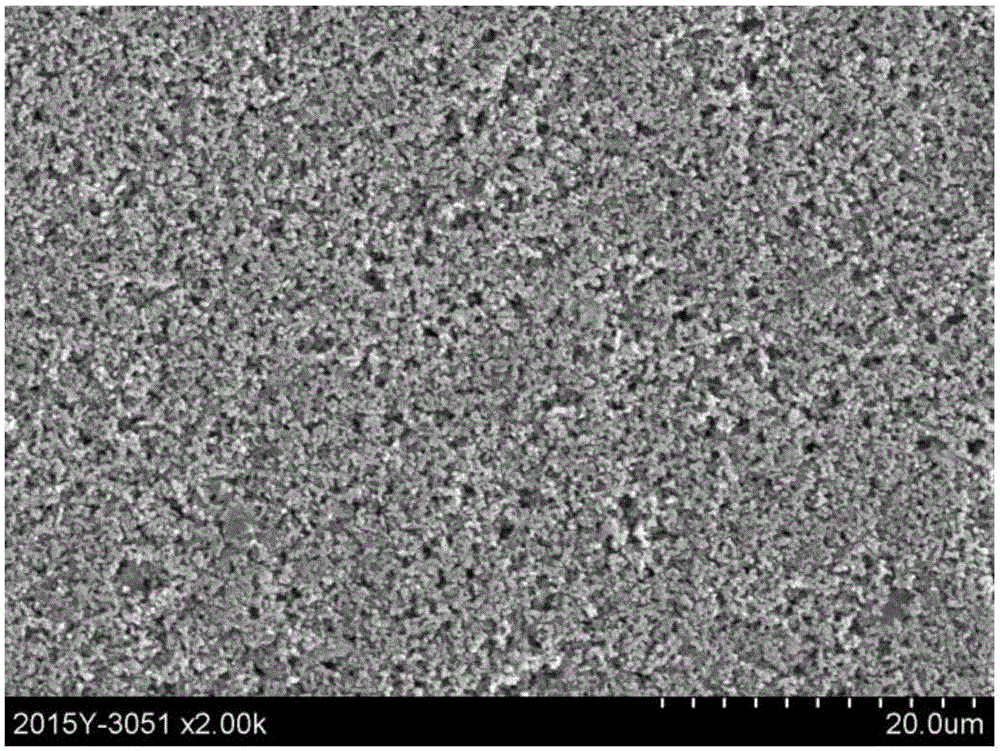

[0068] The coating solution preparation of the hydrophilic layer: 10g (30%) polyacrylate aqueous solution, 1g aziridine crosslinking agent, 10g (5%) polyvinyl alcohol, 0.05g ethylene glycol tert-butyl ether, 0.03g The leveling agent, 0.05g defoamer, 34g alumina particles with an average particle size of 1000nm, 1g20nm silica sol and 43.87g deionized water were mixed uniformly at room temperature.

[0069]...

Embodiment 2

[0073] Preparation of adhesive layer coating solution: 40g (50%) polyurethane aqueous solution, 3g (30%) silica sol, 1g toluene diisocyanate, 0.5g leveling agent and 55.5g deionized water were mixed uniformly at room temperature.

[0074] Preparation of metal plate with bonding layer: Degrease the ungrained aluminum plate with 5% sodium hydroxide solution, wash it with clean water and dry it, and apply the bonding layer by roller coating The solution was coated on an aluminum plate and dried at 120° C. for 20 minutes.

[0075] The coating liquid preparation of hydrophilic layer: 5g (50%) polyacrylate aqueous solution, the toluene diisocyanate of 0.5g, the gelatin of 10g (5%), the leveling agent of 0.03g, the average of 0.05g defoamer, 40g Alumina particles with a particle size of 800 nm and 44.42 g of deionized water were mixed uniformly at room temperature.

[0076] Preparation of the metal printing plate without grains: at room temperature, the coating solution of the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com